Complete service repair manual for John Deere 85G Excavator, with all the workshop information to maintain, repair, and rebuild like professional mechanics.

John Deere 85G Excavator workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM12870 – John Deere 85G Excavator Technical Manual (Repair).pdf

Total Pages: 616 pages

File Format: PDF (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

MAIN SECTION

Foreword

Technical Information Feedback Form

General Information

Tracks

Axles and Suspension Systems

Engine

Engine Auxiliary Systems

Damper Drive (Flex Coupling)

Frame or Supporting Structure

Operator’s Station

Blade (Backfill)

Excavator

Swing or Pivoting System

Dealer Fabricated Tools

BY_SECTION

01 – Tracks

Front Idler Disassemble and Assemble.pdf

Front Idler Remove and Install.pdf

Inspect Metal Face Seals.pdf

Sprocket Remove and Install.pdf

Track Adjuster and Recoil Spring Disassemble and Assemble.pdf

Track Adjuster and Recoil Spring Remove and Install.pdf

Track Carrier Roller Remove and Install.pdf

Track Chain Disassemble and Assemble.pdf

Track Chain Remove and Install.pdf

Track Chain Repair to Replace Broken Part.pdf

Track Roller Disassemble and Assemble.pdf

Track Roller Pressure Test.pdf

Track Roller Remove and Install.pdf

Track Shoe Remove and Install.pdf

02 – Axles and Suspension Systems

00 – General Information

01 – Safety

Add and Operate Attachments Safely.pdf

Add Cab Guarding for Special Uses.pdf

Avoid Backover Accidents.pdf

Avoid High-Pressure Fluids.pdf

Avoid High-Pressure Oils.pdf

Avoid Machine Tip Over.pdf

Avoid Unauthorized Machine Modifications.pdf

Avoid Work Site Hazards.pdf

Clean Debris from Machine.pdf

Clean Exhaust Filter Safely.pdf

Control Pattern Selector—If Equipped.pdf

Dispose of Waste Properly.pdf

Drive Metal Pins Safely.pdf

Exhaust Filter Ash Handling and Disposal.pdf

Follow Safety Instructions.pdf

Handle Chemical Products Safely.pdf

Inspect and Maintain ROPS.pdf

Inspect Machine.pdf

Keep Riders Off Machine.pdf

Make Welding Repairs Safely.pdf

Operate Only If Qualified.pdf

Park and Prepare for Service Safely.pdf

Prepare for Emergencies.pdf

Prevent Battery Explosions.pdf

Prevent Fires.pdf

Prevent Unintended Machine Movement.pdf

Recognize Safety Information.pdf

Remove Paint Before Welding or Heating.pdf

Service Cooling System Safely.pdf

Start Only From Operator’s Seat.pdf

Stay Clear of Moving Parts.pdf

Use and Maintain Seat Belt.pdf

Use Special Care When Lifting Objects.pdf

Use Steps and Handholds Correctly.pdf

Wear Protective Equipment.pdf

Work In Ventilated Area.pdf

03 – Torque Values

Additional Metric Cap Screw Torque Values.pdf

Inch Series Four Bolt Flange Fitting For High Pressure Service Recommendations.pdf

Metric 24° O-Ring Seal DIN 20078 Service Recommendations.pdf

Metric Bolt and Cap Screw Torque Values.pdf

O-Ring Boss Fittings In Aluminum Housing Service Recommendations—Excavators.pdf

O-Ring Face Seal Fittings With Metric Hex Nut And Stud End For High Pressure Service Recommendations.pdf

O-Ring Face Seal Fittings With Metric Hex Nut And Stud End For Standard Pressure Service Recommendations.pdf

O-Ring Face Seal Fittings With SAE Inch Hex Nut And Stud End For High Pressure Service Recommendations.pdf

Service Recommendations for 37° Flare and 30° Cone Seat Connectors.pdf

Service Recommendations For Flared Connections—Straight or Tapered Threads.pdf

Service Recommendations For Flat Face O-Ring Seal Fittings.pdf

Service Recommendations For Inch Series Four Bolt Flange Fittings.pdf

Service Recommendations for Metric Series Four Bolt Flange Fitting.pdf

Service Recommendations For Non-Restricted Banjo (Adjustable) Fittings.pdf

Service Recommendations for O-Ring Boss Fittings.pdf

Service Recommendations For O-Ring Boss Fittings With Shoulder.pdf

Unified Inch Bolt and Cap Screw Torque Values.pdf

Park Brake Valve Disassemble and Assemble.pdf

Travel Gear Case Disassemble and Assemble.pdf

Travel Gear Case Remove and Install.pdf

Travel Motor and Park Brake Disassemble and Assemble.pdf

Travel Motor and Park Brake Remove and Install.pdf

Travel Motor and Park-Brake Start-Up Procedure.pdf

04 – Engine

Engine Remove and Install.pdf

05 – Engine Auxiliary Systems

Air Cleaner Remove and Install.pdf

Coolant Recovery Tank Remove and Install.pdf

Cooling Package Remove and Install.pdf

Diesel Particulate Filter (DPF) Remove and Install.pdf

Exhaust Filter Disassemble and Assemble.pdf

Exhaust Filter Remove and Install.pdf

Fan and Fan Guard Remove and Install.pdf

Final Fuel Filter Housing Remove and Install.pdf

Fuel Cooler Remove and Install.pdf

Fuel Tank Remove and Install.pdf

Hydraulic Oil Cooler Remove and Install.pdf

Primary Fuel Filter and Water Separator Housing Remove and Install.pdf

Radiator Remove and Install.pdf

07 – Dampener Drive

Damper Drive (Flex Coupling) Remove and Install.pdf

17 – Frames, Chassis, or Supporting Structure

Counterweight Remove and Install.pdf

Welding on Machine.pdf

18 – Operator’s Station

Air Conditioner Compressor Remove and Install.pdf

Cab Remove and Install.pdf

Charge R134a System.pdf

Condenser Remove and Install.pdf

Evacuate R134a System.pdf

Flush and Purge Air Conditioning System.pdf

Heater and Air Conditioner Blower Motor Remove and Install.pdf

Heater and Air Conditioner Remove and Install.pdf

Left and Right Console Covers Remove and Install.pdf

R134a Compressor Oil Charge Check.pdf

R134a Compressor Oil Removal.pdf

R134a Refrigerant Oil Information.pdf

R134a Refrigerant Recovery, Recycling, and Charging Station Installation Procedure.pdf

Receiver-Dryer Remove and Install.pdf

Recover R134a Refrigerant.pdf

Refrigerant Cautions and Proper Handling.pdf

Seat Belt Remove and Install.pdf

Seat Remove and Install.pdf

Windowpanes Dimensions.pdf

Windowpanes Remove and Install.pdf

Windshield Remove and Install.pdf

32 – Blade (Backfill)

Blade Cylinder Disassemble and Assemble.pdf

Blade Cylinder Remove and Install.pdf

Blade Disassemble and Assemble.pdf

Blade Pilot Controller Disassemble and Assemble.pdf

Blade Pilot Valve Remove and Install.pdf

Blade Remove and Install.pdf

33 – Excavator

Apply Vacuum to Hydraulic Oil Tank.pdf

Arm Cylinder Disassemble and Assemble.pdf

Arm Cylinder Remove and Install.pdf

Arm Remove and Install.pdf

Boom Cylinder Disassemble and Assemble.pdf

Boom Cylinder Remove and Install.pdf

Boom Remove and Install.pdf

Boom Swing Cylinder Disassemble and Assemble.pdf

Boom Swing Cylinder Remove and Install.pdf

Boom Swing Pilot Valve Disassemble and Assemble.pdf

Boom Swing Pilot Valve Remove and Install.pdf

Boom Swing Post Remove and Install.pdf

Bucket Cylinder Disassemble and Assemble.pdf

Bucket Cylinder Remove and Install.pdf

Bucket Links Remove and Install.pdf

Bucket Pin-Up Data.pdf

Bucket Remove and Install.pdf

Bushing and Seal Remove and Install.pdf

Control Lever Pattern Selector Disassemble and Assemble.pdf

Control Lever Pattern Selector Remove and Install.pdf

Control Valve Disassemble and Assemble.pdf

Control Valve Remove and Install.pdf

General Hydraulic Oil Cleanup Procedure.pdf

Hydraulic Component Failure Cleanup Procedure.pdf

Hydraulic Cylinder Bleed Procedure.pdf

Hydraulic Oil Cooler Bypass Valve Remove and Install.pdf

Hydraulic Oil Tank Disassemble and Assemble.pdf

Hydraulic Oil Tank Remove and Install.pdf

Hydraulic Pump Assembly Remove and Install.pdf

Hydraulic Pump Start-Up Procedure.pdf

Inspect Pins and Bushings—Front Attachment and Blade.pdf

Pilot Pressure Regulating Valve and Filter Remove and Install.pdf

Pilot Pump Disassemble and Assemble.pdf

Pilot Pump Remove and Install.pdf

Pilot Shutoff Solenoid Valve Disassemble and Assemble.pdf

Pilot Shutoff Solenoid Valve Remove and Install.pdf

Pilot Valve (Left and Right) Disassemble and Assemble.pdf

Pilot Valve (Left and Right) Remove and Install.pdf

Pump 1 and 2 Disassemble and Assemble.pdf

Pump 1 and 2 Inspection.pdf

Pump 3 Disassemble and Assemble.pdf

Pump 3 Inspection.pdf

Solenoid Valve Manifold Remove and Install.pdf

Travel Pilot Valve Disassemble and Assemble.pdf

Travel Pilot Valve Remove and Install.pdf

43 – Swing or Pivoting System

Center Joint Air Test .pdf

Center Joint Disassemble and Assemble.pdf

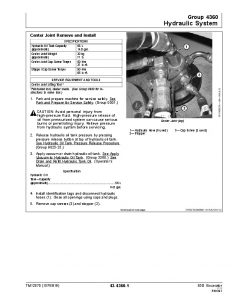

Center Joint Remove and Install.pdf

Crossover Relief Valve and Make-Up Check Valve Remove and Install.pdf

Swing Bearing Disassemble and Assemble.pdf

Swing Bearing Lower Seal Install.pdf

Swing Bearing Remove and Install.pdf

Swing Bearing Upper Seal Install.pdf

Swing Gear Case Disassemble and Assemble.pdf

Swing Gear Case Remove and Install.pdf

Swing Motor and Park Brake Disassemble and Assemble.pdf

Swing Motor and Park Brake Inspection.pdf

Swing Motor and Park Brake Remove and Install.pdf

Swing Motor and Park Brake Start-Up Procedure.pdf

Upperstructure Remove And Install.pdf

9900 – Dealer Fabricated Tools

Center Joint (Rotary Manifold) Lifting Tool .pdf

DFT1087 Track Recoil Spring Disassembly and Assembly Guard Tool.pdf

DFT1112A Spacer.pdf

DFT1360 Swing Gear Roller Bearing Tool.pdf

ST4920 Track Recoil Spring Disassembly and Assembly Tool.pdf

External_Files5

H70406 – O-Ring Face Seal Fitting.pdf

T113889 – Connection.pdf

T113948 – Non-Restricted Banjo Fitting.pdf

T113957 – O-Ring Boss Fitting With Shoulder.pdf

T150148 – Cap Screw Tightening Sequence.pdf

T165793 – Blade Cylinder.pdf

T165794 – Blade Cylinder Cross Section.pdf

T166098 – Inner Race Puller.pdf

T188509 – Travel Motor Retainer and Bushing Arrangement.pdf

T188539 – Counterweight Support Beams.pdf

T188540 – Boom Bracket.pdf

T188541 – Upperstructure.pdf

T188542 – Swing Bearing.pdf

T196315 – O-Ring Boss Straight and Adjustable Fittings.pdf

T196337 – O-Ring Face Seal Fittings.pdf

T216779 – Unintended Machine Movement.pdf

T6234AC – Cone Seat Connector.pdf

T6557JB – Center Joint Air Test.pdf

T6585UY – Track Recoil Spring Disassembly and Assembly Tool.pdf

T6641DO – Center Joint Lifting Tool.pdf

T6873AD – Tapered Thread.pdf

T6873AE – Straight Thread.pdf

T6890BB – Flange Fittings.pdf

T6890BB – Four Bolt Flange Fittings.pdf

T6890BB – Metric Series Four Bolt Flange Fitting.pdf

T7029CG – ST4920 Dimensions.pdf

T7029CH – ST4920 Dimensions.pdf

T7029CI – ST4920 Dimensions.pdf

T7162AF – DFT1087 Dimensions.pdf

T7969AB – DFT1112A Spacer Dimensions.pdf

TS1693 – Moving Parts.pdf

TS1695 – Stop.pdf

TX1008208 – Seal Inspection Areas.pdf

TX1008209 – Examples Of Worn Seal Rings.pdf

TX1010083 – Bucket.pdf

TX1036620 – Swing Motor Hose Identification.pdf

TX1040135 – Travel Gear Case.pdf

TX1040324 – Piston Removal.pdf

TX1040490 – Pipe Dimensions.pdf

TX1040491 – Dust Seals.pdf

TX1040510 – Cover Removal.pdf

TX1040511 – Valve Plate and Notch.pdf

TX1040512 – Sleeve and Housing.pdf

TX1040513 – Feedback Link.pdf

TX1040593 – Piston-to-Bore Clearance.pdf

TX1040595 – Piston and Piston Slipper.pdf

TX1040596 – Cylinder Block Springs.pdf

TX1040597 – Retainer and Bushing Height.pdf

TX1041942 – Boom Swing Cylinder.pdf

TX1043234 – Swing Motor and Park Brake.pdf

TX1043361A – Hydraulic Pressure Release Button.pdf

TX1043362A – Pressure Release Button Housing.pdf

TX1043363A – Vacuum Pump Installation.pdf

TX1045655 – Boom Swing Control.pdf

TX1092021 – Pilot Shutoff Solenoid Valve.pdf

TX1092915A – Seal.pdf

TX1092921 – Swing Bearing Cross Section.pdf

TX1093550A – Track Shoe (steel track shoe shown).pdf

TX1096302 – Pilot Control Valve.pdf

TX1096325 – Spring Removal Tools.pdf

TX1096326 – Snap Ring Installation Tool.pdf

TX1098001 – Track Pin.pdf

TX1098002 – Bushing.pdf

TX1098003 – Track Link Assembly.pdf

TX1098008 – Track Pin.pdf

TX1098035 – Bushing.pdf

TX1098617 – Refrigerant Recovery, Recycling, and Charging Station.pdf

TX1113412 – Swing Bearing Lower Seal.pdf

TX1122068 – Swing Bearing Cap Screws.pdf

TX1124992 – Swing Bearing Cross Section.pdf

TX1124993 – Swing Bearing Cross Section.pdf

TX1128437A – Pilot Control Levers (shown tied back).pdf

TX1128440A – Wiring Cover.pdf

TX1128441A – Heater and Air Conditioner and Wiring Harness.pdf

TX1132651 – Track Shoe Cap Screw and Nut.pdf

TX1132924A – Seat Belt.pdf

TX1132925A – Buckle.pdf

TX1133214 – Track Recoil Spring Tool.pdf

TX1133218 – Installing Track Adjuster in Disassembly and Assembly Tool.pdf

TX1133220 – Track Recoil Spring Guard Tool.pdf

TX1133223 – Track Recoil Spring Guard Tool—Guard Raised.pdf

TX1133703A – Arm Rest.pdf

TX1133704A – Rear Switch Console.pdf

TX1133705A – Pilot Control Lever Boot.pdf

TX1133706A – Pilot Control Lever.pdf

TX1133707A – Right Switch Console.pdf

TX1133723A – Rear Switch Console (bottom view).pdf

TX1133724A – Right Switch Console (bottom view).pdf

TX1133785A – Left Console.pdf

TX1133787A – Boot.pdf

TX1133788A – Left Console (shown with inside cover removed).pdf

TX1134367 – Control Lever Pattern Selector.pdf

TX1134741A – Fuel Injectors.pdf

TX1134743A – Exhaust Filter Connectors.pdf

TX1134758A – Engine Lifting Points.pdf

TX1135532A – Exhaust Filter.pdf

TX1135533 – Exhaust Filter (exploded view).pdf

TX1136128A – Cylinder Pin.pdf

TX1136470 – Excavator Bucket Pin-Up Data.pdf

TX1137195 – Grease Fitting.pdf

TX1137198A – Master Pin.pdf

TX1137200 – Master Pin.pdf

TX1137323 – Boom-to-Arm Angle.pdf

TX1137758A – Pilot Pump.pdf

TX1137760A – Hydraulic Pump.pdf

TX1138049A – Covers.pdf

TX1138113A – Intake and Coolant Hoses.pdf

TX1138121A – Engine Harness Electrical Connectors.pdf

TX1138124A – Air Conditioner Compressor.pdf

TX1138134A – High-Pressure Fuel Pump.pdf

TX1138143A – Return Fuel Hose and Engine Harness Connectors.pdf

TX1138146A – Starter Motor.pdf

TX1138148A – Alternator.pdf

TX1138180 – Track Chain.pdf

TX1138248A – Cross Member Cover.pdf

TX1138251 – Front Idler.pdf

TX1138254A – Front Idler.pdf

TX1138255A – Sprocket.pdf

TX1138265A – Hydraulic Pump Assembly.pdf

TX1138266A – Support Assembly.pdf

TX1138282A – Engine Cover.pdf

TX1138283A – Washer Fluid Bracket.pdf

TX1138284A – Counterweight Cap Screws.pdf

TX1138403 – Control Valve Mounting.pdf

TX1138410A – Control Valve (front).pdf

TX1138532A – Flywheel Cover.pdf

TX1138579A – Cab Harness Connectors.pdf

TX1138609A – Cabin Air Filter Duct.pdf

TX1138611A – Windshield Washer Tank Hose.pdf

TX1138612 – Cab Mount Locations.pdf

TX1138637A – Travel Gear Case.pdf

TX1138640A – Travel Gear Case Cover.pdf

TX1138655A – Hydraulic Pump Suction Line.pdf

TX1138671A – Air Conditioner Lines.pdf

TX1138675A – Support Assembly.pdf

TX1138699 – Travel Motor and Park Brake Disassemble and Assemble.pdf

TX1138715A – Hydraulic Pump Compartment.pdf

TX1138716A – Hydraulic Oil Tank (rear).pdf

TX1138720 – Hydraulic Lines.pdf

TX1138749A – Travel Motor and Park Brake Start-Up Procedure.pdf

TX1138822A – Control Valve Covers.pdf

TX1138826A – Engine Cover.pdf

TX1138828A – Exhaust Filter Connections.pdf

TX1138831A – Exhaust Filter.pdf

TX1138841A – Primary Fuel Filter.pdf

TX1138846A – Shutoff Valve.pdf

TX1138847A – Final Fuel Filter.pdf

TX1138851A – Hydraulic Oil Cooler Bypass Valve.pdf

TX1138853A – Return Line.pdf

TX1138910A – Control Lever Pattern Selector Cover and Door.pdf

TX1138911A – Control Lever Pattern Selector.pdf

TX1138913A – Track Carrier Roller.pdf

TX1138918A – Air Filter Connection.pdf

TX1138922 – Track Roller Disassemble and Assemble.pdf

TX1138929A – Track Roller.pdf

TX1138986A – Solenoid Valve Manifold.pdf

TX1138998A – Track Roller Oil Leakage Test Components.pdf

TX1139000A – Radiator Access Door.pdf

TX1139002A – Cooling Package Covers.pdf

TX1139003A – Upper Radiator Hose.pdf

TX1139004A – Lower Radiator Hose.pdf

TX1139005A – Radiator.pdf

TX1139019A – Fuel Cooler.pdf

TX1139020A – Condenser.pdf

TX1139023 – Solenoid Valves.pdf

TX1139055A – Fuel Cooler.pdf

TX1139092 – Park Brake Valve Disassemble and Assemble.pdf

TX1139116A – Fan Guard.pdf

TX1139122A – Fan.pdf

TX1139123A – Fan Pulley.pdf

TX1139133A – Travel Pilot Valve.pdf

TX1139134A – Front Cover (below cab).pdf

TX1139136A – Travel Pilot Valve (bottom view).pdf

TX1139149A – Auxiliary Flow Control Valve.pdf

TX1139152A – Auxiliary Flow Control Valve (bottom).pdf

TX1139154A – Pilot Pressure Regulating Valve Mounting Bracket Cap Screws.pdf

TX1139176A – Pilot Pressure Regulating Valve.pdf

TX1139209A – Coolant Recovery Tank.pdf

TX1139329A – Seat (front of seat shown).pdf

TX1139330A – Air Conditioner Compressor.pdf

TX1139384A – Hydraulic Oil Tank (front and side).pdf

TX1139386A – Control Valve Compartment.pdf

TX1139464A – Fuel Regulator.pdf

TX1139473A – Hydraulic Hoses.pdf

TX1139477A – Arm Cylinder Pin.pdf

TX1139511A – Rear Frame.pdf

TX1139515A – Hydraulic Lines.pdf

TX1139516A – Hydraulic Lines.pdf

TX1139702 – Track Adjuster Cylinder.pdf

TX1139703A – Track Adjuster and Recoil Spring.pdf

TX1139704A – Track Adjuster and Recoil Spring.pdf

TX1139731A – Condenser.pdf

TX1139732A – Fuel Cooler.pdf

TX1139733A – Cooling Package Access Door.pdf

TX1139734A – Cooling Package Covers.pdf

TX1139735A – Upper Cooling Package Hoses.pdf

TX1139736A – Paneling.pdf

TX1139737A – Cooling Package.pdf

TX1139738A – Lower Radiator Hoses.pdf

TX1139739A – Lower Hydraulic Oil Cooler Hose.pdf

TX1139740A – Cooling Package Mount.pdf

TX1139741A – Lifting Device.pdf

TX1139745A – Air Filter Housing.pdf

TX1139761A – Boom Swing Pilot Valve Line Connections.pdf

TX1139875A – Boom Swing Pilot Valve.pdf

TX1139893A – Pilot Shutoff Solenoid Valve.pdf

TX1140155A – Cooling Package.pdf

TX1140200A – Boom Pin.pdf

TX1140201A – Boom Cylinder Pin.pdf

TX1140218A – Boom Light Connector.pdf

TX1140221A – Arm Pin.pdf

TX1140308A – Pilot Valve (left side shown).pdf

TX1140311A – Bucket Links.pdf

TX1140312A – Bucket and Arm Links.pdf

TX1140433 – Boom, Arm, Bucket, and Blade Pins and Bushings.pdf

TX1140444 – Hydraulic Valves.pdf

TX1140507 – Pump 1 and 2 Disassemble.pdf

TX1140580 – Boom Cylinder.pdf

TX1140582 – Bucket Cylinder.pdf

TX1140583 – Arm Cylinder.pdf

TX1140587A – Swing Gear Case Assembly.pdf

TX1140591 – Swing Gear Case.pdf

TX1140600 – Second Stage Carrier Pins.pdf

TX1140641 – Swing Post.pdf

TX1140711 – Pump 3 Disassemble and Assemble.pdf

TX1140714 – Valve Plate and Notch.pdf

TX1140795 – Pilot Pump Components.pdf

TX1140866 – Travel Pilot Valve Components.pdf

TX1140872 – Blade.pdf

TX1140884 – Lifting Brackets.pdf

TX1140885 – Position of Machine.pdf

TX1140909 – Swing Bearing (exploded view).pdf

TX1140914A – Blade Pilot Valve.pdf

TX1140921 – Blade Pilot Vale.pdf

TX1140937A – Center Joint (top).pdf

TX1140938A – Center Joint (bottom).pdf

TX1140945A – Blade Cylinder.pdf

TX1140965A – Blade.pdf

TX1141046 – Center Joint Components.pdf

TX1141051 – Hydraulic Oil Tank.pdf

TX1141148A – Cover.pdf

TX1141254 – Control Valve—3-Spool Section.pdf

TX1141306A – Hydraulic Hoses.pdf

TX1141312A – Boom Cylinder Rod End.pdf

TX1141313A – Cylinder Pin.pdf

TX1141332 – Swing Park Brake Release Pilot Valve.pdf

TX1141333 – Bucket Spool.pdf

TX1141334 – Boom 1 Spool.pdf

TX1141336 – Arm 2 Spool.pdf

TX1141337 – Swing Spool.pdf

TX1141338 – Arm In Flow Combiner Selector Valve.pdf

TX1141339 – Auxiliary Flow Combiner Valve Spool.pdf

TX1141341A – Hydraulic Cylinder Pin and Hoses.pdf

TX1141342A – Cylinder Pin.pdf

TX1141400A – Swing Motor and Park Brake.pdf

TX1141414 – Swing Motor and Park Brake.pdf

TX1141516 – Boom Reduced Leakage Valve—Switched Valve.pdf

TX1141517 – Check Valve (lift check)—Arm 2 Neutral Passage.pdf

TX1141518 – Check Valve (lift check) and System Relief Valve Isolation Check Valve.pdf

TX1141519 – Check Valve (lift check)—Right Travel Neutral Passage.pdf

TX1141520 – Check Valve (lift check)—Bucket Flow Combiner Circuit.pdf

TX1141523A – Hydraulic Hoses.pdf

TX1141524A – Cylinder Pin.pdf

TX1141528A – JT30043-30 Hex Piston Nut Wrench.pdf

TX1141529A – Sliding Housing and Stand Assembly.pdf

TX1141530A – Ring Compressor.pdf

TX1141535 – Check Valve (lift check)—Boom Up Flow Combiner Circuit.pdf

TX1141536 – Right Travel Spool.pdf

TX1141538 – Flow Combiner Valve.pdf

TX1141539 – Boom 2 Spool.pdf

TX1141540 – Arm 1 Spool.pdf

TX1141541 – Auxiliary Spool 1.pdf

TX1141565A – Rear (rear of seat shown).pdf

TX1141584A – Track Shoe (rubber track shoe shown).pdf

TX1141594A – Boom Swing Cylinder.pdf

TX1141604A – Condenser.pdf

TX1141643A – Receiver-Dryer.pdf

TX1141656 – Upper Front Glass.pdf

TX1141657 – Lower Front Glass.pdf

TX1141660 – Cab Roof Glass.pdf

TX1141661 – Cab Door.pdf

TX1141663 – Rear Cab Glass.pdf

TX1141664 – Right Side Cab Glass.pdf

TX1141665 – Rear Left Side Sliding Window (upper).pdf

TX1141666 – Rear Left Side Sliding Window (lower).pdf

TX1141680A – Bucket Pins.pdf

TX1141726A – Windshield Latch (left side).pdf

TX1141727A – Windshield Latch (right side).pdf

TX1141728A – Windshield Roller (right side).pdf

TX1141729A – Windshield Roller (left side).pdf

TX1141730A – Windshield Wiper Motor Connector.pdf

TX1141738 – Control Valve—Relief Valves.pdf

TX1141743 – Control Valve—6-Spool Section.pdf

TX1141744 – Boom Swing Spool.pdf

TX1141745 – Control Valve—5-Spool Section.pdf

TX1141746 – Blade Spool.pdf

TX1141747 – Control Valve—Poppets, Plugs, and Boom Reduced Leakage Valve.pdf

TX1141869 – Plunger and Bore.pdf

TX1141870A – Panels.pdf

TX1141871 – Plunger and Shoe.pdf

TX1141872A – Right Side of Fuel Tank.pdf

TX1141874A – Left Side of Fuel Tank.pdf

TX1141880A – Under Tank.pdf

TX1141891A – Cover.pdf

TX1142100A – Boom Swing Cylinder Hose.pdf

TX1142247 – Swing Gear Roller Bearing Tool.pdf

TX1142298A – Cover Assembly.pdf

TX1142356A – Adjusting Washer.pdf

TX1175575 – Track Adjuster Cylinder.pdf

Table of Contents – Expanded View

Foreword

Technical Information Feedback Form

General Information

Safety

Recognize Safety Information

Follow Safety Instructions

Operate Only If Qualified

Wear Protective Equipment

Avoid Unauthorized Machine Modifications

Control Pattern Selector—If Equipped

Add Cab Guarding for Special Uses

Inspect Machine

Stay Clear of Moving Parts

Avoid High-Pressure Fluids

Avoid High-Pressure Oils

Work In Ventilated Area

Prevent Fires

Prevent Battery Explosions

Handle Chemical Products Safely

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Exhaust Filter Ash Handling and Disposal

Prepare for Emergencies

Clean Debris from Machine

Use Steps and Handholds Correctly

Start Only From Operator’s Seat

Use and Maintain Seat Belt

Prevent Unintended Machine Movement

Avoid Work Site Hazards

Keep Riders Off Machine

Avoid Backover Accidents

Inspect and Maintain ROPS

Avoid Machine Tip Over

Use Special Care When Lifting Objects

Add and Operate Attachments Safely

Park and Prepare for Service Safely

Service Cooling System Safely

Remove Paint Before Welding or Heating

Make Welding Repairs Safely

Drive Metal Pins Safely

Clean Exhaust Filter Safely

Torque Values

Metric Bolt and Cap Screw Torque Values

Additional Metric Cap Screw Torque Values

Unified Inch Bolt and Cap Screw Torque Values

Service Recommendations for 37° Flare and 30° Cone Seat Connectors

Service Recommendations for O-Ring Boss Fittings

Service Recommendations for Flared Connections—Straight or Tapered Threads

Service Recommendations for Flat Face O-Ring Seal Fittings

O-Ring Boss Fittings in Aluminum Housing Service Recommendations—Excavators

O-Ring Face Seal Fittings With SAE Inch Hex Nut and Stud End for High-Pressure Service Recommendations

O-Ring Face Seal Fittings With Metric Hex Nut and Stud End for Standard Pressure Service Recommendations

O-Ring Face Seal Fittings With Metric Hex Nut and Stud End for High-Pressure Service Recommendations

Service Recommendations for Metric Series Four Bolt Flange Fitting

Service Recommendations For Inch Series Four Bolt Flange Fittings

Inch Series Four Bolt Flange Fitting for High-Pressure Service Recommendations

Service Recommendations For Non-Restricted Banjo (Adjustable) Fittings

Service Recommendations For O-Ring Boss Fittings With Shoulder

Metric 24° O-Ring Seal DIN 20078 Service Recommendations

Tracks

Track System

Track Roller Remove and Install

Track Roller Disassemble and Assemble

Track Roller Pressure Test

Track Carrier Roller Remove and Install

Inspect Metal Face Seals

Track Shoe Remove and Install

Track Chain Remove and Install

Track Chain Disassemble and Assemble

Track Chain Repair to Replace Broken Part

Sprocket Remove and Install

Front Idler Remove and Install

Front Idler Disassemble and Assemble

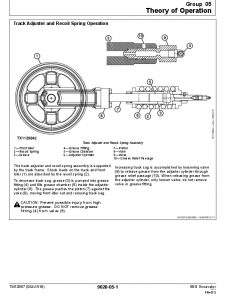

Track Adjuster and Recoil Spring Remove and Install

Track Adjuster and Recoil Spring Disassemble and Assemble

Axles and Suspension Systems

Axle Shaft, Bearings, and Reduction Gears

Travel Gear Case Remove and Install

Travel Gear Case Disassemble and Assemble

Hydraulic System

Travel Motor and Park Brake Remove and Install

Travel Motor and Park Brake Disassemble and Assemble

Park Brake Valve Disassemble and Assemble

Travel Motor and Park-Brake Start-Up Procedure

Engine

Removal and Installation

Engine Remove and Install

Engine Auxiliary Systems

Cooling System

Radiator Remove and Install

Hydraulic Oil Cooler Remove and Install

Fuel Cooler Remove and Install

Cooling Package Remove and Install

Fan and Fan Guard Remove and Install

Coolant Recovery Tank Remove and Install

Intake System

Air Cleaner Remove and Install

External Exhaust Systems

Diesel Particulate Filter (DPF) Remove and Install

Exhaust Filter Remove and Install

Exhaust Filter Disassemble and Assemble

External Fuel Supply Systems

Fuel Tank Remove and Install

Primary Fuel Filter and Water Separator Housing Remove and Install

Final Fuel Filter Housing Remove and Install

Damper Drive (Flex Coupling)

Elements

Damper Drive (Flex Coupling) Remove and Install

Frame or Supporting Structure

Frame Installation

Welding on Machine

Chassis Weights

Counterweight Remove and Install

Operator’s Station

Removal and Installation

Cab Remove and Install

Operator Enclosure

Windshield Remove and Install

Windowpanes Remove and Install

Windowpanes Dimensions

Seat and Seat Belt

Seat Remove and Install

Seat Belt Remove and Install

Left and Right Console Covers Remove and Install

Heating and Air Conditioning

Refrigerant Cautions and Proper Handling

Flush and Purge Air Conditioning System

R134a Refrigerant Oil Information

R134a Refrigerant Recovery, Recycling, and Charging Station Installation Procedure

R134a Compressor Oil Charge Check

R134a Compressor Oil Removal

Recover R134a Refrigerant

Evacuate R134a System

Charge R134a System

Air Conditioner Compressor Remove and Install

Condenser Remove and Install

Heater and Air Conditioner Remove and Install

Heater and Air Conditioner Blower Motor Remove and Install

Receiver-Dryer Remove and Install

Blade (Backfill)

Blades

Blade Remove and Install

Blade Disassemble and Assemble

Hydraulic System

Blade Cylinder Remove and Install

Blade Cylinder Disassemble and Assemble

Blade Pilot Valve Remove and Install

Blade Pilot Controller Disassemble and Assemble

Excavator

Buckets

Bucket Remove and Install

Bucket Pin-Up Data

Frames

Bucket Links Remove and Install

Arm Remove and Install

Boom Remove and Install

Boom Swing Post Remove and Install

Inspect Pins and Bushings—Front Attachment and Blade

Cylinder Specifications

Bushing and Seal Remove and Install

Hydraulic System

Apply Vacuum to Hydraulic Oil Tank

General Hydraulic Oil Cleanup Procedure

Hydraulic Component Failure Cleanup Procedure

Hydraulic Pump Assembly Remove and Install

Pump 1 and 2 Disassemble and Assemble

Pump 1 and 2 Inspection

Pump 3 Disassemble and Assemble

Pump 3 Inspection

Pilot Pump Remove and Install

Pilot Pump Disassemble and Assemble

Hydraulic Pump Start-Up Procedure

Pilot Pressure Regulating Valve and Filter Remove and Install

Pilot Shutoff Solenoid Valve Remove and Install

Pilot Shutoff Solenoid Valve Disassemble and Assemble

Solenoid Valve Manifold Remove and Install

Solenoid Valve Remove and Install—Travel Speed (SI) and Torque Control (ST)

Pilot Valve (Left and Right) Remove and Install

Pilot Valve (Left and Right) Disassemble and Assemble

Travel Pilot Valve Remove and Install

Travel Pilot Valve Disassemble and Assemble

Boom Swing Pilot Valve Remove and Install

Boom Swing Pilot Valve Disassemble and Assemble

Control Valve Remove and Install

Control Valve Disassemble and Assemble

Control Lever Pattern Selector Remove and Install

Control Lever Pattern Selector Disassemble and Assemble

Hydraulic Oil Tank Remove and Install

Hydraulic Oil Tank Disassemble and Assemble

Hydraulic Oil Cooler Bypass Valve Remove and Install

Boom Cylinder Remove and Install

Boom Cylinder Disassemble and Assemble

Arm Cylinder Remove and Install

Arm Cylinder Disassemble and Assemble

Bucket Cylinder Remove and Install

Bucket Cylinder Disassemble and Assemble

Boom Swing Cylinder Remove and Install

Boom Swing Cylinder Disassemble and Assemble

Hydraulic Cylinder Bleed Procedure

Swing or Pivoting System

Mechanical Drive Elements

Swing Gear Case Remove and Install

Swing Gear Case Disassemble and Assemble

Upperstructure Remove And Install

Swing Bearing Remove and Install

Swing Bearing Disassemble and Assemble

Swing Bearing Upper Seal Install

Swing Bearing Lower Seal Install

Hydraulic System

Center Joint Remove and Install

Center Joint Disassemble and Assemble

Center Joint Air Test

Swing Motor and Park Brake Remove and Install

Swing Motor and Park Brake Disassemble and Assemble

Swing Motor and Park Brake Inspection

Swing Motor and Park Brake Start-Up Procedure

Crossover Relief Valve and Make-Up Check Valve Remove and Install

Dealer Fabricated Tools

Dealer Fabricated Tools

ST4920 Track Recoil Spring Disassembly and Assembly Tool

DFT1112A Spacer

DFT1087 Track Recoil Spring Disassembly and Assembly Guard Tool

Center Joint (Rotary Manifold) Lifting Tool

DFT1360 Swing Gear Roller Bearing Tool

John Deere 85G Excavator Repair Technical Manual (TM12870)