Complete Repair Technical Manual for John Deere Tractors 5325N, 5425N, 5525N, with all the shop information to maintain, diagnostic, repair, refurbish/rebuild like professional mechanics.

John Deere Tractors 5325N, 5425N & 5525N workshop Repair technical manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

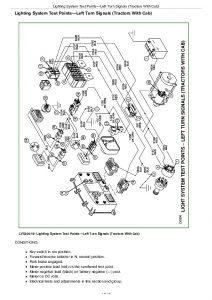

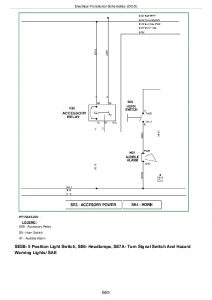

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

tm2188 – 5325N, 5425N and 5525N Tractors Repair Technical Manual.pdf

Category: Repair

Language: English

Published on 12/29/2013

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Total Pages: 1,121 pages

TM2917 Spanish – Manual técnico de reparación de los tractores 5325N, 5425N y 5525N

tm2907 French – Manuel technique de remise en état des tracteurs 5325N, 5425N et 5525N

tm9093 Russian – Техническое руководство по ремонту

OMLVU13146 Operator’s Manual 49 Backhoe

OMLVU13504 Operator’s Manual Retro excavadora 49 para tractores 5200-5500, 5210-5510 y 5220-5520

OMLVU13505 Operator’s Manual Rétropelle 49 pour tracteurs 5200-5500, 5210-5510 et 5220-5520

OMSU300537 Operator’s Manual 5325N, 5425N and 5525N Narrow Tractors

OMRE225601 Operator’s Manual 5325N, 5425N, 5525N Narrow Tractors

OMRE224589 Operator’s Manual 5325N, 5425N, 5525N Narrow Tractors

OMRE224590 Operator’s Manual Manual del operador de tractores 5325N, 5425N y 5525N (Norteamérica)

OMRE224591 Operator’s Manual Livret d’entretien des tracteurs 5325N, 5425N et 5525N (Amérique du Nord)

PC9413 Parts Catalog 49 BACKHOE – FOR UTILITY TRACTORS

PC9413F Parts Catalog 49 BACKHOE – FOR UTILITY TRACTORS

PC9413G Parts Catalog 49 BACKHOE – FOR UTILITY TRACTORS

PC10844 Parts Catalog 5325N Tractors

CTM104 Component Technical Manual CTM104_19_20240307

CTM105 Component Technical Manual CTM104_19_20240307

CTM106 Component Technical Manual CTM104_19_20240307

CTM107 Component Technical Manual CTM104_19_20240307

CTM108 Component Technical Manual CTM104_19_20240307

CTM111 Component Technical Manual Alternators and Starting Motors

CTM116 Component Technical Manual CTM104_19_20240307

CTM117 Component Technical Manual CTM104_19_20240307

CTM164 Component Technical Manual DÍLENSKÁ PÍRUKA Alternátorya startéry

CTM165 Component Technical Manual CTM104_19_20240307

CTM186 Component Technical Manual Alternators and Starting Motors

CTM205 Component Technical Manual CTM104_19_20240307

CTM206 Component Technical Manual CTM104_19_20240307

CTM207 Component Technical Manuals PowerTech™ 4.5L and 6.8L Diesel EnginesMechanical Fuel Systems, (Worldwide Edition)

CTM208 Component Technical Manual Motores diésel PowerTech™ de 4.5 l y 6.8 l Sistemas mecánicos de combustible -: (Edición mundial)

CTM209 Component Technical Manual Circuits d’alimentation mécaniques des moteurs diesel PowerTech™ 4,5 l et 6,8 l -: (Édition mondiale)

CTM210 Component Technical Manual PowerTech™ 4,5-l- und 6,8-l-Dieselmotoren Mechanische Kraftstoffsysteme -: (Weltweite Ausgabe)

CTM211 Component Technical Manual Sistemi del carburante meccanici per motori diesel PowerTech™ da 4,5 l e 6,8 l -: (Edizione universale)

CTM212 Component Technical Manual PowerTech™ 4,5- och 6,8-liters dieselmotorer Mekaniska bränslesystem -: (Världsupplaga)

CTM213 Component Technical Manual PowerTech™-dieselmotoren van 4,5 l en 6,8 l Mechanische brandstofsystemen -: (Wereldwijde uitgave)

CTM214 Component Technical Manual Дизельные двигатели PowerTech™ объемом 4,5 л и 6,8 л Механические топливные системы -: (Исполнение для всех стран)

CTM215 Component Technical Manual Motores Diesel PowerTech™ 4,5 L e 6,8 L Sistemas Mecânicos de Combustível -: (Edição Mundial)

CTM216 Component Technical Manual Vznětové motory PowerTech™ 4.5 l a 6.8 l Mechanické palivové soustavy -: (Celosvětové vydání)

CTM278 Component Technical Manual Alternadores y arrancadores

CTM301 Component Technical Manuals 2.4L and 3.0L Diesel Engines

CTM302 Component Technical Manuals Moteurs diesel 2,4 l et 3,0 l -: (Édition mondiale)

CTM303 Component Technical Manuals 2,4-l- und 3,0-l- Dieselmotoren -: (Weltweite Ausgabe)

CTM304 Component Technical Manuals Motores diesel de 2.4 l y 3.0 l -: (Edición mundial)

CTM305 Component Technical Manuals Motori diesel da 2,4 l e 3,0 l -: (Edizione universale)

CTM463 Component Technical Manual CTM104_19_20240307

CTM464 Component Technical Manual CTM104_19_20240307

CTM465 Component Technical Manual CTM104_19_20240307

CTM472 Component Technical Manual CTM104_19_20240307

CTM473 Component Technical Manual CTM104_19_20240307

CTM474 Component Technical Manual CTM104_19_20240307

CTM475 Component Technical Manual Κινητήρες ντίζελ PowerTech™ 4,5 l και 6,8 l Μηχανικά συστήματα καυσίμου -: (Διεθνής έκδοση)

CTM481 Component Technical Manual PowerTech™ 4,5 l i 6,8 l dizelski motori Mehanički sustavi goriva -: (Svjetsko izdanje)

CTM482 Component Technical Manual 4,5 l ir 6,8 l dyzeliniai varikliai “PowerTech™” Mechaninės degalų tiekimo sistemos -: (Tarptautinis leidinys)

CTM4820 Component Technical Manuals Two-Piece Front-Wheel Drive Axles 730 to 755 (Version 1) One-Piece Front-Wheel Drive Axles 725 and 730, (Worldwide Edition)

CTM483 Component Technical Manual Dizelski motorji PowerTech™ 4,5 l in 6,8 Mehanski sistemi za gorivo -: (Izvedba za vse celine in države)

CTM485 Component Technical Manual PowerTech™ 4,5 l ve 6,8 l Dizel Motorlar Mekanik Yakıt Sistemleri -: (Dünya Çapındaki Sürüm)

CTM570 Component Technical Manuals Alternators and Starting Motors

CTM571 Component Technical Manual Lichtmaschinen und Anlasser

CTM572 Component Technical Manuals Vekselstrømsgeneratorer og startmotorer

CTM574 Component Technical Manuals Vaihtovirtalaturit ja ka¨ynnistinmoottorit

CTM575 Component Technical Manuals Alternateurs et démarreurs

CTM579 Component Technical Manual Dynamo’s en startmotoren

CTM580 Component Technical Manual Riðstraumsrafalar og Ræsihreyflar

CTM582 Component Technical Manuals Maiņstrāvas ģeneratori un starteru motori

CTM583 Component Technical Manuals Dynamo’s en startmotoren

CTM584 Component Technical Manuals Vekselstrømgeneratorer og startmotorer

CTM586 Component Technical Manual Alternatoare și Demaroare

CTM587 Component Technical Manuals Generatorer och startmotorer

CTM590 Component Technical Manuals Generatorer och startmotorer

CTM704 Component Technical Manual PowerTech⢠4.5 L and 6.8 L Diesel Engines Base Engine

CTM715 Component Technical Manual CTM104_19_20240307

CTM732 Component Technical Manual Motoarele diesel PowerTech™ de 4,5 l şi 6,8 l Sistemele mecanice de carburant -: (Ediţie mondială)

CTM77 Component Technical Manuals Alternators and Starter Motors

CTM88 Component Technical Manual Alternatori e motorini di avviamento

MAIN SECTIONS

Foreword

General Information

Safety

General Specifications

Fuel and Lubricants

Serial Number Locations

Features and Accessories

Engine Repair

Engine

Cooling System

Fuel and Air Repair

Fuel System

Air Intake System

Speed Control Linkage

Electrical Repair

Battery, Starter and Alternator

Electrical System Components

Wiring Harness

Power Train Repair

Clutch Housing

Clutch Assembly-PowrReverser™ Transmission

POWRREVERSERPOWRREVER™

POWRREVERSERPOWRREVER™ Transmission

Rear PTO Drive Shaft

Differential

Final Drives

Mechanical Front Wheel Drive

Creeper Assembly

Steering and Brake Repair

Steering Repair

Brake Repair

Hydraulic Repair

Hydraulic Pump and Filter

Hydraulic Oil Cooler

Rockshaft

Selective Control Valve

Hydraulic Mid-Mount Control Valve

Miscellaneous Repair

Front Axle-2WD

Wheels

3-Point Hitch

Fenders

Hood

Operator Station Repair

Seat and Support

Control Console and Panel

ROLL-GARD™

Rear Bar

Cab Components

Air Conditioning System

Heating System

Dealer Fabricated Tools

tm2188 – 5325N, 5425N and 5525N Tractors Repair Technical Manual

Table of Contents

Foreword

Section 10: General Information

Group 05: Safety

Recognize Safety Information

Handle Fluids Safely—Avoid Fires

Prevent Battery Explosions

Prepare for Emergencies

Prevent Acid Burns

Service and Operate Chemical Sprayers Safely

Handle Chemical Products Safely

Avoid High-Pressure Fluids

Park Machine Safely

Support Machine Properly

Wear Protective Clothing

Work in Clean Area

Service Machines Safely

Work In Ventilated Area

Illuminate Work Area Safely

Replace Safety Signs

Use Proper Lifting Equipment

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Keep ROPS Installed Properly

Service Tires Safely

Avoid Harmful Asbestos Dust

Practice Safe Maintenance

Use Proper Tools

Dispose of Waste Properly

Prevent Machine Runaway

Handle Starting Fluid Safely

Service Cooling System Safely

Stay Clear of Rotating Drivelines

Protect Against High Pressure Spray

Construct Dealer-Made Tools Safely

Clean Vehicle of Hazardous Pesticides

Live With Safety

Group 10: General Specifications

Machine Specifications 5325N

Machine Specifications 5425N, 5525N, 5083EN, 5093EN, and 5101EN

POWRREVERSER™ Transmission Ground Speed Estimates

POWRREVERSER™ Creeper Transmissions Ground Speed Estimates

Correction Factors for Other Tire Sizes

Machine Dimensions (Straddle Mount)

Machine Dimensions (Cab)

Repair Specifications

Service Recommendations for O-Ring Boss Fittings

Service Recommendations For Flat Face O-Ring Seal Fittings

Metric Cap Screw Torque Values—Grade 7

Metric Bolt and Screw Torque Values

Unified Inch Bolt and Screw Torque Values

Abbreviations

Group 20: Fuel and Lubricants

Diesel Fuel

Handling and Storing Diesel Fuel

Do Not Use Galvanized Containers

Lubricity of Diesel Fuel

Testing Diesel Fuel

BioDiesel Fuel

Filling Fuel Tank

Diesel Engine Break-In Oil (5425N, 5525N, 5083EN, 5093EN, and 5101EN)

Diesel Engine Oil — Non-Emissions Certified and Certified Tier 1 and Stage I

Oil Filters

Diesel Engine Coolant (engine with wet sleeve cylinder liners)

Operating in Warm Temperature Climates

Additional Information About Diesel Engine Coolants and John Deere LIQUID COOLANT CONDITIONER

Testing Diesel Engine Coolant

Transmission and Hydraulic Oil

Use Correct Transmission-Hydraulic Filter Element

MFWD Axle Housing and Wheel Hub Oil

Grease

Grease (Specific Application)

Mixing of Lubricants

Alternative and Synthetic Lubricants

Lubricant Storage

Group 25: Serial Number Locations

Serial Numbers

Product Identification Number Location

Engine Serial Number Location—4-Cylinder Engine

Engine Serial Number Location—5-Cylinder Engine

Fuel Injection Pump Serial Number Location

Alternator Identification Number Location

Power Steering Valve Serial Number Location

Starter Serial Number Location—4-Cylinder Engine

Starter Serial Number Location—5-Cylinder Engine

Transmission Serial Number Location

Front Axle (2WD) Serial Number Location

Mechanical Front Wheel Drive (MFWD) Serial Number Location

Air Conditioning Compressor Serial Number Location

Group 30: Features and Accessories

Features and Accessories

Standard Features—Straddle Mount

Standard Features—Cab Tractor

Standard Features—5325N through 5525N, 5083EN, 5093EN, and 5101EN

Factory Installed Optional Equipment—5325N through 5525N, 5083EN, 5093EN, and 5101EN

Field Installed Optional Kits and Accessories—5325N through 5525N, 5083EN, 5093EN, and 5101EN

Section 20: Engine Repair

Group 05: Engine

Service Equipment and Tools

Specifications

John Deere Engine Repair—Use CTM104 or CTM301

Remove Engine

Install Engine

Group 10: Cooling System

Specifications

Engine Coolant Pump Repair—Use CTM104 or CTM301

Remove and Install Coolant Recovery Tank

Remove and Inspect Radiator

Install Radiator

Remove and Install Thermostat—4-Cylinder Engine

Remove and Install Thermostat—5-Cylinder Engine

Inspect and Replace Belt Tensioner—4-Cylinder Engine

Inspect and Replace Belt Tensioner—5-Cylinder Engine

Section 30: Fuel and Air Repair

Group 05: Fuel System

Specifications

Injection Pump, Nozzle and Governor Repair—Use CTM207 or CTM301

Remove, Inspect, and Install Fuel Tank—Straddle Mount

Remove, Inspect, and Install Fuel Tanks—Cab Tractors

Replace Fuel Filter—5325N

Replace Fuel Filter—5425N, 5525N, 5083EN, 5093EN, and 5101EN

Remove and Install Fuel Transfer Pump—5083EN, 5093EN, and 5101EN

Replace In-Line Fuel Filter—5325N, 5425N, and 5525N

Remove and Install Fuel Filter/Primer Pump Assembly

Group 10: Air Intake System

Turbocharger Repair—Use CTM104 or CTM301

Specifications

Remove, Inspect, and Install Air Cleaner Elements

Remove Turbocharger—4-Cylinder Tractors

Install Turbocharger—4-Cylinder Tractors

Remove Turbocharger—5-Cylinder Tractors

Install Turbocharger—5-Cylinder Tractors

Turbocharger Break-In

Group 15: Speed Control Linkage

Inspect and Repair Speed Control Linkage—4-Cylinder Engine—Straddle Mount

Inspect and Repair Speed Control Linkage—5-Cylinder Engine—Straddle Mount

Inspect and Repair Speed Control Linkage—4-Cylinder Engine—Cab Tractors

Inspect and Repair Speed Control Linkage—5-Cylinder Engine—Cab Tractors

Inspect and Repair Speed Control Linkage—540/1000 PTO

Section 40: Electrical Repair

Group 05: Battery, Starter and Alternator

Starter Repair—Use CTM77

Prevent Battery Explosions

Remove and Install Battery

Remove and Install Starter—5-Cylinder Engine

Remove and Install Starter—4-Cylinder Engine

Replace Alternator/Regulator—4-Cylinder Engine

Replace Alternator/Regulator—5-Cylinder Engine

Group 10: Electrical System Components

Essential Tools

Other Material

Specifications

Replace Air Filter Restriction Switch

Replace Cold Start Advance Switch

Replace Coolant Temperature Sender—5325N Tractor

Replace Coolant Temperature Sender—5425N, 5525N, 5083EN, 5093EN, and 5101EN Tractors

Replace Engine Speed Sensor

Replace Engine Oil Pressure Switch

Replace Key Switch—Straddle Mount

Replace Key Switch—Cab Tractors

Replace Light Switch

Replace Turn Signal Switch

Replace Instrument Panel

Program Instrument Cluster

Replace Rear PTO Switch—Straddle Mount

Replace Rear PTO Switch—Cab Tractors

Replace Rear PTO Switch—Electro-Hydraulic PTO

Replace Rockshaft Control Module—Electro-Hydraulic Hitch

Replace Load Depth Control—Electro-Hydraulic Hitch

Replace Fuel Level Sender—Straddle Mount

Replace Fuel Level Sender—Cab Tractors

Replace Front Wiper/Washer Control Switch

Replace Wiper Motor—Tractor with Cab

Replace Blower Control Switch

Replace A/C Temperature Control Switch

Replace Blower Motor Resistor

Replace Air Conditioning High/Low Pressure Switch

Replace Dome Light

Replace Door Switch

Replace Seat Switch—Cab Tractors

Replace Load Center Panel—Cab Tractors

Replace VEC Load Center—Straddle Mount

Replace Electro-Hydraulic Control Unit—Cab Tractors

Replace Hitch Solenoids—Cab Tractors

Replace Countershaft Speed Sensor—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Tractors

Replace Wheel Speed Sensor

Replace Enable Pressure Sensor—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace Clutch Pedal Position Sensor—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace Clutch Disengage Switch—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace Rear PTO Sensor—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission—With Electro-Hydraulic PTO

Replace Hitch Draft Sensor—Electro-Hydraulic Hitch

Replace Hitch Position Sensor—Electro-Hydraulic Hitch

Replace Electro-Hydraulic Directional Reverser—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace Park Switch—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace Brake Pedal Switch—Electro-Hydraulic Tractors

Replace Hi/Lo Shifter Switch—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace External Raise/Lower Switch

Replace Clutch Enable Solenoid—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace Trans Forward Solenoid—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace Trans Reverse Solenoid—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission

Replace High Solenoid—POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmission—With Electro-Hydraulic Hi/Lo

Replace Rear PTO Solenoid—Electro-Hydraulic PTO

Replace MFWD Solenoid

Replace MFWD Switch

Replace Speakers

Group 15: Wiring Harness

Service Equipment and Tools

Service Parts Kits

Replace Connector Body—Blade Terminals

Replace WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Connector

Install WEATHER PACK WEATHER PACK is a trademark of Packard Electric. Contact

Repair (Pull Type) METRI-PACK METRI-PACK is a trademark of Delphi Packard Electric Systems Connectors

Repair (Push Type) METRI-PACK Connectors

Replace Headlight Wiring Harness

Replace Fused Power Wiring Harness

Replace Front Wiring Harness—4-Cylinder

Replace Front Wiring Harness—5-Cylinder

Replace Rear Electrical Harness—Straddle Mount

Replace Rear Wiring Harness—Cab Tractors

Replace Console Wiring Harness—Cab Tractors

Replace Cab Roof and HVAC Wiring Harnesses

Section 50: Power Train Repair

Group 05: Clutch Housing

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Separate Engine from Clutch Housing—Straddle Mount

Install Engine to Clutch Housing—Straddle Mount

Separate Engine from Clutch Housing—Cab Tractors

Install Engine to Clutch Housing—Cab Tractors

Inspect and Repair Clutch Pedal and Linkage—Straddle Mount (POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmissions)

Inspect and Repair Clutch Pedal and Linkage—Cab Tractors (POWRREVERSER POWRREVERSER is a trademark of Deere & Company Transmissions)

Group 10: Clutch Assembly—PowrReverser™ Transmission

Specifications

Remove and Install Clutch Assembly

Remove, Inspect, and Repair Transmission Pump

Group 11: POWRREVERSERPOWRREVERSER is a trademark of Deere & Company

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Remove and Install POWRREVERSER POWRREVERSER is a trademark of Deere & Company Control Valve

Disassemble, Inspect, and Repair POWRREVERSER POWRREVERSER is a trademark of Deere & Company Control Valve

Remove and Install EH Hi/Lo Valve

Disassemble, Inspect, and Repair EH Hi/Lo Valve

Remove and Install POWRREVERSER POWRREVERSER is a trademark of Deere & Company —Transmissions Without EH Hi/Lo

Remove and Install POWRREVERSER POWRREVERSER is a trademark of Deere & Company —Transmissions With EH Hi/Lo

Disassemble, Inspect, and Repair Reverse Idle Gear—Transmissions Without EH Hi/Lo

Disassemble, Inspect, and Repair Reverse Idle Gear—Transmissions With EH Hi/Lo

Disassemble, Inspect, and Repair Clutch Gear—Transmissions Without EH Hi/Lo

Disassemble, Inspect, and Repair Connect Shaft—Transmissions With EH Hi/Lo

Disassemble, Inspect, and Repair Driven Shaft—Transmissions Without EH Hi/Lo

Disassemble, Inspect, and Repair Driven Shaft—Transmissions With EH Hi/Lo

Disassemble, Inspect, and Repair Hi/Lo Clutch Shaft—Transmissions With EH Hi/Lo

Disassemble, Inspect, and Repair POWRREVERSER POWRREVERSER is a trademark of Deere & Company —Transmissions Without EH Hi/Lo

Disassemble, Inspect, and Repair POWRREVERSER POWRREVERSER is a trademark of Deere & Company —Transmissions With EH Hi/Lo

Group 15: POWRREVERSERPOWRREVERSER is a trademark of Deere & Company Transmission

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Separate Clutch Housing from Transmission—Straddle Mount

Install Clutch Housing to Transmission—Straddle Mount

Separate Clutch Housing from Transmission—Cab Tractors

Install Clutch Housing to Transmission—Cab Tractors

Remove Transmission

Disassemble and Inspect Transmission

Assemble Transmission

Install Transmission

Disassemble, Inspect, and Assemble Gearshift Shaft Assemblies

Disassemble, Inspect, and Assemble Transmission Bottom Shaft

Disassemble, Inspect, and Assemble Range Reduction Shaft

Disassemble, Inspect, and Assemble Top Shaft

Remove, Inspect, and Install MFWD and Range Gears

Group 20: Rear PTO Drive Shaft

Service Equipment and Tools

Other Material

Specifications

Inspect and Repair 540/540E PTO Shift Lever and Linkage

Remove and Install Rear 540/540E or 540/1000 Electro-Hydraulic PTO Shaft Assembly

Disassemble, Inspect, and Assemble Rear 540/540E Electro-Hydraulic and 540/1000 Electro-Hydraulic Pinion Shaft

Disassemble, Inspect, and Assemble Rear 540/540E Electro-Hydraulic PTO Output Shaft Assembly

Disassemble, Inspect, and Assemble Rear 540/1000 Electro-Hydraulic PTO Output Shaft Assembly

Remove, Inspect and Install Electro-Hydraulic PTO Valve

Group 25: Differential

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Service Parts Kits

Remove and Install Differential Assembly

Disassemble, Inspect, and Assemble Differential Assembly

Remove and Inspect Differential Drive Shaft

Install Differential Drive Shaft

Remove, Inspect, and Install Differential Lock Assembly

Differential Cone Point Adjustment

Differential Backlash Adjustment

Group 30: Final Drives

Service Equipment and Tools

Other Material

Specifications

Remove and Install Final Drive Assembly

Remove and Inspect Planetary Drive Assembly

Install Planetary Drive Assembly

Remove, Inspect, and Install Axle Shaft Assembly

Group 35: Mechanical Front Wheel Drive

Essential Tools

Service Equipment and Tools

Other Material

Specifications

Remove and Install MFWD Drop Gearbox

Disassemble and Inspect MFWD Drop Gearbox

MFWD Drop Gearbox Cross Section

Assemble MFWD Drop Gearbox

Remove, Inspect, and Install MFWD Drive Shaft

Remove and Install MFWD Axle

Remove and Install MFWD Axle Pivot Pin and Pivot Bushings

Disassemble and Inspect MFWD Outer Drive

Assemble MFWD Outer Drive

Remove, Inspect, and Install MFWD Swivel Housing

Remove, Inspect, and Install MFWD Axle Shaft

Remove and Install MFWD Differential Carrier Assembly

Disassemble and Inspect MFWD Differential Carrier Assembly

Assemble MFWD Differential Carrier Assembly

Group 40: Creeper Assembly

Other Material

Specifications

Remove and Install Creeper Assembly

Disassemble, Inspect, and Assemble Creeper Assembly

Section 60: Steering and Brake Repair

Group 05: Steering Repair

Other Material

Specifications

Service Parts Kits

Remove and Install Straight Steering Column and Valve

Remove and Install Tilt/Telescoping Steering Column

Remove and Install Steering Valve—Tilt/Telescoping Steering Column

Disassemble and Inspect Steering Valve

Assemble Steering Valve

Remove and Install Steering Cylinder—2WD Axle

Disassemble, Inspect, and Assemble Steering Cylinder—2WD Axle

Disassemble, Inspect and Assemble Steering Cylinder—MFWD Axle

Remove, Inspect and Install Tie Rod Assembly—2WD Axle

Remove, Inspect and Install Tie Rod Assembly—MFWD Axle

Inspect and Replace Steering Hydraulic Lines—Straddle Mount

Inspect and Replace Steering Hydraulic Lines—Cab Tractors

Group 10: Brake Repair

Service Equipment and Tools

Other Material

Specifications

Remove and Install Brake Valve and Pedals

Disassemble and Inspect Brake Pedals and Valve

Brake Valve Cross Section

Assemble Brake Valve

Remove and Inspect Brakes

Install Brakes

Inspect and Replace Brake Hydraulic Lines

Section 70: Hydraulic Repair

Group 05: Hydraulic Pump and Filter

Service Parts Kit

Service Equipment and Tools

Specifications

Remove, Inspect, and Install Hydraulic Oil Pick-Up Screen

Remove and Install Hydraulic Pump—5-Cylinder Engine

Remove Hydraulic Pump External Components—5-Cylinder Engine

Disassemble and Inspect Hydraulic Pump—5-Cylinder Engine

Assemble Hydraulic Pump—5-Cylinder Engine

Install Hydraulic Pump External Components—5-Cylinder Engine

Remove and Install Hydraulic Pump—4-Cylinder Engine

Remove Hydraulic Pump External Components—4-Cylinder Engine

Disassemble and Inspect Hydraulic Pump—4-Cylinder Engine

Assemble Hydraulic Pump—4-Cylinder Engine

Install Hydraulic Pump External Components—4-Cylinder Engine

Remove and Install Hydraulic Oil Filter/Manifold

Inspect and Replace Hydraulic Supply/Return Lines—4-Cylinder Tractors (With SCV)

Inspect and Replace Hydraulic Supply/Return Lines—4-Cylinder Tractors (Without SCV)

Inspect and Replace Hydraulic Supply/Return Lines—5-Cylinder Tractors (With SCV)

Inspect and Replace Hydraulic Supply/Return Lines—5-Cylinder Tractors (Without SCV)

Group 06: Hydraulic Oil Cooler

Remove, Inspect, and Install Hydraulic Oil Cooler

Group 10: Rockshaft

Service Parts Kits

Other Material

Specifications

Inspect and Repair Draft Sensing Support Assembly

Rockshaft Control Valve (RCV) Repair

Rockshaft Control Valve Exploded View

Remove and Install Rockshaft Control Valve—Straddle Mount

Remove and Install Rockshaft Control Valve—Cab Tractors

Remove and Install Rockshaft Case—Straddle Mount

Remove and Install Rockshaft Case—Cab Tractors

Remove, Inspect, and Install Rockshaft Lift Arms

Remove, Inspect, and Install Rockshaft Piston and Cylinder

Group 15: Selective Control Valve

Service Parts Kits—Triple SCVs

Service Parts Kits—Dual SCVs

Other Material

Specifications

Inspect and Repair SCV Levers and Linkage

Remove and Install Dual or Triple Selective Control Valve (SCV)

Disassemble, Inspect, and Assemble Dual Selective Control Valve (SCV)

Triple Selective Control Valve (SCV) Cross-Sectional View

Disassemble, Inspect, and Assemble Triple Selective Control Valve (SCV)

Inspect and Replace Hydraulic Hoses—Control Valve (SCV)

Inspect and Replace Hydraulic Hoses—Control Valve (SCV) With Mid-Mount

Group 20: Hydraulic Mid-Mount Control Valve

Service Parts Kits

Other Material

Specifications

Inspect and Repair Joystick and Linkage

Remove and Install Mid-Mount Control Valve

Disassemble, Inspect, and Assemble Dual Mid-Mount Control Valve

Inspect and Replace Hydraulic Lines Dual Mid-Mount Control Valve—Straddle Mount

Inspect and Replace Hydraulic Lines Dual Mid-Mount Control Valve—Cab Tractors

Section 80: Miscellaneous Repair

Group 05: Front Axle—2WD

Specifications

Remove and Install Front Axle—2WD

Inspect and Replace Pivot Pin and Bushings—2WD Axle

Remove and Install Spindle Assembly—2WD Axle

Inspect and Replace Spindle Shaft Bushings—2WD Axle

Group 10: Wheels

Specifications

Inspect and Replace Front Wheel Bearings

Group 15: 3-Point Hitch

Specifications

Inspect and Repair Draft Links

Inspect and Repair Adjustable Lift Links

Inspect and Repair Center Link

Remove and Install Drawbar and Support

Group 20: Fenders

Specifications

Remove and Install Fenders—Straddle Mount

Group 25: Hood

Remove and Install Hood

Section 90: Operator Station Repair

Group 05: Seat and Support

Remove and Install Seat and Support

Group 06: Control Console and Panel

Remove and Install Right-Side Control Console—Straddle Mount

Remove and Install Left-Side Control Console—Straddle Mount

Remove and Install Right-Side Control Console—Cab Tractors

Remove and Install Left-Side Control Console—Cab Tractors

Remove and Install Cowl Cover

Group 10: ROLL-GARDROLL-GARD is a trademark of Deere & Company.

Specifications

Remove and Install ROLL-GARD ROLL-GARD is a trademark of Deere & Company

Group 15: Rear Bar

Specifications

Remove and Install Rear Bar—Straddle Mount

Group 20: Cab Components

Other Material

Essential Tools

Specifications

Remove Cab

Install Cab

Remove and Install Cab Outer Roof

Remove and Install Lower Front Windows

Remove and Install Rear Corner Cab Windows

Remove and Install Right Hand Cab Window

Remove and Install Rear Cab Window

Remove and Install Windshield

Remove and Install Cab Door

Remove, Inspect, and Install Cab Recirculating/Fresh Air Filter

Group 25: Air Conditioning System

Essential Tools

Service Equipment and Tools

Other Material

Service Parts Kits

Specifications

Recover/Recycle Air Conditioning Refrigerant

Replace Air Conditioning Receiver/Dryer

Remove, Inspect, and Install Air Conditioning Condenser

Remove, Inspect, and Install Air Conditioning Compressor

Test Volumetric Efficiency of Compressor

Test Compressor Shaft Seal Leakage

Disassemble and Assemble Compressor Clutch

Disassemble, Inspect, and Assemble Compressor

Check Compressor Clutch Hub Clearance

Inspect Compressor Manifold

Remove and Install Compressor Relief Valve

Remove Evaporator/Heater Core Housing

Install Evaporator/Heater Core Housing

Remove and Install Blower Motors

Remove Evaporator/Heater Core

Leak Test Evaporator/Heater Core

Install Evaporator/Heater Core

Service Expansion Valve

Expansion Valve Bench Test

Refrigerant Oil Information

Check Compressor Oil Charge

Determine Correct Refrigerant Oil Charge

Add Refrigerant Oil to System

System Information

Flush Air Conditioning System

Evacuate Air Conditioning System

Charge Air Conditioning System

Group 30: Heating System

Remove Heater Control Valve

Leak Test Heater Control Valve

Install Heater Control Valve

Section 99: Dealer Fabricated Tools

Group 05: Dealer Fabricated Tools

DFLV1A—Final Drive Turning Tool

DFRW20—Compressor Holding Fixture

DFT1162—Snap Ring Removal Tool