Complete Diagnosis and Tests technical manual with electrical wiring diagrams for John Deere Tractors 1654, JD1854, JD2054, JD2104, 6165J, 6185J, 6205J & 6210J 2WD / MFWD, with all the shop information to maintain, diagnose, rebuild like professional mechanics.

John Deere JD1654, 1854, 2054, 2104, 6165J, 6185J, 6205J, 6210J Tractors workshop Operation and Tests manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM802219 TM – All Inclusive 1654, 1854, 2054, 2104, 6165J, 6185J, 6205J & 6210J Tractors Diagnostic.pdf

TM802214 TM-All Inclusive 1654、1854、2054、2104、6165J、6185J、6205J 和 6210J拖拉机诊断.pdf

OMAL221436 Operator’s Manual JD1654, JD1854, JD2054, and JD2104 Tractors, (Asia, English).pdf

OMAL221437 Operator’s Manual 拖拉机 JD1654、JD1854、JD2054 和 JD2104.pdf

OMAL221438 Operator’s Manual Tractors JD1654, JD1854, JD2054&JD2104

PC4667 Parts Catalog 1654 Tractor \ China Edition.pdf

PC4667Z Parts Catalog 1654 Tractor \ China Edition.pdf

Total Pages: 1,511 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality)

Language: English Chinese

MAIN SECTIONS

Foreword

General Information

Safety Information

General References

Diagnostic Trouble Codes

BCU Diagnostic Trouble Codes

ECU Control Unit

Observable Symptoms

Electrical System

Electronic Control Units

PowrQuad Transmissions

Drive Systems

Steering and Brakes

Hydraulic System

Operator’s Cab

System Diagnosis

Electronics

Hydraulic System

Engine

General Information

Operational Checks

Tests and Adjustments

Fuel, Air Intake and Cooling Systems

Tests and Adjustments

Fuel System

Air Intake System

Cooling System

Cold-Weather Starting Aids

Electrical System

Fuse Box

Starting and Charging Circuit

CAN BUS and Service Connector

ECU – Power

ECU – Throttle and Fuel System

ECU – Fuel Preheater and Aid Heater

ECU – Sensors

BCU – Electronic Hitch-Control

BCU – Brakes

BCU – PTO

BCU – Front-Wheel Drive

BCU – Differential Lock

BCU – Hall Sending Unit Speedmeter

BCU – Turn Signal and Hazard Warning Lights

Panel Warning Lights

Lights, Tail Lights and License Plate

Work Lights

Radio, Dome Light, Console Light and Beacon Light

Horn and Accessories Socket

Power Outlet

Seat Compressor and Cigarette Lighter

Fan and A/C

Front Windshield Wiper and Washer

Rear Windshield Wiper and Washer

Trailer Connector

Wiring Harnesses

Connectors

Electronic Control Units

Operation and General Information on Diagnostics

Interactive Tests

Interactive Calibrations

Information on How to Reprogram Control Units

Data BUS Systems, Operation

BCU – Basic Control Unit

ECU Control Unit

PowrQuad Transmissions

Operational Check

Tests and Adjustments

Operation

Range Box

Drive Systems

Operational Check

Tests and Adjustments

Operation

Steering and Brakes

Preliminary Checks

Operational Check

Tests and Adjustments

Hydrostatic Steering

Brakes

Air brake system

Hydraulic System

Operational Check

Tests and Adjustments

Theory of operation

Oil Filter, Charge Pump and Hydraulic Pump

Hitch

Selective control valves (SCV)

Hydraulic block

Operator’s Cab

Tests and Adjustments

Operation

Special Tools (Dealer-Fabricated)

Special Tools (Dealer-Fabricated)

Special Tools (Available as Spare Parts)

TABLE OF CONTENTS

Section 210: General Information….32

Group 05: Safety Information….1379

Recognize Safety Information….1379

Follow Safety Instructions….36

Replace Safety Signs….37

Wear Protective Clothing….38

Prevent Battery Explosions….39

Service Tires Safely….40

Keep ROPS Installed Properly….41

Park Machine Safely….42

Handle Fluids Safely—Avoid Fires….43

Handle Fuel Safely—Avoid Fires….44

Prepare for Emergencies….45

Work in Clean Area….46

Prevent Machine Runaway….47

Work In Ventilated Area….48

Avoid High-Pressure Fluids….49

Use Proper Lifting Equipment….50

Illuminate Work Area Safely….51

Use Proper Tools….52

Live With Safety….53

Safety Measures on Electronic Control Units….54

Group 15: General References….32

General References—Summary of References….56

Unified Inch Bolt and Cap Screw Torque Values….57

Metric Bolt and Cap Screw Torque Values….59

Hydraulic System Unified Inch Fitting Torques….61

Hydraulic system metric fitting torques….62

Component Identification Table….63

How to use an Electrical Diagram….65

Electrical Diagram Symbols….68

Wire Numbers and Color Codes….70

Troubleshooting Unsolved Problems….71

Electrical System Visual Inspection….72

Circuit Malfunctions….73

Seven Steps Electrical Test Procedure….78

Hydraulic System — Circuit Symbols….80

Electrical System, Worksheet for Circuit/Harness Test….86

Section 211: Diagnostic Trouble Codes….88

Group BCU: BCU Diagnostic Trouble Codes….88

BCU 000084.02 – B09 – Hall Sending Unit Speedmeter, out of Valid Range….88

BCU 000168.03 – Control Unit, Supply Voltage Too High….88

BCU 000168.04 – Control Unit, Supply Voltage Too Low….88

BCU 000168.16 – Control Unit, Supply Voltage Too High (Engine Speed Above 500 rpm)….88

BCU 000168.17 – Control Unit, Supply Voltage Too Low (Engine Speed Above 1500 rpm)….88

BCU 000168.18 – Control Unit, Supply Voltage Too Low (Engine Speed Above 500 rpm)….88

BCU 000177.18 – Non-Existent Function Activated….88

BCU 000186.02 – B06 – Sensor for Rear PTO Speed, Open Circuit….88

BCU 000186.15 – B06 – Rear PTO Speed Sensor, Speed Present Despite Rear PTO Being Switched Off….88

BCU 000186.17 – B06 – Rear PTO Speed Sensor, Speed Not Present….88

BCU 000190.02 – Non-Existent Function Activated….88

BCU 000237.02 – VIN Information, Mismatch….88

BCU 000237.14 – VIN Information, System De-Activated….88

BCU 000237.31 – VIN Information, Incorrect….88

BCU 000629.12 – Control Unit Internal Fault….88

BCU 000639.12 – Vehicle CAN BUS, High Error Rate….88

BCU 000639.14 – Vehicle CAN BUS, Very High Error Rate….88

BCU 000746.31 – Y05 – Differential Lock Solenoid Valve, Fault….88

BCU 000980.07 – S21 – Rear PTO Switch, Fault….88

BCU 001058.18 – Non-Existent Function Activated….88

BCU 001079.03 – 5-volt Power Supply, Voltage Too High….88

BCU 001079.04 – 5-volt Power Supply, Voltage Too Low….88

BCU 001873.03 – B21 – Hitch Position Sensor, Voltage Too High….88

BCU 001873.04 – B21 – Hitch Position Sensor, Voltage Too Low….88

BCU 001873.15 – B21 – Hitch Position Sensor, Voltage Too High During Calibration….88

BCU 001873.17 – B21 – Hitch Position Sensor, Voltage Too Low During Calibration….88

BCU 001882.02 – Non-Existent Function Activated….88

BCU 001882.15 – Non-Existent Function Activated….88

BCU 001882.17 – Non-Existent Function Activated….88

BCU 001883.31 – Rear PTO Speed Too High….89

BCU 001890.03 – Non-Existent Function Activated….89

BCU 001890.04 – Non-Existent Function Activated….89

BCU 001890.31 – Non-Existent Function Activated….89

BCU 001893.07 – Non-Existent Function Activated….89

BCU 001894.31 – INFORMATION FOR OPERATOR: Rear PTO Switch was On When Engine was Started….89

BCU 002000.09 – Incorrect CAN BUS Message, Information from ECU….89

BCU 002392.31 – Non-Existent Function Activated….89

BCU 002818.31 – Non-Existent Function Activated….89

BCU 002876.07 – S08 – Turn signal switch, Fault (Turn Signal)….89

BCU 303053.03 – B26 – Sensitivity Potentiometer, Signal Voltage Too High During Calibration….89

BCU 303053.04 – B26 – Sensitivity Potentiometer, Signal Voltage Too Low During Calibration….89

BCU 303054.03 – B27 – Depth-Setting Potentiometer, Signal Voltage Too High During Calibration….89

BCU 303054.04 – B27 – Depth-Setting Potentiometer, Signal Voltage Too Low During Calibration….89

BCU 303056.03 – B27 – Raise-Limit Potentiometer, Signal Voltage Too High During Calibration….89

BCU 303056.04 – B27 – Raise-Limit Potentiometer, Signal Voltage Too Low During Calibration….89

BCU 303057.03 – B27 – Rate-of-Drop Potentiometer, Signal Voltage Too High During Calibration….89

BCU 303057.04 – B27 – Rate-of-Drop Potentiometer, Signal Voltage Too Low During Calibration….89

BCU 522451.03 – Non-Existent Function Activated….89

BCU 522451.04 – Non-Existent Function Activated….89

BCU 522451.14 – Non-Existent Function Activated….89

BCU 522507.31 – Control Unit Not Calibrated….89

BCU 523438.02 – Control Unit Internal Fault….89

BCU 523652.02 – Control Unit Connected to Wrong Harness Connector….89

BCU 523689.31 – S22 – Differential Lock Switch, Fault….89

BCU 523690.02 – S68 – Switches for Remote Control of Hitch (Left), Fault….89

BCU 523701.05 – M08 – Stepper Motor for Hitch (Coil 2), Open Circuit….89

BCU 523701.06 – M08 – Stepper Motor for Hitch (Coil 2), Current Too High….89

BCU 523702.14 – VIN Information, System De-Activated….89

BCU 523702.31 – VIN Information, Incorrect….89

BCU 523703.02 – B41 – Draft Sensor, Distorted Signal During Calibration….89

BCU 523703.03 – B41 – Draft Sensor, Voltage Too High During Calibration….89

BCU 523703.04 – B41 – Draft Sensor, Voltage Too Low During Calibration….90

BCU 523703.15 – B41 – Draft Sensor, Voltage Too High….90

BCU 523703.17 – B41 – Draft Sensor, Voltage Too Low….90

BCU 523704.02 – Non-Existent Function Activated….90

BCU 523704.03 – Non-Existent Function Activated….90

BCU 523704.04 – Non-Existent Function Activated….90

BCU 523704.15 – Non-Existent Function Activated….90

BCU 523704.17 – Non-Existent Function Activated….90

BCU 523751.05 – M08 – Stepper Motor for Hitch (Coil 1), Open Circuit….90

BCU 523751.06 – M08 – Stepper Motor for Hitch (Coil 1), Current Too High….90

BCU 523753.16 – M08 – Stepper Motor for Hitch, Raising Deadband Too High During Calibration….90

BCU 523753.18 – M08 – Stepper Motor for Hitch, Raising Deadband Too Low During Calibration….90

BCU 523756.16 – M08 – Stepper Motor for Hitch, Lowering Deadband Too High During Calibration….90

BCU 523756.18 – M08 – Stepper Motor for Hitch, Lowering Deadband Too Low During Calibration….90

BCU 523758.11 – Non-Existent Function Activated….90

BCU 523759.11 – Non-Existent Function Activated….90

BCU 523760.04 – Turn Signal/Hazard Flasher System, Supply Voltage Too Low….90

BCU 523760.31 – Turn Signal/Hazard Flasher System, Fault….90

BCU 523826.03 – Non-Existent Function Activated….90

BCU 523826.04 – Non-Existent Function Activated….90

BCU 523834.03 – B27 – Depth-Setting Potentiometer, Voltage Too High….90

BCU 523834.04 – B27 – Depth-Setting Potentiometer, Voltage Too Low….90

BCU 523839.31 – Non-Existent Function Activated….90

BCU 523843.02 – S24 – Quick Withdrawal Switch, Switch Status out of Valid Range….90

BCU 523843.03 – S24 – Quick Withdrawal Switch, Voltage Too High….90

BCU 523843.04 – S24 – Quick Withdrawal Switch, Voltage Too Low….90

BCU 523904.31 – Non-Existent Function Activated….90

BCU 523905.31 – Non-Existent Function Activated….90

BCU 523908.14 – Non-Existent Function Activated….90

BCU 523908.31 – Non-Existent Function Activated….90

BCU 524055.11 – Control Unit Internal Fault….90

BCU 524055.31 – Control Unit Not Calibrated….90

BCU 524216.14 – Non-Existent Function Activated….91

BCU 524216.31 – Non-Existent Function Activated….91

BCU 524224.14 – Non-Existent Function Activated….91

BCU 524224.31 – INFORMATION FOR OPERATOR: Rear PTO was Switched On When Engine Was Started….91

BCU 524235.02 – Non-Existent Function Activated….91

BCU 524235.31 – Y03 – Front-Wheel Drive Solenoid Valve, Fault….91

BCU 524252.31 – Y04 – Solenoid Valve for Rear PTO, Fault….91

Group ECU: ECU Control Unit….91

ECU 000029.03 – B96 – Hand Throttle Potentiometer, Voltage Too High….91

ECU 000029.04 – B96 – Hand Throttle Potentiometer, Voltage Too Low….91

ECU 000084.31 – Incorrect CAN BUS Message, Wheel Speed from BCU….91

ECU 000091.03 – B79 – Accelerator Pedal Potentiometer, Voltage Too High….91

ECU 000091.04 – B79 – Accelerator Pedal Potentiometer, Voltage Too Low….91

ECU 000097.03 – Water In Fuel Signal Out of Range….91

ECU 000097.04 – Water In Fuel Signal Out of Range Low….91

ECU 000097.16 – Water In Fuel Detected….91

ECU 000105.00 – Manifold Air Temperature Signal Extremely High….91

ECU 000105.03 – Manifold Air Temperature Signal Out of Range High….91

ECU 000105.04 – Manifold Air Temperature Signal Out of Range Low….91

ECU 000105.15 – Manifold Air Temperature Signal Slightly High….91

ECU 000105.16 – Manifold Air Temperature Signal Moderately High….91

ECU 000108.02 – Barometric Air Pressure Signal Invalid….91

ECU 000110.00 – Coolant Temperature Signal Extremely High….91

ECU 000110.03 – Coolant Temperature Signal Out of Range High….91

ECU 000110.04 – Coolant Temperature Signal Out of Range Low….91

ECU 000110.15 – Coolant Temperature Signal Slightly High….91

ECU 000110.16 – Engine Coolant Temperature Moderately High….91

ECU 000157.03 – Fuel Rail Pressure Signal Out of Range High….91

ECU 000157.04 – Fuel Rail Pressure Signal Out of Range Low….91

ECU 000157.10 – Fuel Rail Pressure Loss Detected….91

ECU 000157.17 – Fuel Rail Pressure Not Developed….91

ECU 000158.17 – ECU Power Down Error….91

ECU 000160.02 – Wheel Speed Signal Incorrect….92

ECU 000174.00 – Fuel Temperature Signal Extremely High….92

ECU 000174.03 – Fuel Temperature Signal Out of Range High….92

ECU 000174.04 – Fuel Temperature Signal Out of Range Low….92

ECU 000174.16 – Fuel Temperature Signal Moderately High….92

ECU 000189.00 – Engine Speed Derate Condition Exists….92

ECU 000190.00 – Engine Speed Extremely High….92

ECU 000190.16 – Engine Overspeed Moderate….92

ECU 000237.02 – VIN Information, Mismatch….92

ECU 000237.13 – VIN Option Code Invalid….92

ECU 000237.31 – VIN Information, Incorrect….92

ECU 000611.03 – Injector Shorted to Voltage Source….92

ECU 000611.04 – Injector Shorted to Ground….92

ECU 000627.01 – All Injector Circuits Have High Resistance….92

ECU 000629.12 – ECU EEPROM Error….92

ECU 000629.13 – ECU Boot Block Error….92

ECU 000636.02 – Camshaft Position Signal Invalid….92

ECU 000636.05 – Camshaft Position Circuit Has High Resistance….92

ECU 000636.06 – Camshaft Position Circuit Has Low Resistance….92

ECU 000636.08 – Camshaft Position Signal Missing….92

ECU 000636.10 – Camshaft Position Signal Rate of Change Abnormal….92

ECU 000637.02 – Crankshaft Position Signal Invalid….92

ECU 000637.05 – Crankshaft Position Circuit Has High Resistance….92

ECU 000637.06 – Crankshaft Position Circuit Has Low Resistance….92

ECU 000637.07 – Crankshaft and Camshaft Position Signals Out of Sync….92

ECU 000637.08 – Crankshaft Position Signal Missing….92

ECU 000637.10 – Crankshaft Position Signal Rate of Change Abnormal….92

ECU 000651.02 – Injector #1 Part Number Invalid….92

ECU 000651.05 – Injector #1 Circuit Has High Resistance….92

ECU 000651.06 – Injector #1 Circuit Has Low Resistance….92

ECU 000651.07 – Injector #1 Not Responding….92

ECU 000651.13 – Injector #1 Calibration Fault….92

ECU 000652.02 – Injector #2 Part Number Invalid….92

ECU 000652.05 – Injector #2 Circuit Has High Resistance….93

ECU 000652.06 – Injector #2 Circuit Has Low Resistance….93

ECU 000652.07 – Injector #2 Not Responding….93

ECU 000652.13 – Injector #2 Calibration Fault….93

ECU 000653.02 – Injector #3 Part Number Invalid….93

ECU 000653.05 – Injector #3 Circuit Has High Resistance….93

ECU 000653.06 – Injector #3 Circuit Has Low Resistance….93

ECU 000653.07 – Injector #3 Not Responding….93

ECU 000653.13 – Injector #3 Calibration Fault….93

ECU 000654.02 – Injector #4 Part Number Invalid….93

ECU 000654.05 – Injector #4 Circuit Has High Resistance….93

ECU 000654.06 – Injector #4 Circuit Has Low Resistance….93

ECU 000654.07 – Injector #4 Not Responding….93

ECU 000654.13 – Injector #4 Calibration Fault….93

ECU 000655.02 – Injector #5 Part Number Invalid….93

ECU 000655.05 – Injector #5 Circuit Has High Resistance….93

ECU 000655.06 – Injector #5 Circuit Has Low Resistance….93

ECU 000655.07 – Injector #5 Not Responding….93

ECU 000655.13 – Injector #5 Calibration Fault….93

ECU 000656.02 – Injector #6 Part # Data Invalid….93

ECU 000656.05 – Injector #6 Circuit Has High Resistance….93

ECU 000656.06 – Injector #6 Circuit Has Low Resistance….93

ECU 000656.07 – Injector #6 Not Responding….93

ECU 000656.13 – Injector #6 Calibration Fault….93

ECU 000676.03 – Glow Plug Relay Voltage Too High….93

ECU 000676.05 – Glow Plug Relay Voltage Too Low….93

ECU 001069.31 – Tire Size Error….93

ECU 001347.03 – Suction Control Valve Signal Out of Range High….93

ECU 001347.05 – Suction Control Valve Circuit Has High Resistance….93

ECU 001347.07 – Fuel Rail Pressure Actual to Desired Mismatch….93

ECU 001569.31 – Engine in Power Derate Condition….93

ECU 002033.09 – Incorrect CAN BUS Message, CAN Message from BCU….93

ECU 002033.14 – Communication Problem between ECU and BCU….93

ECU 002033.19 – Communication Problem between ECU and BCU….94

ECU 003509.03 – Sensor Supply #1 Voltage Out of Range High….94

ECU 003509.04 – Sensor Supply #1 Voltage Out of Range Low….94

ECU 003510.03 – Sensor Supply Voltage 2 Too High….94

ECU 003510.04 – Sensor Supply Voltage 2 Too Low….94

ECU 003511.03 – Sensor Supply Voltage 3 Too High….94

ECU 003511.04 – Sensor Supply Voltage 3 Too Low….94

Section 212: Observable Symptoms….421

Group 40: Electrical System….421

Control Unit(s) Not Displayed….421

Diagnostic Mode Cannot Be Entered or Connection Problems with Service ADVISOR (Cab Tractors)….421

Problems with the CAN-BUS Connection to Service ADVISOR….421

Problems with the Battery….421

Problems with the Starter Motor….421

Problems with the Fuel Preheater, Aid Heater and Fuel Pump….421

Problems with the Instrument Unit….421

Problems with the Horn….421

Problems with Cigarette Lighter (E05)….421

Problems with Seat with Compressor and Heater (A29)….421

Problems with the Parking Lights….421

Problems with Low-Beam Headlights….421

Problems with High-Beam Headlights….421

Problems with the Worklights on Front of Roof….421

Problems with the Worklights on Rear of Roof….421

Problems with the Radio….421

Problems with the Air-Conditioning System and/or with the Fan….421

Problems with the Front Windshield Wiper….421

Problems with the Front Windshield Washer….421

Problems with the Rear Windshield Wiper….421

Problems with the Rear Windshield Washer….421

Problems with the Beacon Light….421

Group 45: Electronic Control Units….421

Problems when Programming the BCU Control Unit….421

Problems when Programming the ECU Control Unit….421

Problem with the BCU Control Unit….421

Problem with the Instrument Unit (Adjustment)….421

Group 55: PowrQuad Transmissions….421

Problems with PowrQuad Transmission….421

Group 56: Drive Systems….422

Problems with the PTO….422

Group 60: Steering and Brakes….422

Problems with the Brakes….422

Problems with the Steering….422

Group 70: Hydraulic System….422

Problems with the Rockshaft….422

Problems with the Rockshaft's Remote Control….422

Group 90: Operator's Cab….422

Problems with the Air-Conditioning System….422

Section 213: System Diagnosis….527

Group 45: Electronics….527

29-bit CAN BUS – Check (Cab Tractors)….532

VIN Security Fault Diagnosis….536

Group 70: Hydraulic System….527

Check for PFC Hydraulic System….557

Section 220: Engine….576

Group 05: General Information….576

Information on Engine….578

Group 10: Operational Checks….576

Engine – Safety Measures….580

Engine – Preliminary Engine Tests….581

Group 15: Tests and Adjustments….576

Engine – Tune-Up, Summary of References….583

Engine – Measuring PTO Power Output….584

Engine – Engine Tests with Service ADVISOR….590

Section 230: Fuel, Air Intake and Cooling Systems….591

Group 15: Tests and Adjustments….591

Fuel, Air Intake and Cooling Systems – Tests and Adjustments, Summary of References….594

Fuel, Air Intake and Cooling Systems – General Information….595

Fuel, Air Intake and Cooling Systems – Explanation of Checks….596

Fuel, Air Intake and Cooling Systems – Safety Measures….597

Fuel, Air Intake and Cooling Systems – Special Tools, Summary of References….598

Fuel, Air Intake and Cooling Systems – Specifications….601

Air Intake System – System Check….602

Cooling System – Filling/Bleeding the System….603

Cooling System – Leak Test….604

Cooling System – Test Thermostat Opening Temperature….606

Cooling System – Flow Testing in the Low-Temperature Circuit….608

Cooling System – Check the Viscous Fan Drive….612

Fuel System – Check the Fuel Transfer Pump….614

Group 20A: Fuel System….591

Fuel System – Theory of Operation, Summary of References….617

Fuel System – Theory of Operation….618

Fuel System – Fuel Cooler, Component Information….620

Fuel System – Fuel Transfer Pump, Component Information….621

Group 20B: Air Intake System….591

Air Intake System – Theory of Operation, Summary of References….623

Air Intake System – Theory of Operation….624

Group 20C: Cooling System….591

Cooling System – Summary of References….626

Coolant Circuit – Description….627

Cooling System Radiator – Description….629

Itercooler – Description….630

Ring-Shaped (Transmission Oil) Cooler – Description….631

Automatic Drive Belt Tensioner – Theory of Operation….633

Group 20D: Cold-Weather Starting Aids….591

Cold-Weather Starting Aids – Summary of References….635

Cold-Weather Starting Aids – General Information….636

Cold-Weather Starting Aids – Coolant Heater – Component Information….637

Cold-Weather Starting Aids – Transmission Oil Heater – Component Information….638

Cold-Weather Starting Aids – Charge Pump Preheater – Component Information….639

Section 240: Electrical System….640

Group 05A: Fuse Box….640

Fuse Box – Theory of Operation….650

Fuse Box – Electrical Diagram….651

Group 05B: Starting and Charging Circuit….640

Starting and Charging Circuit – Theory of Operation….654

Starting and Charging Circuit – Electrical Diagram….655

Circuit test for Starter motor checks (M01)….656

Circuit test for Alternator (G02)….659

Circuit test for Battery (G01)….664

Circuit test for K01 Starter relay….667

Group 05C: CAN BUS and Service Connector….640

CAN BUS System – Theory of Operation….669

CAN BUS System – Electrical Diagram….670

Group 05D: ECU – Power….640

ECU Power – Theory of Operation….672

ECU Power – Electrical Diagram….673

Group 05E: ECU – Throttle and Fuel System….640

ECU Throttle and Fuel System – Theory of Operation….675

ECU Throttle and Fuel System – Electrical Diagram….676

Circuit test for Foot throttle (B79)….677

Circuit test for Electrical hand throttle (B96)….680

Group 05F: ECU – Fuel Preheater and Aid Heater….640

ECU Fuel Preheater and Aid Heater – Theory of Operation….684

ECU Fuel Preheater and Aid Heater – Electrical Diagram….685

Circuit test for Fuel Pump (M31)….687

Circuit test for Heating Element of Fuel Preheater (R02)….689

Circuit test for Sender for Electrical starting aid heater (R15)….691

Group 05G: ECU – Sensors….640

ECU Sensors – Theory of Operation….694

ECU Sensors – Electrical Diagram….695

Circuit test for Engine Speed Sender (B72)….696

Group 05H: BCU – Electronic Hitch-Control….641

BCU – Electronic Hitch-Control – Theory of Operation….700

BCU – Electronic Hitch-Control – Electrical Diagram….701

Circuit test for Rockshaft Control Stepper Motor (M08)….703

Circuit test for Sensitivity Potentiometer (B26)….705

Circuit test for Depth-setting Potentiometer (R08)….708

Circuit test for Rate-of-Drop Potentiometer (R06)….711

Circuit test for Raise-Limit Potentiometer (R07)….714

Circuit test for Position Sensor (B21)….717

Circuit test for Position Sensor (B41)….721

Circuit/harness test for Rapid Raise Switch (S24)….724

Circuit test for Left Remote Control Switch (S68)….727

Circuit test for Supply Voltage for 5-Volt BCU Components….730

Group 05I: BCU – Brakes….641

BCU – Brakes – Theory of Operation….734

BCU – Brakes – Electrical Diagram….735

Circuit test for Brake Pedal Sensor Unit (B88)….737

Group 05J: BCU – PTO….641

BCU – PTO – Theory of Operation….739

BCU – PTO – Electrical Diagram….740

Circuit test for PTO Switch (S21)….742

Circuit test for PTO Solenoid Valve (Y04)….745

Circuit test for Rear PTO Speed Sensor (B06)….748

Group 05K: BCU – Front-Wheel Drive….641

BCU – Front-Wheel Drive – Theory of Operation….752

BCU – Front-Wheel Drive – Electrical Diagram….753

Circuit test for Front-Wheel Drive Switch (S63)….755

Circuit test for Front-Wheel Drive Solenoid Valve (Y03)….758

Group 05L: BCU – Differential Lock….641

BCU – Differential Lock – Theory of Operation….762

BCU – Differential Lock – Electrical Diagram….763

Circuit test for Differential Lock Switch (S22)….765

Circuit test for Differential Lock Solenoid Valve (Y05)….768

Group 05M: BCU – Hall Sending Unit Speedmeter….642

BCU Hall Sending Unit Speedmeter – Theory of Operation….772

BCU Hall Sending Unit Speedmeter – Electrical Diagram….773

Circuit test for Hall Sending Unit Speedmeter (B09)….774

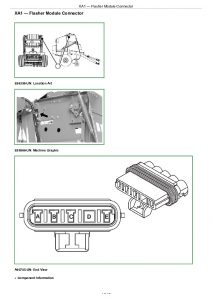

Group 05N: BCU – Turn Signal and Hazard Warning Lights….642

BCU – Turn Signal and Hazard Warning Lights – Theory of Operation….778

BCU – Turn Signal and Hazard Warning Lights – Electrical Diagram….779

Circuit test for hazard warning switch (S106)….781

Circuit test for Turn Signal Switch (S08)….785

Group 05O: Panel Warning Lights….642

Panel Warning Lights – Theory of Operation….790

Panel Warning Lights – Electrical Diagram….791

Circuit test for Sender for air cleaner restriction warning light (B02)….793

Circuit test for Fuel gauge sender (B03)….794

Circuit test for Engine oil pressure sender (B04)….795

Circuit test for Sender for the transmission oil filter sender (B07)….796

Circuit test for Coolant temperature sender (B08)….797

Circuit test for Transmission oil pressure sender (B31)….798

Circuit test for Transmission oil temperature sender (B29)….799

Group 05P: Lights, Tail Lights and License Plate….642

Lights and Tail Lights – Theory of Operation….801

Lights and Tail Lights – Electrical Diagram….802

Lighting Circuits….804

Group 05Q: Work Lights….642

Work Lights – Theory of Operation….809

Work Lights – Electrical Diagram….810

Work lights….811

Group 05R: Radio, Dome Light, Console Light and Beacon Light….642

Radio, Dome Light, Console Light and Beacon Light – Theory of Operation….814

Radio, Dome Light, Console Light and Beacon Light – Electrical Diagram….815

Circuit test for Radio (A60 – Radio Circuits)….816

Circuit test forDome Light (A08)….817

Circuit test for Beacon light (E27)….819

Group 05S: Horn and Accessories Socket….643

Horn and Accessories Socket – Theory of Operation….821

Horn and Accessories Socket – Electrical Diagram….822

Circuit test for Horn (H01)….823

Group 05T: Power Outlet….643

Power Outlet – Theory of Operation….826

Power Outlet – Electrical Diagram….827

Group 05U: Seat Compressor and Cigarette Lighter….643

Seat Compressor and Cigarette Lighter – Theory of Operation….829

Seat Compressor and Cigarette Lighter – Electrical Diagram….830

Seat and Cigarette lighter System….831

Group 05V: Fan and A/C….643

Fan and A/C – Theory of Operation….834

Fan and A/C – Electrical Diagram….835

Fan, Air Conditioning and Automatic A/C control….837

Group 05W: Front Windshield Wiper and Washer….643

Front Windshield Wiper and Washer – Theory of Operation….843

Front Windshield Wiper and Washer – Electrical Diagram….844

Front Windshield Wiper and Washer System….845

Group 05X: Rear Windshield Wiper and Washer….643

Rear Windshield Wiper and Washer – Theory of Operation….848

Rear Windshield Wiper and Washer – Electrical Diagram….849

Rear Windshield Wiper and Washer System….851

Group 05Y: Trailer Connector….643

Trailer Connector – Theory of Operation….854

Trailer Connector – Electrical Diagram….855

Group 10: Wiring Harnesses….643

Disconnecting Electrical Circuits….857

Location of Ground Points….858

Removing and Installing Wiring Harness W01 — Power link Box….860

Removing and Installing Wiring Harness W02 — Engine Wiring Harness (Cab Tractors)….861

Removing and Installing Wiring Harness W04 — Headlights….863

Removing and Installing Wiring Harness W08 — (Cab Tractors)….864

Removing and Installing Wiring Harness W09 — Hood (Cab Tractors)….866

Removing and Installing Wiring Harness W19 — Cab Roof….868

Removing and Installing Wiring Harness W26 — Fan and Air Conditioning….869

Removing and Installing Wiring Harness W28 — Front End of Transmission (Cab Tractors)….870

Removing and Installing Wiring Harness W30 — Rear End of Transmission (Cab Tractors)….872

Wiring Harness W31 — Power Take-Off for 7-Pin Socket….874

Group 15: Connectors….644

Connectors – Summary of References….877

A01 – Fuse and relay box….879

A02 – Fuse Box 2….882

A03 – Fuse Box 3….883

A04 – Fuse Box 4….884

A05 – Fuse Box 5….885

A06 – Power Link Box….886

A08 – Dome Light….887

A29 – Pneumatic operator's seat and rear wiper….888

A60 – Radio….889

A62 – Bus terminator….890

A84 – Bus terminator engine….891

B02 – Sender for air cleaner restriction warning light….892

B03 – Fuel gauge sensor unit….893

B04 – Sender for engine oil pressure indicator light….894

B06 – Rear PTO Speed Sensor….895

B07 – Transmission oil filter pressure sensor – Without AutoTrac™ Integrated….896

B08 – Coolant temperature sensor….897

B09 – Hall Sending Unit Speedmeter….898

B14 – Compressor and thermostat switch….899

B15 – Air conditioning system pressure switch….900

B21 – Hitch-control position sensor….901

B26 – Sensitivity potentiometer….902

B27 – Feedback unit….903

B29 – Transmission oil temperature sensor….904

B30 – Hydrostatic oil temperature sensor….905

B31 – Transmission oil pressure sender….906

B36 – Neutral start switch….907

B37 – Interface handbrake….908

B41 – Draft potentiometer….909

B56 – Water temperature engine sensor….910

B59 – Manifold air temperature sensor….911

B72 – Crankshaft speed sensor….912

B74 – Event sensor….913

B79 – Foot throttle….914

B88 – Brake switch….915

B96 – Electrical hand throttle….916

B114 – Fuel temperature sensor….917

B121 – Water in fuel sensor….918

B137 – Fuel rail pressure sensor….919

E01 – Right-hand front light….920

E02 – Left-hand front light….921

E05 – Cigarette lighter….922

E09-R – Right-hand front working light….923

E09-L – Left-hand front working light….924

E11-1 – Right-hand rear working light….925

E11-2 – Left-hand rear working light….926

E12-2 – Console light….927

E27 – Beacon light….928

G01 – Battery….929

G02 – Alternator….930

H01 – Horn….931

H77 – Aid heater indicator light….932

K01 – Starter relay….933

M01 – Starter motor….934

M02 – Air conditioning compressor….935

M03 – Wiper motor….936

M04 – Wiper motor….937

M05 – Windshield washer pump….938

M06 – Windshield washer pump….939

M07 – Fan motor….940

M08 – Hitch-control stepper motor….941

M10 – Fan motor….942

M31 – Fuel pump….943

R02 – Fuel preheater….944

R03 – Resistors….945

R15 – Electrical starting aid heater….946

S01 – Starter switch….947

S04 – Horn switch….948

S08 – Turn signal switch….949

S09 – Light switch….950

S10 – Full/low beam light switch….951

S14 – Fan switch….952

S15 – Windshield wiper switch….953

S18 – Rear wiper switch….954

S20 – Windshield switch….955

S21 – PTO switch….956

S22 – Differential lock switch….957

S36 – Beacon light switch….958

S63 – Front-wheel drive switch….959

S68 – External hitch-control switch….960

S92-2 – Rear work lights switch….961

S106 – Hazard warning lights switch….962

W25 – Radio antenna….963

X05 – Trailer connector….964

X25 – Instrument right panel connector….965

X26 – Instrument left panel connector….967

X37 – Accessories socket….969

X40 – Connector (W22 and W23)….970

X42 – Connector (W21 and W22)….971

X106 – Tail, brake and turn signal lights (right-hand)….972

X107 – Tail, brake and turn signal lights (left-hand)….973

X108 – Front right- hand turn signal light….974

X109 – Front left-hand turn signal light….975

X113 – License Light Connector….976

X182 – Connector (W08 and W26)….977

X234 – Connector (W30 and W31)….979

X239 – Outlet Socket Connector….980

X305 – Cooler grounding….981

X400 – Connector (W08 and W19)….982

X411 – Connector (W02 and W04)….985

X430 – Connector (W08 and W30)….987

X431 – Connector (W08 and W28)….990

X450 – Connector (W02 and W08)….993

X473 – Connector (W01 and W08)….996

X504 – Connector (W08 and W09)….998

X505 – Connector (W08 and W09)….1001

X547 – Connector (W02 and W03)….1003

X571 – Service connector (CAN Bus)….1004

X612 – Speaker connector….1005

X616-1 Basic control unit (BCU)….1006

X616-2 Basic control unit (BCU)….1008

X616-3 Basic control unit (BCU)….1011

X844-1 — Engine control unit (ECU)….1013

X844-2 — Engine control unit (ECU)….1015

XGND1 – Cab ground wire….1017

XGND2 – Cab ground wire….1018

XGND5 – Cab ground wire….1019

XGND6 – Rear wiper ground wire….1020

XGND9 – Engine grounding….1021

XGND10 – Cab roof ground wire….1022

XGND14 – Cab roof ground wire….1023

XGND58 – Fan and A/C wiring harness grounding….1024

Y03 – Front-wheel drive solenoid valve….1025

Y04 – PTO Solenoid….1026

Y05 – Differential lock solenoid valve….1027

Y44 – Suction control valve….1028

Y47 – Injection valve….1029

Section 245: Electronic Control Units….1030

Group 05: Operation and General Information on Diagnostics….1030

Operation and General Information – Summary of References….1036

Eletronic Control Units – Special Tools….1037

Operation and General Information on Diagnostics – Abbreviations for Control Units….1038

Operation and General Information on Diagnostics – Instrument Unit Adjustment….1039

Operation and General Information on Diagnostics – Operation and Entering the Program Mode using the Performance Monitor….1045

Operation and General Information on Diagnostics – Procedure for Dealing with Diagnostic Trouble Codes….1052

Operation and General Information on Diagnostics – Accessing Addresses and Diagnostic Trouble Codes….1056

Operation and General Information on Diagnostics – Approved Software for Control Units….1067

Operation and General Information on Diagnostics – Locations and Allocations of Control Units….1068

Group 10A: Interactive Tests….1030

Interactive Tests – Summary of References….1070

Procedure in the Event of Problems with Interactive Tests….1071

BCU: Recording in Debug Mode….1072

BCU: Control Unit Information and Input Addresses – Summary….1073

BCU: BCU Test….1074

ECU: Cylinder Misfire Test….1075

ECU: Compression Test….1076

ECU: Cylinder Cut-Out Test….1077

ECU: Harness diagnostic mode test….1078

ECU: Internal Data Monitor (IDM)….1079

ECU: Communication Error Test….1080

ECU: Control Unit Information and Summary….1081

ECU: Engine Speed Change Test….1082

Group 10B: Interactive Calibrations….1030

Interactive Calibrations – Summary of References….1084

Procedure in the Event of Problems with Interactive Calibration….1085

BCU: Calibrate the Hitch Control….1086

ECU: Calibrate the Electronic Fuel Injectors (Move Injectors to Different Positions or Replace Injectors, and Display Progress of Calibration)….1090

Group 15: Information on How to Reprogram Control Units….1031

Information on How to Program Control Units – Summary of References….1092

General Information on How to Reprogram Control Units….1093

Check and Download Tractor-Specific Software Information….1094

Procedure When Replacing Control Units….1095

Important Notes on Programming….1096

Procedure When Programming Control Units….1097

Procedure in the Event of a Problem Programming Control Units Protected by VIN….1098

Procedure in the Event of a Programming Problem….1101

Group 20: Data BUS Systems, Operation….1031

Data BUS systems – Summary of References….1104

Data BUS Systems – CAN BUS Systems….1105

Data BUS Systems – CAN BUS Systems on Engines with Level 16 Control Unit (2-Valve HPCR Fuel System)….1107

Data BUS systems – Plug Layout….1108

Data BUS systems – Determining the Type of the CAN BUS Fault….1109

Group BCU: BCU – Basic Control Unit….1031

BCU – Summary of References….1112

BCU – Summary of Addresses….1113

BCU – Calibration and Input Addresses….1120

BCU – Summary of Operational Checks….1122

BCU – Theory of Operation (Basic Functions)….1123

BCU – Theory of Operation (Hitch Control)….1125

BCU – CAN BUS Information….1127

Address BCU020 – Input Address, Engine Speed Sensor/Pulses per Engine Revolution….1128

Address BCU021 – Input Address, Rear PTO Speed Sensor/Pulses per PTO Revolution….1129

Address BCU022 – Input Address, Front-Wheel Drive Control Function….1130

Address BCU023 – Vacant Input Address….1131

Address BCU024 – Input Address, Settings for Units of Measurement in Display and for Acoustic Indicator for Turn Signal….1132

Address BCU026 – Vacant Input Address….1133

Address BCU027 – Vacant Input Address….1134

Address BCU028 – Input Address, Rear PTO Present/Not Present….1135

Address BCU029 – Vacant Input Address….1136

Address BCU030 – Input Address, Sensor Diagnostics….1137

Address BCU031 – Vacant Input Address….1138

Address BCU034 – Input Address, Configuration of Instrument Unit and Self-Canceling Turn Signals….1139

Address BCU035 – Input Address, Service Interval Setting….1140

Address BCU041 – Vacant Input Address….1141

Address BCU042 – Vacant Input Address….1142

Address BCU043 – Vacant Input Address….1143

Address BCU045 – Vacant Input Address….1144

Address BCU046 – Input Address, Activate/De-activate Delayed Activation of Alternator….1145

Address BCU047 – Input Address, Delayed Activation of Alternator, Configuration….1146

Address BCU048 – Vacant Input Address….1147

Address BCU049 – Vacant Input Address….1148

Address BCU050 – Vacant Input Address….1149

Address BCU051 – Vacant Input Address….1150

Address BCU052 – Vacant Input Address….1151

Address BCU055 – Input Address, Configuration of Acoustic Alarm….1152

Address BCU056 – Input Address, Tire Configuration….1153

Address BCU058 – Input Address, Sensor for Wheel Speed / Transmission Pulses per Axle Revolution….1154

Address BCU060 – Vacant Input Address….1155

Address BCU063 – Vacant Input Address….1156

Address BCU065 – Vacant Input Address….1157

Address BCU071 – Vacant Input Address….1158

Address BCU073 – Vacant Input Address….1159

Address BCU074 – Vacant Input Address….1160

Address BCU075 – Vacant Input Address….1161

Address BCU077 – Vacant Input Address….1162

Address BCU078 – Vacant Input Address….1163

Address BCU088 – Vacant Input Address….1164

Address BCU089 – Vacant Input Address….1165

Address BCU090 – Vacant Input Address….1166

Address BCU091 – Vacant Input Address….1167

Address BCU092 – Vacant Input Address….1168

Address BCU093 – Vacant Input Address….1169

Address BCU094 – Vacant Input Address….1170

Address BCU097 – Input Address, Low Fuel Level Acoustic Alarm….1171

Address BCU099 – Input Address, Automatic Deletion of Diagnostic Trouble Codes….1172

Address BCU101 – Input Address, Leak-Off Function of Hitch Valve On or Off….1173

Address BCU118 – Input Address, Quick Withdrawal and Hitch Dampening On or Off….1174

Address BCU122 – Hitch Control Calibration….1175

Address BCU138 – Input Address, Leak-off Function of Hitch Valve (Adjusting Stepper Motor Steps)….1183

Address BCU145 – Input Address, Hitch Control On or Off….1184

Address BCU154 – Input Address, Leak-off Function of Hitch Valve (Time Setting)….1185

Address BCU162 – Input Address, Switching Off Hydraulic Oil Temperature Access (During Calibration)….1186

Address BCU165 – Input Address, Raise Rate Setting….1187

Address BCU167 – Input Address, Activate/De-activate Hitch Components….1188

Address BCU174 – Input Address, Index for Load Control….1189

Address BCU247 – Tractor Model Designation….1190

Address BCU248 – Tractor Serial Number….1191

B06 – Rear PTO Speed Sensor, Operational Check….1192

B09 – Hall Sending Unit Speedmeter, Operational Check….1193

B21 – Hitch Position Sensor, Operational Check….1194

B26 – Sensitivity Potentiometer, Operational Check….1195

B27 – Position Feedback Unit for Hitch Control, Operational Check….1196

B41 – Draft Sensor, Operational Check….1198

B88 – Brake Pedal Sensor Unit, Operational Check….1199

M08 – Stepper Motor for Hitch, Operational Check….1200

S08 – Turn Signal Switch, Operational Check….1201

S21 – Rear PTO Switch, Operational Check….1202

S22 – Differential Lock Switch, Operational Check….1203

S24 – Quick Withdrawal Switch, Operational Check….1204

S63 – Front-Wheel Drive Switch, Operational Check….1205

S68 – Switch for Hitch Remote Control (Left), Operational Check….1206

S106 – Hazard Warning Light Switch, Operational Check….1208

Supply Voltage for 5-volt BCU Components, Operational Check….1209

Group ECU: ECU Control Unit….1034

ECU – Summary of References….1211

ECU – Summary of Addresses (Level 16 ECU for 2-Valve Engine with HPCR)….1212

ECU – Calibration and Input Addresses (Level 16 ECU for 2-Valve Engine with HPCR)….1215

ECU – Summary of Operational Checks….1217

ECU – Theory of Operation (Level 16 ECU for 2-Valve Engine with HPCR)….1218

B02 – Air Cleaner Restriction Sensor, Operational Check….1221

B96 – Hand Throttle Potentiometer, Operational Check….1222

B79 – Accelerator Pedal Potentiometer, Operational Check….1224

R15 – Heating Element of Electrical Starting Aid (2-Valve Engine with HPCR), Operational Check….1226

Section 255: PowrQuad Transmissions….1228

Group 10: Operational Check….1228

PowrQuad Transmission—Operational Check….1237

Group 15: Tests and Adjustments….1228

PowrQuad Transmission—Summary of References….1245

PowrQuad Transmission— Special Tools….1246

PowrQuad Transmission—System Check….1247

PowrQuad Transmission—Test Ports….1255

PowrQuad Transmission—Checking Rate of Flow at Cooler….1257

PowrQuad Transmission—Checking the Cooler Relief Valve….1260

PowrQuad Transmission—System Pressure Check….1263

PowrQuad Transmission—Checking Lube Oil Pressure….1264

PowrQuad Transmission—Checking Cooling Oil Pressure (Forward Clutch)….1266

PowrQuad Transmission—Checking Cooling Oil Pressure (Reverse Brake)….1267

PowrQuad Transmission—Checking Pressure at Forward Clutch….1268

PowrQuad Transmission—Checking Pressure at Reverse Brake….1269

PowrQuad Transmission—Checking Pressure at Brake B1….1270

PowrQuad Transmission—Checking Pressure at Brake B2….1271

PowrQuad Transmission—Checking Pressure at Brake B3….1272

PowrQuad Transmission—Checking Pressure at Clutch C4….1273

PowrQuad Transmission—Adjusting System Pressure….1275

PowrQuad Transmission—Test Result Table….1277

PowrQuad Transmission—Adjusting Gear Shift….1280

PowrQuad Transmission—Adjusting Forward/Reverse Cable….1282

PowrQuad Transmission—Adjusting Park Lock….1284

Group 20: Operation….1228

PowrQuad Transmission — Summary of References….1286

PowrQuad Transmission—Layout….1287

PowrQuad Module—Layout….1288

PowrQuad Module—Cross-Sectional and 3D View….1290

PowrQuad Module—Location of Valves, Sensors and Switches….1292

PowrQuad Module—Element Engagement Chart….1295

PowrQuad Module—Pneumatic Pump….1296

PowrQuad Module—Transmission Oil Pump….1299

PowrQuad Module — Pressure-Regulating Valve and Filter Relief Valve….1301

PowrQuad Module—Overspeed Relief Valve and Anti-Cavitation Check Valve….1306

PowrQuad Module—Clutch Cooling Components….1308

PowrQuad Module —Clutch Cooling Valve (Forward/Reverse)….1309

PowrQuad Module—System 1 Oil and System 2 Oil….1310

PowrQuad Module—Hydraulic Schematic, Mechanically Actuated PowrQuad Module….1311

PowrQuad Module—Operation of Forward/Reverse Modulation, Mechanically Actuated PowrQuad Module….1313

PowrQuad Module—Neutral Start Circuit, Mechanically Actuated PowrQuad Module….1316

PowrQuad Module—Operation of Gear-to-Gear Modulation, Mechanically Actuated PowrQuad Module….1317

Group 30: Range Box….1229

Range Transmission — Cross-Sectional View….1322

Section 256: Drive Systems….1324

Group 10: Operational Check….1324

Power train – operational check….1328

Group 15: Tests and Adjustments….1324

Tests and Adjustments—Summary of References….1443

Tests and Adjustments—Special Tools….1333

Drive Systems—System Check….1334

Checking Pressure at the Front-Wheel Drive Clutch….1338

Checking Pressure at the Hydraulic Differential Lock….1339

Checking Pressure at the PTO….1340

Drive Systems—Test Result Table….1343

Group 20: Operation….1324

Drive Systems—Summary of References….1345

Front Wheel Drive Clutch—Cross-Sectional View….1346

Front Wheel Drive Clutch—Oil Flow and Power Flow….1348

Front Wheel Drive Clutch Disengaged—Oil Flow….1350

Differential—Cross-Sectional View….1352

Differential—Power Flows….1354

Differential—Oil Flows….1356

Final Drives—Operation and Cross-Sectional View….1359

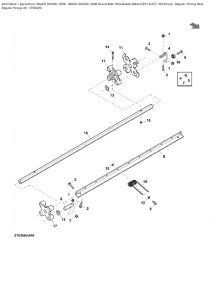

PTO Options—Description….1360

PTO Options—PTO Modulating Valve and Solenoid Valve….1362

PTO Options—PTO brake and PTO clutch….1364

PTO Options—Power Flows….1366

Section 260: Steering and Brakes….1368

Group 05: Preliminary Checks….1368

Preliminary Checks—Summary of References….1371

Preliminary Checks – Steering System….1372

Preliminary Checks – Brake System….1376

Group 10: Operational Check….1368

Operational Checkout—Summary of References….1378

Safety Information….1379

Steering Check….1380

Checking Brakes….1381

Group 15: Tests and Adjustments….1368

Tests Tests Tests & Adjustments—Summary of References{pgNO}1368 Adjustments—Summary of References{pgNO}1383 Adjustments—Summary of References….1382

Steering and Brakes – Special Tools….1384

Steering and Brakes – Specifications….1386

Checking Steering Valve….1387

Checking Brake System….1390

Bleeding the Rear Brakes….1391

Adjusting Brake Pedals and Switches….1392

Group 20A: Hydrostatic Steering….1368

Description of Steering Valves, Operation….1400

Group 20B: Brakes….1368

Brakes—Summary of Reference….1408

Operation of Brake Piston, Plate and Disks….1409

Brake released….1411

Initial Braking….1413

Brake Engaged….1415

Rear Wheel Brakes, Operation….1417

Group 20C: Air brake system….1368

Steering and Brakes – Air Brakes, Summary of References….1419

Steering and Brakes – Air Brakes, Description….1420

Steering and Brakes – Air Brakes, Compressor….1422

Steering and Brakes – Air Brakes, Pressure Regulating Valve….1423

Steering and Brakes – Air Brakes, Compressed Air Tank….1424

Steering and Brakes – Air Brakes, Trailer Control Valve….1425

Steering and Brakes – Air Brakes, Coupling Ends….1426

Section 270: Hydraulic System….1427

Group 10: Operational Check….1427

Hydraulic System – Operational Check—Summary of References….1430

General Information – Transmission and Hydraulic System, Introductory Checks….1431

Hydraulic System – Load Check….1435

Hitch Control – Operational Check….1436

Hydraulic System – External Control of Hitch, Operational Check-Out….1438

Hydraulic System – Selective Control Valves (M-SCV), Operational Check-Out….1439

Group 15: Tests and Adjustments….1427

Tests and Adjustments—Summary of References….1443

Hydraulic System – Special Tools….1444

Safety Measures for Hydraulic Checks….1446

PFC Hydraulic System – Worksheet for the Hydraulic System Diagnostics….1448

PFC Hydraulic System – Oil Pressure Test Ports….1451

PFC Hydraulic System – Checking and Adjusting the Maximum Load Sense Pressure….1452

PFC Hydraulic System – Check and Adjust System Oil Pressure….1454

PFC Hydraulic System – Check and Adjust Differential Pressure….1456

PFC Hydraulic System – Priority Circuit 1, Checking and Adjusting the Load Sense Oil Pressure for Steering….1458

PFC Hydraulic System – Priority Circuit 3, Checking the Oil Pressure….1460

PFC Hydraulic System – Hydraulic Pump, Checking the Delivery Rate….1462

Hydraulic System – Hitch Valve, Rough Adjustment of the Raise and Lower Valves….1464

Hydraulic System – Hitch Valve, Checking and Adjusting the Draft Potentiometer….1466

Group 20: Theory of operation….1427

Hydraulic System Theory of Operation—Summary of References….1469

Hydraulic System – Summary of Abbreviations….1470

PFC Hydraulic System – Summary of Components….1471

PFC Hydraulic System — Symbolic Representation….1473

Group 20A: Oil Filter, Charge Pump and Hydraulic Pump….1427

Oil Filter, Charge Pump and Hydraulic Pump―Summary of References….1475

PFC Hydraulic System – Hydraulic Oil Filter, Operation….1476

PFC Hydraulic System – Charge Pump, Operation….1478

PFC Hydraulic System – Hydraulic Pump, Operation….1480

PFC Hydraulic System – Hydraulic Pump, Operating Modes….1484

PFC Hydraulic System – Hydraulic Oil Primary Filter, Component Information….1491

PFC Hydraulic System – Hydraulic Oil Filter, Component Information….1492

PFC Hydraulic System – Charge Pump, Component Information….1493

PFC Hydraulic System – Hydraulic Pump, Component Information….1495

Group 20B: Hitch….1428

Hitch – Summary of References….1497

Hitch – Summary of Components….1498

Hitch – Hitch Control, Operation….1500

Hitch – Hitch Valve, Operation….1502

Hitch – Position Sensor, Operation….1504

Hitch – Draft Sensor, Operation….1505

Hitch – Controls….1506

Hitch – Direct Control….1507

Group 20C: Selective control valves (SCV)….1428

Selective Control Valves (SCVs) – Summary of References….1509

Selective Control Valve (M-SCV 100) – Operation….1510

Selective Control Valve (M-SCV 200) – Operation….1518

Group 20D: Hydraulic block….1428

PFC Hydraulic System – Hydraulic Block, Summary of References….1530

PFC Hydraulic System – Hydraulic Block, Summary of Components….1531

PFC Hydraulic System – Priority 1 Control Block, Component Information….1533

PFC Hydraulic System – Priority 3 Control Block, Component Information….1535

Section 290: Operator's Cab….1537

Group 15: Tests and Adjustments….1537

Operational Checkout―Summary of References….1539

Safety in the Workplace….1540

Handling Refrigerant….1541

Safety Equipment….1542

In the Event of an Emergency….1543

Storage of Refrigerant Containers….1544

Refrigerant R134a….1545

Important….1546

Operator's Cab – Special Tools….1547

Specification….1548

Explanation Of Checks….1549

Pressure Deviations….1563

Group 20: Operation….1537

Air Condtioning System – Summary of References….1566

Air Condtioning System – R134A Refrigerant….1567

Air Condtioning System – Principle of Heat Exchange….1568

Refrigerant Circuit Layout (Cab Tractors)….1569

Refrigerant Circuit Operation….1570

Component Description….1572

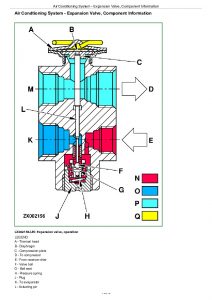

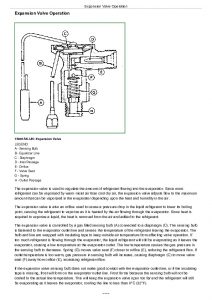

Air Condtioning System – Expansion Valve, Component Information….1576

Thermostat Switch….1578

Heating and Ventilation….1579

Section 299: Special Tools (Dealer-Fabricated)….1581

Group 05: Special Tools (Dealer-Fabricated)….1581

Special Tools (Dealer-Fabricated) — Summary….1583

Retainer Tool….1584

Adjustment Tool….1585

DFRW2—Needle Valve Test Hose Assembly….1586

DFLX10 and DFLX11—Test Harnesses….1587

DFLX12—Special Tool for 11-bit and 29-bit CAN BUS….1588

DFLX14—Solenoid Valve Test Harness….1589

Group 10: Special Tools (Available as Spare Parts)….1581

Special tool information….1591

John Deere 1654, 1854, 2054, 2104, 6165J, 6185J, 6205J, 6210J Tractors Diagnosis & Tests Service Manual (TM802219)