INSTANT DOWNLOAD

Complete Electrical Wiring Diagrams for Detroit Diesel Diesel Engines, with all the shop information to diagnose, and repair like professional mechanics.

PRODUCT DETAILS:

Total Size: 371 MB

File Format: PDF (Windows & Mac & Linux)

Language: English

Electrical Wiring Diagrams

Electrical Wiring Diagrams/DD Platform EPA07 (DDECVI) EPA10 (DDEC10) GHG14 (DDEC13)

Electrical Wiring Diagrams/DD Platform EPA07 (DDECVI) EPA10 (DDEC10) GHG14 (DDEC13).pdf

Electrical Wiring Diagrams/Detroit™ Transmissions TCM Wiring Harness.png

Electrical Wiring Diagrams/Detroit Transmissions TCM Wiring Harness.png

Electrical Wiring Diagrams/Electrical wiring schematisc.JPG

Electrical Wiring Diagrams/EPA07 DD13 Motor Control Module (MCM) Engine Harness.pdf

Electrical Wiring Diagrams/EPA10 14-Pin Connectors.pdf

Electrical Wiring Diagrams/EPA10 Aftertreatment 1-BOX™ Wiring Schematic.pdf

Electrical Wiring Diagrams/EPA10 Aftertreatment 2HH Pierce Wiring Schematic.pdf

Electrical Wiring Diagrams/EPA10 Aftertreatment 2HV Two-Box Wiring Schematic.pdf

Electrical Wiring Diagrams/EPA10 Aftertreatment 2V2 Two-Box Wiring Schematic.pdf

Electrical Wiring Diagrams/EPA10 Aftertreatment Control Module (ACM2) Electrical Schematic.pdf

Electrical Wiring Diagrams/EPA10 Common Powertrain Controller (CPC2+) Vehicle Interface Harness (VIH).pdf

Electrical Wiring Diagrams/EPA10 DD13 Motor Control Module (MCM2) Engine Harness (page 1).pdf

Electrical Wiring Diagrams/EPA10 DD13 Motor Control Module (MCM2) Engine Harness (page 2).pdf

Electrical Wiring Diagrams/EPA10 DD15 Motor Control Module (MCM2) Engine Harness (page 1).pdf

Electrical Wiring Diagrams/EPA10 DD15 Motor Control Module (MCM2) Engine Harness (page 2).pdf

Electrical Wiring Diagrams/EuroIV Common Powertrain Controller (CPC2) Vehicle Interface Harness (VIH).pdf

Electrical Wiring Diagrams/EuroIV Export DD15 Motor Control Module (MCM) Engine Harness (page 1).pdf

Electrical Wiring Diagrams/EuroIV Export DD15 Motor Control Module (MCM) Engine Harness (page 2).pdf

Electrical Wiring Diagrams/GHG14 Aftertreatment Control Module (ACM2.1) Electrical Schematic.pdf

Electrical Wiring Diagrams/GHG14 Common Powertrain Controller (CPC4) Vehicle Interface Harness (VIH).pdf

Electrical Wiring Diagrams/GHG14 DD13 Motor Control Module (MCM2.1) Engine Harness (page 1).pdf

Electrical Wiring Diagrams/GHG14 DD13 Motor Control Module (MCM2.1) Engine Harness (page 2).pdf

Electrical Wiring Diagrams/GHG14 DD15 and DD16 Motor Control Module (MCM2.1) Engine Harness (page 1).pdf

Electrical Wiring Diagrams/GHG14 DD15 and DD16 Motor Control Module (MCM2.1) Engine Harness (page 2).pdf

Electrical Wiring Diagrams/Horizontal ATD wiring – OEM and DDC Responsibility.pdf

Electrical Wiring Diagrams/MBE 900 (EPA04) DDEC-ECU EGR Engine Harness and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/MBE 900 (EPA04) DDEC-ECU EGR Engine Harness and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/MBE 900 (EPA07) Engine Harness (MCM-CPC) and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/MBE 900 (EPA07) Engine Harness (MCM-CPC) and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/MBE 4000 (EPA04) DDEC-ECU EGR Engine Harness and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/MBE 4000 (EPA04) DDEC-ECU EGR Engine Harness and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/MBE 4000 (EPA07) Engine Harness (MCM-CPC) and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/MBE 4000 (EPA07) Engine Harness (MCM-CPC) and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/MBE Platform Electronic Wiring Schematics.pdf

Electrical Wiring Diagrams/Series 50, 50G & 60 Electronic Wiring Schematics.pdf

Electrical Wiring Diagrams/Series 50 DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/Series 50 DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/Series 50G DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/Series 50G DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/Series 60 DDEC III-IV Engine Harness and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/Series 60 DDEC III-IV Engine Harness and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/Series 60 DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/Series 60 DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/Series 60 DDEC V EGR Engine Harness and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/Series 60 DDEC V EGR Engine Harness and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/Series 60 DDEC V Engine Harness and Vehicle Interface Harness (Non-Road Equipment) page 1.pdf

Electrical Wiring Diagrams/Series 60 DDEC V Engine Harness and Vehicle Interface Harness (Non-Road Equipment) page 2.pdf

Electrical Wiring Diagrams/Series 60 (EPA07) DDEC VI MCM-CPC EGR Engine Harness and Vehicle Interface Harness (page 1).pdf

Electrical Wiring Diagrams/Series 60 (EPA07) DDEC VI MCM-CPC EGR Engine Harness and Vehicle Interface Harness (page 2).pdf

Electrical Wiring Diagrams/Vertical ATD wiring – OEM and DDC Responsibility.pdf

Others/DDEC6_X_2007-2012_epa07_10

Others/2-Box Diesel Oxidation Catalyst – Diesel Particulate Filter.pdf

Others/2-Box Selective Catalytic Reduction (SCR Catalyst).pdf

Others/2HH Soot Sensor.pdf

Others/2V2 GHG14 Selective Catalytic Reduction NOx Sensor.pdf

Others/7SE500 0409 – UNIT FUEL INJECTORS AND UNIT PUMP TECHNICIAN GUIDE.pdf

Others/61527967-Ajuste-Valvulas-e-Inyectores-Detroit.pdf

Others/289329134-Detroit-DD15-Valve-Adjustment.pdf

Others/Aftertreatment Device Electronics.pdf

Others/Aftertreatment System Overview.pdf

Others/Allison Transmission – AT540 AT1542 Service Manual.pdf

Others/DD13 Exhaust Flanged Manifold.pdf

Others/DD13 Exhaust Gas Recirculation Cooler Water Manifold Assembly.pdf

Others/DD13 Exhaust Gas Recirculation Valve.pdf

Others/DD13 Exhaust Gas Recirculation Valve Actuator.pdf

Others/DD13 Exhaust Gas Recirculation Valve Actuator Pull Rod.pdf

Others/DD15 and DD16 Exhaust Gas Recirculation Cooler.pdf

Others/DD15 and DD16 Exhaust Gas Recirculation Valve.pdf

Others/DD15 and DD16 Exhaust Gas Recirculation Valve Actuator.pdf

Others/DD15 and DD16 Exhaust Gas Recirculation Valve Actuator Pull Rod.pdf

Others/DD15 and DD16 Exhaust S-pipe (Elbow).pdf

Others/DDC-SVC-MAN-0073 – DD PLATFORM APPLICATION AND INSTALLATION MANUAL.pdf

Others/DDC-SVC-MAN-0081 2010 – EPA07_10 DD PLATFORM WORKSHOP MANUAL – ENGINE.pdf

Others/DDC-SVC-MAN-0110 – DDEC IV APPLICATION AND INSTALLATION MANUAL.pdf

Others/DDECIV_EGRddc-svc-man-0109.pdf

Others/DDECVddc-svc-man-0108.pdf

Others/DD_EuroIV_DDECVIddc-svc-man-0185.pdf

Others/Detroit_dd13.pdf

Others/Detroit Diesel – Cooling System – Technicians Guide.pdf

Others/Detroit Diesel – DDEC II to III-IV Conversion .pdf

Others/Detroit Diesel – DDEC VI – Application And Installation Manual.pdf

Others/Detroit Diesel – DDEC VI SERIES 60 MCM EGR Engine Harness Schematic.pdf

Others/Detroit Diesel – Fuel System Bulletin – MBE 4000-06a.pdf

Others/Detroit Diesel – Low Power Bulletin – MBE4000-07.pdf

Others/Detroit Diesel – MBE 4000 Application And Installation ch13.pdf

Others/Detroit Diesel – MBE 4000 ENGINE EPA04 OPERATOR’S MANUAL – DDC-SVC-MAN-0056.pdf

Others/Detroit Diesel – Series 50G – 60G Training Program.ppt

Others/Det_Trans_ddc-svc-man-0128.pdf

Others/Diesel Exhaust Fluid and Coolant Lines.pdf

Others/Diesel Exhaust Fluid Tank.pdf

Others/Diesel Exhaust Fluid Tank Header Unit.pdf

Others/Diesel Oxidation Catalyst Inlet Pressure Sensor.pdf

Others/EPA07 10 GHG14 Exhaust – EGR – ATS Manual (DDC-SVC-MAN-0083)_.pdf

Others/EPA07 Aftertreatment Device Cleaning and Maintenance.pdf

Others/EPA07 Aftertreatment Device Removal and Installation on Vehicle.pdf

Others/EPA07 Aftertreatment Device Sensors.pdf

Others/EPA07 Aftertreatment System Overview.pdf

Others/EPA07_DDECVIddc-svc-man-0054.pdf

Others/EPA10 1-BOX from the Vehicle.pdf

Others/EPA10 1-BOX Sensor Box.pdf

Others/EPA10 2-BOX from the Vehicle.pdf

Others/EPA10_DDEC10ddc-svc-man-0045.pdf

Others/EPA10 Diesel Exhaust Fluid Metering Unit.pdf

Others/EPA10 Diesel Exhaust Fluid Nozzle.pdf

Others/EPA10 Diesel Exhaust Fluid Pump Module and Components.pdf

Others/EPA10 Diesel Particulate Filter.pdf

Others/Exhaust Gas Recirculation Actuator Lever.pdf

Others/Exhaust Gas Recirculation Crossover Tube.pdf

Others/Exhaust Gas Recirculation Hot Pipe.pdf

Others/Exhaust Gas Recirculation System – Cleaning.pdf

Others/Exhaust Gas Recirculation Venturi.pdf

Others/Fuel Compensation Pressure Sensor.pdf

Others/Fuel Doser Injector Valve.pdf

Others/GHG14 1-BOX from the Vehicle.pdf

Others/GHG14 2-BOX (2V2) From the Vehicle.pdf

Others/GHG14 2-BOX From the Vehicle.pdf

Others/GHG14 DD15 AT Exhaust Gas Recirculation Actuator Pull Rod.pdf

Others/GHG14 DD15 AT Exhaust Gas Recirculation Valve.pdf

Others/GHG14 DD15 AT Exhaust Gas Recirculation Valve Actuator.pdf

Others/GHG14 DD15 AT Flanged Exhaust Manifold.pdf

Others/GHG14_DDEC13ddc-svc-man-0127.pdf

Others/GHG14 Diesel Exhaust Fluid Dosing System.pdf

Others/GHG14 Diesel Exhaust Fluid Lines.pdf

Others/Grid Heater (EPA07).pdf

Others/Hydrocarbon Doser Block.pdf

Others/Hydrocarbon Doser Block Feed Line.pdf

Others/Hydrocarbon Doser Coolant Lines.pdf

Others/Hydrocarbon Fuel Doser Housing.pdf

Others/Intake Throttle Valve and Adaptor.pdf

Others/Mixer Pipe.pdf

Others/Resetting Diesel Particulate Filter Ash Accumulators.pdf

Others/SCR.pdf

Others/DDEC6_X_2007-2012_epa07_10/epa7 10 faults.pdf

Others/DDEC6_X_2007-2012_epa07_10/in_ex_turbo.pdf

Others/DDEC6_X_2007-2012_epa07_10/lube.pdf

Others/DDEC6_X_2007-2012_epa07_10/mechanical.pdf

Others/DDEC6_X_2007-2012_epa07_10/V4_PV776_370_98198_1_EngineECU_CumminsISX_VN_B9_98.pdf

Electrical Wiring Diagrams…..2

DD Platform EPA07 (DDECVI) EPA10 (DDEC10) GHG14 (DDEC13)…..4

EPA07 DD13 Motor Control Module (MCM) Engine Harness (page 1)…..5

EPA07 DD13 Motor Control Module (MCM) Engine Harness (page 2)…..6

EPA07 DD15 Motor Control Module (MCM) Engine Harness (page 1)…..7

EPA07 DD15 Motor Control Module (MCM) Engine Harness (page 2)…..8

EPA10 14-Pin Connectors…..9

EPA10 Aftertreatment 1-BOX™ Wiring Schematic…..10

EPA10 Aftertreatment 2HH Pierce Wiring Schematic…..11

EPA10 Aftertreatment 2HV Two-Box Wiring Schematic…..12

EPA10 Aftertreatment 2V2 Two-Box Wiring Schematic…..13

EPA10 Aftertreatment Control Module (ACM2) Electrical Schematic…..14

EPA10 Common Powertrain Controller (CPC2+) Vehicle Interface Harness (VIH)…..15

EPA10 DD13 Motor Control Module (MCM2) Engine Harness (page 1)…..16

EPA10 DD13 Motor Control Module (MCM2) Engine Harness (page 2)…..17

EPA10 DD15 Motor Control Module (MCM2) Engine Harness (page 1)…..18

EPA10 DD15 Motor Control Module (MCM2) Engine Harness (page 2)…..19

EuroIV Common Powertrain Controller (CPC2) Vehicle Interface Harness (VIH)…..20

EuroIV Export DD15 Motor Control Module (MCM) Engine Harness (page 1)…..21

EuroIV Export DD15 Motor Control Module (MCM) Engine Harness (page 2)…..22

GHG14 Aftertreatment Control Module (ACM2.1) Electrical Schematic…..23

GHG14 Common Powertrain Controller (CPC4) Vehicle Interface Harness (VIH)…..24

GHG14 DD13 Motor Control Module (MCM2.1) Engine Harness (page 1)…..25

GHG14 DD13 Motor Control Module (MCM2.1) Engine Harness (page 2)…..26

GHG14 DD15 and DD16 Motor Control Module (MCM2.1) Engine Harness (page 1)…..27

GHG14 DD15 and DD16 Motor Control Module (MCM2.1) Engine Harness (page 2)…..28

Horizontal ATD wiring – OEM and DDC Responsibility…..29

MBE 4000 (EPA04) DDEC-ECU EGR Engine Harness and Vehicle Interface Harness (page 1)…..30

MBE 4000 (EPA04) DDEC-ECU EGR Engine Harness and Vehicle Interface Harness (page 2)…..31

MBE 4000 (EPA07) Engine Harness (MCM-CPC) and Vehicle Interface Harness (page 1)…..32

MBE 4000 (EPA07) Engine Harness (MCM-CPC) and Vehicle Interface Harness (page 2)…..33

MBE 900 (EPA04) DDEC-ECU EGR Engine Harness and Vehicle Interface Harness (page 1)…..34

MBE 900 (EPA04) DDEC-ECU EGR Engine Harness and Vehicle Interface Harness (page 2)…..35

MBE 900 (EPA07) Engine Harness (MCM-CPC) and Vehicle Interface Harness (page 1)…..36

MBE 900 (EPA07) Engine Harness (MCM-CPC) and Vehicle Interface Harness (page 2)…..37

MBE Platform Electronic Wiring Schematics…..38

Series 50 DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 1)…..39

Series 50 DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 2)…..40

Series 50, 50G & 60 Electronic Wiring Schematics…..41

Series 50G DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 1)…..42

Series 50G DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 2)…..43

Series 60 (EPA07) DDEC VI MCM-CPC EGR Engine Harness and Vehicle Interface Harness (page 1)…..44

Series 60 (EPA07) DDEC VI MCM-CPC EGR Engine Harness and Vehicle Interface Harness (page 2)…..45

Series 60 DDEC III-IV Engine Harness and Vehicle Interface Harness (page 1)…..46

Series 60 DDEC III-IV Engine Harness and Vehicle Interface Harness (page 2)…..47

Series 60 DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 1)…..48

Series 60 DDEC IV My2003 EGR Engine Sensor Harness and Vehicle Interface Harness (page 2)…..49

Series 60 DDEC V EGR Engine Harness and Vehicle Interface Harness (page 1)…..50

Series 60 DDEC V EGR Engine Harness and Vehicle Interface Harness (page 2)…..51

Series 60 DDEC V Engine Harness and Vehicle Interface Harness (Non-Road Equipment) page 1…..52

Series 60 DDEC V Engine Harness and Vehicle Interface Harness (Non-Road Equipment) page 2…..53

Vertical ATD wiring – OEM and DDC Responsibility…..54

Others…..55

2-Box Diesel Oxidation Catalyst – Diesel Particulate Filter…..59

59.1 Diesel Oxidation Catalyst – Diesel Particulate Filter Additional Removal Information…..59

59.2 Removal of the 2–Box Diesel Oxidation Catalyst / Diesel Particulate Filter…..60

59.3 Installation of the 2–Box Diesel Oxidation Catalyst / Diesel Particulate Filter…..61

59.4 Removal of the GHG14 Two-Box Diesel Oxidation Catalyst…..63

59.5 Installation of the GHG14 Two-Box Diesel Oxidation Catalyst…..64

59.6 Removal of the 2-Box Diesel Particulate Filter…..65

59.7 Installation of the 2-Box Diesel Particulate Filter…..66

2-Box Diesel Oxidation Catalyst – Diesel Particulate Filter…..67

59.1 Diesel Oxidation Catalyst – Diesel Particulate Filter Additional Removal Information…..67

59.2 Removal of the 2–Box Diesel Oxidation Catalyst / Diesel Particulate Filter…..68

59.3 Installation of the 2–Box Diesel Oxidation Catalyst / Diesel Particulate Filter…..69

59.4 Removal of the GHG14 Two-Box Diesel Oxidation Catalyst…..71

59.5 Installation of the GHG14 Two-Box Diesel Oxidation Catalyst…..72

59.6 Removal of the 2-Box Diesel Particulate Filter…..73

59.7 Installation of the 2-Box Diesel Particulate Filter…..74

2-Box Selective Catalytic Reduction (SCR Catalyst)…..75

60.1 Selective Catalytic Reduction (SCR Catalyst) Additional Removal Information…..75

60.2 Removal of the Selective Catalytic Reduction (SCR Catalyst) from the Stanchion…..76

60.3 Installation of the Selective Catalytic Reduction (SCR) Catalyst to the Stanchion…..77

60.4 Removal of the Selective Catalytic Reduction (SCR Catalyst)…..79

60.5 Installation of the Selective Catalytic Reduction (SCR Catalyst)…..80

2-Box Selective Catalytic Reduction (SCR Catalyst)…..81

60.1 Selective Catalytic Reduction (SCR Catalyst) Additional Removal Information…..81

60.2 Removal of the Selective Catalytic Reduction (SCR Catalyst) from the Stanchion…..82

60.3 Installation of the Selective Catalytic Reduction (SCR) Catalyst to the Stanchion…..83

60.4 Removal of the Selective Catalytic Reduction (SCR Catalyst)…..85

60.5 Installation of the Selective Catalytic Reduction (SCR Catalyst)…..86

289329134-Detroit-DD15-Valve-Adjustment…..87

2HH Soot Sensor…..90

62.1 Removal of the 2V2/2HH Soot Sensor…..90

62.2 Installation of the 2V2/2HH Soot Sensor…..93

2V2/2HH Soot Sensor…..95

62.1 Removal of the 2V2/2HH Soot Sensor…..95

62.2 Installation of the 2V2/2HH Soot Sensor…..98

2V2 GHG14 Selective Catalytic Reduction NOx Sensor…..100

61.1 Removal of the 2V2 GHG14 Selective Catalytic Reduction NOx Sensor…..100

61.2 Installation of the 2V2 GHG14 Selective Catalytic Reduction NOx Sensor…..102

2V2 GHG14 Selective Catalytic Reduction NOx Sensor…..104

61.1 Removal of the 2V2 GHG14 Selective Catalytic Reduction NOx Sensor…..104

61.2 Installation of the 2V2 GHG14 Selective Catalytic Reduction NOx Sensor…..106

61527967-Ajuste-Valvulas-e-Inyectores-Detroit…..108

toc…..108

INTRODUCTION…..108

DETAILS AND REASON…..108

Disconnect starting power for engine…..108

Remove the engine valve rocker cover as outlined. Refer to secti…..108

Insert a 3/4 in. drive breaker bar or ratchet into the square ho…..108

Bar the engine in the direction of rotation and observe a cylind…..108

Stop turning the engine and mount a magnetic base dial indicator…..108

Set the pedestal of the dial indicator on the top of the injecto…..108

Continue to slowly bar the engine over in the direction of rotat…..108

This is the point of maximum injector roller lift, the injector …..108

If you rotate the engine beyond this point you will have to bar …..108

Stop engine rotation and note which cylinder this is, and follow…..109

This injector can now be set using this procedure:…..109

Loosen the locknut on the adjusting screw at least two full turn…..109

Tighten the adjusting screw until the injector plunger bottoms o…..109

Back the adjusting screw off 3/4 of a turn 0.75 mm 0.25 mm and…..109

The injector is now adjusted…..109

Adjust the valves on the corresponding cylinders listed in Table…..109

To adjust the intake valves, insert a 0.203 mm (0.008 in.) feele…..110

Loosen the locknut, and turn the adjusting set screw until the f…..110

Torque the locknut to 41 – 47 N m (30 – 35 lb ft) and remove the…..110

The exhaust valves are adjusted the same way as the intake valve…..111

Repeat steps 4 thru 11 until all injectors and valves have been …..111

Install the engine rocker cover. Refer to section 1.6.8 for one-…..111

Reconnect starting power to the engine…..111

INTRODUCTION…..108

DETAILS AND REASON…..108

Disconnect starting power for engine…..108

Remove the engine valve rocker cover as outlined. Refer to secti…..108

Insert a 3/4 in. drive breaker bar or ratchet into the square ho…..108

Bar the engine in the direction of rotation and observe a cylind…..108

Stop turning the engine and mount a magnetic base dial indicator…..108

Set the pedestal of the dial indicator on the top of the injecto…..108

Continue to slowly bar the engine over in the direction of rotat…..108

This is the point of maximum injector roller lift, the injector …..108

If you rotate the engine beyond this point you will have to bar …..108

Stop engine rotation and note which cylinder this is, and follow…..109

This injector can now be set using this procedure:…..109

Loosen the locknut on the adjusting screw at least two full turn…..109

Tighten the adjusting screw until the injector plunger bottoms o…..109

Back the adjusting screw off 3/4 of a turn 0.75 mm 0.25 mm and…..109

The injector is now adjusted…..109

Adjust the valves on the corresponding cylinders listed in Table…..109

To adjust the intake valves, insert a 0.203 mm (0.008 in.) feele…..110

Loosen the locknut, and turn the adjusting set screw until the f…..110

Torque the locknut to 41 – 47 N m (30 – 35 lb ft) and remove the…..110

The exhaust valves are adjusted the same way as the intake valve…..111

Repeat steps 4 thru 11 until all injectors and valves have been …..111

Install the engine rocker cover. Refer to section 1.6.8 for one-…..111

Reconnect starting power to the engine…..111

7SE500 0409 – UNIT FUEL INJECTORS AND UNIT PUMP TECHNICIAN GUIDE…..114

Aftertreatment Device Electronics…..190

38.1 Description and Operation of the Aftertreatment Control Module…..190

38.2 EPA10/GHG14 Aftertreatment Device Sensor Locations…..191

1-BOX™ Sensor Locations…..191

Diesel Oxidation Catalyst, Diesel Particulate Filter, and Selective Catalytic Reduction (SCR Catalyst) Mounted Vertically…..193

Diesel Oxidation Catalyst, Diesel Particulate Filter Mounted Horizontally, Selective Catalytic Reduction (SCR Catalyst) Mounted Vertically…..195

38.3 Removal of the Aftertreatment Control Module…..198

38.4 Installation of the Aftertreatment Control Module…..199

EPA10/GHG14 Aftertreatment Device Electronics…..200

38.1 Description and Operation of the Aftertreatment Control Module…..200

38.2 EPA10/GHG14 Aftertreatment Device Sensor Locations…..201

1-BOX™ Sensor Locations…..201

Diesel Oxidation Catalyst, Diesel Particulate Filter, and Selective Catalytic Reduction (SCR Catalyst) Mounted Vertically…..203

Diesel Oxidation Catalyst, Diesel Particulate Filter Mounted Horizontally, Selective Catalytic Reduction (SCR Catalyst) Mounted Vertically…..205

38.3 Removal of the Aftertreatment Control Module…..208

38.4 Installation of the Aftertreatment Control Module…..209

Aftertreatment System Overview…..210

37.1 Description and Operation of the EPA10 Aftertreatment System…..210

1-BOX™ Aftertreatment System Configuration…..210

2-Box Aftertreatment Systems Configurations…..210

Diesel Oxidation Catalyst, Diesel Particulate Filter, and Selective Catalytic Reduction Mounted Vertically…..210

Diesel Oxidation Catalyst, Diesel Particulate Filter Mounted Horizontally, Selective Catalytic Reduction Mounted Vertically…..211

Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR Catalyst) Mounted Horizontal…..212

37.2 Description and Operation of the Diesel Particulate Filter…..214

37.3 Description and Operation of the Selective Catalytic Reduction (SCR Catalyst)…..215

37.4 Description and Operation of the EPA10 Diesel Exhaust Fluid Heating…..216

37.5 Description and Operation of the GHG14 Diesel Exhaust Fluid Heating…..217

37.6 Description and Operation of the Diesel Exhaust Fluid Flow…..218

37.7 Description and Operation of the Diesel Exhaust Fluid (Compressed Air Flow)…..219

37.8 EPA10/GHG14 Aftertreatment Regeneration Strategy…..220

EPA10/GHG14 Zone Trigger…..220

EPA10/GHG14 Regeneration Strategy…..220

Passive Regeneration…..221

Active Regeneration…..221

Parked Regeneration…..222

37.9 Performing a Parked Regeneration – EPA10/GHG14…..224

37.10 Performing a Parked Regeneration Using DiagnosticLink®…..226

37.11 EPA10/GHG14 Aftertreatment Diesel Exhaust Fluid Gauge/Lamps…..227

37.12 Instrument Panel Lamps…..228

Amber Warning Lamp…..228

Red Stop Lamp…..228

Diesel Particulate Filter Regeneration Lamp…..228

High Exhaust System Temperature Lamp…..229

Malfunction Indicator Lamp…..229

Fuel Filter Restriction Sensor Lamp: Fuel Filter Failed…..229

Water-In-Fuel Lamp (WIF)…..230

EPA10/GHG14 Aftertreatment System Overview…..231

37.1 Description and Operation of the EPA10 Aftertreatment System…..231

1-BOX™ Aftertreatment System Configuration…..231

2-Box Aftertreatment Systems Configurations…..231

Diesel Oxidation Catalyst, Diesel Particulate Filter, and Selective Catalytic Reduction Mounted Vertically…..231

Diesel Oxidation Catalyst, Diesel Particulate Filter Mounted Horizontally, Selective Catalytic Reduction Mounted Vertically…..232

Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalytic Reduction (SCR Catalyst) Mounted Horizontal…..233

37.2 Description and Operation of the Diesel Particulate Filter…..235

37.3 Description and Operation of the Selective Catalytic Reduction (SCR Catalyst)…..236

37.4 Description and Operation of the EPA10 Diesel Exhaust Fluid Heating…..237

37.5 Description and Operation of the GHG14 Diesel Exhaust Fluid Heating…..238

37.6 Description and Operation of the Diesel Exhaust Fluid Flow…..239

37.7 Description and Operation of the Diesel Exhaust Fluid (Compressed Air Flow)…..240

37.8 EPA10/GHG14 Aftertreatment Regeneration Strategy…..241

EPA10/GHG14 Zone Trigger…..241

EPA10/GHG14 Regeneration Strategy…..241

Passive Regeneration…..242

Active Regeneration…..242

Parked Regeneration…..243

37.9 Performing a Parked Regeneration – EPA10/GHG14…..245

37.10 Performing a Parked Regeneration Using DiagnosticLink®…..247

37.11 EPA10/GHG14 Aftertreatment Diesel Exhaust Fluid Gauge/Lamps…..248

37.12 Instrument Panel Lamps…..249

Amber Warning Lamp…..249

Red Stop Lamp…..249

Diesel Particulate Filter Regeneration Lamp…..249

High Exhaust System Temperature Lamp…..250

Malfunction Indicator Lamp…..250

Fuel Filter Restriction Sensor Lamp: Fuel Filter Failed…..250

Water-In-Fuel Lamp (WIF)…..251

Allison Transmission – AT540 AT1542 Service Manual…..252

SM1241-9602-TOC.pdf…..0

Section 1. GENERAL INFORMATION…..256

Section 2. DESCRIPTION AND OPERATION…..256

Section 3. PREVENTIVE MAINTENANCE…..257

Section 4. GENERAL OVERHAUL INFORMATION…..258

Section 5. DISASSEMBLY OF TRANSMISSION…..258

Section 6. REBUILD OF SUBASSEMBLIES…..259

Section 7. ASSEMBLY OF TRANSMISSION…..260

Section 8. WEAR LIMITS AND SPRING DATA…..260

Section 9. CUSTOMER SERVICE…..260

CROSS-SECTION VIEWS…..261

SCHEMATIC VIEW…..261

EXPLODED VIEWS…..261

SM1241-9602-01.pdf…..0

1–1. SCOPE OF MANUAL…..262

a. Coverage…..262

b. Illustrations. Overhaul procedures are illustrated mainly by photographs. Line drawings are us……262

c. Maintenance Information. Each task outlined in this Service Manual has been successfully accom……262

1–2. SUPPLEMENTARY INFORMATION…..262

1–3. ORDERING PARTS…..262

a. Transmission Nameplate. The nameplate (Figure 1–5) is located on the right-rear side of the tr……262

b. Parts Catalog. Do not order by illustration item numbers on exploded views in this manual. All……262

Figure 1–1. AT 1545 Automatic Transmission — Left-Front View…..263

Figure1–2. AT 545R Automatic Transmission — Right-Rear View…..263

Figure1–3. AT 543 Automatic Transmission — Left-Front View…..264

Figure1–4. AT 542, 543, 1542 Automatic Transmission — Right-Rear View…..264

Figure1–5. Transmission Nameplate…..265

1–4. GENERAL DESCRIPTION…..265

a. Automatic, Four Speeds. The AT 500 and 1500 Series transmissions have four forward speeds and ……265

b. Torque Converter and Lockup Clutch. An Allison three-element torque converter (Foldout 1, 2, o……265

c. Planetary Gearing, Clutches. Ratios for four forward speeds and reverse are established by pla……265

d. Main Control Valve Body. The main control valve body consists of a series of spring-loaded spo……265

1–5. OPERATING INSTRUCTIONS…..265

1–6. SPECIFICATIONS AND DATA…..265

Table 1–1. Specifications and Data (cont’d)…..265

Table 1–1. Specifications and Data (cont’d)…..268

SM1241-9602-02.pdf…..0

2–1. SCOPE…..270

2–2. MOUNTING…..270

a. To Engine. The front of the transmission housing is an SAE size 3 flange. This flange is bolte……270

b. To Vehicle. Two 5⁄8-11 tapped holes at each side of the transmission are provided for mounting……270

2–3. INPUT DRIVE…..270

a. For models other than AT 543, six tapped lugs are on the front of torque converter 1 (Foldout ……270

b. For AT 543 models, six threaded studs are on the front of torque converter 2 (Foldout 7,A) for……270

2–4. TRANSMISSION HOUSING…..270

2–5. TORQUE CONVERTER ASSEMBLY AND LOCKUP CLUTCH…..270

a. Description…..270

b. Operation (Foldout 1, 2, or 3)…..270

2–6. OIL PUMP ASSEMBLY…..271

a. Description (Foldout 7,B)…..271

b. Operation (Foldout 7,B)…..271

2–7. FORWARD CLUTCH AND TURBINE SHAFT…..271

a. Description (Foldout 8)…..271

b. Operation (Foldout 8)…..271

2–8. FOURTH CLUTCH…..272

a. Description (Foldout 9,A)…..272

b. Operation (Foldout 9,A)…..272

2–9. SECOND AND THIRD CLUTCH AND CENTER SUPPORT…..272

a. Description (Foldout 9,B)…..272

b. Operation of Third Clutch (Foldout 9,B)…..272

c. Operation of Second Clutch (Foldout 9,B)…..273

2–10. FIRST CLUTCH…..273

a. Description (Foldout 10,B)…..273

b. Operation (Foldout 10,B)…..273

2–11. PLANETARY GEAR UNIT…..273

a. Description (Foldout 10,A)…..273

b. Operation. Refer to Paragraph 2–19…..273

2–12. SPEEDOMETER DRIVE/SPEED SENSOR WHEEL…..274

a. Description (Foldout 12,B)…..274

b. Operation (Foldout 12,B)…..274

2–13. GOVERNOR…..274

a. Description (Foldout 12,A). Governor assembly 19 is a centrifugal (flyweight) governor, driven……274

b. Operation (Foldout 12,A). When the governor rotates, centrifugal force causes weights to move ……274

2–14. MODULATOR…..274

a. Vacuum Modulator (Foldout 12,A)…..274

b. Mechanical Modulator…..274

c. Electric Modulator…..274

2–15. OIL PAN AND FILTER…..275

a. Description (Foldout 12,B)…..275

b. Function (Foldout 12,B)…..275

2–16. HYDRAULIC RETARDER…..275

a. Description…..275

b. Operation…..275

2–17. MAIN CONTROL VALVE ASSEMBLY…..276

2–18. HYDRAULIC SYSTEM…..276

a. System Functions. The hydraulic system generates, directs, and controls the pressure and flow ……276

b. System Schematic (Foldout 5 or 6). Color- coded foldouts of the hydraulic systems are presente……276

c. Filter, Pump Circuit. Transmission fluid is drawn from the sump through a filter screen by the……276

d. Main-Pressure Circuit (Red)…..276

e. Converter-In (Yellow), Converter-Out (Orange), Lubrication (Green) Circuits…..277

f. Selector Valve, Neutral, Forward Regulator Circuit (Orange and Yellow)…..277

g. Governor Valve, Governor Circuit (Green and White)…..277

h. Modulator Pressure Circuit (Red and Green)…..277

i. Clutch Circuits…..278

j. Hold Regulator Valve…..278

k. Automatic Upshifts…..278

l. Automatic Downshifts…..278

m. Downshift Inhibiting…..278

n. Trimmer Valves…..279

o. Priority Valve…..279

p. Trimmer Regulator Valve…..279

Figure 2–1. Neutral Power Flow…..280

2–19. TORQUE PATHS THROUGH TRANSMISSION…..280

a. Converter Operation. Power is transmitted hydraulically through the torque converter. The engi……280

b. Neutral Operation (Figure 2–1)…..280

Figure2–2. First Range Power Flow…..281

c. First-Range Operation (Figure 2–2)…..281

Figure2–3. Second Range Power Flow…..282

d. Second-Range Operation (Figure 2–3)…..282

Figure2–4. Third Range Power Flow…..283

e. Third-Range Operation (Figure 2–4). The forward and the third clutches are applied. The third ……283

f. Converter Operation (AT 1500 Series Models). During converter operation, 3–4 clutch feed press……283

g. Lockup Operation (AT 1500 Series Models). After the 2–3 upshift has occurred, main pressure be……283

Figure2–5. Fourth Range Power Flow…..284

h. Fourth-Range Operation (Figure 2–5). The forward and fourth clutches are applied. With the clu……284

i. Fourth-Range Lockup Operation (AT 1500 Series Models). Except for a momentary shift to convert……284

Figure2–6. Reverse Power Flow…..285

j. Reverse Operation (Figure 2–6). Reverse is the only range in which the forward clutch is not e……285

SM1241-9602-03.pdf…..0

3–1. SCOPE…..286

3–2. PERIODIC INSPECTION AND CARE…..286

a. Clean and inspect the exterior of the transmission at regular intervals. The severity of servi……286

b. Check the transmission hydraulic level at the intervals specified in the vehicle operator manual…..286

3–3. IMPORTANCE OF PROPER TRANSMISSION FLUID LEVEL…..286

a. Effects of Improper Fluid Level. Because the transmission fluid cools, lubricates, and transmi……286

b. Foaming and Aerating…..286

3–4. DIPSTICK MARKINGS…..286

Figure 3–1. Dipstick With FULL and ADD Markings…..287

Figure3–2. Dipstick With HOT RUN Markings…..287

Figure3–3. Dipstick With HOT OVERFULL Markings…..287

3–5. TRANSMISSION FLUID LEVEL CHECK PROCEDURE…..287

a. Preparation…..287

b. Cold Check…..288

c. Hot Check…..288

3–6. KEEPING TRANSMISSION FLUID CLEAN…..288

3–7. TRANSMISSION FLUID RECOMMENDATIONS…..288

Table 3–1. Operating Temperature Requirements for Transmission Fluid…..289

3–8. TRANSMISSION FLUID AND FILTER CHANGE INTERVALS…..289

3–9. TRANSMISSION FLUID CONTAMINATION…..289

a. Examine at Fluid Change. At each fluid change, examine the fluid which is drained for evidence……289

b. Metal Particles. Metal particles in the fluid (except for the minute particles normally trappe……289

c. Coolant Leakage. If engine coolant leaks into the transmission hydraulic system, immediate act……289

d. Auxiliary Filter (Figure 3–4)…..289

Table 3–2. Transmission Fluid and Filter Change Intervals …..290

Table 3–3. Fluid Oxidation Measurement Limits…..290

Figure3–4. Installation of Auxiliary Filter (Models Without Retarder)…..291

3–10. TRANSMISSION FLUID AND FILTER CHANGE PROCEDURES…..292

a. Disassembly (Foldout 12,B)…..292

b. Assembly (Foldout 12,B)…..292

3–11. BREATHER…..293

Figure3–5. Measuring the Length of Oil Pan Boss to Identify Torque Requirements…..293

Figure3–6. Fluid and Filter Change Reminder Labels…..293

Figure3–7. Breather Configurations…..294

3–12. LINKAGE…..294

b. Mechanical Actuator Adjustment. It is imperative the mechanical linkage be properly adjusted f……294

c. Other Linkage Adjustments. For adjustments to other linkage, such as PTO, speedometer, etc., r……294

3–13. ADJUSTMENT OF SHIFT POINTS…..294

b. Location of Adjusting Components…..294

c. Checks Before Adjusting Shift Points…..295

d. Calibration by Road Test Method…..295

e. Calibration by Speedometer Readings Method…..295

f. Calibration by Test Stand Method…..295

Table 3–4. Hold Regulator Pressure…..296

Table 3–5. Modulator Pressure…..296

Table 3–6. Governor Pressure…..296

Table 3–7. AT 500 Shift Points — Models With S/N 3210302450 and Before (Without Lockup)…..297

Table 3–8. AT 500 Shift Points — Models After S/N 3210302450 (Without Lockup)…..298

Table 3–9. AT 1500 Shift Points (With Lockup)…..299

3–14. TRANSMISSION STALL TEST AND NEUTRAL COOL-DOWN CHECK…..300

b. Stall Testing Preparation…..300

c. Stall Test Procedures — Vehicles Without Smoke-Controlled Engines…..300

d. Stall Test Procedures — Vehicles With Smoke-Controlled Engines…..301

e. Neutral Cool-Down Check Procedure…..301

f. Results…..301

3–15. PRESERVATION AND STORAGE…..301

a. Storage, New Transmissions (prior to installation). New transmissions are tested at the Alliso……301

b. Preservation Methods. When the transmission is to be stored or remain inactive for an extended……301

c. Storage, One Year — Without Transmission Fluid…..301

d. Storage, One Year — With Transmission Fluid (Normally in a Vehicle Chassis)…..302

e. Restoring Transmission to Service…..302

3–16. REPLACEMENT OF COMPONENTS WHILE TRANSMISSION IS IN THE VEHICLE CHASSIS…..303

b. Removal of Output Flange, Output Seal…..303

c. Removal of Output Shaft Bearing (Foldout 12,B)…..303

d. Removal of Speedometer Drive Gear or Speed Sensor Wheel and Selective Spacer (Foldout 12,B). R……303

e. Installation of Speedometer Drive Gear or Speed Sensor Wheel and Selective Spacer (Foldout 12,B)…..303

Figure3–8. Removing Ten-Ball Bearing from Output Shaft…..303

f. Installation of Output Shaft Bearing and Snapring…..304

g. Installation of Output Seal (Foldout 12,B)…..304

h. Installation of Output Flange…..304

3–17. TROUBLESHOOTING — BEFORE REMOVAL OR OPERATION OF TRANSMISSION…..304

a. Visual Inspection. Do not operate the vehicle prior to completing the procedures described in ……304

b. Vacuum Modulator Check…..304

Figure3–9. Identification of Flange Retaining Bolt…..305

Figure3–10. Gauge for Comparing Vacuum Modulators…..306

3–18. TROUBLESHOOTING — BEFORE REMOVAL AND DURING OPERATION…..306

b. Proper Engine Tuning. In order to make a thorough test of the transmission while it is mounted……306

c. Hydraulic Pressure Checking Procedures…..306

3–19. TROUBLESHOOTING — TRANSMISSION REMOVED FROM VEHICLE…..306

3–20. TROUBLESHOOTING PROCEDURES…..306

Figure3–11. Transmission Check Points…..307

Figure3–12. Transmission Check Points (Models Without Retarder)…..307

Figure3–13. Transmission Check Points (Models With Retarder)…..308

Table 3–10. Main Pressure Check Procedure (Models With Demodulated Main Pressure)…..308

Table 3–11. Main Pressure Check Procedure (Models With Modulated Main Pressure)…..309

Table 3–12. Retarder Pressure Check Procedure…..309

Table 3–13. Troubleshooting Chart (cont’d)…..310

SM1241-9602-04.pdf…..0

4–1. SCOPE…..320

4–2. TOOLS AND EQUIPMENT…..320

a. Improvised Tools and Equipment. The following items may be improvised…..320

b. Special Tools. Special tools are illustrated in Figures 4–2 through 4–4. They are identified i……320

Figure 4–1. Typical Work Table…..320

Figure4–2. Special Tools (1 thru 34)…..321

Figure4–3. Special Tools (35 thru 45)…..322

Figure4–4. Special Tools (46 thru 77)…..323

Table 4–1. Special Tools (cont’d)…..324

c. Mechanic’s Tools, Shop Equipment. The following tools, in addition to the common tools ordinar……327

4–3. REPLACEMENT PARTS…..328

a. Ordering Information. Refer to the latest edition of Parts Catalog PC1235EN for parts informat……328

b. Parts Normally Replaced. The following parts are normally replaced at each transmission overhaul…..328

4–4. CAREFUL HANDLING…..328

4–5. CLEANING AND INSPECTION…..328

a. Dirt-Free Assembly. All parts must be clean to permit effective inspection. It is very importa……328

b. Cleaning Parts…..328

c. Cleaning Bearings…..328

d. Inspecting Bearings…..329

e. Keeping Bearings Clean. Because the presence of dirt or grit in bearings is usually responsibl……329

f. Inspecting Cast Parts, Machined Surfaces…..329

g. Inspecting Bushings, Thrust Washers…..330

h. Inspecting Oil Seals, Gaskets…..330

Figure4–5. Transmission Housing — Main Control Valve Body Mounting Surface Tracks…..330

i. Inspecting Gears…..331

j. Inspecting Splined Parts. Inspect splined parts for stripped, twisted, chipped, or burred spli……331

k. Inspecting Threaded Parts. Inspect parts for burred or damaged threads. Remove burrs with a so……331

l. Inspecting Snaprings. Inspect all snaprings for nicks, distortion, and excessive wear. Replace……331

m. Inspecting Springs. Inspect springs for signs of overheating, permanent set, or wear due to ru……331

n. Inspecting Clutch Plates…..331

o. Inspecting Swaged, Interference-Fit Parts. If there is evidence of looseness, replace the asse……331

p. Inspecting Balls in Clutch Housings. Inspect all balls in rotating clutch housings for free mo……331

q. Inspecting Seal Contact Surfaces…..331

Figure4–6. Method of Measuring Clutch Plate Cone…..331

4–6. ASSEMBLY PROCEDURES…..332

a. Clutches, Pistons…..332

b. Parts Lubrication. During final assembly, lubricate all moving parts with transmission fluid. ……332

c. External Pipe Plugs, Hydraulic Fittings…..332

d. Oil-Soluble Grease…..332

e. Lip-Type Seals (Metal-Encased)…..332

f. Interference-Fit Parts. Assembly of interference-fit parts may be accomplished by heating and ……332

g. Sleeve-Type Bearings and Bushings. The use of a locking compound such as Loctite® Sleeve Retai……332

h. Bearings (Ball or Roller)…..332

4–7. REMOVING (OR INSTALLING) TRANSMISSION…..333

a. Drain Transmission Fluid. Drain the transmission fluid from the transmission before removal fr……333

b. Check Linkages and Lines. Make sure that all linkage controls, cooler lines, temperature conne……333

c. Remove, Clean Transmission. Clean the exterior of the transmission. If steam cleaning is used,……333

d. Transmission Installation…..333

4–8. WEAR LIMITS…..333

4–9. SPRING SPECIFICATIONS…..333

4–10. TORQUE SPECIFICATIONS…..333

SM1241-9602-05.pdf…..0

5–1. SCOPE…..334

5–2. GENERAL INFORMATION…..334

a. General Information. Refer to Sections 4 and 8 for general information as follows:…..334

b. Removal of Exterior Hoses and Lines. Remove hoses 1 and 4 (Foldout 13) and adapters as require……334

5–3. TRANSMISSION DISASSEMBLY…..334

a. Mounting of Transmission in Table-Mounted Holding Fixture…..334

Figure 5–1. Transmission in Holding Fixture…..334

b. Removal of Torque Converter…..335

c. Removal of Vacuum Modulator, Mechanical Actuator…..335

d. Removal of Breather…..335

Figure5–2. Removing Torque Converter During Overhaul…..335

Figure5–3. Removing Vacuum Modulator Retainer Bolt…..335

Figure5–4. Removing Vacuum Modulator…..336

e. Removal of Governor…..336

f. Removal of Oil Pan…..336

Figure5–5. Removing Governor Assembly…..336

Figure5–6. Removing Oil Pan…..336

g. Removal of Filter…..336

h. Removal of Main Control Valve Body…..336

Figure5–7. Removing Main Control Valve Body…..337

i. Removal of Pump…..338

Figure5–8. Removing Governor Check Ball (Earlier Models)…..338

Figure5–9. Removing Pump Assembly (Models without Retarder)…..338

Figure5–10. Removing Pump Assembly (Models with Retarder)…..338

j. Removal of Forward Clutch and Turbine Shaft…..339

k. Removal of Retarder Components, Forward Clutch and Turbine Shaft…..339

Figure5–11. Removing Front Support Gasket (Models Without Retarder)…..339

Figure5–12. Removing Front Support Gasket (Models With Retarder)…..339

Figure5–13. Removing Forward Clutch and Turbine Shaft Assembly and Front Stator (Models With Re……339

l. Removal of Fourth Clutch…..340

Figure5–14. Removing Retarder Housing Assembly (Models With Retarder)…..340

Figure5–15. Removing Fourth-Clutch Assembly…..340

m. Removal of Third Clutch…..340

n. Removal of Center Support Assembly…..340

Figure5–16. Removing Sun Gear Shaft Assembly (Models Without Retarder)…..340

Figure5–17. Removing Third Clutch Plates…..341

o. Removal of Planetary Gearing…..341

Figure5–18. Removing Center Support Assembly…..341

Figure5–19. Removing Front Sun Gear Thrust Washer…..341

Figure5–20. Removing Planetary Gear Unit…..342

p. Removal of Second Clutch…..342

q. Removal of First Clutch…..342

Figure5–21. Removing Second Clutch Snapring…..342

Figure5–22. Removing Second Clutch Backplate…..342

Figure5–23. Removing First Clutch Spring Retainer Snapring…..343

Figure5–24. Removing Output Shaft Bearing Snapring…..343

r. Removal of Output Shaft Seal and Bearing…..343

SM1241-9602-06.pdf…..0

6–1. SCOPE…..344

6–2. GENERAL INFORMATION FOR SUBASSEMBLY REBUILD…..344

6–3. INSPECTING AND TESTING TORQUE CONVERTER…..344

a. Preliminary Inspection. Clear the torque converter of transmission fluid. Examine the fluid fo……344

b. End Play Check…..344

Figure 6–1. Checking End Play of Torque Converter Element…..344

Table 6–1. Converter Turbine End Play…..345

c. Leak Check…..345

Figure6–2. Pressurizing Torque Converter for Leak Test…..345

d. Inspection of Hub…..345

e. Preparation for Reuse of Converter. If the torque converter is to be reused, flush the convert……345

6–4. TORQUE CONVERTER ASSEMBLY — AT 543 MODELS…..345

a. Preliminary Check of End Play. Check the torque converter for end play of internal components ……345

b. Disassembly (Foldout 7,A)…..345

Figure6–3. Removing (or Installing) Torque Converter Cover Nuts (AT 543)…..345

Figure6–4. Removing (or Installing) Torque Converter Cover (AT 543)…..346

Figure6–5. Removing (or Installing) Spacer, Bearing, and Races at Front of Torque Converter Tur……346

Figure6–6. Removing (or Installing) Torque Converter Turbine (AT 543)…..346

Figure6–7. Removing (or Installing) Torque Converter Stator Assembly (AT 543)…..346

c. Replacement of Needle Bearing Assembly in Stator Assembly…..347

Figure6–8. Removing (or Installing) Torque Converter Pump Bearing and Race (AT 543)…..347

d. Assembly (Foldout 7,A)…..347

Figure6–9. Installing Stator Thrust Bearing (AT 543)…..347

Figure6–10. Stator Bearing Installation (AT 543)…..348

Figure6–11. Installing Freewheel Roller Race (AT 543)…..348

Figure6–12. Spring and Roller in Stator Cam (AT 543)…..349

Figure6–13. Measuring Dimension A for Selection of Converter Spacer (AT 543)…..350

Figure6–14. Measuring Dimension B for Selection of Converter Spacer (AT 543)…..350

Figure6–15. Measuring Dimension C for Selection of Converter Spacer (AT 543)…..350

Figure6–16. Measuring Dimension D for Selection of Converter Spacer (AT 543)…..350

6–5. GOVERNOR…..350

a. Disassembly (Foldout 12,A)…..350

b. Assembly (Foldout 12,A)…..351

6–6. MAIN CONTROL VALVE BODY…..351

a. Disassembly (Foldout 11)…..351

Figure6–17. Governor Assembly — Showing Port Openings…..351

Figure6–18. Step Numbers for Recording the Positions of Adjusting Rings…..351

Figure6–19. 1–2 Relay Valve…..352

b. Assembly (Foldout 11)…..353

Figure6–20. Control Valve Body Assembly — With Components Installed…..354

Figure6–21. Adjusting Modulator Valve Ring…..355

6–7. RETARDER CONTROL VALVE BODY…..355

a. Disassembly (Foldout 13)…..355

b. Assembly…..356

6–8. TRANSFER PLATE ASSEMBLY (Retarder Models) (Foldout 13)…..356

a. Disassembly…..356

Figure6–22. Terminal Removal…..356

b. Assembly…..357

Figure6–23. Terminal Installation…..357

6–9. OIL PUMP AND FRONT SUPPORT ASSEMBLY…..357

a. Disassembly (Foldout 7,B)…..357

Figure6–24. Removing (or Installing) Main-Pressure Regulator Valve…..358

b. Installation of Stator Shaft and Bushing (Foldout 7,B)…..359

Figure6–25. Installation of Stator Shaft, Machining of Bushing and Bearing Bores (AT 500 Series)…..359

c. Pump Gear Clearance Check (Foldout 7,B)…..360

Figure6–26. Installation of Stator Shaft (AT 1500 Series)…..360

d. Assembly (Foldout 7,B)…..361

Figure6–27. Installing Stator Shaft Front Bushing (AT 500 Series Models)…..361

Figure6–28. Zero Dial Indicator on Oil Pump Body Surface…..361

Figure6–29. Dial Indicator Check of Oil Pump Driven Gear End Clearance…..361

Figure6–30. Dial Indicator Check of Oil Pump Drive Gear End Clearance…..361

Figure6–31. Checking Diametrical Clearance of Oil Pump Driven Gear…..361

Figure6–32. Installing Stator Shaft Rear Bearing (Models without Lockup)…..362

Figure6–33. Installing Oil Pump Seal…..363

Figure6–34. Rework Dimensions for Front Support…..363

6–10. FORWARD CLUTCH AND TURBINE SHAFT ASSEMBLY…..363

a. Disassembly…..363

Figure6–35. Removing PTO Gear From Forward Clutch Housing (Later Models Without Retarder)…..364

Figure6–36. Forward Clutch Housing Identification…..365

Figure6–37. Removing (or Installing) Forward Clutch Spring Retainer Snapring…..365

b. Checking Clutch Pack Clearance (Models Without Wave Plate)…..365

Figure6–38. Fourth Clutch Drive Hub Identification…..366

Figure6–39. Checking Forward Clutch Clearance (Models Without Wave Plate)…..366

c. Assembly (Foldout 8)…..366

Figure6–40. Forward Clutch Clearance Check Point (Models Without Wave Plate)…..366

Figure6–41. Installing Forward Clutch Thrust Bearing…..367

Figure6–42. Installing Forward Clutch Plates (Models Without Wave Plate)…..367

6–11. RETARDER HOUSING ASSEMBLY…..368

a. Disassembly…..368

b. Assembly…..368

6–12. FOURTH CLUTCH ASSEMBLY…..368

a. Disassembly (Foldout 9,A)…..368

Figure6–43. Removing (or Installing) Fourth Clutch Spring Retainer Snapring…..368

b. Checking Clutch Pack Clearance…..369

Figure6–44. Checking Fourth Clutch Clearance…..369

Figure6–45. Fourth Clutch Clearance Check Point…..369

c. Assembly (Foldout 9,A)…..370

6–13. CENTER SUPPORT ASSEMBLY…..370

a. Disassembly (Foldout 9,B)…..370

Figure6–46. Removing Self-Locking Retainer Washers…..370

b. Rework of Center Support Piston Retainer Locating Notches (Foldout 9,B)…..371

c. Assembly (Foldout 9,B)…..371

Figure6–47. Rework of Center Support Piston Retainer Locating Notches…..371

Figure6–48. Center Support Assembly…..372

Figure6–49. Installing Center Support Bushing…..372

6–14. PLANETARY GEAR UNIT…..372

a. Disassembly (Foldout 10,A)…..372

Figure6–50. Installing Self-Locking Retainer Washer…..372

b. Assembly (Foldout 10,A)…..373

Figure6–51. Output Shaft Assembly…..373

Figure6–52. Installing Output Shaft Bushing…..373

Figure6–53. Sun Gear Shaft and Bushings…..374

Figure6–54. Installing Sun Gear Shaft Bushing…..374

Figure6–55. Governor Drive Gear Configurations…..375

6–15. TRANSMISSION MAIN HOUSING ASSEMBLY…..375

a. Disassembly…..375

Figure6–56. Selector Shaft Components…..375

Figure6–57. Governor Support Pin Location…..375

b. Assembly…..376

Figure6–58. Installing Selector Shaft Oil Seal…..376

6–16. PLANETARY CARRIER ASSEMBLIES…..376

a. Inspection…..377

Figure6–59. Planetary Rebuild Tool Identification…..377

b. Removal of Pinion Components…..378

c. Replacing Bushing in Front Planetary Carrier…..378

Figure6–60. Front Carrier Assembly Bushing Installation…..378

d. Installation of Pinion Components…..379

Figure6–61. Typical Swaging Pattern on Pinion Pin…..379

6–17. CLUTCH STACK MEASUREMENT…..380

a. Assembly Line…..380

b. Forward Clutch…..380

c. Fourth Clutch…..380

Figure6–62. Determining Forward Clutch Piston Thickness (Models Not Using a Wave Plate)…..380

Figure6–63. Determining Forward Clutch Piston Thickness (Models Using a Wave Plate)…..380

d. Third Clutch. Refer to Paragraph 7–7a for clutch clearance…..381

e. Second Clutch…..381

Figure6–64. Determining Fourth Clutch Piston Thickness…..381

Figure6–65. Fourth Clutch Housing Identification…..381

Figure6–66. Checking Second Clutch Plate Running Clearance…..381

Figure6–67. Determining First Clutch Backplate Thickness…..381

f. First Clutch…..382

SM1241-9602-07.pdf…..0

7–1. SCOPE…..384

7–2. GENERAL INFORMATION FOR FINAL ASSEMBLY…..384

7–3. SELECTIVE COMPONENTS…..384

a. Establish Clearances…..384

b. Clutch Plate Stack Measurements…..384

7–4. INSTALLATION OF FIRST CLUTCH AND GEARING…..384

a. First Clutch (Foldout 10,B)…..384

Figure 7–1. Installing First Clutch Piston…..384

Figure7–2. Installing First Clutch Spring Retainer Snapring…..385

b. First Clutch Running Clearance (Foldout 10,B)…..385

Figure7–3. Installing First Clutch Plates Onto Rear Planetary Ring Gear…..386

Figure7–4. Installing First Clutch Backplate…..386

Figure7–5. Checking First Clutch Running Clearance…..386

c. Planetary Gear Unit…..387

7–5. INSTALLATION OF SECOND CLUTCH AND CENTER SUPPORT…..387

a. Second Clutch Pack (Foldout 9,B)…..387

Figure7–6. Installing Planetary Gear Unit…..387

Figure7–7. Installing Sun Gear Shaft Assembly and Thrust Washer…..387

Figure7–8. Installing Second Clutch Plates…..388

b. Center Support and Pistons (Foldout 9,B)…..388

Figure7–9. Second Clutch Snapring Installed…..388

Figure7–10. Compressing Center Support For Snapring Measurement…..389

7–6. INSTALLATION OF REAR BEARING SPACER AND FOURTH CLUTCH…..389

a. Selecting, Installing Rear Bearing Spacer (Foldout 12,B)…..389

Figure7–11. Measuring For Selection of Center Support Snapring…..389

Figure7–12. Installing Sun Gear Shaft Retainer…..390

Figure7–13. Installing Governor Drive Gear…..390

Figure7–14. Measuring For Selection of Rear Bearing Spacer…..390

Figure7–15. Installing Rear Output Shaft Bearing…..391

Figure7–16. Checking End Play of Output Shaft…..391

b. Fourth Clutch (Foldout 9,A)…..391

Figure7–17. Positioning Components For Front Thrust Washer Measurements…..391

Figure7–18. Sun Gear Shaft Clearance…..392

7–7. INSTALLATION OF THIRD AND FORWARD CLUTCHES…..392

a. Third Clutch (Foldout 9,B)…..392

b. Retarder Housing Assembly. Install the retarder housing assembly, stator blades upward, aligni……392

Figure7–19. Installing Third Clutch Plates…..393

Figure7–20. Checking Third Clutch Running Clearance (Models Without Retarder)…..393

Figure7–21. Installing Retarder Housing Assembly (Models With Retarder)…..393

c. Forward Clutch and Turbine Shaft Assembly (Foldout 8)…..393

Figure7–22. Installing Thrust Washer at Rear of Forward Clutch Hub…..393

7–8. INSTALLATION OF OIL PUMP ASSEMBLY…..394

a. Selection of Front Thrust Washer (Foldout 7,B)…..394

Figure7–23. Installing Retarder Housing Assembly Guide Pins (Models With Retarder)…..394

Figure7–24. Installing Retarder Front Stator (Models With Retarder)…..394

Figure7–25. Measuring For Selection of Front Thrust Washer…..394

b. Pump Assembly (Foldout 7,B)…..395

Figure7–26. Installing Hook-Type Sealrings Onto Oil Pump Assembly…..395

Figure7–27. Installing Front Support Gasket (Models Without Retarder)…..395

Figure7–28. Installing Oil Pump Assembly (Models Without Retarder)…..395

Figure7–29. Installing Oil Pump Assembly (Models With Retarder)…..395

7–9. INSTALLATION OF OUTPUT SHAFT OIL SEAL (Foldout 12,B)…..396

Figure7–30. Measuring Turbine Shaft End Play…..396

7–10. INSTALLATION OF MAIN CONTROL VALVE BODY, OIL FILTER, AND OIL PAN…..396

a. Main Control Valve Body…..396

Figure7–31. Installing Output Shaft Oil Seal…..396

Figure7–32. Installing Governor Check Ball (Earlier Models)…..397

Figure7–33. Installing Valve Body and Sump Components…..398

b. Filter…..398

c. Oil Pan…..398

Figure7–34. Installing Oil Filter Screw and Washer (Models Prior to S/N 3210622842)…..399

Figure7–35. Installing Transmission Oil Pan (Shallow Pan Models)…..399

7–11. INSTALLATION OF GOVERNOR, MODULATOR, AND TORQUE CONVERTER…..399

a. Governor…..399

b. Vacuum Modulator…..399

Figure7–36. Installing Governor Assembly…..399

Figure7–37. Installing Vacuum Modulator…..400

Figure7–38. Installing Vacuum Modulator Retainer Bolt…..400

c. Torque Converter Assembly (Foldout 7,A or B)…..400

Figure7–39. Installing Torque Converter Assembly…..400

7–12. REMOVAL OF TRANSMISSION FROM OVERHAUL STAND AND INSTALLATION OF EXTERNAL COMPONENTS…..401

a. Supporting Transmission…..401

b. Determining Third Clutch Clearance…..401

c. Installing Retarder Valve Body…..401

d. Installing PTO Cover (Foldout 12,A)…..401

e. Installing Neutral Start Switch, Speedometer Components…..401

f. Shift Lever Installation. Refer to Paragraph 3–12 for installation specifications…..401

7–13. CHECKING AND ADJUSTING SHIFT POINTS…..402

7–14. POWER TAKEOFF COMPONENTS (Models Without Retarder)…..402

a. Existing Installation…..402

b. Determining Turbine-Driven PTO Backlash…..402

c. New Installation…..402

Figure7–40. Measuring Turbine-Driven PTO Backlash (Models Without Retarder)…..403

SM1241-9602-08.pdf…..0

8–1. WEAR LIMIT DATA…..404

8–2. SPRING DATA…..404

Table 8–1. Wear Limits (Cont’d)…..404

Table 8–2. Spring Data (Cont’d)…..407

SM1241-9602-09.pdf…..0

9–1. OWNER ASSISTANCE…..418

9–2. SERVICE LITERATURE…..419

Table 9–1. Service Literature…..419

DD13 Exhaust Flanged Manifold…..442

DD13 Exhaust Flanged Manifold…..442

3.1 Description and Operation of the DD13 Exhaust Flanged Manifold…..442

3.2 Removal of the DD13 Exhaust Flanged Manifold…..444

3.3 Installation of the DD13 Exhaust Flanged Manifold…..446

DD13 Exhaust Gas Recirculation Cooler Water Manifold Assembly…..448

DD13 Exhaust Gas Recirculation Cooler Water Manifold Assembly…..448

10.1 Description and Operation of DD13 Exhaust Gas Recirculation Cooler Water Manifold Assembly…..448

10.2 Removal of the DD13 Exhaust Gas Recirculation Cooler Water Manifold Assembly…..451

10.3 Inspection of the DD13 EGR Cooler Water Manifold Assembly…..453

10.4 Testing of the DD13 Exhaust Gas Recirculation Cooler Water Manifold Assembly – In Chassis…..454

10.5 Installation of the DD13 EGR Cooler Water Manifold Assembly…..456

DD13 Exhaust Gas Recirculation Valve Actuator Pull Rod…..458

DD13 Exhaust Gas Recirculation Valve Actuator Pull Rod…..458

12.1 Removal of the Exhaust Gas Recirculation Valve Actuator Pull Rod…..458

12.2 Inspection of DD13 Exhaust Gas Recirculation Valve Actuator Pull Rod…..460

12.3 Installation of the DD13 Exhaust Gas Recirculation Valve Actuator Pull Rod…..461

DD13 Exhaust Gas Recirculation Valve Actuator…..463

DD13 Exhaust Gas Recirculation Valve Actuator…..463

15.1 Description and Operation of the DD13 Exhaust Gas Recirculation Valve Actuator…..463

15.2 Removal of the DD13 Exhaust Gas Recirculation Valve Actuator…..466

15.3 Installation of the DD13 Exhaust Gas Recirculation Valve Actuator…..467

DD13 Exhaust Gas Recirculation Valve…..469

21.1 Description and Operation of the DD13 Exhaust Gas Recirculation Valve…..469

DD13 Exhaust Gas Recirculation Valve…..470

DD15 and DD16 Exhaust Gas Recirculation Cooler…..471

DD15 and DD16 Exhaust Gas Recirculation Cooler…..471

11.1 Description and Operation of the DD15 and DD16 Exhaust Gas Recirculation Cooler…..471

11.2 Removal of the DD15 and DD16 Exhaust Gas Recirculation Cooler…..475

11.3 Testing of the DD15 and DD16 Exhaust Gas Recirculation Cooler – In Chassis…..476

11.4 Installation of the DD15 and DD16 Exhaust Gas Recirculation Cooler…..478

DD15 and DD16 Exhaust Gas Recirculation Valve Actuator Pull Rod…..480

DD15 and DD16 Exhaust Gas Recirculation Valve Actuator Pull Rod…..480

13.1 Removal of the DD15 and DD16 Exhaust Gas Recirculation Valve Actuator Pull Rod…..480

13.2 Installation of the DD15 and DD16 Exhaust Gas Recirculation Valve Actuator Pull Rod…..483

DD15 and DD16 Exhaust Gas Recirculation Valve Actuator…..485

DD15 and DD16 Exhaust Gas Recirculation Valve Actuator…..485

16.1 Description and Operation of the DD15 and DD16 Exhaust Gas Recirculation Valve Actuator…..485

16.2 Removal of the DD15 and DD16 Delphi© Exhaust Gas Recirculation Valve Actuator…..489

16.3 Installation of the DD15 and DD16 Delphi© Exhaust Gas Recirculation Valve Actuator…..491

16.4 Removal of the DD15 and DD16 Sonceboz® Exhaust Gas Recirculation Valve Actuator…..493

16.5 Installation of the DD15 and DD16 Sonceboz® Exhaust Gas Recirculation Valve Actuator…..496

DD15 and DD16 Exhaust Gas Recirculation Valve…..499

DD15 and DD16 Exhaust Gas Recirculation Valve…..499

22.1 Description and Operation of the DD15 and DD16 Exhaust Gas Recirculation Valve…..499

22.2 Removal of the DD15 and DD16 Exhaust Gas Recirculation Valve…..502

22.3 Installation of the DD15 and DD16 Exhaust Gas Recirculation Valve…..503

DD15 and DD16 Exhaust S-pipe (Elbow)…..504

DD15 and DD16 Exhaust S-pipe (Elbow)…..504

4.1 Description and Operation of the DD15 and DD16 Exhaust S-Pipe (Elbow) and Related Parts…..504

4.2 Removal of the DD15 and DD16 Exhaust S-pipe…..505

4.3 Installation of the DD15 and DD16 Exhaust S-pipe…..506

DDC-SVC-MAN-0073 – DD PLATFORM APPLICATION AND INSTALLATION MANUAL…..507

DDC-SVC-MAN-0081 2010 – EPA07_10 DD PLATFORM WORKSHOP MANUAL – ENGINE…..811

DDC-SVC-MAN-0110 – DDEC IV APPLICATION AND INSTALLATION MANUAL…..1253

DDEC6_X_2007-2012_epa07_10…..2011

V4_PV776_370_98198_1_EngineECU_CumminsISX_VN_B9_98…..2012

epa7 10 faults…..2017

in_ex_turbo…..2488

lube…..2597

mechanical…..2612

DDECIV_EGRddc-svc-man-0109…..2735

DDECVddc-svc-man-0108…..3333

DD_EuroIV_DDECVIddc-svc-man-0185…..3930

1 Attention…..3933

2 Abstract…..3934

3 Introduction…..3935

3.1 Introduction…..3935

4 Safety Precautions…..3936

4.1 Safety Precautions…..3936

5 Hardware and Wiring…..3940

5.1 Motor Control Module…..3940

5.1.1 Environmental Conditions…..3940

5.1.2 Engine Harness…..3940

5.2 Common Powertrain Controller…..3945

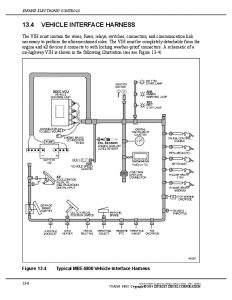

5.2.1 CPC Vehicle Interface Harness…..3947

5.2.2 VIH Wiring…..3951

5.2.3 Power Supply – 12 Volt System…..3959

5.2.4 Fuses…..3962

5.2.5 Connectors…..3963

5.3 Wires and Wiring…..3965

5.4 Conduit and Loom…..3977

5.5 Tape and Taping…..3978

5.6 Sensors…..3978

5.6.1 Factory-installed Sensors…..3979

5.6.2 OEM-installed Sensors…..3979

5.7 Lamps…..3988

5.7.1 Amber Warning Lamp (AWL)…..3988

5.7.2 Cruise Active Lamp…..3988

5.7.3 Deceleration Lamp…..3989

5.7.4 Fuel Filter Restriction Lamp…..3990

5.7.5 Low Battery Voltage Lamp…..3991

5.7.6 Low Coolant Level Lamp…..3992

5.7.7 Low Oil Pressure Lamp…..3993

5.7.8 Malfunction Indicator Lamp (MIL)…..3994

5.7.9 Optimized Idle Active Lamp…..3994

5.7.10 Red Stop Lamp…..3995

5.7.11 Wait-to-Start Lamp…..3996

5.7.12 Water-In-Fuel Lamp (R2.0 or Later)…..3997

6 Inputs and Outputs…..3999

6.1 Digital Inputs Overview – CPC…..3999

6.1.1 Inputs – Air Condition Status…..3999

6.1.2 Inputs – Auxiliary Shutdown #1…..4000

6.1.3 Inputs – Clutch Switch…..4001

6.1.4 Inputs – Cruise Control ON/OFF Switch…..4002

6.1.5 Inputs – Cruise Control Resume/Accel Switch and Set/Coast Switch…..4002

6.1.6 Inputs – Diagnostic Request Switch…..4003

6.1.7 Inputs – Dual-Speed Axle Switch…..4004

6.1.8 Inputs – Engine Brake Disable…..4004

6.1.9 Inputs – Engine Brake Low and Medium…..4005

6.1.10 Inputs – Fan Override…..4006

6.1.11 Inputs – Fast Engine Heat-Up Switch…..4006

6.1.12 Inputs – Idle Validation 1 and Idle Validation 2…..4007

6.1.13 Inputs – Limiters for Torque, Engine Speed, and Vehicle Speed…..4007

6.1.14 Inputs – Optimized Idle Hood Tilt Switch…..4007

6.1.15 Inputs – Optimized Idle Thermostat…..4007

6.1.16 Inputs – Park Brake Switch…..4008

6.1.17 Inputs – Remote Throttle Select Switch…..4008

6.1.18 Inputs – Remote PTO Switch…..4009

6.1.19 Inputs – RPM Freeze…..4010

6.1.20 Inputs – Service Brake Released Switch…..4010

6.1.21 Inputs – Stop Engine Override…..4011

6.1.22 Inputs – Throttle Inhibit…..4011

6.1.23 Inputs – Transmission Neutral Switch…..4012

6.1.24 Inputs – Transmission Retarder Active…..4012

6.2 Switch Inputs Received Over J1939 Data Link…..4013

6.3 Digital Outputs Overview – CPC…..4015

6.3.1 Outputs – Amber Warning Lamp…..4016

6.3.2 Outputs – Cruise Active Lamp…..4016

6.3.3 Outputs – Deceleration Lamp…..4017

6.3.4 Outputs – Engine Brake Active…..4018

6.3.5 Outputs – Fuel Filter Restriction Lamp…..4019

6.3.6 Outputs – Low Battery Voltage Lamp…..4019

6.3.7 Outputs – Low Coolant Level Lamp…..4020

6.3.8 Outputs – Low Oil Pressure Lamp…..4021

6.3.9 Outputs – Malfunction Indicator Lamp (MIL)…..4022

6.3.10 Outputs – Optimized Idle Active Lamp…..4022

6.3.11 Outputs – Optimized Idle Alarm…..4023

6.3.12 Outputs – Red Stop Lamp…..4024

6.3.13 Outputs – Vehicle Power Shutdown…..4024

6.3.14 Outputs – Wait to Start Lamp…..4025

6.3.15 Outputs – Water-In-Fuel Lamp…..4025

6.4 PWM Outputs – CPC…..4026

7 Features…..4028

7.1 Acceleration Limiter…..4028

7.2 Common Driver Reward…..4028

7.3 Cruise Control…..4031

7.4 Diagnostics…..4040

7.5 Dual Speed Axle…..4043

7.6 Engine Brake Controls – EuroIV DD15…..4044

7.7 Engine Protection…..4049

7.8 Engine Ratings…..4051

7.9 Engine Starter Control…..4052

7.10 Fan Control…..4055

7.11 Fleet Management…..4072

7.12 Fuel Economy Incentive…..4078

7.13 Idle Adjust…..4080

7.14 Idle Protection…..4081

7.15 Idle Shutdown Timer and PTO Shutdown…..4082

7.16 Limiters…..4088

7.17 Low Gear Torque Reduction…..4090

7.18 Optimized Idle…..4092

7.19 PasSmart…..4099

7.20 Passwords…..4101

7.21 Progressive Shift…..4102

7.22 Soft Cruise…..4105

7.23 Starter Lockout…..4106

7.24 Tachometer Drive…..4107

7.25 Throttle Control / Governors…..4108

7.26 Transmission Interface…..4122

7.27 Vehicle Speed Limiting…..4126

7.28 Vehicle Speed Sensor Anti-Tampering…..4128

8 Communication Protocols…..4130

8.1 Communication Protocols – Overview…..4130

8.2 SAE J1939 Messages and Message Format…..4130

8.2.1 SAE J1939 Supported Messages…..4131

9 Appendix A: Harness Wiring Diagrams…..4173

9.1 Harness Wiring Diagrams…..4173

10 Appendix B: Parameter Lists…..4178

10.1 Parameter List…..4178

11 Appendix C: Acronyms…..4197

11.1 Acronyms…..4197

Det_Trans_ddc-svc-man-0128…..4199

1 California Proposition 65 Warning and Engine Idle Notice…..4201

2 Attention…..4202

3 Abstract…..4203

4 Introduction…..4204

4.1 Introduction…..4204

5 Safety Precautions…..4205

5.1 Safety Precautions…..4205

6 Hardware and Wiring…..4209

6.1 Transmission Control Module (TCM)…..4209

6.2 TCM Electrical Limits…..4209

6.3 TCM 21-Pin Connectors…..4209

6.4 Wires and Wiring…..4213

6.5 Conduit and Loom…..4222

6.6 Tape and Taping…..4223

6.7 Power Supply – 12-Volt System…..4223

6.8 Fuses…..4224

6.9 Communications – Proprietary Powertrain – CAN Data Link…..4224

6.10 Lamps/Instrument Cluster Messages/Driver Interface…..4228

6.10.1 Check Trans Lamp…..4228

6.10.2 Engine Retarder Enabled Lamp…..4230

6.10.3 Hill Start Aid Lamp…..4231

6.10.4 Transmission Oil Temperature Gauge…..4232

6.11 Detroit Transmission Sensors and Actuators…..4233

7 Features…..4234

7.1 Active Driveline Protection…..4234

7.2 Auto Neutral Feature…..4234

7.3 Creep Mode…..4234

7.4 Hill Start Aid (Optional)…..4235

7.5 Driving Modes…..4236

7.6 Dual Channel Analog Accelerator Pedal Position Sensor…..4238

7.7 eCoast Feature…..4243

7.8 Engine Brake Controls…..4244

8 Communication Protocols…..4248

8.1 Communication Protocols – Overview…..4248

8.1.1 SAE J1939 Messages and Message Format…..4248

8.2 Required SAE J1939 Detroit Transmission Messages (Drivers Interface)…..4249

8.3 SAE J1939 Detroit Transmission Supported Messages…..4252

9 Transmission Special Requirements…..4264

9.1 Detroit Transmission Air Supply Requirements…..4264

9.2 Detroit Transmission Required Learning Routines and TCM Required Information…..4266

10 Appendix A: Detroit Transmissions TCM Wiring Harness…..4269

10.1 Detroit Transmission TCM Wiring Harness…..4269

11 Appendix B: Parameter Lists…..4271

11.1 PARAMETER LIST…..4271

12 Appendix C: Acronyms…..4277

12.1 ACRONYMS…..4277

Detroit Diesel – Cooling System – Technicians Guide…..4279

Detroit Diesel – DDEC II to III-IV Conversion …..4313

freightliner.com…..0

18SP546REV.PDF – Install DDEC II to DDEC IV Wire Harness and Hardware Conversion Kit on 1991-1993 Series 60® On-Highway Manual Transmission Trucks…..4313

…..4313

18SP546* – Install DDEC II to DDEC IV Wire Harnes…..4313

Hardware Conversion Kit on 1991-1993 Series 60® �…..4313

Detroit Diesel – DDEC VI – Application And Installation Manual…..4321

Detroit Diesel – DDEC VI SERIES 60 MCM EGR Engine Harness Schematic…..4859

Detroit Diesel – Fuel System Bulletin – MBE 4000-06a…..4860

Detroit Diesel – Low Power Bulletin – MBE4000-07…..4936

Detroit Diesel – MBE 4000 Application And Installation ch13…..4976

Detroit Diesel – MBE 4000 ENGINE EPA04 OPERATOR'S MANUAL – DDC-SVC-MAN-0056…..4986

Detroit_dd13…..5096

Diesel Exhaust Fluid Tank Header Unit…..5262

39.1 Description and Operation of the Diesel Exhaust Fluid Tank Header Unit…..5262

39.2 Removal of the EPA10 13 and 23 Gallon Diesel Exhaust Fluid Tank Header Unit…..5264

39.3 Installation of the EPA10 13 and 23 Gallon Diesel Exhaust Fluid Tank Header Unit…..5267

39.4 Removal of the GHG14 13 and 23 Gallon Diesel Exhaust Fluid Tank Header Unit…..5269

39.5 Installation of the GHG14 13 and 23 Gallon Diesel Exhaust Fluid Tank Header Unit…..5271

39.6 Removal of the GHG14 Six-Gallon Diesel Exhaust Fluid Tank Header…..5273

39.7 Installation of the GHG14 Six-Gallon Diesel Exhaust Fluid Tank Header…..5274

EPA10/GHG14 Diesel Exhaust Fluid Tank Header Unit…..5275

39.1 Description and Operation of the Diesel Exhaust Fluid Tank Header Unit…..5275

39.2 Removal of the EPA10 13 and 23 Gallon Diesel Exhaust Fluid Tank Header Unit…..5277

39.3 Installation of the EPA10 13 and 23 Gallon Diesel Exhaust Fluid Tank Header Unit…..5280

39.4 Removal of the GHG14 13 and 23 Gallon Diesel Exhaust Fluid Tank Header Unit…..5282

39.5 Installation of the GHG14 13 and 23 Gallon Diesel Exhaust Fluid Tank Header Unit…..5284

39.6 Removal of the GHG14 Six-Gallon Diesel Exhaust Fluid Tank Header…..5286

39.7 Installation of the GHG14 Six-Gallon Diesel Exhaust Fluid Tank Header…..5287

Diesel Exhaust Fluid Tank…..5288

40.1 Description and Operation of the Diesel Exhaust Fluid Tank…..5288

40.2 Description and Operation of the EPA10 Diesel Exhaust Fluid Heating…..5289

40.3 Removal of the Six-Gallon Diesel Exhaust Fluid Tank…..5290

40.4 Installation of the Six-Gallon Diesel Exhaust Fluid Tank…..5293

40.5 Removal of the GHG14 Six-Gallon Diesel Exhaust Fluid Tank…..5295

40.6 Installation of the GHG14 Six-Gallon Diesel Exhaust Fluid Tank…..5297

40.7 Removal of the 13 and 23 Gallon Diesel Exhaust Fluid Tank…..5299

40.8 Installation of the 13 and 23 Gallon Diesel Exhaust Fluid Tank…..5302

40.9 Removal of the GHG14 13 and 23 Gallon Diesel Exhaust Fluid Tank…..5304

40.10 Installation of the GHG14 13 and 23 Gallon Diesel Exhaust Fluid Tank…..5306

EPA10/GHG14 Diesel Exhaust Fluid Tank…..5308

40.1 Description and Operation of the Diesel Exhaust Fluid Tank…..5308

40.2 Description and Operation of the EPA10 Diesel Exhaust Fluid Heating…..5309

40.3 Removal of the Six-Gallon Diesel Exhaust Fluid Tank…..5310

40.4 Installation of the Six-Gallon Diesel Exhaust Fluid Tank…..5313

40.5 Removal of the GHG14 Six-Gallon Diesel Exhaust Fluid Tank…..5315

40.6 Installation of the GHG14 Six-Gallon Diesel Exhaust Fluid Tank…..5317

40.7 Removal of the 13 and 23 Gallon Diesel Exhaust Fluid Tank…..5319

40.8 Installation of the 13 and 23 Gallon Diesel Exhaust Fluid Tank…..5322

40.9 Removal of the GHG14 13 and 23 Gallon Diesel Exhaust Fluid Tank…..5324

40.10 Installation of the GHG14 13 and 23 Gallon Diesel Exhaust Fluid Tank…..5326

Diesel Exhaust Fluid and Coolant Lines…..5328

41.1 Removal of the Diesel Exhaust Fluid Lines (Tank to Pump)…..5328

41.2 Installation of the Diesel Exhaust Fluid Lines (Tank to Pump)…..5330

41.3 Removal of the Diesel Exhaust Fluid Line Connections…..5331

41.4 Installation of the Diesel Exhaust Fluid Line Connections…..5332

41.5 Removal of DEF Supply Unit Coolant Line Fittings…..5333

41.6 Installation of the DEF Supply Unit Coolant Line Fittings…..5334

EPA10 Diesel Exhaust Fluid and Coolant Lines…..5335

41.1 Removal of the Diesel Exhaust Fluid Lines (Tank to Pump)…..5335

41.2 Installation of the Diesel Exhaust Fluid Lines (Tank to Pump)…..5337

41.3 Removal of the Diesel Exhaust Fluid Line Connections…..5338

41.4 Installation of the Diesel Exhaust Fluid Line Connections…..5339

41.5 Removal of DEF Supply Unit Coolant Line Fittings…..5340

41.6 Installation of the DEF Supply Unit Coolant Line Fittings…..5341

Diesel Oxidation Catalyst Inlet Pressure Sensor…..5342

50.1 Removal of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor…..5342

50.2 Installation of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor…..5344

50.3 Removal of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor without Sensor Box…..5345

50.4 Installation of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor without Sensor Box…..5347

50.5 Removal of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor with Sensor Box…..5348

50.6 Installation of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor with Sensor Box…..5350

EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor…..5352

50.1 Removal of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor…..5352

50.2 Installation of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor…..5354

50.3 Removal of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor without Sensor Box…..5355

50.4 Installation of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor without Sensor Box…..5357

50.5 Removal of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor with Sensor Box…..5358

50.6 Installation of the EPA10 Diesel Oxidation Catalyst Inlet Pressure Sensor with Sensor Box…..5360

EPA07 10 GHG14 Exhaust – EGR – ATS Manual (DDC-SVC-MAN-0083)_…..5362

Exhaust Manifold…..5362

2.1 Description and Operation of the Exhaust Manifold and Related Parts…..5362

DD13 Exhaust Manifold…..5362

DD15 Exhaust Manifold…..5362

GHG14 DD15 AT Exhaust Manifold…..5363

EPA10 DD16 High-Horsepower Exhaust Manifold…..5364

2.2 Removal of the Exhaust Manifold…..5366

2.3 Removal of the GHG14 DD15 Asymmetrical Turbocharger Exhaust Manifold…..5367

2.4 Inspection of an Assembled Exhaust Manifold…..5368

2.5 Inspection of a Disassembled Exhaust Manifold…..5370

2.6 Disassembly of the Exhaust Manifold…..5371

2.7 Assembly of the Exhaust Manifold…..5372

2.8 Cleaning of the Exhaust Manifold…..5373

2.9 Installation of the Exhaust Manifold…..5374

2.10 Installation of the GHG14 DD15 Asymmetrical Turbocharger Exhaust Manifold…..5377

EPA07 Aftertreatment Device Cleaning and Maintenance…..5379

33.2 Requirements – EPA07…..5379

Service Record…..5379

EPA07 Aftertreatment Device Cleaning and Maintenance…..5380

33.1 Accumulated Ash – EPA07…..5380

33.2 EPA07 Diesel Particulate Filter Ash Measurement Procedure…..5381

33.3 Requirements – EPA07…..5386

Service Record…..5386

EPA07 Aftertreatment Device Removal and Installation on Vehicle…..5387

34.1 Removal of the EPA07 Aftertreatment Device from the Vehicle…..5387

34.2 Installation of the EPA07 Aftertreatment Device…..5393

EPA07 Aftertreatment Device Removal and Installation on Vehicle…..5395

34.1 Removal of the EPA07 Aftertreatment Device from the Vehicle…..5395

34.2 Installation of the EPA07 Aftertreatment Device…..5401

EPA07 Aftertreatment Device Sensors…..5403

EPA07 Aftertreatment Device Sensors…..5403

32.1 Description and Operation of the EPA07 Aftertreatment Device Temperature Sensors…..5403

32.2 Removal of the EPA07 Temperature Sensors…..5404

32.3 Installation of the EPA07 Temperature Sensors…..5405

32.4 Removal of the EPA07 Pressure Sensors…..5406

32.5 Installation of the EPA07 Pressure Sensors…..5407

EPA07 Aftertreatment System Overview…..5408

EPA07 Aftertreatment System Overview…..5408

31.1 Overview of EPA07 Aftertreatment System…..5408

31.2 Description and Operation of the EPA07 Aftertreatment Device…..5409

31.3 Description and Operation of the Diesel Particulate Filter…..5411

31.4 EPA07 Aftertreatment Operating Requirements…..5412

31.5 EPA07 Aftertreatment System Component Overview…..5413

31.6 EPA07 Aftertreatment Regeneration Strategy…..5415

EPA07 DD15 Regeneration Strategy…..5415

EPA07 DD15 Idle Timing…..5415

Passive Regeneration…..5416

Active Regeneration…..5416

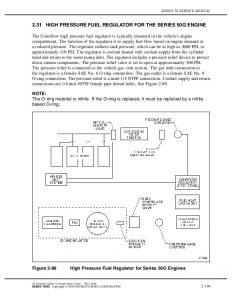

Parked Regeneration…..5417