Complete repair service manual with electrical wiring diagrams for Deutz-Fahr AGROTRON 108, AGROTRON 118, AGROTRON 128, with technical information to maintain, diagnose, repair, and service like professional mechanics.

Deutz-Fahr Tractors AGROTRON 108, AGROTRON 118, AGROTRON 128 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

AGROTRON 108

AGROTRON 118

AGROTRON 128

Deutz-Fahr AGROTRON 108, AGROTRON 118, AGROTRON 128 Workshop Manual.pdf

Total Pages: 840 pages

File Format: PDF (bookmarked, Searchable, Printable, high quality)

Language: English

HOW THE MANUAL IS STRUCTURED

SECTION 00 Contains the general safety rules, information on how to use and update the manual, the symbols used, the products required, the standard tightening torques and a conversion table for units of measurement.

SECTION 10 Contains technical descriptions and information regarding the mechanical and hydraulic operation of machine components, the designations of the various components, hydraulic diagrams and general technical data.

SECTION 20 Contains information on the tractor’s electrical and electronic systems, the procedures for putting into service, the list of alarms and a guide to the use of the software required for tractor and engine configuration and access to diagnostic codes.

SECTION 30 Contains the methods, checks and adjustments regarding the external components; the operations dealt with in this section do not require removal of the various assemblies that form the tractor frame and cab.

SECTION 40 Contains information and diagrams regarding the machine’s electrical and electronic systems.

ATTENTION!

Engine DEUTZ 2012

Trasmission/rear axle 7200 L-S-H

Front axle ZF 2025-2035-2045 AS

0312 0361 Italian

0298 6831 German

0298 6832 English

0298 6833 French

0298 6834 Spanish

0298 6803 German

0298 6856 English

0298 6857 French

0298 6858 Spanish

307.1116.3.6 AGROTRON 108-118-128….1

INTRODUCTION….3

SAFETY NOTES….5

GENERAL SAFETY RULES….5

SAFETY PRECAUTIONS FOR REMOVAL AND REFITTING OPERATIONS….8

LIFTING INSTRUCTIONS….10

HOW THE MANUAL IS STRUCTURED….11

HOW TO CONSULT THE MANUAL….12

HOW TO USE AND UPDATE THE MANUAL….13

STANDARD TIGHTENING TORQUES….14

1. NUTS AND BOLTS….14

2. FITTINGS….15

3. PLUGS….16

4. FITTINGS WITH SEAL AT 37….17

5. FITTINGS FOR PIPES WITH EYE ATTACHMENT….17

THREADLOCKERS, ADHESIVES, SEALANTS AND LUBRICANTS….18

CONVERSION FACTORS….20

SECTION 10….21

1. TRANSMISSION….23

INTRODUCTION….23

1.1 TRANSMISSION (Power Shuttle version)….25

1.1.1 MAIN COMPONENTS….25

1.1.2 TRANSMISSION HYDRAULIC SYSTEM….28

1.1.3 GEARBOX….29

1.1.4 MAIN CLUTCH….31

1.1.5 HYDRAULIC GEARBOX AND SHUTTLE DISTRIBUTION VALVE….32

1.1.6 CLUTCH ENGAGEMENT AND SOLENOID VALVE OPERATION SCHEMATIC….36

1.1.7 TRANSMISSION ELECTRONIC SYSTEM SCHEMATIC….38

1.2 REAR AXLE….39

DESCRIPTION….39

COMPONENTS….39

1.3 REAR PTO….41

2. BRAKING SYSTEM….43

2.1 BRAKE MASTER CYLINDER….44

2.2 BRAKE….45

2.3 TRAILER BRAKING SYSTEM….46

2.3.1 HYDRAULIC TRAILER BRAKING (ITALY VERSION)….46

2.3.2 HYDRAULIC TRAILER BRAKING (EXPORT VERSION)….48

2.3.3 AIR TRAILER BRAKING (ITALY VERSION)….50

2.3.4 AIR TRAILER BRAKING (EXPORT VERSION)….51

COMPRESSOR….52

PRESSURE LIMITING VALVE….53

CAB SUSPENSION FEED VALVE….54

TRAILER BRAKING VALVE (2-WAY)….55

TRAILER BRAKING VALVE (1-WAY)….56

3. HYDRAULIC FRONT AXLE SUSPENSION….57

3.1 FRONT SUSPENSION CONTROL VALVE….58

4. FRONT AXLE….62

4.1 HUB CARRIER AND FINAL REDUCTION UNIT….63

4.2 DIFFERENTIAL….65

5. HYDRAULIC SYSTEM….67

HYDRAULIC SYSTEM (CC version)….68

HYDRAULIC SYSTEM (LS version)….69

5.1 VARIABLE DISPLACEMENT PUMP….70

5.1.1 BOOST PUMP….73

5.1.2 HYDRAULIC PUMP….74

5.1.3 LOAD SENSING VALVE, PRESSURE CUT-OFF VALVE….76

5.2 HYDRAULIC SERVICES GEAR PUMP….84

5.3 STEERING GEAR PUMP….85

5.4 PRIORITY VALVE….86

5.5 AUXILIARY SERVICES CONTROL VALVE….87

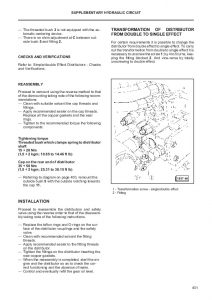

5.5.1 TYPES OF CONTROL VALVE WITH FIXED DISPLACEMENT PUMP (CC)….89

5.5.2 TYPES OF CONTROL VALVE WITH VARIABLE DISPLACEMENT PUMP (LS)….91

5.5.3 SERVICES CONTROL SECTION….92

5.5.4 DESCRIPTIONS OF COMPONENTS….93

5.5.5 FLOW CONTROL SECTION (CC version)….95

5.5.6 LIFT CONTROL VALVE SECTION….98

SECTION 20….103

1. DIAGNOSIS TOOLS “ALL ROUND TESTER”….105

1.1 ALL ROUND TESTER….105

1.1.1 DESCRIPTION OF THE KIT….105

1.1.2 NOTES ON CORRECT USE….106

1.1.3 DESCRIPTION OF THE TESTER….106

1.1.4 GENERAL NOTES ON CONNECTING AND POWERING UP THE TESTER….107

1.1.5 SELECTION OF THE DISPLAY LANGUAGE….107

1.1.6 SETTING THE SERIAL PORTS….109

1.2 “SERDIA 3.5 LEVEL III” SOFTWARE….111

1.2.1 DESCRIPTION OF THE KIT….111

1.3 “EDS EST45” SOFTWARE….112

1.3.1 DESCRIPTION OF THE KIT….112

2. CONNECTING THE TESTER TO THE ELECTRONIC CONTROL UNITS….113

2.1 CONNECTING THE ART TO THE HYDRAULIC LIFT AND FRONT AXLE SUSPENSION CONTROL UNITS….113

2.2 CONNECTING THE PORTABLE COMPUTER WITH “SERDIA 3.5” SOFTWARE TO THE ENGINE CONTROL UNIT….114

2.3 CONNECTING THE PORTABLE COMPUTER WITH “EDS” SOFTWARE TO THE TRANSMISSION CONTROL UNIT AND INFOCENTER….115

2.3.1 CONNECTION TO THE TRANSMISSION CONTROL UNIT….115

2.3.2 CONNECTION TO THE INFOCENTER….115

3. INTRODUCTION TO THE ELECTRONIC SYSTEM OF THE TRACTOR….117

3.1 ENGINE CONTROL UNIT (DEUTZ EMR2)….117

3.2 TRANSMISSION CONTROL UNIT….119

3.3 POWER LIFT CONTROL UNIT….120

3.3.1 HYDRAULIC LIFT SYSTEM….120

3.3.2 ASM SYSTEM….121

3.4 INFOCENTER 2 or 3….122

3.5 FRONT AXLE SUSPENSION CONTROL UNIT….123

3.6 FRONT AND REAR PTO CONTROL UNIT….124

4. PUTTING THE TRACTOR INTO SERVICE….125

4.1 INTRODUCTION….125

4.2 RENEWAL OF THE ENGINE CONTROL UNIT….125

4.2.1 READING AND SAVING DATA….125

4.2.2 PROGRAMMING THE CONTROL UNIT….126

4.2.3 CALIBRATION OF THE ACCELERATOR PEDAL….127

4.2.4 CALIBRATION OF THE HAND THROTTLE….128

4.2.5 READING AND SAVING DATA….129

4.3 RENEWAL OF THE TRANSMISSION CONTROL UNIT….130

4.3.1 SETTING THE TRACTOR VERSION AND SERIAL NUMBER….130

4.3.2 CALIBRATION OF THE CLUTCH PEDAL POSITION SENSOR….132

4.3.3 CALIBRATION OF THE MAIN CLUTCH PROPORTIONAL SOLENOID VALVE….134

4.4 RENEWAL OF HYDRAULIC LIFT AND ASM CONTROL UNIT….136

4.4.1 PROGRAMMING THE TYPE OF TRACTOR….137

4.4.2 CONFIGURING NO RADAR STATUS….138

4.4.3 CALIBRATION OF THE LIFT POSITION SENSOR….139

4.4.4 CHECKING AND CALIBRATING THE LIFT CONTROL LEVER….141

4.5 RENEWAL OF THE INFOCENTER….144

4.5.1 ENTERING CONSTANTS….144

4.6 RENEWAL OF AXLE SUSPENSION CONTROL UNIT….146

4.6.1 CHECKING CALIBRATION OF THE SUSPENSION POSITION SENSOR….146

5. ALARMS….147

5.1 LIFT AND ASM CONTROL UNIT ALARMS….147

5.1.1 LIST OF ALARMS BY EXTENDED CODE….148

5.1.2 LIST OF ALARMS BY STANDARD CODE….150

5.1.3 LIST OF ALARMS DISPLAYED ON ART….152

5.1.4 ANALYSIS OF LIFT AND ASM ALARMS….154

5.2 LIST OF TRANSMISSION CONTROL UNIT ALARMS….183

5.2.1 ABNORMALITIES NOT DETECTED BY THE TRANSMISSION CONTROL UNIT….183

5.2.2 ALARMS INDICATED ON THE TRANSMISSION DISPLAY AND BY THE EDS PROGRAM….183

5.5.3 DEFINITION OF TRANSMISSION OPERATING MODES….188

5.2.3 ANALYSIS OF ALARMS….189

5.3 LIST OF ALARMS DISPLAYED BY SERDIA….253

5.3.1 ALARMS DISPLAYED USING THE SERDIA PROGRAM….253

5.3.2 ANALYSIS OF ALARMS….255

5.4 LIST OF FRONT AXLE SUSPENSION CONTROL VALVE ALARMS….275

5.4.1 LIST OF ALARMS BY TEXT CODE….275

5.4.2 LIST OF ALARMS BY STANDARD CODE….276

5.4.3 LIST OF ALARMS DISPLAYED BY ART….277

5.4.4 ANALYSIS OF ALARMS….278

6. OPERATOR’S MANUAL EDS (Electronic Diagnosis System)….291

1. GENERAL INTRODUCTION….291

1.1 FUNCTIONAL SCOPE….291

1.2 HARDWARE REQUIREMENTS….292

1.3 STARTING AND TERMINATING OF THE EDS PROGRAM….294

2. TRANSMISSION DIAGNOSIS….296

2.1 THE MAIN MENU….296

2.2 ONLINE HELP….298

3. POWER-SHUTTLE DIAGNOSISPROGRAMM DEST 45….299

3.1 PREPARATIONS FOR TRANSMISSION DIAGNOSIS WITH DEST 45….299

3.2 DEST 45 PROGRAM DESCRIPTION….300

3.3 ERROR CODES POWER-SHUTTLE /DEST 45….315

3.4 DISPLAY POWERSHUTTLE….316

3.5 ERROR CODE LIST WITH DESCRIPTION….317

3.6 OTHER INFORMATIONS….328

3.7 SENSORS AND SOLENOID VALVES AT THE TRANSMISSION T-7100….329

3.8 ELECTRO-HYDRAULIC GEAR SHIFT T-7100….330

3.9 SENSORS AND SOLENOID VALVES AT THE TRANSMISSION T-7200….331

3.10 ELECTRO-HYDRAULIC GEAR SHIFT T-7200 / T-7300….332

3.11 ERROR ANALYSIS….333

4. PREPARATIONS FOR DIAGNOSIS OF THE INFOCENTER….335

4.1 PROGRAM DESCRIPTION….336

4.2 CONSTANT VALUES FOR INFOCENTER….346

7. ALL ROUND TESTER FOR LIFT AND ASM CONTROL UNIT….351

PRESENTATION SCREEN….351

MAIN MENU….351

1. MONITOR….352

1.1 LIFT….352

1.2 CONSOLE….354

1.3 ASM….354

1.4 POWER….355

1.5 SENSORS….356

2. CONFIGURATION….356

2.1 SPEED CONSTANTS….357

2.2 OPTIONS….357

3. CALIBRATIONS….358

3.1 MINIMUM HEIGHT….359

3.2 MAXIMUM HEIGHT….359

3.3 LOCK SPEED….360

3.5 TRANSPORT….361

3.6 STOP….361

3.7 CONTROL….362

3.8 FLOAT….362

4. ALARMS LIST….363

8. ALL ROUND TESTER FOR AXLE SUSPENSION CONTROL UNIT….365

PRESENTATION SCREEN….365

MAIN MENU….365

1. MONITOR….366

1.1 SUSPENSION….366

2. PARAMETERS….367

3. ALARMS LIST….369

4. CONFIGURATIONS….369

9. SERDIA (LEVEL III)….371

1. SETUP AND COMMUNICATIONS….371

1.1 MINIMUM EQUIPMENT REQUIRED….371

1.2 ORDERING….372

1.3 SWITCHING ON AND INSTALLING THE SOFTWARE….373

1.4 USING THE PROGRAM….377

1.5 CLOSING THE PROGRAM….380

2. ECU SELECTION….381

2.1 SELECTING TWO CONTROL UNITS….381

2.2 PRINTING….382

2.3 PROTOCOL….383

2.4 IDENTIFICATION AND MEASUREMENT DATA….383

3. MEASURED VALUES….385

3.1 ACTUAL MEASURED VALUES (GENERAL)….385

3.2 RAM-VALUES….390

3.3 DATA LOGGER (ONLY EMS2)….394

3.4 INPUT/OUTPUT ASSIGNMENT….394

3.5 CAN STATUS….394

4. PARAMETERS….397

4.1 CONFIGURATION (GENERAL)….397

4.2 OVERALL PROGRAMMING….398

4.2 CALIBRATION….399

5. ERROR MEMORY….400

5.1 GENERAL….400

5.2 ERROR TABLE….401

6. EXTRAS….411

6.1 MAXIMUM SPEED….411

6.2 LOGISTIC DATA….411

6.3 LOAD SPECTRUM….412

6.4 MAINTENANCE INTERVAL EXCEEDED….412

6.5 OVERRIDE MEMORY….412

6.6 MAINTENANCE DATA….412

7. TASKS….413

7.1 EMR1….413

8. WHAT TO DO IF…?….417

8.1 SERDIA GENERAL….417

8.2 EMR1….419

SECTION 30….431

METHOD FOR REMOVAL AND REFITTING OF RIGID PIPES AND WIRING….433

HYDRAULIC SYSTEMS AND WIRING (TOP VIEW)….434

HYDRAULIC SYSTEMS (TOP VIEW)….435

HYDRAULIC SYSTEMS (SIDE VIEW)….436

REAR HYDRAULIC SYSTEMS (SIDE VIEW)….437

FRONT HYDRAULIC SYSTEMS (SIDE VIEW)….438

ENGINE HOOD – LAMP ASSEMBLIES….439

REMOVAL….439

REFITTING….442

CAB ACCESS STEPS….443

REMOVAL….443

REFITTING….443

BATTERY….444

REMOVAL….444

REFITTING….445

AIR RESERVOIR AND BATTERY SUPPORT….446

REMOVAL….446

REFITTING….446

STARTER MOTOR….447

REMOVAL….447

REFITTING….447

ALTERNATOR….448

REMOVAL….448

REFITTING….448

AIR CONDITIONING COMPRESSOR DRIVEBELT AND FANBELT….449

RENEWAL….449

AIR COMPRESSOR….452

REMOVAL….452

REFITTING….453

TRAILER PARKING AND SERVICE AIR BRAKE CONTROL VALVES….454

REMOVAL….454

REFITTING….455

PRESSURE TRANSDUCER….456

REMOVAL….456

REFITTING….456

AIR PRESSURE REGULATING/REDUCTION VALVE FOR CAB LIFTING….457

REMOVAL….457

REFITTING….457

TRAILER AIR BRAKES COUPLING VALVE….458

1. Removal….458

2. Renewal….458

HYDRAULIC TRAILER BRAKING VALVE….459

REMOVAL….459

REFITTING….460

AIR CONDITIONING SYSTEM….461

TECHNICAL SPECIFICATIONS….461

OPERATION….462

MAINTENANCE….463

ADJUSTING THE TENSION OF THE COMPRESSOR DRIVEBELT….463

DISCHARGING, FLUSHING AND RECHARGING THE AIR CONDITIONING SYSTEM….464

AIR CONDITIONING COMPRESSOR….465

REMOVAL….465

REFITTING….466

RECEIVER-DRIER….467

REMOVAL….467

REFITTING….467

CONDENSER ASSEMBLY….468

REMOVAL….468

REFITTING….470

INTERCOOLER….471

REMOVAL….471

REFITTING….473

GEARBOX OIL/FUEL COOLERS….474

REMOVAL….474

REFITTING….475

RADIATOR….476

REMOVAL….476

REFITTING….479

EXPANSION TANK….480

REMOVAL….480

REFITTING….480

RADIATORS – COOLERS ASSEMBLY….481

REMOVAL….481

REFITTING….485

FAN….486

REMOVAL….486

REFITTING….486

FRONT PTO FLEXIBLE COUPLING….487

REMOVAL….487

REFITTING….488

AIR CLEANER….489

REMOVAL….489

REFITTING….490

TURBOCHARGER….491

REMOVAL….491

REFITTING….492

AIR INLET PIPE….493

REMOVAL….493

REFITTING….494

SILENCER….495

REMOVAL….495

REFITTING….495

EXHAUST PIPE….496

REMOVAL….496

REFITTING….496

4WD PROPELLER SHAFT….497

REMOVAL….497

REFITTING….499

BRAKE MASTER CYLINDERS….500

REMOVAL….500

REFITTING….502

BLEEDING THE BRAKING SYSTEM….503

BRAKE LIGHT SWITCHES….505

ADJUSTMENT….505

POWER STEERING UNIT….506

1. Testing….506

2. Adjustment….506

3. Removal….506

REFITTING….507

1. Disassembly….509

2. Removal of the seals….511

3. Removal of the dust seal….511

4. Installing the inner seal (15)….512

5. Installing the control valve….512

6. Final assembly….513

FRONT WHEELS….516

REMOVAL….516

REFITTING….516

FRONT FENDERS….517

REMOVAL….517

REFITTING….517

REAR WHEELS….518

REMOVAL….518

REFITTING….518

LIFT VALVE BLOCK….519

REMOVAL….519

REFITTING….519

FRONT LIFT CYLINDERS….520

REMOVAL….520

REFITTING….521

FRONT LIFT ASSEMBLY….522

REMOVAL….522

REFITTING….524

FRONT PTO ASSEMBLY….525

REMOVAL….525

REFITTING….525

FRONT SUSPENSION CYLINDERS….526

REMOVAL….526

REFITTING….528

1. Disassembly….529

2. Assembly….530

FRONT AXLE AND SWINGING SUPPORT….531

REMOVAL….531

REFITTING….533

FRONT SUSPENSION VALVES….534

REMOVAL….534

REFITTING….534

FRONT SUSPENSION POSITION SENSOR….535

1. Removal….535

2. Positioning….535

3. Testing….536

REINFORCING SIDE MEMBERS….537

REMOVAL….537

REFITTING….537

FRONT CARRIER….538

REMOVAL….538

REFITTING….538

ACCELERATOR POTENTIOMETER….539

1. Renewal….539

2. Potentiometer calibration….540

FUEL TANK….541

REMOVAL….541

INSTALLATION….544

POWER STEERING PUMP….545

REMOVAL….545

REFITTING….547

TESTING THE AUXILIARY SERVICES PUMPS….548

1. Flow meter connection (CC version)….548

2. Flow meter connection (LS version)….548

3. Measuring the flow rate….548

GEAR PUMP….550

REMOVAL….550

REFITTING….551

VARIABLE DISPLACEMENT PUMP….552

REMOVAL….552

REFITTING….556

PRIORITY VALVE….557

REMOVAL….557

REFITTING….557

CREEPER ENGAGEMENT LEVER….558

REMOVAL….558

REFITTING….558

CONTROL VALVE ASSEMBLIES (Version CC)….559

REMOVAL….559

REFITTING….562

CONTROL VALVE ASSEMBLIES (LS version)….563

REMOVAL….563

REFITTING….567

CONTROL VALVE SECTIONS AND SEALS….568

REMOVAL….568

REFITTING….574

LIFT CYLINDERS….575

REMOVAL….575

REFITTING….576

DISASSEMBLY AND ASSEMBLY….577

LIFT POSITION SENSOR….579

TESTING….578

RENEWAL….579

LIFT DRAFT SENSOR….582

REMOVAL….582

REFITTING….582

DRIVER'S SEAT….583

REMOVAL….583

REFITTING….583

CONTROLS IN THE MULTIFUNCTION ARMREST CONSOLE (OPTIONAL)….584

REMOVAL….584

REFITTING….585

STEERING WHEEL, STEERING COLUMN SWITCH UNIT AND INSTRUMENT PANEL….586

REMOVAL….586

REFITTING….587

STEERING COLUMN SWITCH UNIT AND THE SHUTTLE CONTROL LEVER….588

RENEWAL….588

ASSEMBLY….589

CENTRE CONSOLE AND SHROUD….590

REMOVAL….590

REFITTING….593

RIGHT-HAND CONSOLE….594

OPENING AND REMOVAL….594

REFITTING….600

LEFT-HAND CONSOLE….601

REMOVAL….601

REFITTING….602

TRANSMISSION LIFT AND FRONT SUSPENSION ELECTRONIC CONTROL UNITS….603

REMOVAL….603

REFITTING….604

FUSE AND RELAY BOARD….605

REMOVAL….605

REFITTING….606

ENGINE ECU….607

REMOVAL….607

REFITTING….607

CLUTCH PEDAL AND RELATED DEVICES….608

1. Removal of the potentiometer….608

1.1. Refitting the potentiometer….608

2. Adjustment of the clutch pedal position and travel….609

3. Renewal of the proximity sensor….609

CONTROL PANELS AND LEVERS OF THE AUXILIARY SERVICE VALVES AND THE PTO….610

REMOVAL….610

REFITTING….614

PTO ENGAGEMENT AND SELECTION CONTROL CABLES….615

RENEWAL….615

REFITTING….616

AUXILIARY SERVICE VALVE CONTROL CABLES….618

RENEWAL….618

REFITTING….619

ADJUSTMENT OF THE PARKING BRAKE SWITCH….620

CLIMATE CONTROL PANEL….621

REMOVAL….621

REFITTING….621

HEATER VALVE….622

RENEWAL….622

REMOVAL….624

HEATER MATRIX….624

REMOVAL….624

REFITTING….626

AIR CONDITIONING EVAPORATOR….627

REMOVAL….627

REFITTING….628

RIGHT-HAND AIR CONDITIONING FAN….629

REMOVAL….629

REFITTING….629

LEFT-HAND AIR CONDITIONING FAN….630

REMOVAL….630

REFITTING….630

ADJUSTMENT OF THE PARKING BRAKES….631

CAB DOOR CABLE….632

RENEWAL….632

TRAILER BRAKING AIR PRESSURE GAUGE….634

REMOVAL….634

REFITTING….634

POWERSHIFT – POWERSHUTTLE STATUS DISPLAY….635

REMOVAL….635

REFITTING….635

CAB….636

REMOVAL….636

REFITTING….644

ENGINE….645

REMOVAL….645

REFITTING….653

SECTION 40….655

THE STRUCTURE OF THE UNIT….657

HOW TO CONSULT THE UNIT….658

1. INTRODUCTION….659

1.1 LIST OF WIRING HARNESSES….659

1.2 DEFINITION OF COMPONENTS AND SYMBOLS….660

1.3 GENERAL RULES….660

1.3.1 MODIFICATION OF THE TRACTOR'S ELECTRICAL/ELECTRONIC CIRCUITS….660

1.3.2 MAIN WIRING FAULTS….660

1.3.3 REMOVAL, REFITTING AND DRYING OF CONNECTORS AND WIRING….661

1.4 DIAGNOSTIC INSTRUMENTS….662

1.5 WIRE COLOUR CODES….662

2. INDICES….663

2.1 COMPONENT DESCRIPTION INDEX….663

2.2 COMPONENT CODE INDEX….668

2.3 CONNECTOR INDEX….673

3. COMPONENTS….682

3.1 CONNECTOR LAYOUTS….682

3.2 COMPONENT TECHNICAL DATA….687

3.3 PINOUTS AND DESCRIPTIONS OF ELECTRONIC CONTROL UNITS….696

3.3.1 ENGINE CONTROL UNIT….696

3.3.2 TRANSMISSION CONTROL UNIT….698

3.3.3 INFOCENTER….700

3.3.4 HPSA CONTROL UNIT….702

3.3.5 FRONT SUSPENSION CONTROL UNIT….704

4. SYSTEMS….705

4.1 GROUND POINTS….705

4.2 ENGINE START….706

4.3 PREHEATING….707

4.4 ELECTRICAL ENGINE CONTROL….708

4.5 LIGHTS – LIGHT SELECTOR SWITCH (MACHINE WITHOUT FRONT LIFT)….709

4.6 LIGHTS – LIGHT SELECTOR SWITCH (MACHINE WITH FRONT LIFT)….710

4.7 CAB ACCESSORY….711

4.8 WORKING LIGHTS (MACHINE WITHOUT FRONT LIFT)….712

4.9 WORKING LIGHTS (MACHINE WITH FRONT LIFT)….713

4.10 WINDSCREEN WIPER….714

4.11 INFOCENTER….715

4.12 ELECTRICAL POWER SUPPLY….716

4.13 AUTORADIO – CB….717

4.14 AIR CONDITIONING – HEATING FAN….718

4.15 BRAKES….719

4.16 TRAILER BRAKES….720

4.17 FRONT AXLE SUSPENSION….721

4.18 TRANSMISSION….722

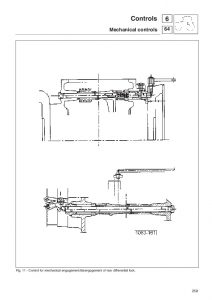

4.19 ASM – 4WD – DIFFERENTIAL….723

4.20 REAR LIFTER….724

4.21 FRONT AND REAR PTO….725

5. WIRING….727

ENGINE WIRING (1/2)….727

ENGINE WIRING (2/2)….728

ENGINE WIRING (1/2)….733

ENGINE WIRING (2/2)….734

ENGINE HOOD WIRING….743

TRANSMISSION WIRING (1/2)….747

TRANSMISSION WIRING (2/2)….748

TRAILER BRAKE WIRING (ITALY)….759

TRAILER BRAKE WIRING….760

FRONT AXLE SUSPENSION WIRING (ROPS)….763

CAB POWER SUPPLY WIRING….767

FRONT AXLE SUSPENSION WIRING….773

FENDER WIRING – WIDE….777

NUMBER PLATE LIGHT WIRING (WIDE FENDERS)….778

FENDER WIRING – NARROW….783

NUMBER PLATE LIGHT WIRING (NARROW FENDERS)….784

FRONT CONSOLE WIRING (1/2)….789

FRONT CONSOLE WIRING (2/2)….790

SIDE CONSOLE WIRING (1/3)….795

SIDE CONSOLE WIRING (2/3)….796

SIDE CONSOLE WIRING (3/3)….797

AIR CONDITIONING WIRING (CAB)….807

DISPLAY WIRING….813

ROOF WIRING (1/2)….817

ROOF WIRING (2/2)….818

CAB ROOF FRONT AND REAR WORKLIGHTS WIRING….827

CAB LOWER HEADLIGHTS WIRING….825

WINDSCREEN WIPER MOTOR WIRING….825

CAB LOWER FRONT WORKLIGHTS WIRING….826

(MACHINE WITHOUT FRONT LIFT)….826

CAB FULL AND DIPPED BEAM HEADLIGHTS (WITH FRONT LIFT)….826

LIGHTS SELECTOR SWITCH WIRING….833

ARMREST WIRING….837

FUSES AND RELAYS CONTROL UNIT (1/2)….839

FUSES AND RELAYS CONTROL UNIT (2/2)….840

Deutz-Fahr Tractors AGROTRON 108, AGROTRON 118, AGROTRON 128 Repair Service Manual