Complete Operator’s Manual for John Deere Tractors 6090MC, 6100MC, 6110MC, 6090RC, 6100RC and 6110RC, with all the technical information to maintain and operate.

OMAL216252 English – Tractors 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (European Edition) Operator’s Manual.pdf

omal216251 German – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Europäische Ausgabe)

omal216253 French – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Version pour l’Europe)

omal216255 Swedish – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Europeisk utgåva)

omal216256 Norwegian – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC

omal216257 Danish – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Europæisk version)

omal216258 Finnish – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Euroopan painos)

omal216259 Italian – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Versione europea)

omal216260 Dutch – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Europese versie)

omal216261 Portuguese – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Edição Europeia)

omal216262 Greek – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC

omal216263 Croatian – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Europsko izdanje)

omal216264 Czech – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Evropské vydání)

omal216265 Hungarian – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Európai kiadás)

omal216266 Bulgarian – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC

omal216267 Polish – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC

omal216269 Lithuanian – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC

omal216272 Latvian-lettish – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Eiropas versija)

omal216273 Romanian – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Ediţie europeană)

omal216274 Estonian – Traktoren 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (Euroopa versioon)

omal216276 English – Tractors 6090MC, 6100MC, 6110MC, 6090RC, 6100RC und 6110RC -: (European / Export Edition) Operator’s Manual

omal212736 English – Standard Radio,Standard Radio with CD,Premium Radio (EU),Premium Radio without CD (U.S.) and Premium Radio for North America -: (Worldwide Edition) Operator’s Manual

omal212738 Spanish – Radio estándar, Radio estándar con CD, Radio Premium (UE), Radio Premium sin CD (EE.UU) y Radio Premium para Norteamérica -: (Edición mundial)

omal212735 German- Standard-Radio Standard-Radio mit CD-Player Premium-Radio (EU) Premium-Radio ohne CD-Player (USA) und Premium-Radio für Nordamerika -: (Weltweite Ausgabe)

omal212737 French – Radio standard, radio standard avec lecteur CD, radio Premium (UE), radio Premium sans CD (États-Unis) et radio Premium pour l’Amérique du Nord -: (Édition internationale)

omal212743 Italian – Radio Standard, radio Standard con CD, radio Premium (UE), radio Premium senza CD (USA) e radio Premium per il Nord America -: (Edizione universale)

omal212745 Portuguese – Rádio Standard, Rádio Standard com CD, Rádio Premium (UE), Rádio Premium sem CD (EUA) e Rádio Premium para América do Norte -: (Edição Mundial)

omal212764 Russian – Станд. радиоc.,станд.радиос.с проигр.для компакт-дисков,радиос. -: (Исполнение для всех стран)

PRODUCT DETAILS:

Total Pages: 753 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

Section 00: Identification Views….19

Identification View….20

Trademarks….21

Section 05: Safety….23

Recognize Safety Information….25

Understand Signal Words….26

Follow Safety Instructions….27

Prepare for Emergencies….28

Wear Protective Clothing….29

Protect Against Noise….30

Handle Fuel Safely—Avoid Fires….31

Fire Prevention….32

In Case of Fire….33

Use Foldable ROPS and Seat Belt Properly….34

Stay Clear of Rotating Drivelines….35

Use Steps and Handholds Correctly….37

Read Operator Manuals for ISOBUS Implements….38

Use Seat Belt Properly….39

Vibration….698

Operating the Tractor Safely….41

Avoid Backover Accidents….43

Limited Use in Forestry Operation….44

Operating the Loader Tractor Safely….45

Keep Riders Off Machine….46

Passenger Seat….128

Use Safety Lights and Devices….48

Towing Trailers/Implements Safely (Mass)….49

Use Caution On Slopes and Uneven Terrain….50

Freeing a Mired Machine….466

Avoid Contact with Agricultural Chemicals….114

Handle Agricultural Chemicals Safely….53

Handling Batteries Safely….55

Avoid Heating Near Pressurized Fluid Lines….57

Remove Paint Before Welding or Heating….58

Handle Electronic Components and Brackets Safely….59

Practice Safe Maintenance….60

Avoid Hot Exhaust….61

Clean Exhaust Filter Safely….62

Work In Ventilated Area….65

Support Machine Properly….66

Prevent Machine Runaway….67

Park Machine Safely….68

Transport Tractor Safely….69

Service Cooling System Safely….70

Service Accumulator Systems Safely….71

Service Tires Safely….395

Service Front-Wheel Drive Tractor Safely….73

Tightening Wheel Retaining Bolts/Nuts….74

Avoid High-Pressure Fluids….75

Do Not Open High-Pressure Fuel System….76

Store Attachments Safely….77

Dispose of Waste Properly….78

Section 10: Safety Decals….79

Pictorial Safety Signs….80

Operator's Manual….81

Riders on Tractors with Passenger Seat….128

Hitch Remote Control….255

Pick-Up Hitch….555

Front-Axle Suspension Accumulators….85

Section 15: Controls and Instruments….86

Vehicle Controls….87

Immobilizer….88

Emergency and Park Brake System….229

PTO Controls….90

Creeper Control….91

Attachment Controls….92

Heater and Air-Conditioning Controls….93

Indicator Lights and Displays….94

Digital Display – User Interface….96

Digital Display – Display Properties (Basic Settings)….98

Digital Display – Information Menu….100

Digital Display – More Settings….102

Software Update….103

Section 20: Lights….105

Lights….105

Light Switch….106

Additional Headlights (Optional Equipment)….107

Switch for Turn-Signal Lights and Horn….108

Operate the Hazard Warning Light Switch….109

Beacon Light (Option)….110

Worklight Switches….111

Seven-Terminal Trailer Socket….112

Section 25: Cab….113

Avoid Contact with Agricultural Chemicals….114

Clean Vehicle of Hazardous Pesticides….116

Cab Classification According to EN 15695-1 (for Application of Crop Protection Chemicals and Liquid Fertilizer)….117

Emergency Exits….119

Roll-Over Protective Structure….120

Seat Belt….121

Comfort Seat MSG85….122

Air Comfort Seat MSG95GL….124

Air Comfort Seat MSG95AL….126

Passenger Seat….128

Wiper and Washer System….129

Fan and Air Louvers….131

Heater….132

Air-Conditioning System….133

Tips On Using the Air-Conditioning System….134

Storage Rack….135

Additional Storage Area….136

Dome Light….137

Adjust the Steering Wheel….138

Beacon Light….139

Install Monitor….140

Sockets….141

Multiple Power-Outlet Socket Strip (If Equipped)….143

Service Socket (CAN Bus)….144

Cigarette Lighter and Ashtray….145

ISOBUS Socket….146

Open Windows….147

Opening Sun Roof (Option)….148

Routing Cables Through the Window….149

Section 30: Break-In Period….150

After the First 4 and 8 Hours of Operation….151

Within the First 100 Hours of Operation….153

After the First 100 Hours of Operation….154

Section 35: Prestarting Checks….156

Prestarting Checks….156

Comply with Operator's Manuals of Implement Manufacturers….160

Section 40: Operating the Engine….642

Important Information Regarding the Engine….642

Start the Engine….642

Cold-Weather Starting Aids….165

Coolant Heater….166

Starting the Engine With a Slave Battery….167

Engines with Turbocharger….168

Engine Protection….169

Towing the Tractor….465

Parking the Tractor….171

Stopping the Engine….642

Battery Cut-Off Switch (if equipped)….173

Section 42: Exhaust Cleaning System….174

Exhaust Filter Cleaning, General Information….175

Exhaust Cleaning System, Information for Operator….176

Access the Engine Menu on the Digital Display….178

Passive Exhaust Filter Cleaning….179

Automatic Exhaust Filter Cleaning….180

Exhaust Filter Cleaning with Tractor Parked….182

Exhaust Filter, Service Cleaning….187

Section 45: Operating the Tractor — General….188

Reduce Fuel Consumption….190

Select Correct Travel Speed….193

Notes on Changing to a Different Size of Tire….194

Travel Speed Tables….195

Travel Speeds, PowrQuad™ PLUS Transmission for 30 km/h (16/16) – Tires with SRI 750 and 800….196

Travel Speeds, PowrQuad™ PLUS Transmission for 30 km/h (16/16) – Tires with SRI 825….198

Travel Speeds, PowrQuad™ PLUS Transmission for 40 km/h (16/16) – Tires with SRI 700 and 800….200

Travel Speeds, PowrQuad™ PLUS Transmission for 40 km/h (16/16) – Tires with SRI 825….202

Travel Speeds, PowrQuad™ PLUS Transmission for 40 km/h (24/24) – Tires with SRI 700 and 725….204

Travel Speeds, PowrQuad™ PLUS Transmission for 40 km/h (24/24) – Tires with SRI 750 and 775….206

Travel Speeds, PowrQuad™ PLUS Transmission for 40 km/h (24/24) – Tires with SRI 800 and 825….208

Travel Speeds, AutoQuad™ PLUS Transmission for 40 km/h (24/24) – Tires with SRI 700 and 725….210

Travel Speeds, AutoQuad™ PLUS Transmission for 40 km/h (24/24) – Tires with SRI 750 and 775….212

Travel Speeds, AutoQuad™ PLUS Transmission for 40 km/h (24/24) – Tires with SRI 800 and 825….214

Travel Speeds, AutoQuad™ PLUS Transmission with EcoShift for 40 km/h (24/24) – Tires with SRI 700 and 725….216

Travel Speeds, AutoQuad™ PLUS Transmission with EcoShift for 40 km/h (24/24) – Tires with SRI 750 and 775….218

Travel Speeds, AutoQuad™ PLUS Transmission with EcoShift for 40 km/h (24/24) – Tires with SRI 800 and 825….220

Engage Front-Wheel Drive….222

Tractors with TLS Front Axle….224

Engage Creeper Transmission….225

Engage Differential Lock….226

Hydraulic Foot Brakes….227

Emergency and Park Brake System….229

Hydraulic Trailer Brakes….230

Trailer Air Brakes….231

Park the Tractor….233

Chock Block….234

Section 47: Operating the Tractor — PowrQuad™ PLUS….235

Shifting the PowrQuad™ PLUS Transmission….236

PowrQuad™ PLUS Transmission — Settings….239

Section 48: Operating the Tractor — AutoQuad™ PLUS….242

Shifting the AutoQuad™ PLUS Transmission….243

AutoQuad Plus Transmission — Settings….248

Section 50: Hitch….251

Hitch Control….252

Hitch – Maximum Lifting Force….254

Hitch Remote Control….255

Hitch – Lift Limit….256

Hitch – Transporting Mounted Implements….257

Hitch – Hitch Dampening….258

Hitch – Adjust Rate of Implement Drop….259

Hitch – Adjust the Rate of Lift….260

Hitch – Adjust Working Depth….261

Hitch – Load/Depth Adjustment….262

Hitch – Using Draft Control….264

Hitch – Float Position….266

Hitch – Direct Control….267

Front Hitch….268

Three-Point Hitch….274

Flat Steel Draft Links….275

Telescopic Draft Links….276

Quick-Coupling (Hook-Type) Draft Links….277

Attach Three-Point Hitch Mounted and Drawn Implements….280

Leveling the Implement….282

Center Link….283

Center Link Positions….284

Quick-Coupling (Hook-Type) Center Link….285

Lift Links….287

Adjust for Vertical Float….289

Sway Blocks (If Equipped)….290

Stabilizer Bar….291

Stabilizing System (If Equipped)….292

Draft Link, Categories 2 and 3N — Adjust Spreading Dimension….293

Section 51: iTEC™ Basic — Intelligent Total Equipment Control….295

iTEC™ Basic – Operating the Intelligent Total Equipment Control….296

Section 55: Power Take-Off….298

PTO Guard….299

Operating Instructions….301

PTO Options….303

PTO Speeds….304

Front PTO….305

Operating PTOs….306

Select Standard Speed of Rear PTO….308

Operating the Rear PTO by Fender Control….310

Connect an Implement to the Rear PTO….312

Section 60: Ballast….314

Selection of Weights….315

Ballasting Rear Wheels….316

Measuring Rear Wheel Slip….317

Wheel Weights….318

Filling Tires With Liquid Ballast….319

Draining the Tires….320

Attach the Pick-Up Weight to the Front Hitch….321

Pre-Assembling the Pick-Up Weight….322

Attaching to Rear Hitch….325

Attaching to Basic Weight….327

Weight in the Three-Point Hitch….330

Install Front Weights….331

Section 65: Wheels, Tires….332

General Wheel, Tire, and Tread Guidelines….334

Changing to a Different Tire Size….336

Change Wheels Safely….337

Tires on Front Wheels….339

Checking and Adjusting Toe-In….340

Check Toe-In….341

Adjust Toe-In (Tractors with Front-Wheel Drive Axle)….343

Adjust Toe-In – Adjustable Front Axle without Front-Wheel Drive….344

Adjustable Front Axle without Front-Wheel Drive – Tighten Axle Bolts and Wheels Bolts….345

Adjustable Front Axle without Front-Wheel Drive – Adjust Tread Widths….346

Adjustable Front Axle without Front-Wheel Drive – Tread Widths without Axle Extensions….349

Instructions for Front-Wheel Tread Adjustment with Rims for 2, 8 and 16 Positions….350

Front-Wheel Tread Adjustment with Rims for 2 Positions….352

Front-Wheel Tread Adjustment with Rims for 8 Positions….356

Front-Wheel Tread Adjustment with Rims for 16 Positions….359

Adjust the Fixed Fenders….365

Adjust the Pivoting Fenders….368

Fender Settings….371

Front Axle – Adjust Steering Stop….378

Instructions for Rear Wheel Tread Adjustment with Rims for 2, 8 and 16 Positions – Flanged Axle….383

Rear Wheel Tread Adjustment with Rims for 2 Positions – Flanged Axle….385

Rear Wheel Tread Adjustment with Rims for 8 Positions – Flanged Axle….388

Rear Wheel Tread Adjustment with Rims for 16 Positions – Flanged Axle….389

Service Tires Safely….395

Tire Combinations – Tractors without Front-Wheel Drive Axle….396

Tire Combinations – Tractors with Front-Wheel Drive Axle….397

Calculate Tire Combinations (Graphic)….401

Calculate Tire Combination….402

Tire Pressures….406

Tire Inflation Pressure Guidelines….407

Front Wheels – Recommended Pressures, Bias Single Front Tires (Two-Wheel Drive)….408

Front Wheels – Recommended Pressures, Group 42….409

Front Wheels – Recommended Pressures, Group 42 (Continued)….411

Front Wheels – Recommended Pressures, Group 43….413

Front Wheels – Recommended Pressures, Group 43 (Continued)….415

Rear Wheels – Recommended Pressures, Group 47….417

Rear Wheels – Recommended Pressures, Group 47 (Continued)….421

Rear Wheels – Recommended Pressures, Group 47 (Continued)….421

Section 70: Additional Equipment — Hydraulic System….641

Selective Control Valves….424

Selective Control Valves – Pressure Adjustment on 450 Series….425

Levers for Mechanical Selective Control Valves….426

Additional Functions for Mechanical Selective Control Valves….428

Selective Control Valves – Couplers….429

Selective Control Valves – Hose Unions….430

Selective Control Valves – Maximum Permissible Oil Withdrawal….431

Selective Control Valves – Oil Withdrawal with Hydrostatic Drive (with PC Hydraulic System)….433

Selective Control Valves – Oil Withdrawal with Hydrostatic Drive (with PFC Hydraulic System)….434

Additional Oil Reservoir….435

Pressure-Free Return Circuit….436

Mechanical Multi-Function Lever with Front-Loader Dampening….437

Section 71: Additional Equipment — Other….439

Drawbar….440

Proper Use of Drawbar….441

Locking the Height-Adjustable Trailer Hitch….453

Locking the Hitch Pins….443

Front Loader Implements – Front Loader Brackets for Loaders H310 and H340….446

Front Jaw Hitch….448

Tow Hitch (Piton-Fix/Ball-Type)….450

Height-Adjustable Trailer Hitch….453

Remote Control (If Equipped)….455

Hydraulic Pick-Up Hitch (Mechanically Actuated)….456

Lockable Tank Filler Cap….459

Section 75: Transport….460

Driving on Public Roads….461

Towing Loads and Transporting with Ballast….463

Transporting the Tractor….464

Towing the Tractor….465

Freeing a Mired Machine….466

Section 80: Fuel, Lubricants, Hydraulic Oil and Coolant….467

John Deere Break-In™ Plus Engine Oil….468

Engine Oil and Filter Service Intervals—Interim Tier 4 and Stage III B Engines….469

Transmission and Hydraulic Oil….470

Front-Wheel Drive Axle Oil….472

Grease….474

Mixing of Lubricants….475

Lubricant Storage….476

Alternative and Synthetic Lubricants….477

John Deere COOL-GARD™ II Coolant Extender….478

Heavy Duty Diesel Engine Coolant….479

Supplemental Coolant Additives….480

Operating in Warm Temperature Climates….481

Testing Diesel Engine Coolant….482

Storing Fuel….483

Handling and Storing Diesel Fuel….485

Diesel Fuel….485

Minimizing the Effect of Cold Weather on Diesel Engines….487

Lubricity of Diesel Fuel….489

Biodiesel Fuel….490

Testing Diesel Fuel….492

Oilscan™ and CoolScan™….493

Section 85: Lubrication and Periodic Service….517

Scope of This Manual….495

Service Tractor Safely….496

Observe Service Intervals….501

Safe Maintenance and Cleaning….498

Using High Pressure Washers….499

Lubricate All Lubricating Points….622

Service Intervals….501

General Instructions Regarding the Condition of the Tractor….502

Open the Hood….503

Open Service Doors….504

Access to Battery….505

Access to Fuses….506

Jack Up the Tractor – Lifting Points….508

Important Instructions Regarding Alternator….511

Service After the First 100 Hours….512

Service As Required….513

Check/Replace Hydraulic Hoses….514

Other Service Jobs….515

Note Regarding the Service Interval for Engine Coolant….612

Periodic Service….517

Service (Daily / Every 10, 250 and 500 Hours)….518

Service (Every 750, 1000, 1500 Hours, Annually and Every 2000 Hours)….521

Service (Every 2 Years, Every 3000, 4500, 6000 and 10000 Hours)….522

Section 90: Service / Daily or Every 10 Hours….523

Check Brakes….524

Check the Lights….525

Clean Dust-Unloading Valve….526

Clean the Radiator, Condenser and Area Surrounding the Engine….642

Check Coolant Level….529

Air Brake System – Check for Condensed Water….530

Check Transmission/Hydraulic Oil Level….531

Check Engine Oil Level….532

Check the Fuel Filters….533

Lubricate Front Hitch….534

Lubricate the Front Axle and U.j. Shafts….535

Lubricate Hitch Jaw….537

Lubricate the Three-Point Hitch….538

Lubricating the Pick-Up Hitch….555

Section 95: Service / Every 250 Hours….540

Checking Neutral Start Circuit….541

Service the Fuel Tank….542

Front-Wheel Drive Axle – Check Oil Level in Axle Housing….543

Front-Wheel Drive Axle – Check Oil Level in Final Drives….544

Front PTO – Check Oil Level….545

Check Air Intake Hoses….546

Front Axle without Front-Wheel Drive – Tighten Screws….547

Tighten Wheel Bolts and Wheel Weights….548

Front Loader Bracket – Tighten Screws on H310 and H340 Loaders….550

Front Hitch – Tighten the Screws….551

Drawbar – Tighten the Screws….552

Height-Adjustable Trailer Hitch – Tighten the Screws….553

Ball-Type Tow Hitch with Forced Steering System – Tighten the Screws….554

Pick-Up Hitch….555

Front Axle without Front-Wheel Drive – Lubricate the Grease Fittings….556

Lubricate Pivoting Fenders….557

Rear PTO, Lubricate Stub Shaft Support….558

Check the Manually-Operated Trailer Hitch for Wear….559

Check the Manually-Operated Hitch for Wear (Italy and Spain Only)….561

Check the Remote-Controlled Trailer Hitch for Wear….563

Trailer Hitch, Check the Guide Rails….566

Check for Wear at Tow Hitch (Piton Fix)….567

Check for Wear at Ball-Type Tow Hitch….568

Check the Drawbar for Wear….569

Check Tow Hook on Pick-Up Hitch for Wear….571

Change Activated Carbon Filters….573

Section 100: Service / Every 500 Hours….574

Change Engine Oil….575

Engine – Change the Oil Filter….577

Change the Fuel Filters….578

Lubricate the Rear Axle….579

Engine – Check Drive Belt for Wear….580

Check Engine Ground Connection….581

Check the Cab Ground Connection….582

Section 105: Service / Every 750 Hours….583

Replace Transmission/Hydraulic Oil Filters….584

Front PTO – Change Oil Filter (if equipped)….585

Section 110: Service / Once Every Year….586

Check the Seat Belt….587

Test Engine Coolant Using Test Strips – 4-Cylinder Engines….588

Inspect Hydraulic Hoses….590

Other Annual Service Jobs….591

Section 115: Service / Every 1500 Hours or 2 Years….592

Change Cab Air Filters and Recirculation Air Filters….593

Change the Engine Air Cleaner….597

Engine – Change Filter of Oil Separator in Crankcase Vent….599

Changing Oil in Front-Wheel Drive Axle and Final Drives….600

Change Oil In Front-Wheel Drive Axle Housing….601

Change Oil in Front-Wheel Drive Final Drives….602

Change Transmission/Hydraulic Oil and Oil Filter….603

Front PTO – Change Oil and Oil Filter (if equipped)….606

Air brake system – Change air-drier cartridge….607

Section 117: Service / Every 4500 Hours….608

Engine Air Cleaner – Change the Secondary Element….609

Section 120: Service / Every 6000 Hours….611

Note Regarding the Service Interval for Engine Coolant….612

Change the Coolant – 4-Cylinder Engines….613

Section 125: Service / As Required….616

Clean Cab Air Filters….617

Bleed Air from Fuel System….621

Lubricate All Lubricating Points….622

Operator's Seat….623

Starter Motor….624

Replace Diesel Particulate Filter (DPF)….625

Replace the Drive Belt….626

Starter Relays….629

Fuse and Relay of Electrical Starting Aid….630

Fuse and Relays of Battery Cut-Off Switch (BBO)….631

Fuses (PLB)….632

Fuses and Relays (PSB)….634

Fuses and Relays (LCS) and (FRM), General Information – Tractors with Cab….636

Fuses and Relays (LCS) and (FRM)….638

Section 130: Troubleshooting….640

Hydraulic System….641

Engine….642

Electrical System….699

Section 135: Diagnostic Trouble Codes and Customization….645

Operation and Entering the Diagnostic Addresses with Digital Display (Customer Level)….646

AIC – Control Software….649

BLC – Control Software….650

CCU – Control Software….652

ECU – Control Software….653

EIC – Control Software….657

FCC – Control Software….658

HCC – Control Software….659

OIC – Control Software….660

PTF – Control Software….661

PTQ – Control Software….662

TEI – Control Software….663

RPT – Control Software….664

SFA – Control Software….665

TEC – Control Software….666

TIQ – Control Software….667

Section 140: Storage….668

Storage for a Long Period….669

Removing Tractor from Storage….670

Section 145: Specifications….671

Dimensions – 6090MC to 6110MC Tractors, Without Front-Wheel Drive Axle….673

Dimensions – 6090MC to 6110MC Tractors, With Front-Wheel Drive Axle….675

Dimensions – 6090RC to 6110RC Tractors, With Front-Wheel Drive Axle….677

Engine – 6090MC to 6110MC Tractors….679

Engine – 6090RC to 6110RC Tractors….680

PTO Power Output – 6090MC to 6110MC Tractors….682

PTO Power Output – 6090RC to 6110RC Tractors….683

Transmission – 6090MC to 6110MC Tractors….684

Transmission – 6090RC to 6110RC Tractors….685

Hitch – 6090MC to 6110MC Tractors….686

Hitch – 6090RC to 6110RC Tractors….687

Hydraulic System – 6090MC to 6110MC….688

Hydraulic System – 6090RC to 6110RC….689

Oil Withdrawal – 6090MC to 6110MC Tractors….690

Oil Withdrawal – 6090RC to 6110RC Tractors….691

Loads and Weights….692

How to Calculate Maximum Permissible Download on Trailer Hitch….694

Towed Mass….696

How to Calculate Permissible Mass….697

Vibration….698

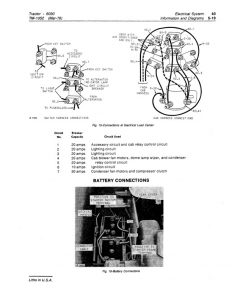

Electrical System….699

Capacities – 6090MC to 6110MC Tractors….700

Capacities – 6090RC to 6110RC Tractors….701

Sound Level….702

Permissible Front Axle Load in Relation to Tires (Normal Operation) – 6090MC to 6110MC Tractors, Without Front-Wheel Drive….703

Permissible Front Axle Load in Relation to Tires (Front Loader Operation) – 6090MC to 6110MC Tractors, Without Front-Wheel Drive….704

Permissible Front Axle Load in Relation to Tires (Normal Operation) – 6090MC, 6100MC, 6090RC and 6100RC Tractors, With Front-Wheel Drive….705

Permissible Front Axle Load in Relation to Tires (Front Loader Operation) – 6090MC, 6100MC, 6090RC and 6100RC Tractors, With Front-Wheel Drive….709

Permissible Front Axle Load in Relation to Tires (Normal Operation) – 6110MC and 6110RC Tractors, With Front-Wheel Drive….713

Permissible Front Axle Load in Relation to Tires (Front Loader Operation) – 6110MC and 6110RC Tractors, With Front-Wheel Drive….717

Permissible Rear Axle Load in Relation to Tires – 6090MC, 6100MC, 6090RC and 6100RC Tractors….721

Permissible Rear Axle Load in Relation to Tires – 6110MC and 6110RC Tractors….725

Unified Inch Bolt and Screw Torque Values….728

Metric Bolt and Screw Torque Values….730

Safety Note Regarding the Subsequent Installation of Electrical and Electronic Appliances and/or Components….732

Section 150: Serial Numbers….733

Type Plates….734

Plate for Product Identification and Serial Numbers of Components….735

Plate for Product Identification Number….737

Engine Serial Number….738

Transmission Serial Number….739

Front-Wheel Drive Serial Number….740

Serial Number of Operator's Cab….741

Serial Number of Operator's Seat….742

Sub-Assembly Serial Numbers….743

Section 155: Glossary….745

Glossary….745

John Deere Tractors 6090MC, 6100MC, 6110MC, 6090RC, 6100RC and 6110RC Operator’s Manual (OMAL216252)