INSTANT DOWNLOAD

Complete Diagnosis & Tests Technical Manual with electrical wiring diagrams for John Deere Tractors 5620, 5720, 5820 (2WD or MFWD), with all the shop information to maintain, test, and service like professional mechanics.

John Deere Tractors 5620, 5720, 5820 workshop Diagnostics technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM4791 – 5620, 5720 and 5820 Tractors Technical Manual – Operation & Test.pdf

tm4790 – Traktoren 5620, 5720 und 5820 Wirkungsweise undPrüfungen

tm4792 French – Tracteurs 5620, 5720 et 5820 Fonctionnement etcontrôles

tm4846 Italian – Funzionamento e prove trattori 5620, 5720 e 5820

tm4847 Dutch – TECHNISCH HANDBOEK Trekkers 5620, 5720 en 5820 Werking en controles

tm4848 Finnish – TEKNINEN KASIKIRJA Traktorit 5620, 5720 ja 5820 Toiminta ja testaukset

tm4849 Norwegian – VERKSTEDHANDBOK 5620, 5720 og 5820 traktorer Bruk og tester

tm4850 Swedish – VERKSTADSHANDBOK Traktorer 5620, 5720 och 5820 Funktion och kontroller

tm8080 Romanian – Tractoare5620, 5720 şi 5820Operare şi Testare -: (Versiunea europeană)

tm8082 Croatian – Traktori5620, 5720 i 5820Rad i ispitivanja -: (Europska inačica)

tm8167 Czech – Traktory 5620, 5720 a 5820 Činnost a testy

tm8170 Slovenian – Traktorji 5620, 5720 in 5820 Delovanje in preizkusi

TM4795 English – 5620, 5720 and 5820 Tractors Diagnosis and Tests Technical Manual.pdf

tm4794 German – Traktoren 5620, 5720 und 5820 Diagnose

tm4796 French – Tracteurs 5620, 5720 et 5820 Diagnostics

tm4851 Italian – Diagnosi trattori 5620, 5720 e 5820

tm4852 Dutch – TECHNISCH HANDBOEK Trekkers 5620, 5720 en 5820 Diagnose

tm4853 Finnish – TEKNINEN KASIKIRJA Traktorit 5620, 5720 ja 5820 Vianetsinta

tm4854 Norwegian – VERKSTEDHANDBOK 5620, 5720 og 5820 traktorer Diagnose

tm4855 Swedish – VERKSTADSHANDBOK Traktorer 5620, 5720 och 5820 Felsokning

tm8162 Romanian – Tractoare 5620, 5720 și 5820 Diagnosticare

tm8171 Czech – Traktory 5620, 5720 a 5820 Diagnostika

PRODUCT DETAILS:

Total Pages: 1,995 pages

File Format: PDF (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English etc.

ctm104 – 4.5L AND 6.8L DIESEL ENGINES (BASE ENGINE) -: (WORLDWIDE EDITION)

ctm4870 – 00.16, 20.09, 20.09C, 20.11, 20.16, G20.16 and G20.09 Front Wheel Drive Axles

ctm207 – PowerTech™ 4.5L and 6.8L Diesel EnginesMechanical Fuel Systems -: (Worldwide Edition)

ctm8289 Portuguese – Eixos da Tração Dianteira 00.16, 20.09, 20.09C, 20.11 e 20.16

MAIN SECTIONS

Foreword

Version Date

General Information

Safety Measures

General References

Engine

Operational Checks

Tests And Adjustments

Fuel, Air Intake and Cooling Systems

Tests And Adjustments

Theory Of Operation

Electrical System

Electrical Circuit Checks

Component Testing

Functional Schematics

Summary of Wiring Harnesses

Wiring Harnesses

Wiring Harnesses from Serial Number 424816

Electronic Control Units

Operation and General Information on Diagnostics

Data BUS Systems, Theory of Operation

BCU – Basic Control Unit

BIF – Basic Informator

EPC – Control Unit for PowrQuad Plus Transmission

PRF – Performance Monitor

PowrQuad and PowrQuad Plus Transmissions

Introductory Checks

Operational Check-Out

Tests and Adjustments

Theory of Operation

Drive Systems

Operational Check-Out

Tests and Adjustments

Theory of Operation

Steering and Brakes

Troubleshooting

Operational Check-Out

Tests and Adjustments

Theory of Operation

Hydraulic System

Operational Check-Out

Tests and Adjustments

Theory of Operation

Miscellaneous

Operational Check-Out

Tests and Adjustments

Theory of Operation

Operator’s Cab

Operational Check-Out

Tests and Adjustments

Theory of Operation

Special Tools

Special Tools (Dealer-Fabricated)

Special Tools and Test Equipment

tm4791 – 5620, 5720 and 5820 Tractors

Table of Contents

Foreword

Version Date

Section 210: General Information

Group 05: Safety Measures

Recognize Safety Information

”Important” Information

”Note” Information

Prevent Machine Runaway

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Avoid High-Pressure Fluids

Service Cooling System Safely

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Work In Ventilated Area

Wear Protective Clothing

Practice Safe Maintenance

Park Machine Safely

Use Proper Lifting Equipment

Construct Dealer-Made Tools Safely

Support Machine Properly

Work in Clean Area

Illuminate Work Area Safely

Service Machines Safely

Use Proper Tools

Service Tires Safely

Service Front-Wheel Drive Tractor Safely

Safety Information – Air Brake System

Avoid Eye Contact With Radar

Keep ROPS Installed Properly

Replace Safety Signs

Dispose of Waste Properly

Live With Safety

Safety Measures on Electronic Control Units

Group 15: General References

Reference 210-15-001, General References—Summary

Reference 210-15-010, Unified Inch Bolt and Cap Screw Torque Values

Reference 210-15-015, Metric Bolt and Cap Screw Torque Values

210-15-020, Hydraulic System Inch Fitting Torques

210-15-025, Hydraulic System Metric Fitting Torques

210-15-030, Component Identification Table

Reference 210-15-035, How to Read a Functional Schematic

210-15-040, How to Read a Diagnostic Schematic

210-15-042, Wire Numbers and Color Codes

210-15-045, Schematic, Wiring and Harness Symbols

Reference 210-15-046, Troubleshooting Unsolved Problems

210-15-050, Visual Check of the Electrical System

Reference 210-15-055, Electrical Circuit Malfunctions

Reference 210-15-060, Seven Step Electrical Test Procedure

210-15-065, Hydraulic System — Circuit Symbols

Section 220: Engine

Group 10: Operational Checks

Reference 220-10-010, Safety

Reference 220-10-020, Preliminary Engine Tests

Group 15: Tests And Adjustments

Reference 220-15-001, Tests and Adjustments—Summary of References

220-15-010, Dynamometer Test

Reference 220-15-020, Measuring PTO Power Output

Section 230: Fuel, Air Intake and Cooling Systems

Group 15: Tests And Adjustments

Reference 230-15-001, Tests and Adjustments—Summary of References

Reference 230-15-010, General Information

Reference 230-15-020, Explanation of Checks

Reference 230-15-030, Safety

Reference 230-15-040, Special Tools

Reference 230-15-050, Specifications

Reference 230-15-060, Testing Air Intake System

Reference 230-15-061, Testing the Low-Pressure Switch in Air Intake System

Reference 230-15-070, Checking the Cooling System for Leaks

Reference 230-15-080, Testing the Temperature at which the Thermostat opens

Reference 230-15-090, Checking the Viscous Clutch of the Fan

Reference 230-15-100, Checking the Fuel Transfer Pump

Reference 230-15-110, Hand Throttle Lever and Accelerator Pedal Adjustment

Group 20: Theory Of Operation

Reference 230-20-001, Component Description – Summary of References

Reference 230-20-010, Fuel System – Description

Reference 230-20-020, Air Intake System – Theory of Operation

Reference 230-20-030, Coolant Circuit – Description

Reference 230-20-040, Cooling System Radiator – Description

Reference 230-20-070, Viscous Clutch of Fan – Theory of Operation

Reference 230-20-080, Automatic Drive Belt Tensioner – Theory of Operation

Reference 230-20-090, Cold Weather Starting Aids – Theory of Operation

Section 240: Electrical System

Group 10: Electrical Circuit Checks

Reference 240-10-001, Checking Electrical Circuits — Summary of References

Reference 240-10-002, Special Tools

Reference 240-10-003, SE1 – Starting Motor and Charging Circuit

Reference 240-10-004, SE2 – Basic Informator/Instrument Unit

Reference 240-10-005, SE3 – Horn

Reference 240-10-006, SE4 – Cigarette Lighter and Operator’s Seat

Reference 240-10-007, SE6 – Lights

Reference 240-10-008, SE7 – Worklights

Reference 240-10-009, SE8 – Front Loader Plug

Reference 240-10-010, SE9 – Radio, Dome Light and Console Light

Reference 240-10-011, SE10 – Fan and Air Conditioner

Reference 240-10-012, SE11 – Windshield Wiper and Washer

Reference 240-10-013, SE12 – Rear Window Wiper and Washer

Reference 240-10-014, SE13 – Beacon Light

Reference 240-10-015, SE14 – 3- and 7-Terminal Power Outlet Sockets

Reference 240-10-016, SE15 – Electronic Hitch Control

Reference 240-10-017, SE16A – Basic Control Unit (BCU) (Rear PTO and External Control)

Reference 240-10-018, SE16B – Basic Control Unit (BCU) (Front PTO)

Reference 240-10-019, SE16C – Basic Control Unit (BCU) (Front-Wheel Drive)

Reference 240-10-020, SE16D – Basic Control Unit (BCU) (Differential Lock)

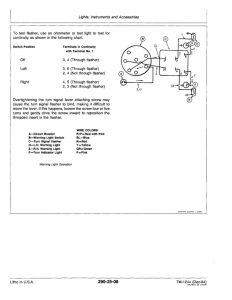

Reference 240-10-021, SE16E – Basic Control Unit (BCU) (Hazard Warning and Turn Signal Lights)

Reference 240-10-022, SE16F – Basic Control Unit (BCU) (Speed Sending Units and Radar)

Reference 240-10-023, SE16G – Basic Control Unit (BCU) (Headland Management System II)

Reference 240-10-024, SE16H – Basic Control Unit (BCU) (Power Supply, Acoustic Alarm)

Reference 240-10-026, SE16J – Basic Control Unit (BCU) (Brake System and Handbrake Monitor Unit)

Reference 240-10-027, SE17 – Signal Socket and Service Plug

Reference 240-10-028, SE18 – Performance Monitor

Reference 240-10-033, SE22 – BUS Terminating Resistor

Reference 240-10-035, SE26 – Transmission Control Unit (PowrQuad Plus Transmission)

Group 15: Component Testing

Reference 240-15-001, SE01 – Starting Motor and Charging Circuit

Reference 240-15-002, SE02 – Basic Informator or Instrument Unit

Reference 240-15-003, SE03 – Horn

Reference 240-15-004, SE04 – Cigarette Lighter and Operator’s Seat

Reference 240-15-005, SE06 – Lighting System

Reference 240-15-006, SE07 — Worklights

Reference 240-15-007, SE09 — Radio, Dome Light and Console Light

Reference 240-15-008, SE10 — Fan and Air-Conditioning System

Reference 240-15-009, SE11 and SE12 – Windshield Wiper and Washer

Reference 240-15-010, SE13 – Beacon Light

Reference 240-15-011, SE14 — 3- and 7-Terminal Power Outlet Sockets

Reference 240-15-012, SE15 — Electronic Hitch Control

Reference 240-15-013, SE16A – Basic Control Unit (BCU) (Rear PTO and External Control)

Reference 240-15-014, SE16B – Basic Control Unit (BCU) (Front PTO)

Reference 240-15-015, SE16C – Basic Control Unit (BCU) (Front-Wheel Drive)

Reference 240-15-016, SE16D — BCU (Differential Lock)

Reference 240-15-017, SE16E — Basic Control Unit (BCU) (Hazard Warning and Turn Signal Lights)

Reference 240-15-018, SE16G – Basic Control Unit (BCU) (Headland Management System)

Reference 240-15-019, SE16H – Basic Control Unit (BCU) (Power Supply, Acoustic Alarm)

Reference 240-15-021, SE16J — Basic Control Unit (BCU) (Brake System and Handbrake Monitor Unit)

Reference 240-15-024, SE22 – CAN BUS Terminating Resistor

Reference 240-15-026, SE26A – Transmission Control Unit (PowrQuad Plus Transmission)

Group 25: Functional Schematics

Reference 240-25-001, Circuit Diagram — Summary of References

Reference 240-25-010, Fuses and Relays

Reference 240-25-011, Designation of Parts Shown in Functional Schematic and Harness Diagram

Reference 240-25-012, Designation of Sections Shown in Functional Schematic

Reference 240-25-013, Wiring Harness Designations

Reference 240-25-014, Functional Schematic (Complete Tractor)

Group 26: Summary of Wiring Harnesses

Reference 240-26-001, Wiring Harnesses for Tractors with PowrQuad Transmission — Summary of References

Reference 240-26-003, Wiring Harnesses for Tractors with PowrQuad Transmission from Serial No. 436758 — Summary of References

Reference 240-26-002, Wiring Harnesses for Tractors with PowrQuad Plus Transmission — Summary of References

Reference 240-26-004, Wiring Harnesses for Tractors with PowrQuad Plus Transmission from Serial No. 424816 – Summary of References

Group 26A: Wiring Harnesses

Reference 240-26-011, W01 — Wiring Harness – Power Supply and Starting Aid

Reference 240-26-021, W02 – Wiring Harness – Engine

Reference 240-26-041, W04 — Wiring Harness – Headlights

Reference 240-26-072, W07 — Wiring Harness – Front PTO

Reference 240-26-081, W08 — Wiring Harness – Cab (Tractors with PowrQuad Transmission)

Reference 240-26-082, W08 — Wiring Harness – Cab (Tractors with PowrQuad Plus Transmission)

Reference 240-26-131, W13 — Wiring Harness – Clutch Sender

Reference 240-26-141, W14 — Wiring Harness – 3-Terminal Power Outlet Socket

Reference 240-26-181, W18 — Wiring Harness – Windshield Wiper Switch (Without Intermittent Wipe)

Reference 240-26-182, W18 — Wiring Harness – Windshield Wiper Switch (With Intermittent Wipe)

Reference 240-26-191, W19 – Wiring Harness – Cab Roof and Fan

Reference 240-26-201, W20 — Wiring Harness – Turn Signal and Clearance Lights

Reference 240-26-211, W21 — Wiring Harness – Cab Roof Worklights, Adapter

Reference 240-26-231, W23 — Wiring Harness – Windshield Wiper (with Hinged Windshield)

Reference 240-26-281, W28 — Wiring Harness – Front End of Transmission (Tractors with PowrQuad Transmission)

Reference 240-26-282, W28 — Wiring Harness – Front End of Transmission (Tractors with PowrQuad Plus Transmission)

Reference 240-26-301, W30 – Wiring Harness – Rear End of Transmission

Reference 240-26-421, W42 — Wiring Harness – Battery Cut-Off Switch (Version 1)

Reference 240-26-461, W46 — Wiring Harness – Front PTO, Adapter

Group 26B: Wiring Harnesses from Serial Number 424816

W01 — Wiring Harness – Power Supply and Starting Aid from Serial No. 436764

W01 — D31

W01 — F09

W01 — F11

W01 — F13

W01 — F14

W01 — G02

W01 — K01

W01 — K36

W01 — M01

W01 — R15

W01 — X473

W01 — X547

W08 — Wiring Harness – Cab for Tractors with PowrQuad Transmission from Serial No. 436758

W08 — B28/LH

W08 — F03

W08 — F04

W08 — F05

W08 — F06

W08 — K01

W08 — K02

W08 — K07

W08 — K08

W08 — R19

W08 — S01

W08 — S01/1

W08 — S04

W08 — S08

W08 — S09

W08 — X10/1

W08 — X10/2

W08 — X10/3

W08 — X14/1

W08 — X14/2

W08 — X34

W08 — X35

W08 — X37

W08 — X38

W08 — X44

W08 — X106

W08 — X107

W08 — X113/1

W08 — X113/2

W08 — X120/1

W08 — X120/2

W08 — X122/2

W08 — X125

W08 — X127

W08 — X128

W08 — X174

W08 — X230

W08 — X235

W08 — X239

W08 — X243

W08 — X245

W08 — X285

W08 — X311/1

W08 — X311/2

W08 — X324

W08 — X400

W08 – X430

W08 — X450

W08 — X473

W08 — X474

W08 — X488

W08 — X500

W08 — X516

W08 — X571

W08 — X579/1

W08 — X579/2

W08 – X616/1

W08 — X616/2

W08 — X616/3

W08 — X617

W08 — X618

W08 — X620

W08 — X623

W08 — X629

W08 — XGND1

W08 — XGND4

W08 — XGND5

W08 — XGND6

W08 — XGND43

W08 — XGND47

W08/1 — Wiring Harness – Cab for Tractors with PowrQuad Plus Transmission from Serial No. 434662

W08/1 — B28/LH

W08/1 — F03

W08/1 — F04

W08/1 — F05

W08/1 — F06

W08/1 — K01

W08/1 — K02

W08/1 — K07

W08/1 — K08

W08/1 — S01

W08/1 — S09

W08/1 — X14/1

W08/1 — X14/2

W08/1 — X20

W08/1 — X25

W08/1 — X26

W08/1 — X34

W08/1 — X35

W08/1 — X37

W08/1 — X38

W08/1 — X39

W08/1 — X44

W08/1 — X106

W08/1 — X107

W08/1 — X113/1

W08/1 — X113/2

W08/1 — X120/1

W08/1 — X120/2

W08/1 — X122/2

W08/1 — X125

W08/1 — X126

W08/1 — X127

W08/1 — X128

W08/1 — X132

W08/1 — X174

W08/1 — X230

W08/1 — X235

W08/1 — X239

W08/1 — X242

W08/1 — X243

W08/1 — X245

W08/1 — X247

W08/1 — X249/3

W08/1 — X285

W08/1 — X322

W08/1 — X324

W08/1 — X400

W08/1 – X430

W08/1 — X440

W08/1 — X450

W08/1 — X471

W08/1 — X473

W08/1 — X474

W08/1 — X487

W08/1 — X488

W08/1 — X489

W08/1 – X490/1

W08/1 – X490/1

W08/1 — X500

W08/1 — X503

W08/1 — X571

W08/1 — X615

W08/1 – X616/1

W08/1 — X616/2

W08/1 — X616/3

W08/1 — X620

W08/1 — X623

W08/1 — XGND1

W08/1 — XGND5

W08/1 — XGND43

W08/1 — XGND47

W28 — Front Transmission Wiring Harness for Tractors with PowrQuad Transmission from Serial No. 431378

W28 — X80

W28 — X81

W28 — X82

W28 — X83

W28 — X86

W28 — X91

W28 — X93

W28 — X500

W28 — XGND46

W28/1 — Front Transmission Wiring Harness for Tractors with PowrQuad Plus Transmission from Serial No. 424816

W28/1 — X30

W28/1 — X80

W28/1 — X83

W28/1 — X86

W28/1 — X91

W28/1 — X307

W28/1 — X459

W28/1 — X493

W28/1 — X494

W28/1 — X495

W28/1 — X499

W28/1 — X500

W28/1 — X546

W28/1 — X701

W28/1 — X702

W28/1 — XGND46

W42 — Wiring Harness – Battery Cut-Off Switch (Version 2)

W42 — F25

W42 — K24/2

W42 — K56

W42 — K57

W42 — X696

W42 — XGND56

Section 245: Electronic Control Units

Group 05: Operation and General Information on Diagnostics

Reference 245-05-000, Operation and General Information on Diagnostics – Summary of References

Special Tools

Reference 245-05-001, General Operation and Entering the Program Mode

Reference 245-05-002, Accessing the Addresses and Diagnostic Trouble Codes

Reference 245-05-009, Adjusting the Instrument Unit on Tractors with PowrQuad Transmission

Reference 245-05-005, Driving in the Diagnostic Mode

Reference 245-05-004, Electronic Control Units – Summary of Addresses

Reference 245-05-010, BCU – Basic Control Unit – Summary of Addresses

Reference 245-05-011, BIF – Basic Informator – Summary of Addresses

Reference 245-05-012, EPC – Controller for PowrQuad Plus Transmission – Summary of Addresses

Reference 245-05-013, PRF – Performance Monitor – Summary of Addresses

Reference 245-05-006, Approved Software for Control Units

Reference 245-05-007, Electronic Control Units – Location and Allocation

Group 20: Data BUS Systems, Theory of Operation

Reference 245-20-001, Data BUS Systems – Summary of References

Reference 245-20-002, Data-BUS Systems

Reference 245-20-003, Operation of the CAN BUS System

Reference 245-20-011, CAN BUS Systems on Tractors with PowrQuad Transmission

Reference 245-20-012, CAN BUS Systems on Tractors with PowrQuad Plus Transmission

Group BCU: BCU – Basic Control Unit

Reference 245-BCU-001, Calibration and Input Addresses of Basic Functions

Reference 245-BCU-002, Calibration and Input Addresses of Hitch Control

Reference 245-BCU-100, Preliminary Test of BCU Circuit

Reference 245-BCU-101, Circuit Test for Rear PTO Remote Control Switch on L.h. Fender (S44)

Reference 245-BCU-102, Circuit Test for Rear PTO Remote Control Switch on R.h. Fender (S121)

Reference 245-BCU-103, Circuit Test for Rear PTO Switch (S21)

Reference 245-BCU-104, Circuit Test for PTO Preselector Switch (S45)

Reference 245-BCU-106, Circuit Test for Front PTO Switch (S06)

Reference 245-BCU-107, Circuit Test for Front-Wheel Drive Switch (S63) (without HMS II)

Reference 245-BCU-108, Circuit Test for Front-Wheel Drive Switch (S05) (with HMS II)

Reference 245-BCU-109, Circuit Test for Differential Lock Switch (S22)

Reference 245-BCU-110, Circuit Test for Hazard Warning Light Switch (S62)

Reference 245-BCU-111, Circuit Test for Hazard Warning Light Switch (S106)

Reference 245-BCU-112, Circuit Test for Turn Signal Switch (S08)

Reference 245-BCU-115, Circuit Test for Wheel Speed Sending Unit (B35)

Reference 245-BCU-117, Circuit Test for Record/Save Switch (S95)

Reference 245-BCU-118, Circuit Test for HMS Program Switch (S100)

Reference 245-BCU-119, Circuit Test for Handbrake Switch (B37)

Reference 245-BCU-120, Circuit Test for Engine Speed Sender (B01)

Reference 245-BCU-121, Circuit Test for Rear PTO Speed Sender (B06)

Reference 245-BCU-122, Circuit Test for Alternator Relay (K07/6)

Reference 245-BCU-123, Circuit Test on Sensitivity Potentiometer (B26)

Reference 245-BCU-126, Circuit Test for Depth-Setting Potentiometer (B27)

Reference 245-BCU-127, Circuit Test for Position Sensor (B21)

Reference 245-BCU-128, Circuit Test on Rate-of-Drop Potentiometer (B27)

Reference 245-BCU-130, Circuit Test on Raise-Limit Potentiometer (B27)

Reference 245-BCU-132, Circuit Test for Rapid-Raise Switch (S24)

Reference 245-BCU-134, Circuit Test for Rear PTO Solenoid Valve (Y04)

Reference 245-BCU-135, Circuit Test for Front-Wheel Drive Solenoid Valve (Y03)

Reference 245-BCU-136, Circuit Test for Differential Lock Solenoid Valve (Y05)

Reference 245-BCU-137, Circuit Test for Front PTO Solenoid Valve (Y01)

Reference 245-BCU-138, Circuit Test on R.h. Draft Sensor (B19)

Reference 245-BCU-141, Circuit Test for Right Remote Control Switch (S23)

Reference 245-BCU-142, Circuit Test for Left Remote Control Switch (S68)

Reference 245-BCU-143, Circuit Test for Rockshaft Control Stepper Motor (M08)

Reference 245-BCU-145, Circuit Test for HMS Switch (S43)

Reference 245-BCU-146, Circuit Test for Brake Pedal Switch (B112)

Reference 245-BCU-147, Circuit Test for Seat Switch (S40)

Reference 245-BCU-148, Circuit Test for Reverse Drive Lever without N Indicator Light (A47)

Reference 245-BCU-149, Circuit Test for Reverse Drive Lever with N Indicator Light (A68/1)

Reference 245-BCU-175, Circuit Test for Turn Signal Switch (S08) – Tractors with PowrQuad Transmission

Reference 245-BCU-200, Theory of Operation (Basic Functions)

Reference 245-BCU-201, Theory of Operation (Hitch Control)

Group BIF: BIF – Basic Informator

Reference 245-BIF-001, Calibration and Input Addresses

Reference 245-BIF-100, Preliminary Test of BIF Circuit

Reference 245-BIF-101, Circuit Test for Fuel Gauge Sending Unit (B03)

Reference 245-BIF-102, Circuit Test for Coolant Temperature Gauge Sender (B08)

Reference 245-BIF-103, Circuit Test for Hydraulic Oil Temperature Sender (B60)

Reference 245-BIF-104, Circuit Test for Engine Oil Pressure Sender (B04)

Reference 245-BIF-105, Circuit Test for Transmission Oil Pressure Sender (B31)

Reference 245-BIF-106, Circuit Test of Sender for Restricted Air Cleaner Warning Light (B02)

Reference 245-BIF-107, Circuit Test for Alternator D+ Voltage

Reference 245-BIF-108, Circuit Test of Sender for Restricted Oil Filter Warning Light (B07)

Reference 245-BIF-110, Circuit Test for Switch that Warns of a Restriction at Hydraulic Oil Filter (B111)

Reference 245-BIF-200, Theory of Operation

Group EPC: EPC – Control Unit for PowrQuad Plus Transmission

Reference 245-EPC-001, Calibration and Input Addresses

Reference 245-EPC-002, EPC – Fine-Tuning

Reference 245-EPC-100, Test Procedure in the Event of Occasional EPC Circuit Problems

Reference 245-EPC-101, Circuit Test for Enable Proportional Solenoid Valve (Y38)

Reference 245-EPC-102, Circuit Test for Forward Solenoid Valve (Y33)

Reference 245-EPC-103, Circuit Test for Reverse Solenoid Valve (Y36)

Reference 245-EPC-104, Circuit Test for K1 Solenoid Valve (Y40)

Reference 245-EPC-105, Circuit Test for K2 Solenoid Valve (Y39)

Reference 245-EPC-106, Circuit Test for K3 Solenoid Valve (Y32)

Reference 245-EPC-107, Circuit Test for Transmission Speed Sender (B104)

Reference 245-EPC-108, Circuit Test for Enable Pressure Sender (B105)

Reference 245-EPC-109, Circuit Test for Clutch Pedal Switch (S72)

Reference 245-EPC-110, Circuit Test for Clutch Pedal Potentiometer (B65)

Reference 245-EPC-111, Circuit Test for Upshift/Downshift Switch (S81)

Reference 245-EPC-112, Circuit Test for Transmission Enable Relay (K07/4)

Reference 245-EPC-113, Circuit Test for Come-Home Plug (K08/4)

Reference 245-EPC-114, Circuit Test for Reverse Drive Lever without N Indicator Light (A47)

Reference 245-EPC-115, Circuit Test for Park Switch (S114)

Reference 245-EPC-116, Circuit Test for Reverse Drive Lever with N Indicator Light (A68/1)

Reference 245-EPC-117, Circuit Test for Solenoid Valve 1 (Y62)

Reference 245-EPC-118, Circuit Test for Solenoid Valve 2 (Y63)

Reference 245-EPC-119, Circuit Test for Reverse Drive Lever with N Indicator Light (A68/2)

Reference 245-EPC-200, Theory of Operation

Group PRF: PRF – Performance Monitor

Reference 245-PRF-001, Calibration and Input Addresses

Reference 245-PRF-011, Calibration of Ground Speed Sensor (Radar)

Reference 245-PRF-021, Setting Wheel Slip Back to Zero

Reference 245-PRF-101, Circuit Test for Keypad Operation

Reference 245-PRF-200, Theory of Operation

Section 255: PowrQuad and PowrQuad Plus Transmissions

Group 05: Introductory Checks

Reference 255-05-001, Introductory Checks for Transmission and Hydraulic Diagnosis

Group 10: Operational Check-Out

Reference 255-10-001, PowrQuad Transmission — Operational Check-Out

Group 15: Tests and Adjustments

Reference 255-15-000, PowrQuad Transmission — Summary of References

Reference 255-15-030, Special Tools

Reference 255-15-001, PowrQuad Transmission — System Check

Reference 255-15-002, PowrQuad Transmission — Test Ports

Reference 255-15-003, PowrQuad Transmission — Checking Rate of Flow at Cooler

Reference 255-15-021, PowrQuad Transmission — Check Cooler Relief Valve

Reference 255-15-004, PowrQuad Transmission — Checking System Pressure

Reference 255-15-005, PowrQuad Transmission—Checking Lube Oil Pressure

Reference 255-15-006, PowrQuad Transmission—Checking Cooling Oil Pressure (Forward Clutch)

Reference 255-15-007, PowrQuad Transmission — Checking Cooling Oil Pressure (Reverse Brake)

Reference 255-15-008, PowrQuad Transmission—Checking Pressure at Forward Clutch

Reference 255-15-009, PowrQuad Transmission — Checking Pressure at Reverse Brake

Reference 255-15-010, PowrQuad Transmission — Checking Pressure at B1 Brake

Reference 255-15-011, PowrQuad Transmission — Checking Pressure at B2 Brake

Reference 255-15-012, PowrQuad Transmission — Checking Pressure at B3 Brake

Reference 255-15-013, PowrQuad Transmission — Checking Pressure at C4 Clutch

Reference 255-15-014, PowrQuad Transmission—Adjusting System Pressure

Reference 255-15-015, PowrQuad Transmission — Test Result Table

Reference 255-15-016, PowrQuad Transmission — Adjusting the Reverse Drive Linkage

Reference 255-15-017, PowrQuad Transmission — Checking and Adjusting the Shift Units

Reference 255-15-018, Adjusting the Reverse Drive Lever (Reverser Control on Steering Column)

Reference 255-15-019, PowrQuad Transmission — Adjusting the Clutch Pedal

Reference 255-15-025, Reduction Gear – Adjusting the Shift Linkage

Group 20: Theory of Operation

Reference 255-20-001, PowrQuad and PowrQuad Plus Transmissions — Summary of References

Reference 255-20-050, PowrQuad Transmission — Layout

Reference 255-20-100, PowrQuad Module — Layout

Reference 255-20-280, PowrQuad Module—Sectional and 3D View

Reference 255-20-290, PowrQuad Module — Location of Valves, Sensors and Switches

Reference 255-20-110, PowrQuad Module—Element Engagement Chart

Reference 255-20-120, PowrQuad Module—Pneumatic Pump

Reference 255-20-130, PowrQuad Module—Transmission Oil Pump

Reference 255-20-140, PowrQuad Module—Pressure-Regulating Valve and Filter Relief Valve

Reference 255-20-150, PowrQuad Module—Overspeed Relief Valve and Anti-Cavitation Check Valve

Reference 255-20-160, PowrQuad Module—Clutch Cooling Components

Reference 255-20-170, PowrQuad Module—Clutch Cooling Valve (Forward/Reverse)

Reference 255-20-180, PowrQuad Module—System 1 Oil and System 2 Oil

Reference 255-20-190, PowrQuad Module—Hydraulic Schematic, Mechanically Actuated PowrQuad Module

Reference 255-20-200, PowrQuad Module—Operation of Forward/Reverse Modulation, Mechanically Actuated PowrQuad Module

Reference 255-20-210, PowrQuad Module—Neutral Start Circuit, Mechanically Actuated PowrQuad Module

Reference 255-20-220, PowrQuad Module—Operation of Gear-to-Gear Modulation, Mechanically Actuated PowrQuad Module

Reference 255-20-230, PowrQuad Module—Hydraulic Schematic, Electrically Actuated PowrQuad Module

Reference 255-20-240, PowrQuad Module—Operation of Forward/Reverse Modulation, Electrically Actuated PowrQuad Module

Reference 255-20-250, PowrQuad Module — Operation of Gear-to-Gear Modulation, Electrically Actuated PowrQuad Module

Reference 255-20-260, PowrQuad Module—Reverse Drive Lever and Gear Shift Lever, Mechanically Actuated PowrQuad Module

Reference 255-20-270, PowrQuad Module — Reverse Drive Lever and Range Shift Lever with Gearshift Switches, Electrically Actuated PowrQuad Module

Reference 255-20-400, PowrQuad Plus Transmission — Summary of Transmission Versions

Reference 255-20-410, PowrQuad Plus Transmission—Sub-Assemblies

Reference 255-20-420, PowrQuad Plus Transmission — Description of Shift Functions

Reference 255-20-440, PowrQuad Plus Transmission — Description of Clutch Actuation

Reference 255-20-500 — Range Transmission, Layout

Reference 255-20-510 — Range Transmission, Power Flow

Reference 255-20-520—Range Transmission, Park Lock

Reference 255-20-800, Reduction Gear—Operation

Reference 255-20-810, Reduction Gear — Power Flow

Section 256: Drive Systems

Group 10: Operational Check-Out

Reference 256-10-001, Drive Systems — Operational Check

Group 15: Tests and Adjustments

Reference 256-15-000, Drive Systems — Summary of References

Reference 256-15-010, Special Tools

Reference 256-15-001, Drive Systems — System Check

Reference 256-15-002, Checking Pressure at the Front-Wheel Drive Clutch

Reference 256-15-003, Checking Pressure at the Hydraulic Differential Lock

Reference 256-15-004, Checking Pressure at the Rear PTO

Reference 256-15-005, Checking Pressure at the Front PTO

Reference 256-15-006, Drive Systems — Test Result Table

Group 20: Theory of Operation

Reference 256-20-001, Drive Systems — Summary of References

Reference 256-20-100, Front-Wheel Drive Clutch—Layout

Reference 256-20-110, Front-Wheel Drive Clutch—Oil and Power Flows

Reference 256-20-120, Front-Wheel Drive Clutch — Cooling and Lubrication

Reference 256-20-200, Differential—Layout

Reference 256-20-220, Differential — Power Flows

Reference 256-20-230, Differential—Oil-Flows

Reference 256-20-300, Final Drives—Operation and Layout

Reference 256-20-400, Rear PTO Options—Description

Reference 256-20-410, Rear PTO Options—PTO Modulating Valve and Solenoid Valve

Reference 256-20-420, Rear PTO Options—PTO Clutch and PTO Brake

Reference 256-20-440, Rear PTO Options — Power Flows

Reference 256-20-500, Front PTO Options — Operation

Reference 256-20-510, Front PTO Options — Description, Hydraulic Circuit

Reference 256-20-520, Front PTO Options — Solenoid Valve

Reference 256-20-530, Front PTO Options — Hydraulic Pump

Reference 256-20-540, Front PTO Options — Oil Cooler

Section 260: Steering and Brakes

Group 05: Troubleshooting

Reference 260-05-010, Hydrostatic Steering

Reference 260-05-020, Hydraulic Brakes

Reference 260-05-030, Handbrake

Reference 260-05-040, Hydraulic Trailer Brake

Reference 260-05-050, Air Brakes

Group 10: Operational Check-Out

Reference 260-10-001, Safety Information

Reference 260-10-010, Steering Check

Reference 260-10-020, Brake Check

Group 15: Tests and Adjustments

Reference 260-15-001, Tests and Adjustments — Summary of References

Reference 260-15-010, Special Tools

Reference 260-15-020, Connecting SensoControl Test Equipment

Reference 260-15-030, Specifications

Reference 260-15-040, Checking the Steering System

Reference 260-15-050, Checking the Brake System

Reference 260-15-060, Bleeding the Brakes

Reference 260-15-070, Adjusting the Brake Pedals and Switches

Reference 260-15-080, Checking the Handbrake

Reference 260-15-090, Checking the Trailer Brake Valve

Reference 260-15-100, Adjusting the Trailer Brake Valve

Reference 260-15-110, Checking the Air Brake

Reference 260-15-110, Checking the Air Brake (Visual Inspection)

Reference 260-15-120, Checking the System for Leaks

Reference 260-15-130, Checking the Coupling End (Supply)

Reference 260-15-150, Checking the Dual-Line Brake

Reference 260-15-160, Checking the Single-Line Brake

Reference 260-15-170, Adjusting the Handbrake when Air Brakes are Equipped

Reference 260-15-180, Checking the Pressure-Regulating Valve and Air-Brake Fill Time

Group 20: Theory of Operation

Reference 260-20-001, Theory of Operation — Summary of References

Reference 260-20-010, Description of Steering System, Operation

Reference 260-20-030, Brake Valve, Operation

Reference 260-20-031, Two-Stage Brake Valve

Reference 260-20-040, Rear Wheel Brakes, Operation

Reference 260-20-050, Handbrake, Description

Reference 260-20-060, Trailer Brake Valve, Description

Reference 260-20-080, Description of Air Brake System

Section 270: Hydraulic System

Group 10: Operational Check-Out

Reference 270-10-001, Operational Checkout of Hydraulic System, Summary of References

Reference 270-10-010, Hydraulic System Load Check

Reference 270-10-020, Hitch Control – Operational Checkout

Reference 270-10-030, External Control of Hitch – Operational Checkout

Reference 270-10-040, Selective Control Valves – Operational Checkout

Group 15: Tests and Adjustments

Reference 270-15-000, PC Hydraulic System — Summary of References

Reference 270-15-001, Safety Measures for Hydraulic Checks

Reference 270-15-002, Special Tools

Reference 270-15-003, Connecting SensoControl Test Equipment

Reference 270-15-010, Heating Up Hydraulic Oil

Reference 270-15-020, Checking the PC Hydraulic System

Reference 270-15-021, PC Hydraulic System — Test Result Table

Reference 270-15-052, Checking the Delivery Rate of the Hydraulic Pump

Reference 270-15-070, Preparing Pressure Test

Reference 270-15-071, Checking the LS Pressure

Reference 270-15-072, Checking the System Pressure

Reference 270-15-073, Checking the Steering Pressure (Primary Circuit)

Reference 270-15-074, Checking the Braking Pressure of the Hydraulic Trailer Brake (Primary Circuit)

Reference 270-15-075, Checking the LS Pressure of the Steering System

Pressure Relief Valve Test

Reference 270-15-091, Selective Control Valves — Checking for Leaks at Couplers

Reference 270-15-110, Checking the Stepper Motor and Rockshaft Valve

Reference 270-15-130, Rockshaft Valve — Checking for Leaks

Reference 270-15-131, Rockshaft Valve (Wide Version) — Checking the Pressure-Relief Valve

Reference 270-15-132, Rockshaft Valve — Checking Depth to Which Pressure and Discharge Valves are Screwed In

Reference 270-15-150, Rockshaft — Checking the Position Sensor

Reference 270-15-151, Rockshaft Valve — Testing and Adjusting the Draft Sensor

Group 20: Theory of Operation

Reference 270-20-002, PC Hydraulic System — Summary of References

Reference 270-20-060, PC Hydraulic System — Description

Reference 270-20-070, PC Hydraulic System — Operation

Reference 270-20-080, PC Hydraulic System — Symbolic Representation

Reference 270-20-090, PC Hydraulic System — Schematic View

Reference 270-20-160, PC Hydraulic System — Description of Hydraulic Pump

Reference 270-20-170, PC Hydraulic System — Oil Lines of Hydraulic Pump

Reference 270-20-180, PC Hydraulic System—Operation of Hydraulic Pump

Reference 270-20-190, Filter Screen — Description

Reference 270-20-200, Transmission Oil Cooler — Description

Reference 270-20-260, PC Hydraulic System — Description and Arrangement of Shuttle Valves

Reference 270-20-290, PC Hydraulic System — Description of Priority Valve and By-Pass Valve

Reference 270-20-300, PC Hydraulic System — Operation of Priority Valve and By-Pass Valve

PC Hydraulic System – Operation of Pressure-Relief Valve

Reference 270-20-320, Rockshaft — Description

Reference 270-20-330, Rockshaft — Operation of Rockshaft Control

Reference 270-20-340, Rockshaft — Operation of Rockshaft Valve

Reference 270-20-350, Rockshaft — Operation of Position Sensor

Reference 270-20-360, Rockshaft — Operation of Draft Sensor

Reference 270-20-370, Rockshaft — Description of Controls

Reference 270-20-380, Rockshaft — Direct Actuation

Reference 270-20-390, 105, 205 and 305 Series Selective Control Valves — Description

Reference 270-20-480, Couplers — Description

Reference 270-20-600, 105 Series Selective Control Valves — Operation

Reference 270-20-610, 205 Series Selective Control Valves — Operation

Reference 270-20-620, 305 Series Selective Control Valves — Operation

Reference 270-20-625, 305 Series Selective Control Valves — Flow Control

Reference 270-20-630, LS Valve, Shuttle Valve and By-Pass Valve — Operation

Section 280: Miscellaneous

Group 10: Operational Check-Out

Reference 280-10-001, Various Operational Tests, Summary of References

Reference 280-10-010, Operational Test on Front-Wheel Drive Axle

Check Positive Front Wheel Lead at Front-Wheel Drive Axle

Group 15: Tests and Adjustments

Reference 280-15-001, Various Tests and Adjustments, Summary of References

Reference 280-15-010, Checking Accumulator of Front Hitch

Reference 280-15-015, Checking Front Hitch for Leaks

Group 20: Theory of Operation

Reference 280-20-001, Theory of Operation, Summary of References

Reference 280-20-008, Front Hitch Functional Group – Identification

Reference 280-20-009, Circuit Plan – Front Hitch

Reference 280-20-010, Operation of Multi-Valve

Section 290: Operator’s Cab

Group 10: Operational Check-Out

Reference 290-10-001, Air-Conditioning System, Heater and Operator’s Seat——Summary of References

Reference 290-10-002, Air-Conditioning System and Heater—Test Sequence

Reference 290-10-004, Air Comfort Seat—Test Sequence

Group 15: Tests and Adjustments

Reference 290-15-001, Air-Conditioning System, Heater and Operator’s Seat, Test and Adjustments—Summary of References

Reference 290-15-010, Safety at Work

Reference 290-15-015, Handling Refrigerant

Reference 290-15-020, Safety Equipment

Reference 290-15-025, In an Emergency

Reference 290-15-030, Storage of Refrigerant Containers

Reference 290-15-035, R134a Refrigerant

Reference 290-15-040, Important

Reference 290-15-050, Special Tools

Reference 290-15-060, Specifications

Reference 290-15-065, Explanation of Checks

Reference 290-15-070, Pressure Deviations

Group 20: Theory of Operation

Reference 290-20-001, Air-Conditioning, Heating and Ventilation Systems, Operation—Summary of References

Reference 290-20-010, Principle of Heat Exchange

Reference 290-20-015, R134a Refrigerant

Reference 290-20-020, Refrigerant Circuit Layout

Reference 290-20-030, Functional Description of Components—Refrigerant Circuit

Reference 290-20-031, Functional Description of Components—Compressor

Reference 290-20-032, Functional Description of Components—Condenser

Reference 290-20-033, Functional Description of Components—Receiver-Drier

Reference 290-20-034, Functional Description of Components—Expansion Valve

Reference 290-20-035, Functional Description of Components—Thermostat Switch

Reference 290-20-036, Functional Description of Components—Evaporator

Reference 290-20-037, Functional Description of Components—High/Low Pressure Switch

Reference 290-20-038, Functional Description of Components—Control Knobs for Heating and Cooling

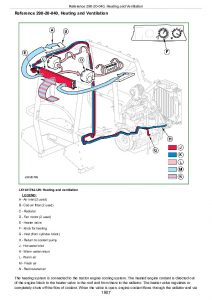

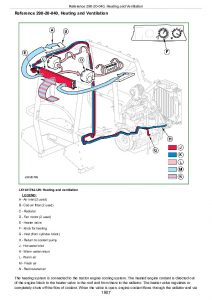

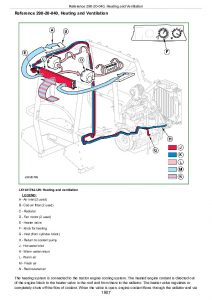

Reference 290-20-040, Heating and Ventilation

Section 299: Special Tools

Group 05: Special Tools (Dealer-Fabricated)

Reference 299-05-001, Special Tools (Dealer-Fabricated) — Summary

Reference 299-05-010, Holding Tool

Reference 299-05-011, Adjusting Tool

Reference 299-05-012, DFRW2—Needle Valve Test Hose Assembly

Reference 299-05-015, Special Tool for 29-BIT CAN BUS—DFLX12

Reference 299-05-016, DFLX14—Solenoid Test Harness

Group 10: Special Tools and Test Equipment

AR52361 – Socket

D01019AA – Manually operated hydraulic pump

FKM10002 or JT05470 – Pressure test kit

Battery Load Tester FKM10409

FKM10443 – Charging valve

FKM10444 – Leak detector

FKM10445 – Universal pressure test kit

FKM10447 – Refrigerant container (R134a; 920g; 750 ml)

FKM10470 – Pressure Measuring System (stage 1)

FKM10471 – Pressure measuring system (stage 2)

FKM10472 – Flow measurement system

FKM10472-4 – Temperature sensor

FKM10482 – Pressure Test Kit

Clamp-on Current Probe JT02153

JT03248 – Fitting

JT05791A – Multimeter

JT07115 – Pressure test kit

KJD10128 – Fitting

KJD10292 – Diagnostic Harness

KJD10194 – Pressure Test Kit

KJD10352 – Restriction fitting

KJD10495 – Hose connector

RE200689 – Performance monitor

RE37996 – Adjusting tool

John Deere Tractors Models 5620, 5720 and 5820 Diagnosis and Tests Technical Manual (TM4791)

INSTANT DOWNLOAD