Complete Operator’s manual for John Deere 5075GV, 5075GN, 5075GF, 5075GL, 5090GV, 5090GN, 5090GF, 5090GL, 5100GL, 5105GN and 5105GF (MY20- ) Tractors.

omer525732 – 5075GV, 5075GN, 5075GF, 5075GL, 5090GV, 5090GN, 5090GF, 5090GL, 5100GL, 5105GN and 5105GF (MY20- ) Tractors – (European Edition) Operator’s Manual.pdf

omer525737 – Τρακτέρ 5075GV, 5075GN, 5075GF, 5075GL, 5090GV, 5090GN, 5090GF, 5090GL, 5100GL, 5105GN και 5105GF (MY20- ) -: (Ευρωπαϊκή έκδοση) Greek.pdf

PRODUCT DETAILS:

Total Pages: 913 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English Greek

TABLE OF CONTENTS

TABLE OF CONTENTS…………….1

Section 00: Glossary…………….21

Glossary…………….21

Trademarks…………….23

Section 05: Safety…………….25

Recognize Safety Information…………….593

Understand Signal Words…………….28

Follow Safety Instructions…………….29

Prepare for Emergencies…………….30

Wear Protective Clothing…………….31

Protect Against Noise…………….32

Handle Fuel Safely—Avoid Fires…………….33

Fire Prevention…………….34

In Case of Fire…………….35

Avoid Static Electricity Risk When Refueling…………….36

Use Foldable ROPS and Seat Belt Properly…………….38

Stay Clear of Rotating Drivelines…………….39

Use Steps and Handholds Correctly…………….41

Read Operator’s Manuals for ISOBUS Controllers…………….42

Use Seat Belt Properly…………….43

Vibration…………….871

Operating the Tractor Safely…………….45

Avoid Backover Accidents…………….47

Limited Use in Forestry Operation…………….48

Operating the Loader Tractor Safely…………….49

Keep Riders Off Machine…………….50

Passenger Seat…………….51

Use Safety Lights and Devices…………….52

Towing Trailers/Implements Safely…………….53

Use Caution on Slopes, Uneven Terrain, and Rough Ground…………….244

Freeing a Mired Machine…………….55

Avoid Contact with Agricultural Chemicals…………….447

Handle Agricultural Chemicals Safely…………….445

Handling Batteries Safely…………….59

Avoid Heating Near Pressurized Fluid Lines…………….61

Remove Paint Before Welding or Heating…………….62

Handle Electronic Components and Brackets Safely…………….63

Practice Safe Maintenance…………….64

Avoid Hot Exhaust…………….65

Clean Exhaust Filter Safely…………….66

Work In Ventilated Area…………….69

Support Machine Properly…………….70

Prevent Machine Runaway…………….71

Park Machine Safely…………….72

Transport Tractor Safely…………….73

Service Cooling System Safely…………….74

Service Accumulator Systems Safely…………….75

Service Tires Safely…………….387

Service Front-Wheel Drive Tractor Safely…………….77

Tightening Wheel Retaining Bolts/Nuts…………….78

Avoid High-Pressure Fluids…………….558

Do Not Open High-Pressure Fuel System…………….826

Store Attachments Safely…………….81

Decommissioning — Proper Recycling and Disposal of Fluids and Components…………….82

Section 05A: Safety Decals…………….83

Pictorial Safety Signs…………….84

Operator’s Manual…………….85

No Riders (Foldable ROPS)…………….86

Use Seat Belt Properly (Cab or Fixed ROPS)…………….87

Use Seat Belt Properly (Foldable ROPS)…………….88

ROPS in Normal Position (Foldable ROPS)…………….89

Hitch Remote Control (Mechanical Hitch)…………….90

Hitch Remote Control (Electronic Hitch)…………….91

Accumulator — Front Hitch…………….291

Accumulator — Front Suspended Axle…………….93

Pick-Up Hitch…………….346

Hydraulic Lines and Hydraulic Components — Rear Hitch…………….95

Hydraulic Lines and Hydraulic Components — Front Hitch…………….291

Hydraulic Lines and Hydraulic Components — Front Distributors…………….97

Section 10: Vehicle Overview…………….98

Product Identification View…………….99

Section 10A: Operator's Manual – General Information…………….593

Scope of This Manual…………….102

Operator Manual Usage Information…………….593

Comply with Operator's Manuals of Implement Manufacturers…………….104

Operator Training Required…………….105

Section 20: Operating the Engine…………….818

Neutral Start Switch…………….107

Starting the Engine…………….818

Start with a Booster Battery…………….662

Start the Engine with a Slave Battery…………….662

Battery — Disconnect Electrical Circuit (5GV, 5GN, 5GF)…………….117

Battery — Disconnect Electrical Circuit (5GL, 5GL-N)…………….120

Observe Instruments After Starting the Engine…………….818

Engine Oil Pressure Indicator Light…………….123

Alternator Indicator Light…………….124

Air Cleaner Indicator Light…………….125

Transmission Oil Filter Indicator Light…………….126

Coolant Temperature Gauge…………….127

Observe Fuel Level…………….128

Fill Fuel Tank…………….129

Change Engine Speeds…………….130

Warm up the Engine…………….818

Restart a Stalled Engine…………….818

Engines with Turbocharger…………….134

Avoid Idling the Engine…………….818

Observe Engine Work and Idle Speeds…………….136

Stop the Engine…………….818

Park the Tractor…………….138

Section 20A: Cold Weather Operation…………….139

Cold-Weather Operation…………….140

Section 20B: Aftertreatment Equipment (DOC/DPF)…………….142

Note on Exhaust Cleaning System…………….143

Exhaust Filter Cleaning, General Information…………….593

Aftertreatment General Warning (Tractor with DPF System)…………….146

DPF Soot Load, General Information…………….593

Access the DPF Menu on the Digital Display…………….149

Manual Regeneration, General Information…………….593

DPF Soot Load…………….820

Section 30: Controls…………….156

Vehicle Controls (Cab) (5GV, 5GN, 5GF)…………….157

Vehicle Controls (Open Operator Station) (5GF)…………….159

Vehicle Controls (5GL)…………….161

Vehicle Controls (Mechanical Transmission) (Cab) (5GL-N)…………….163

Vehicle Controls (PowrReverser™ Transmission) (Cab) (5GL-N)…………….165

Vehicle Controls…………….167

Section 30A: Instrument Panel…………….173

Instruments and Indicator Lights…………….174

F Inducement General Warning…………….176

Section 30B: Digital Display…………….178

Digital Display – User Interface…………….179

User Menu…………….183

Digital Display – Initial Setup (Matching with Tractor)…………….190

Oil Service Message Reset…………….564

Section 50: Drive Train…………….205

Drive Train – Overview…………….206

Section 50A: Front-Wheel Drive…………….207

Operate Front-Wheel Drive…………….208

Setting of the Steering Angle (Auto 4WD)…………….210

Activation of the Auto 4WD…………….212

Controls on the Right-Hand Cab Post…………….214

Activation of the Suspension System…………….217

Malfunction Error Codes and Indicator Lights…………….220

Section 50B: Differential Lock…………….221

Use Differential Lock…………….222

Section 50C: Brakes…………….827

Use Brakes…………….827

Stop the Tractor…………….225

Hydraulic Trailer Brakes…………….827

Chock Block…………….232

Section 50D: Transmission – General Information…………….593

Reduce Fuel Consumption…………….234

Travel Speeds…………….238

Use Caution on Slopes, Uneven Terrain, and Rough Ground…………….244

Select a Gear…………….245

Cruise Control…………….246

Manually Adjusting the Engine Speed Memories MEM1/ MEM2 (Optional)…………….250

Section 50E: PowrReverser™ Transmission…………….821

Shifting Transmission…………….821

Electrohydraulic Hi-Lo (24/12 – Speed Transmission) (If Equipped)…………….254

Operate Transmission Shift Levers…………….263

Section 50L: Mechanical Transmission…………….821

Shifting Transmission…………….821

Mechanical Hi-Lo (24/24 – Speed Transmission) (5GV, 5GN, 5GF, 5GL, and 5GL-N)…………….262

Operate Transmission Shift Levers…………….263

Section 60: PTO Shaft and Hitch…………….264

Maximum Lifting Force…………….841

Section 60A: PTO Shaft – General Information…………….593

Front PTO — PTO Shield…………….267

PTO Guard…………….269

Operating Instructions…………….271

PTO Automatic Shutoff Function…………….273

Selecting PTO Speeds…………….274

Attaching PTO-Driven Implement…………….275

Section 60B: Front PTO…………….825

Front PTO…………….825

Section 60C: Rear PTO…………….280

Operating the Rear PTO (Mechanical Version)…………….281

Operating the Rear PTO (Electrohydraulic Version)…………….285

Selecting Ground Drive PTO…………….287

Ground Drive PTO Revolution Speeds…………….289

Section 60D: Front Hitch…………….291

Front Hitch…………….291

Front Implement Fixing Points…………….296

Section 60E: Rear Hitch…………….298

Three-Point Hitch Components…………….299

Match Tractor Power to Implement…………….301

Hitch Control Levers (Mechanical Hitch)…………….302

Use the Hitch Position Control (Mechanical Hitch)…………….303

Use the Draft Control (Mechanical Hitch)…………….305

Adjust the Rate-of-Drop…………….307

Transporting Mounted Implements (EHS II)…………….309

Depth Adjustment (EHS II)…………….310

Load/Depth Adjustment (EHS II)…………….311

Raise/Lower Switch (EHS II)…………….313

Height Adjustment (EHS II)…………….314

Adjusting Rate-of-Drop (EHS II)…………….315

Reset the Electronic Hitch Sensing (EHS II)…………….316

Hitch Remote Control (EHS II)…………….317

Prepare the Implement…………….319

Converting Category II Hitch to Category IN or Category I…………….321

Positioning Draft Link Ends…………….322

Quick-Coupling (Hook-Type) Draft Links…………….323

Attaching Implements…………….324

Attach Implements to 3-Point Hitch…………….326

Adjust Sway Blocks…………….329

3-Point Hitch Leveling System (If Equipped)…………….298

Position the Center Link…………….333

Level the Hitch…………….334

Adjust Hitch Control Lever Friction…………….337

Electronic Hitch Sensing II (EHS II)…………….338

Calibrating the System (EHS II)…………….339

Section 60F: Coupling Devices…………….341

Drawbar…………….342

Proper Use of Drawbar…………….343

Height Adjustable Trailer Hitches…………….344

Pick-Up Hitch…………….346

Pick-Up Hitch Decal…………….348

Tow the Tractor…………….349

Section 70: Hydraulic System…………….823

Maximum Permissible Oil Withdrawal…………….353

Section 70A: Hydraulic Connections…………….354

Use Correct Hose Tips…………….355

Connecting Cylinder Hoses…………….356

Connect Hose Under Pressure…………….358

Section 70B: Selective Control Valves – Controls…………….359

Selective Control Valve (SCV) Levers…………….360

Control Lever and Coupler Identification…………….364

Electrically-Actuated Selective Control Valve (Optional)…………….368

Section 70C: Selective Control Valves – Settings…………….377

Double/Single Acting SCVs Conversion…………….378

Flow Divider Valve…………….379

Remote Hydraulic Cylinders…………….382

Section 80: Wheels and Tires…………….386

Service Tires Safely…………….387

Changing Wheels Safely…………….388

Check Implement-to-Tire Clearance…………….389

Tire Pressures…………….573

Mounting Tires…………….391

Tire Combinations…………….392

Section 80A: Front Wheels, Tires, and Treads…………….399

Tighten Wheel Bolts…………….400

Adjusting Front Axle Tread Width…………….402

Check Toe-In…………….404

Adjust Toe-In…………….406

Direction of Tire Rotation…………….408

Tread Adjustment…………….432

Section 80B: Steering Stop and Fender – Settings…………….424

Steering Angle Adjustment…………….425

Section 80C: Rear Wheels, Tires, and Treads…………….427

Tighten Rear Wheel Nuts and Bolts…………….428

Rear Wheel Weights…………….429

Observe Rear Wheel Tread Width Limitations…………….876

Tread Adjustment…………….432

Section 90: Operator's Station and Cab…………….438

Cab Classification According to EN 15695-1 (for Application of Crop Protection Chemicals and Liquid Fertilizer)…………….439

Roll-Over Protective Structure…………….441

Emergency Exits…………….442

Clean Vehicle of Hazardous Pesticides…………….444

Handle Agricultural Chemicals Safely…………….445

Avoid Contact with Agricultural Chemicals…………….447

Operating Roll-Over Protective Structure…………….449

Use the Seat Belt…………….451

Fuse Box…………….452

Section 90A: Seat Adjustment…………….454

Seat Adjustment…………….454

Section 90C: Mirrors…………….456

Mirrors (Open Operator Station)…………….457

Section 90D: Access Steps…………….458

Steps and Handrails…………….459

Section 90E: Wiper / Washer System…………….461

Operator’s Cab Switches…………….462

Section 90F: Heater / Ventilation / Air Conditioning (HVAC)…………….464

Heater and Air Conditioning System Controls (5GV, 5GN, 5GF)…………….465

Heater and Air Conditioning System Controls (5GL-N)…………….471

Section 90G: Lights…………….476

Total View – Lights (Cab) (5GV, 5GN, 5GF)…………….477

Total View – Lights (Open Operator Station)…………….478

Total View – Lights (Cab) (5GL)…………….480

Light Switch and Turn Signal Switch…………….481

Low Beam and High Beam Indicator Light…………….483

Wake up Mode…………….484

Front Clearance Lights, Turn Signal Lights, and Tail Lights…………….485

Turn Signal Lights…………….488

Hazard Warning Light Switch…………….489

Beacon Light…………….490

H4 Farm Headlights (Optional)…………….492

Dome Light…………….493

Worklight Switches (Open Operator Station)…………….494

Worklight Switches (Cab)…………….495

Section 90H: Power Outlet Sockets…………….497

Seven-Terminal Trailer Socket…………….498

Section 90I: Accessories…………….499

Tool Box…………….500

Sun Visor…………….501

Section 100: Performance Ballast…………….502

Select Ballast…………….503

Ballast Limitations…………….504

Measuring Rear Wheel Slip…………….505

Installing Front Weights…………….509

Ballasting Front Wheel Drive Tractors…………….507

With Weight in Three-Point Hitch…………….828

Front Weights…………….509

Section 110: Transport…………….511

Transporting the Tractor…………….512

Select Tire Inflation Pressure…………….513

Drive on Public Roads…………….515

Driving Tractor on Public Roads…………….517

Towing Tractor…………….520

Section 200: Fuel, Lubricants, Hydraulic Oil and Coolant…………….521

Oilscan™ and CoolScan™…………….522

Section 200A: Diesel Fuel…………….524

Diesel Fuel…………….524

Handling and Storing Diesel Fuel…………….526

Lubricity of Diesel Fuel…………….527

Testing Diesel Fuel…………….528

Biodiesel Fuel…………….529

Minimizing the Effect of Cold Weather on Diesel Engines…………….531

Supplemental Diesel Fuel Additives…………….533

Section 200C: Engine Oil…………….534

John Deere Break-In Plus™ Engine Oil…………….535

Engine Break-In Period…………….536

Diesel Engine Oil — Interim Tier 4, Final Tier 4, Stage IIIB, and Stage IV…………….537

Engine Oil and Filter Service Intervals…………….539

Section 200D: Engine Coolant…………….540

Diesel Engine Coolant…………….541

Operating in Warm Temperature Climates…………….543

Water Quality for Mixing with Coolant Concentrate…………….544

Testing Diesel Engine Coolant…………….545

Supplemental Coolant Additives…………….546

Section 200E: Other Lubricants…………….547

Transmission and Hydraulic Oil…………….548

Front-Wheel Drive Axle Oil…………….549

Grease for Automated Lubrication Systems…………….551

Mixing of Lubricants…………….552

Lubricant Storage…………….553

Alternative and Synthetic Lubricants…………….554

Section 210: Service — General Information…………….593

Safe Maintenance and Cleaning…………….556

Using High Pressure Washers…………….557

Avoid High-Pressure Fluids…………….558

Storing Fuel…………….559

Ultra Low Sulfur Fuel…………….560

When Performing Services…………….561

Lubrication and Periodic Service…………….563

Oil Service Message Reset…………….564

Use Correct Lubricant…………….567

Other Service Jobs…………….568

Oil Vapor Recirculation System Maintenance…………….569

Turbo Compressor Maintenance…………….570

Overhaul Injection Pump…………….571

Fuel Filters…………….572

Tire Pressures…………….573

Inspect All Tires…………….574

Service Tractor Safely…………….575

Air Intake System Components…………….576

Fuel System Components…………….577

Engine Cooling System Components…………….578

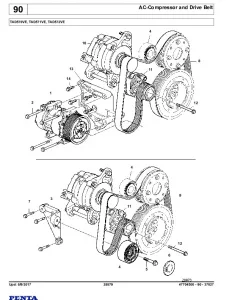

Air-Conditioning System…………….581

Open Hood…………….583

Lifting Points…………….584

Jack up the Tractor – Lifting Points…………….585

Metric Bolt and Screw Torque Values…………….587

Unified Inch Bolt and Screw Torque Values…………….589

Section 210B: Service Intervals…………….591

Information…………….593

Service (Daily / Every 10, After First 50, Every 250, 500, and 750 Hours)…………….594

Service (Every 1000, 1250, 1500, 3000 Hours and Service — As Required)…………….597

Information on Changing Engine Oil…………….600

Engine Oil and Filter Change…………….605

Engine Oil and Filter Change…………….605

Engine Oil and Filter Change…………….605

Engine Oil and Filter Change…………….605

Engine Oil and Filter Change…………….605

Engine Air Cleaner and Cab Air Filters, Service…………….607

Engine Air Cleaner and Cab Air Filters, Service…………….607

Activated Carbon Filters in Cab, Service (If Equipped)…………….611

Activated Carbon Filters in Cab, Service (If Equipped)…………….611

Activated Carbon Filters in Cab, Service (If Equipped)…………….611

Activated Carbon Filters in Cab, Service (If Equipped)…………….611

Cooling System, Service…………….613

Cooling System, Service…………….613

Yearly Service…………….615

Yearly Service…………….615

50 Hour Service…………….591

250 Hour Service…………….591

500 Hour Service…………….591

750 Hour Service…………….591

1000 Hour Service…………….591

1250 Hour Service…………….591

1500 Hour Service…………….591

1750 Hour Service…………….591

2000 Hour Service…………….591

2250 Hour Service…………….591

2500 Hour Service…………….591

2750 Hour Service…………….591

3000 Hour Service…………….591

3250 Hour Service…………….592

3500 Hour Service…………….592

3750 Hour Service…………….592

4000 Hour Service…………….592

4250 Hour Service…………….592

4500 Hour Service…………….592

4750 Hour Service…………….592

5000 Hour Service…………….592

5250 Hour Service…………….592

5500 Hour Service…………….592

5750 Hour Service…………….592

6000 Hour Service…………….592

Information About Further Services…………….641

Record for Further Services…………….642

Section 220A: Service — Cleaning…………….646

Cleaning the Dust Unloading Valve…………….647

Clean Radiator and Oil Cooler…………….648

Radiators, Cleaning…………….650

Clean Air-Conditioning System Condenser…………….654

Service Air Cleaner at Regular Intervals…………….656

Clean Cab Air Filters (5GV, 5GN, 5GF)…………….657

Clean Cab Air Filters (5GL-N)…………….658

Section 220B: Service — Electrical System…………….824

Observe Electrical Service Precautions…………….660

Battery…………….662

Battery Cut-off Switch (If Equipped)…………….667

Bulb Replacement — Safety Instructions…………….669

Checking on Lights…………….670

Adjusting the Headlights…………….671

Replace Headlight Bulbs…………….672

Replace Clearance, Brake, and Turn Signal Light Bulbs…………….673

Replace Rear Working Light Bulb…………….674

Battery, Checking Status / Charge…………….675

Starting Motor…………….676

Main Fuses and Relays (Open Operator Station) (5GL, 5GL-N)…………….677

Main Fuses and Relays (Cab) (5GL, 5GL-N)…………….682

Fuse Check (5GL, 5GL-N)…………….687

Engine Fuses and Relays (5GL, 5GL-N)…………….688

Main Power Supply Fuses and Additional Relays (5GL, 5GL-N)…………….690

Main Fuses and Relays (5GV, 5GN, 5GF)…………….691

Fuses and Relays (E-SCV) (5GV, 5GN, 5GF)…………….692

Fuse Box (Cab) (If Equipped) (5GV, 5GN, 5GF)…………….693

Relays (Cab) (5GV, 5GN, 5GF)…………….695

Engine Fuses and Relays (5GV, 5GN, 5GF)…………….696

Main Power Supply Fuses and Additional Relays (5GV, 5GN, 5GF)…………….698

Fuse and Relay Box (Mechanical Transmission) (5GV, 5GF, 5GN)…………….702

Fuse and Relay Box (PowrReverser™ Transmission) (5GV, 5GN, 5GF)…………….704

Section 220C: Maintenance — Checking Hardware Torques…………….706

After the First 4 and 8 Hours of Operation…………….707

Mounting Bolts of Operator's Cab / Open Station and ROPS…………….709

Section 220D: Service — Checks…………….710

Check Torque of Wheel and Rim Bolts…………….711

Check Engine Oil Level…………….714

Prestarting Checks…………….715

Check the Fuel Filter…………….717

Check Coolant Level…………….720

Check Transmission/Hydraulic System Oil Level…………….722

Check Brake System Oil Level…………….723

Check Brake Operation…………….725

Check Oil Levels in Front-Wheel Drive Axle…………….726

Check Oil Levels in Front-Wheel Drive (Final Drive) Axle…………….728

Check Neutral Start System – 24/12 Transmission…………….821

Check Neutral Start System – 12/12 and 24/24 Transmission…………….821

Check Belt Wear and Belt Tension…………….734

Check Torque of Drawbar Attaching Screws…………….735

Check Front PTO Oil Level…………….736

Check Clutch Pedal Free Travel…………….737

Check Hoses and Hose Clamps…………….739

Check Components of Drawbar and Trailer Hitches…………….740

Check Engine Idle Speeds…………….741

Check and Lubricate Front Axle Pivot Pin…………….742

Check the Seat Belt…………….743

Check Condition of Diesel Engine Coolant…………….744

Radiator Pressure Cap Check…………….745

Inspect Hydraulic Hoses…………….746

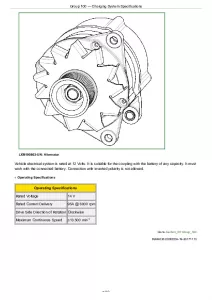

Inspect Alternator…………….747

Inspect Suspended Front Axle…………….748

Section 220E: Service — Change…………….749

Change Engine Oil and Replace Oil Filter…………….750

Changing Oil in Front-Wheel Drive Axle…………….752

Change Oil in Front-Wheel Drive Axle Housing…………….753

Change Oil in Front-Wheel Drive Final Drives…………….755

Change Brake System Oil…………….756

Change Engine Coolant…………….757

Change Cooling System Coolant…………….758

Replace Transmission Hydraulic Oil and Suction Strainer…………….759

Change Oil and Replace Oil Filter of Front PTO…………….825

Replace Transmission/Hydraulic Oil Filter Cartridge (First and Second Pump)…………….763

Replace Cab Air Filters…………….765

Replace Diesel Particulate Filter…………….766

Replace Alternator Drive Belt…………….767

Replace Water Pump…………….768

Replace Fuel Filter…………….769

Replace and Clean Engine Air Filter…………….772

Replace Transmission/Hydraulic Oil Filter Cartridge (Third Pump)…………….776

Drain Water and Sediment from Fuel Filter…………….778

Drain Water and Sediment from Fuel Tank…………….780

Adjust PTO Clutch Linkage…………….781

Replace E-SCV End Cover Valve Filter…………….782

Section 220F: Service — Lubrication…………….783

Lubricate Front-Wheel Drive Axle…………….784

Lubricate Front Axle King Pins…………….786

Lubricate Suspended Front Axle…………….787

Lubricate 4WD Shaft…………….789

Lubricate Front Hitch King Pins…………….790

Lubricate 3-Point Hitch…………….792

Lubricate Hub Bearings (Tractors without Front-Wheel Drive)…………….794

Lubricate Draft Links…………….795

Lubricate…………….796

Lubricate Rear Axle Bearings…………….797

Lubricate Front PTO…………….825

Section 300A: Troubleshooting…………….799

Diagnostic Trouble Codes – Operator Information…………….800

Engine Troubleshooting…………….801

Transmission Troubleshooting…………….806

Brakes Troubleshooting…………….807

Rockshaft and Quick-Coupler 3-Point Hitch Troubleshooting…………….808

Remote Hydraulic Cylinders Troubleshooting…………….810

Electrical System Troubleshooting…………….811

Section 400: Storage…………….813

Storage for Long Period…………….814

Remove Tractor from Storage…………….815

Section 500A: Specifications…………….817

Engine…………….818

DPF Soot Load…………….820

Transmission…………….821

Front-Wheel Drive Clutch…………….822

Hydraulic System…………….823

Electrical System…………….824

Front PTO…………….825

Fuel System…………….826

Brakes…………….827

Three-Point Hitch…………….828

Loads and Weights…………….829

Capacities…………….836

Sound Level…………….839

Maximum Lifting Force…………….841

Towable Loads…………….842

Shipping Weights…………….843

Maximum Permissible Axle Loads and Total Weights…………….844

Maximum Permissible Axle Load in Relation to Tires (Normal Operation)…………….846

Load Capacity of Tires with Front Loader…………….861

Vehicle Dimensions…………….862

Safety Note Regarding the Subsequent Installation of Electrical and Electronic Appliances and/or Components…………….869

How to Calculate Permissible Mass…………….870

Vibration…………….871

Limited Battery Warranty…………….872

How to Calculate Maximum Permissible Download on Trailer Hitch…………….874

Observe Rear Wheel Tread Width Limitations…………….876

Section 500B: Serial Numbers…………….878

Type Plates…………….879

Identification Plates…………….880

Product Identification Number…………….881

Engine Serial Number…………….884

Transmission Serial Number…………….885

Front Axle Serial Number…………….886

Suspended Front Axle Serial Number…………….887

Section 600: Change of Ownership…………….888

List of Owners…………….889

Section 700: Service — Predelivery Inspection…………….890

Service Procedure…………….891

Copy for Dealer…………….893

Copy for Owner…………….895

John Deere 5075GV, 5075GN, 5075GF, 5075GL, 5090GV, 5090GN, 5090GF, 5090GL, 5100GL, 5105GN and 5105GF Operator’s manual (OMER525732)