Complete service manual for Deutz-Fahr AGROPLUS 60, AGROPLUS 70, AGROPLUS 80, with workshop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Deutz-Fahr Tractors AGROPLUS 60, AGROPLUS 70, AGROPLUS 80 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

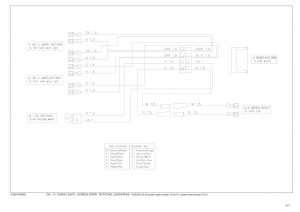

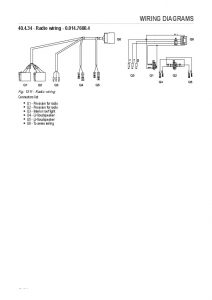

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

307.1064.3.6 – Deutz-Fahr AGROPLUS 60, AGROPLUS 70, AGROPLUS 80 Workshop Manual.pdf

Total Pages: 509 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

List of contents

Tractor configurations AGROPLUS 60 – 70 – 80 ..6

Dimensions and weights..7

Prescribed lubricants and capacities ..8

Conversion tables ..9

Parts ..10

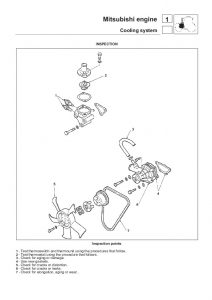

1 – ENGINE

2 – CLUTCH

Gearshift clutch..12

General specifications ..12

Cecking clutch ..16

Adjusting clutch control pedal ..16

Bleeding air from the hydraulic circuit..16

Stripping the slave cylinder..17

Stripping the master cylinder ..18

Diagnosing malfunctions ..20

POWERSHIFT unit, general specifications ..21

POWERSHIFT unit detach from the gear box ..24

Assembly of POWERSHIFT unit ..35

Re-assembly of the POWERSHIFT unit. ..37

Fitting the oil manifolds of the POWERSHIFT unit ..39

Diagnosing malfunctions ..44

3 – TRANSMISSION

General specifications ..45

Technical specifications ..45

Speed change configurations ..47

Section through transmission ..51

Section through transmission with POWERSHIFT unit ..52

Separating the front gearbox from the engine ..61

Dismantling the gearbox ..62

Removal of the gearbox input and P.T.O. shafts ..62

Separating the POWERSHIFT unit from the gearbox ..62

Removal of the gear train positioned in the front gearbox ..63

Disassembly of the inversor control rods and forks ..64

Dismantling of the gearchange rod and fork assembly ..65

Dismantling of the gearchange selector rods and forks assembly ..66

Removal of the shaft with the actuator for engagement/disengagement of the front-wheel drive ..67

Removal of the range gear shaft .. 67

Examining parts removed ..68

Adjusting play of the gearbox shafts by means of the thrust plates on the mini/inversor

shaft and the secondary shaft ..69

Warnigns related to assembly of the gears of the P.T.O. unit, the range reduction unit and synchronised

P.T.O. shaft ..73

Assembly of the P.T.O. ..73

Installation of the range reduction unit, the gear for the front-wheel drive shaft

and the parking brake discs..73

Points where sealant is to be used ..75

Tightening torques ..78

Bevel drive adjustment ..81

Servicing operations ..82

Rear power take-off ..83

P.T.O. clutch ..88

Technical specifications ..89

Correct positions of P.T.O. sensors and cables ..89

Clutch inspection ..91

Checking clutch hydraulic pressures ..92

Checking the end-play of the front shaft of the P.T.O. clutch ..93

Renewal of the rear P.T.O. clutch ..94

Main operations for removal of the rear P.T.O. unit ..95

Diagnosing malfunctions ..100

4 – AXLES

Rear axle ..101

Installing the rear half-shafts ..102

Removal and disassembly of the epicyclic reduction unit..104

Fitting lateral stub axles of the wheel ..105

2WD extendible axle..106

Removing the axle from the front support ..108

Centre steering lever ..111

Wheel hub ..112

End float adjustment ..114

Front-wheel drive..115

Specifications ..115

Epicyclic reduction unit ..119

Side hubs..121

Tightening torques..122

Adjusting bevel gears ..124

Adjustment of the internal control of the mechanical differential lock..125

Installing the differential assembly into the drive axle ..125

Diagnosing malfunctions ..126

5 – VEHICLE

Brakes – General information..127

Hydraulic pump..128

Assembly of brake master cylinder ..130

Checking the front brake disks on 2WD and 4WD front axles and the rear brake disks.. 131

Adjusting service brake pedals ..131

Correct installation of inspection cover for parking brake discs..132

Checking parking brake pads ..134

Bleeding air from the brake hydraulic system..135

“Separate Brakes” valve ..136

Diagnosing malfunctions ..140

Hydraulic lift with “load sensing” ..141

Installing the lift and front cover plate of the gearbox ..142

Lift mechanism ..142

Checking the safety valves ..142

Checking the protrusion of the non-return valve..143

Adjusting the lift ..145

Lift hydraulic circuit ..147

Sensing arm assemblyMontaggio dell’organo sensibile ..154

Power-lift distributor valve spring setting specifications ..155

Electronic lift ..156

Control panel ..157

Control level or depth control knob ..157

Mix position/draft control..157

Lowering speed control knob..158

Maximum lift height control knob ..158

Up/Down control switch ..158

Up control ..158

Control/Float mode ..158

Lift status indicator light ..158

Remote pushbuttons for lift operation from ground ..159

Lift operation ..160

List of electronic lift tests ..164

Precautions for electronic equipment ..173

Checking the electronics system ..173

Checking mechanical components ..173

Front hydraulic liftSollevatore idraulico anteriore..174

Hydraulic accumulator and antishock valve for front lift ..176

Front power take-off – General information..177

Section of the P.T.O. ..178

Fitting the “RING-FEEDER” rings..182

Checking the clutch ..183

Diagnosing malfuntions ..184

Spring specifications..184

6 – CONTROLS

Hydrostatic steering ..185

Inspections and checks ..186

Steering pump ..186

Directional control valve ..186

Check the setting of the pressure relief valve..186

Bleeding the hydraulic circuit ..186

Assembly of orbital pump unit ..186

Teering wheel shaft and steering cylinders ..187

Instructions for the hydrostatic steering distributor assembly ..189

Diagnosing malfuntions ..192

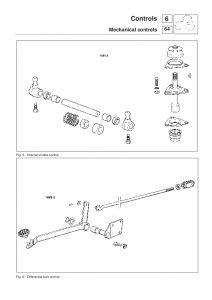

Mechanical controls ..196

Electro-hydraulic controls ..197

Front P.T.O. clutch engagement control..202

Rear P.T.O. clutch engagement control ..202

Differential lock engagement control ..202

Front-wheel drive engagement control ..202

Rear P.T.O. engagement control ..202

Gearbox ..202

Front and rear lift ..202

Hydraulic circuit diagram ..202

Solenoid valve – Specifications ..207

Adjustment of front and rear differential lock control ..214

7 – BODYWORK

Platform ..215

Cab – General information ..216

Cab air filter ..218

Screen wash ..218

Screen wipers (front and rear) ..218

Removing the driving platform complete with cab ..219

Breakage of the top hood release cable ..220

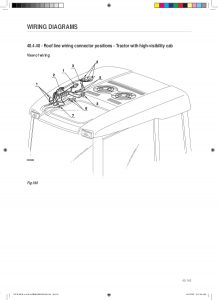

High visibility cab roof ..222

8 – SYSTEMS

Ventilation ..223

Heating System ..223

Air conditioning unit for cabs ..227

Operation and maintenance of the air-conditioning system ..228

Water dripping from the points at which condensate drain lines are connected to the conditioning unit ..229

Checking system ..231

System safety elements ..231

Temperature regulation ..231

Charging the system..232

Filling the metering unit ..232

Refilling the system with oil ..232

Verifying operation of the system after recharging ..234

Directions for tightening air conditioning system pipeline fittings ..234

Diagnosing malfuntions ..241

Hydraulic system ..242

Oil filters ..243

Hydraulic pumps ..243

Checking the relief valves of the hydraulic lift system ..243

Stripping the hydraulic pump ..244

Auxiliary hydraulic spool valves ..247

Checking the pressure relief valve setting ..250

Checking the operating pressure ..250

Conversion of auxiliary spool valves from double acting to single acting operation..250

Checking the surface of the valve spools ..250

Trailer hydraulic braking system ..251

Use of the tractor with CUNA 341/01 hydraulic trailer braking ..253

Installing the hydraulic braking valve for trailers equipped with “safety brake”

( ITALIAN version) ..258

Electrical system AGROPLUS 60 (up serial number1017) – 70 (up serial number 2773) – 80..261

Electrical system AGROPLUS 60 (under serial number 1016) – 70 (under serial number 2772) ..445

General safety directions..446

Jump start utilizing another battery..447

Recharge system..449

Heating system ..450

Starting system ..450

Ignition key ..452

Ventilation control ..452

Push button control..452

Beacon push button..454

Work ligths..454

2-Speed windscreen wiper switch ..454

Relay ..455

Electronic flasher unit ..455

Switch controlling..456

Switch controlling: differential lock – P.T.O. clutch – 4RM – 540 1000 rpm/min P.T.O. speed selector –

Economy P.T.O. – Live P.t.o. – electric starter system..456

Switch for emergency brake ..456

Fuse box ..457

Instrument panel with digital display ..458

Operation of the broken belts alarm control unit..460

Engine stop operation with a type 2MH engine control unit ..462

Electrical wiring..465

9 – APPENDIX

Power lift tester version 1.24a ..I

Deutz-Fahr AGROPLUS 60, AGROPLUS 70, AGROPLUS 80 Repair Service Manual