Complete Diagnosis and Test manual with Electrical Wiring Diagrams for John Deere 4WD Loaders 544E, 544E LL, 544E TC, 624E, 644E, with all the shop information to maintain, diagnose, test, and service like professional mechanics.

John Deere 4WD Loaders 544E, 544E LL, 544E TC, 624E, 644E workshop Diagnostics and Test manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

TM1413 – John Deere 544E, 544E LL, 544E TC, 624E and 644E 4WD Loader Technical Manual (Operation and Test ).PDF

Total Pages: 1,120 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable)

Language: English

ctm138519 English – TeamMate™ II 1200 Series Inboard Planetary Axles -: (Worldwide Edition) CTM

ctm4 English – Series 300 – 3179,4239,6359,4276,6414 Diesel Engines CTM

ctm6 English – Series 400, 6076 Diesel Engines ( – 499999) CTM

ctm8 English – Series 300 3029 (S.N. -499999), 4039, 4045, 6059 and 6068 Diesel Engines CTM

omt131709 English – OPERATORS MANUAL 544E, 544E LL, AND 544E TC LOADERS 624E LOADER 644E LOADER Operator’s Manual

omt131709 English – OPERATORS MANUAL 544E, 544E LL, AND 544E TC LOADERS 624E LOADER 644E LOADER Operator’s Manual

MAIN SECTIONS

Foreword

General Information

Safety Information

General Specifications

Torque Values

Fuels And Lubricants

Wheels

Powered Wheels And Fastenings

Axles And Suspension Systems

Removal And Installation

Axle Shafts, Bearings And U-Joints

Hydraulic System

Transmission

Removal And Installation

Controls Linkage

Input Drive Shafts And U-Joints

Gear, Shafts, Bearings And Power Shift Clutch

Hydraulic System

Engine

Removal And Installation

Engine Auxiliary Systems

Cold Weather Starting Aids

Cooling System

Speed Controls

Intake System

External Fuel Supply System

Dampener Drive

Elements

Steering System

Secondary Steering

Hydraulic System

Service Brakes

Active Elements

Hydraulic System

Park Brake

Active Elements

Controls Linkage

Equipment Attaching

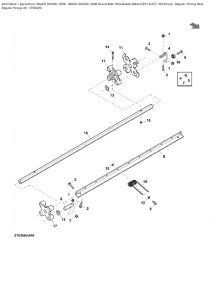

Drawbar

Electrical Systems

Batteries, Support And Cables

Alternator, Regulator And Charging System Wiring

Lighting System

Wiring Harness And Switches

Motors And Actuators

Frame Or Supporting Structure

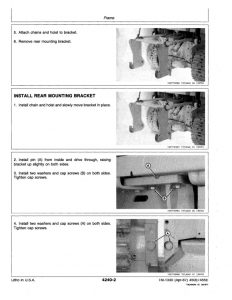

Frame Installation

Frame Bottom Guards

Chassis Weights

Operator`s Station

Removal And Installation

Operator Enclosure

Seat And Seat Belt

Heating And Air Conditioning

Loader

Bucket

Frames

Hydraulic System

TABLE OF CONTENTS

Section 9000: General Information…16

Group 01: Safety Information…16

Handle Fluids Safely-Avoid Fires…19

Prevent Battery Explosions…20

Prepare for Emergencies…21

Prevent Acid Burns…22

Handle Chemical Products Safely…24

Avoid High-Pressure Fluids…25

Park Machine Safely…26

Support Machine Properly…27

Wear Protective Clothing…28

Work in Clean Area…29

Service Machines Safely…30

Work In Ventilated Area…31

Illuminate Work Area Safely…32

Replace Safety Signs…33

Use Proper Lifting Equipment…34

Remove Paint Before Welding or Heating…35

Avoid Heating Near Pressurized Fluid Lines…36

Keep ROPS Installed Properly…37

Service Tires Safely…38

Avoid Harmful Asbestos Dust…39

Practice Safe Maintenance…40

Use Proper Tools…41

Dispose of Waste Properly…42

Live With Safety…43

Group 02: General Specifications…16

544E Specifications…48

544E Drain And Refill Capacities…52

544E LL Specifications…53

544E LL Drain And Refill Capacities…57

544E TC Specifications…58

544E TC Drain And Refill Capacities…62

624E Specifications…63

624E Drain And Refill Capacities…67

644E Specifications…68

644E Drain And Refill Capacities…72

Group 03: Torque Values…17

Hardware Torque Specifications…74

ROPS Torque Specifications…75

Metric Bolt and Cap Screw Torque Values…76

Additional Metric Cap Screw Torque Values…77

Unified Inch Bolt and Cap Screw Torque Values…79

Check Oil Lines And Fittings…80

Service Recommendations for O-Ring Boss Fittings…81

Service Recommendations for Flat Face O-Ring Seal Fittings…83

Service Recommendations for Metric Series Four Bolt Flange Fitting…85

Service Recommendations For Inch Series Four Bolt Flange Fittings…87

Group 04: Fuels And Lubricants…17

Fuel Specifications…90

Storing Fuel…91

Fuel Tank…92

Engine Oil…93

Transmission Oil…94

Hydraulic System Oil…95

Differential Oil…96

Grease…97

Alternative and Synthetic Lubricants…99

Synthetic Lubricants…99

Lubricant Storage…100

Cold Weather Operation…101

Engine Coolant…102

Section 9005: Operational Checkout Procedure…103

Group 10: Operational Checkout Procedure…103

Operational Checkout Record Sheet-544E, 624E, And 644E…108

Complete Machine Operational Checkout…112

Section 9010: Engine Operation And Tests…166

Group 05: Theory Of Operation…166

Cooling System Operation-544E, 624E…169

Cooling System Operation-644E…170

Thermostat Operation…171

Air Cleaner Operation…172

Turbocharger Operation…174

Engine Lubrication-544E, 624E…176

Engine Lubrication Operation-644E…178

Fuel System Operation-544E, 624E…180

Fuel System Operation-644E…181

Fuel Supply Pump Operation-544E, 624E…182

Fuel Pump Operation-644E…183

Fuel Filter Operation…185

Fuel Injection Pump Operation-544E, 624E…186

Fuel Injection Pump Operation-644E…188

Fuel Injection Nozzle Operation-544E, 624E…189

Fuel Injection Nozzle Operation-644E…190

Group 10: System Operational Checks…166

Engine Operational Checks…208

Group 15: Diagnostic Information…166

Diagnose Engine Malfunctions…236

Coolant Requirements…248

Group 20: Adjustments…166

JT05801 Clamp-On Electronic Tachometer Installation…824

JT05800 Digital Thermometer Installation…825

D01084AA Tachometer Reader Installation Procedure…254

Valve Clearance Adjustment-544E, 624E…255

Valve Clearance Adjustment-644E…257

Fan Belt Tension Adjustment…259

Injection Pump Static Timing Adjustment-544E, 624E…261

Injection Pump Static Timing Adjustment-644E…263

Slow And Fast Idle Adjustment-544E, 624E…265

Slow Idle Adjustment-644E…267

Fast Idle Adjustment-644E…269

Speed Control Linkage Adjustment…270

Fuel Shut-Off Cable Adjustment-644E…272

Bleed The Fuel System-544E, 624E…273

Bleed The Fuel System-644E…274

Group 25: Tests…167

JT05801 Clamp-On Electronic Tachometer Installation…824

JT05800 Digital Thermometer Installation…825

Dampener Runout Check…278

Valve Lift Check…279

Compression Pressure Test-544E, 624E…280

Compression Pressure Test-644E…282

Engine Oil Pressure Test-544E, 624E…284

Engine Oil Pressure Test-644E…285

Turbocharger Shaft Axial End Play Test…287

Turbocharger Shaft Radial Movement Test…288

Cooling System Test…289

Fuel Pump Pressure Test-544E, 624E…291

Fuel Pump Pressure Test-644E…292

Air Filter Restriction Indicator Switch Test…294

Radiator Air Flow Test…296

JT05529 Airflow Meter Test Record…298

Engine Power Test Using Engine Pulldown…300

Engine Power Test Using Turbocharger Boost Pressure…302

Air Intake System Leakage Test…304

Fuel Line Leakage Test…306

Section 9015: Electrical System Operation And Test…307

Group 00: Electrical System Operation And Test…307

Safety Precautions…314

Using Booster Batteries-12 Volt System…317

Visually Inspect Electrical System…320

Testing The Electrical System…321

Common Circuit Test…322

Electrical Operational Checks…323

Electrical Schematic Symbols…324

Wiring Diagram Information…325

Battery-Diagnose Malfunctions…327

Battery Operation…328

Battery Specifications…330

Fuse Specifications…331

Bulb Replacement Specifications…332

Diagnose Power And Ground Circuit Malfunctions…333

Power Circuit Operation…336

Power Circuit Wiring Diagram…338

Power Circuit Test…339

Diagnose Starter Circuit Malfunctions…344

Diagnose Fuel Shut-Off Malfunctions-544E, 624E…347

Starting Circuit And Fuel Shut-Off Solenoid Operational Checks…348

Starting Circuit And Fuel Shut-Off Solenoid Operation…354

Starter Operation…356

Start Circuit And Fuel Shut-Off Solenoid Wiring Diagram…359

Start Circuit And Fuel Shut-Off Solenoid Tests…360

Diagnose Charging Circuit Malfunctions-65 Amp Alternator…361

Alternator Operation-65 Amp Motorola…365

Charging Circuit Operation-65 Amp Motorola Alternator-(Serial No. -532819)…367

Charging Circuit Wiring Diagram-65 Amp Motorola-(S.N. -532819)…368

Charging Circuit Operation-65 Amp Motorola Alternator-(Serial No. 532820-)…369

Charging Circuit Wiring Diagram-65 Amp Motorola-(S.N. 532820-)…370

Diagnose Charging Circuit Malfunctions-90 Amp And 105 Amp Alternator…371

Alternator Operation-90 Amp And 105 Amp Delco Remy…374

Charging Circuit Operation-105 Amp Delco-Remy Alternator-(S.N. 518774-)…376

Charging Circuit Wiring Diagram-105 Amp Alternator-(S.N. 518774-)…377

Charging Circuit Operation-90 Amp Delco-Remy Alternator…378

Charging Circuit Wiring Diagram-90 Amp Delco-Remy Alternator…379

Diagnose Charging Circuit Malfunctions-130 Amp Alternator…380

Alternator Operation-130 Amp Motorola…388

Charging Circuit Operation-130 Amp Motorola Alternator…389

Charging Circuit Wiring Diagram-130 Amp Motorola Alternator…390

130 Amp Alternator Voltage Adjustment…391

Diagnose Logic Module And Warning Alarm Circuit Malfunctions…392

Logic Module And Warning Alarm Circuit Operation…393

Logic Module And Warning Alarm Wiring Diagram…395

Logic Module Test In Machine…396

Logic Module Bench Test…399

Diagnose Indicator Circuit Malfunctions-Top Row…401

Indicator Circuits Operation-Top Row…409

Indicator Circuits Wiring Diagram-Top Row…410

Diagnose Indicator Circuit Malfunctions-Middle Row…411

Indicator Circuits Operation-Middle Row…419

Indicator Circuits Wiring Diagram (Middle Row)…421

Park Brake Switch Adjustment…422

Pressure Switch And Sender Test…423

Diagnose Gauges And Horn Circuit Malfunctions…424

Gauges And Horn Circuits Operation…430

Gauges And Horn Circuit Wiring Diagram…431

Diagnose Return-To-Dig And Boom Height Kickout Malfunctions…432

Return-To-Dig And Boom Height Kickout Circuit Operation…437

Return-To-Dig And Boom Height Kickout Wiring Diagram…439

Boom Height Kickout Adjustment…818

Return-To-Dig Adjustment…820

Diagnose Start Aid, Reverse Warning Alarm, And Cigar Lighter Circuit Malfunctions…444

Start Aid, Reverse Warning Alarm, And Cigar Lighter Circuit Operation…448

Start Aid, Reverse Warning Alarm, And Cigar Lighter Circuit Operation Wiring Diagram…449

Diagnose Secondary Steering System Malfunctions…450

Secondary Steering Circuit Operation…456

Secondary Steering Wiring Diagram…458

Secondary Steering Circuit Test…459

Secondary Steering Controller Test…460

Secondary Steering Pressure Switch…461

Diagnose Hour Meter Circuit Malfunctions…462

Hour Meter Circuit Operation…468

Hour Meter Circuit Wiring Diagram…470

Diagnose Boom Down Circuit Malfunctions…471

Boom Down Circuit Operation-(Serial No. -518527)…476

Boom Down Circuit Wiring Diagram-(Serial No. -518527)…477

Boom Down Circuit Operation-(Serial No. 518528-521102)…478

Boom Down Circuit Wiring Diagram-(Serial No. 518528-521102)…479

Boom Down Circuit Operation-(Serial No. 521103-)…480

Boom Down Circuit Wiring Diagram-(Serial No. 521103-)…481

Diagnose Differential Lock And Clutch Cut-Off Circuit Malfunctions…482

Differential Lock And Clutch Cut-Off Circuit Operation…487

Differential Lock And Clutch Cut-Off Circuits Wiring Diagram…488

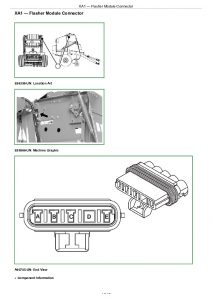

Diagnose Turn Signal And Flasher Circuit Malfunctions…489

Turn Signal And Flasher Indicator Circuit Operation…493

Turn Signal And Flasher Indicator Circuit Wiring Diagram…494

Diagnose Drive, Work, Brake And Gauge Light Circuit Malfunctions…495

Drive, Work, Brake And Gauge Light Circuit Operation…501

Drive, Work, Brake And Gauge Light Circuits Wiring Diagram…503

Diagnose Windshield Wiper And Washer Circuit Malfunctions…504

Windshield Wiper And Washer Circuit Operation…509

Windshield Wiper/Washer Circuit Wiring Diagram…510

Diagnose Pin Disconnect Circuit Malfunctions…511

Pin Disconnect Circuit Operation…513

Pin Disconnect Circuit Wiring Diagram…514

Radio Circuit Operation…515

Electrical Component Location Drawing…516

Section 9020: Power Train Operation And Tests…517

Group 05: Theory Of Operation…517

Power Train Component Overview…523

Drive Dampener…526

Transmission Clutch Engagement…527

Torque Converter Operation…528

Transmission Operation-Neutral…530

Transmission Operation-1st Gear Forward…532

Transmission Operation-2nd Gear Forward…534

Transmission Operation-3rd Gear Forward…536

Transmission Operation-4th Gear Forward…538

Transmission Operation-1st Gear Reverse…540

Transmission Operation-2nd Gear Reverse…542

Transmission Operation-3rd Gear Reverse…544

Clutch Operation…546

Transmission Hydraulic Components…548

Transmission Hydraulic System…550

Transmission Pump Operation…552

Transmission Control Valve Components…553

Transmission Control Valve-1st Gear Neutral…555

Transmission Control Valve-4th Gear Forward…557

Shift Modulation…559

Shift Modulation-1st Gear (Full Engagement)…561

Shift Modulation-1st Gear (Shift Initiated-Clutch Filling)…563

Shift Modulation-1st Gear (Modulation Starting)…565

Shift Modulation-2nd, 3rd, And 4th Gears…567

Thermal Bypass Valve Operation…569

Differential Lock Operation…570

Final Drive Operation…572

Axle Outer Seal And Bearing Operation…574

Axle Disconnect Operation…575

Brake Hydraulic System…576

Brake Pump Operation…578

Accumulator Operation…580

Brake Valve Operation…581

Wet Chambered Brake Valve…583

Pressure Reducing Valve Operation-Neutral…585

Pressure Reducing Valve Operation-Differential Lock On…587

Group 10: System Operational Checks…518

Power Train Operational Checks…601

Group 15: Diagnostic Information…518

Diagnose Transmission System Malfunctions…622

Diagnose Service Brake Malfunctions…631

Diagnose Differential/Axle Malfunctions…633

Diagnose Drive Line Malfunctions…636

Diagnose Park Brake Malfunctions…637

Hydraulic Circuit Symbols…807

Brake, Differential Lock Circuit Schematic…639

Power Train Schematic…640

Power Train And Brakes System Component Location…641

Group 20: Adjustments…518

Transmission Control Valve Linkage-FNR And Neutral Lock Adjustment…643

Transmission Control Valve Linkage-Speed Control Adjustment…644

Brake Pedal Adjusting Screw Adjustment (Early Units Only)…645

Front Axle Disconnect Adjustment…646

Clutch Cut-Off Switch Adjustment…647

Brake Pad Inspection…648

Hydraulic Brake Bleeding Procedure…650

Charge Brake Accumulator…652

Park Brake Linkage Adjustment…654

Park Brake Indicator Switch Adjustment…656

Brake Pump And Differential Lock System Oil Clean-Up Procedure Using Portable Filter Caddy…657

Group 25: Tests…518

JT05801 Clamp-On Electronic Tachometer Installation…824

JT05800 Digital Thermometer Installation…825

D01084AA Tachometer/Temperature Reader Installation Procedure…826

Transmission Oil Warm-Up Procedure…663

Brake, Differential Lock, And Hydraulic System Oil Warm-Up Procedure…664

Transmission Pump Flow Test…665

Transmission System Pressure, Element Leakage, And Shift Modulation Test…667

Lube Pressure Test…670

Converter Relief Pressure Test…672

Converter-In Pressure Test…674

Converter-Out Pressure Test…676

Converter-Out Flow Test…678

Transmission Oil Cooler Backflush Procedure…680

Transmission Oil Cooler Restriction Test…681

Clutch Cut-Off Valve Pressure Test…683

Pressure Reducing Valve Manifold Leakage Test…685

Transmission Oil Cooler Thermal Bypass Valve Test…687

Transmission Oil Cooler Bypass Valve Pressure Test…689

Torque Converter Stall Speed Test…691

Brake Pump Flow Test…692

Brake Pump Standby Pressure Test…694

Brake Valve Pressure Test…696

Brake Accumulator Precharge Test…698

Brake Valve Leakage Test…700

Brake Accumulator Inlet Check Valve Leakage Test…702

Differential Lock Pressure Test…704

Differential Lock Leakage Test…706

Axle Bearing Adjustment Check…708

No-Spin Differential Test…709

Section 9025: Hydraulic System Operation And Test…710

Group 05: Theory Of Operation…710

Steering Circuit Component Location…714

Steering Circuit Components…715

Steering Circuit Operation-Right Turn…717

Main Hydraulic Pump Operation…719

Priority Valve Operation…720

Steering Valve Operation…723

Crossover Relief Valve Operation…724

Steering Cylinder Operation…725

Steering Accumulator Operation-644E Later Units…726

Secondary Steering System Operation…727

Inlet Manifold Operation…728

Loader Hydraulic System…730

Pressure Reducing Valve-Secondary Boom Lower Operation…732

Pilot Controller Operation…734

Boom Section Operation…736

Bucket Section Orifice Check Valve…738

Bucket Section Operation-544E, 624E, And 644E…739

Bucket Section Operation-544E TC And 544E LL…741

Auxiliary Section Operation…743

System Relief Valve Operation…745

Circuit Relief Valve Operation…746

Anti-Cavitation Valve Operation…749

Loader Cylinder Design…750

Return Filter Operation…751

Pin Disconnect Circuit Operation-544E TC…752

Group 10: System Operational Checks…710

Hydraulic Operational Checks…770

Group 15: Diagnostic Information…710

Diagnose Hydraulic System Malfunctions…797

Hydraulic Circuit Symbols…807

Main Hydraulic System Component Location…808

Main Hydraulic System Schematic…809

Main Hydraulic System Schematic (Tandem Valve)…810

Hydraulic System Component Location-544E TC And 544E LL…811

Group 20: Adjustments…711

Hydraulic Oil Clean-Up Procedure Using Portable Filter Caddy…815

Boom Height Kickout Adjustment…818

Return-To-Dig Adjustment…820

Charge Steering Accumulator-644E Later Machines…821

Group 25: Tests…711

JT05801 Clamp-On Electronic Tachometer Installation…824

JT05800 Digital Thermometer Installation…825

D01084AA Tachometer/Temperature Reader Installation Procedure…826

Hydraulic Oil Warm-Up Procedure…828

Main Hydraulic Pump Flow Test…829

Loader System And Circuit Relief Valve Pressure Test…831

Hydraulic System Restriction Test…835

Loader Cylinder Drift Test…837

Boom And Bucket Cylinder Leakage Test…840

Hydraulic Oil Cooler Restriction Test…842

Steering System Leakage Test…844

Steering Valve Neutral Leakage Test…847

Steering Crossover Relief Valve…849

Steering Stop Wear Check…851

Priority Valve Pressure Test…853

Priority Valve "LS" Port Flow Test…855

Priority Valve Relief Cartridge Leakage Test…857

Secondary Steering Pump Relief Valve Pressure Test…859

Secondary Steering Manifold Primary Check Valve Leakage Test…861

Secondary Steering Manifold Secondary Check Valve Leakage Test…863

Pilot Control Valve Pressure Test…865

Pressure Reducing Valve Pressure Test…869

Cycle Time Test…871

Hydraulic Oil Filter Inspection Procedure…872

Pin Disconnect Solenoid Valve Leakage Test…873

Pin Disconnect Cylinder Leakage Test…875

Section 9031: Heating And Air Conditioning System Operation And Tests…877

Group 05: Theory Of Operation…877

Refrigerant System…880

Electrical System Wiring Diagram-Early Machines…881

Electrical System Schematic-Early Machines…883

Electrical System Wiring Diagram-Later Machines…884

Electrical System Schematic-Later Machines…886

Receiver-Dryer Operation…887

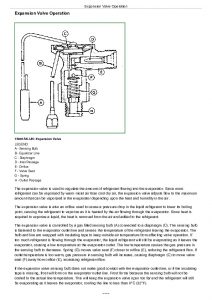

Expansion Valve Operation…889

Thermostat Control Switch Operation…891

Compressor Relief Valve Operation…893

Group 10: System Operational Checks…877

Air Conditioning Operational Checks…914

Group 15: Diagnostic Information…877

Diagnose Air Conditioning Electrical Malfunctions…936

Air Conditioning Component Location Drawing…938

Group 20: Adjustments…877

Refrigerant (R-12) Cautions…959

Check And Add Compressor Oil…942

Air Conditioning Gauge Set Installation Procedure…943

Refrigerant Recovery…945

Flush The System…947

Purge The System…949

Evacuate The System…951

Charge The System…953

Add Refrigerant To System…955

Check And Adjust Compressor Belt Tension…957

Group 25: Tests…877

Refrigerant (R-12) Cautions…959

Air Conditioning System Test…960

Operating Pressure Diagnostic Chart…963

Expansion Valve Operating Test…967

Expansion Valve Bench Test And Adjustment…969

Thermostat Control Switch Operating Test…971

Thermostat Control Switch Bench Test And Adjustment…973

Low Refrigerant Pressure Switch Test…975

High Refrigerant Pressure Switch Test…977

Leak Testing…979

Refrigerant Hoses And Tubing Inspection…980

Air Conditioner, Heater, And Defroster Circuit Test…981

John Deere 4WD Loaders 544E, 544E LL, 544E TC, 624E, 644E Operation & Test Service Manual (TM1413)