Complete Repair Service Technical Manual for John Deere 770G, 770GP, 772G, and 772GP Motor Graders, with all the shop information to maintain, repair, and rebuild like professional mechanics.

John Deere 770G, 770GP, 772G, and 772GP Motor Graders workshop technical manual (repair) includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm14079x19 – John Deere 770G, 770GP, 772G, and 772GP Motor Graders Technical Manual (Repair).pdf

tm14079x63 – Motoniveladoras 770G, 770GP, 772G y 772GP

Category: Repair

Language: Spanish

Published on 2019/08/16

English

tm14079x19 – 770G, 770GP, 772G, and 772GP Motor Graders

Published on 2019/07/11

French

tm14079x28 – Niveleuses 770G, 770GP, 772G et 772GP

Published on 2019/07/26

Portuguese

tm14079x54 – Motoniveladoras 770G, 770GP, 772G e 772GP

Published on 2019/08/16

Russian

tm14079x59 – автогрейдеров 770G, 770GP, 772G и 772GP

Published on 2019/07/26

PRODUCT DETAILS:

Total Pages: 852 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English etc

TABLE OF CONTENTS…………….1

Section 00: General Information…………….16

Group 0001: Safety…………….16

Information for European Union Directives and Eurasian Economic Union Technical Regulations Compliance…………….22

Recognize Safety Information…………….26

Follow Safety Instructions…………….27

Operate Only If Qualified…………….28

Wear Protective Equipment…………….29

Avoid Unauthorized Machine Modifications…………….30

Inspect Machine…………….31

Stay Clear of Moving Parts…………….32

Avoid High-Pressure Fluids…………….33

Avoid High-Pressure Oils…………….34

Work In Ventilated Area…………….35

Avoid Static Electricity Risk When Refueling…………….36

High Debris Applications…………….38

Prevent Fires…………….39

In Case of Machine Fire…………….40

Prevent Battery Explosions…………….41

Handle Chemical Products Safely…………….42

Handle Starting Fluid Safely…………….43

Decommissioning — Proper Recycling and Disposal of Fluids and Components…………….44

Prepare for Emergencies…………….45

Clean Debris from Machine…………….46

Use Steps and Handholds Correctly…………….47

Start Only From Operator's Seat…………….48

Use and Maintain Seat Belt…………….49

Prevent Unintended Machine Movement…………….50

Avoid Work Site Hazards…………….52

Keep Riders Off Machine…………….54

Avoid Backover Accidents…………….55

Avoid Machine Tip Over and Machine Damage…………….56

Operating or Traveling On Public Roads…………….57

Inspect and Maintain ROPS…………….58

Travel Safely…………….59

Prevent Acid Burns…………….60

Add and Operate Attachments Safely…………….62

Park and Prepare for Service Safely…………….63

Service Machines Safely…………….64

Service Cooling System Safely…………….65

Remove Paint Before Welding or Heating…………….66

Make Welding Repairs Safely…………….67

Drive Metal Pins Safely…………….68

Service Tires Safely…………….69

Use Proper Lifting Equipment…………….70

Group 0003: Torque Values…………….17

Metric Bolt and Cap Screw Torque Values…………….73

Additional Metric Cap Screw Torque Values…………….75

Unified Inch Bolt and Cap Screw Torque Values…………….77

Service Recommendations for 37° Flare and 30° Cone Seat Connectors…………….80

Service Recommendations for O-Ring Boss Fittings…………….82

Service Recommendations for Flared Connections—Straight or Tapered Threads…………….84

Service Recommendations for Flat Face O-Ring Seal Fittings…………….86

O-Ring Face Seal Fittings With SAE Inch Hex Nut and Stud End for High-Pressure Service Recommendations…………….88

O-Ring Face Seal Fittings With Metric Hex Nut and Stud End for Standard Pressure Service Recommendations…………….90

O-Ring Face Seal Fittings With Metric Hex Nut and Stud End for High-Pressure Service Recommendations…………….93

Service Recommendations for Metric Series Four Bolt Flange Fitting…………….96

Service Recommendations For Inch Series Four Bolt Flange Fittings…………….98

Inch Series Four Bolt Flange Fitting for High-Pressure Service Recommendations…………….100

Service Recommendations For Non-Restricted Banjo (Adjustable) Fittings…………….102

Service Recommendations For O-Ring Boss Fittings With Shoulder…………….105

Metric 24° O-Ring Seal DIN 20078 Service Recommendations…………….108

Section 01: Wheels…………….112

Group 0110: Powered Wheels and Fasteners…………….112

Wheel Remove and Install…………….114

Tire Remove and Install…………….115

Section 02: Axles and Suspension Systems…………….118

Group 0225: Input Drive Shafts and U-Joints…………….118

Transmission-to-Rear Axle Drive Shaft Remove and Install…………….122

Transmission-to-Rear Axle Drive Shaft Disassemble and Assemble…………….124

Group 0230: Non-Powered Wheel Axles…………….118

Front Wheel Hub and Spindle Remove and Install—Non 6WD…………….130

Front Wheel Hub and Spindle Disassemble and Assemble—Non 6WD…………….134

Front Axle Remove and Install—Non 6WD…………….141

Group 0240: Powered Wheel Axle…………….118

Front Wheel Hub and Spindle Remove and Install—6WD…………….152

Front Wheel Hub and Spindle Disassemble and Assemble—6WD…………….158

Front Wheel Hub and Spindle Disassemble and Assemble With Steering Angle Sensor—6WD…………….165

6WD Drive Hub Disassemble and Assemble…………….172

Planetary Drive Disassemble and Assemble…………….174

Planetary Brake Disassemble and Assemble…………….177

6WD Bearings Remove and Install…………….186

6WD O-Ring Metal Face Seal Remove and Install…………….190

Front Axle Remove and Install—6WD…………….199

Group 0250: Axle Shaft, Bearings, and Reduction Gears…………….118

TeamMate™ II 1400 Series Inboard Planetary Axle—Use CTM138619…………….207

Rear Axle Remove and Install…………….208

Tandem and Wheel Axle Assembly Remove and Install…………….213

Tandem Wheel Axle Assembly Remove and Install…………….217

Tandem Wheel Axle Assembly Disassemble and Assemble…………….220

Tandem Pivot Disassemble and Assemble…………….225

Final Drive Axle Remove and Install…………….230

Tandem Drive Shaft Remove and Install…………….238

Drive Chain Remove and Install…………….244

Group 0260: Hydraulic System…………….118

Six-Wheel Drive (6WD) Pump Remove and Install…………….253

6WD Pump Disassemble and Assemble…………….258

6WD Charge Pump Remove and Install…………….265

6WD Engagement Manifold Remove and Install…………….266

Differential Lock Pump Remove and Install…………….269

6WD Motor Remove and Install…………….271

6WD Motor Disassemble and Assemble…………….273

Section 03: Transmission…………….277

Group 0300: Removal and Installation…………….277

DF180 Transmission…………….280

Transmission Remove and Install…………….282

Group 0360: Hydraulic System…………….277

Transmission Charge Pump Remove and Install…………….292

Section 04: Engine…………….295

Group 0400: Removal and Installation…………….295

John Deere Engine…………….297

Engine Remove and Install—Engine 6090HDW38…………….298

Engine Remove and Install—Engine 6090HDW04…………….312

Section 05: Engine Auxiliary System…………….313

Group 0510: Cooling System…………….313

Fan Blade Remove and Install…………….317

Radiator Remove and Install…………….320

Hydraulic and Differential Oil Cooler Remove and Install…………….324

Transmission Oil Cooler Remove and Install…………….327

Fuel Cooler Remove and Install…………….330

Charge Air Cooler Remove and Install…………….332

Group 0560: External Fuel Supply Systems…………….313

Fuel Tank Remove and Install…………….340

Fast Fill Fuel System Disassemble and Assemble—If Equipped…………….345

Section 07: Torsional Isolator…………….349

Group 0752: Elements…………….349

Torsional Isolator Remove and Install…………….352

Section 09: Steering System…………….354

Group 0920: Power Steering…………….354

Toe-In Check and Adjustment…………….357

Group 0960: Hydraulic System…………….354

Steering Wheel, Column, and Valve Remove and Install—Standard Controls…………….362

Steering Wheel, Column, and Valve Remove and Install—EH Controls…………….365

EH Controls Steering Canceling Valve Remove and Install…………….369

Steering Valve Disassemble and Assemble…………….371

Steering Cylinder Remove and Install…………….378

Hydraulic Cylinder Disassemble and Assemble…………….382

Wheel Lean Cylinder Remove and Install…………….383

Secondary Steering Accumulator Remove and Install—If Equipped…………….387

Section 10: Service Brakes…………….389

Group 1011: Active Elements…………….389

Service Brake Repair…………….391

Group 1060: Hydraulic System…………….389

Service Brake Valve Remove and Install…………….395

Service Brake Bleeding…………….398

Brake Accumulator Remove and Install…………….543

Section 11: Park Brake…………….401

Group 1111: Active Elements…………….401

Park Brake Repair…………….403

Section 16: Electrical System…………….404

Group 1600: Removal and Installation…………….404

Controller Remove and Install…………….407

Steering Angle Sensor Remove and Install…………….409

Replace Weather Pack™ Connector…………….413

Install Weather Pack™ Contact…………….415

Replace DEUTSCH® Connectors…………….417

Replace DEUTSCH® Rectangular or Triangular Connectors…………….419

Install DEUTSCH® Contact…………….421

Replace (Pull Type) Metri-Pack™ Connectors…………….423

Replace (Push Type) Metri-Pack™ Connectors…………….425

Replace CINCH CINCH is a trademark of the Cinch Co. Connectors…………….404

Install CINCH CINCH is a trademark of the Cinch Co. Contact…………….404

Repair 32 and 48 Way CINCH® Connectors…………….430

Section 17: Frame or Supporting Structure…………….434

Group 1740: Frame Installation…………….434

Welding On Machine…………….436

Welding Repair of Major Structure…………….437

Separate Frames at Articulation Joint…………….439

Articulation Bearing Replacement…………….445

Rear Platform Remove and Install…………….449

Section 18: Operator's Station…………….457

Group 1800: Removal and Installation…………….457

Cab Remove and Install…………….467

Cab Remove and Install—GP Machine Only…………….475

Group 1810: Operator Enclosure…………….457

Windowpanes Remove and Install…………….485

Cab Door Handle Remove and Install…………….487

Cab Door Latch Remove and Install…………….489

Rivet Nut Installation…………….491

Wiper Arm Installation…………….496

Group 1815: Pedal Assembly…………….457

Inching Pedal Remove and Install…………….501

Group 1816: Steering Tilt Console…………….457

Steering Support Console Remove and Install—Standard Controls…………….506

Steering Support Console Remove and Install—EH Controls…………….509

Console Tilt Remove and Install…………….512

Steering Tilt Assembly Remove and Install…………….515

Group 1821: Seat and Seat Belt…………….457

Seat Remove and Install…………….519

Seat Belt Remove and Install…………….522

Armrest Remove and Install…………….524

Armrest Remove and Install—EH Controls…………….525

Armrest Disassemble and Assemble—EH Controls…………….527

Standard Seat Disassemble and Assemble…………….529

Deluxe Seat Disassemble and Assemble…………….531

Air Suspension Disassemble and Assemble…………….533

Group 1830: Heating and Air Conditioning…………….457

R134a Refrigerant Cautions and Proper Handling…………….536

Flush and Purge Air Conditioning System…………….537

R134a Refrigerant Oil Information…………….539

R134a Refrigerant Recovery, Recycling, and Charging Station Installation Procedure…………….541

Accumulator Remove and Install…………….543

Recover R134a Refrigerant…………….545

Evacuate R134a System…………….546

Charge R134a System…………….548

Expansion Valve Remove and Install…………….550

Freeze Control Switch Remove and Install…………….555

Heater Control Valve Remove and Install…………….557

Blower Motor Assembly Remove and Install…………….560

Compressor Remove and Install…………….561

Condenser Remove and Install…………….564

Heater and Air Conditioner Remove and Install…………….568

Receiver-Dryer Remove and Install…………….573

Heater Control Valve Leak Check…………….575

Section 19: Sheet Metal and Styling…………….576

Group 1910: Engine Enclosure…………….576

Engine Service Doors and Side Shields Remove and Install…………….578

Engine Covers Remove and Install…………….579

Group 1921: Grille and Grille Housing…………….576

Grille Housing Remove and Install…………….589

Section 21: Main Hydraulic System…………….594

Group 2160: Hydraulic System…………….594

Hydraulic Pump Remove and Install…………….598

Hydraulic Pump Disassemble and Assemble…………….601

Hydraulic System Manifold Remove and Install…………….606

Hydraulic System Manifold Disassemble and Assemble…………….608

Soft Start Valve Remove and Install…………….610

Vacuum Pump Installation…………….611

Hydraulic Fan Pump Remove and Install…………….612

Hydraulic Fan Motor Remove and Install…………….615

Hydraulic Fan Valve Remove and Install…………….617

General Oil Cleanup Procedure…………….620

Hydraulic Component Failure Cleanup Procedure…………….623

Hydraulic Attenuator Remove and Install…………….625

Section 34: Grading Device…………….627

Group 3415: Controls Linkage…………….627

Control Linkage Remove and Install…………….631

Group 3440: Frames…………….627

Lift Arms Remove and Install…………….638

Saddle Locking Cylinder Remove and Install…………….643

Saddle Locking Pin Disassemble and Assemble…………….646

Saddle Frame Remove and Install…………….649

Blade Pitch Frame Remove and Install…………….651

Draft and Circle Frame Remove and Install…………….655

Circle Adjustment…………….660

Blade Side Shift Wear Inserts Remove and Install…………….667

Group 3450: Circle Gearbox…………….627

Circle Drive Gearbox Remove and Install…………….672

Dual Input Circle Drive Gearbox Remove and Install—If Equipped…………….674

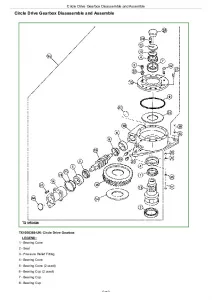

Circle Drive Gearbox Disassemble and Assemble…………….678

Circle Drive Gear Case (With Slip Clutch) Disassemble and Assemble…………….683

Dual Input Circle Drive Gearbox Disassemble and Assemble—If Equipped…………….701

Dual Input Circle Drive Gear Case (With Slip Clutch) Disassemble and Assemble—If Equipped…………….706

Circle Rotate Motor Disassemble and Assemble…………….713

Circle Rotate Sensor Remove and Install…………….731

Group 3460: Hydraulic System…………….627

Grader Control Valve Remove and Install…………….741

Draft Frame Mount Grader Control Valve Remove and Install—EH Controls…………….747

Cab Mount Grader Control Valve Remove and Install—EH Controls…………….751

Grader Control Valve Disassemble and Assemble…………….754

Midmount Scarifier Valve Section Disassemble and Assemble…………….759

Midmount Scarifier Valve Section Disassemble and Assemble—EH Controls…………….762

Blade Lift Valve Section Disassemble and Assemble…………….765

Blade Lift Valve Section Disassemble and Assemble—EH Controls…………….768

Auxiliary (With Float) Valve Section Disassemble and Assemble…………….771

Auxiliary (Without Float) Valve Section Disassemble and Assemble…………….774

Auxiliary Valve Section Disassemble and Assemble—EH Controls…………….777

Wheel Lean, Articulation, Circle Side Shift, Blade Pitch, and Blade Side Shift Valve Section Disassemble and Assemble…………….780

Wheel Lean, Articulation, Circle Side Shift, Blade Pitch, Blade Side Shift, and Steering Valve Section Disassemble and Assemble—EH Controls…………….783

Circle Rotate Valve Section Disassemble and Assemble…………….786

Circle Rotate Valve Section Disassemble and Assemble—EH Controls…………….789

Return Check Poppets Disassemble and Assemble…………….791

Rotary Manifold Remove and Install…………….792

Rotary Manifold Disassemble and Assemble…………….795

Blade Lift, Blade Pitch, and Circle Side Shift Cylinders Remove and Install…………….797

Blade Side Shift Cylinder Remove and Install…………….799

Articulation Cylinders Remove and Install…………….802

Section 42: Ground Conditioning Tool…………….804

Group 4240: Frames…………….804

Midmount Scarifier Remove and Install…………….813

Midmount Scarifier Cylinder Remove and Install…………….821

Ripper Remove and Install…………….823

Ripper Cylinders Remove and Install…………….826

Section 99: Dealer Fabricated Tools…………….829

Group 9900: Dealer Fabricated Tools…………….829

DF1057—Axle Adjusting Tool…………….832

DFT1151—Outboard Bearing Driver…………….834

DFT1152—Inboard Bearing Driver…………….835

DFT1225—Rolling Torque Measurement Tool…………….836

DFT1282—King Pin Torque Adapter…………….837

DFT1308 Transmission Support Bracket…………….838

DFT1310—Cab Mount Control Valve Support Bracket…………….840

DFT1376 Fan Hub Puller…………….841

DFT1380 Lift Bracket…………….842

DFT1382 Lift Bracket…………….847

DFT1382-1 Attachment…………….849

John Deere 770G, 770GP, 772G, and 772GP Motor Graders Repair Service Manual (TM14079X19)