Complete service repair manual with Electrical Wiring Diagrams for John Deere 3150 Tractor with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

John Deere 3150 Tractor workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

John Deere 3150 Tractor (North America Edition) Parts Catalog (PC4207).pdf

TM4410 – John Deere 3150 Tractor Technical Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,023 pages

File Format: PDF

Language: English

See also:

OMN200251 Operator’s Manual 875 Series Folding Min-Till Cultivator

OMW54464 Operator’s Manual 740 Classic Loader Self-Leveling & Non Self-Leveling

OMW54476 Operator’s Manual Chargeur classique740avec??m?se à niveau automatiquesans mise à niveau automatique

OMW54489 Operator’s Manual Cargadora740 Classiccon??n?velación automáticasin????velación automática

PC2024 Parts Catalog 875 Series Min-Till Cultivator

TM1298 TM – All Inclusive Farm Loaders

TM1495 TM – All Inclusive Tillage Equipment

TM2656 TM – All Inclusive Equipo de labranza

OML57483 Operator’s Manual 3150 Utility Tractor

OML57484 Operator’s Manual Tracteur 3150

PC4207 Parts Catalog 3150 Utility Tractor (North American Edition)

TM4410 TM – All Inclusive 3150 Tractor – Operation / Test and Repair

CTM111 Component Technical Manual Alternators and Starting Motors

CTM164 Component Technical Manual DÍLENSKÁ PÍRUKA Alternátorya startéry

CTM186 Component Technical Manual Alternators and Starting Motors

CTM278 Component Technical Manual Alternadores y arrancadores

CTM30 Component Technical Manual Radial Piston Pump

CTM307 Component Technical Manual Air Conditioning Compressor Install Manual

CTM35 Component Technical Manual Accessoires pour moteur OEM

CTM4 Component Technical Manual Series 300, 3179, 4239, 4276, 6359 & 6414 Base Engines

CTM570 Component Technical Manuals Alternators and Starting Motors

CTM571 Component Technical Manual Lichtmaschinen und Anlasser

CTM572 Component Technical Manuals Vekselstrømsgeneratorer og startmotorer

CTM574 Component Technical Manuals Vaihtovirtalaturit ja ka¨ynnistinmoottorit

CTM575 Component Technical Manuals Alternateurs et démarreurs

CTM579 Component Technical Manual Dynamo’s en startmotoren

CTM580 Component Technical Manual Riðstraumsrafalar og Ræsihreyflar

CTM582 Component Technical Manuals Maiņstrāvas ģeneratori un starteru motori

CTM583 Component Technical Manuals Dynamo’s en startmotoren

CTM584 Component Technical Manuals Vekselstrømgeneratorer og startmotorer

CTM586 Component Technical Manual Alternatoare și Demaroare

CTM587 Component Technical Manuals Generatorer och startmotorer

CTM590 Component Technical Manuals Generatorer och startmotorer

CTM67 Component Technical Manual OEM Engine Accessories

CTM68 Component Technical Manual Electronic Fuel Injection Systems (Bosch & Denso Controls)

CTM7 Component Technical Manual Radial Piston Pump

CTM77 Component Technical Manuals Alternators and Starter Motors

CTM88 Component Technical Manual Alternatori e motorini di avviamento

CTM90 Component Technical Manual Bosch Elektronische Kraftstoff Einspritz-Anlagen

CTM91 Component Technical Manual Impianti elettronici Bosch di iniezione del combustibile

CTM92 Component Technical Manual Sistemas electrónicos de inyección de combustible.

CTM97 Component Technical Manual Electronic Fuel Injection Systems (Bosch & Denso Controls)

John Deere 3150 Tractor (North America Edition) Parts Catalog (PC4207)

20 ENGINE….3

ST229315 – SHORT BLOCK ASSEMBLY….5

ST229316 – CYLINDER BLOCK (FRONT AND RH VIEW)….7

ST229317 – CYLINDER BLOCK (REAR AND LH VIEW)….10

ST229318 – Oil Filter and Dipstick….12

ST229319 – FRONT PLATE….14

ST229320 – VENT TUBE….16

ST229321 – ROCKER ARM COVER….18

ST229322 – ROCKER ARMS_SHAFT_TAPPETS_PUSH RODS….20

ST229323 – Rocker Arm_Shaft_Tappet_Push Rod….22

ST229324 – CYLINDER HEAD….24

ST229325 – VALVES_VALVES SEATS_SPRINGS_RETAINERS….26

ST229326 – CYLINDER HEAD – CONVERSION PARTS….29

ST229327 – VALVES_VALVES SEATS_SPRINGS_RETAINERS….31

ST229328 – CAMSHAFT….33

ST229329 – IDLE GEARS….35

ST229330 – IDLE GEARS….37

ST229331 – IDLE GEARS….39

ST229332 – TIMING GEAR COVER….41

ST229333 – TIMING GEAR COVER….44

ST229335 – MAGNETIC PICK UP….47

ST229336 – MAGNETIC PICK-UP….49

ST229337 – OIL FILLER….51

ST229338 – CRANKSHAFT _ BEARINGS – KIT….53

ST229339 – BEARINGS , THRUST BEARING (CRANKSHAFT)….56

ST229340 – BEARINGS , THRUST BEARING (CRANKSHAFT)….59

ST229341 – CRANKSHAFT PULLEY….62

ST229342 – PISTON _ CONNECTING ROD _ LINER….64

ST229343 – FLYWHEEL HOUSING….67

ST229344 – FLYWHEEL….69

ST229345 – SENDING UNIT-COOLANT TEMPERATURE-ENGINE OIL PRESSURE_PILOT BEARING….71

ST229346 – OIL PAN….73

ST229347 – MOUNTING PARTS FOR OIL PAN….75

ST229348 – OIL PUMP….77

ST229349 – OIL PUMP, KIT….79

ST229350 – ENGINE OIL COOLER….81

ST229351 – RADIATOR_COOLANT HOSES….84

ST229353 – ENGINE COOLANT HEATER….87

ST229354 – THERMOSTAT_THERMOSTAT HOUSING….89

ST229356 – WATER PUMP_FAN….91

ST229357 – WATER PUMP….94

ST229359 – ENGINE GASKET SET….96

ST229774 – MAGNETIC PICK UP….98

ST229792 – ENGINE COOLANT HEATER….100

30 FUEL AND AIR….102

ST223753 – FUEL TRANSFER PUMP 'AIRTEX' (REPLACEMENT PUMP)….103

ST229360 – DRY AIR CLEANER….105

ST229361 – PRE-CLEANER….107

ST229362 – AIR PRE-CLEANER (FOR DRY AIR CLEANER)….109

ST229363 – AIR INTAKE MANIFOLD….111

ST229364 – EXHAUST MANIFOLD….113

ST229365 – EXHAUST SYSTEM….115

ST229366 – FUEL TANK….117

ST229369 – ADDITIONAL FUEL TANK-MOUNTING SUPPORT….120

ST229370 – FUEL LINES….122

ST229371 – WATER TRAP….126

ST229372 – FUEL FILTER….129

ST229373 – FUEL PREHEATING SYSTEM….132

ST229374 – FUEL TRANSFER PUMP 'SOFABEX'….134

ST229377 – AIRTEX FUEL TRANSFER PUMP ASSEMBLY (REPLACEMENT PUMP)….136

ST229379 – FUEL INJECTION NOZZLE STANADYNE….138

ST229380 – FUEL INJECTION PUMP….141

ST229381 – FUEL INJECTION PUMP LINES….143

ST229382 – SPEED CONTROL LINKAGE….146

ST229383 – SHUT-OFF KNOB….150

ST229384 – THERMOSTART STARTING AID….152

ST229386 – ETHER COLD WEATHER STARTING AID….154

ST753175 – Additional Fuel Tank….156

ST753176 – Fuel Transfer Pump 'Corona'….158

ST753177 – THERMOSTART STARTING AID….160

40 ELECTRICAL….162

ST229389 – ALTERNATOR (55A)….165

ST229391 – ALTERNATOR (55A)….169

ST229392 – BATTERY….172

ST229394 – STARTING MOTOR KIT….174

ST229395 – STARTING MOTOR….176

ST229397 – INSTRUMENT HOUSING, LEFT-HAND….179

ST229398 – INSTRUMENT HOUSING, RIGHT-HAND….182

ST229399 – SPEED-HOUR METER….185

ST229400 – ELECTRICAL INSTRUMENTS….187

ST229402 – LIGHT BAR….190

ST229403 – HEADLIGHTS (FOUR-POST ROLL-GARD)….192

ST229404 – HEADLIGHTS (SGB)….194

ST229405 – WARNING LIGHTS AND TAIL LIGHTS….196

ST229406 – REAR WORK LIGHT….198

ST229407 – DOME LIGHT-CONSOLE LIGHT (SGB)….201

ST229408 – DOME LIGHT – CONSOLE LIGHT (FOUR-POST ROLL-GARD)….203

ST229409 – RADIO AND LOUDSPEAKER COVERS SGB….205

ST229412 – WIRING HARNESS – ENGINE….207

ST229413 – WIRING HARNESS – DASH….209

ST229414 – CONTROL UNIT-AUTOMATIC ENGAGEMENT OF FRONT WHEEL DRIVE….211

ST229415 – WIRING HARNESS TRANSMISSION….213

ST229416 – WIRING HARNESS (FOUR-POST ROLL-GARD)….215

ST229417 – WIRING HARNESS (SGB)….218

ST229418 – WIRING HARNESS_RADIO AND LOUDSPEAKER (SGB)….222

ST229421 – REPAIR-KIT FOR ROOF WIRING HARNESS LH WINDSHIELD WIPER – SGB….224

ST229425 – ELECTRICAL REMOTE CONTROL….226

ST229427 – TURN SIGNAL CONTROL….229

ST229429 – Electrical Outlet Socket, 7-Terminal….231

ST229430 – Electrical Outlet Socket Supplementary Wiring Kit, 7 Terminal….233

ST229431 – ELECTRICAL OUTLET SOCKET….235

ST229432 – ELECTRICAL OUTLET SOCKET….237

ST229434 – CIGAR LIGHTER….239

ST229435 – MOTOROLA FENDER MOUNT RADIO AND ANTENNA….241

ST229436 – AM AND AM-FM PUSH-BUTTON RADIO (MOTOROLA)….244

ST229437 – RADIO SPEAKER KIT….247

ST229439 – WARNING LAMP (FLASHING) (6.1M (19'11'), 6.2M (20'8'), 6.5M (21'4') SIZES)….249

ST229440 – FLOOD LAMPS….251

ST229441 – REAR FLOOD LAMPS (SOUND-GARD BODY)….254

ST229442 – LAMP EXTENSION KIT….256

ST229443 – PERFORMANCE TRAK II MINI-MONITOR (ANALOG TACHOMETER)….258

ST229444 – RADAR SENSOR FOR DIGITAL TACHOMETER….261

ST753181 – Alternator Attaching Parts….264

ST753182 – Alternator Attaching Parts….266

ST753184 – ALTERNATOR (55A)….268

ST753186 – Battery….271

ST753187 – Starting Motor….273

ST753189 – SOCKET….275

ST753191 – WIRING HARNESS LOUDSPEAKER (SGB)….277

ST753193 – Electrical Connectors….279

ST753196 – Electrical Connectors….283

ST753197 – Electrical Remote Control Kit….287

ST753198 – Electrical Remote Control Wiring Kit….289

ST753201 – Horn….291

ST753203 – CONVENIENCE ELECTRICAL OUTLET SOCKET….293

ST753204 – Radio Antenna Kit….295

50 POWER TRAIN….297

ST223441 – GASKET KIT….300

ST229445 – CLUTCH HOUSING….302

ST229446 – CLUTCH HOUSING….304

ST229448 – ENGINE CLUTCH….307

ST229449 – SLAVE CYLINDER WITH THROW-OUT BEARING _ INDIVIDUAL PARTS….309

ST229450 – CONVERSION KIT FOR ENGINE CLUTCH….311

ST229451 – CLUTCH OPERATING PARTS….313

ST229452 – RESERVOIR FOR CLUTCH….316

ST229453 – Repair Kit For Clutch Master Cylinder….318

ST229454 – OIL PUMP_ PTO DRIVE SHAFT_ CLUTCH SHAFT….320

ST229455 – TRANSMISSION OIL PUMP – OIL LINES….323

ST229456 – SHIFT COVER….325

ST229457 – SHIFT COVER….327

ST229458 – SHIFT COVER….329

ST229459 – CONTROL VALVE_SENDING UNIT….333

ST229460 – HI-LO SHIFT LINKAGE….337

ST229461 – HI-LO SHIFT LINKAGE….340

ST229462 – HI-LO CLUTCH….344

ST229463 – COVER _ LEVER….348

ST229464 – PTO CONTROL LINKAGE….350

ST229465 – PTO CLUTCH….352

ST229467 – FRONT WHEEL DRIVE….355

ST229468 – FRONT WHEEL DRIVE MULTI-DISK CLUTCH….357

ST229469 – FRONT WHEEL DRIVE COVER _ SOLENOID VALVE….360

ST229471 – FRONT WHEEL DRIVE – SOLENOID….362

ST229472 – FRONT WHEEL DRIVE – SOLENOID VALVE _ SERVICE KIT….364

ST229473 – OIL MANIFOLD _ OIL LINES….366

ST229475 – TRANSMISSION CASE _ END COVER….369

ST229476 – TRANSMISSION CASE….371

ST229477 – TRANSMISSION CASE-CONVERSION KIT….373

ST229478 – TRANSMISSION CASE….375

ST229479 – OIL DIPSTICK….379

ST229481 – TRANSMISSION DRIVE SHAFT AND SYNCHRONIZING PARTS….381

ST229482 – HOLLOW DRIVE SHAFT….385

ST229483 – REVERSE RANGE-CONVERSION KIT (SYNCHR. TRANSM. WITH HI-LO AND FWD)….389

ST229484 – PINION SHAFT _ GROUP SHAFT….393

ST229485 – CONSOLE SHIFT….397

ST229486 – CONSOLE SHIFT LINKAGE….400

ST229487 – SHIFTER SHAFT HOUSING….404

ST229488 – COVER FOR SHIFT LINKAGE….406

ST229490 – TRANSMISSION OIL LINES _ OIL CUP….408

ST229491 – LUBRICATING LINES _ OIL CUP….410

ST229492 – TRANSMISSION OIL FILTER….413

ST229494 – INDEPENDENT PTO 540-1000 RPM (INTERCHANGEABLE)….415

ST229496 – FRONT AND REAR PTO GUARDS….418

ST229497 – DIFFERENTIAL LOCK MECHANISM….421

ST229498 – DIFFERENTIAL….425

ST229499 – FINAL DRIVE _ REAR AXLE….428

ST229500 – FRONT WHEEL DRIVE SHAFT….432

ST229501 – FRONT WHEEL DRIVE ANTI-WRAPPING GUARD….434

ST229503 – FRONT WHEEL DRIVE-STEERING AXLE (APL 350)….436

ST229504 – FRONT WHEEL DRIVE ELEMENTS (INPUT)….438

ST229505 – FRONT WHEEL DRIVE DIFFERENTIAL MULTI-DISK LOCK….441

ST229506 – FRONT WHEEL DRIVE – AXLE BRIDGE_TIE ROD….443

ST229507 – FRONT WHEEL DRIVE – KNUCKLE HOUSING….449

ST229508 – FRONT WHEEL DRIVE – UNIVERSAL JOINT DOUBLE….453

ST229509 – FRONT WHEEL DRIVE – UNIVERSAL JOINT DOUBLE….455

ST229510 – FRONT WHEEL DRIVE – PLANETARY DRIVE….457

ST229511 – BELT PULLEY (540 RPM)….460

ST229956 – PTO BEARING QUILL CONVERSION KIT….465

ST229989 – PTO COUNTERSHAFT….467

ST231833 – FRONT WHEEL DRIVE – SOLENOID….469

60 STEERING AND BRAKES….471

ST229512 – HYDROSTATIC STEERING – STEERING COLUMN….472

ST229513 – HYDROSTATIC STEERING – STEERING UNIT….476

ST229514 – HYDROSTATIC STEERING – STEERING UNIT….479

ST229516 – HYDROSTATIC STEERING OIL LINES….481

ST229517 – OIL LINES AND ATTACHING PARTS FOR HYDROSTATIC STEERING….484

ST229518 – STEERING CYLINDER….486

ST229519 – BRAKE DISK….490

ST229521 – BRAKE VALVE….492

ST229522 – RETURN LINE STEERING UNIT _ BRAKE VALVE….494

ST229523 – FIELD INSTALLATION KIT-OIL RETURN (SGB)….498

ST229524 – BRAKE OIL LINES….501

ST229525 – HANDBRAKE LEVER AND LINKAGE….504

ST229526 – HANDBRAKE-BAND….508

70 HYDRAULICS….511

ST223575 – SELECTIVE CONTROL VALVE OVERHAUL KIT….514

ST229527 – HYDRAULIC PUMP DRIVE 40CM3 (2.40IN3)….516

ST229528 – HYDRAULIC PUMP 40CM3 (2.4IN3)….518

ST229529 – HYDRAULIC PUMP 40CM3 (2.4IN3)….520

ST229530 – PUMP COVER AND VALVES 40CM3 (2.4IN3)….524

ST229531 – HYDRAULIC PUMP ELECTRIC DESTROKE KIT….528

ST229532 – HYDRAULIC PUMP KIT MODEL NO. EA1 40CM3 (2.4IN3)….531

ST229534 – FLOW CONTROL VALVE….533

ST229535 – HYDRAULIC OIL LINES….535

ST229536 – HYDRAULIC OIL RESERVOIR _ OIL COOLER….538

ST229537 – TRANSMISSION CASE OIL FILLER NECK….541

ST229538 – PARTS FOR RATE-OF-DROP ADJUSTMENT….543

ST229539 – NEUTRAL START SWITCH _ CONVERSION KIT….545

ST229540 – ROCKSHAFT HOUSING….547

ST229541 – ROCKSHAFT CYLINDER AND VALVE HOUSING….550

ST229542 – ROCKSHAFT _ PISTON _ LIFT ARMS….554

ST229543 – ROCKSHAFT CYLINDER AND VALVE HOUSING-LINKAGE….556

ST229544 – ADDITIONAL LIFT CYLINDER _ ATTACHING PARTS….558

ST229545 – ADDITIONAL LIFT CYLINDER SEAL KIT….561

ST229546 – HYDRAULIC CONTROL LEVER SUPPORT….563

ST229547 – ROCKSHAFT CONTROL LEVER….565

ST229548 – SELECTOR LEVER….568

ST229549 – ROCKSHAFT OVERHAUL KIT….571

ST229550 – PARTS FOR LOAD CONTROL….573

ST229551 – THREE POINT HITCH CENTER LINK….577

ST229552 – THREE POINT HITCH TELESCOPING DRAFT LINKS….580

ST229553 – THREE POINT HITCH LIFT LINK, LEFT-HAND….583

ST229554 – THREE POINT HITCH LIFT LINKS RH….586

ST229555 – SWAY BLOCKS AND SUPPORTS….589

ST229557 – SELECTIVE CONTROL VALVE (POPPET TYPE)….591

ST229558 – SELECTIVE CONTROL VALVE (POPPET TYPE)….595

ST229559 – BRACKET FOR SELECTIVE CONTROL VALVES (POPPET TYPE)….597

ST229560 – OIL LINES FOR SELECTIVE CONTROL VALVES….599

ST229561 – SELECTIVE CONTROL VALVE LINKAGE (POPPET TYPE)….602

ST229562 – OIL LINES FOR BREAKAWAY COUPLERS….605

ST229563 – BREAKAWAY COUPLER….608

ST229564 – RECEPTACLE FOR BREAKAWAY COUPLER….611

ST229565 – DUST CAP FOR BREAKAWAY COUPLERS….614

ST229566 – LEAK-OFF OIL HOSES (FRONT) FOR BREAKAWAY COUPLER….616

ST229567 – LEAK-OFF OIL HOSES (REAR) FOR ISO BREAKAWAY COUPLERS….618

ST229569 – REMOTE CONTROL CYLINDER, INDIVIDUAL PARTS….620

ST229570 – Remote Cylinder Parts, 3' X 8' (Mechanical Stop)….624

ST229571 – Remote Cylinder Parts, 3' X 8' (Hydraulic Stop)….628

ST229573 – REMOTE CYLINDER CONVERSION KIT (3'X8' HYDRAULIC STOP TO MECHANICAL STOP)….632

ST229574 – REMOTE CYLINDER AND HOSES (3'X8')….634

ST229577 – HYDRAULIC PUMP ELECTRIC DESTROKE KIT (REPLACEMENT PUMP WITH SERIAL PLATE)….637

ST229579 – REGULAR-DUTY IMPLEMENT QUICK COUPLER….639

ST229580 – Hitch Quick Coupler, 3- Point….642

ST229583 – IMPLEMENT HYDRAULIC OIL LINES AND FITTINGS….644

ST230088 – SELECTIVE CONTROL VALVE ASSY. (POPPET TYPE)….647

ST230120 – REMOTE CYLINDER OVERHAUL KIT (3'X8' HYDRAULIC STOP)….649

ST230126 – SELECTIVE CONTROL VALVE OIL FILTER RETURN KIT….651

ST232072 – ADAPTER BUSHING….653

ST232075 – O-RING KIT….655

ST232078 – TRANSMISSION AND HYDRAULIC OIL….657

80 WHEELS, FRONT AXLES, SHEET METAL….659

ST229585 – DRAWBAR….661

ST229586 – DRAWBAR HAMMER STRAP….664

ST229587 – GUIDING MEMBERS FOR SAFETY CHAIN ON SWINGING DRAWBAR….666

ST229589 – SIDE FRAMES….668

ST229590 – FRONT SUPPORT….670

ST229591 – QUICK-TATCH FRONT WEIGHTS….673

ST229592 – ADDITIONAL QUICK-TATCH FRONT WEIGHTS….675

ST229595 – FRONT WHEELS….677

ST229596 – REAR WHEELS….679

ST229597 – CAST REAR WHEELS FOR PINION ADJUSTED AXLE….681

ST229598 – WEIGHTS FOR REAR WHEELS….684

ST229600 – WEIGHTS FOR CAST REAR WHEELS (RACK AND PINION AXLE)….686

ST229601 – REAR WEIGHTS FOR 28', 30' OR 38' CAST AND HEAVY CAST WHEELS PINION ADJUSTED AXLE….688

ST229603 – FRONT FENDERS (FRONT WHEEL DRIVE)….690

ST229604 – FRONT FENDERS (FRONT WHEEL DRIVE)….692

ST229605 – REAR FENDERS….694

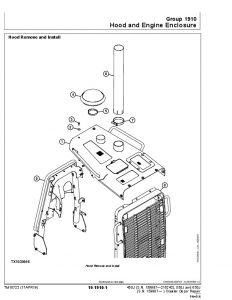

ST229607 – HOOD _ GRILLE….697

ST229608 – BATTERY BOX….700

ST229609 – STEPS….703

ST229610 – STEP ON FRONT AXLE….705

ST229611 – SHEET METAL TOOLBOX INSTALLATION….707

ST229613 – SLOW MOVING VEHICLE (SMV) WARNING SHIELD….709

ST229614 – TOOLS….711

ST229615 – DECALS….713

ST229616 – TORQ-GARD PLUS 50 ENGINE OIL….716

ST230141 – FRONT BLOCK WEIGHTS….719

ST230156 – VALVES FOR TUBELESS TIRES….721

ST230164 – FRONT PLATE….723

ST230172 – TOOLBOX AND SUPPORTS….725

ST230177 – PLASTIC PLUG….727

90 OPERATOR'S STATION….730

ST229620 – SUPPORT BRACKET (SGB)….732

ST229621 – FOUR-POST ROLL-GARD BODY….735

ST229622 – SOUND-GARD BODY FOR REPLACEMENT….737

ST229623 – SOUND-GARD BODY FOR REPLACEMENT (FULLY TRIMMED)….739

ST229624 – SOUND-GARD BODY FRAME WITH DOORS….741

ST229625 – DOOR HANDLES _ LATCH….745

ST229626 – WINDOWS….749

ST229627 – WINDOW RUBBER MOUNTINGS _ SEALS….753

ST229628 – FRAME STRIPS….756

ST229629 – WINDOW RUBBER MOUNTINGS _ SEALS….758

ST229631 – REAR SLIDING WINDOW KIT….760

ST229633 – ROLLGARD ROOF….763

ST229634 – SOUND-GARD BODY ROOF….765

ST229635 – CAB ROOF HEADLINER….768

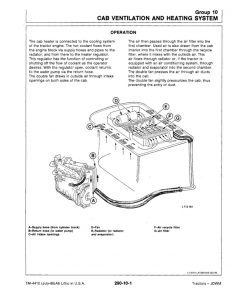

ST229636 – AIR CIRCULATION FILTER PARTS….771

ST229637 – AIR CIRCULATION PARTS – BLOWER….773

ST229639 – HEATER PARTS (SGB)….775

ST229640 – EVAPORATOR AND REAR PIPES….779

ST229641 – AIR CONDITIONING LINES (EARLY DESIGN)….783

ST229642 – AIR CONDITIONING LINES (NEW DESIGN)….786

ST229644 – COMPRESSOR MOUNTING PARTS (WITH AIR CONDITIONING)….789

ST229649 – AIR JETS….791

ST229650 – CAB LINING (SGB)….793

ST229651 – PLATFORM MATS AND COVER….796

ST229652 – CONTROL SUPPORT _ COWL….798

ST229653 – INSTRUMENT PANEL….801

ST229654 – DASH INSULATION….804

ST229655 – ASHTRAY….806

ST229656 – GEAR SHIFT CONSOLE (SGB)….808

ST229657 – FRONT WINDSHIELD WIPER LH….810

ST229658 – FRONT WINDSHIELD WIPER RH….812

ST229659 – WINDSHIELD WIPER MOTOR – REPAIR KIT….815

ST229660 – REAR WINDSHIELD WIPER….817

ST229663 – REAR-VIEW MIRROR (SGB) – LH….819

ST229666 – OUTSIDE REAR VIEW MIRROR….821

ST229667 – SEAT SUPPORT BASE (WITHOUT ROCKSHAFT)….823

ST229668 – PERSONAL-POSTURE SEAT (SGB)….825

ST229669 – SEAT CUSHIONS WITH 4-POST-ROLL-GARD….829

ST229670 – SAFETY BELT WITH 4-POST-ROLL-GARD….831

ST229671 – SEAT ADJUSTMENT AND COVER (PERSONAL-POSTURE SEAT SGB, ROLL-GARD)….833

ST229672 – SEAT SUSPENSION (PERSONAL-POSTURE SEAT SGB, ROLL-GARD)….835

ST230194 – INDIVIDUAL PARTS-FIELD KIT FOR REMOTE CYLINDER CONTROL UNIT….839

ST230207 – COMPRESSOR FOR AIR CONDITIONING….841

ST230208 – CONVERSION KIT – AIR CONDITIONING FROM R12 TO R134A (SGB)….844

ST230209 – CONDENSER (SGB)….846

ST230210 – HEADLINER….848

ST230227 – REAR VIEW MIRROR (SGB) – RH….850

ST232157 – DOOR LH….852

ST232186 – WINDSHIELD WASHER….854

ST232188 – SIDE AND REAR SUN VISOR….857

ST232191 – INSIDE REAR VIEW MIRROR….859

ST232203 – FIRE EXTINGUISHER….861

TM4410 – John Deere 3150 Tractor Technical Manual….863

John Deere 3150 Tractor Technical Manual + Parts Catalog (TM4410 PC4207)