Complete service repair manual with electrical wiring diagrams for Hyster H150-275H, P150-200B (C007) Forklifts Trucks, with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster H150-275H, P150-200B (C007) workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

Total Pages: 765 pages

File Format: PDF

Language: English

Section

Part No.

SRM Number Rev Date

FRAME

910051

0100 SRM 0141

10/88

PERKINS DIESEL ENGINES 6.3544, T6.3544

910054

0600 SRM 0007

05/97

GM ENGINE V8-350 (5.7L)

599805

0600 SRM 0104

09/93

COOLING SYSTEM

897934

0700 SRM 0626

11/01

TWO-BARREL CARBURETOR

910058

0900 SRM 0012

03/97

LPG FUEL SYSTEM

910060

0900 SRM 0016

03/97

WEBER CARBURETOR WITH GOVERNOR

897128

0900 SRM 0347

12/92

OIL CLUTCH and JET PUMP

910062

1200 SRM 0022

02/97

THREE-SPEED PS TRANS – DESCR / OPER

899661

1300 SRM 0033

03/97

FIVE-SPEED MANUAL TRANSMISSION

910066

1300 SRM 0039

10/87

SPEED REDUCER

910068

1300 SRM 0044

01/97

THREE-SPEED PS TRANSMISSION – REPAIR

910070

1300 SRM 0142

04/83

DIFFERENTIAL

910072

1400 SRM 0046

11/03

PLANETARY GEAR AXLE

910030

1400 SRM 0047

11/03

DRIVE AXLE

910073

1400 SRM 0049

09/03

DRIVE AXLE

910076

1600 SRM 0054

10/03

STEERING AXLE

910031

1600 SRM 0071

07/97

BRAKE SYSTEM (AIR)

910084

1800 SRM 0083

10/95

BRAKE SYSTEM (HYDRAULIC)

910085

1800 SRM 0084

10/81

PARKING BRAKE

910088

1800 SRM 0146

06/87

AIR COMPRESSOR

910089

1800 SRM 0150

08/87

HYDRAULIC GEAR PUMPS

910091

1900 SRM 0097

10/03

FLOW CONTROL VALVE

910093

1900 SRM 0147

02/79

MAIN CONTROL VALVE (PARKER)

910098

2000 SRM 0099

02/97

MAIN CONTROL VALVE (HUSCO)

910099

2000 SRM 0100

02/97

TILT CONTROL VALVE

910101

2100 SRM 0102

07/94

TILT CYLINDERS

910102

2100 SRM 0103

10/03

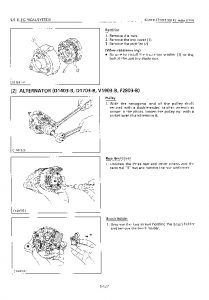

ALTERNATOR

899784

2200 SRM 0002

10/03

STARTER

910107

2200 SRM 0106

02/01

HIGH ENERGY IGNITION SYSTEM

899788

2200 SRM 0107

03/02

INSTRUMENT PANEL INDICATORS and SENDERS

910110

2200 SRM 0143

12/03

ELECTRICAL WARNING DEVICES

910111

2200 SRM 0144

05/97

ELECTRICAL SYSTEM TROUBLESHOOTING

899793

2200 SRM 0153

07/97

UPRIGHT

910117

4000 SRM 0127

09/84

PULPWOOD LOADER

910122

5000 SRM 0154

04/79

DIAGRAMS

910138

8000 SRM 0148

01/79

PERIODIC MAINTENANCE

910140

8000 SRM 0151

04/87

CAPACITIES and SPECIFICATIONS

910141

8000 SRM 0152

01/82

PART NO. 599795

Rev. 12/03

hyster-599805-09-93-srm0104…3

Cooling System…47

Safety Precautions Maintenance and Repair…48

General…51

Description…52

Radiator…52

Radiator Cap…52

Thermostat…52

Water Pump…53

Fan and Fan Shroud…53

Cooling System Checks…53

Radiator…53

Thermostat…53

Water Pump…54

Exhaust Leaks…54

Fan and Fan Shroud…54

Radiator Cleaning…54

Drain…54

Clean…54

Fill…55

Troubleshooting…56

hyster-899784-10-03-srm0002…91

toc…91

Alternator with Regulator…91

Safety Precautions Maintenance and Repair…92

General…95

Description…95

Alternator Repair…97

Alternator Type A…97

Remove and Disassemble…97

Clean…98

Assemble…99

Install…99

Alternator Type B…102

Remove and Disassemble…102

Clean…102

Assemble…103

Install…104

General Check and Adjustment…105

Low Output Check (Type A or Type B)…105

High Output Check (Type A or Type B)…107

Brushes Circuit Check…108

Delco Alternators…108

Motorola Alternators…109

Diodes Check…110

Diode Bridge Check…110

Delco and Leece-Neville Alternators…110

Motorola Alternators…110

Rotor Field Winding Check…111

Stator Windings Check…112

Voltage Regulator Check…112

Troubleshooting…112

hyster-899788-03-02-srm0107…117

toc…117

High Energy Ignition (HEI) System…117

Safety Precautions Maintenance and Repair…118

Description…121

Distributor Repair…123

Remove…123

Disassemble…123

Assemble…128

Install, If Crankshaft WAS NOT Rotated when Distributor was Remo…129

Install, If Crankshaft WAS Rotated when Distributor was Removed…129

Ignition Coil Replacement…130

Some Four- and Six-Cylinder Models…130

Remove…130

Install…131

V8, Some Four- and Six-Cylinder Models…131

Remove…131

Install…132

Electronic Module Replacement…133

Remove…133

Install…133

Sensing Coil Replacement…134

Remove…134

Install…134

Spark Plugs Replacement…134

Remove…134

Install…135

Visual Check…135

High Voltage Wires Check…135

Ignition Coil Check…136

Coil in Distributor Cap Design…136

Separate Coil Design…136

Sensing Coil, Check…137

Electronic Module Check…137

Ignition Timing Adjustment…137

GM V8-366 (6-liter) Ignition System Check…139

GM V6-LPG (4.3 liter) GM V6-LPG (4.3 liter) Ignition Timing and …139

Specifications…139

Troubleshooting…140

hyster-910030-11-03-srm0047…209

toc…209

Planetary Gear Axle…209

Safety Precautions Maintenance and Repair…210

General…213

Description…213

Operation…214

Planetary Gear Axle Repair…215

Remove…215

Disassemble…215

Planetary Axle, Disassemble…218

Assemble and Install…222

Planetary Axle, Assemble…223

Torque Specifications…228

Troubleshooting…231

tables…209

Table 1. Axle-to-Frame Fasteners…222

Table 2. Standard Torque Values for Axle Fasteners…228

Table 3. Drive Wheel Nut Torque…228

Differential…407

Safety Precautions Maintenance and Repair…408

General…411

Description…411

Differential Repair…411

Remove…411

Differential Carrier From Axle Housing, Remove…411

Differential and Ring Gear From Differential Carrier, Remove…415

Drive Pinion and Pinion Carrier From Differential Carrier, Remov…417

Disassemble…418

Differential and Ring Gear Assembly, Disassemble…418

Drive Pinion and Pinion Carrier, Disassemble…420

Clean and Inspect…422

Assemble…423

Pinion, Bearings, and Pinion Carrier, Assemble…423

Pinion Bearings, Adjust Preload…424

Press Method…424

Yoke or Flange Method…424

Triple-Lip Seal, Install…425

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion)…426

Differential and Ring Gear, Assemble…428

Differential Gears Rotating Torque, Check…431

Differential and Ring Gear Assembly, Install…432

Differential Bearings, Preload Adjust…433

Ring Gear, Runout Check…434

Ring Gear Backlash, Adjust…434

Gear Set, Tooth Contact Pattern Check…436

Thrust Screw, Install and Adjust…438

Install…439

Differential Assembly Into Axle Housing, Install…439

Specifications…441

Troubleshooting…445

tables…407

Table 1. Ring Gear Backlash Adjustment Specifications…435

Table 2. Ring and Pinion Tooth Contact Adjustment…437

Table 3. General Specifications…441

Table 4. Rivet Installation Pressure…441

Table 5. Pinion Adjustment…441

Table 6. Pinion Preload Pressure…442

Table 7. Torque Specifications…443

Table 8. Torque Specifications for Metric Hardware…444

Table 9. Torque Specifications for Metric (Fine) Hardware…444

hyster-910073-09-03-srm0049…449

toc…449

Drive Axle…449

Safety Precautions Maintenance and Repair…450

General…453

Description…453

Drive Axle Repair…454

Disassemble (Type 1 Shown)…454

Clean…457

Inspect…457

Assemble (Type 1 Shown)…458

Torque Specifications…461

Troubleshooting…462

Steering Control Unit…465

Safety Precautions Maintenance and Repair…466

General…469

Description…469

Operation…469

Steering Wheel and Column Assembly Repair…471

Steering Column Assembly Repair…471

Type A Steering Column Assembly…471

Remove and Disassemble…471

Assemble and Install…473

Type B Steering Column Assembly…475

Remove and Disassemble…475

Assemble and Install…475

Steering Control Unit…478

Disassemble…478

Clean…481

Assemble…482

System Air Removal…487

Troubleshooting…487

Hydraulic Gear Pumps…543

Safety Precautions Maintenance and Repair…544

Description…547

Operation…548

Flow Control Valve…548

Relief Valve…549

Hydraulic Gear Pump Repair…549

Remove…549

Disassemble…550

Clean…550

Inspect…551

Assemble…554

Install…556

Pump Output Check…556

Method No. 1…556

Method No. 2…557

Hydraulic System Air Check…558

Tilt Cylinders…609

Safety Precautions Maintenance and Repair…610

General…613

Description…613

Tilt Cylinder Repair…613

Remove…613

Disassemble…613

Clean…613

Assemble…614

Tilt Cylinders With O-Ring or Single-Lip Seals…614

Tilt Cylinders for XM and XMS Models…615

Tilt Cylinders for H700-800A and Early Model H700-920B…616

Install…617

Tilt Cylinders Using Chevron Packing…618

Install…619

Tilt Cylinder Leak Check…621

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…622

Torque Specifications…623

Piston Rod Nut…623

Retainer…624

Troubleshooting…626

tables…609

Table 1. Movement Rates (Maximum) for Tilt Cylinders…622

Starter…629

Safety Precautions Maintenance and Repair…630

General…633

Description and Operation…633

Starter Repair…635

Remove…635

Disassemble…635

Clean…636

Assemble…636

Install…637

General Checks and Adjustments…637

Troubleshooting…640

Instrument Panel Indicators and Senders…645

Safety Precautions Maintenance and Repair…646

General…649

Description…650

Steering Column Gauges, Meters, and Indicators…650

LED Display Panel…650

Battery Discharge Indicators…650

Brush Wear Indicators…657

Motor Temperature Indicators…657

LX Series Display Panel…659

Hourmeter Functions…659

Battery Indicator Function…660

Status Code Function…661

ZX Series Display Panels…661

Display Panel…661

Basic Display Panels…661

Performance Display…664

Brush Wear Indicators…667

Adjustments – General…668

Replacement – General Information…668

Meter Replacement…669

Sender Replacement…670

Fuel Level Sender…670

Pressure and Temperature Sender…670

ITW Display Panel Replacement…671

Remove…671

Column Mount Display Panel (EV-100/200ZX Motor Controllers) Repl…672

Remove…672

Display Panel Assembly, Replace…672

Indicator LEDs…673

Battery Indicators…673

Digital Display (Performance Display Panel Only)…673

Status Code or Performance Level Switches and Indicator LEDs (Pe…673

Basic Display Panel, Replace Parts…673

Performance Display Panel, Replace Parts…675

Dash Mount Display Panel (EV100/200ZX Motor Controllers) Replace…676

Remove and Replace…676

Specifications…676

Meter Specifications…676

Sender Specifications…677

Troubleshooting…677

Meter…677

Hyster H150-275H, P150-200B (C007) Repair Service Manual