Complete service repair manual with Electrical Wiring Diagrams for Mercedes-Benz Model 123 , with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Mercedes-Benz Model 123 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

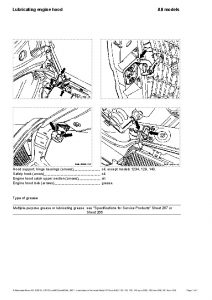

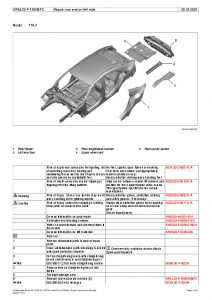

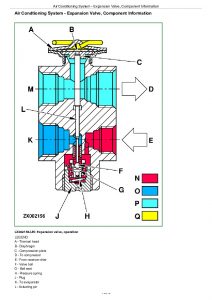

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,612 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

MAKE: Mercedes-Benz

YEAR: 1976 1977 1978 1979 1980 1981 1982 1983 1984 1985

LANGUAGE: German

MODEL: Typ-123 Limousine, T-Limousine, Coupe (200 bis 300 TD) (W123/V123/C123/S123/F123)

Verkaufsbezeichnung Typ Motor

200 123.020 115.938, 115.939 NV

200 123.220 115.920, 115.939 NV

200 T 123.280 115.920, 115.939 NV

230 123.023 115.954, 115.954 NV

230 E 123.223 102.980 KA, 102.980 NV KA

230 T 123.083 115.954, 115.954 NV

230 TE 123.283 102.980 KA, 102.980 NV KA

230 C 123.043 115.954, 115.954 NV

230 CE 123.243 102.980 KA, 102.980 NV KA

230 Spezialaufbau 123.000 115.954, 115.954 NV

230 E Spezialaufbau 123.200 102.980 KA, 102.980 NV KA

250 123.026 123.920, 123.920 NV, 123.921, 123.921 NV

250 lang 123.028 123.920, 123.920 NV, 123.921, 123.921 NV

250 T 123.086 123.920, 123.920 NV, 123.921, 123.921 NV

250 Spezialaufbau 123.003 123.920, 123.920 NV, 123.921, 123.921 NV

280 123.030 110.923, 110.923 NV

280 E 123.033 110.984 KA, 110.988 KA

280 TE 123.093 110.984 KA, 110.988 KA

280 C 123.050 110.923, 110.923 NV

280 CE 123.053 110.984 KA, 110.988 KA

280 E Spezialaufbau 123.007 110.984 KA, 110.988 KA

200 D 123.120 615.940

220 D 123.126 615.941

240 D 123.123 616.912

240 D lang 123.125 616.912

240 TD 123.183 616.912

240 D Spezialaufbau 123.102 616.912

240 D lang Spezialaufbau 123.103 616.912

300 D 123.130 617.912

300 D (J)(USA) Turbodiesel 123.133 617.952

300 D lang 123.132 617.912

300 TD 123.190 617.912

300 TD Turbodiesel 123.193 617.952

300 CD (USA) 123.150 617.912

300 CD Turbodiesel (USA) 123.153 617.952

300 D lang Spezialaufbau 123.105 616.912

Mercedes-Benz Model 123 Repair Service Manual.pdf

000_Overall Vehicle…………….3

00.00 – 000 588 00 28 00 Thread tap (ws00.00-p-0083k)…………….12

00.00 – 000 588 00 80 00 Vehicle lift (ws00.00-p-0040b)…………….13

00.00 – 000 588 01 80 00 Swivel arm vehicle lift (ws00.00-p-0041b)…………….14

00.00 – 000 588 02 80 00 Swivel arm ram-type lift (ws00.00-p-0042b)…………….15

00.00 – 000 588 05 80 00 Pit lift (ws00.00-p-0248b)…………….16

00.00 – 000 588 05 90 00 Clamping grommet (ws00.00-p-0036b)…………….17

00.00 – 000 588 07 80 00 Flat beam vehicle lift (ws00.00-p-0043b)…………….18

00.00 – 000 588 08 80 00 Underfloor runway vehicle lift 5.0-6.

…

00.00 – 000 589 01 10 00 Torx bit set (ws00.00-n-0001z)…………….33

00.00 – 000 589 01 40 00 Bracket (ws00.00-p-0244z)…………….34

00.00 – 000 589 10 99 00 Tool kit (ws00.00-p-0030z)…………….35

00.00 – 000 589 25 33 00 Internal extractor (ws00.00-n-0050z)…………….36

00.00 – 000 589 28 33 00 Puller dia. 28-37 mm (ws00.00-n-3026z)…………….37

00.00 – 000 589 29 33 00 Internal extractor (ws00.00-n-3027z)…………….38

00.00 – 000 589 30 16 00 Hexagon ratchet, 10 mm (ws00.00-p-0002z)…………….39

00.00 – 000 589 31 16 00 Hexagon ratchet, 13 mm (ws00.00-p-0003z)…………….40

00.00 – 000 589 32 16 00 Hexagon ratchet, 17 mm (ws00.00-p-0004z)…………….41

00.00 – 000 589 33 33 00 Counter stay (ws00.00-n-0051z)…………….42

00.00 – 000 589 35 33 00 Countersupport (ws00.00-n-3033z)…………….43

00.00 – 000 589 40 37 00 Clamp (ws00.00-p-0005z)…………….44

00.00 – 000 589 49 98 00 Oil sample container (ws00.00-p-0263b)…………….45

00.00 – 000 589 54 37 00 Clamp (ws00.00-p-0006z)…………….46

00.00 – 000 589 65 33 00 Puller (ws00.00-p-0007z)…………….47

00.00 – 000 589 67 21 00 Torque wrench (ws00.00-p-0008z)…………….48

00.00 – 000 589 68 33 00 Internal extractor (ws00.00-n-3030z)…………….49

00.00 – 000 589 75 03 00 Box wrench bit (ws00.00-p-0009z)…………….50

00.00 – 000 589 76 03 00 Box wrench (ws00.00-p-0010z)…………….51

00.00 – 000 589 87 33 00 Gripper (ws00.00-n-3054z)…………….52

00.00 – 000 589 88 33 00 Puller, two-arm (ws00.00-n-0011z)…………….53

00.00 – 000 589 89 33 00 Puller (ws00.00-n-3022z)…………….54

00.00 – 001 589 00 16 00 Adapter coupling (ws00.00-p-0120z)…………….55

00.00 – 001 589 03 91 00 Set of protective covers (ws00.00-p-3069b)…………….56

00.00 – 001 589 51 21 00 Torque wrench (ws00.00-p-0012z)…………….57

00.00 – 001 589 53 21 00 Dial gage (ws00.00-n-0013z)…………….58

00.00 – 001 589 66 21 00 Torque wrench (ws00.00-n-0015z)…………….59

00.00 – 001 589 67 21 00 Torque wrench (ws00.00-n-0016z)…………….60

00.00 – 001 589 72 21 00 Torque wrench (ws00.00-p-0017z)…………….61

00.00 – 001 589 73 21 00 Hand vacuum pump (ws00.00-p-0018z)…………….62

00.00 – 001 589 74 21 00 Torque wrench (ws00.00-n-0019z)…………….63

00.00 – 001 589 75 21 00 Torque wrench (ws00.00-n-3049b)…………….64

00.00 – 001 589 76 09 00 External torx set (ws00.00-n-0020z)…………….65

00.00 – 001 589 81 09 00 Set of flexible head wrenches (ws00.00-p-0251b)…………….66

00.00 – 001 589 81 21 00 Torque screwdriver (ws00.00-n-0021z)…………….67

00.00 – 001 589 87 21 00 Torque wrench (ws00.00-p-0119z)…………….68

00.00 – 003 589 05 09 00 Torque tool set (ws00.00-n-0261a)…………….69

00.00 – 003 589 06 09 00 Plug-in wrench (ws00.00-p-0262a)…………….70

00.00 – 100 589 02 59 00 Adapter (ws00.00-p-0022z)…………….71

00.00 – 110 589 03 59 00 Mounting wedge (ws00.00-p-0274k)…………….72

00.00 – 112 589 00 25 00 Squeeze gun (ws00.00-p-0052z)…………….73

00.00 – 116 589 02 07 00 Screwdriver, 5 mm (ws00.00-n-0023z)…………….74

00.00 – 116 589 03 07 00 T-handle Allen wrench (ws00.00-p-0024z)…………….75

00.00 – 117 589 02 07 00 Pin box wrench (ws00.00-p-0054z)…………….76

00.00 – 123 589 00 16 00 Extension (ws00.00-p-0025z)…………….77

…

18.00 – Test Sheet for Oil Consumption Test Model des. 107, 116, 123, 126 (wb6516lit7491z)…………….439

18.00 – Test Sheet for Oil Consumption Test Model des. 123, 102.920_939_980 (wb6516lit7493z)…………….441

18.00 – Test Sheet for Oil Consumption Test Models 107 w_ Engine 110.986, 116 w_ Engines 110.922_932_985, and 123 w_ Engines 110.923_984_920 (wb6516lit7462z)…………….443

18.00 – Test Sheet for Oil Consumption Test Models 116 w_ Engine 617.950, 123 w_ Engines 615.940_941, 616.912, 617.912_952 and 126 w_ Engine 617.951 (wb6516lit7461z)…………….445

18.00 – Test and adjustment values Passenger cars Engine lubrication, engine oil cooling (be18.00-z-9999az)…………….447

18.00 – Test sheet for oil consumption test (Weight method) Passenger cars and cross country vehicles (wb6516lit7401z)…………….449

020_Engine Cooling System…………….451

20.00 – 000 589 77 63 00 Adapter (ws20.00-p-0002b)…………….452

20.00 – 124 589 00 91 00 Test cap (ws20.00-p-0018b)…………….453

20.00 – 124 589 24 21 00 Pressure pump (ws20.00-p-0016b)…………….454

20.00 – 2050 – Cooling and heating system – Checking the condition and for leaks Models 107 to 07_85, 123, 126 to 08_85, 201 to 12_84 (wh2050pkw0000x)…………….455

20.00 – 285 589 00 21 00 Cooler vacuum filling device (ws20.00-p-0030b)…………….456

20.00 – 454 589 00 37 00 Hose clamp pliers (ws20.00-p-0052b)…………….457

20.00 – Capacities Passenger cars Engine cooling system (bf20.00-z-9999az)…………….458

20.00 – Safety information Engine cooling system (as20.00-z-9999zz)…………….459

20.00 – Technical modifications Passenger cars Engine cooling system (bt20.00-z-9999az)…………….460

20.00 – Test and adjustment values Passenger cars Engine cooling system (be20.00-z-9999az)…………….461

20.00 – Tightening torques Passenger cars Engine cooling system (ba20.00-z-9999az)…………….462

022_Engine Suspension…………….464

22.00 – 001 589 01 16 00 Engine mount wrench set (ws22.00-p-0008b)…………….465

22.00 – Safety information Engine suspension (as22.00-z-9999zz)…………….466

22.20 – 2291 – Slackening the engine stop Engine 102 in Model 123; Engines 615, 616, 617.91 in Model 126 from 9_85 (wh2291pkw0010x)…………….467

025_Clutch…………….470

25.00 – 000 588 01 82 00 Filling unit (ws25.00-p-0016b)…………….471

25.00 – 000 589 47 31 00 Alignment tool (ws25.00-p-0003b)…………….472

25.00 – 115 589 07 23 00 Inspection gauge (ws25.00-n-0001a)…………….473

25.00 – 201 589 08 15 00 Alignment punch (ws25.00-n-0002b)…………….474

25.00 – Safety information Clutch (as25.00-z-9999zz)…………….475

25.00 – Technical modifications Passenger cars Clutch (bt25.00-z-9999az)…………….476

25.00 – Test and adjustment values Passenger cars Clutch (be25.00-z-9999az)…………….477

25.00 – Tightening torques Passenger cars Clutch (ba25.00-z-9999az)…………….478

25.10 – 2551 – Checking the clutch plate wear Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh2551pkw0000x)…………….479

25.20 – 2910 – Clutch actuation Checking and correcting the fluid level Models 107 to 07_85; 123; 126 to 08_85; 201 to 12_84 (wh2910pkw0000x)…………….480

25.20 – 2950 – Checking clutch actuation for leaks and condition Models 107 to 07_85; 123; 126 to 08_85; 201 to 12_84 (wh2950pkw0000x)…………….481

026_Manual Transmission…………….482

26.00 – 000 588 04 19 00 Articulation angle inclinometer (ws26.00-p-0140b)…………….484

26.00 – 000 588 10 19 00 Adapter standard kit (ws26.00-p-0230b)…………….485

26.00 – 000 588 10 62 00 Support plate (ws26.00-p-3309b)…………….486

26.00 – 000 588 12 19 00 Inclinometer collet (ws26.00-p-0232b)…………….487

26.00 – 000 588 14 19 00 Inclinometer adapter (ws26.00-p-0234b)…………….488

26.00 – 000 589 24 07 00 Box wrench for Allen socket (ws26.00-p-0001a)…………….489

26.00 – 000 589 52 37 00 Pliers (ws26.00-p-0005c)…………….490

26.00 – 001 589 02 33 00 Puller (ws26.00-p-0010c)…………….491

26.00 – 115 589 01 07 00 Pin wrench socket (ws26.00-p-0013b)…………….492

26.00 – 116 589 02 09 00 Socket (ws26.00-n-0014c)…………….493

26.00 – 117 589 02 07 00 Pin ring wrench (ws26.00-p-0018a)…………….494

26.00 – 123 589 02 33 00 Puller (ws26.00-p-0021c)…………….495

26.00 – 124 589 06 15 00 Drift punch (ws26.00-p-0032c)…………….496

26.00 – 126 589 02 09 00 Socket wrench bit (ws26.00-p-0038b)…………….497

26.00 – 129 589 01 07 00 Pin wrench (ws26.00-p-0041b)…………….498

26.00 – 129 589 01 33 00 Puller (ws26.00-p-0042b)…………….499

26.00 – 140 589 00 03 00 Box wrench socket (ws26.00-p-0044b)…………….500

26.00 – 210 589 00 37 00 Pliers (ws26.00-p-0051b)…………….501

26.00 – 711 589 03 15 00 Drift (ws26.00-n-3263b)…………….502

26.00 – 716 589 00 40 00 Set of brackets (ws26.00-p-0103b)…………….503

26.00 – Capacities Passenger cars Manual transmission (bf26.00-z-9999az)…………….504

26.00 – Forms Passenger cars Manual transmission (of26.00-z-3999az)…………….505

26.00 – Safety information Manual transmission (as26.00-z-9999zz)…………….506

26.00 – Technical modifications Passenger cars Manual transmission (bt26.00-z-9999az)…………….507

26.00 – Test and adjustment values Passenger cars Manual transmission (be26.00-z-9999az)…………….508

26.00 – Tightening torques Passenger cars Manual transmission (ba26.00-z-9999az)…………….509

26.10 – 2601 – Manual transmission, Oil change Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh2601pkw0000x)…………….510

027_Automatic Transmission…………….512

27.00 – 115 589 01 07 00 Pin wrench socket (ws27.00-p-0005b)…………….513

27.00 – 115 589 08 07 00 Pin wrench socket (ws27.00-p-0006b)…………….514

27.00 – 116 589 00 15 00 Drive shaft (ws27.00-p-0010c)…………….515

27.00 – 126 589 00 35 00 Assembly device (ws27.00-n-0020c)…………….516

27.00 – 168 589 00 62 00 Handle (ws27.00-p-0062b)…………….517

27.00 – 201 589 03 59 00 Assembly device (ws27.00-n-0043c)…………….518

27.00 – 210 589 00 37 00 Pliers (ws27.00-p-0054b)…………….519

27.00 – 725 589 07 15 00 Drift (ws27.00-p-0187b)…………….520

27.00 – Capacities Passenger cars Automatic transmission (bf27.00-z-9999az)…………….521

27.00 – Forms Passenger cars Automatic transmission (of27.00-z-3999az)…………….522

27.00 – Technical modifications Passenger cars Automatic transmission (bt27.00-z-9999az)…………….523

27.00 – Test and adjustment values Passenger cars Automatic transmission (be27.00-z-9999az)…………….525

27.00 – Tightening torques Passenger cars Automatic transmission (ba27.00-z-9999az)…………….527

27.19 – Service Information Damage code for transmission software release (si27.19-p-0011a)…………….528

028_Transfer Case…………….529

28.00 – Basic function of automatically controlled all-wheel drive (gf28.00-p-9900a)…………….530

28.00 – Capacities Passenger cars Transfer case (bf28.00-z-9999az)…………….531

28.00 – General notes Passenger cars Transfer case (ah28.00-z-9999az)…………….532

28.00 – Technical modifications Passenger cars Transfer case (bt28.00-z-9999az)…………….533

28.00 – Test and adjustment values Passenger cars Transfer case (be28.00-z-9999az)…………….534

28.00 – Tightening torques Passenger cars Transfer case (ba28.00-z-9999az)…………….535

029_Pedal Assembly…………….536

29.00 – Safety information Pedal assembly (as29.00-z-9999zz)…………….537

29.00 – Tightening torques Passenger cars Pedal assembly (ba29.00-z-9999az)…………….538

030_Throttle Control, Speed Control Systems…………….539

30.00 – Certificates Passenger cars Throttle control, cruise control system (of30.00-z-1999az)…………….540

30.00 – General notes Passenger cars Throttle control, cruise control system (ah30.00-z-9999az)…………….541

30.00 – Safety information Throttle control, cruise control system (as30.00-z-9999zz)…………….542

30.00 – Technical modifications Passenger cars Throttle control, cruise control system (bt30.00-z-9999az)…………….543

30.00 – Test and adjustment values Passenger cars Throttle control, cruise control system (be30.00-z-9999az)…………….544

30.00 – Tightening torques Passenger cars Throttle control, cruise control system (ba30.00-z-9999az)…………….545

30.30 – Collision warning system controller unit, basic function (gf30.30-p-9893a)…………….546

30.30 – Distance control controller unit, basic function (gf30.30-p-9891a)…………….547

30.30 – Distance control, basic function (gf30.30-p-9903a)…………….548

30.30 – Intelligent driving control unit, basic function (gf30.30-p-9890a)…………….551

30.30 – Service Information Warranty and goodwill policy for short-range radar sensors (si30.30-p-0003a)…………….552

30.30 – Speed adjustment, basic function (gf30.30-p-9900a)…………….553

30.30 – Speed control, basic function (gf30.30-p-9901a)…………….555

30.30 – Speed limit, basic function (gf30.30-p-9902a)…………….556

031_Frame, Trailer Operation…………….557

31.00 – Certificates Passenger cars Frame, trailer operation (of31.00-z-1999az)…………….558

31.00 – Forms Passenger cars Frame, trailer operation (of31.00-z-3999az)…………….559

31.00 – Test and adjustment values Passenger cars Frame, trailer operation (be31.00-z-9999az)…………….560

31.00 – Tightening torques Passenger cars Frame, trailer operation (ba31.00-z-9999az)…………….561

31.19 – Trailer recognition control unit, basic function (gf31.19-p-9890a)…………….562

032_Suspension…………….563

32.00 – 000 589 12 28 00 Knife (ws32.00-n-3046d)…………….566

32.00 – 116 589 00 17 00 Box wrench (ws32.00-p-0004b)…………….567

32.00 – 116 589 04 09 00 Retainer wrench (ws32.00-p-0007b)…………….568

32.00 – 126 589 12 63 00 Funnel (ws32.00-p-0016a)…………….569

32.00 – 126 589 14 21 00 Tester (ws32.00-p-0017b)…………….570

32.00 – 202 589 00 09 00 Socket wrench (ws32.00-p-0024b)…………….571

32.00 – 202 589 01 31 00 Tensioning device (ws32.00-p-0040b)…………….572

32.00 – 202 589 02 31 00 Tensioning device (ws32.00-p-0041b)…………….573

32.00 – 202 589 13 63 00 Clamping plates (ws32.00-p-0042b)…………….574

32.00 – 202 589 14 63 00 Tensioning plates (ws32.00-p-0043b)…………….575

32.00 – Bescheinigungen Personenwagen Federung (of32.00-z-1999az)…………….576

32.00 – Capacities Passenger cars Suspension (bf32.00-z-9999az)…………….577

32.00 – Locate noises from the suspension (ar32.00-p-2000a)…………….578

32.00 – Safety information Suspension (as32.00-z-9999zz)…………….580

32.00 – Suspension and damping, basic function (gf32.00-p-9900a)…………….581

32.00 – Technical modifications Passenger cars Suspension (bt32.00-z-9999az)…………….582

32.00 – Test and adjustment values Passenger cars Suspension (be32.00-z-9999az)…………….583

32.00 – Tightening torques Passenger cars Suspension (ba32.00-z-9999az)…………….584

32.22 – Air suspension control unit, basic function (gf32.22-p-9890a)…………….587

32.25 – 0510 – Checking the spring struts Level control Models 107, 114, 115, 116, 123, 126 (ra32001070510z)…………….588

32.25 – 0610 – Removal and installation of the spring struts Level control Models 107, 114, 115, 116, 123, 126 (ra32001070610z)…………….591

32.25 – 0612 – Checking and replacing suspension of spring strut Models 107, 114, 115, 116, 123, 126 (T-sedans) (ra32001070612z)…………….603

32.25 – Service Information Assembly of suspension struts and shock absorbers (si32.25-p-0004a)…………….606

32.25 – Service Information Check shock absorbers (si32.25-d-0001bm)…………….607

32.25 – Service Information Lift vehicle in freezing temperatures (si32.25-p-0007a)…………….608

32.30 – 0520 – Checking the pressure reservoir Level control Models 107, 114, 115, 116, 123, 126 (ra32001070520z)…………….609

32.30 – 0530 – Checking the pressure oil-pump and level controller Level control Models 107, 114, 115, 116, 123, 126 (ra32001070530z)…………….614

32.30 – 0620 – Removal and installation of the pressure reservoir Level control Models 107, 114, 115, 116, 123, 126 (ra32001070620z)…………….620

32.30 – 0630 – Draining and filling the pressure oil system Level control Models 107, 114, 115, 116, 123, 126 (ra32001070630z)…………….622

32.30 – 0640 – Removal and installation of the pressure oil-pump Level control Models 107, 114, 115, 116, 123, 126 (ra32001070640z)…………….627

32.30 – 0641 – Conversion of suction and pressure line Level Control Model 123 with diesel engine 3rd version (ra32001070641z)…………….638

32.30 – 0645 – Removal and installation of the pressure oil pump radial sealing ring Level control Models 107, 114, 115, 116, 123, 126 (ra32001070645z)…………….643

32.30 – 0660 – Removal and installation of the level controller connecting rod Level control Models 107, 114, 115, 116, 123, 126 (ra32001070660z)…………….645

32.30 – 0670 – Removal and installation of the level controller Level control Models 107, 114, 115, 116, 123, 126 (ra32001070670z)…………….651

32.30 – 0671 – Conversion of oil lines between level controller and pressure reservoir Production breakpoint Models 107, 116, 123, 126 (ra32001070671z)…………….659

32.30 – 3251 – Checking condition of level control and for leaks Models 107 to 07_85; 123; 126 to 08_85; 201 to 12_84 (wh3251pkw0000x)…………….662

033_Front Axle…………….663

33.00 – 000 588 04 31 00 Assembly device (ws33.00-p-0027b)…………….665

33.00 – 000 588 07 31 00 Axle mount adapter (ws33.00-n-0249b)…………….666

33.00 – 000 589 00 34 00 Chuck (ws33.00-p-0001c)…………….667

33.00 – 001 589 50 33 00 Puller (ws33.00-p-0003c)…………….668

33.00 – 116 589 04 62 00 Installation tool (ws33.00-p-0010c)…………….669

33.00 – 116 589 09 33 00 Puller (ws33.00-p-0012c)…………….670

33.00 – 116 589 11 43 00 Installation tool (ws33.00-p-0013c)…………….671

33.00 – 116 589 16 33 00 Puller (ws33.00-p-0014c)…………….672

33.00 – 116 589 22 33 00 Removal and installation tool (ws33.00-p-0016a)…………….673

33.00 – 140 589 00 01 00 Open-end wrench (ws33.00-p-0030c)…………….674

33.00 – 201 589 10 33 00 Impact extractor (ws33.00-p-0052c)…………….675

33.00 – 203 589 03 33 00 Internal extractor (ws33.00-p-0148b)…………….676

33.00 – 210 589 03 43 00 Extraction and insertion tool (ws33.00-p-0115b)…………….677

33.00 – 210 589 06 43 00 Extraction tool (ws33.00-p-0135b)…………….678

33.00 – Anziehdrehmomente Personenwagen Vorderachse (ba33.00-z-9999az)…………….679

33.00 – Capacities Passenger cars Front axle (bf33.00-z-9999az)…………….681

33.00 – Forms Passenger cars Front axle (of33.00-z-3999az)…………….682

33.00 – Locate noises from the front axle (ar33.00-p-2000a)…………….683

33.00 – Service-Information Geräusche Vorderachsgetriebe (si33.00-p-0003a)…………….685

33.00 – Technical modifications Front axle Model 123 (ra3303123ta00z)…………….686

33.00 – Technical modifications Passenger cars Front axle (bt33.00-z-9999az)…………….687

33.00 – Test and adjustment values Passenger cars Front axle (be33.00-z-9999az)…………….688

33.10 – 0200 – Removal and installation of the front axle half Models 123, 126 (ra33041230200z)…………….689

33.15 – 0515 – Removal and installation of brake support Front Axle in Model 123 (ra33031230515z)…………….697

33.15 – 3353 – Checking condition of the front axle joints A. Supporting joint, B. Follower joint Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh3353pkw0000x)…………….702

035_Rear Axle…………….705

35.00 – 000 589 02 34 00 Collet chuck (ws35.00-p-0002c)…………….708

35.00 – 000 589 03 34 00 Thrust piece (ws35.00-p-0003c)…………….709

35.00 – 000 589 24 07 00 Box wrench for Allen socket (ws35.00-p-0004a)…………….710

35.00 – 000 589 33 34 00 Tensioning clamp (ws35.00-p-0005c)…………….711

35.00 – 000 589 38 19 00 Dial gage (ws35.00-p-0007c)…………….712

35.00 – 000 589 63 34 00 Extension (ws35.00-p-0008c)…………….713

35.00 – 001 589 49 21 00 Torque measuring instrument (ws35.00-p-0009b)…………….714

35.00 – 001 589 50 33 00 Puller (ws35.00-p-0010c)…………….715

35.00 – 111 589 08 23 00 Dial gauge holder (ws35.00-p-0012c)…………….716

35.00 – 115 589 00 33 00 Puller (ws35.00-p-0013c)…………….717

35.00 – 115 589 01 07 00 Pin wrench socket (ws35.00-p-0015b)…………….718

35.00 – 115 589 02 07 00 Pin wrench (ws35.00-p-0016c)…………….719

35.00 – 115 589 02 43 00 Drift punch (ws35.00-p-0017c)…………….720

35.00 – 115 589 04 61 00 Assembly drift (ws35.00-p-0018c)…………….721

35.00 – 115 589 05 21 00 Adjusting gauge (ws35.00-p-0019c)…………….722

35.00 – 116 589 07 21 00 Measuring device (ws35.00-p-0030c)…………….723

35.00 – 116 589 11 31 00 Clamping jaws (ws35.00-p-0035c)…………….724

35.00 – 116 589 11 61 00 Installer (ws35.00-p-0036c)…………….725

35.00 – 116 589 13 43 00 Puller and installation tool (ws35.00-p-0037c)…………….726

35.00 – 116 589 15 15 00 Drift (ws35.00-p-0038c)…………….727

35.00 – 116 589 18 61 00 Assembly drift (ws35.00-p-0040c)…………….728

35.00 – 117 589 02 07 00 Pin ring wrench (ws35.00-p-0041a)…………….729

35.00 – 123 589 06 15 00 Assembly drift (ws35.00-p-0043c)…………….730

35.00 – 123 589 08 33 00 Puller (ws35.00-p-0044c)…………….731

35.00 – 124 589 02 15 00 Drift (ws35.00-p-0048b)…………….732

35.00 – 126 589 00 15 00 Drift (ws35.00-p-0057c)…………….733

35.00 – 126 589 00 21 00 Measuring device (ws35.00-p-0058c)…………….734

35.00 – 126 589 00 31 00 Spreader (ws35.00-p-0059c)…………….735

35.00 – 126 589 02 09 00 Socket wrench bit (ws35.00-p-0062b)…………….736

35.00 – 126 589 08 21 00 Contact arm (ws35.00-p-0065c)…………….737

35.00 – 129 589 01 07 00 Pin wrench (ws35.00-p-0071b)…………….738

35.00 – 129 589 01 33 00 Puller (ws35.00-p-0072b)…………….739

35.00 – 136 589 05 31 00 Retaining plate (ws35.00-p-0077c)…………….740

35.00 – 140 589 00 01 00 Open-end wrench (ws35.00-p-0078c)…………….741

35.00 – 140 589 06 15 00 Drift (ws35.00-p-0100c)…………….742

35.00 – 201 589 01 63 00 Stops (ws35.00-p-0128c)…………….743

35.00 – 201 589 02 31 00 Plate (ws35.00-p-0130c)…………….744

35.00 – 201 589 02 43 00 Removal and installation tool (ws35.00-p-0132c)…………….745

35.00 – 201 589 10 33 00 Impact extractor (ws35.00-p-0139c)…………….746

35.00 – 210 589 03 43 00 Extraction and insertion tool (ws35.00-p-0154c)…………….747

35.00 – Capacities Passenger cars Rear axle (bf35.00-z-9999az)…………….748

35.00 – Forms Passenger cars Rear axle (of35.00-z-3999az)…………….749

35.00 – Locate noises from rear axle (ar35.00-p-2000a)…………….750

35.00 – Service Information Repair information on self-locking threaded connections at the axle mounts (si35.00-p-0005a)…………….752

35.00 – Service information Differential leaky (si35.00-p-0004a)…………….753

35.00 – Service-Information Geräusche Hinterachsgetriebe (si35.00-p-0002a)…………….754

35.00 – Technical modifications Passenger cars Rear axle (bt35.00-z-9999az)…………….755

35.00 – Test and adjustment values Passenger cars Rear axle (be35.00-z-9999az)…………….757

35.00 – Tightening torques Passenger cars Rear axle (ba35.00-z-9999az)…………….758

35.10 – 3501 – Oil change in the rear axle Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh3501pkw0000x)…………….761

35.10 – 3510 – Rear axle, Checking and correction of oil level Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh3510pkw0000x)…………….763

040_Wheels, Chassis Alignment Check…………….765

40.00 – 000 588 00 83 00 Tire mounting device (ws40.00-p-0006b)…………….769

…

82.00 – 000 589 30 63 00 FAKRA adapter cable (ws82.00-p-0025b)…………….1385

82.00 – 000 589 52 98 00 ESD kit (ws82.00-p-0029b)…………….1386

82.00 – 001 589 38 33 00 Puller (ws82.00-n-3001b)…………….1387

82.00 – 110 589 02 63 00 Adjusting tool (ws82.00-p-0001k)…………….1388

82.00 – 8252 – Operational check Windshield wipers, windshield washer, headlamp cleaning system Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh8252pkw0000x)…………….1389

82.00 – Capacities Passenger cars Electrical system body (bf82.00-z-9999az)…………….1393

82.00 – Forms Passenger cars Electrical system body (of82.00-z-3999az)…………….1394

82.00 – Interior equipment, basic function (gf82.00-p-9910a)…………….1395

82.00 – Safety information Electrical system body (as82.00-z-9999zz)…………….1396

82.00 – Service Information Repair of damaged audio_COMAND wiring harnesses (si82.00-p-0004a)…………….1397

82.00 – Technical modifications Passenger cars Electrical system body (bt82.00-z-9999az)…………….1398

82.00 – Test and adjustment values Passenger cars Electrical system body (be82.00-z-9999az)…………….1399

82.00 – Tightening torques Passenger cars Electrical system body (ba82.00-z-9999az)…………….1400

82.00 – User interface, basic function (gf82.00-p-9901a)…………….1401

82.10 – 8251 – Checking all the functions of the front and rear lights Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh8251pkw0000x)…………….1403

82.10 – Exterior lighting, basic function (gf82.10-p-9900a)…………….1405

82.10 – Headlamp control unit, basic function (gf82.10-p-9890a)…………….1406

82.10 – Overview – Check_correct headlamp adjustment (ap82.10-p-8249u)…………….1407

82.10 – Service Information Lamp unit in rear-mounted bicycle carrier for trailer hitch (si82.10-p-0013a)…………….1409

82.10 – Service information Notes on fogged headlamps or lamps in the outer area (si82.10-p-0001a)…………….1410

82.20 – Ambient lighting control unit, basic function (gf82.20-p-9892a)…………….1411

82.20 – Ambient lighting, basic function (gf82.20-p-9901a)…………….1412

82.20 – Interior lighting, basic function (gf82.20-p-9900a)…………….1413

82.20 – Overhead control panel control unit, basic function (gf82.20-p-9890a)…………….1414

82.25 – Special vehicle multifunction control unit, basic function (gf82.25-p-9892a)…………….1415

82.25 – Taxi, basic function (gf82.25-p-9900a)…………….1416

82.30 – 8280 – Replacing rubber section of wiper blade Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh8280pkw0000x)…………….1417

82.30 – Heat wiper blade, basic function (gf82.30-p-9902a)…………….1419

82.30 – Service Information Bulletin Wiper blades (si82.30-p-0011c)…………….1420

82.30 – Service Information Wiper arm tightening torque (si82.30-p-0009a)…………….1422

82.30 – Service information Warranty and goodwill policies for wiper blades (si82.30-p-0010a)…………….1423

82.30 – Service-Information Schadteilru¨ckversand (si82.30-p-0012a)…………….1424

82.30 – Windshield wiping and washing, basic function (gf82.30-p-9900a)…………….1425

82.35 – 8210 – Checking and correcting the windshield washer fluid level Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh8210pkw0000x)…………….1427

82.35 – Heat spray nozzles and spray nozzle hose, basic function (gf82.35-p-9901a)…………….1428

82.35 – Service Information Repair of leaky washer fluid hoses (si82.35-p-0003a)…………….1429

82.35 – Service information Wiping quality and noise development (si82.35-p-0002a)…………….1430

82.60 – Engine sound, basic function (gf82.60-p-9901a)…………….1431

82.60 – Front camera video recording, basic function (gf82.60-p-9905a)…………….1432

82.60 – Media mode,basic function (gf82.60-p-9903a)…………….1433

…

98.00 – 000 588 03 98 00 Cover (ws98.00-p-0003b)…………….1603

98.00 – 000 588 04 98 00 Cover (ws98.00-p-0005b)…………….1604

98.00 – 000 588 06 98 00 Cover (ws98.00-p-0013b)…………….1605

98.00 – 000 588 08 98 00 Cover (ws98.00-p-0014b)…………….1606

98.00 – 9850 – Checking the body for paintwork damage Model 107 from 8_85; 123; 124, 129, 140 up to 6_93; 126 from 9_85; 201 from 1_85 (wh9850pkw0000x)…………….1607

98.00 – Application of nano paint sealer (ap98.00-p-9830a)…………….1608

98.00 – Application of paintwork care and polishing agents (ap98.00-p-0635a)…………….1610

98.00 – Application of paintwork care and polishing agents (ap98.00-p-0635rq)…………….1611

98.00 – Covering, masking and aids when painting (ar98.00-p-0200a)…………….1613

98.00 – Forms Passenger cars Paintwork (of98.00-z-3999az)…………….1617

98.00 – Paintwork Passenger vehicles incl. cross country vehicles (wb6516lit7502z)…………….1619

98.00 – Safety information Paintwork (as98.00-z-9999zz)…………….1622

98.00 – Service Information Cleaning of tin-plated surfaces (si98.00-p-0019a)…………….1623

98.00 – Service Information Inquiries regarding factory finish (si98.00-p-0014a)…………….1624

98.00 – Service Information Matching color due to work on body shell complaints (si98.00-p-0024a)…………….1625

98.00 – Service Information Notes on paint drying in drying facility (si98.00-p-0020a)…………….1626

98.00 – Service Information Processing of preparatory work for paintwork and body shell complaints (si98.00-p-0025a)…………….1627

98.00 – Service Information Refinishing paint (si98.00-p-0002a)…………….1628

98.00 – Service Information Water-based paint (si98.00-p-0028a)…………….1630

98.00 – Service Information bulletin Painting systems for warranty operations (si98.00-p-0010a)…………….1631

98.00 – Service information Matt paintwork (si98.00-p-0017a)…………….1632

98.00 – Table of contents for paintwork and anticorrosion materials in series production (gf98.00-p-0991a)…………….1634

98.00 – Use of fine polishing paste (ap98.00-p-0638a)…………….1635

98.00 – Use of gloss preserver (ap98.00-p-0641a)…………….1637

98.00 – Use of metal dust remover (ap98.00-p-0636a)…………….1638

98.00 – Use of paint cleaners (ap98.00-p-0637a)…………….1639

98.00 – Use of polish (ap98.00-p-0639a)…………….1640

98.30 – Cleaning and care of MB vehicle paintwork (ap98.30-p-8070a)…………….1641

099_Printed Matter…………….1643

99.00 – Anziehdrehmomente Personenwagen Druckschriften (ba99.00-z-9999az)…………….1644

99.00 – Füllmengen Personenwagen Druckschriften (bf99.00-z-9999az)…………….1645

99.00 – Prüf- und Einstellwerte Personenwagen Druckschriften (be99.00-z-9999az)…………….1646

99.00 – Safety information Publications (as99.00-z-9999zz)…………….1647

99.00 – Structure test for SI KD (si99.00-z-0000mr)…………….1648

99.00 – Technical modifications Passenger cars Publications (bt99.00-z-9999az)…………….1649

99.20 – Body exposure Passenger vehicles incl. cross country vehicles (wb6516lit7490z)…………….1650

99.20 – Center section, Rear end Passenger vehicles incl. cross country vehicles (wb6516lit7501z)…………….1654

99.20 – Fault code documentation Passenger cars and Off Road Vehicles (wb6516lit7481z)…………….1658

99.20 – Front end Passenger cars and cross country vehicles (wb6516lit7500z)…………….1660

99.20 – Test Sheet Passenger Cars (wb6516lit7438z)…………….1663

99.20 – TÜV_FKÜ-Erfassungsblatt Typ 107, 116, 123 (wb6516lit7482z)…………….1664

Mercedes-Benz Model 123 Repair Service Manual