Complete Repair Service Technical Manual for John Deere Tractors 6100J, 6115J, 6125J, 6135J, 6150J, 6170J, 6190J, 6210J, with all the workshop information to maintain, repair, and rebuild like professional mechanics.

John Deere Tractors 6100J, 6115J, 6125J, 6135J, 6150J, 6170J, 6190J, 6210J workshop technical manual (repair) includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM808719 – 6J Tractors (600000 – )—Repair Technical Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,902 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Language: English French Portuguese Spanish

TM808719 Repair Technical Manual 6J Tractors (600001 – )—Repair Technical Manual

Language: English

Equipment Model: 6100J, 6115J, 6125J, 6135J, 6150J, 6170J, 6190J, 6210J

Serial Number: 600000-

Edition: South America

TM808728 Repair Technical Manual 6J Tractors (600001 – )—Repair Technical Manual

Language: French

TM808754 Repair Technical Manual 6J Tractors (600001 – )—Repair Technical Manual

Language: Portuguese

TM808763 Repair Technical Manual 6J Tractors (600001 – )—Repair Technical Manual

Language: Spanish

TABLE OF CONTENTS

Section 05: Safety…32

Group 05: Safety…32

Recognize Safety Information…457

Understand Signal Words…36

Follow Safety Instructions…37

Practice Safe Maintenance…38

Live With Safety…39

Handle Fluids Safely—Avoid Fires…40

Prepare for Emergencies…41

Wear Protective Clothing…42

Work in Clean Area…43

Work In Ventilated Area…44

Illuminate Work Area Safely…45

Remove Paint Before Welding or Heating…46

Avoid Heating Near Pressurized Fluid Lines…47

Use Proper Tools…48

Construct Dealer-Made Tools Safely…49

In Case of Fire…50

Avoid Harmful Asbestos Dust…51

Decommissioning — Proper Recycling and Disposal of Fluids and Components…52

Precautions for Welding…53

Park Machine Safely…55

Support Machine Properly…56

Replace Safety Signs…57

Clean Vehicle of Hazardous Pesticides…58

Handle Agricultural Chemicals Safely…59

Service Machines Safely…61

Use Proper Lifting Equipment…62

Avoid High-Pressure Fluids…63

Service Accumulator Systems Safely…64

Wait Before Opening High-Pressure Fuel System…65

Keep ROPS Installed Properly…66

Service Tires Safely…67

Avoid Static Electricity Risk When Refueling…68

Prevent Acid Burns…70

Handling Batteries Safely…72

Prevent Battery Explosions…74

Section 10: General Information…225

Group 05: References for Technical Information…75

Sealants and Adhesives Cross-Reference Chart…79

Metric Bolt and Screw Torque Values…82

Unified Inch Bolt and Screw Torque Values…84

Face Seal Fittings Assembly and Installation—All Pressure Applications…87

Metric Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressures…88

Metric Face Seal and O-Ring Stud End Fitting Torque Chart—High Pressure Applications…90

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—Standard Pressures…92

SAE Face Seal and O-Ring Stud End Fitting Torque Chart—High Pressure Applications…94

Four Bolt Flange Fittings Assembly and Installation—All Pressure Applications…96

SAE Four Bolt Flange Cap Screw Torque Values—Standard Pressure Applications…97

SAE Four Bolt Flange Cap Screw Torque Values—High Pressure Applications…98

External Hexagon Port Plug Torque Chart…99

Prevent Hydraulic System Contamination…101

Identify Zinc-Flake Coated Fasteners…102

Use Torque Wrench Adapter…103

Servicing and Connecting Snap to Connect STC™ Fittings…105

Use Special Wrench…1930

Install Hydraulic Fittings…108

Section 20: Engine…110

Group 05: Remove and Install Components…110

John Deere Engine Component Information…192

Special Tools…1845

Specifications…1856

Remove and Install 4.5L Engine…116

Remove and Install 6.8L Engine…139

Engine Mountings—Exploded View…165

Replace Engine Mountings…166

Section 30: Fuel, Air Intake, Cooling, and Exhaust System…171

Group 05: Speed Control…171

General Information…225

Specifications…1856

Other Material…1855

Mechanical Hand Throttle Lever—Exploded View…177

Mechanical Speed Control Pedal—Exploded View…179

Mechanical Hand Throttle Lever and Speed Control Pedal Adjustment…184

Mechanical Speed Control Link Adjustment…183

Speed Control Pedal Adjustment…184

Remove and Install Hand Throttle Potentiometer…185

Remove and Install Speed Control Pedal Assembly…186

Remove and Install Speed Control Pedal Potentiometer…188

Group 10: Fuel System…171

John Deere Engine Component Information…192

General information…1857

Specifications…1856

Other Material…1855

Fuel System 4.5L Engine…196

Fuel System 6.8L Engine…198

Drain Fuel Filters…200

Drain Fuel Tank…202

Remove and Install Fuel Tank…204

Remove and Install Fuel Transfer Pump…209

Remove and Install Fuel Filters…213

Bleed Fuel System…217

Restarting an Engine Which Has Run Out of Fuel…220

Group 15: Air Intake System…171

General Information…225

Specifications…1856

Engine Air Cleaner—Exploded View…227

Remove and Install Engine Air Cleaner Housing…228

Group 20: Cooling System…172

General information…1857

Specifications…1856

Remove and Install Radiator…232

Remove and Install Expansion Tank…241

Remove and Install Engine Fan…245

Remove and Install Viscous Fan Drive Clutch…250

Remove and Install Oil Cooler/Air Conditioner Condenser…252

Remove and Install Ring-Shaped Oil Cooler…254

Remove and Install Charge Air Cooler…255

Releasing Drive Belt Tension…260

Replace Engine Fan Belt…261

Remove and Install Automatic Belt Tensioner…266

Remove and Install Fan Console…267

Disassemble, Repair, and Assemble Fan Console…270

Group 25: Exhaust System…172

General information…1857

Specifications…1856

Other Materials…1669

Remove and Install Muffler…276

Remove and Install Exhaust Pipe…278

Section 40: Electrical System…283

Group 05: Harness and Connectors Repair…283

Special Tools…1845

General…289

Use of High-Pressure Washers…290

Replace SURE-SEAL® Connectors…291

Install Weather Pack™ Contact…293

Service Parts Kits…295

Replace CPC™, Large Mate-N-Lok®, and Metrimate® Pin-Type Connectors…296

Replace CPC™ Blade Type Connectors…297

Replace Small Mate-N-Lok® Socket Connector…298

Replace Small Mate-N-Lok® Pin Connector…299

Replace DEUTSCH® Connectors…300

Replace Weather Pack™ Connector…302

Replace SURE-SEAL® Connector with Weather Pack™ Connector…304

Remove Connector Body from Blade Terminals…306

Install DEUTSCH® Contact…307

Installation of Repair Wire Assembly (RWA)…309

Group 15: Charging System…283

Special Tools…1845

Specifications…1856

Replacing Alternator…321

Disconnecting Electrical Circuits…460

Remove and Install Alternator…323

Remove and Install Alternator Pulley…325

Remove and Install the Battery…327

Group 20: Starter Motor Circuit…283

Special Tools…1845

Specifications…1856

Repairing Starter Motor…332

Disconnecting Electrical Circuits…460

Remove and Install Starter Motor…334

Group 25: Fuses, Relays, and Switches…284

Special Tools…1845

Specifications…1856

Disconnecting Electrical Circuits…460

Access to the Fuses and Relays…340

Main Fuses (If Equipped)…342

Fuse Box—Tractors with Open Operator’s Station…344

Fuse Box—Tractors with Cab…346

Power Link Box (If Equipped)…348

Power Link Box Components (If Equipped)…349

Remove and Install Starter Relay…350

Remove and Install Key Switch…353

Remove and Install Brake Switch…354

Remove and Install Light Switch…355

Remove and Install High-Beam and Low-Beam Headlights Switch…356

Remove and Install Worklights Switch…357

Remove and Install Hazard Warning Light Switch…358

Remove and Install Turn-Signal Switch…359

Remove and Install Horn Switch…360

Remove and Install Windshield Wiper and Windshield Washer Switch…361

Remove and Install Front-Wheel Drive Switch…362

Remove and Install Power Take-off Switch…363

Remove and Install Load Depth Control Potentiometer—Cab Tractors…364

Remove and Install Hitch Control Unit—Cab Tractors…365

Remove and Install FieldCruise™ Control Potentiometer…366

Remove and Install Fan Switch…368

Remove and Install Differential Lock Switch—Tractors with Open Operator’s Station…369

Remove and Install Differential Lock Switch—Tractors with Cab…370

Remove and Install Hydraulic Hitch Remote Control Switch—Tractors with Cab…371

Group 30: Electrical Components…284

Note…373

Special Tools…1845

Specifications…1856

Disconnecting Electrical Circuits…460

Lights with Halogen Bulbs…377

Remove and Install Instrument Panel…379

Remove and Install Trailer Socket…382

Remove and Install Service ADVISOR™ Socket…384

Remove and Install Windshield Wiper Motor…387

Removing Windshield Washer Pump…389

Handle Halogen Light Bulbs Safely…390

Replace High and Low Beam Headlights Bulbs…391

Replace Rear Worklight Bulb—Open Operator’s Station Tractors…393

Replace Front Turn-Signal Lights, Hazard Warning Lights, and Clearance Lights Bulbs—Open Operator’s Station Tractors…395

Replace Worklight Bulbs—Cab Tractors…397

Replace Front Turn-Signal Light, and Hazard Warning Lights Bulbs—Cab Tractors…399

Replace Rear Turn-Signal Light, Hazard Warning Light, and Brake Light Bulbs…400

Replace Backup Light Bulb…402

Replace License Plate Light Bulb…404

Group 35: Monitoring Systems…285

Replace Engine Speed Sensor (B001)…407

Replace Engine Air Cleaner Restriction Pressure Switch (B002)…408

Replace Fuel Level Sensor (B003)…409

Replace Engine Oil Pressure Switch (B004)…411

Replace Rear PTO Speed Sensor (B006)…413

Replace Transmission Oil Filter Restriction Switch (B007)…414

Replace Coolant Temperature Sensor (B008)…415

Replace Wheel Speed Sensor (B009)…417

Replace A/C Pressure Switch (B015)…418

Replace Draft Sensors (B019) and (B020)…419

Replace Rear Hitch Position Sensor (B021)…422

Replace Transmission Oil Pressure Switch (B031)…423

Replace Transmission Forward Pressure Switch (B032)…424

Replace Transmission Reward Pressure Switch (B033)…425

Replace Wheel Speed Sensor (B035)…426

Replace Neutral Start Switch (B036)…427

Replace Draft Sensor (B041)…428

Replace Coolant Temperature Sensor (B056)…430

Replace Manifold Air Temperature Sensor (B059)…431

Replace Hydraulic Oil Temperature Sensor (B066)…432

Replace Crankshaft Speed Sensor (B072)…433

Replace Event Sensor (B074)…434

Replace Fuel Temperature Sensor (B114)…435

Replace Water-in-Fuel Sensor (B121)…436

Replace Rail Pressure Sensor (B137)…438

Replace Steering Input Device (B138)…439

Replace Wheel Angle Sensor (B139)…440

Replace A/C Thermostat Switch (S070)…441

Section 45: Electronic Control Units…442

Group 05: General Information…225

Basic Electrical Component Handling / Precautions For Vehicles Equipped With Computer Controlled Systems…444

Servicing Electronic Control Units…445

Welding Near Electronic Control Units…446

Keep Electronic Control Unit Connectors Clean…447

Special Tools…1845

Control Unit Locations…449

Control Unit Functions…452

Group 10: Remove and Install Components…442

Safety Information…457

Instructions when Replacing a Control Unit…458

Instructions when Replacing a VIN Control Unit…459

Disconnecting Electrical Circuits…460

Specifications…1856

Remove and Install MHPC Control Unit (A064)…462

Remove and Install ECU Control Unit (A086)…465

Remove and Install MTG Control Unit (A155)…466

Remove and Install SBBC Control Unit (A132)…468

Replace Vehicle CAN Bus Active Terminator (A062)…470

Replace Vehicle CAN Bus Passive Terminator (A084)…471

Replace Implement CAN Bus Active Terminator (A083)…472

Replace Implement CAN Bus Passive Terminator (A063)…473

Section 50A: Drivetrain…474

Group 05: Remove and Install Components—6100J, 6115J, 6125J and 6135J Tractors…474

Special Tools…1845

Specifications…1856

Other Materials…1669

Remove and Install Front-Wheel Drive Clutch Housing…559

Remove and Install Drivetrain—Tractors with Open Operator’s Station…487

Remove and Install Drivetrain—Tractors with Cab…495

Remove and Install Final Drive—Tractors with Open Operator's Station…506

Remove and Install Final Drive—Tractors with Cab…511

Remove and Install Power Take-Off Housing—Tractors with Open Operator's Station…517

Remove and Install Power Take-Off Housing—Tractors with Cab…522

Group 06: Remove and Install Components—6150J Tractor…474

Special Tools…1845

Specifications…1856

Other Materials…1669

Remove and Install Front-Wheel Drive Clutch Housing…559

Remove and Install Drivetrain…562

Remove and Install Final Drive…574

Remove and Install Power Take-Off Housing…581

Group 07: Remove and Install Components—6170J, 6190J, and 6210J Tractor…474

Special Tools…1845

Specifications…1856

Other Materials…1669

Remove and Install Front-Wheel Drive Clutch Housing…559

Remove and Install Drivetrain…562

Remove and Install Final Drive…574

Remove and Install Power Take-Off Housing…581

Group 10: Universal Joints, Driveshafts, and Torsional Damper…474

Special Tools…1845

Specifications…1856

Front-Wheel Drive Driveshaft—Exploded View…588

Remove Front-Wheel Drive Driveshaft…589

Repairing MFWD Universal-Joint Drive Shaft…591

Install Front-Wheel Drive Driveshaft…595

Remove and Install Engine Driveshaft…597

Remove and Install Torsional Damper…599

Replace Torsional Damper Bearing…601

Group 15: Front-Wheel Drive Clutch—6100J, 6115J, 6125J and 6135J Tractors…475

Special Tools…1845

Specifications…1856

Other Material…1855

MFWD Clutch Repair Instructions…641

Front-Wheel Drive Clutch—Cross-Sectional View…607

Front-Wheel Drive Clutch — Exploded View…608

Disassemble, Inspect, and Assemble Front-Wheel Drive Clutch…610

Group 16: Front-Wheel Drive Clutch—6150J Tractor…475

Special Tools…1845

Specifications…1856

MFWD Clutch Repair Instructions…641

MFWD Clutch — Cross-Sectional View…642

Disassemble Front-Wheel Drive Clutch…646

Disassembling MFWD Clutch Assembly…649

Mounting MFWD Clutch Assembly…651

Mounting MFWD Clutch…655

Group 17: Front-Wheel Drive Clutch—6170J, 6190J, and 6210J Tractors…475

Special Tools…1845

Specifications…1856

MFWD Clutch Repair Instructions…641

MFWD Clutch — Cross-Sectional View…642

MFWD Clutch Exploded View…644

Disassemble Front-Wheel Drive Clutch…646

Disassembling MFWD Clutch Assembly…649

Mounting MFWD Clutch Assembly…651

Mounting MFWD Clutch…655

Group 20: Rear Differential—6100J, 6115J, 6125J, and 6135J Tractors…476

Specifications…1856

Other Materials…1669

Rear Differential Repair Instructions…712

Differential — Exploded View…665

Rear Differential—Cross-Sectional View…667

Remove Rear Differential…668

Disassemble Rear Differential…670

Assembling the differential…675

Install Rear Differential…681

Adjust Differential Bearings Preload…683

Adjust Rear Differential Backlash…733

Group 21: Rear Differential—6150J Tractor…476

Special Tools…1845

Specifications…1856

Rear Differential Repair Instructions…712

Rear Differential — Cross Sectional View…714

Rear Differential — Exploded View…716

Remove and Install Rear Differential…718

Disassembling Rear Differential…721

Assembling Rear Differential…725

Adjust Rear Differential Preload…731

Adjust Rear Differential Backlash…733

Group 22: Rear Differential—6170J, 6190J, and 6210J Tractors…476

Special Tools…1845

Specifications…1856

Rear Differential Repair Instructions…712

Rear Differential — Cross Sectional View…714

Rear Differential — Exploded View…716

Remove and Install Rear Differential…718

Disassembling Rear Differential…721

Assembling Rear Differential…725

Adjust Rear Differential Preload…731

Adjust Rear Differential Backlash…733

Group 25: Hydraulic Pump Drive…477

Special Tools…1845

Specifications…1856

Hydraulic Pump Drive—Cross-Sectional View…738

Remove and Disassemble Pump Drive Pinion…741

Remove and Disassemble Pump Drive Gear…745

Assemble and Install Pump Drive Gear…749

Assembling and Installing Pump Drive Pinion…755

Adjust Hydraulic Pump Drive…760

Group 30: Final Drives—6100J, 6115J, 6125J, and 6135J Tractors…477

Special Tools…1845

Specifications…1856

Final Drive Repair Instructions…783

Final Drive—Cross-Sectional View…767

Final Drive—Exploded View…768

Disassemble, Repair and Assemble Final Drives…770

Adjust Rear Axle Rolling Drag…778

Group 31: Final Drives—6150J, 6170J, 6190J, and 6210J Tractors…477

Special Tools…1845

Specifications…1856

Final Drive Repair Instructions…783

Final Drive Housing — Cross Sectional View…784

Final Drive Housing — Exploded View…785

Removing Planetary Carrier…787

Disassembling Planetary Carrier…789

Planetary Carrier — Exploded View…791

Assembling Planetary Carrier…792

Removing Final Drive Housing to Axle…794

Disassembling and Assembling Final Drive Housing…796

Disassembling and Assembling Axle…797

Installing Final Drive Housing to Axle…799

Installing Planetary Carrier…800

Measuring Rolling Drag…802

Checking Final Drive Shaft and Retainer…1926

Group 35: Rear Power Take—Off-6100J, 6115J, 6125J, and 6135J Tractors…478

Special Tools…1845

Specifications…1856

Other Material…1855

Replacing Output Shaft Retainer…1926

Replacing O-Ring of Reversible PTO…814

Rear Power Take-Off—Exploded View…815

Rear Power Take-Off—Cross-Sectional View…816

Remove and Install Power Take-Off Clutch…819

Repair Power Take-Off Clutch…820

Reconditioning PTO Brake…825

Power Take-Off Transmission—Cross-Sectional View…975

Disassemble Power Take-Off Transmission…828

Reconditioning Output Shaft (540/1000 RPM Reversible)…829

Mounting Output Shaft (540/1000 RPM)…832

Reconditioning Countershaft (540/1000 RPM)…834

Mounting PTO Transmission…835

Adjusting Output Shaft Cone Bearing…837

Adjusting Countershaft Cone Bearing…838

Installing Support and Adjusting Cone Bearings…840

Remove, Repair, and Install Rear Power Take-Off Solenoid Valve…886

Group 36: Rear Power Take-Off—6150J, 6170J, 6190J, and 6210J Tractors…478

Special Tools…1845

Specifications…1856

Replacing Output Shaft Seal Ring…846

Rear PTO Clutch – Cross Sectional View…847

Rear PTO Clutch – Exploded View…849

Remove Rear Power Take-Off Clutch…850

Disassemble, Repair, and Assemble Rear Power Take-Off Clutch…853

Repair Rear Power Take-Off Brake…862

Install Rear Power Take-Off Clutch…863

Rear PTO Drive Train – Cross Sectional View…866

Rear PTO Drive Train – Exploded View…867

Remove Rear Power Take-Off Drive Train…869

Disassemble, Repair, and Assemble Output Shaft…873

Disassemble, Repair, and Assemble Countershaft…878

Install Rear Power Take-Off Drive Train…880

Adjust Tapered Roller Bearing of Countershaft…881

Adjust Tapered Roller Bearing of Bearing Support…883

Remove, Repair, and Install Rear Power Take-Off Solenoid Valve…886

Section 50B: SyncroPlus™ Transmission…888

Group 05: Remove and Install Components…888

Special Tools…1845

Specifications…1856

Remove and Install Clutch Housing…894

Remove and Install SyncroPlus™ Housing…902

Group 10: Transmission Selectors Control…888

Specifications…1856

Other Materials…1669

Reconditioning Gearshift Mechanism…908

Reconditioning Range-Shift Lever Mechanism…912

Checking and Adjusting Shift Units…915

Adjusting the Clutch Pedal…920

Group 15: Clutch…888

Special Tools…1845

Specifications…1856

Other Materials…1669

Removing Clutch…927

Repairing Clutch…928

Installing Clutch…937

Transmission Oil Pump—Exploded View…939

Removing Transmission Oil Pump…1144

Repair Transmission Oil Pump…944

Install Transmission Oil Pump…947

Valves and Other Hydraulic Components…950

Repairing Engagement Override Valve (EOV)…952

Repairing Clutch Cooling Valve…953

Repairing Cooling Pilot Valve…954

Repairing Bypass Valve…955

Repairing Pressure Regulating Valve…956

Repairing Lube Relief Valve…957

Repairing Cooler Relief Valve…958

Repair Clutch Pedal Valve…959

Replacing Pressure and Temperature Sensor Units…968

Group 20: Gearbox…889

Special Tools…1845

Specifications…1856

Transmission—Exploded View…973

Transmission—Cross-Sectional View…975

Disassemble SyncroPlus™ Housing…977

Disassemble, Repair, and Assemble Drive Shaft…979

Disassemble, Repair, and Assemble Intermediate Shaft…986

Assemble SyncroPlus™ Housing…988

Preparing to Install Transmission…991

Repairing Shift Cover…996

Adjusting Gear Shift Actuating Mechanism…998

Adjusting Neutral Start Switch…999

Group 25: Creeper Transmission…889

Specifications…1856

Creeper Transmission—Cross-Sectional View…1003

Preparations…1005

Removing Creeper Transmission…1006

Disassembling Creeper Transmission…1008

Installing Creeper Transmission…1021

Shifting Mechanism — Cross-Sectional View…1015

Installing Gear Shift Elements…1017

Repairing Creeper Transmission Gearbox Cover…1018

Final Assembly…1019

Installing Creeper Transmission…1021

Group 30: Remove and Install Range Box…1222

Special Tools…1845

Specifications…1856

Other Material…1855

Remove and Install Range Box…1222

Group 35: Range Box…890

Special Tools…1845

Specifications…1856

Input Shaft—Exploded View…1231

Range box—Cross-Sectional View…1230

Remove and Install Input Shaft…1233

Adjust Input Shaft End Play…1236

Output Shaft—Exploded View…1239

Remove Output Shaft…1242

Disassemble and Assemble Output Shaft…1044

Install Output Shaft…1257

Range Box Cover—Exploded View…1267

Remove and Install Range Box Cover…1269

Shifting Mechanism—Exploded View…1272

Disassemble, Repair, and Assemble Shifting Mechanism…1274

Adjust Range Shift…1276

Park Lock—Exploded View…1278

Disassemble, Inspect, and Assemble Park Lock…1281

Disassemble, Inspect, and Assemble Park Lock Cam…1066

Adjust Park Lock Cam…1068

Section 50C: PowrQuad™ Transmission…1070

Group 05: Remove and Install PowrQuad™ Module…1070

Special Tools…1845

Specifications…1856

Remove and Install PowrQuad™ Housing…1076

Group 10: Transmission Selectors Control…1070

Specifications…1856

Other Materials…1669

Reconditioning of Gearshift, Park Brake, and Forward/Reverse Mechanism…1084

Reconditioning of Range-Shift Mechanism…1088

Adjust Gear-Shift and Range-Shift Cables…1091

Adjusting Forward/Reverse Cable…1093

Adjusting Cable and Stop Screw Park Break…1095

Adjust Clutch Pedal…1096

Group 15: PowrQuad™ Module…1070

Special Tools…1845

Specifications…1856

Other Materials…1669

Transmission Components…1105

Removing and Installing Oil Filter Base…1106

Replacing Oil Filter…1107

Removing and Installing Front Valve Housing…1108

Removing and Installing Front Valve Housing Valves (With Mechanically Actuated PowrQuad Module)…1111

Removing and Installing Transmission Front Cover…1124

Removing and Installing Transmission Front Cover Valves (With Mechanically Actuated PowrQuad Module)…1126

Removing Clutch Pedal Valve (Mechanically Actuated PowrQuad Module)…1131

Removing and Installing Shift Valve Housing (With Mechanically Actuated PowrQuad Module)…1137

Removing and Installing Shift Valve Housing Valves (With Mechanically Actuated PowrQuad Module)…1140

Removing Transmission Oil Pump…1144

Servicing Transmission Oil Pump…1145

Installing Transmission Oil Pump…1151

Removing Planetary Drive Gears…1152

Repairing Planetary Drive Gears…1154

Installing Planetary Drive Gears…1160

Removing B1 Brake Housing…1165

Reconditioning B1 Brake…1166

Installing B1 Brake Housing…1168

Removing B2-B3 Brake Housing…1169

Reconditioning B2 Brake…1170

Reconditioning B3 Brake…1172

Installing B2-B3 Brake Housing…1175

Removing C4 Clutch…1176

Reconditioning C4 Clutch…1177

Installing C4 Clutch…1188

Removing Reverse Brake…1189

Servicing Reverse Brake…1190

Installing Reverse Brake…1193

Removing Forward Clutch with Planetary Drive (Forward/Reverse)…1194

Servicing Forward Clutch with Planetary Drive (Forward/Reverse)…1195

Installing Forward Clutch with Planetary Drive (Forward/Reverse)…1209

Clutch Carriers for C4 Clutch and Forward Clutch—Exploded View…1211

Replace Clutch Carriers for C4 Clutch and Forward Clutch…1212

Replacing Output Shaft…1216

Group 20: Remove and Install Range Box…1222

Special Tools…1845

Specifications…1856

Other Material…1855

Remove and Install Range Box…1222

Group 25: Range Box…1071

Special Tools…1845

Specifications…1856

Range box—Cross-Sectional View…1230

Input Shaft—Exploded View…1231

Remove and Install Input Shaft…1233

Adjust Input Shaft End Play…1236

Output Shaft—Exploded View…1239

Remove Output Shaft…1242

Disassemble and Assemble Output Shaft (6100J—6135J Tractors)…1246

Install Output Shaft…1257

Adjust Output Shaft End Play (6150J—6210J Tractors)…1265

Range Box Cover—Exploded View…1267

Remove and Install Range Box Cover…1269

Shifting Mechanism—Exploded View…1272

Disassemble, Repair, and Assemble Shifting Mechanism…1274

Adjust Range Shift…1276

Park Lock—Exploded View…1278

Disassemble, Inspect, and Assemble Park Lock…1281

Disassemble, Inspect, and Assemble Park Lock Cam (6100J-6135J Tractors)…1286

Adjust Park Lock Cam (6100J-6135J Tractors)…1288

Section 60A: Steering…1290

Group 05: Hydrostatic Steering…1290

Special Tools…1845

Other Material…1855

Specifications…1856

Preliminary Tasks…1295

Disconnect and Connect the Steering or Brake Hoses…1296

Steering Wheel—Exploded View…1298

Remove and Install Steering Wheel…1301

Steering Column—Exploded View…1302

Remove and Install Steering Column—Tractors with Cab…1304

Remove and Install Steering Column—Tractors with Open Operator’s Station…1308

Exploded View of Steering Valve…1311

Remove and Install Steering Valve…1313

Disassembling Steering Valve…1314

Assembling Steering Valve…1318

Adjusting Shock Valves…1326

Group 10: AutoTrac™ Integrated Steering…1290

Specifications…1856

Preliminary Work…1330

Steering Column (with AutoTrac™ Integrated)—Exploded View…1331

AutoTrac™ Integrated—Components…1333

Remove and Install AutoTrac™ Integrated Steering Valve…1334

Replace Solenoid Valves…1337

Section 60B: Brakes…1339

Group 05: Brake Valve…1339

Special Tools…1845

Specifications…1856

Brake Valve Repair Instructions…1344

Remove and Install Brake Valve…1345

Disassembling Brake Valve…1347

Manual Dual Stage Brake Valve—Exploded View…1352

Remove and Install the Manual Dual Stage Brake Valve…1354

Adjusting Brake Pedals…1378

Adjusting Brake Switches…1379

Group 10: Power-Fill Brake Valve…1339

Special Tools…1845

Specifications…1856

Power-Fill Brake Valve—Exploded View…1361

Remove and Install the Power-Fill Brake Valve…1363

Disassemble, Repair, and Assemble the Power-Fill Brake Valve…1365

Adjusting Brake Pedals…1378

Adjusting Brake Switches…1379

Group 15: Rear Wheel Brakes—6100J, 6115J, 6125J, and 6135J Tractors…1339

Special Tools…1845

Other Materials…1669

Specifications…1856

Rear Wheel Brakes—Exploded View…1384

Remove the Rear Wheel Brakes…1385

Inspect and Repair Rear Wheel Brakes…1402

Install the Rear Wheel Brakes…1389

Check Brake Piston Return Movement and Leaks…1391

Bleeding Brakes without Air Brakes…1406

Group 16: Rear Wheel Brakes—6150J, 6170J, 6190J, and 6210J Tractors…1339

Special Tools…1845

Specifications…1856

Rear Wheel Brakes – Exploded View…1399

Remove Rear Wheel Brakes…1400

Inspect and Repair Rear Wheel Brakes…1402

Install Rear Wheel Brakes…1404

Bleeding Brakes without Air Brakes…1406

Bleeding Brakes with Air Brakes…1410

Section 60C: Air Trailer Brake…1412

Group 05: Air Brake System…1412

Special Tools…1845

Specifications…1856

Air Brake System Repair Instructions…1416

Screw Union Installation…1417

Remove and Install Air Trailer Brake Compressor…1419

Disassemble, Repair, and Assemble Trailer Brake Air Compressor…1421

Remove and Install Compressed-Air Tank…1423

Remove and Install Pressure Control Valve…1424

Remove and Install Trailer Control Valve (Dual-Line Brakes)…1425

Remove and Install Manual Control Valve…1427

Changing Coupling Ends…1429

Test Sequence…1430

Checking System for Leaks…1431

Check Dual-Line Brakes Pressure…1432

Section 70: Hydraulic System…1434

Group 05: Hydraulic System Identification…1434

Hydraulic System Identification of Type…1436

Section 70A: Hydraulic System—Gear-Driven Pump (OOS Tractors)…1437

Group 05: Rockshaft Controls…1437

Special Tools…1845

Remove, Install, and Adjust the Hitch Control Lever…1441

Remove, Install, and Adjust the Selective Control Valve Levers…1443

Group 10: Hydraulic Pump…1437

Special Tools…1845

Specifications…1856

Hydraulic System Repair Instructions…1644

Hydraulic Pump—Exploded View…1627

Remove Hydraulic Pump…1637

Remove Mounting Plate…1547

Replace Lube Oil Valve…1455

Install Mounting Plate…1550

Install Hydraulic Pump…1639

Group 15: Priority Valve, Hitch Valve, and Hydraulic Oil Filter…1437

Special Tools…1845

Specifications…1856

Other Materials…1669

Hydraulic System Repair Instructions…1644

Remove and Install the Priority Valve…1466

Hitch Valve—Exploded View…1468

Remove Hitch Valve…1646

Repair Hitch Valve…1471

Remove and Install the Control Lever Console…1477

Regulating Components—Exploded View…1479

Disassemble, Repair, and Assemble the Regulating Components…1481

Install Hitch Valve…1651

Recondition Hydraulic Oil Filter…1491

Group 20: Rockshaft…1437

Special Tools…1845

Specifications…1856

Other Materials…1669

Rockshaft—Exploded View…1675

Remove and Install Rockshaft…1679

Remove and Install Lift Cylinders…1684

Repair Lift Cylinders…1502

Remove and Install Draft Link Bearing Pins…1590

Group 25: Selective Control Valves and Quick Couplers…1438

Special Tools…1845

Other Material…1855

Specifications…1856

Remove the Selective Control Valves…1513

Repair Selective Control Valves Without Float Position…1515

Repair Selective Control Valves with Float Position…1517

Repair Inlet Plate…1519

Repair Outlet Plate…1521

Install the Selective Control Valves…1522

Quick Couplers—Exploded View…1524

Remove and Install Quick Couplers…1717

Disassemble, Repair, and Assemble Quick Couplers…1526

Section 70B: Hydraulic System—Gear-Driven Pump (Cab Tractors)…1528

Group 05: Rockshaft Controls…1528

Special Tools…1845

Specifications…1856

Selective Control Valves — Removing and Installing Actuating Elements…1616

Selective Control Valves — Adjusting Bowden Cable…1620

Group 10: Hydraulic Pump…1528

Special Tools…1845

Specifications…1856

Hydraulic System Repair Instructions…1644

Hydraulic Pump—Exploded View…1627

Remove Hydraulic Pump…1637

Remove Mounting Plate…1547

Replace Lube Priority Valve…1549

Install Mounting Plate…1550

Install Hydraulic Pump…1639

Group 15: Valve Block…1528

Special Tools…1845

Specifications…1856

Hydraulic System Repair Instructions…1644

Remove Hitch Valve…1646

Disassemble, Repair, and Assemble Hitch Valve…1648

Install Hitch Valve…1651

Remove and Install Stepper Motor…1653

Remove Priority Valves 1 and 3…1568

Disassemble, Repair, and Assemble Priority Valves 1 and 3…1570

Install Priority Valve 1 and 3…1574

Group 20: Rockshaft…1528

Special Tools…1845

Other Materials…1669

Specifications…1856

Position Sensor and Toothed Segment—Exploded View…1671

Remove and Install Position Sensor and Toothed Segment…1672

Rockshaft—Exploded View…1675

Remove and Install Rockshaft…1679

Remove and Install Lift Cylinders…1684

Remove and Install Draft Link Bearing Pins…1590

Group 25: Selective Control Valves and Quick Couplers…1529

Special Tools…1845

Specifications…1856

Repair Instructions for the Selective Control Valves (SCVs) and Couplers…1701

Remove Selective Control Valves (SCVs)…1703

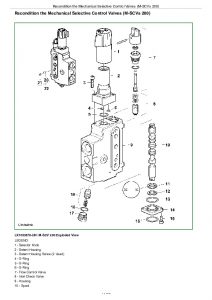

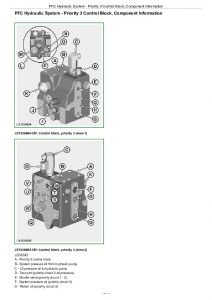

Recondition the Mechanical Selective Control Valves (M-SCVs 200)…1705

Recondition the Selective Control Valves (M-SCVs 450)…1708

Install Selective Control Valves (SCVs)…1711

Remove and Install Quick Couplers…1717

Section 70C: Hydraulic System—Axial Piston Pump (Cab Tractors)…1611

Group 05: Rockshaft Controls…1611

Special Tools…1845

Specifications…1856

Selective Control Valves — Removing and Installing Actuating Elements…1616

Selective Control Valves — Adjusting Bowden Cable…1620

Group 10: Charge Pump and Hydraulic Pump…1611

Special Tools…1845

Specifications…1856

Charge Pump—Exploded View…1624

Remove and Install Charge Pump…1625

Hydraulic Pump—Exploded View…1627

Remove, Inspect, and Install Lube Oil Valve…1629

Hydraulic Oil Reservoir — Restrictor…1630

Pressure and Flow Regulator—Exploded View…1631

Remove, Inspect, and Install Pressure and Flow Regulator…1633

Repair Pressure and Flow Regulator…1635

Remove Hydraulic Pump…1637

Install Hydraulic Pump…1639

Group 15: Valve Block…1611

Special Tools…1845

Specifications…1856

Hydraulic System Repair Instructions…1644

Remove Hitch Valve…1646

Disassemble, Repair, and Assemble Hitch Valve…1648

Install Hitch Valve…1651

Remove and Install Stepper Motor…1653

Remove Priority Valve 1…1654

Disassemble, Repair, and Assemble Priority Valve 1…1655

Install Priority Valve 1…1657

Remove Priority Valves 2 and 3…1658

Disassemble, Repair, and Assemble Priority Valves 2 and 3…1661

Install Priority Valves 2 and 3…1665

Group 20: Rockshaft…1612

Special Tools…1845

Other Materials…1669

Specifications…1856

Position Sensor and Toothed Segment—Exploded View…1671

Remove and Install Position Sensor and Toothed Segment…1672

Rockshaft—Exploded View…1675

Remove and Install Rockshaft…1679

Remove and Install Rockshaft Support…1682

Remove and Install Lift Cylinders…1684

Draft Sensor and Draft Link Support—Exploded View…1686

Remove and Install Draft Link Support…1690

Group 25: Selective Control Valves and Quick Couplers…1612

Special Tools…1845

Specifications…1856

Repair Instructions for the Selective Control Valves (SCVs) and Couplers…1701

Remove Selective Control Valves (SCVs)…1703

Recondition the Mechanical Selective Control Valves (M-SCVs 200)…1705

Recondition the Selective Control Valves (M-SCVs 450)…1708

Install Selective Control Valves (SCVs)…1711

Remove and Install Quick Couplers…1717

Section 80: Miscellaneous…1719

Group 05: Remove and Install Components…1719

Special Tools…1845

Specifications…1856

Remove and Install Hood…1723

Remove and Install Main Frame—6100J, 6115J, 6125J, and 6135J Tractors…1725

Remove and Install Main Frame—6150J, 6170J, 6190J, and 6210J Tractors…1731

Remove and Install Front Axle—Standard Front Axle…1738

Remove and Install Front Axle—John Deere 3 Meters Front Axle…1742

Group 10: Main Frame…1719

Special Tools…1845

Specifications…1856

Repair Main Frame…1748

Group 15: Front Wheels, Rear Wheels and Fenders…1719

Special Tools…1845

Specifications…1856

Remove and Install Front Fenders…1756

Remove and Install Front and Rear Wheels…1763

Repair Front and Rear Wheels…1767

Service Heavy-Duty Wheel Clamps…1773

Group 20: Center Link Bracket and Swinging Drawbar…1719

Specifications…1856

Check Swinging Drawbar Wear…1781

Remove and Install Center Link Bracket…1782

Repair Swinging Drawbar—6100J, 6115J, 6125J, and 6135 Tractors…1784

Repair Swinging Drawbar—6150J, 6170J, 6190J, 6210J Tractors…1788

Repair Swinging Drawbar—6150J, 6170J, 6190J, 6210J Tractors…1788

Repair Drawbar with Ball Pin—6170J, 6190J, and 6210J Tractors…1790

Adjust Hammer Strap…1792

Section 90A: Open Operator's Station…1793

Group 05: Remove and Install Components…1793

Specifications…1856

Remove and Install Open Operator's Station…1796

Remove and Install Open Operator’s Station Console Cover…1804

Group 10: Open Operator's Station…1793

Specifications…1856

Remove and Install Open Operator’s Station Roof…1808

Section 90B: Cab…1810

Group 05: Remove and Install Components…1810

Special Tools…1845

Specifications…1856

Cab Mounts—Exploded View…1815

Swing Up Cab…1818

Swing Down Cab…1826

Remove and Install Cab…1830

Remove and Install Front Console Cover…1841

Group 10: Air-Conditioning System…1810

Special Tools…1845

Tightening Torque for Refrigerant Hoses…1846

Safety Regulations…1847

Handling Refrigerant…1848

Air Conditioning System – Safety at Work…1849

Storage of Refrigerant Containers…1851

Refrigerant R134a…1852

Air Conditioning System – Preventive Maintenance…1853

Important…1854

Other Material…1855

Specifications…1856

General information…1857

Air conditioning system – Instructions for starting up the DENSO air conditioning compressor…1858

Filling the Cylinder…1859

Charging Air Conditioning System (With Loading Cylinder)…1861

Charging Air Conditioning System (With Recovery/Recycling and Charging Station)…1863

Adding Oil to the Air Conditioning System…1864

Leak Test…1865

Evacuate Air Conditioning System…1866

Cleaning the Air Conditioning System…1868

Remove and Install Compressor…1869

Check Refrigerant Oil Level…1873

Disassemble and Assemble Magnetic Clutch of Air Conditioner Compressor…1874

Check Clutch Hub Clearance…1876

Remove and Install Condenser…1877

Replace Air Conditioner Receiver-Drier…1879

Replace Expansion Valve…1880

Remove and Install Evaporator and Expansion Valve…1881

Installing Condensation Water Drain Hoses…1883

Layout of Condensation Water Drain Hoses…1884

Vacuum Pump — General Information…1885

Group 15: Heating System…1811

Fan and Heater, Disassembling…1888

Replace Cab Air Filter…1890

Separating and Installing Fan…1892

Separating and Installing Heater Regulator…1893

Separating Heater/Evaporator Housing…1894

Group 20: Operator's Cab…1811

Removing Cab Frame…1897

Remove and Install Outer Roof…1898

Removing and Installing Windshield…1899

Remove and Install Rear Window…1900

Installing Door Lock…1902

Adjusting Window Contact Pressure…1904

Remove and Install Operator's Cab Door…1905

Removing and Installing Sun-Visor Roller…1907

Remove and Install Operator’s Seat…1908

Remove and Install Instructional Seat…1910

Section 99: Tools…1911

Group 05: Special Tools (Dealer-Fabricated)…1911

DFLX1 – Adapter Strut…1913

DFLX7 – Turning Device…1914

DFLX13 – Holding Device…1915

DFLX15 – Holding Device for Tractor Components…1916

DFLX29 – Support…1917

DFLX42 – Turning Device…1918

Lifting Device…1919

Suspension Device…1920

Suspension Eyes for Operator's Cab…1921

Holding Tool…1922

Wooden Block…1923

DFRW79 – Piston Retainer Tool…1924

Retainer Installer…1925

Retainer…1926

Socket Wrench Insert…1927

Seal Installer…1928

Assembling and Guide Drivers…1929

Special Wrench…1930

Bushing…1931

Quick Coupler Securing Support…1932

Lifting Tool…1933

John Deere Tractors 6100J, 6115J, 6125J, 6135J, 6150J, 6170J, 6190J, 6210J Repair Service Manual (TM808719)