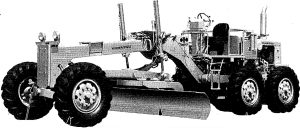

Komatsu GD555-3C, GD655-3C, GD675-3C Motor Grader

Complete digital official shop manual contains service, maintenance, and troubleshooting information for the Komatsu GD555-3A, GD555-3C, GD555-5, GD655-3A, GD655-3C, GD655-3E0, GD655-5, GD675-3A, GD675-3C, GD675-3E0, GD675-5 Motor Grader. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your motor grader like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for Komatsu Motor Grader GD555-3A, GD555-3C, GD555-5, GD655-3A, GD655-3C, GD655-3E0, GD655-5, GD675-3A, GD675-3C, GD675-3E0, GD675-5 is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

FILELIST:

GSAM042401 – Motoniveladora GALEO GD555-3A Manual de Operacion y Mantenimiento.pdf

GSBM021002 – GD555-3A, GD655-3A, GD675-3A Manual de Taller.pdf

KEAM037900 – Motor Grader GALEO GD655-3C Operation & Maintenance Manual.pdf

KEAM038000 – Motor Grader GALEO GD675-3C Operation & Maintenance Manual.pdf

KEAM038100 – Motor Grader GALEO GD555-3C Operation & Maintenance Manual.pdf

PEN00178-01 – Motor Grader GD555-3A Operation & Maintenance Manual.pdf

SEAM23DA03 – Motor Grader GD605A-1, GD655A-1 Operation & Maintenance Manual.pdf

SEAM023DUS01 – Motor Grader GD605A-3, GD655A-3 Operation & Maintenance Manual.pdf

SEAM037902T – Motor Grader GD655-3C Operation & Maintenance Manual.pdf

SEAM038002 – Motor Grader GD675-3C Operation & Maintenance Manual.pdf

SEAM038003 – Motor Grader GD675-3C Operation & Maintenance Manual.pdf

SEAM038102T – Motor Grader GD555-3C Operation & Maintenance Manual.pdf

SEAM042401 – Motor Grader GALEO GD555-3A Operation & Maintenance Manual.pdf

SEAM052800T – Motor Grader GALEO GD655-3A Operation & Maintenance Manual.pdf

SEBM020906 – Motor Grader GD555-3C, GD655-3C, GD675-3C Shop Manual.pdf

SEBM020909 – Motor Grader GD555-3C, GD655-3C, GD675-3C Shop Manual.pdf

SEBM021007 – Motor Grader GD555-3A, GD655-3A, GD675-3A Shop Manual.pdf

SEBM021008 – Motor Grader GD555-3A, GD655-3A, GD675-3A Shop Manual.pdf

SEN01775-05 – Motor Grader GD655-3E0, GD675-3E0 Shop Manual.pdf

SEN05215-06 – Motor Grader GD555-5, GD655-5, GD675-5 Shop Manual.pdf

TEN00095-01 – Motor Grader GALEO GD655-3C Operation & Maintenance Manual.pdf

TEN00149-05 – Motor Grader GD655-3E0 Operation & Maintenance Manual.pdf

TEN00150-05 – Motor Grader GD675-3E0 Operation & Maintenance Manual.pdf

TEN00177-02 – Motor Grader GD555-3A Operation & Maintenance Manual.pdf

TEN00178-02 – Motor Grader GD555-3C Operation & Maintenance Manual.pdf

TEN00179-02 – Motor Grader GD655-3A Operation & Maintenance Manual.pdf

TEN00368-01 – Motor Grader GD655-5 Operation & Maintenance Manual.pdf

TEN00369-01 – Motor Grader GD675-5 Operation & Maintenance Manual.pdf

TEN00445-02 – Motor Grader GD555-5 Operation & Maintenance Manual.pdf

TEN00446-02 – Motor Grader GD655-5 Operation & Maintenance Manual.pdf

TEN00447-02 – Motor Grader GD675-5 Operation & Maintenance Manual.pdf

TEN00448-00 – Motor Grader GD655-3E0 Operation & Maintenance Manual.pdf

TEN00449-01 – Motor Grader GD675-3E0 Operation & Maintenance Manual.pdf

EXCERPT:

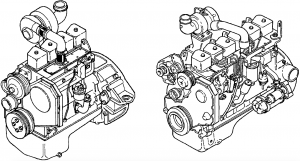

STRUCTURE, FUNCTION AND MAINTENANCE STANDARD HYDRAULIC PUMP

FUNCTION

• The engine rotation and torque transmitted to the pump shaft is converted into hydraulic energy, and pressurized oil is discharged according to the load.

• It is possible to change the discharge amount by changing the swash plate angle.

STRUCTURE

• Cylinder block (7) is supported to shaft (1) by spline a, and shaft (1) is supported by the front and rear bearings.

• The tip of piston (6) is a concave ball, and shoe (5) is caulked to it to form one unit. Piston (6) and shoe (5) form a spherical bearing.

• Rocker cam (4) has flat surface A, and shoe (5) is always pressed against this surface while sliding in a circular movement. Rocker cam (4) brings high pressure oil at cylindrical surface B with cradle (2), which is secured to the case and forms a static pressure bearing when it slides.

• Piston (6) carries out relative movement in the axial direction inside each cylinder chamber of cylinder block (7).

• Cylinder block (7) seals the pressure oil to valve plate (8) and carries out relative rotation. This surface is designed so that the oil pressure balance is maintained at a suitable level.

The oil inside each cylinder chamber of cylinder block (7) is sucked in and discharged through valve plate (8).

OPERATION

1. Operation of pump

i) Cylinder block (7) rotates together with shaft (1), and shoe (5) slides on flat surface A.

When this happens, rocker cam (4) moves along cylindrical surface B, so angle between center line X of rocker cam (4) and the axial direction of cylinder block (7) changes. Angle is called the swash plate angle.

ii) Center line X of rocker cam (4) maintains swash plate angle in relation to the axial direction of cylinder block (7), and flat surface A moves as a cam in relation to shoe (5).

In this way, piston (6) slides on the inside of cylinder block (7), so a difference between volume E and F is created inside cylinder block (7). The suction and discharge is carried out by this difference F – E.

In other words, when cylinder block (7) rotates and the volume of chamber E becomes smaller, the oil is discharged during that stroke.

At the same time, the volume of chamber F becomes larger, and as the volume becomes larger, oil is sucked in.

(The diagram shows chamber F at the end of the suction process and chamber E at the end of the discharge process.)

iii) If center line X of rocker cam (4) is in line with the axial direction of cylinder block (7) (swash plate angle = 0), the difference between volumes E and F inside cylinder block (7) becomes 0, so the pump does not carry out any suction or discharge of oil. (In actual fact, the swash plate angle never becomes 0.)

iv) In other words, there is a proportional relationship between swash plate angle and the pump discharge amount.

…