Complete repair service manual for Daewoo Solar 210W-V Excavator, with all the workshop information to maintain, diagnostic, repair, and rebuild like professional mechanics.

Daewoo Solar 210W-V Excavator workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

023-00064E – Daewoo Solar 210W-V SHOP MANUAL (Serial Number 1001 and Up).pdf

CENS21WV0002.pdf

S210W-V_HYD_CIRCUIT.pdf

Total Pages: 824 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

Safety

Wheel Excavator Safety … S0102025K

Specifications

Specifications for Solar 210W-V … S0202045K

General Maintenance

General Maintenance Procedures …S0302000

Standard Torques ..S0309000

Upper Structure

Cab … S0402040K

Counterweight… S0403015K

Fuel Tank.. S0405075K

Fuel Transfer Pump …S0405500

Swing Bearing..S0407010

Swing Reduction Gearbox …S0408040

Lower Structure and Chassis

Ram Lock Valve Operation..S0503000

Engine and Drive Train

Front Axle ..S0602100

Transmission (ZF 2HL-100)…S0602110

Air-Conditioner.. S0605060K

Drive Coupling (Main Pump)..S0609000

Hydraulics

Hydraulic System Troubleshooting, Testing and Adjustment … S0702115K

Accumulator.. S0703010K

Center Joint (Swivel)..S0704070

Cylinders..S0705000

Swing Motor…S0707250

Travel Motor…S0707350

Main Pump (With Regulator, Steering Pump and Brake Pump)..S0708430

Brake Supply Valve …S0709220

Counterbalance Valve …S0709300

Main Control Valve (Toshiba DX28) ..S0709440

Pilot Control Valve (Work Lever / Joystick)… S0709451K

Steering Valve …S0709710

Dozer Control Valve.. S0709905K

Hydraulic Schematic (Solar 210W-V) … S0792101K

Electrical System

Electrical System .. S0802125K

Electrical Schematic (Solar 210W-V).. S0892101K

Attachments

Boom and Arm…S0902080

Bucket..S0904000

Publication Request for Proposed Revision

023-00064E – Daewoo Solar 210W-V SHOP MANUAL (Serial Number 1001 and Up)…2

Safety…8

Wheel Excavator Safety S0102025K…10

To the Operator of a Daewoo Excavator…12

Learn the Signal Words Used with the Safety Alert Symbol…14

General Safety Essentials…15

Accessory Applications…15

Lifting Capacity Rating Configuration…15

Location of Safety Labels…15

Summary of Safety Precautions for Lifting in Digging Mode…16

Unauthorized Modifications…17

General Hazard Information…17

Safety Rules…17

Safety Features…17

Inside Operator's Compartment…18

Clothing and Personal Protective Items…19

Breathing Masks, Ear Protection May be Required…19

Mounting and Dismounting…20

Fuel, Oil and Hydraulic Fluid Fire Hazards…21

Precautions When Handling Fluids at High Temperature…21

Asbestos Dust Hazard Prevention…22

Injury from Work Equipment…22

Fire Extinguisher and First Aid Kit…23

Protection from Falling or Flying Objects…23

Attachment Precautions…24

Accumulator…24

Indoor Ventilation…25

Emergency Exit…25

Before Starting Engine…26

Work Site Precautions…26

Checks Before Starting Engine…27

Engine Starting…28

Before Operating Machine…28

Machine Operation…29

When Swinging or Changing Direction of Travel…29

Travel Precautions…29

Traveling on Slopes…30

Prohibited Operations…31

Precautions for Operation…31

Avoid High-voltage Cables…32

Operate Carefully on Snow, Ice and in Very Cold Temperatures…32

Operations on Slopes…33

Parking Machine…33

Never Let Anyone Ride on Attachment…33

Maintenance…34

Warning Tag…34

Clean Before Inspection or Maintenance…34

Proper Tools…35

Use of Lighting…35

Fire Prevention and Explosion Prevention…35

Burn Prevention…36

Welding Repairs…37

Warning for Counterweight and Front Attachment Removal…37

Precautions for Removal, Installation, and Storage of Attachments…38

Precautions when Working on Machine…38

Lock Inspection Covers…38

Crushing Prevention and Cutting Prevention…38

Supports and Blocking for Work Equipment…39

Action When Abnormally Is Found During Inspection…40

Precautions with High Pressure Line, Tubes and Hoses…40

Waste Materials…41

Battery…42

Battery Hazard Prevention…42

Boost Starting or Charging Engine Batteries…43

Towing…44

Precautions When Towing…44

Shipping and Transportation…45

Obey State and Local Over-the-Road Regulations…45

Lifting With Sling…45

Specifications…46

Specifications for Solar 210W-V S0202045K…48

General Description…50

Component Location…51

General Dimensions…53

Dimensions…53

Working Range…55

Hydraulic Cylinders…59

Engine Specifications…61

Engine Performance Curves (DIN 6270 Standard)…63

Approximate Weight of Workload Materials…65

General Specifications…69

Hydraulic System Component Specifications…71

System Component Specifications…73

Drive System…73

Swing Mechanism…73

Brake System…74

Steering System…74

Chocking System…75

Performance Tests and Standards…76

Standards…76

Tests…77

Test Conditions…77

Travel Speed Tests…78

Swing Speed Test…79

Swing Speed Test…79

Swing Force Test…79

Cylinder Performance Tests…80

Boom Cylinders Test…80

Arm Cylinder Test…80

Bucket Cylinder Test…80

Hydraulic Cylinder Natural Drop Test…80

General Maintenance…82

General Maintenance Procedures S0302000…84

Welding Precautions and Guidelines…86

Hydraulic System – General Precautions…87

Maintenance Service and Repair Procedure…88

General Precautions…88

Hydraulic System Cleanliness and Oil Leaks…89

Maintenance Precautions for Hydraulic System Service…89

Oil Leakage Precautions…89

Cleaning and Inspection…90

General Guidelines…90

Bearing inspection…91

Standard Torques S0309000…98

Torque Values for Standard Metric Fasteners…100

Torque Values for Standard U.S. Fasteners…101

Type 8 Phosphate Coated Hardware…103

Torque Values for Hose Clamps…104

Torque Values for Split Flanges…105

Torque Wrench Extension Tools…106

Torque Multiplication…106

Other Uses for Torque Wrench Extension Tools…107

Tightening Torque Specifications (Metric)…107

Upper Structure…110

Cab S0402040K…112

Removal…114

Installation…117

Counterweight S0403015K…120

General…122

Removal…124

Installation…126

Fuel Tank S0405075K…128

General Description…130

Parts List…131

Specifications…132

Removal…133

Installation…137

Start-up Procedures…139

Fuel Transfer Pump S0405500…140

General Description…142

Theory of Operation…142

Troubleshooting…143

Replacement of Rotor and Vane…143

Replacement of Rear Cover…144

Replacement of Armature…145

Swing Bearing S0407010…146

Swing Bearing Maintenance…148

Operating Recommendation…148

Measuring Swing Bearing Axial Play…148

Measuring Bearing Lateral Play…148

Swing Bearing Basic Operation…149

Rebuilding Swing Bearing…149

Swing Reduction Gearbox S0408040…152

General Description…154

Theory of Operation…154

Parts List…155

Specifications…156

Special Tools and Materials…157

Special Tools…157

Troubleshooting, Testing and Adjustment…158

Removal…159

Disassembly…161

Cleaning and Inspection (Wear Limits and Tolerances)…166

Reassembly…167

Installation…176

Lower Structure and Chassis…178

Ram Lock Valve Operation S0503000…180

Theory of Operation…182

Engine and Drive Train…184

Front Axle S0602100…186

Special Tools…188

Hub Nut Tool…188

Disassembly…189

Planetary End…189

Differential Gear…196

Cleaning and Inspection (Wear Limits and Tolerances)…201

Reassembly…202

Differential Gear…202

Planetary End…213

Start-up Procedures…228

Axle Lubrication…228

Transmission (ZF2HL-100) S0602110…230

Transmission Operation…233

Special Tools…234

Hub Nut Tool…234

Transmission Disassembly…235

Detaching Drive (Input) Housing…235

Disassembly of Input Shaft and Brake Assembly…236

Disassembly of Clutch…238

Disassembly of Planetary Carrier…243

Disassembly of Shift Lever and Helical Gear…244

Disassembly of Shift Lock (Version A)…249

Disassembly of Shift Lock (Version B)…251

Final Drive Disassembly…253

Rear Axle Disassembly…257

Differential Gear Disassembly…264

Cleaning and Inspection (Wear Limits and Tolerances)…269

Differential Gear Reassembly…270

Rear Axle Reassembly…282

Final Drive Reassembly…297

Transmission Reassembly…302

Reassembly of Helical Gear…302

Reassembly of Shift Lever…304

Reassembly of Planetary Carrier…305

Adjusting Shift Lever…307

Pre assembling and Installing Clutch…308

Checking Clutch…315

Reassembly of Brake and Input Shaft Assembly…316

Installing Drive (Input) Housing…320

Assembly of Shift Lock (Version A)…323

Assembly of Shift Lock (Version B)…327

Installing Oil Pump…329

Installing Screw Plugs and Oil Lines…332

Start-up Procedures…333

Axle Lubrication…333

Lubrication…333

Air-Conditioner S0605060K…334

General Description…336

Refrigerant Circulation…338

Control Panel…340

Control Specifications…341

Temperature Level Control and Display…342

Air Discharge According to Path Selection…343

Air-conditioning System Circuit Diagram…345

Troubleshooting…347

Weight of R134a Gas Used In Machines…350

Refrigerant System Repairs…352

Refrigerant Safe Handling Procedures…352

Repair and Replacement Procedure…353

Refrigerant Recovery…355

Vacuuming Refrigerant System…355

Leakage Check…356

Refrigerant Charging…357

Inspecting System For Leakage…359

Drive Coupling (Main Pump) S0609000…360

Drive Coupling…362

Special Tools…363

Kawasaki / Tong Myung Pump Tool…363

Uchida Pump Tool…366

Drive Coupling Installation…367

Installation Procedure…372

Hydraulics…374

Hydraulic System Troubleshooting, Testing and Adjustment S0702115K…376

Hydraulic System – General Notes…379

Operation of Working Components…380

Boom Operating Circuit…380

Boom Up Circuit…380

Boom Down Circuit…380

Arm Operating Circuit…381

Arm Crowd Circuit…381

Arm Dump Circuit…382

Bucket Operating Circuit…382

Bucket Crowd Circuit…382

Bucket Dump Circuit…383

Swing Operating Circuit…384

Right Swing Operating Circuit…384

Left Swing Operating Circuit…384

Swing Relief Valve and Make-up Valve…384

Procedural Troubleshooting Baseline Recommendations…385

Initial Checks and Tests to Establish Operating Condition of the Excavator…385

Pilot Pressure…386

Adjustment and Testing…386

Power Mode Valve…387

Current Signal and Hydraulic Pressure Adjustments…387

Boom/Swing Priority Valve…388

Control Valve Pressure and Current Adjustments…388

Pressure Up Valve…389

Checks and Adjustments…389

Pump Input Power Control…390

Pump Regulator Adjustment…390

Flow Meter and Flow Meter Kit Installation and Testing…393

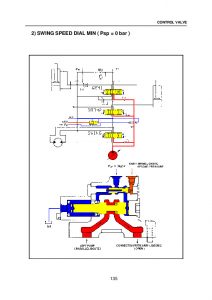

Swing System Troubleshooting…394

Precautions/Initial Checks…394

Swing Relief Valve Checking and Adjustment…394

Troubleshooting – Swing Gearbox…396

Troubleshooting – Hydraulic Problems…397

Troubleshooting – Control Valve…399

Troubleshooting – Joystick Control Valve…400

Accumulator S0703010K…402

General Description…404

Specifications…405

Center Joint (Swivel) S0704070…408

General Description…410

Parts List…411

Troubleshooting, Testing and Adjustment…413

Inspection…413

Testing…413

Disassembly…414

Reassembly…415

Cylinders S0705000…416

General Description…418

Theory of Operation…418

Parts List…419

Special Tools and Materials…421

Piston Nut…421

Piston Jig…425

Steel bush Jig…429

Dust Wiper Jig…433

Slipper Seal Jig…439

Slipper Seal Straightening Jig…443

Disassembly…446

Assembly…452

Swing Motor S0707250…456

General Description…458

Theory of Operation…458

Swing Motor Anti-cavitation Make-up Valve…459

Relief Valve…460

Swing Brake Operation…460

Parts List…463

Specifications…465

Special Tools…466

Disassembly…467

Cleaning and Inspection (Wear Limits and Tolerances)…474

Reassembly…476

Travel Motor S0707350…484

General Description…487

Theory of Operation…487

Parts List…489

Specifications…490

Travel Motor General Disassembly and Reassembly Instructions…491

Recommended Tools…491

Precautions for Disassembly and Assembly…491

Disassembly of Travel Motor…492

Appearance of Motor…492

Removal of counterbalance Valve…492

Removal of Outer Piping…493

Removal of Stroke Limiter…494

Removal of Oil Seal…495

Removal of Control Unit…495

Removal of Control Valve…497

Disassemble Control Valve…499

Disassemble Stroke Limiter…500

Reassemble Stroke Limiter…501

Reassemble Control Valve…501

Installation of Control Valve…502

Reassembly of Travel Motor…505

Assembly of Control Unit…505

Installation of Oil Seal…507

Installation of Stroke Limiter…508

Installation of Outer Piping…508

Installation of Counterbalance Valve…509

Main Pump (With Regulator, Steering Pump and Brake Pump) S0708430…510

General Description…513

Gear (Pilot) Pump…515

Relief Valve…515

Pump Regulator Description…516

Horsepower Control…516

Power Shift Control…516

Negative Oil Discharge (Pump Bypass) Control…516

Pump Regulator Operation…517

Pump Output Decrease…519

Pump Discharge Decrease…519

Pump Discharge Increase…519

Horsepower Control…519

Overload Protection…520

Regulator Adjustment…520

Pump Input Power Control Adjustment…521

Parts List…523

Specifications…528

Hydraulic Pump Performance Characteristics…529

Troubleshooting, Testing and Adjustment…530

Main Pump…530

Disassembly…531

General Disassembly…531

Main Pump Disassembly…532

Pump Regulator Disassembly…534

Cleaning and Inspection (Wear Limits and Tolerances)…538

Reassembly…540

Pump Regulator Reassembly…540

Main Pump Reassembly…544

Brake Supply Valve S0709220…548

Parts List…551

Specifications…552

Counterbalance Valve S0709300…554

General Description…556

While Operating to Run Forward…556

While Operating to Stop…556

While Operating to Back…556

Adjustment of Relief Valve…557

Troubleshooting…558

Counterbalance Valve…559

Recommended Tools…559

Disassembly…559

Order of Disassembly and Torque Values…560

Reassembly…561

Main Control Valve (Toshiba DX28) S0709440…566

Control Valve Operation…570

Arm Priority Circuit…571

Bucket (Junction) Circuit…573

Main Relief Valve…575

Overload Relief Valve…576

Arm Load Holding Valve…578

Boom Load Holding Valve…581

Arm Regeneration…583

Boom Regeneration…585

Foot Relief Valve…586

Parts List…587

Specifications…596

Control Valve Drawing and Hydraulic Circuit…597

Disassembly and Reassembly…602

General Disassembly…602

General Reassembly…602

Plunger Replacement…603

Main Plunger Element – Disassembly and Assembly…604

Tool…604

Main Relief Valve…607

Overload Relief Valve…610

Arm Load Holding Valve…612

Boom Load Holding Valve…615

Arm Regeneration Valve…617

Bucket Unity Check…618

Foot Relief Valve…619

Center Bypass Valve (CB Valve)…620

Boom Parallel Switch Valve…621

Boom Unity Check Valve…623

Check Valve – Locations…624

Check Valve…625

Pilot Control Valve (Work Lever / Joystick) S0709451K…628

General Description…630

Theory of Operation…630

Parts List…631

Specifications…632

Removal…633

Disassembly…636

Cleaning and Inspection (Wear Limits and Tolerances)…640

Reassembly…641

Installation…646

Start-up Procedures…647

Steering Valve S0709710…648

General Description…650

Theory of Operation…651

Parts List…653

Specifications…654

Special Tools and Materials…655

Special Tools…655

Disassembly…657

Reassembly…666

Dozer Control Valve S0709905K…680

Parts List…682

Specifications…683

Hydraulic Schematic (Solar 210W-V) S0792101K…684

General Description…686

Solar 210W-V…687

General Notes…691

Electrical System…692

Electrical System S0802125K…694

Troubleshooting – Electrical System…698

Overview…699

Electric Supply System…700

Engine Starting Circuit…701

Operation During Start Process…701

Operation After Start Process…702

Engine Preheating System…703

Engine Stop System…704

Charging System…707

Monitoring System…709

Instrument Panel…711

Monitoring System Schematic…713

Operation…715

Instruments…715

Warning and Indicator Lights…717

Control Unit…719

Operation Schematic…719

Operation Specification…720

Console Warning Light…721

Initial Operation…723

Mode Select Switch…724

Graphic Information Area Display…725

Overview…725

Main Menus for the Graphic Display Area…726

Menu Selection Buttons…726

Main Menu…727

Language setting…727

Time Setting…727

Filter/Oil information…728

Special Menu…729

Entering/Accessing and Exiting/Escaping Menus…729

Special Menu Selections…730

Electronic Hydraulic Control System (e-EPOS)…743

Power Mode Control…745

Operation…746

Throttle Position Sensor…749

Power Mode Control – Circuit Diagram…751

Work Mode Control…753

Operation…754

Work Mode Control – Circuit Diagram…755

Engine Control System…757

Engine Control Motor…758

Engine Control Dial…759

Engine Control Circuit Diagram…761

Automatic Deceleration Control (Auto Idle Control)…762

Automatic Deceleration Control Circuit…763

Operation…764

Engine Overheat Protection System…765

Power Boost Mode…766

Operation…766

Power Boost Control – Circuit Diagram…767

Cruise Control…769

Cruise Control Circuit…771

Adjusting Method of Engine Control Unit…773

Adjusting Method of Engine Control System…773

Adjusting Method of Engine RPM…775

Adjustment of TPS (Throttle Position Sensor)…780

Self-diagnostic Function…785

e-EPOS Controller…785

Engine Throttle Controller…789

Wiper System…791

Wiper Circuit…791

Wiper Operation…791

Window Washer Operation…792

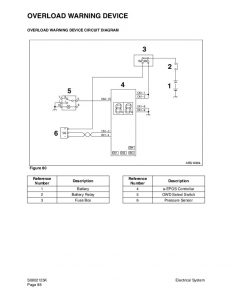

Overload Warning Device…793

Overload Warning Device Circuit Diagram…793

Electrical Schematic (Solar 210W-V) S0892101K…794

General Description…796

Solar 210W-V…797

Attachments…800

Boom and Arm S0902080…802

Front Attachment Pin Specifications…804

Front Attachment – Removal and Installation…805

Arm Removal Procedure…805

Boom Removal Procedure…807

Installation…808

Arm Installation Procedure…808

Boom Installation Procedure…808

Start-up Procedures…809

Bucket S0904000…810

Bucket Tooth Inspection and Replacement…812

Type 1…812

Type 2…813

Type 3…814

Bucket O-ring Replacement…816

Type 1…816

Type 2…817

Bucket Shimming Procedures…819

New Bucket Installation…819

Type 1…819

Type 2…820

Bucket Attachment, Removal and Reversal…821

Detaching the Bucket…821

Attaching The bucket…821

Reversing the Bucket…822

Publication Request for Proposed Revision…824

CENS21WV0002…826

S210W-V_HYD_CIRCUIT…827

Model…827

Daewoo Solar 210W-V Excavator Repair Service Manual