Complete service repair manual with Electrical Wiring Diagrams for Caterpillar 834G Wheel Tractors and 836G Landfill Compactors, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Caterpillar 834G Wheel Tractors and 836G Landfill Compactors workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

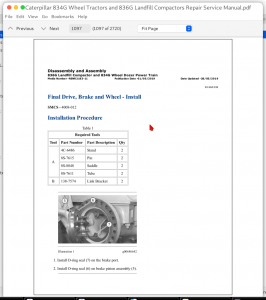

* Numbered instructions guide you through every repair procedure step by step.

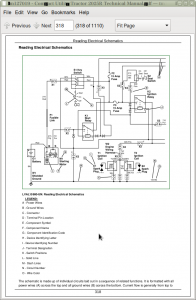

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

RENR2180 – Specifications (834G Wheel Dozer and 836G Landfill Compactor Power Train).pdf

RENR2181 – Systems Operation (834G Wheel Dozer and 836G Landfill Compactor Power Train).pdf

RENR2182 – Testing and Adjusting (834G Wheel Dozer and 836G Landfill Compactor Power Train).pdf

RENR2182 – Troubleshooting (834G Wheel Dozer and 836G Landfill Compactor Power Train).pdf

RENR2183 – Disassembly and Assembly (836G Landfill Compactor and 834G Wheel Dozer Power Train).pdf

RENR2184 – Specifications (834G Wheel Dozer and 836G Landfill Compactor Steering System).pdf

RENR2185 – Systems Operation (834G Wheel Tractor and 836G Landfill Compactor Steering System).pdf

RENR2186 – Testing and Adjusting (834G Wheel Dozer and 836G Landfill Compactor Steering System).pdf

RENR2187 – Specifications (834G Wheel Tractor and 836G Landfill Compactor Braking System).pdf

RENR2188 – Systems Operation (834G Wheel Tractor and 836G Landfill Compactor Braking System).pdf

RENR2189 – Testing and Adjusting (834G Wheel Dozer and 836G Landfill Compactor Braking System).pdf

RENR2190 – Specifications (834G Wheel Dozer and 836G Landfill Compactor Electrohydraulic System).pdf

RENR2191 – Systems Operation (834G Wheel Tractor and 836G Landfill Compactor Electrohydraulic System).pdf

RENR2192 – Testing and Adjusting (834G Wheel Dozer and 836G Landfill Compactor Electrohydraulic System).pdf

RENR2192 – Troubleshooting (834G Wheel Dozer and 836G Landfill Compactor Electrohydraulic System).pdf

RENR2193 – Disassembly and Assembly (834G Wheel Tractor and 836G Landfill Compactor Machine Systems).pdf

RENR2194 – Schematic (834G Wheel Tractor and 836G Landfill Compactor Hydraulic System).pdf

RENR2195 – Schematic (834G Wheel Tractor; 836G Landfill Compactor; and 988G Wheel Loader Electrical System).pdf

RENR2196 – Disassembly and Assembly (834G Wheel Tractor and 836G Landfill Compactor Engine Supplement).pdf

RENR6005 – Specifications (988G Wheel Loader; 834G Wheel Tractor and 836G Landfill Compactor Machine Systems).pdf

PRODUCT DETAILS:

Total Pages: 2,721 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

RENR2180 – Specifications (834G Wheel Dozer and 836G Landfill Compactor Power Train)…1

Torque Converter and Pump Drive Housing…3

Torque Converter (Lockup)…5

Torque Converter Priority Valve…8

Modulating Valve (Torque Converter Impeller Clutch)…10

Modulating Valve (Torque Converter Lockup Clutch)…11

Relief Valve (Torque Converter Outlet)…12

Speed Sensor (Torque Converter Output)…14

Temperature Sensor (Torque Converter Oil)…15

Transmission Oil Pump…16

Oil Filter (Power Train)…21

Bypass Switch (Power Train Oil Filter)…23

STIC Control…24

STIC Control Lock…28

Limit Switch (STIC Control Lock)…32

Pinout Specifications for Power Train Electronic Control…34

Transmission Hydraulic Control…38

Relief Valve (Transmission Hydraulic Control)…40

Modulating Valve (Transmission Clutch)…42

Temperature Sensor (Transmission Oil)…43

Transmission Planetary…44

Input Drive Shaft…47

Input Transfer Gears…48

Output Transfer Gears…51

Speed Sensor (Transmission Output)…54

Drive Shaft…57

Differential and Bevel Gear…59

NoSPIN Differential…64

Fixed Axle (Front)…65

Oscillating Axle (Rear)…66

Final Drive and Wheel…69

Axle Mounting…71

Compactor Wheel Mounting…73

Gear Motor (Axle Oil Cooler Fan)…75

Temperature Sensor (Axle Oil)…77

RENR2181 – Systems Operation (834G Wheel Dozer and 836G Landfill Compactor Power Train)…78

General Information…79

Power Train Electronic Control System…81

Electronic Control Module (Power Train)…89

Switches…94

Sensors…104

Data Link…109

Monitoring System (Power Train Functions)…111

Torque Converter and Pump Drive Housing…113

Torque Converter (Lockup)…116

Modulating Valve (Torque Converter Impeller Clutch)…124

Modulating Valve (Torque Converter Lockup Clutch)…127

Transmission Hydraulic System…129

Transmission Oil Pump…134

Oil Filter (Power Train)…137

Transmission Magnetic Screen…139

Transmission Oil Cooler…140

Transmission Lubrication…142

Transmission Hydraulic Control…146

Modulating Valve (Transmission Clutch)…149

Transmission Hydraulic Control Operation…152

Transmission Planetary…161

Input Transfer Gears…169

Output Transfer Gears…172

Input Transfer Gear And Output Transfer Gear Lubrication…175

Differential…177

NoSPIN Differential…180

Final Drive and Wheel…189

RENR2182 – Testing and Adjusting (834G Wheel Dozer and 836G Landfill Compactor Power Train)…192

Wiring Harness (Open Circuit) – Test…194

Wiring Harness (Short Circuit) – Test…195

Electrical Connector – Inspect…196

Electronic Control Module (ECM) – Replace…202

Electronic Control Module (ECM) – Flash Program…203

Calibration…204

Forward High Speed Lockout – Program…206

Reverse High Speed Lockout – Program…210

Fill Pressure for the Impeller Clutch of the Torque Converter (Electronic Technician) – Calibrate…214

Position Sensor (Left Brake Pedal) (Electronic Technician) – Calibrate…217

Engagement Pressure for the Lockup Clutch of the Torque Converter (Electronic Technician) – Calibrate…220

Engagement Pressure for the Transmission Clutch (Electronic Technician) – Calibrate…226

Fill Time for the Transmission Clutch (Electronic Technician) – Calibrate…234

Fill Pressure for the Impeller Clutch of the Torque Converter (Caterpillar Monitoring System) – Calibrate…237

Position Sensor (Left Brake Pedal) (Caterpillar Monitoring System) – Calibrate…240

Engagement Pressure for the Lockup Clutch of the Torque Converter (Caterpillar Monitoring System) – Calibrate…242

Engagement Pressure for the Transmission Clutch (Caterpillar Monitoring System) – Calibrate…249

Fill Time for the Transmission Clutch (Caterpillar Monitoring System) – Calibrate…259

Limit Switch (STIC Lockout Control) – Adjust…264

Speed Sensor – Adjust…267

Torque Converter Impeller Clutch Pressure – Test…268

Torque Converter Lockup Clutch Pressure – Test…275

Torque Converter Stall – Test…282

Transmission Pressures – Test and Adjust…287

Input Transfer Gears – Adjust…296

Output Transfer Gears – Adjust…299

Differential Pinion Preload – Adjust…302

Differential Backlash and Bearings – Adjust…307

Wheel Bearings – Adjust…313

Glossary of Electrical Terms…316

System Schematic…318

RENR2182 – Troubleshooting (834G Wheel Dozer and 836G Landfill Compactor Power Train)…320

General Information…323

Service Tools…326

Connector Locations…329

Diagnostic Capabilities…332

Machine Preparation for Troubleshooting…338

Visual Inspection…341

Torque Converter Troubleshooting…344

Transmission Troubleshooting…352

Differential and Final Drive Troubleshooting…361

Diagnostic Code List…365

Using Caterpillar Monitoring System to Determine Diagnostic Codes…375

MID 081 – CID 0041 – FMI 03…378

MID 081 – CID 0041 – FMI 04…381

MID 081 – CID 0168 – FMI 00…384

MID 081 – CID 0168 – FMI 01…387

MID 081 – CID 0177 – FMI 03…389

MID 081 – CID 0177 – FMI 04…394

MID 081 – CID 0190 – FMI 02…397

MID 081 – CID 0248 – FMI 12…401

MID 081 – CID 0254 – FMI 12…406

MID 081 – CID 0368 – FMI 03…407

MID 081 – CID 0368 – FMI 04…410

MID 081 – CID 0444 – FMI 03…413

MID 081 – CID 0444 – FMI 05…416

MID 081 – CID 0444 – FMI 06…419

MID 081 – CID 0485 – FMI 03…423

MID 081 – CID 0485 – FMI 05…426

MID 081 – CID 0485 – FMI 06…429

MID 081 – CID 0585 – FMI 02…432

MID 081 – CID 0590 – FMI 09…437

MID 081 – CID 0590 – FMI 12…439

MID 081 – CID 0596 – FMI 09…442

MID 081 – CID 0623 – FMI 03…444

MID 081 – CID 0623 – FMI 04…447

MID 081 – CID 0626 – FMI 03…450

MID 081 – CID 0626 – FMI 04…455

MID 081 – CID 0627 – FMI 03…460

MID 081 – CID 0627 – FMI 04…465

MID 081 – CID 0650 – FMI 09…470

MID 081 – CID 0650 – FMI 12…474

MID 081 – CID 0670 – FMI 00…478

MID 081 – CID 0670 – FMI 01…484

MID 081 – CID 0670 – FMI 03…490

MID 081 – CID 0670 – FMI 04…495

MID 081 – CID 0670 – FMI 13…498

MID 081 – CID 0672 – FMI 00…500

MID 081 – CID 0672 – FMI 01…506

MID 081 – CID 0673 – FMI 02…512

MID 081 – CID 0678 – FMI 03…517

MID 081 – CID 0678 – FMI 05…520

MID 081 – CID 0678 – FMI 06…523

MID 081 – CID 0678 – FMI 13…526

MID 081 – CID 0679 – FMI 03…528

MID 081 – CID 0679 – FMI 05…531

MID 081 – CID 0679 – FMI 06…534

MID 081 – CID 0679 – FMI 13…537

MID 081 – CID 1401 – FMI 03…539

MID 081 – CID 1401 – FMI 05…543

MID 081 – CID 1401 – FMI 06…547

MID 081 – CID 1401 – FMI 13…551

MID 081 – CID 1402 – FMI 03…553

MID 081 – CID 1402 – FMI 05…557

MID 081 – CID 1402 – FMI 06…561

MID 081 – CID 1402 – FMI 13…565

MID 081 – CID 1403 – FMI 03…567

MID 081 – CID 1403 – FMI 05…571

MID 081 – CID 1403 – FMI 06…575

MID 081 – CID 1403 – FMI 13…579

MID 081 – CID 1404 – FMI 03…581

MID 081 – CID 1404 – FMI 05…585

MID 081 – CID 1404 – FMI 06…589

MID 081 – CID 1404 – FMI 13…593

MID 081 – CID 1405 – FMI 03…595

MID 081 – CID 1405 – FMI 05…599

MID 081 – CID 1405 – FMI 06…603

MID 081 – CID 1405 – FMI 13…607

MID 081 – CID 1406 – FMI 03…609

MID 081 – CID 1406 – FMI 05…613

MID 081 – CID 1406 – FMI 06…617

MID 081 – CID 1406 – FMI 13…621

Backup Alarm Always Off…623

Backup Alarm Always On…626

Starting System…628

RENR2183 – Disassembly and Assembly (836G Landfill Compactor and 834G Wheel Dozer Power Train)…630

Steering Frame Lock – Separate and Connect…633

System Pressure – Release…636

Power Actuator (Crankcase Guard) – Remove and Install…638

Crankcase Guard (Rear) – Remove and Install…646

Crankcase Guard (Front) – Remove and Install…651

Power Actuator (Power Train Guard) – Remove and Install…653

Power Train Filter Guard – Remove and Install…659

STIC Control – Remove…664

STIC Control – Install…668

Torque Converter – Remove…671

Torque Converter (Lockup) – Disassemble…676

Torque Converter (Lockup) – Assemble…706

Torque Converter – Install…733

Modulating Valve (Torque Converter Lockup Clutch) – Remove and Install…738

Modulating Valve (Torque Converter Impeller Clutch) – Remove and Install…741

Relief Valve (Torque Converter Outlet) – Remove…744

Relief Valve (Torque Converter Outlet) – Disassemble…747

Relief Valve (Torque Converter Outlet) – Assemble…750

Relief Valve (Torque Converter Outlet) – Install…753

Torque Converter Priority Valve – Remove…755

Torque Converter Priority Valve – Disassemble…757

Torque Converter Priority Valve – Assemble…760

Torque Converter Priority Valve – Install…763

Transmission Oil Pump – Remove…765

Transmission Oil Pump – Disassemble…771

Transmission Oil Pump – Assemble…776

Transmission Oil Pump – Install…783

Modulating Valve (Transmission Clutch) – Remove…788

Modulating Valve (Transmission Clutch) – Disassemble…792

Modulating Valve (Transmission Clutch) – Assemble…794

Modulating Valve (Transmission Clutch) – Install…796

Relief Valve (Transmission Hydraulic Control) – Remove…799

Relief Valve (Transmission Hydraulic Control) – Disassemble…804

Relief Valve (Transmission Hydraulic Control) – Assemble…808

Relief Valve (Transmission Hydraulic Control) – Install…812

Input Drive Shaft – Remove and Install…817

Transmission; Input Transfer Gears and Output Transfer Gears – Remove…819

Transmission from Input Transfer Gears and Output Transfer Gears – Separate…832

Input Transfer Gears – Disassemble…836

Input Transfer Gears – Assemble…843

Transmission Planetary – Disassemble…851

Transmission Planetary – Assemble…882

Output Transfer Gears – Disassemble…911

Output Transfer Gears – Assemble…927

Transmission to Input Transfer Gears and Output Transfer Gears – Connect…939

Transmission; Input Transfer Gears and Output Transfer Gears – Install…942

Parking Brake – Remove…954

Parking Brake – Disassemble…959

Parking Brake – Assemble…962

Parking Brake – Install…967

Drive Shaft (Front) and Drive Shaft Support Bearing – Remove…971

Drive Shaft (Front) and Drive Shaft Support Bearing – Install…975

Drive Shaft (Center) – Remove and Install…979

Drive Shaft (Rear) – Remove and Install…984

Striker Bar – Remove…988

Striker Bar – Install…993

Compactor Wheel – Remove…997

Compactor Wheel – Install…1001

Axle Guards (Front) – Remove and Install…1005

Axle Guards (Rear) – Remove and Install…1010

Fixed Axle (Front) – Remove…1018

Fixed Axle (Front) – Install…1023

Oscillating Axle (Rear) – Remove…1027

Trunnion Support (Oscillating Axle; Front) – Remove…1031

Trunnion Support (Oscillating Axle; Front) – Disassemble…1033

Trunnion Support (Oscillating Axle; Front) – Assemble…1035

Trunnion Support (Oscillating Axle; Front) – Install…1037

Trunnion Support (Oscillating Axle; Rear) – Remove…1039

Trunnion Support (Oscillating Axle; Rear) – Disassemble…1044

Trunnion Support (Oscillating Axle; Rear) – Assemble…1045

Trunnion Support (Oscillating Axle; Rear) – Install…1047

Axle Shaft – Remove and Install…1052

Final Drive; Brake and Wheel – Remove…1058

Final Drive Spindle – Disassemble…1063

Final Drive Spindle – Assemble…1065

Service Brake – Disassemble…1067

Service Brake – Assemble…1070

Final Drive and Wheel – Disassemble…1073

Duo-Cone Conventional Seals – Install…1081

Final Drive and Wheel – Assemble…1088

Final Drive; Brake and Wheel – Install…1097

Differential and Bevel Gear – Remove – Rear…1100

Differential and Bevel Gear – Disassemble…1104

Differential and Bevel Gear – Assemble…1117

Differential and Bevel Gear – Install – Rear…1140

NoSPIN Differential – Disassemble…1144

NoSPIN Differential – Assemble…1148

Oscillating Axle (Rear) – Install…1153

RENR2184 – Specifications (834G Wheel Dozer and 836G Landfill Compactor Steering System)…1157

Hydraulic Tank…1158

Breaker Relief Valve…1163

Oil Filter (Steering and Implement Pilot)…1164

Pressure Switch (Pilot Oil Filter Bypass)…1165

Relief Valve (Steering Pilot; Implement Pilot)…1167

Piston Pump (Steering)…1169

Check Valve (Steering Pilot)…1173

Pilot Valve (STIC Steering)…1174

Steering Control (Wheel Steering)…1176

Pilot Valve (Wheel Steering)…1178

Steering Neutralizer Valve…1181

Check Valve (Steering Quad)…1182

Steering Control Valve…1183

Pressure Reducing Valve (Steering)…1185

Relief Valve (Steering Cylinder Crossover)…1186

Relief Valve (Pump Backup)…1187

Steering Cylinder…1189

Articulated Hitch…1191

RENR2185 – Systems Operation (834G Wheel Tractor and 836G Landfill Compactor Steering System)…1194

General Information…1195

Monitoring System (Steering Functions)…1200

Steering Pilot System…1203

Pilot Valve (STIC Steering)…1207

Pilot Valve (Wheel Steering)…1211

Steering Neutralizer Valve…1213

Steering High Pressure System…1215

Piston Pump (Steering)…1218

Steering Control Valve…1227

RENR2186 – Testing and Adjusting (834G Wheel Dozer and 836G Landfill Compactor Steering System)…1233

Machine Preparation for Troubleshooting…1234

Visual Inspection…1237

Steering System Troubleshooting…1240

System Pressure – Release…1243

Hydraulic Oil Contamination – Test…1245

Pump Performance (Steering) – Test…1248

Relief Valve (Steering Pilot; Implement Pilot) – Test and Adjust…1250

Relief Valve (Steering Cylinder Crossover) – Test and Adjust…1253

Steering System Pressure (High Pressure Stall) – Test and Adjust…1258

Piston Pump (Steering) Low Pressure Standby – Test…1265

Piston Pump (Steering) Margin Pressure – Test and Adjust…1269

Relief Valve (Pump Backup) – Test and Adjust…1276

Steering Neutralizer Valve – Check and Adjust…1281

Steering Turn Stop – Adjust…1283

Steering Time – Check and Adjust…1285

Articulated Hitch – Adjust…1287

RENR2187 – Specifications (834G Wheel Tractor and 836G Landfill Compactor Braking System)…1292

Hydraulic Tank…1293

Breaker Relief Valve…1298

Gear Pump (Implement; Pilot; Brake)…1299

Brake Accumulator…1301

Accumulator Charging Valve (Brake)…1303

Pressure Switch (Brake Accumulator Charge)…1305

Foot Brake Control…1307

Limit Switch (Stop Light)…1310

Position Sensor (Torque Converter Impeller Clutch; Left Pedal)…1312

Limit Switch (Throttle Lock Deactivation; Right Pedal)…1313

Brake Control Valve (Service)…1315

Brake Control Valve (Parking)…1317

Pressure Switch (Parking Brake Oil)…1318

Parking Brake Control Cable…1320

Service Brakes…1321

Parking Brake…1323

RENR2188 – Systems Operation (834G Wheel Tractor and 836G Landfill Compactor Braking System)…1328

General Information…1329

Monitoring System (Braking Functions)…1333

Gear Pump (Implement; Pilot; Brake)…1335

Brake Accumulator…1337

Accumulator Charging Valve (Brake)…1339

Brake Control Valve (Service)…1342

Torque Converter Impeller Clutch Operation…1349

Brake Control Valve (Parking)…1351

Service Brakes…1355

Parking Brake…1357

Parking Brake Interlock…1360

RENR2189 – Testing and Adjusting (834G Wheel Dozer and 836G Landfill Compactor Braking System)…1362

Machine Preparation for Troubleshooting…1363

Visual Inspection…1366

Brake System Troubleshooting…1369

System Pressure – Release…1373

Hydraulic Oil Contamination – Test…1375

Brake Accumulator – Test and Charge…1378

Service Braking System Pressure – Test…1384

Service Brakes – Test…1387

Brake System Air – Purge…1390

Service Brake Discs – Check…1392

Limit Switch (Stop Light) – Adjust…1397

Limit Switch (Throttle Lock Deactivation) (Electronic Technician) – Adjust…1400

Parking Brake – Test…1407

Parking Brake System Air – Purge…1411

Parking Brake – Manual Release…1414

Parking Brake Control Cable – Adjust…1417

RENR2190 – Specifications (834G Wheel Dozer and 836G Landfill Compactor Electrohydraulic System)…1419

Hydraulic Tank…1420

Breaker Relief Valve…1425

Oil Filter (Steering and Implement Pilot)…1426

Pressure Switch (Pilot Oil Filter Bypass)…1427

Gear Pump (Implement; Pilot; Brake)…1429

Relief Valve (Steering Pilot; Implement Pilot)…1431

Relief Valve (Steering and Implement Pilot)…1433

Piston Pump (Hydraulic Fan)…1435

Gear Motor (Hydraulic Fan)…1439

Thermostatic Valve (Hydraulic Fan)…1441

Fan Reversing Valve…1442

Electrohydraulic Control…1445

Position Sensor (Control Lever)…1451

Pilot Control Actuator…1453

Combination Valve (Pilot Supply)…1455

Check Valve (Pilot)…1457

Main Control Valve…1458

Relief Valve (Main)…1462

Relief Valve (Line)…1464

Pinout Specifications for Implement Electronic Control…1466

Temperature Sensor (Hydraulic Oil)…1470

Check Valve (Hydraulic Oil Cooler Bypass)…1471

Lift Cylinder…1472

Bulldozer Pin…1474

Ground Engaging Tool Torques…1476

RENR2191 – Systems Operation (834G Wheel Tractor and 836G Landfill Compactor Electrohydraulic System)…1477

General Information…1478

Implement Electronic Control System…1482

Electronic Control Module (Implement)…1484

Switches…1488

Sensors…1490

Solenoid Valves…1494

Cat Data Link…1496

Monitoring System (Hydraulic Functions)…1498

Pilot Hydraulic System…1500

Gear Pump (Implement; Pilot; Brake)…1504

Relief Valve (Steering Pilot; Implement Pilot)…1506

Combination Valve (Pilot Supply)…1508

Pilot Control Actuator…1511

Main Hydraulic System…1514

Main Control Valve…1517

Relief Valve (Main)…1521

Relief Valve (Line)…1523

Hydraulic Fan System…1525

Piston Pump (Hydraulic Fan)…1530

Gear Motor (Hydraulic Fan)…1539

Fan Reversing Valve…1541

RENR2192 – Testing and Adjusting (834G Wheel Dozer and 836G Landfill Compactor Electrohydraulic System)…1544

Wiring Harness (Open Circuit) – Test…1545

Wiring Harness (Short Circuit) – Test…1547

Electrical Connector – Inspect…1549

Electronic Control Module (ECM) – Replace…1555

Electronic Control Module (ECM) – Flash Program…1556

Calibration…1557

Position Sensor for the Control Lever (Electronic Technician) – Calibrate…1558

Main Control Valve (Electronic Technician) – Calibrate…1560

Position Sensor for the Control Lever (Caterpillar Monitoring System) – Calibrate…1562

Main Control Valve (Caterpillar Monitoring System) – Calibrate…1564

System Pressure – Release…1570

Hydraulic Oil Contamination – Test…1572

Pump Performance – Test…1575

Torque Converter Stall – Test…1578

Torque Converter Stall and Implement Pump Double Stall – Test…1583

Lift Cylinder – Isolation and Drift Check…1588

Pilot Control Actuator Pressure – Check…1596

Relief Valve (Steering Pilot; Implement Pilot) – Test and Adjust…1599

Pressure Reducing Valve (Lowering Control) for Dead Engine Condition – Test and Adjust…1602

Relief Valve (Main) – Test and Adjust…1605

Relief Valve (Line) – Test and Adjust…1608

Piston Pump Cutoff Pressure (Hydraulic Fan) – Test and Adjust…1614

Piston Pump Margin Pressure (Hydraulic Fan) – Test and Adjust…1617

Glossary of Electrical Terms…1622

System Schematic…1624

RENR2192 – Troubleshooting (834G Wheel Dozer and 836G Landfill Compactor Electrohydraulic System)…1630

General Information…1632

Service Tools…1633

Connector Locations…1636

Diagnostic Capabilities…1638

Machine Preparation for Troubleshooting…1643

Visual Inspection…1645

Hydraulic System Troubleshooting…1648

Diagnostic Code List…1656

Using Caterpillar Electronic Technician to Determine Diagnostic Codes…1665

Using Caterpillar Monitoring System to Determine Diagnostic Codes…1667

MID 082 – CID 0168 – FMI 00…1670

MID 082 – CID 0168 – FMI 01…1672

MID 082 – CID 0296 – FMI 09…1674

MID 082 – CID 0296 – FMI 12…1680

MID 082 – CID 0352 – FMI 03…1685

MID 082 – CID 0352 – FMI 04…1690

MID 082 – CID 0352 – FMI 13…1693

MID 082 – CID 0353 – FMI 03…1695

MID 082 – CID 0353 – FMI 04…1700

MID 082 – CID 0353 – FMI 13…1703

MID 082 – CID 0354 – FMI 03…1705

MID 082 – CID 0354 – FMI 05…1708

MID 082 – CID 0354 – FMI 06…1711

MID 082 – CID 0354 – FMI 13…1714

MID 082 – CID 0355 – FMI 03…1716

MID 082 – CID 0355 – FMI 05…1719

MID 082 – CID 0355 – FMI 06…1722

MID 082 – CID 0355 – FMI 13…1725

MID 082 – CID 0356 – FMI 03…1727

MID 082 – CID 0356 – FMI 05…1730

MID 082 – CID 0356 – FMI 06…1733

MID 082 – CID 0356 – FMI 13…1736

MID 082 – CID 0357 – FMI 03…1738

MID 082 – CID 0357 – FMI 05…1741

MID 082 – CID 0357 – FMI 06…1744

MID 082 – CID 0357 – FMI 13…1747

MID 082 – CID 0358 – FMI 03…1749

MID 082 – CID 0358 – FMI 05…1752

MID 082 – CID 0358 – FMI 06…1755

MID 082 – CID 0490 – FMI 03…1758

MID 082 – CID 0490 – FMI 04…1763

MID 082 – CID 0562 – FMI 09…1768

MID 082 – CID 0562 – FMI 12…1774

MID 082 – CID 0590 – FMI 09…1779

MID 082 – CID 0590 – FMI 12…1785

MID 082 – CID 0591 – FMI 12…1790

MID 082 – CID 0650 – FMI 09…1792

MID 082 – CID 0650 – FMI 11…1796

MID 082 – CID 0650 – FMI 12…1801

MID 082 – CID 1393 – FMI 04…1805

MID 082 – CID 1400 – FMI 03…1807

MID 082 – CID 1400 – FMI 05…1810

MID 082 – CID 1400 – FMI 06…1813

RENR2193 – Disassembly and Assembly (834G Wheel Tractor and 836G Landfill Compactor Machine Systems)…1816

Steering Frame Lock – Separate and Connect…1819

System Pressure – Release…1822

Cab – Raise…1824

Cab – Lower…1840

Hydraulic Tank Guard – Remove…1851

Hydraulic Tank Guard – Install…1855

Hydraulic Tank – Remove…1859

Hydraulic Tank – Disassemble…1868

Hydraulic Tank – Assemble…1874

Hydraulic Tank – Install…1881

Relief Valve (Steering and Implement Pilot) – Remove and Install…1890

Pump Control Valve (Steering) – Remove and Install…1893

Piston Pump (Steering) – Remove…1896

Piston Pump (Steering) – Disassemble…1900

Piston Pump (Steering) – Assemble…1912

Piston Pump (Steering) – Install…1927

STIC Control and Pilot Valve (Steering) – Remove…1930

STIC Control and Pilot Valve (Steering) – Disassemble…1933

STIC Control and Pilot Valve (Steering) – Assemble…1942

STIC Control and Pilot Valve (Steering) – Install…1951

Steering Neutralizer Valve – Remove and Install…1953

Steering Control Valve – Remove…1956

Steering Control Valve – Disassemble…1961

Steering Control Valve – Assemble…1969

Steering Control Valve – Install…1978

Steering Cylinder – Remove…1982

Steering Cylinder – Install…1990

Brake Accumulator – Remove…1996

Brake Accumulator – Disassemble…2000

Brake Accumulator – Assemble…2003

Brake Accumulator – Install…2006

Accumulator Charging Valve (Brake) – Remove…2009

Accumulator Charging Valve (Brake) – Install…2013

Brake Control Valve (Service) – Remove and Install…2017

Brake Control Valve (Parking) – Remove and Install…2021

Parking Brake – Remove…2025

Parking Brake – Disassemble…2030

Parking Brake – Assemble…2033

Parking Brake – Install…2038

Gear Pump (Implement; Pilot and Braking) – Remove…2042

Gear Pump (Implement; Pilot and Braking) – Disassemble…2045

Gear Pump (Implement; Pilot and Braking) – Assemble…2052

Gear Pump (Implement; Pilot and Braking) – Install…2059

Pump Control Valve (Hydraulic Fan) – Remove and Install…2061

Piston Pump (Hydraulic Fan) – Remove…2065

Piston Pump (Hydraulic Fan) – Disassemble…2068

Piston Pump (Hydraulic Fan) – Assemble…2082

Piston Pump (Hydraulic Fan) – Install…2096

Thermostatic Valve (Hydraulic Fan) – Remove and Install…2099

Gear Motor (Hydraulic Fan) – Remove…2105

Gear Motor (Hydraulic Fan) – Disassemble…2107

Gear Motor (Hydraulic Fan) – Assemble…2112

Gear Motor (Hydraulic Fan) – Install…2116

Electrohydraulic Control – Remove…2118

Electrohydraulic Control – Install…2125

Main Control Valve – Remove…2131

Main Control Valve – Disassemble…2137

Main Control Valve – Assemble…2144

Main Control Valve – Install…2150

Combination Valve (Pilot Supply) – Remove…2155

Combination Valve (Pilot Supply) – Disassemble…2158

Combination Valve (Pilot Supply) – Assemble…2160

Combination Valve (Pilot Supply) – Install…2162

Fan Reversing Valve – Remove…2165

Fan Reversing Valve – Disassemble…2170

Fan Reversing Valve – Assemble…2178

Fan Reversing Valve – Install…2185

Blade – Remove…2189

Blade – Install…2194

Lift Cylinder – Remove…2198

Lift Cylinder – Install…2202

Window Wiper and Wiper Motor (Front) – Remove…2205

Window Wiper and Wiper Motor (Front) – Install…2210

Window Wiper and Wiper Motor (Rear) – Remove…2217

Window Wiper and Wiper Motor (Rear) – Install…2220

Swingout Ladder – Remove…2225

Swingout Ladder – Install…2228

Cab – Remove…2231

Cab – Install…2245

Operator Platform – Remove…2258

Operator Platform – Install…2262

Seat – Remove…2266

Seat – Install…2275

Evaporator Coil – Remove and Install…2283

Heater Coil – Remove and Install…2285

Blower Motor (Air Conditioner; Heater) – Remove…2287

Blower Motor (Air Conditioner; Heater) – Install…2293

Front Frame from Rear Frame – Separate…2299

Front Frame to Rear Frame – Connect…2314

RENR2194 – Schematic (834G Wheel Tractor and 836G Landfill Compactor Hydraulic System)…2333

Main…2334

Feature…2334

Cover Page…2335

Information…0

Component Location…0

Volume 1 of 2 – 836G Landfill Compactor…2336

Volume 2 of 2 – 834G Wheel Tractor…0

Page 1 of 2…2337

Page 2 of 2…2338

Tap Location…0

Volume 1 of 2 – 836G Landfill Compactor…2339

Volume 2 of 2 – 834G Wheel Tractor…2340

Related Manuals…2341

Fluid Power Symbols…2342

Electrical Symbols…2343

Schematic…0

Volume 1 of 2 – 836G Landfill Compactor…2344

Volume 2 of 2 – 834G Wheel Tractor…2345

Machine Views…0

Machine Component Locations – 836G…2346

Machine Component Locations – 834G…2347

Collage…2348

RENR2195 – Schematic (834G Wheel Tractor; 836G Landfill Compactor; and 988G Wheel Loader Electrical System)…2381

Main…2382

Features…2382

Cover Page…2383

Information…0

Component Location…0

Volume 1 of 2 – Cab …2384

Volume 2 of 2 – Engine and Chassis …2385

Connector Location…0

Volume 1 of 2 – Cab…2386

Volume 2 of 2 – Engine and Chassis …2387

CID / MID / FMI…0

Volume 1 of 2 – Cab…0

Page 1 of 3…2388

Page 2 of 3…2389

Page 3 of 3…2390

Volume 2 of 2 – Engine and Chassis …0

Page 1 of 3…2391

Page 2 of 3…2392

Page 3 of 3…2393

Specification and Related Manual…0

Volume 1 – Cab …2394

Volume 2 – Engine And Chassis…2395

Standard Electrical…2396

Schematics…0

Volume 1 – Cab …2397

Volume 2 – Engine and Chassis…2398

Machine View…0

Cab – Front and Top View …2399

838G – Top and Rigth Side View …2400

836G – Top and Rigth Side View…2401

988G – Top and Rigth Side View…2402

Dash Front and Rear View…2403

View of Area – 938G…2404

View of Area 834G and 846G…2405

Collage…2406

RENR2196 – Disassembly and Assembly (834G Wheel Tractor and 836G Landfill Compactor Engine Supplement)…2438

Steering Frame Lock – Separate and Connect…2440

System Pressure – Release…2443

Hood and Engine Enclosure – Remove…2445

Hood and Engine Enclosure – Install…2455

Hood Panels (Front and Rear) – Remove…2464

Hood Panels (Front and Rear) – Install…2471

Belt Tensioner – Remove and Install…2477

Alternator – Remove and Install…2483

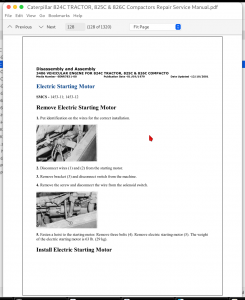

Electric Starting Motor – Remove…2490

Electric Starting Motor – Install…2496

Fuel Tank – Remove…2502

Fuel Tank – Install…2512

Water Temperature Regulator – Remove and Install – Engine In Chassis…2521

Water Pump – Remove – Engine In Chassis…2532

Water Pump – Install – Engine In Chassis…2537

Crankshaft Front Seal and Wear Sleeve – Remove – Engine In Chassis…2541

Crankshaft Front Seal and Wear Sleeve – Install – Engine In Chassis…2544

Radiator Top Tank – Remove…2548

Radiator Top Tank – Install…2553

Radiator Core – Remove…2557

Radiator Core – Install…2561

Radiator Guard – Remove…2565

Radiator Guard – Install…2574

Fan Group (Includes Fan; Fan Shroud; and Hydraulic Fan Motor) – Remove…2582

Fan Group (Includes Fan; Fan Shroud; and Hydraulic Fan Motor) – Install…2588

Fan Shroud – Remove…2593

Fan Shroud – Install…2596

Fan Blade (Spider) – Remove…2600

Fan Blade (Spider) – Install…2605

Hydraulic Oil Cooler – Remove…2608

Hydraulic Oil Cooler – Install…2613

Transmission Oil Cooler – Remove – Engine In Chassis…2617

Transmission Oil Cooler – Install – Engine In Chassis…2623

Engine Oil Cooler – Remove – Engine In Chassis…2628

Engine Oil Cooler – Install – Engine In Chassis…2631

Turbocharger – Remove – Engine In Chassis…2634

Turbocharger – Install – Engine In Chassis…2639

Aftercooler – Remove…2643

Aftercooler – Install…2646

Air Cleaner – Remove…2649

Air Cleaner – Install…2654

Muffler – Remove and Install…2659

Refrigerant Compressor – Remove and Install – Engine In Chassis…2665

Refrigerant Condenser – Remove and Install…2670

Engine and Torque Converter – Remove…2677

Engine from Torque Converter – Separate…2690

Engine to Torque Converter – Connect…2693

Engine and Torque Converter – Install…2695

RENR6005 – Specifications (988G Wheel Loader; 834G Wheel Tractor and 836G Landfill Compactor Machine Systems)…2708

Cab Mounting…2709

Window Wiper and Wiper Motor…2711

Governor Pedal…2714

Position Sensor (Throttle)…2716

Fuel Level Sender…2717

Engine Brake Switch…2719

Caterpillar 834G Wheel Tractors and 836G Landfill Compactors Repair Service Manual