Complete workshop manual contains service, maintenance, and troubleshooting information for the 1992-2002 Iveco EuroTech, EuroStar. Diagnostic and repair procedures are covered in great detail to repair, maintain, rebuild, refurbish or restore your vehicle like a professional mechanic in local service/repair workshop. This cost-effective quality manual is 100% complete and intact as should be without any missing pages. It is the same factory shop manual used by dealers that guaranteed to be fully functional to save your precious time.

This manual for 1992-2002 Iveco EuroTech, EuroStar is divided into different sections. Each section covers a specific component or system and, in addition to the standard service procedures, includes disassembling, inspecting, and assembling instructions. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. It is in the cross-platform PDF document format so that it works like a charm on all kinds of devices. You do not need to be skilled with a computer to use the manual.

MAKE: Iveco

MODEL: EuroTech, EuroStar

YEAR: 1992, 1993, 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002

’92-’02 EuroTech Cursor, EuroStar Cursor (603.43.391).pdf

EUROTECH CURSOR EUROSTAR CURSOR REPAIR MANUAL; 944 pages

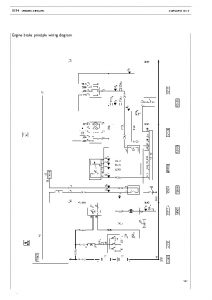

EuroTrakker_EuroTech_EuroStar Cursor 8-10-13 EWD (603.93.121).pdf

EUROTRAKKER EUROTECH EUROSTAR CURSOR 8/10/13 REPAIR MANUAL ELECTRIC/ELECTRONIC SYSTEM; 396 pages

EXCERPT:

INDEX

Section

General 1

Engine 2

Clutch 3

Transmission* 4

Intarder – ZF hydraulic retarder 5

Propeller shafts 6

Rear axles 7

Axles 8

Suspension 9

Wheels and tyres 10

Steering system 11

Hydraulic system – Brakes 12

Scheduled Maintenance 13

603.43.391 – Iveco Trucks EuroTech Cursor, EuroStar Cursor Repair Manual ('92-'02)….2

EUROTECH CURSOR – EUROSTAR CURSOR….2

REPAIR MANUAL….2

NOTE….4

Graphs and symbols….5

INDEX….6

SECTION 1 – General….7

General….7

COMPOSITION OF MODELS….9

P.I.C. CODE NUMBER….13

Vehicle Identification Data (EUROTECH)….17

Vehicle Identification Data (EUROSTAR)….18

FILLING UP….19

International designations of lubricants and fluids….20

SECTION 2 – Engine….21

Engine….21

VIEWS OF THE ENGINE….27

TECHNICAL DESIGNATION….29

GENERAL CHARACTERISTICS….32

ASSEMBLY CLEARANCE DATA….35

FAULT DIAGNOSIS….41

DESCRIPTION….41

DIAGNOSTIC INSTRUMENTS….41

CONTROL UNIT TEST….42

ENGINE TEST….42

AUXILIARY FUNCTIONS….42

DETECTION OF MECHANICAL FAILURE….43

TIGHTENING TORQUE….46

TOOLS….51

ENGINE REMOVAL – REFITTING….61

Removal….61

Refitting….62

DISMANTLING THE ENGINE ON THE BENCH….65

REPAIR OPERATIONS….72

CYLINDER BLOCK….72

Checks and measurements….72

CYLINDER LINERS….73

Replacing cylinder liners….74

Removal….74

Fitting and checking protrusion….74

CRANKSHAFT….75

Measuring main journals and crank pins….76

Preliminary measurement of main and big end bearing shell selection data….77

Replacing the timing control gear and oil pump….85

Checking main journal installation clearance….85

Checking crankshaft end float….86

PISTON-CONNECTING ROD ASSEMBLY….87

Removal….87

Measuring the diameter of the pistons….88

Conditions for correct gudgeon pin-piston coupling….88

Piston rings….89

CONNECTING ROD….90

Bushings….91

Checking connecting rods….91

Mounting the piston rings piston assembly….92

Mounting the piston rings….92

Fitting the big end bearing shells….92

Fitting connecting rod – piston assemblies in the cylinder liners ….93

Checking piston protrusion….93

Checking assembly clearance of big end pins….95

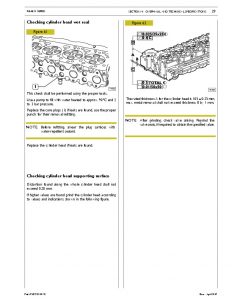

CYLINDER HEAD….95

Taking down the valves….95

Checking the planarity of the head on the cylinder block….95

VALVES….95

Removing deposits and checking the valves….95

VALVE GUIDES….96

Replacing of valve guides….97

Replacing – Reaming the valve seats….97

REPLACING INJECTOR HOLDER CASES….97

Removal….97

Checking protrusion of injectors….99

TIMING GEAR….100

Checking cam lift and pin alignment….100

Camshaft….101

Bushes….101

Replacing camshaft bushes using beater 99360499….102

Valve springs….103

Fitting the valves and oil seal ring….103

ROCKER SHAFT….104

ROCKERS….104

LUBRICATION….105

Oil pump….107

Overpressure valve….107

Oil pressure control valve….108

Heat exchanger….108

Engine oil filters….109

COOLING….110

Water pump….110

Thermostat….110

TURBOCHARGING….113

Turbocharger….113

Holset HX55V turbocharger….115

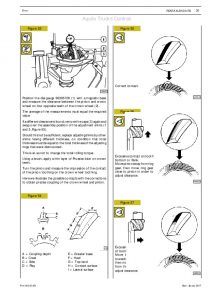

ACTUATOR ADJUSTMENT….118

VGT Control solenoid valve….118

Holset HY55V turbocharger….119

Actuator….120

Solenoid valve for VGT control….120

FEEDING….121

Fuel pump….122

Injector-pump….122

Pumping element….122

Nozzle….122

Solenoid valve….122

Replacing injectors-pump….122

INJECTOR PHASES….123

Filling phase….123

Injection phase….124

Pressure Reduction phase….124

ASSEMBLING THE ENGINE ON THE BENCH….125

DIAGRAM SHOWING THE UNDERBLOCK FIXING SCREWS TIGHTENING ORDER….127

Fitting the connecting rod-piston assembly into the cylinder liners….128

ENGINE FLYWHEEL….131

Fitting engine flywheel….131

Fitting camshaft….132

Fitting pump-injectors….133

Fitting rocker-arm shaft assembly….133

Camshaft timing….134

Phonic wheel timing….136

Adjusting rocker armclearance, intake, exhaust and pre-load of pump injector governing rocker arms….137

ENGINE COMPLETION….139

SECTION 3 – Clutch….141

Clutch….141

DESCRIPTION….143

Clutch….143

CHARACTERISTICS AND DATA….143

DIAGNOSTICS….144

TIGHTENING TORQUES….147

TOOLS….147

REMOVING AND REFITTING….148

Removal….148

Refitting….148

REMOVING AND FITTING BACK THE THRUST BEARING ….148

REPLACING THE SUPPORT BEARING OF THE CLUTCH SHAFT….148

DRIVEN PLATE CONTROL….149

Damping hub control….149

Friction seal….149

BLEEDING AIR FROM THE CLUTCH SYSTEM….149

HYDRAULIC CONTROL….150

CLUTCH ACTUATOR FOR ZF 16 S151/181/221 GEARBOX….151

Fitting and adjusting the clutch wear indicator….151

Push rod adjustment (new clutch)….152

CLUTCH ACTUATOR FOR EUROTRONIC GEARBOX….153

Clutch actuator push rod adjustment (new clutch)….153

Fitting the clutch actuator….153

Replacing the clutch actuator….153

CHECKING AND ADJUSTING THE CLUTCH PEDAL STOPS (excluded vehicles with EuroTronic gearbox)….154

Clutch stop….154

Clutch pedal idle stroke….154

Pedal timing gear stroke….154

SECTION 4 – Gearbox….155

Gearbox….155

Gearboxes: ZF 16 S 181 D.D. ZF 16 S 181 O.D. ZF 16 S 221 D.D….158

LOCATION OF GEARBOX DESCRIPTION PLATE….160

DESCRIPTION….161

OPERATION….163

Slow range….163

Fast range….164

EPICYCLIC REDUCTION GEAR CONTROL….165

Reduced speeds….165

Normal speeds….166

SPECIFICATIONS AND DATA….167

TIGHTENING TORQUES….171

TOOLS….172

GEARBOX FAULT DIAGNOSIS….177

REMOVING-REFITTING THE GEARBOX….180

Removal….180

Refitting….181

OVERHAULING THE GEARBOX….182

Servoshift gear box….182

Removal….182

Refitting….182

Disassembly….182

Assembly….184

Removing the rear box….187

Removing the epicyclic reduction gear unit (ERG)….187

Fitting the epicyclic reduction gear unit (ERG)….190

Refitting the epicyclic reduction gear unit (ERG) rear box ….193

Removing the gearbox….193

Removing the main shaft….196

Removing the drive input shaft….199

Removing the transmission shaft….200

CHECKS….200

Gearbox….200

Hubs – sliding sleeves – forks….200

Bearings….200

Shafts – gears….200

Synchronizing devices….200

BK-type single-cone synchronizing devices….200

Fitting the transmission shaft….201

Fitting the drive input shaft….201

Fitting the main shaft….202

Adjusting the main shaft….204

Fitting the gearbox….205

Oil pump….206

Adjusting the transmission shaft bearing end float….206

Drive input shaft cover….207

PNEUMATIC CONTROL OF GEARBOX….209

ZF gearboxes with INTARDER hydraulic retarder, types: 16 S 151 D.D. 16 S 181 D.D. 16 S 221 D.D….211

SPECIFICATIONS AND DATA….213

TOOLS….214

Removing the hydraulic retarder from the gearbox on the stand….221

Refitting the hydraulic retarder….221

Removing the epicyclic reduction gear unit (ERG) rear box….222

Removing the epicyclic reduction gear unit (ERG)….222

Component parts of the epicyclic reduction gear unit….225

Fitting the epicyclic reduction gear unit (ERG)….226

Refitting the epicyclic reduction gear unit (ERG) rear box….228

Gearbox EUROTRONIC 1800….230

DESCRIPTION….232

CHARACTERISTICS AND DATA….234

TIGHTENING TORQUES….237

EQUIPMENT….238

DIAGNOSIS OF MECHANICAL TYPE FAULTS….244

EUROTRONIC 1800 TRANSMISSION REMOVAL-REFITTING….247

Removal….247

Refitting….248

REPAIRS….249

Disassembly of front box….249

Disassembling the intermediate casing….250

Disassembly of rear box and epicyclic reduction unit….252

Installation of rear box and epicyclic reduction unit….254

Axial clearance regulation on epicyclic reduction gear bearing….254

Removal of primary shaft….258

Primary shaft installation….259

Removal of Splitter synchroniser….261

Installation of Splitter synchroniser….261

Forks installation-disinstallation….261

Secondary shafts….261

Central box installation….262

Shafts timing….264

Disinstallation of movement input shaft….265

Installation of movement input shaft….266

Installation of front box….266

Disinstallation of front cover….267

Installation of front cover….267

Regulation of axial clearance on movement input shaft bearing ….268

Regulation of axial clearance on secondary shaft bearings….268

EUROTRONIC IT (INTARDER)….272

CHARACTERISTICS AND DATA….272

REPAIRS….273

Disinstallation of rear box….273

Rear box installation….274

Regulation of axial clearance on epicyclic reduction gear bearing….274

Regulation of axial clearance on stator….275

CLUTCH ACTUATOR….276

Description….276

CHARACTERISTICS AND DATA….276

SAFETY RULES….277

Disinstallation….278

Installation….280

Operating checks….281

Measure of piston stroke….281

Gearbox EuroTronic 12 AS 2301 D.D….283

DESCRIPTION….285

SPECIFICATIONS AND DATA….286

TIGHTENING TORQUES….289

TOOLS….290

OVERHAULING THE GEARBOX ….295

Checks….295

Gearbox actuator….295

Removal….295

Refitting….296

Removing the rear box….296

Removing the rear box….297

Removing the epicyclic reduction gear train (E.R.G.)….298

Fitting the epicyclic reduction gear train (E.R.G.)….300

Adjusting epicyclic reduction gear train bearing end float….301

Adjusting main shaft end float….302

Synchronizing device assembly for engaging normal or reduced gears….304

Removal….304

Removing the middle box….307

Removing the main shaft….309

Removing the drive input shaft….311

Removing the splitter synchronizing device….312

Fitting the splitter synchronizing device….313

Fitting the main shaft….314

Fitting the drive input shaft….314

Splitter control fork….317

Disassembly – Assembly….317

Gear control forks….317

Removal….317

Fitting….318

Transmission shafts….319

Disassembly – Assembly….319

Fitting the middle box….319

Fitting the front box….322

Front cover….324

Removal….324

Fitting the front cover….324

Adjusting drive input shaft bearing end float….324

Adjusting transmission shaft bearing end float….325

Clutch release lever….327

Gearbox EuroTronic 12 AS 2301 D.D. with Intarder (IT)….330

SPECIFICATION AND DATA….332

OVERHAULING THE GEARBOX….333

Removing the hydraulic retarder….333

Refitting the hydraulic retarder….334

Adjusting epicyclic reduction gear train bearing end float….334

Adjusting stator end float….335

Removing the rear box….336

Removing the E.R.G….337

Fitting the E.R.G….338

EXPERIMENTAL TOOLS….343

SECTION 5 – Intarder – ZF hydraulic retarder….344

Intarder – ZF hydraulic retarder….344

LOCATION OF INTARDER HYDRAULIC RETARDER DESCRIPTION PLATE….346

GENERAL INFORMATION….347

OPERATION….347

Retarder engaged….348

Retarder disengaged….349

LAYOUT OF MAIN SYSTEM COMPONENTS ON THE RETARDER….350

REMOVING AND REFITTING THE RETARDER ON THE ZF S 181/221-OD GEARBOX….351

Removal….351

Refitting….352

Filling with oil….352

SPECIFICATIONS AND DATA….353

TIGHTENING TORQUES….354

TOOLS….355

FAULT DIAGNOSIS….357

OVERHAULING THE INTARDER HYDRAULIC RETARDER….361

Hydraulic accumulator….361

Removal….361

Fitting….361

Removing hydraulic retarder….361

Checking the component parts of the hydraulic retarder….366

Fitting the hydraulic retarder….367

For hydraulic retarders without friction reducing valves only….367

For both types of hydraulic retarder….368

Stator end float adjustment….372

SECTION 6 – Propeller shafts….374

Propeller shafts….374

SPECIFICATIONS AND DATA….376

SPECIFICATIONS AND DATA (Vehicles 4×2)….378

SPECIFICATIONS AND DATA (Vehicles 6 x 2)….379

DIAGNOSTIC….380

TIGHTENING TORQUES….382

REMOVING AND REASSEMBLING THE PROPELLER SHAFT….383

Removal….383

Reassembly….383

CHECKING THE PROPELLER SHAFT ON THE VEHICLE….384

REMOVING AND FITTING BACK THE UNIVERSAL JOINTS ….385

REMOVING AND REASSEMBLING THE SUPPORT….385

SECTION 7 – Rear axles….386

Rear axles….386

Rear axle MERITOR U 177 E whit drum brakes….388

DESCRIPTION….390

SPECIFICATIONS AND DATA….390

DIAGNOSTIC….393

TIGHTENING TORQUES….395

TOOLS….397

REMOVING THE REAR AXLE….402

FITTING BACK THE REAR AXLE….402

REAR AXLE ASSEMBLY OVERHAULING….404

WHEEL HUB OVERHAULING….404

Removal….404

Wheel hub component check….405

REPLACING THEWHEEL HUB BOLTS….406

Wheel hub reassembly….406

REMOVINGANDREASSEMBLING THE DIFFERENTIAL (with axle on stand 99322215) ….408

Removal….408

Axle casing check….408

Reassembly….409

REPAIRING THE DIFFERENTIAL….409

Removing the differential….409

Removing the gearcase….411

REMOVING THE BEVEL PINION FROM THE SUPPORT….413

Differential component check….413

Ressembling the gearcase….414

REASSEMBLING THE BEVEL PINION SUPPORT….415

Reassembling the differential housing….417

CAP OPENING ADJUSTMENT….419

CROWNWHEEL AND PINION CONTACT CORRECTION (AFTER ASSEMBLY)….422

Instructions for the adjustment and operation check of the transmitter for the differential block operation control….425

Rear Axle MERITOR U 177 E with disc brakes….426

DESCRIPTION….428

CHARACTERISTICS AND DATA….429

TIGHTENING TORQUES….430

TOOLS….432

OVERHAULING THE REAR AXLE ASSEMBLY….436

OVERHAULING THEWHEEL HUBS….436

Removal….436

Replacing wheel hub bearings….438

Checking the parts forming the wheel hubs….438

Replacing the wheel fixing pins….438

REMOVING AND REFITTING THE DIFFERENTIAL (with axle on stand 99322215)….442

Removal….442

Checking axle housing….442

Rear axle MERITOR MS 13-175 with drum brakes….444

DESCRIPTION….446

CHARACTERISTICS AND DATA….446

Rear Axle MERITOR MS 13-175 with disc brakes….448

DESCRIPTION….450

CHARACTERISTICS AND DATA….450

Rear axle 451391/1 (R 8284)….452

DESCRIPTION….454

SPECIFICATIONS AND DATA….455

TIGHTENING TORQUES….456

TOOLS….458

REAR AXLES ASSEMBLY OVERHAUL….464

Disassembly….464

Epicycloid reduction gear disassembly….464

Wheel hub disassembly….465

CLEANING AND CHECKING WHEEL HUB AND EPICYCLOID GEAR PARTS….467

WHEEL HUB ASSEMBLY….468

Assembling the epicycloid reduction gear….470

REMOVING-REFITTING THE DIFFERENTIAL….473

REFITTING….474

REPAIRING THE DIFFERENTIAL….475

Removal….475

Gear housing disassembly….476

Removing the bevel pinion from the support….477

CHECKING THE DIFFERENTIAL COMPONENTS….479

Gear housing assembly….480

Assembling the bevel pinion support….481

Procedure to follow to determine the thickness of the bevel pinion rolling torque adjusting ring….481

Differential housing assembly….483

Gear housing bearings rolling torque adjustment….484

Axles in Tandem….488

Axles in Tandem (Intermediate) Meritor RP 160 E (R 2478)….490

DESCRIPTION….492

SPECIFICATIONS AND DATA….492

TIGHTENING TORQUES….494

TOOLS….498

EXPERIMENTAL TOOLS….505

SERVICING INTERMEDIATE AXLEASSEMBLY RP 160 E (R2478) ….508

AIR BREATHER REMOVAL-REFITTING….508

SERVICINGWHEEL HUBS….508

Checking wheel hub components….509

ASSEMBLINGWHEEL HUBS….510

REMOVING DIFFERENTIAL GEAR . TRANSFER BOX(with rear axle on stand 99322215) ….513

REFITTING DIFFERENTIAL GEAR . TRANSFER BOX (with rear axle on stand 99322215)….513

REPAIRING INTER-AXLE UNIT….514

Dismantling inter-axle unit….514

Checking inter-axle unit components….516

Fitting inter-axle unit….516

Adjusting drive input shaft bearing end float….518

Adjusting differential lock and inter-axle control pin end-stop….518

REPAIRING MAIN DIFFERENTIAL – DISMANTLING DIFFERENTIAL CASING….519

Dismantling gear cage….522

Checking differential components….522

Assembling gear cage….523

ASSEMBLING DIFFERENTIAL CASING….524

Calculatingbevel pinion positionin differential casing ….524

COMPUTATIONAL EXAMPLES….525

Determining the thickness of the bevel pinion bearing clearance adjustment rings ….525

Adjusting the cap gap….528

CORRECTING THE CROWNWHEEL AND PINION CONTACTS (AFTER ASSEMBLY)….530

REMOVING-SERVICING-REFITTIN G INTER-AXLEOUTPUT SHAFT….533

Axles in Tandem (Rear) Meritor RR 160 E (R 0878)….536

DESCRIPTION….538

SPECIFICATIONS AND DATA….538

TIGHTENING TORQUE….540

TOOLS….542

SERVICING REAR AXLE ASSEMBLY RR 160 E (R 0878)….547

AIR BREATHER REMOVAL/ INSTALLATION….547

SERVICINGWHEEL HUBS….547

REMOVING DIFFERENTIAL (with axle on stand 99322215) ….547

REFITTING DIFFERENTIAL (with axle on stand 99322215)….547

REPAIRING DIFFERENTIAL….548

Removing differential lock….548

Dismantling differential casing….549

Dismantling gear cage….550

Dismantling bevel pinion support….550

Checking differential components….554

Assembling gear cage….554

Specimen calculations….556

Assembling differential casing….556

ADJUSTING THE CAP GAP….558

CORRECTING THE CROWNWHEEL AND PINION CONTACTS (AFTER ASSEMBLY)….561

Axles in Tandem (Rear) Meritor RR 167 E (R 0878)….564

DESCRIPTION….566

CHARACTERISTICS AND DATA….566

TIGHTENING TORQUES….568

TOOLS….570

OVERHAULING REAR AXLE ASSEMBLY RR 167 E (R 0878)….576

SECTION 8 – Axles….578

Axles….578

Front axle….580

Front axle 5876/4 (F 8021) 5876/5 (F 8021) Steering central added axle 5876/2 (F 8021)….580

DESCRIPTION….582

SPECIFICATIONS AND DATA….583

FAULT DIAGNOSIS….585

TIGHTENING TORQUES….587

TOOLS….590

REMOVING AND REFITTING FRONT AXLE….594

Vehicles with mechanical front suspension….594

Removal….594

Refitting….594

REMOVING AND REFITTING FRONT AXLE….595

Vehicles with pneumatic front suspension and longitudinal bars….595

Removal….595

Refitting….596

VEHICLE CHECKS….597

Tie rods….597

Swivel heads….597

CHECKING SWIVEL HEAD PLAY….597

FRONT AXLE ASSEMBLY OVER- HAUL….598

REMOVING – REFITTINGWHEEL HUBS….598

Removal….598

Replacing wheel hub bearings….599

Replacing wheel fixing pins….600

Refitting wheel hubs….600

Checking wheel hub bearing end float….600

Measuring rolling torque….601

REMOVING AND REFITTING TRANSVERSE TIE ROD ….601

REPLACING TRANSVERSE TIE ROD SWIVEL HEADS ….602

REMOVING AND REFITTING LEVERS FOR LONGITUDINAL TIE ROD ….602

REMOVING – REFITTING LEVER FOR TRANSVERSE TIE ROD….602

REMOVING AND REFITTING PIN FOR STUB AXLE….602

Removal….602

Replacing kingpin bearing….603

Checking and adjusting clearance between stub axle and axle….604

CHECKING AND MEASURING THE AXLE BODY….605

Checking levelness of leaf spring supporting surfaces with respect to the holes for the kingpins….605

Checking angle of holes for kingpins….606

Axle 5876 (F 8021)….608

DESCRIPTION….610

SPECIFICATIONS AND DATA….611

TIGHTENING TORQUE….612

TOOLS….613

FRONT AXLE ASSEMBLY OVERHAUL….617

REMOVING – REFITTINGWHEEL HUBS….617

Removal….617

Refitting wheel hubs….618

Rear axle….620

Additional rigid rear axle 55080….620

DESCRIPTION….622

CHARACTERISTICS AND DATA….622

TIGHTENING TORQUES….623

TOOLS….624

REPAIR OPERATIONS….626

Additional rigid rear axle 56082/1….628

CHARACTERISTICS AND DATA….630

TIGHTENING TORQUES….631

TOOLS….632

Pneumaically lifted steering additional rear axle (57080)….634

CHARACTERISTICS AND DATA….636

TIGHTENING TORQUES….638

TOOLS….639

REPAIR OPERATIONS….643

PNEUMATIC LIFT GENERAL….643

GENERAL INFORMATION….643

LOCATION OF THE MAIN HYDRAULIC SYSTEM COMPONENTS ON THE VEHICLE….644

HYDRAULIC SYSTEM….645

HYDRAULIC SYSTEM OUTLINE DIAGRAM….646

VEHICLESWITH REAR AIR SPRING SUSPENSIONS AND PNEUMATIC LIFT….647

Location of the main components on the vehicle….647

Pneumatic principle diagram, rear air spring suspensions and pneumatic lift for additional axles with single wheels….648

FAULT DIAGNOSIS….649

TIGHTENING TORQUES (Steering and lifting device linkage)….652

CHARACTERISTICS AND DATA….653

Steering and third axle hydraulic system….653

MAIN HYDRAULIC SYSTEM COMPONENTS….654

HYDRAULIC ACCUMULATOR….654

Nitrogen pressure checking and recharging….654

OPERATOR CYLINDER….654

Disassembly….655

Assembly….655

Checking cylinder oil sealing on the vehicle….655

CENTRING CYLINDER….655

Disassembly….656

Assembly….656

Checking cylinder oil sealing on the vehicle….656

ADDITIONAL AXLE PNEUMATIC LIFTING DEVICE REMOVAL AND REFITTING….657

Removal….657

Refitting….657

AIR BLEEDING FROM THE HYDRAULIC CIRCUIT….658

Filling up and bleeding the power steering hydraulic circuit (circuit 1)….659

Filling up and bleeding the power steering hydraulic circuit (circuit 2)….659

Wheel geometry….660

GENERAL INFORMATION….662

Steering wheel angles….662

FRONTWHEEL GEOMETRY (4X2 vehicles)….663

Positioning clips and headlights….663

Electronic compensation of rim eccentricity….664

Wheel alignment….664

Checking wheel toe-in….665

Checking wheel deviation….665

Checking camber….665

Checking kingpin angle and caster….666

Checking rear axle alignment….667

VEHICLE WHEEL GEOMETRY WITH CENTRAL ADDED AXLE (6X2 C)….667

Checking steering angles….669

Vehicle wheel geometry with steering rear added axle and pneumatic lifting….669

SECTION 9 – Suspensions….672

SUSPENSIONS….676

DESCRIPTION….676

Mechanical front suspension….676

Air spring front suspension….676

Air spring rear suspension….676

Mechanical rear suspension….676

FRONT SUSPENSION CHARACTERISTICS AND DATA….677

Front leaf spring (vehicles with mechanical suspension)….677

Front leaf spring (vehicles with air spring suspension)….678

Leaf spring for additional central axle (vehicles with air spring suspension)….679

Rear leaf spring (6×4 vehicles)….680

Front shock absorbers….682

Rear shock absorbers….683

CHECKING SHOCK ABSORBERS BRAKING CAPACITY….684

MECHANICAL FRONT SUSPENSION ASSEMBLY….686

MECHANICAL REAR SUSPENSION ASSEMBLY….688

REAR CANTILEVER SUSPENSION (6X2 – 6X4 vehicles) ….689

Removing-reassembling the central support….689

Removing-reassembling the central support shaft….689

Replacing the bearings….689

Removing-reassembling the bracket….689

Removing the central support….689

Removing the central support shaft….689

Replacing the bracket….689

Replacing the half bearings….689

Reassembling the bracket….690

Reassembling the central support shaft….691

Reassembling the central support….691

AIR SUSPENSION….693

Chassis frame lifting, lowering and self-levelling with remote control ….693

Saving Levels….693

AIR SPRING SUSPENSION ASSEMBLIES….694

Front air spring suspension for 4×2 vehicles: MP190E39/FP, LD440E43T/FP….694

Front air spring suspension for 6x2P vehicles: LD260E43Y/FS – 43Y/FP….694

Additional central axle air spring suspension for 6x2C vehicles: LD440E43TX/P….695

Rear air spring suspension for 4×2 vehicles: LD190E39/P – 43/P, MP190E39/FP….695

Rear air spring suspension for 4×2 vehicles: MP440E39T/P, LD440E43T/P….696

Rear air spring suspension for 4×2 vehicles: LD440E43T/FP….696

Rear air spring suspension for 6x2C vehicles: LD440E43TX/P….697

Rear air spring suspension for 6x2P vehicles: MP-LD260E43Y/P….697

Rear air spring suspension for 6x2P vehicles: LD260E43Y/FS-43Y/FP….698

Rear air spring suspension for 6×4 vehicles: 260E..Z/P – 440E..TZ/P….698

ATTITUDE VALUES….699

In self-levelling conditions….699

AIR SUSPENSION SYSTEM DIAGRAMS….701

Rear air suspension main diagram for 4X2P vehicles….701

Air suspension main diagram for 4x2FP vehicles….702

Rear air suspension main diagram for 4X2T/P vehicles….703

Air suspension main diagram for 4x2T/FP vehicles….704

Suspension main diagram for 4×2 FP-CT/FP-GV/FP-D vehicles….705

Suspension main diagram for 4x2FP-CM vehicles….706

Rear air suspension main diagram for 6x2Y/PS vehicles….707

Rear air suspension main diagram for 6x2Y/PT vehicles….708

Air suspension main diagram for 6x2Y/FP/FS/FT vehicles….710

Air suspension main diagram for 6x2TX/P vehicles….711

Air suspension main diagram for 6x2Y/FP/FS-GV/FS-D vehicles….712

Air suspension main diagram for 6x2Y/FP/FS-CM vehicles….713

Air suspension main diagram for 6×4 Z/P – HM vehicles….714

Air suspension main diagram for 6×4 TZ/P – HM vehicles….715

TIGHTENING TORQUES….716

Mechanical front suspension….716

Pneumatic front suspension….717

Pneumatic front suspension with bars….718

Additional central axle air suspension 6x2C vehicles….719

Rear air suspensions 4×2 + 6×2 C vehicles….720

Rear air suspensions 6×2 P/PT/FT vehicles….722

Rear air suspensions 6×2 P/PF/FS vehicles….723

Rear air suspensions 6×2 P vehicles….724

Rear air suspensions 6×4 vehicles….725

TOOLS….727

CHARACTERISTICS AND DATA….731

Relief valve….732

IDRAULIC SYSTEM MAIN COMPONENTS….732

Pneumatic system….731

Diagnostic….732

Level sensor….732

Electropneumatic distributor….733

Suspension pressure gauge….733

Air low pressure manometer switch….733

Air spring….733

DIAGNOSTIC….734

Diagnosis Instruments….734

Blink code table for ECAS .4X2 /6X4. suspension control unit….736

Blink code table for ECAS 6X2C suspension control unit….737

Blink code table for air-operated hoist ECAS 6X2 suspension control unit….738

REAR SUSPENSIONS….744

Removal….744

Refitting….744

REMOVING-REFITTING THE REAR AXLE LONGITUDINAL SUSPENSION ARM….745

REMOVING-REFITTING THE REAR ADDED AXLE LONGITUDINAL SUSPENSION ARM….745

REMOVING-REFITTING THE REAR AXLE TRIANGULAR SUSPENSION ARM….745

REMOVING-REFITTING THE REAR ADDED AXLE TRIANGULAR SUSPENSION ARM….745

Removal….745

Refitting….745

REPLACING THE SUSPENSION ARM FLEXIBLE PIN….746

Removal….746

Refitting….746

STABILIZER BAR….747

FRONT STABILIZER BAR….747

CENTRAL ADDED AXLE STABILIZER BAR (6×2 C vehicles)….747

REAR STABILIZER BAR….747

REAR ADDED AXLE STABILIZER BAR (6x2P vehicles)….747

Removal….747

Refitting….747

RUBBER BUSHINGS….750

Replacing front stabilizer bar rubber bushings….750

Replacing rear stabilizer bar rubber bushings….750

SHOCK ABSORBERS….751

Removal-refitting….751

Front axle shock absorbers (6×2 C vehicles)….751

Central added axle shock absorbers….751

Rear axle shock absorbers….751

Rear added axle shock absorbers (6×2 P vehicles)….751

Removal….751

Refitting….751

SECTION 10 – Wheels and tyres….752

Wheels and tyres….752

DESCRIPTION….754

CHARACTERISTICS AND DATA….754

Tyre inflation pressures….754

TOOLS….755

FAULT DIAGNOSIS….755

STATIC BALANCING OF THE WHEELS….758

CORRECTING RESIDUAL STATIC IMBALANCE….759

TYRE PRESSURE….759

HOW TYRE BEHAVIOUR DEPENDS ON PRESSURE….760

SECTION 11 – Steering system….762

Steering system….762

DESCRIPTION….764

4×2 vehicle control diagram (mechanical front suspension)….765

4×2 FP – 6×2 FP Vehicle steering control diagram with front air suspension and leaf spring….766

4×2 – 6×2 FP Vehicle steering control diagram with front air suspension and longitudinal bars….767

6×2 C Vehicle steering control diagram with auxiliary central axle….768

6x2p (steering rear axle) Vehicle steering control diagram with front mechanical suspension….769

6x2p (steering rear axle) Vehicle steering control diagram with front air suspension and longitudinal bars….770

6x2p (steering rear axle) Vehicle steering control diagramwithfront air suspension andand leaf spring….771

CHARACTERISTICS AND DATA….775

FAULT DIAGNOSIS….776

TIGHTENING TORQUES….781

TOOLS….782

REMOVING AND REFITTING THE POWER STEERING UNIT….784

Removal….784

Refitting….785

Removing-Fitting the Steering Lever….785

REMOVING AND REFITTING THE STEERING CONTROL ASSEMBLY….786

Removal….786

Refitting….787

BLEEDING AIR FROM THE POWER STEERING CIRCUIT….788

MEASURING PLAYS IN THE STEERING BOX DETECTED ON THE STEERINGWHEEL ….788

CHECKING THE POWER STEERING SYSTEM MAXIMUM PRESSURE….788

ADJUSTING THE HYDRAULIC STEERING LIMITING DEVICE….788

Checking the hydraulic limiting of steering with vehicle running….789

Setting the automatic hydraulic steering limit….789

Checking….789

SECTION 12 – Pneumatic system – Brakes….790

Pneumatic system – Brakes….790

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (TANKS AND ACCUMULATORS)….794

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (VALVES)….795

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (TANKS AND ACCUMULATORS)….801

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (CONVERTERS, CYLINDERS AND CALLIPERS)….802

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (CALLIPERS AND CYLINDERS)….803

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (SEMI-COUPLINGS AND COUPLING CONNECTORS)….804

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (SEMI-COUPLINGS AND COUPLING CONNECTORS)….805

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (INDICATORS AND SWITCHES)….806

SYMBOLS FOR AIR/HYDRAULIC SYSTEM CIRCUIT DIAGRAMS (BRAKES)….807

PIPES AND COUPLINGS….808

In general….808

End forming on rigid pipes….808

Bending rigid pipes….809

Cutting rigid pipes….809

Replacing flexible hoses with threaded couplings….810

Replacing flexible hoses with quick-connection couplings….811

BRAKING SYSTEM….813

Outline diagram for 4×2 vehicles 190 E…P/FP….813

Outline diagram for 4×2 vehicles 440 E…T/P-T/FP….814

Outline diagram for 6x2C vehicles 440 E…TX/P….815

Outline diagram for 6x2P vehicles 260 E…Y/PS – Y/FS – Y/FP….816

Outline diagram for 6x2P vehicles 260 E…Y/TN….817

Outline diagram for 6×4 vehicles 260 E…Z/P-HM….818

ABS-ASR system wiring diagram (for 4×2 vehicles)….819

ABS-ASR system wiring diagram (for 6x2C vehicles)….820

ABS-ASR system wiring diagram (for 6x2P vehicles)….821

ABS-ASR system wiring diagram (for 6x2P Y/TN vehicles)….822

ABS-ASR system wiring diagram (for 6×4 vehicles)….823

EBS system wiring diagram (for 4×2 vehicles) 440 E… T/P-T/FP….824

EBS system wiring diagram (for 6x2C vehicles) 440 E… TX/P….825

Layout of the main brake system components on the vehicle….826

Layout of the main ABS-ASR system components on the vehicle….827

Layout of the main EBS system components on the vehicle….828

DESCRIPTION….829

Service braking….829

Emergency braking….829

Exhaust braking….829

Parking brake….829

BRAKES….829

Front brakes (KNORR SB7 – SN7 type)….829

Rear brakes (PERROT type dia. 410 x 180 – 410 x 200) ….829

DIAGNOSTICS….830

Diagnosis Instruments….830

ABS Troubleshooting….832

EBS Troubleshooting….840

TIGHTENING TORQUES….876

TOOLS….879

SPECIFICATIONS AND DATA – AIR SYSTEM….889

CHARACTERISTICS AND DATA – BRAKES….896

CHECKING MAIN BRAKE SYSTEM COMPONENTS….900

BRAKING SYSTEM MAIN COMPONENTS….902

Compressor….902

Head locking screw tightening….902

Fault diagnosis….903

A.P.U. (Air Processing Unit)….903

Distributor with electric (vehicles not fitted with EBS)….904

Duplex Distributor with electric (vehicles not fitted with EBS) ….904

Fault diagnosis (vehicles not fitted with EBS)….904

Triple-control servo-distributor (vehicles not fitted with EBS)….905

Predominance adjustment….905

KNORR – BREMSE AC 567 B….905

WABCO 973009013….905

Fault Diagnosis….906

Trailer control servo-distributor (vehicles fitted with EBS ….906

Relief valve (towing vehicles)….906

Coupling heads….906

Parking brake control hand distributor (towing vehicles)….907

Parking brake control hand distributor (towing vehicles)….907

Fault Diagnosis (Parking brake control hand distributor (towing vehicles)….907

Rear axle electro-pneumatic modulator (for vehicles with EBS)….908

Fault Diagnosis….908

Relay valve (vehicles not fitted with EBS) ….909

Axle proportional relay valve (vehicles fitted with EBS)….909

Fault Diagnosis (vehicles not fitted with EBS)….909

Exhaust brake control pedal valve….909

Low-pressure switch….909

Controlled pressure valve….910

Fault Diagnosis….910

Dual stop valve….910

Pressure test point valve….910

Diaphragm brake cylinder (for front and added front axle disc brake) ….911

Diaphragm brake cylinder (for front and added front axle drum brake)….911

(for front and added front axle Combined brake cylinder ….911

Combined brake cylinder (for drum brake)….912

Combined cylinder emergency brake release device ….912

ANTI-SKID SYSTEMS….913

Antilock braking system (ABS)….913

Anti-skid system (ASR)….913

EBS (Electronic Brake System)….913

Electronic control unit….914

Brake antilock distributor….914

ASR electropneumatic valve….914

Revolution sensor….914

Phonic wheels….914

BRAKE REPAIR….915

KNORR SB7 type front disk brakes (vehicles not fitted with EBS)….915

KNORR SBY type front disk brakes (vehicles fitted with EBS)….916

KNORR SB7 type front disk brakes (vehicles not fitted with EBS)….915

Operation….919

CHECKS….919

KNORR SBY type front disk brakes (vehicles fitted with EBS)….916

SN7 TYPE DISK BRAKES….917

CHECKS….919

Checking the automatic play recovery system efficiency….919

Checking brake lining thickness….920

Brake lining replacement….921

Remov.-fitting back the brake calipers Remover….924

Remover….924

Refitting….925

Removing-fitting the wheel hubs….925

Removing….925

Refitting….926

SB7 BRAKE CALLIPER OVERHAULING….927

Disassembly….927

Cleaning and checking the components….927

Assembly….928

BRAKE DISC OVERHAULING….929

BRAKE DISCS TURNING AND GRINDING….929

FRONT DRUM BRAKES….930

REAR BRAKES….930

Disassembly….930

Assembly….930

REAR DISK BRAKES….930

REAR DRUM BRAKES….931

REAR DRUM BRAKES OVERHAULING….931

Disassembly….931

Turning drums….934

Replacing brake linings….934

SECTION 13 – Scheduled Maintenance….938

SCHEDULED MAINTENANCE….940

DESCRIPTION….940

Service plan….940

OPERATIONS….941

DIAGRAM OF POINTS FOR CHECKS AND/OR MAINTENANCEWORK….944

603.93.121 – Iveco Trucks EuroTrakker, EuroTech, EuroStar Cursor 8-10-13 Electrical Wiring Diagrams….946

EUROTRAKKER – EUROTECH – EUROSTAR CURSOR 8/10/13….946

REPAIR MANUAL ELECTRIC/ELECTRONIC SYSTEM….946

FOREWORD….948

GENERAL LIST OF CONTENTS….950

Introduction….952

General cautions for electric/electronic components….955

Concept of earth and electromagnetic compatibility….957

Concept of CAN LINE….962

Technical Codes….966

Graphic symbols and abbreviations….972

General….978

DESCRIPTION OF BASE SYSTEM….980

Technical and electric specifications….980

Cab structure….980

Components on the engine F2B….982

Frame structure….986

Complete vehicle with cab tilted….987

Vehicle transparency (Euro Tech/EuroStar)….988

POWER NETWORK….990

Negative network….990

Earth points on the vehicle….991

Positive network….1002

Starting….1006

MAIN COMPONENTS….1009

Interconnecting Control Unit (UCI)….1009

Central panel – Cursor 8 (On Road)….1027

Starter motor….1035

Alternator….1039

Steering column lever unit….1041

Ignition switch….1047

Front wall connectors (A) (EuroTech – EuroStar)….1048

Rear wall connector ( " )….1059

Connectors between cables (Base vehicle) Cursor 8/10/13….1066

Specific circuits….1094

ABS OPERATION DIAGRAM (CURSOR 8 – 10 – 13)….1096

EDC MS6.2 (Cursor 8 – 10 – 13)….1157

ECAS….1188

IMMOBILIZER….1229

Circuit Charts….1248

Keys….1250

Chart No. 1: Start up from driver’s seat….1251

Chart No. 2: Start up from engine compartment….1252

Chart No. 3: Pre-heating….1253

Chart No. 4: Recharge….1254

Chart No. 5: Instruments (fuel level – water temperature)….1255

Chart No. 6: Instruments (engine oil and brake air pressure)….1256

Chart No. 7a: Instruments (tachograph – rev counter) F2B (on)….1257

Chart No. 7b: Instruments (tachograph – rev counter) F3A/F3B (on) – F2B/F3B (off)….1258

Chart No. 8a: Warning lights (iveco control)….1259

Chart No. 8b: Warning lights F2B (on)….1260

Chart No. 8c: Warning lights F3A/F3B (on)….1261

Chart No. 8d: Warning lights F2B/F3B (off)….1262

Chart No. 9: Sidelights (cabin interior)….1263

Chart No. 10: Sidelights (vehicle exterior)….1264

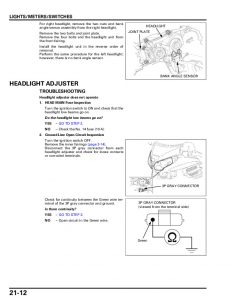

Chart No. 11: Main/dipped beam headlights….1265

Chart No. 12: Additional headlights and rear foglights….1266

Chart No. 13: Direction indicators – hazard lights….1267

Chart No. 14: Brake lights – Reverse light – Horn….1268

Chart No. 15: Windscreen wiper….1269

Chart No. 16a: Interior lighting and service F2B (on)….1270

Chart No. 16b Interior lighting and service F3A/F3B (on)….1271

Chart No. 16c: Interior lighting and service F2B/F3B (off)….1272

Chart No. 17: Rearview mirrors….1273

Chart No. 18a: Window winders F2B (on) F2B/F3B (off)….1274

Chart No. 18b: Window winders F3A/F3B (on)….1275

Chart No. 19a: ABS / ASR F2B (on)….1276

Chart No. 19b: ABS / ASR F3A/F3B (on)….1277

Chart No. 19c: ABS / ASR F2BF3B (off)….1278

Chart No. 20: EBS F3A/F3B (on)….1279

Chart No. 21a: EDC (connector B) F2B (on)….1280

Chart No. 21b: EDC (connector B) F3A/F3B (on) F2B/F3B (off)….1281

Chart No. 22a: EDC (connector a – F2B)….1282

Chart No. 22b: EDC (connector A – F3B)….1283

Chart No. 23a: EUROTRONIC 1 F2B (on)….1284

Chart No. 23b: EUROTRONIC I I F3A/F3B (on) F2B/F3B (off)….1285

Chart No. 24: Manual climate control system….1286

Chart No. 25: Automatic climate control system….1287

Chart No. 26: Additional air heating manual mode….1288

Chart No. 27: Additional air heating manual mode (GGVS)….1289

Chart No. 28: Independent heating unit manual control for cabin and engine….1290

Chart No. 29: Independent heating unit manual control for cabin and engine (TMP)….1291

Chart No. 30: Main remote control switch….1292

Chart No. 31: ADR electronic main remote control switch….1293

Chart No. 32: Air TMP emergency switch….1294

Chart No. 33: Air TMP emergency switch (French)….1295

Chart No. 34: Ground startup and recharge….1296

Chart No. 35: 15-Pole socket….1297

Chart No. 36: 2X7 Pole socket (only tractor)….1298

Chart No. 37: Heated windscreen….1299

Chart No. 38: Drier heating heated pre-filter….1300

Chart No. 39: Trip computer level 1….1301

Chart No. 40: Trip computer level1 (with main current switch)….1302

Chart No. 41A: Electronic speedometer F2B (ON)….1303

Chart No. 41B: Electronic speedometer F3A/F3B (ON) F2B/F3B (OFF)….1304

Chart No. 42: Hour counter….1305

Chart No. 43: Economy Power….1306

Chart No. 44: Central door lock….1307

Chart No. 45: Multipower takeoff….1308

Chart No. 46: Right and left beacon light….1309

Chart No. 47: Sunroof….1310

Chart No. 48: Central lubrication “Lincoln” – “Vogel”….1311

Chart No. 49: Hydraulic power steering circuit….1312

Chart No. 50: Hydraulic power steering circuit (northern countries)….1313

Chart No. 51: Headlight washer and windscreen wiper….1314

Chart No. 52: Trailer braking system….1315

Chart No. 53: Immobilizer….1316

Chart No. 54: Intarder ZF….1317

Chart No. 55: ECAS for 4X2 and 6X2 (ON)….1318

Chart No. 56: ECAS for 4X2 and tractor (ON)….1319

Chart No. 57: ECAS for 6X2 P/FP and PT/FT with additional hydraulic steering axis (ON)….1320

…

Iveco EuroTech, EuroStar Trucks Workshop Repair Service Manual 1992-2002