INSTANT DOWNLOAD

Complete repair service manual for Deutz-Fahr Agrokid 30, Agrokid 40, Agrokid 50, with workshop information to maintain, diagnose, repair, and service like professional mechanics.

Deutz-Fahr Tractors Agrokid 30, Agrokid 40, Agrokid 5 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

307.W.0430.EN.6.02 – Deutz-Fahr Agrokid 30, Agrokid 40, Agrokid 50 Workshop Manual.pdf

PRODUCT DETAILS:

Total Pages: 430 pages

File Format: PDF (bookmarked, Searchable, Printable, high quality)

Language: English

1. TRANSMISSION

2. FRONT AXLE

3. CONTROLS

4. HYDRAULIC SYSTEM

307.1108.3.6 AGROKID 30-40-50…1

INTRODUCTION…3

SAFETY NOTES…5

SAFETY PRECAUTIONS FOR REMOVAL AND REFITTING OPERATIONS…8

LIFTING INSTRUCTIONS…10

HOW THE MANUAL IS STRUCTURED…11

HOW TO CONSULT THE MANUAL…12

HOW TO USE AND UPDATE THE MANUAL…13

STANDARD TIGHTENING TORQUES FOR NUTS AND BOLTS…14

THREADLOCKERS, ADHESIVES, SEALANTS AND LUBRICANTS…15

CONVERSION FACTORS…17

SECTION 10…19

1. TRANSMISSION…21

1.1 INTRODUCTION…21

1.2 DESCRIPTION…22

1.2.1 DRIVE TRANSMISSION…23

1.3 CLUTCH HOUSING…24

1.4 GEARBOX AND SHUTTLE ASSEMBLY…25

1.5 4WD RANGE GEARS ASSEMBLY…26

1.6 PINION AND DIFFERENTIAL ASSEMBLY…27

1.7 BRAKES AND REAR AXLE ASSEMBLY…28

1.8 REAR PTO AND MID PTO…29

1.8.1 COMPONENTS…29

1.8.2 MAIN COMPONENTS…30

2. FRONT AXLE…31

2.1 STEERING CYLINDER…32

2.2 DIFFERENTIAL- PINION – FINAL DRIVE UNIT…33

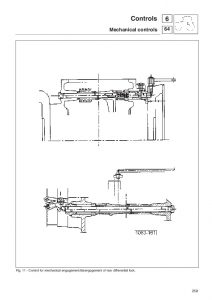

3. CONTROLS…34

3.1 RIGHT-HAND SIDE VIEW…34

3.2 LEFT-HAND SIDE VIEW…35

3.3 TOP VIEW…36

4. HYDRAULIC SYSTEM…37

4.1 DESCRIPTION…37

4.2 HYDRAULIC DIAGRAM…38

4.3 STEERING CIRCUIT…39

4.3.1 FUNCTION…39

4.3.2 OPERATION…39

4.3.3 GEAR PUMP…40

4.3.4 POWER STEERING…41

4.3.5 DIFFERENTIAL LOCK CONTROL ASSEMBLY…43

4.3.6 AUXILIARY SERVICES CONTROL VALVE (4 WAYS)…45

4.3.7 POWER LIFT CONTROL VALVE…46

SECTION 30…53

ENGINE HOOD…55

Removal…55

Refitting…55

SAFETY ROLL BAR…56

Removal…56

Refitting…56

SILENCER…57

Removal…57

Refitting…58

RADIATOR…59

Removal…59

Refitting…61

FRONT SUPPORT…62

Removal…62

Refitting…64

WHEELS…65

FRONT WHEELS…65

Removal…65

Refitting…65

REAR WHEELS…66

Removal…66

Refitting…66

INSTRUMENT PANEL…67

Removal…67

Refitting…68

CONSOLE SHROUDS…69

Removal…69

Refitting…70

POWER STEERING…71

Removal…71

Refitting…72

FUEL TANK…73

Removal…73

Refitting…74

PLATFORM…75

Removal…75

Refitting…77

STARTER MOTOR…78

Removal…78

Refitting…80

HYDRAULIC PUMP…81

Removal…81

Refitting…81

ALTERNATOR…82

Removal…82

Refitting…83

Tensioning the drivebelt…83

ENGINE…85

Separating the engine from the transmission…85

Reconnecting the engine to the transmission…90

Removal…91

Refitting…95

CLUTCH ASSEMBLY…96

PTO CLUTCH…96

Removal and renewal of the PTO clutch plate…96

Check PTO clutch plate wear…96

Refitting the PTO clutch plate…96

Adjustment of the clutch levers…97

PTO DRIVE SHAFT OIL SEAL…98

Renewal…98

CLUTCH RELEASE BEARINGS…99

Removal…99

Refitting…101

LIFT…102

COMPLETE ASSEMBLY…102

Removal…102

Refitting…103

POWER LIFT CONTROL VALVE…104

Removal…104

Refitting…105

Disassembly…106

Assembly…109

CYLINDER…111

Disassembly…111

Assembly…112

LIFT ARM OIL SEAL…113

Removal…113

Refitting…115

BUSHES…116

Renewal…116

INTERNAL LINKAGE…117

Removal…117

Refitting…118

HYDRAULIC LEVER LIMIT…119

Adjustment…119

LIFT CONTROL VALVE…120

Disassembly…120

Assembly…121

AUXILIARY SERVICES CONTROL VALVE (4 WAYS)…122

AUXILIARY SERVICES CONTROL VALVE…122

Removal…122

Refitting…122

CONTROL RODS…123

Disassembly…123

Assembly…123

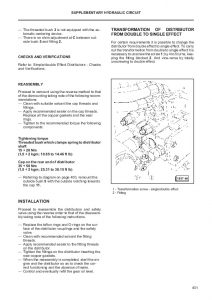

DOUBLE/ SINGLE ACTING CONVERTER…124

Overhaul…124

CLUTCH HOUSING…125

Separation from the transmission…125

Reconnection to the transmission…130

GEARBOX AND SHUTTLE ASSEMBLY…131

COMPLETE ASSEMBLY…131

Removal…131

Refitting…132

Disassembly…133

Assembly…135

INPUT SHAFT…137

Disassembly…137

Assembly…138

PRIMARY SHAFT…139

Disassembly…139

Assembly…139

SECONDARY SHAFT…140

Disassembly…140

Assembly…143

GEAR SELECTOR FORKS…144

Check flatness…144

REAR AXLE AND BRAKES…145

REAR AXLE…145

Removal…145

Refitting…146

Disassembly…147

Assembly…149

BRAKE…153

Renewal of the braking discs…153

REAR PTO…155

Disassembly…155

Assembly…158

RANGE GEARBOX AND REAR DIFFERENTIAL ASSEMBLY…159

RANGE GEARBOX INPUT SHAFT…159

Disassembly…159

Assembly…160

DIFFERENTIAL…161

Removal…161

Refitting…162

Disassembly…163

Assembly…164

BEVEL GEAR PAIR…165

Disassembly…165

Preparation for installation…167

Adjustment of the differential preload…168

Adjustment of the pinion position…169

Adjustment of the pinion and crown wheel…172

Final assembly…173

4WD AND GROUND SPEED PTO OUTPUT SHAFT…174

Disassembly…174

Assembly…175

PEDALS AND CONTROL LEVERS…176

BRAKE PEDALS…176

Adjustment…176

PARKING BRAKE LEVER…176

Adjustment…176

CLUTCH PEDAL…177

Adjustment…177

PTO SPEED SELECTOR LEVER…177

Adjustment…177

PTO ENGAGEMENT LEVER…177

Adjustment…177

RANGE GEAR LEVER…177

Adjustment…177

MAIN GEAR LEVER…178

Adjustment…178

FRONT AXLE…179

COMPLETE AXLE ASSEMBLY…179

Removal…179

Refitting…181

BEVEL GEAR PAIR…182

Disassembly…182

Assembly…187

FINAL DRIVE REDUCTION UNITS…193

Removal…193

Refitting…193

OUTPUT FLANGE…195

Disassembly…195

Assembly…197

STEERING JOINT…198

Disassembly…198

Preparation For Assembly…200

Final assembly…202

STEERING CYLINDER…203

Disassembly…203

Assembly…206

SECTION 40…209

THE STRUCTURE OF THE UNIT…211

HOW TO CONSULT THE UNIT…212

1. INTRODUCTION…213

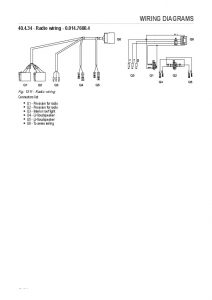

1.1 LIST OF WIRING LOOMS…213

1.2 DEFINITION OF COMPONENTS AND SYMBOLS…213

1.3 GENERAL RULES…214

1.3.1 MODIFICATION OF THE TRACTOR'S ELECTRICAL/ELECTRONIC CIRCUITS…214

1.3.2 MAIN WIRING FAULTS…214

1.3.3 REMOVAL, REFITTING AND DRYING OF CONNECTORS AND WIRING…215

1.4 DIAGNOSTIC INSTRUMENTS…216

1.5 WIRE COLOUR CODES…216

2. INDICES…217

2.1 INDEX BY PART DESCRIPTION…217

2.2 INDEX BY PART CODE…219

2.3 INDEX BY CONNECTOR…221

3. COMPONENTS…223

3.1 COMPONENT TECHNICAL DATA…223

3.2 PREHEATING SYSTEM…226

3.3 ENGINE STOP SYSTEM…226

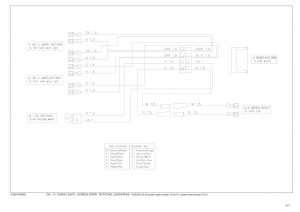

4. SYSTEMS…227

4.1 EARTHING POINTS…227

4.2 STARTING…228

4.3 FRONT AXLE DIFFERENTIAL LOCK…229

4.4 LIGHTS-SWITCH UNIT-BRAKES…230

4.5 INSTRUMENT PANEL…231

5. LAYOUTS, ELECTRICAL WIRING DIAGRAMS, CONNECTOR POSITIONS…233

FRONT WIRING (1/2)…233

FRONT WIRING (2/2)…234

CENTRAL WIRING (1/2)…241

CENTRAL WIRING (2/2)…242

REAR WIRING (1/2)…253

REAR WIRING (2/2)…254

SECTION 50…259

Introduction…261

HOW TO USE THIS MANUAL…262

General information…265

MODEL IDENTIFICATION AND SERIAL NUMBER LOCATION…265

COMPONENT POSITIONS – NATURALLY ASPIRATED ENGINE (S4L/S4L2)…266

COMPONENT POSITIONS – TURBO ENGINE (S4L-T/S4L2-T)…267

SPECIFICATIONS…268

Overhaul instructions…269

DETERMINING WHEN TO OVERHAUL THE ENGINE…269

COMPRESSION PRESSURE MEASUREMENT…270

TROUBLESHOOTING…271

BASIC PRECAUTIONS FOR DISASSEMBLY AND ASSEMBLY…279

Disassembly…281

PREPARATION FOR DISASSEMBLY…281

ELECTRICAL SYSTEM…282

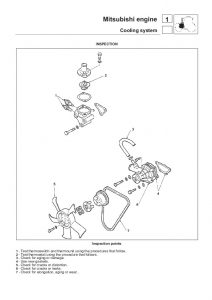

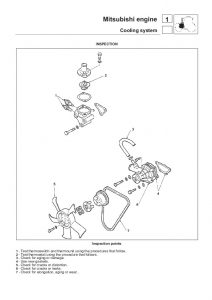

COOLING SYSTEM…287

FUEL SYSTEM…288

LUBRICATION SYSTEM…290

AIR INLET SYSTEM AND EXHAUST SYSTEM…291

CYLINDER HEAD AND VALVE MECHANISM…292

TIMING GEARS AND FLYWHEEL…295

CYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN…301

Inspection…307

CYLINDER HEAD AND VALVE MECHANISM…307

TIMING GEARS AND FLYWHEEL…314

CYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN…319

Assembly…328

CYLINDER BLOCK, CRANKSHAFT PISTONS AND OIL PAN…328

TIMING GEARS AND FLYWHEEL…337

CYLINDER HEAD AND VALVE MACHANISM…344

AIR INLET SYSTEM AND EXHAUST SYSTEM…349

FUEL SYSTEM…350

LUBRICATION SYSTEM…352

COOLING SYSTEM…353

ELECTRICAL SYSTEM…355

Electrical system…357

GENERAL…357

STARTER MOTOR…361

ALTERNATOR…369

KEY SHUTOFF SYSTEM…375

AUTOMATIC GLOW PLUG SYSTEM…377

Cooling system…380

GENERAL…380

INSPECTION…381

Lubrication system…385

GENERAL…385

INSPECTION…386

Fuel system…389

GENERAL…389

FUEL INJECTION NOZZLE…390

FUEL INJECTION PUMP…393

GOVERNOR…400

FUEL PUMP…403

FUEL FILTER…403

Air inlet system and exhaust system…406

GENERAL…406

INSPECTION…407

Maintenance…409

LUBRICATION AND MAINTENANCE CHART…409

ENGINE OIL AND OIL FILTER…410

VALVE CLERANCE…412

FUEL INJECTION TIMING…414

FUEL FILTER…417

IDLE RPM SETTING…419

FUEL INJECTION NOZZLES…420

FAN BELT…421

Service data…423

SPECIFICATIONS…423

TIGHTENING TORQUES…427

SEALANTS…429

SPECIAL TOOLS…430

Deutz-Fahr Agrokid 30, Agrokid 40, Agrokid 50 Repair Service Manual

INSTANT DOWNLOAD