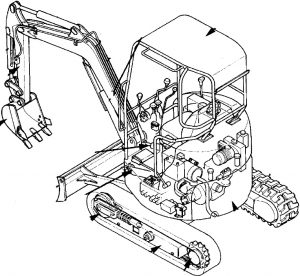

Pages from W154ENA – Hitachi EX110-5, EX110M-5 Excavator Workshop Manual

Complete workshop & service manual with electrical wiring diagrams for Hitachi EX100, EX100-3, EX100-5, EX100M-5, EX110-5, EX100M, EX100M-3, EX110M-5 Excavators. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page.

This Hitachi EX100, EX100M, EX110, EX110M Excavators service & repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

FILELIST:

T154E00 – Hitachi EX100-5, EX100M-5, EX110-5, EX110M-5 Excavator Technical Manual

Section 0 – Index.pdf

Section 1 – General.pdf

Section 2 – System.pdf

Section 3 – Component Operation.pdf

Section 4 – Operational Performance Test.pdf

Section 5 – Troubleshooting.pdf

T154E00CIR – Hitachi EX100-5, EX100M-5, EX110-5, EX110M-5 Excavator Electrical Circuit Diagram

W154E00 – Hitachi EX100-5, EX100M-5, EX110-5, EX110M-5 Excavator Workshop Manual

Section 0 – Index.pdf

Section 1 – General Information.pdf

Section 2 – Upperstructure.pdf

Section 3 – Undercarriage.pdf

Section 4 – Front attachment.pdf

Section 5 – Engine and Accessory.pdf

EM1E9EN13 – Hitachi EX100-5, EX100M-5 Excavator Operator’s Manual.pdf

EM1E813 – Hitachi EX100-5, EX100M-5, EX120-5, EX130H-5 Excavator Operator’s Manual.pdf

EM12E14 – Hitachi EX100 Excavator Operator’s Manual.pdf

EM12SNA13 – Hitachi EX100-3, EX100M-3 Excavator Operator’s Manual.pdf

KM08800 – Hitachi EX100, EX100M Excavator Technical Shop Manual (Service & Repair).pdf

T133E00 – Hitachi EX100-3, EX100M-3 Excavator Technical Manual.pdf

TM1733 – Hitachi EX110-5 Excavator Repair Technical Manual.pdf

TO154E01 – Hitachi EX100-5, EX100M-5 Excavator Technical Manual (Operational Principle).pdf

TO154ENA – Hitachi EX110-5, EX110M-5 Excavator Technical Manual (Operational Principle).pdf

W133E00 – Hitachi EX100M-3 Excavator Workshop Manual.pdf

W154ENA – Hitachi EX110-5, EX110M-5 Excavator Workshop Manual.pdf

EXCERPT:

UNDERCARRIAGE I Travel Device

Disassemble Travel Devise

• Be sure to thoroughly read “Precautions for Disassembly and Assembly” on page W1-1-1 before starting the disassembly work.

• Put matching marks between cover (17) and ring gear (13) and between housing (43) and drum (44) to aid in reassembly.

1 . Loosen the socket bolts to separate the travel motor assembly from the travel device.

2. Place the reduction gear on its travel motor mounting side on a workbench.

3. Loosen socket bolts (30) to remove cover (17) from ring gear (13).

-: 8mm

4. Remove thrust plate (20), shaft (22), and first stage carrier (24) as a unit from ring gear (13).

5. Remove thrust plate (19), second stage sun gear (21), and second stage carrier (36) as a unit from ring gear (13).

6. Loosen socket bolts (37). Using a crane, remove ring gear (13).

-: 10mm

7. Remove third stage sun gear (23) from third stage carrier (16).

8. Loosen socket bolts (38) and (42). Remove third stage carrier (16) assembly.

-: 14mm

9. Remove shims (5) from drum (44).

IMPORTANT: Count the number of the shims.

Do not lose any. Exactly the same number of the shims are needed for reassembly.

10. Using a crane, lift housing (43). Tap drum (44) using plastic hammer to remove housing (43).

…