Complete service repair manual with electrical wiring diagrams for Hyster H360-650C TO S/N1550 (C008) & H370-700C S/N1550-UP (C008), with all the workshop information to maintain, diagnose, repair, and service like professional mechanics.

Hyster H360C-H650C (C008) & H370C-H700C workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

599974 – Hyster H360-650C TO S/N1550 (C008) & H370-700C S/N1550-UP (C008) Service Repair Manual.pdf

Total Pages: 804 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section |

Part No.

|

SRM Number | Rev Date |

| FRAME |

910467

|

0100 SRM 0267

|

02/97

|

| PERKINS DIESEL ENGINES TV8.540, TV8.640 |

910760

|

0600 SRM 0269

|

08/87

|

| COOLING SYSTEM |

897934

|

0700 SRM 0626

|

11/01

|

| THREE-SPEED PS TRANS-DESCR /OPER (HYSTER) |

910188

|

1300 SRM 0017

|

06/84

|

| THREE-SPEED PS TRANS-REPAIR (HYSTER) |

910015

|

1300 SRM 0171

|

06/84

|

| THREE-SPEED PS TRANS-REPAIR (HYSTER) |

897240

|

1300 SRM 0375

|

11/01

|

| THREE-SPEED PS TRANS-REPAIR (CLARK) |

897241

|

1300 SRM 0376

|

09/97

|

| DIFFERENTIAL |

910072

|

1400 SRM 0046

|

11/03

|

| PLANETARY GEAR AXLE |

910030

|

1400 SRM 0047

|

11/03

|

| STEERING CONTROL UNIT |

899776

|

1600 SRM 0058

|

07/80

|

| STEERING AXLE |

910031

|

1600 SRM 0071

|

07/97

|

| BRAKE SYSTEM (TO S/N 1550) |

910755

|

1800 SRM 0273

|

02/97

|

| BRAKE SYSTEM (S/N 1550-UP) |

897359

|

1800 SRM 0425

|

06/89

|

| HYDRAULIC GEAR PUMPS |

910091

|

1900 SRM 0097

|

10/03

|

| HYDRAULIC SYSTEM |

910462

|

1900 SRM 0253

|

01/97

|

| REMOTE CONTROL VALVE |

910450

|

2000 SRM 0249

|

01/97

|

| MAIN CONTROL VALVE |

910451

|

2000 SRM 0250

|

01/97

|

| ATACHMENT CONTROL VALVE |

910452

|

2000 SRM 0251

|

01/97

|

| FLOW CONTROL VALVE |

910463

|

2000 SRM 0252

|

01/97

|

| TILT CONTROL VALVE |

910101

|

2100 SRM 0102

|

07/94

|

| TILT CYLINDERS |

910102

|

2100 SRM 0103

|

10/03

|

| ALTERNATOR |

899784

|

2200 SRM 0002

|

10/03

|

| STARTER |

910107

|

2200 SRM 0106

|

02/01

|

| INSTRUMENT PANEL INDICATORS and SENDERS |

910110

|

2200 SRM 0143

|

12/03

|

| UPRIGHT |

910468

|

4000 SRM 0268

|

02/97

|

| EXTENDABLE CONTAINER ATTACHMENT |

910457

|

5000 SRM 0265

|

11/97

|

| FIXED CONTAINER ATTACHMENT |

910466

|

5000 SRM 0266

|

11/97

|

| INCH (SAE) and METRIC FASTENERS |

910442

|

8000 SRM 0231

|

03/03

|

| PERIODIC MAINTENANCE (TO S/N 1550) |

910752

|

8000 SRM 0271

|

05/84

|

| DIAGRAMS |

910751

|

8000 SRM 0276

|

01/97

|

| CAPACITIES and SPECIFICATIONS (TO S/N 1550) |

910758

|

8000 SRM 0277

|

07/87

|

| PERIODIC MAINTENANCE (S/N 1550-UP) |

897381

|

8000 SRM 0440

|

08/89

|

| CAPACITIES and SPECIFICATIONS (S/N 1550-UP) |

897387

|

8000 SRM 0446

|

07/89

|

| PART NO. 599974 | |||

| Rev. 12/03 | |||

C008 (H17.00-32.00C Europe)…2

100267…4

INTRODUCTION…4

GENERAL…4

DESCRIPTION…4

REPAIRS…4

COUNTERWEIGHT…4

Removal…4

Installation…4

FENDERS…4

Installation…5

HOOD AND BALLAST COVER…5

HYDRAULIC TANK…5

Removal, H16.00-32.00C (H360-650, H370-700C)…5

Removal, H46.00-44.00B (H700-920B)…6

Repairs, All Units…6

Steam Method of Cleaning…6

Chemical Solution Method of Cleaning…7

Other Methods Of Preparation For Repair…7

Installation, H16.00-32.00C (H360-650C, H370-700C)…7

Installation, H36.00-44.00B (H700-920B)…7

FUEL TANK…7

Removal, H16.00-32.00C (H360-650C, H370-700C)…7

Removal, H36.00-44.00B (H700-920B)…7

Repair, All Units…7

Installation, H16.00-32.00C (H360-650C, H370-700C)…7

Installation, H36.00-44.00B (H700-920B)…8

RADIATOR…8

Removal, H16.00-32.00C (H360-650C, H370-700C)…8

Removal, H36.00-44.00B (H700-920B)…8

Installation, H16.00-32.00C (H360-650C, H370-700C)…8

Installation, H36.00-44.00B (H700-920B)…8

ENGINE…8

Removal, H16.00-32.00C (H360-650C, H370-700C)…8

Installation, H16.00-32.00C (H360-650C, H370-700C)…9

Removal, H36.00-44.00B (H700-920B)…9

Installation, H36.00-44.00B (H700-920B)…10

OPERATOR'S COMPARTMENT AND CAB (See FIGURE 2.)…10

General…10

Removal…11

Repairs…13

Installation…14

LABEL REPLACEMENT…16

130017…18

INTRODUCTION…18

General…18

MECHANICAL DESCRIPTION…18

General…18

Torque Converter…18

Description…18

Operation…19

Clutch Assemblies…20

Description…20

Operation…21

First Stage Shaft…21

Second Stage Shaft…22

Third Stage Shaft…23

Inching Clutch…24

HYDRAULIC OPERATION…25

Sump, Filter and Pump…25

Control Valve, H360-620B…26

Control Valve, H360-650C…28

Inching Valve…30

Description…30

Operation…30

TRANSMISSION CONTROL CIRCUIT, H360-650C…33

HYDRAULIC CIRCUITS…33

Cooling and Lubrication…33

NEUTRAL-FIRST, H360-620B…33

NEUTRAL, H360-650C…35

FORWARD-FIRST, H360-620B…35

FORWARD-FIRST, H360-650C…37

REVERSE-FIRST, H360-620B…39

REVERSE-FIRST, H360-650C…40

SHIFT FROM FIRST TO SECOND SPEED, H360-620B…40

SHIFT FROM FIRST TO SECOND SPEED, H360-650C…40

1300171…42

INTRODUCTION…42

General…42

TRANSMISSION…42

Removal…42

Disassembly…43

Cleaning and Inspection…53

Assembly…53

Installation…67

TORQUE CONVERTOR…69

Removal and Disassembly…69

Cleaning and Inspection…71

Assembly and Installation…71

INCHING CLUTCH…74

Removal and Disassembly…74

Cleaning and Inspection…76

Assembly and Inspection…76

CONTROL VALVE…80

Removal…80

Disassembly…80

Cleaning and Inspection…81

Assembly…81

INCHING VALVE…82

Removal…82

Disassembly…82

Cleaning…82

Assembly…82

Installation…83

OIL PUMP…84

Removal…84

Disassembly…84

Cleaning and Inspection…85

Assembly…85

Installation…86

RANGE SELECTOR ASSEMBLY, H360-650C…86

Removal and Disassembly…86

Assembly and Installation…88

1300375…100

INTRODUCTION…100

General…100

MECHANICAL DESCRIPTION…101

General…101

Torque Converter…101

Description…101

Operation…102

Clutch Assemblies…102

Description…102

Operation…103

Forward Shaft…104

Reverse Shaft…104

First Speed Shaft…104

Output Shaft…104

HYDRAULIC OPERATION…105

Sump, Filter And Operation…105

Shift Control Valve…107

Solenoid Valves…107

Inching Spool…107

Direction Spools…107

Range Spools…107

Modulator Valve And Manifold Block…108

Operation…109

Transmission Control System, H17.00-32.00C(H370-700C)…111

Transmission Control System, H20.00-32.00F(H440-700F)…112

Hydraulic Circuits…114

Cooling and Lubrication…114

Operation Of The Transmission, NEUTRAL…115

Operation Of The Transmission, FORWARD-FIRST…116

Operation Of The Transmission, REVERSE-FIRST…117

Operation Of The Transmission, FORWARD-SECOND…118

Operation Of The Transmission, FORWARD-THIRD-INCHING…119

1300376…120

INTRODUCTION…120

General…120

Transmission…120

Removal…120

Transmission, Disassembly…122

Cleaning…138

Inspection…138

Transmission, Assembly…141

Installation…160

Modulator Valve And Manifold Block…164

Removal…164

Disassembly…164

Cleaning And Inspection…164

Assembly…165

Installation…165

Shift Control Valve…166

Removal…166

Disassembly…166

Cleaning And Inspection…167

Assembly…167

Installation…167

Oil Pump…168

Removal…168

Disassembly…168

Cleaning And Inspection…169

Assembly And Installation…169

Transmission Control Assembly H17.00-32.00C (H360-700C)…170

Removal And Disassembly…170

Assembly And Installation…171

Transmission Control Assembly H20.00-32.00 (H440-700F/FS)…172

Removal And Disassembly…172

Assembly And Installation…174

CHECKS AND ADJUSTMENTS…174

Check The Stall Speed Of The Torque Converter…174

Check The Oil Pressure Of The Transmission…175

TROUBLESHOOTING…176

140046…178

DIFFERENTIAL…178

GENERAL…178

DESCRIPTION…178

REPAIRS…179

REMOVAL…179

DISASSEMBLY…179

ASSEMBLY…179

Assemble The Pinion, Bearings And Pinion Carrier…179

Adjust Preload For Pinion Bearings…179

Adjust Thickness Of Shim Set For The Pinion Carrier (Depth Of Pinion)…180

Assemble The Differential And Ring Gear…182

Assemble Differential Pinion And Side Gear Assembly…183

Check The Rotating Torque Of Differential Gears…184

Install The Differential And Ring Gear Assembly…185

Adjust Preload Of The Differential Bearings…186

Check Runout Of Ring Gear…186

Adjust The Gear Clearance…186

Check Tooth Contact Pattern Of The Gear Set…187

Installation Into The Axle Housing…187

SPECIFICATIONS…190

TABLE 1. GENERAL SPECIFICATIONS…190

TABLE 2. RIVET INSTALLATION PRESSURE…190

TABLE 3. PINION PRELOAD PRESSURE…190

TABLE 4. PINION ADJUSTMENT…190

TABLE 5. TORQUE SPECIFICATIONS…191

TROUBLESHOOTING…192

140047…193

INTRODUCTION…193

GENERAL…193

DESCRIPTION…193

OPERATION…193

REPAIRS…194

REMOVAL…194

DISASSEMBLY…197

ASSEMBLY AND INSTALLATION…199

TROUBLESHOOTING…202

160058…205

INTRODUCTION…205

General…205

Description…207

Operation…207

REPAIRS…208

Removal…208

Disassembly…208

Inspection…213

Assembly…213

Installation…213

CHECKS AND ADJUSTMENTS…219

TROUBLESHOOTING…220

160071…221

INTRODUCTION…221

GENERAL …221

DESCRIPTION…221

REPAIRS…222

STEERING AXLE…222

Removal…222

Installation…222

STEERING CYLINDER…222

Removal…222

Inspection…224

Assembly…224

Installation…224

HUBS, H7.00-12.50H (H150-275H), H13.50-16.00B (H300-350B), P7.00-9.00B (P150-200B)…225

Removal…225

Installation…225

HUBS, H360-620B, H16.00-30.00C, H17.00-32.00C, H700-800A, H36.00-44.00B, H36.00-48.00C, H20.00-32.00F…226

Removal…226

Installation…226

SPINDLES…226

Removal…226

Installation…226

CHECKS AND ADJUSTMENTS…228

REMOVE THE AIR FROM THE STEERING SYSTEM…228

ADJUST THE CYLINDER STOPS…228

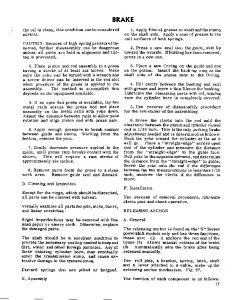

1800273…229

INTRODUCTION…229

GENERAL…229

DESCRIPTION…229

OPERATION…231

Service Brakes…231

Parking Brake…231

REPAIRS…232

AIR TANKS…232

Relief Valve…232

Drain Valve…232

BRAKE PEDAL VALVE…233

Removal…233

Disassembly and Repair…233

Assembly…233

Installation…233

PARKING BRAKE VALVE…233

Removal…233

Disassembly and Repair…234

Assembly…234

Installation…234

AIR CHAMBERS…234

Removal…234

Disassembly…235

Inspection…236

Assembly…236

Installation…237

ACTUATOR ARMS…237

Removal…237

Installation…237

BRAKE SHOES…237

Removal…238

Cleaning…238

Repair…239

Installation…239

BRAKE DRUMS (SERVICE BRAKES)…239

DISC BRAKE ASSEMBLY (SERVICE BRAKES)…239

Brake Pads Replacement…239

Brake Caliper, Removal…240

Brake Caliper, Disassembly…240

Brake Caliper, Repair…241

Brake Caliper, Assembly…241

Brake Caliper, Installation…241

Brake Rotor, Removal…241

Brake Rotor, Installation…241

Brake Booster, Removal…241

Brake Booster, Disassembly…241

Brake Booster, Inspection…241

Brake Booster, Assembly…242

Brake Booster, Installation…242

DISC BRAKE ASSEMBLY (PARKING BRAKE)…242

Brake Pads, Replacement…242

Brake Caliper, Removal And Disassembly…243

Brake Caliper, Cleaning…243

Air Chamber, Service…244

CHECKS AND ADJUSTMENTS…244

REMOVING AIR FROM THE BRAKE SYSTEM…244

CHECK AND ADJUST THE GOVERNOR FOR THE AIR COMPRESSOR…244

ADJUSTMENT OF THE BRAKE SHOES…245

CHECK WEAR ADJUSTMENT FOR THE PARKING BRAKE…245

TROUBLESHOOTING…246

1800425…248

INTRODUCTION…248

GENERAL…248

DESCRIPTION…248

H26.00-32.00C (H550-700C)…248

H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…248

OPERATION…248

Service Brakes, H26.00-32.00C (H550-700C)…248

Service Brakes, H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…252

Parking Brake, H26.00-32.00C (H550-700C)…252

Parking Brake, H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…253

REPAIRS…254

AIR TANKS…254

Relief Valve…254

Drain Valve…254

BRAKE PEDAL VALVES…254

Removal…254

Disassembly and Repair…255

Assembly…255

Installation…255

PARKING BRAKE VALVE…256

Removal…256

Disassembly and Repair…256

Assembly…256

Installation…257

PARKING BRAKE ACTUATOR, H26.00-32.00C (H550-700C)…257

Removal…257

Disassembly…257

Inspection…258

Assembly…258

Installation…258

PARKING BRAKE ACTUATOR, H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…258

Removal…258

Disassembly…258

Inspection…259

Assembly…259

Installation…260

PARKING BRAKE ASSEMBLY…260

Removal and Installation…260

Cleaning…260

Inspection…260

Assembly and Installation…260

SERVICE BRAKE ACTUATORS…261

Removal…261

Disassembly…261

Cleaning and Inspection…261

Assembly…261

Installation…261

BRAKE CALIPERS…262

Removal…262

Disassembly…263

Cleaning…263

Inspection…264

Assembly…264

Installation…265

INCHING VALVE ACTUATOR, H36.00-44.00B (H700-920B)…265

Removal…266

Disassembly…266

Cleaning and Inspection…266

Assembly…266

Installation…266

CHECKS AND ADJUSTMENTS…267

REMOVE THE AIR FROM THE BRAKE SYSTEM…267

INCHING ADJUSTMENT…267

CHECK AND ADJUST THE GOVERNOR FOR THE AIR COMPRESSOR…267

CHECK AND ADJUST THE PRESSURE REGULATORS FOR THE PARKING BRAKE, H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…267

TROUBLESHOOTING…269

1900253…271

INTRODUCTION H16.00-30.00C (H360-650C), H17.00-32.00C (H370-700C)…271

GENERAL…271

DESCRIPTION AND OPERATION…271

Right-Hand Hydraulic Pump…271

Left-Hand Hydraulic Pump…271

Auxiliary Hydraulic Pump (Left-Hand)…271

Auxiliary Hydraulic Pump (Right-Hand)…271

Main Control Valve…273

Attachment Control Valve…273

Remote Control Valve…273

Pressure Reduction Valve…273

Solenoid Valves…273

Steering Control Unit…273

INTRODUCTION H36.00-44.00B (H700-920B)…279

GENERAL…279

DESCRIPTION AND OPERATION…279

Main Control Valve…279

Attachment Control Valve…279

Remote Control Valve…279

Pressure Reduction Valve…279

Solenoid Valves…280

Steering Control Unit…281

TROUBLESHOOTING…286

SPECIFICATIONS H16.00-30.00C (H360-650C), H17.00-32.00C (H370-700C)…289

SPECIFICATIONS H36.00-44.00B (H700-920B)…290

190097…291

INTRODUCTION…291

DESCRIPTION…291

OPERATION…291

Flow Control Valve…293

Relief Valve…293

REPAIRS…294

REMOVAL…294

DISASSEMBLY…294

CLEANING…296

INSPECTION…296

ASSEMBLY…297

INSTALLATION…298

CHECKS AND ADUSTMENTS…299

CHECK THE OUTPUT OF THE PUMP…299

CHECK FOR AIR IN THE HYDRAULIC SYSTEM…299

TROUBLESHOOTING…301

2000249…304

INTRODUCTION…304

GENERAL…304

DESCRIPTION…304

OPERATION…304

REPAIRS…307

REMOVAL…307

DISASSEMBLY…307

INSPECTION…308

ASSEMBLY…308

INSTALLATION…310

ADJUSTMENT…311

TROUBLESHOOTING…311

2000250…312

INTRODUCTION…312

GENERAL…312

DESCRIPTION…312

OPERATION…312

Lift Circuit, High Speed (Light Load or No Load)…312

Lift Circuit, Normal Speed (Heavy Load)…313

Lowering…314

Two Speed Spool…315

Tilt Circuit…315

Relief Valve…316

REPAIRS…317

REMOVAL…317

DISASSEMBLY…317

CLEANING AND INSPECTION…317

ASSEMBLY…317

INSTALLATION…318

CHECKS AND ADJUSTMENTS…318

CHECKING THE RELIEF PRESSURE…318

CHECKING THE PRESSURE OF THE TWO SPEED CARTRIDGE…318

TROUBLESHOOTING…319

2000251…321

INTRODUCTION…321

GENERAL…321

DESCRIPTION…321

OPERATION…321

REPAIRS…322

REMOVAL…322

DISASSEMBLY…322

CLEANING AND INSPECTION…322

ASSEMBLY…323

INSTALLATION…323

CHECKS AND ADJUSTMENTS…324

CHECK AND ADJUST THE RELIEF VALVE…324

TROUBLESHOOTING…325

2000252…326

INTRODUCTION…326

GENERAL…326

DESCRIPTION AND OPERATION…326

FLOW REGULATORS…326

RELIEF VALVE…327

PRESSURE REDUCTION VALVE…327

TWIST LOCK SOLENOID VALVE…329

LOCK OUT SOLENOID VALVE…329

REPAIRS…330

FLOW REGULATORS…330

Removal…330

Disassembly…330

Cleaning and Inspection…330

Assembly…330

Installation…330

RELIEF VALVE…330

PRESSURE REDUCTION VALVE…330

TWIST LOCK SOLENOID VALVE AND LOCK OUT SOLENOID VALVE…330

CHECKS AND ADJUSTMENTS…331

CHECK THE CONTROLLED FLOW OF THE FLOW REGULATORS…331

CHECK AND ADJUST THE RELIEF VALVE (STEERING SYSTEM)…331

CHECK THE PRESSURE REDUCTION VALVE…332

TROUBLESHOOTING…333

2100102…335

INTRODUCTION…335

GENERAL…335

DESCRIPTION AND OPERATION…335

Tilt Forward…335

Tilt Backward…336

REPAIRS…338

REMOVAL…338

DISASSEMBLY…338

CLEANING…338

ASSEMBLY…338

INSTILLATION…339

TROUBLESHOOTING…339

2100103…340

INTRODUCTION…343

GENERAL…343

DESCRIPTION…343

REPAIRS…343

REMOVAL…343

DISASSEMBLY…343

CLEANING…343

ASSEMBLY…343

Tilt Cylinders for the XM and XMS Models…343

Tilt Cylinders with O-Ring or Single Lip Seals…345

Tilt Cylinders for H700-800A and Early Model H700-920B…345

INSTALLATION…345

Tilt Cylinders with Chevron Packing…345

CHECKS AND ADJUSTMENTS…349

CHECK THE TILT CYLINDERS FOR LEAKS…349

ADJUST THE TILT CYLINDER STROKE AND THE MAST TILT ANGLE…349

TROUBLESHOOTING…352

2200106…355

INTRODUCTION…355

GENERAL…355

DESCRIPTION AND OPERATION…355

REPAIRS…357

REMOVAL…357

DISSASEMBLY…357

CLEANING…358

ASSEMBLY…358

INSTALLATION…358

CHECKS AND ADJUSTMENTS…359

GENERAL…359

TROUBLESHOOTING…361

2200143…363

INTRODUCTION…363

GENERAL…363

DESCRIPTION…363

GENERAL…363

STEERING COLUMN GAUGES, METERS AND INDICATORS…366

LED DISPLAY PANEL…366

Battery Discharge Indicators …366

Brush Wear Indicators…367

Motor Temperature Indicators…368

"LX" SERIES INSTRUMENT PANEL DISPLAY…369

Hourmeter Functions…370

Battery Indicator Function…370

Status Code Function…370

CHECKS AND ADJUSTMENTS…370

GENERAL…370

REPLACEMENT…371

GENERAL…371

METER REPLACEMENT…371

SENDER REPLACEMENT…372

Fuel Level Sender…372

Pressure And Temperature Sender…373

I.T.W. DISPLAY PANEL…373

Removal…373

SPECIFICATIONS…374

TROUBLESHOOTING…375

2200144…376

ELECTRICAL WARNING DEVICES…376

GENERAL…376

DESCRIPTION…376

Operator Controlled Horns…376

System Warning Lights, Buzzers and Bells…376

Reverse Warning Horns…377

Warning Lights…377

REPLACEMENT…378

General…378

Replacing Horns or Bells…378

Replacing Horn Relay or Buzzer…378

Replacing Warning Lights…378

Light Assemblies…379

Replacing Flashing Units…379

22002…380

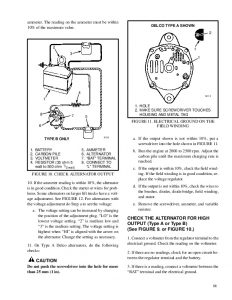

INTRODUCTION…380

GENERAL…380

DESCRIPTION…380

REPAIRS…382

GENERAL…382

REMOVAL AND DISASSEMBLY (Type A)…382

CLEANING…382

ASSEMBLY (Type A)…383

REMOVAL AND DISAASSEMBLY (Type B)…385

CLEANING…387

ASSEMBLY (Type B)…387

INSTALLATION (Type A and Type B)…388

CHECKS AND ADJUSTMENTS…388

GENERAL…388

CHECK THE ALTERNATOR FOR LOW OUTPUT (Type A or Type B)…389

CHECK THE ALTERNATOR FOR HIGH OUTPUT (Type A or Type B)…390

CHECK THE CIRCUIT FOR THE BRUSHES…392

Delco Alternators…392

Motorola Alternators…392

CHECK THE DIODES…392

CHECK THE DIODE BRIDGE…392

Delco and Leece–Neville Alternators…392

Motorola Alternators…392

CHECK THE FIELD WINDING FOR THE ROTOR…393

CHECK THE WINDINGS IN THE STATOR…393

CHECK THE VOLTAGE REGULATOR…394

TROUBLESHOOTING…394

4000135…395

SAFETY PROCEDURES WHEN WORKING NEAR THE MAST…395

SAFETY PROCEDURES WHEN WORKING NEAR THE MAST…395

LIFT CYLINDERS…398

GENERAL…398

DESCRIPTION…398

Lowering Control Valve…398

Cylinders (General)…401

Cylinders (H520-620B,H700-800A)…403

Cylinders (H360-460B)…404

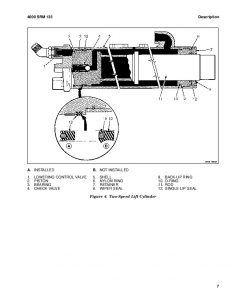

Cylinders (Two-Speed)…404

REPAIRS…405

REMOVAL OF THE LIFT CYLINDER WITHOUT REMOVING THE MAST…405

Standard Masts with the Main Lift Cylinder Fastened to the Crossmember of the Inner Mast…405

Standard and Full Free-Lift Masts with the Lift Cylinder to a Crosshead…409

Masts that have Two Cylinders, A Main Lift Cylinder and a Free-Lift Cylinder…407

DISASSEMBLY…407

ASSEMBLY…409

INSTALLATION OF THE LIFT CYLINDER IN THE MAST…409

Standard Masts with the Main Lift Cylinder Fastened to the Crossmember of the Inner Mast…409

Standard and Full-Free-Lift Masts with the Lift Cylinder Fastened to a Crosshead…409

CHEVRON PACKING…410

LIFT CYLINDERS FOR VISTA MASTS…413

DESCRIPTION…413

Lowering Control Valve…415

REMOVAL…416

DISASSEMBLY…416

ASSEMBLY…416

INSTALLATION…417

Main Lift Cylinders…417

Free-Lift Cylinders…417

CHECKS AND ADJUSTMENTS…418

CHECK FOR LEAKS IN LIFT SYSTEM…418

TROUBLESHOOTING…419

SPECIFICATIONS…420

4000268…421

INTRODUCTION…421

GENERAL…421

DESCRIPTION AND OPERATION…421

General…421

Lifting – High Speed…421

Lifting – Low Speed…422

Lowering…423

REPAIRS…423

FORKS…423

Removal…423

Low Mount Forks…423

Hight Mount Forks…423

Installation…423

Low Mount Forks…423

High Mount Forks…424

CARRIAGE…424

Removal…424

Disassembly…426

Cleaning and Inspection…427

Assembly…427

Installation…430

MAST…430

Removal…430

Disassembly…431

Cleaning and Inspection…433

Assembly…433

Installation…434

LIFT CYLINDERS…435

Removal…435

Disassembly…435

Cleaning and Inspection…435

Assembly…435

Installation…436

SIDE-SHIFT CYLINDER…436

Removal…436

Disassembly…436

Cleaning and Inspection…437

Assembly…437

Installation…437

FORK POSITIONER CYLINDERS…437

Removal…437

Disassembly…437

Cleaning and Inspection…437

Assembly…437

Installation…438

SLEW CYLINDERS…438

Removal…438

Disassembly…438

Assembly…438

Installation…438

ATTACHMENT CONNECTOR…438

HEADER HOSES…439

Replacement…439

CHECKS AND ADJUSTMENTS…440

ADJUST THE SIDE ROLLERS ON THE CARRIAGE…440

ADJUST THE SIDE ROLLERS ON THE MAST…440

ADJUST THE LIFT CHAINS…440

5000265…442

INTRODUCTION…442

GENERAL…442

DESCRIPTION…442

OPERATION…442

Extend And Retract Circuit…442

Twist Lock Circuit…443

Slew Circuit…444

REPAIRS…446

CONTAINER ATTACHMENT…446

Removal…446

Installation…446

HYDRAULIC VALVES…446

Removal…446

Disassembly…447

Cleaning And Inspection…447

Assembly…448

Installation…449

FORK ROLLERS…449

Removal and Disassembly…449

Ceaning and Inspection…450

Assembly and Installation…450

SLEW CYLINDERS…450

Removal…450

Disassembly…450

Assembly…450

Installation…451

BOOM SECTIONS…451

Disassembly…451

Cleaning and Inspection…451

Assembly…452

TWIST LOCKS…455

Disassembly…455

Assembly…455

CHECKS AND ADJUSTMENTS…460

ADJUST THE WIDTH OF THE ATTACHMENT…460

CHECK THE PRESSURE OF THE RELIEF VALVES…462

TROUBLESHOOTING…463

5000266…465

INTRODUCTION…465

GENERAL…465

DESCRIPTION…465

OPERATION…465

Slew Circuit…468

Twist Lock Circuit…465

REPAIRS…469

CONTAINER ATTACHMENT…469

Removal …469

Installation…469

HYDRAULIC VALVES…469

Disassembly…469

Cleaning and Inspection…469

Assembly…469

Installation…469

FORK ROLLERS…472

Removal and Disassembly…472

Cleaning and Inspection…472

Removal…472

Assembly and Installation…472

SLEW CYLINDERS…472

Removal…472

Disassembly…472

Assembly…472

Installation…472

TWIST LOCKS…473

Disassembly…473

Assembly…474

CHECKS AND ADJUSTMENTS…479

CHECK THE PRESSURE OF THE RELIEF VALVES…479

TROUBLESHOOTING…480

600269…482

INTRODUCTION…482

General…482

Description…482

CYLINDER HEAD AND VALVE MECHANISM…482

Cylinder Head…482

Valve Mechanism…484

LUBRICATION SYSTEM…487

Oil Pump…487

Idler Gear for the Oil Pump…488

Relief Valve for Oil Pressure…488

Relief Valve for Cold Oil…489

Oil Cooler…489

Control Valve for the Piston Cooling Jets…490

Piston Cooling Jets…490

TIMING GEARS AND CAMSHAFT…491

Timing Gear Case…491

Camshaft Gear…491

Camshaft…492

Camshaft Idler Gear…492

CRANKSHAFT…493

Removal…493

Repair…494

Installation…494

PISTON AND CONNECTING RODS…496

Removal…496

Repairs…496

Installation…497

CYLINDER LINERS…499

Removal and Installation…499

FLYWHEEL AND FLYWHEEL HOUSING…500

Removal…500

Repairs…500

Installation…500

FUEL SYSTEM…501

Fuel Pump…501

Fuel Injection Pump…502

Fuel Injectors…503

TURBOCHARGER…503

Removal…503

Disassembly…503

Cleaning and Inspection…504

Assembly…504

COOLING SYSTEM…505

Water Pump…505

AIR COMPRESSOR…506

Removal…506

Disassembly…506

Inspection…507

Assembly…507

Installation…508

CHECKS AND ADJUSTMENTS…508

Removing Air from the Fuel System…508

Timing the Fuel Injection Pump…509

Adjusting the Clearance of the Valves…510

Adjusting the Idle Speed…511

Adjusting the Stall Device…511

TROUBLESHOOTING…512

SPECIFICATIONS…513

700626…518

COOLING SYSTEM…518

INTRODUCTION…518

DESCRIPTION…518

RADIATOR…518

RADIATOR CAP…518

THERMOSTAT…518

WATER PUMP…519

FAN AND FAN SHROUD …519

REPAIRS…519

COOLING SYSTEM CHECKS…519

Exhaust Leaks…519

RADIATOR…519

Checks…519

Cleaning The Radiator…519

Drain The Cooling System…521

Fill The Cooling System…521

WATER PUMP…521

Checks…521

THERMOSTAT…522

Checks…522

FAN AND FAN SHROUD …522

TROUBLESHOOTING…523

8000231…524

INTRODUCTION…524

NOMENCLATURE, THREADS…524

STRENGTH IDENTIFICATION…525

TABLE 1. BOLTS AND SCREWS…525

TABLE 2. STUDS AND NUTS…526

TABLE 3. TORQUE NUTS…527

TABLE 4. TORQUE NUTS WITH NYLON INSERT…528

TABLE 5. TORQUE VALUES FOR INCH FASTENERS…529

TABLE 6. TORQUE VALUES FOR METRIC FASTENERS…530

8000271…533

INTRODUCTION…533

General…533

Maintenance Schedule…533

MAINTENANCE PROCEDURES…536

Every 8 Hours or Daily…536

Checks With The Engine Stopped…536

Checks With The Engine Running…539

Every 150 Hours or Monthly…541

Every 350 Hours or Monthly…544

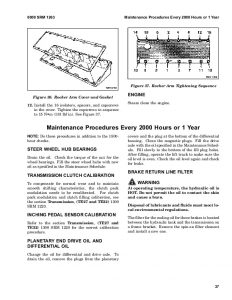

Every 2000 Hours or Yearly…545

8000276…550

FIGURE 1. HYDRAULIC SYSTEM SCHEMATIC EARLY MODEL H16.00-30.00C (H360-650C)…550

FIGURE 2. HYDRAULIC SYSTEM SCHEMATIC LATE MODEL H17.00-32.00C (H370-700C)…552

FIGURE 3. ELECTRICAL SYSTEM SCHEMATIC EARLY MODEL H16.00-30.00C (H360-650C)…554

FIGURE 4. ELECTRICAL SYSTEM SCHEMATIC LATE MODEL H17.00-32.00C (H370-700C)…556

FIGURE 5. ELECTRICAL SYSTEM SCHEMATIC U.S. LIGHT SYSTEM…558

FIGURE 6. ELETRICAL SYSTEM SCHEMATIC EUROPEAN LIGHT SYSTEM…559

FIGURE 7. ELECTRICAL SYSTEM SCHEMATIC CAB…560

FIGURE 8. ELECTRICAL SYSTEM SCHEMATIC CONTAINER ATTACHMENT…561

8000277…562

8000440…568

INTRODUCTION…568

General…568

Welding Repairs…568

How to Move a Disabled Lift Truck…568

How to Put a Lift Truck on Blocks…569

MAINTENANCE SCHEDULE…570

MAINTENANCE PROCEDURES…573

EVERY 8 HOURS OR DAILY…573

How To Make Checks with the Engine Stopped…573

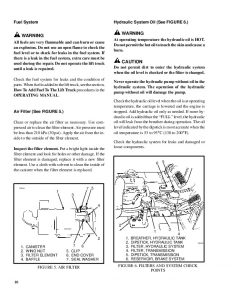

Hydraulic Sytem Oil…573

Air Filter…574

Engine Oil…574

Battery…574

Cooling System…575

Fuel System…575

Drive Belts…575

Upright, Forks and Lift Chains…575

Tires and Wheels…577

Operator Restraint System…578

How To Make Checks With The Engine Running…578

Guages, Lights, Horn, Fuses, Control Levers and Pedals…579

Transmission Oil…579

Lift System Operation…579

Attachment…579

Hydraulic Oil Filters…579

Brakes…580

Steering System…580

EVERY 150 HOURS OR MONTHLY…580

Engine Oil and Filters…580

Fuel Filters…580

Drive Shafts…580

Steering Axle…580

Brake Fluid Reservoir…580

Shafts for Brake Actuators…581

Brake Actuator Arms…581

Air Tanks…581

Upright…581

Lift Chains…581

Wheel Nuts…582

Steer Wheel Hubs…582

Drive Axle and Differential…582

Hydraulic Tank Breather…583

Container Attachments…583

EVERY 350 HOURS OR TWO MONTHS…583

Upright Pivots…583

Fork Pins and Fork Guides…583

Forks…583

Lift Chains…583

Drive Belts…584

Other Lubrication…584

Fuel Sytem…584

EVERY 500 HOURS…585

Transmission Oil Filter…585

EVERY 1000 HOURS…585

Transmission oil…585

EVERY 2000 HOURS OR YEARLY…585

Hydraulic System…585

Differential and Drive Axle…585

Drive Wheel Bearings…586

Service Brakes…586

GENERAL PROCEDURES…586

Check the Lift and Tilt System…586

Remove Air From The Perkins Diesel Fuel System…587

REPAIR OF TIRES AND WHEELS…588

Remove Wheels from the Lift Truck…588

Remove the Wheel from the Tire…589

Install the Wheel in the Tire…589

Add Air to the Tires…590

Install the Wheels…591

8000446…593

C008 (H360-700C)…599

100267…601

INTRODUCTION…601

GENERAL…601

DESCRIPTION…601

REPAIRS…601

COUNTERWEIGHT…601

Removal…601

Installation…601

FENDERS…601

Installation…602

HOOD AND BALLAST COVER…602

HYDRAULIC TANK…602

Removal, H16.00-32.00C (H360-650, H370-700C)…602

Removal, H46.00-44.00B (H700-920B)…603

Repairs, All Units…603

Steam Method of Cleaning…603

Chemical Solution Method of Cleaning…604

Other Methods Of Preparation For Repair…604

Installation, H16.00-32.00C (H360-650C, H370-700C)…604

Installation, H36.00-44.00B (H700-920B)…604

FUEL TANK…604

Removal, H16.00-32.00C (H360-650C, H370-700C)…604

Removal, H36.00-44.00B (H700-920B)…604

Repair, All Units…604

Installation, H16.00-32.00C (H360-650C, H370-700C)…604

Installation, H36.00-44.00B (H700-920B)…605

RADIATOR…605

Removal, H16.00-32.00C (H360-650C, H370-700C)…605

Removal, H36.00-44.00B (H700-920B)…605

Installation, H16.00-32.00C (H360-650C, H370-700C)…605

Installation, H36.00-44.00B (H700-920B)…605

ENGINE…605

Removal, H16.00-32.00C (H360-650C, H370-700C)…605

Installation, H16.00-32.00C (H360-650C, H370-700C)…606

Removal, H36.00-44.00B (H700-920B)…606

Installation, H36.00-44.00B (H700-920B)…607

OPERATOR'S COMPARTMENT AND CAB (See FIGURE 2.)…607

General…607

Removal…608

Repairs…610

Installation…611

LABEL REPLACEMENT…613

130017…615

INTRODUCTION…615

General…615

MECHANICAL DESCRIPTION…615

General…615

Torque Converter…615

Description…615

Operation…616

Clutch Assemblies…617

Description…617

Operation…618

First Stage Shaft…618

Second Stage Shaft…619

Third Stage Shaft…620

Inching Clutch…621

HYDRAULIC OPERATION…622

Sump, Filter and Pump…622

Control Valve, H360-620B…623

Control Valve, H360-650C…625

Inching Valve…627

Description…627

Operation…627

TRANSMISSION CONTROL CIRCUIT, H360-650C…630

HYDRAULIC CIRCUITS…630

Cooling and Lubrication…630

NEUTRAL-FIRST, H360-620B…630

NEUTRAL, H360-650C…632

FORWARD-FIRST, H360-620B…632

FORWARD-FIRST, H360-650C…634

REVERSE-FIRST, H360-620B…636

REVERSE-FIRST, H360-650C…637

SHIFT FROM FIRST TO SECOND SPEED, H360-620B…637

SHIFT FROM FIRST TO SECOND SPEED, H360-650C…637

1300171…639

INTRODUCTION…639

General…639

TRANSMISSION…639

Removal…639

Disassembly…640

Cleaning and Inspection…650

Assembly…650

Installation…664

TORQUE CONVERTOR…666

Removal and Disassembly…666

Cleaning and Inspection…668

Assembly and Installation…668

INCHING CLUTCH…671

Removal and Disassembly…671

Cleaning and Inspection…673

Assembly and Inspection…673

CONTROL VALVE…677

Removal…677

Disassembly…677

Cleaning and Inspection…678

Assembly…678

INCHING VALVE…679

Removal…679

Disassembly…679

Cleaning…679

Assembly…679

Installation…680

OIL PUMP…681

Removal…681

Disassembly…681

Cleaning and Inspection…682

Assembly…682

Installation…683

RANGE SELECTOR ASSEMBLY, H360-650C…683

Removal and Disassembly…683

Assembly and Installation…685

1300375…697

INTRODUCTION…697

General…697

MECHANICAL DESCRIPTION…698

General…698

Torque Converter…698

Description…698

Operation…699

Clutch Assemblies…699

Description…699

Operation…700

Forward Shaft…701

Reverse Shaft…701

First Speed Shaft…701

Output Shaft…701

HYDRAULIC OPERATION…702

Sump, Filter And Operation…702

Shift Control Valve…704

Solenoid Valves…704

Inching Spool…704

Direction Spools…704

Range Spools…704

Modulator Valve And Manifold Block…705

Operation…706

Transmission Control System, H17.00-32.00C(H370-700C)…708

Transmission Control System, H20.00-32.00F(H440-700F)…709

Hydraulic Circuits…711

Cooling and Lubrication…711

Operation Of The Transmission, NEUTRAL…712

Operation Of The Transmission, FORWARD-FIRST…713

Operation Of The Transmission, REVERSE-FIRST…714

Operation Of The Transmission, FORWARD-SECOND…715

Operation Of The Transmission, FORWARD-THIRD-INCHING…716

1300376…717

INTRODUCTION…717

General…717

Transmission…717

Removal…717

Transmission, Disassembly…719

Cleaning…735

Inspection…735

Transmission, Assembly…738

Installation…757

Modulator Valve And Manifold Block…761

Removal…761

Disassembly…761

Cleaning And Inspection…761

Assembly…762

Installation…762

Shift Control Valve…763

Removal…763

Disassembly…763

Cleaning And Inspection…764

Assembly…764

Installation…764

Oil Pump…765

Removal…765

Disassembly…765

Cleaning And Inspection…766

Assembly And Installation…766

Transmission Control Assembly H17.00-32.00C (H360-700C)…767

Removal And Disassembly…767

Assembly And Installation…768

Transmission Control Assembly H20.00-32.00 (H440-700F/FS)…769

Removal And Disassembly…769

Assembly And Installation…771

CHECKS AND ADJUSTMENTS…771

Check The Stall Speed Of The Torque Converter…771

Check The Oil Pressure Of The Transmission…772

TROUBLESHOOTING…773

140046…775

General…777

Description…777

Differential Repair…777

Remove…777

Disassemble…777

Assemble…777

Pinion, Bearings, and Pinion Carrier, Assemble…777

Pinion Bearings, Adjust Preload…779

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion)…779

Differential and Ring Gear, Assemble…781

Differential Pinion and Side Gear Assembly, Assemble…783

Differential Gears Rotating Torque, Check…784

Differential and Ring Gear Assembly, Install…785

Differential Bearings, Preload Adjust…786

Ring Gear, Runout Check…786

Gear Clearance, Adjust…787

Gear Set, Tooth Contact Pattern Check…787

Install into Axle Housing…787

Specifications…790

General Specifications…790

Rivet Installation Pressure…790

Pinion Preload Pressure…790

Pinion Adjustment…790

Troubleshooting…793

160071…795

INTRODUCTION…795

GENERAL …795

DESCRIPTION…795

REPAIRS…796

STEERING AXLE…796

Removal…796

Installation…796

STEERING CYLINDER…796

Removal…796

Inspection…798

Assembly…798

Installation…798

HUBS, H7.00-12.50H (H150-275H), H13.50-16.00B (H300-350B), P7.00-9.00B (P150-200B)…799

Removal…799

Installation…799

HUBS, H360-620B, H16.00-30.00C, H17.00-32.00C, H700-800A, H36.00-44.00B, H36.00-48.00C, H20.00-32.00F…800

Removal…800

Installation…800

SPINDLES…800

Removal…800

Installation…800

CHECKS AND ADJUSTMENTS…802

REMOVE THE AIR FROM THE STEERING SYSTEM…802

ADJUST THE CYLINDER STOPS…802

1800273…803

INTRODUCTION…803

GENERAL…803

DESCRIPTION…803

OPERATION…805

Service Brakes…805

Parking Brake…805

REPAIRS…806

AIR TANKS…806

Relief Valve…806

Drain Valve…806

BRAKE PEDAL VALVE…807

Removal…807

Disassembly and Repair…807

Assembly…807

Installation…807

PARKING BRAKE VALVE…807

Removal…807

Disassembly and Repair…808

Assembly…808

Installation…808

AIR CHAMBERS…808

Removal…808

Disassembly…809

Inspection…810

Assembly…810

Installation…811

ACTUATOR ARMS…811

Removal…811

Installation…811

BRAKE SHOES…811

Removal…812

Cleaning…812

Repair…813

Installation…813

BRAKE DRUMS (SERVICE BRAKES)…813

DISC BRAKE ASSEMBLY (SERVICE BRAKES)…813

Brake Pads Replacement…813

Brake Caliper, Removal…814

Brake Caliper, Disassembly…814

Brake Caliper, Repair…815

Brake Caliper, Assembly…815

Brake Caliper, Installation…815

Brake Rotor, Removal…815

Brake Rotor, Installation…815

Brake Booster, Removal…815

Brake Booster, Disassembly…815

Brake Booster, Inspection…815

Brake Booster, Assembly…816

Brake Booster, Installation…816

DISC BRAKE ASSEMBLY (PARKING BRAKE)…816

Brake Pads, Replacement…816

Brake Caliper, Removal And Disassembly…817

Brake Caliper, Cleaning…817

Air Chamber, Service…818

CHECKS AND ADJUSTMENTS…818

REMOVING AIR FROM THE BRAKE SYSTEM…818

CHECK AND ADJUST THE GOVERNOR FOR THE AIR COMPRESSOR…818

ADJUSTMENT OF THE BRAKE SHOES…819

CHECK WEAR ADJUSTMENT FOR THE PARKING BRAKE…819

TROUBLESHOOTING…820

1800425…822

INTRODUCTION…822

GENERAL…822

DESCRIPTION…822

H26.00-32.00C (H550-700C)…822

H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…822

OPERATION…822

Service Brakes, H26.00-32.00C (H550-700C)…822

Service Brakes, H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…826

Parking Brake, H26.00-32.00C (H550-700C)…826

Parking Brake, H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…827

REPAIRS…828

AIR TANKS…828

Relief Valve…828

Drain Valve…828

BRAKE PEDAL VALVES…828

Removal…828

Disassembly and Repair…829

Assembly…829

Installation…829

PARKING BRAKE VALVE…830

Removal…830

Disassembly and Repair…830

Assembly…830

Installation…831

PARKING BRAKE ACTUATOR, H26.00-32.00C (H550-700C)…831

Removal…831

Disassembly…831

Inspection…832

Assembly…832

Installation…832

PARKING BRAKE ACTUATOR, H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…832

Removal…832

Disassembly…832

Inspection…833

Assembly…833

Installation…834

PARKING BRAKE ASSEMBLY…834

Removal and Installation…834

Cleaning…834

Inspection…834

Assembly and Installation…834

SERVICE BRAKE ACTUATORS…835

Removal…835

Disassembly…835

Cleaning and Inspection…835

Assembly…835

Installation…835

BRAKE CALIPERS…836

Removal…836

Disassembly…837

Cleaning…837

Inspection…838

Assembly…838

Installation…839

INCHING VALVE ACTUATOR, H36.00-44.00B (H700-920B)…839

Removal…840

Disassembly…840

Cleaning and Inspection…840

Assembly…840

Installation…840

CHECKS AND ADJUSTMENTS…841

REMOVE THE AIR FROM THE BRAKE SYSTEM…841

INCHING ADJUSTMENT…841

CHECK AND ADJUST THE GOVERNOR FOR THE AIR COMPRESSOR…841

CHECK AND ADJUST THE PRESSURE REGULATORS FOR THE PARKING BRAKE, H36.00-44.00B (H700-920B), H36.00-48.00C (H800-1050C)…841

TROUBLESHOOTING…843

1900253…845

INTRODUCTION H16.00-30.00C (H360-650C), H17.00-32.00C (H370-700C)…845

GENERAL…845

DESCRIPTION AND OPERATION…845

Right-Hand Hydraulic Pump…845

Left-Hand Hydraulic Pump…845

Auxiliary Hydraulic Pump (Left-Hand)…845

Auxiliary Hydraulic Pump (Right-Hand)…845

Main Control Valve…847

Attachment Control Valve…847

Remote Control Valve…847

Pressure Reduction Valve…847

Solenoid Valves…847

Steering Control Unit…847

INTRODUCTION H36.00-44.00B (H700-920B)…853

GENERAL…853

DESCRIPTION AND OPERATION…853

Main Control Valve…853

Attachment Control Valve…853

Remote Control Valve…853

Pressure Reduction Valve…853

Solenoid Valves…854

Steering Control Unit…855

TROUBLESHOOTING…860

SPECIFICATIONS H16.00-30.00C (H360-650C), H17.00-32.00C (H370-700C)…863

SPECIFICATIONS H36.00-44.00B (H700-920B)…864

190097…865

INTRODUCTION…865

DESCRIPTION…865

OPERATION…865

Flow Control Valve…867

Relief Valve…867

REPAIRS…868

REMOVAL…868

DISASSEMBLY…868

CLEANING…870

INSPECTION…870

ASSEMBLY…871

INSTALLATION…872

CHECKS AND ADUSTMENTS…873

CHECK THE OUTPUT OF THE PUMP…873

CHECK FOR AIR IN THE HYDRAULIC SYSTEM…873

TROUBLESHOOTING…875

2000249…878

INTRODUCTION…878

GENERAL…878

DESCRIPTION…878

OPERATION…878

REPAIRS…881

REMOVAL…881

DISASSEMBLY…881

INSPECTION…882

ASSEMBLY…882

INSTALLATION…884

ADJUSTMENT…885

TROUBLESHOOTING…885

2000250…886

INTRODUCTION…886

GENERAL…886

DESCRIPTION…886

OPERATION…886

Lift Circuit, High Speed (Light Load or No Load)…886

Lift Circuit, Normal Speed (Heavy Load)…887

Lowering…888

Two Speed Spool…889

Tilt Circuit…889

Relief Valve…890

REPAIRS…891

REMOVAL…891

DISASSEMBLY…891

CLEANING AND INSPECTION…891

ASSEMBLY…891

INSTALLATION…892

CHECKS AND ADJUSTMENTS…892

CHECKING THE RELIEF PRESSURE…892

CHECKING THE PRESSURE OF THE TWO SPEED CARTRIDGE…892

TROUBLESHOOTING…893

2000251…895

INTRODUCTION…895

GENERAL…895

DESCRIPTION…895

OPERATION…895

REPAIRS…896

REMOVAL…896

DISASSEMBLY…896

CLEANING AND INSPECTION…896

ASSEMBLY…897

INSTALLATION…897

CHECKS AND ADJUSTMENTS…898

CHECK AND ADJUST THE RELIEF VALVE…898

TROUBLESHOOTING…899

2000252…900

INTRODUCTION…900

GENERAL…900

DESCRIPTION AND OPERATION…900

FLOW REGULATORS…900

RELIEF VALVE…901

PRESSURE REDUCTION VALVE…901

TWIST LOCK SOLENOID VALVE…903

LOCK OUT SOLENOID VALVE…903

REPAIRS…904

FLOW REGULATORS…904

Removal…904

Disassembly…904

Cleaning and Inspection…904

Assembly…904

Installation…904

RELIEF VALVE…904

PRESSURE REDUCTION VALVE…904

TWIST LOCK SOLENOID VALVE AND LOCK OUT SOLENOID VALVE…904

CHECKS AND ADJUSTMENTS…905

CHECK THE CONTROLLED FLOW OF THE FLOW REGULATORS…905

CHECK AND ADJUST THE RELIEF VALVE (STEERING SYSTEM)…905

CHECK THE PRESSURE REDUCTION VALVE…906

TROUBLESHOOTING…907

2100102…909

INTRODUCTION…909

GENERAL…909

DESCRIPTION AND OPERATION…909

Tilt Forward…909

Tilt Backward…910

REPAIRS…912

REMOVAL…912

DISASSEMBLY…912

CLEANING…912

ASSEMBLY…912

INSTILLATION…913

TROUBLESHOOTING…913

2100103…914

General…916

Description…916

Tilt Cylinder…916

Remove…916

Disassemble…916

Clean…916

Assemble…916

Tilt Cylinders with O-Ring or Single-Lip Seals…916

Tilt Cylinders for XM and XMS Models…918

Tilt Cylinders for H700-800A and Early Model H700-920B…919

Install…920

Tilt Cylinders Using Chevron Packing…921

Install…922

Tilt Cylinder Leak Check…924

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…925

Torque Specifications…925

Piston Rod Nut…925

Retainer…927

Troubleshooting…928

2200106…931

General…933

Description and Operation…933

Starter Repair…935

Remove…935

Disassemble…935

Clean…936

Assemble…936

Install…937

General Checks and Adjustments…937

Troubleshooting…940

2200143…944

INTRODUCTION…944

GENERAL…944

DESCRIPTION…944

GENERAL…944

STEERING COLUMN GAUGES, METERS AND INDICATORS…947

LED DISPLAY PANEL…947

Battery Discharge Indicators…947

Brush Wear Indicators…948

Motor Temperature Indicators…949

"LX" SERIES DISPLAY PANEL…950

Hourmeter Functions…951

Battery Indicator Function…951

Status Code Function…951

"ZX" SERIES DISPLAY PANELS…951

Display Panel…952

Basic Display Panels…952

Performance Display…954

Brush Wear Indicators…957

CHECKS AND ADJUSTMENTS…957

GENERAL…957

REPLACEMENT…958

GENERAL…958

METER REPLACEMENT…958

SENDER REPLACEMENT…959

Fuel Level Sender…959

Pressure And Temperature Sender…959

I.T.W. DISPLAY PANEL…960

Removal…960

DISPLAY PANELS FOR THE EV – 100/200ZX MOTOR CONTROLLERS, COLUMN MOUNT…961

Removal…961

Replacing Display Panel Assembly…961

Indicator LEDs…961

Battery Indicators…961

Digital Display (Performance Disply Panel Only)…961

Status Code Or Performance Level Switches And Indicator LEDs (Performance Display Panel Only)…961

Replacing Parts Of The Basic Display Panel…962

Replacing Parts Of The Performance Display Panel…964

DISPLAY PANELS FOR THE EV-100/200ZX MOTOR CONTROLLERS, DASH MOUNT…964

Removal And Replacement…964

SPECIFICATIONS…965

TROUBLESHOOTING…966

2200144…967

ELECTRICAL WARNING DEVICES…967

GENERAL…967

DESCRIPTION…967

Operator Controlled Horns…967

System Warning Lights, Buzzers and Bells…967

Reverse Warning Horns…968

Warning Lights…968

REPLACEMENT…969

General…969

Replacing Horns or Bells…969

Replacing Horn Relay or Buzzer…969

Replacing Warning Lights…969

Light Assemblies…970

Replacing Flashing Units…970

22002…971

General…973

Description…973

Alternator Repair…975

Alternator Type A…975

Remove and Disassemble…975

Clean…976

Assemble…976

Install…977

Alternator Type B…980

Remove and Disassemble…980

Clean…980

Assemble…981

Install…982

General Check and Adjustment…983

Low Output Check (Type A or Type B)…983

High Output Check (Type A or Type B)…985

Brushes Circuit Check…986

Delco Alternators…986

Motorola Alternators…987

Diodes Check…988

Diodes Bridge Check…988

Delco and Leece-Neville Alternators…988

Motorola Alternators…988

Rotor Field Winding Check…989

Stator Windings Check…990

Voltage Regulator Check…990

Troubleshooting…991

4000135…993

Safety Procedures When Working Near Mast…995

General…1000

Description…1000

Lowering Control Valve…1000

Cylinders (General)…1003

Cylinders (H520-620B, H700-800A)…1003

Retainer, Install…1003

Cylinders (H360-460B)…1005

Cylinders (Two-Speed)…1008

Lift Cylinder Repair…1009

Lift Cylinder Removal Without Removing Mast…1009

Standard Masts With Main Lift Cylinders Fastened to Crossmember of Inner Mast…1009

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to Crosshead…1010

Masts That Have Two Cylinders, Main Lift Cylinder and Free-Lift Cylinder…1011

Disasemble…1011

Assemble…1011

Lift Cylinder Installation in Mast…1013

Standard Masts With Main Lift Cylinder Fastened to Crossmember of Inner Mast…1013

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to Crosshead…1013

Chevron-Style Packing…1013

Chevron-Style Packing Installation on Piston…1014

Chevron-Style Packing Installation in Packing Gland…1016

Lift Cylinders for Vista Masts…1017

Description…1017

Lowering Control Valve…1017

Remove…1019

Disassemble…1020

Assemble…1021

Install…1022

Main Lift Cylinders…1022

Free-Lift Cylinder…1022

Lift System Leak Check…1022

Specifications…1023

Troubleshooting…1024

4000268…1027

INTRODUCTION…1027

GENERAL…1027

DESCRIPTION AND OPERATION…1027

General…1027

Lifting – High Speed…1027

Lifting – Low Speed…1028

Lowering…1029

REPAIRS…1029

FORKS…1029

Removal…1029

Low Mount Forks…1029

Hight Mount Forks…1029

Installation…1029

Low Mount Forks…1029

High Mount Forks…1030

CARRIAGE…1030

Removal…1030

Disassembly…1032

Cleaning and Inspection…1033

Assembly…1033

Installation…1036

MAST…1036

Removal…1036

Disassembly…1037

Cleaning and Inspection…1039

Assembly…1039

Installation…1040

LIFT CYLINDERS…1041

Removal…1041

Disassembly…1041

Cleaning and Inspection…1041

Assembly…1041

Installation…1042

SIDE-SHIFT CYLINDER…1042

Removal…1042

Disassembly…1042

Cleaning and Inspection…1043

Assembly…1043

Installation…1043

FORK POSITIONER CYLINDERS…1043

Removal…1043

Disassembly…1043

Cleaning and Inspection…1043

Assembly…1043

Installation…1044

SLEW CYLINDERS…1044

Removal…1044

Disassembly…1044

Assembly…1044

Installation…1044

ATTACHMENT CONNECTOR…1044

HEADER HOSES…1045

Replacement…1045

CHECKS AND ADJUSTMENTS…1046

ADJUST THE SIDE ROLLERS ON THE CARRIAGE…1046

ADJUST THE SIDE ROLLERS ON THE MAST…1046

ADJUST THE LIFT CHAINS…1046

5000265…1048

INTRODUCTION…1048

GENERAL…1048

DESCRIPTION…1048

OPERATION…1048

Extend And Retract Circuit…1048

Twist Lock Circuit…1049

Slew Circuit…1050

REPAIRS…1052

CONTAINER ATTACHMENT…1052

Removal…1052

Installation…1052

HYDRAULIC VALVES…1052

Removal…1052

Disassembly…1053

Cleaning And Inspection…1053

Assembly…1054

Installation…1055

FORK ROLLERS…1055

Removal and Disassembly…1055

Ceaning and Inspection…1056

Assembly and Installation…1056

SLEW CYLINDERS…1056

Removal…1056

Disassembly…1056

Assembly…1056

Installation…1057

BOOM SECTIONS…1057

Disassembly…1057

Cleaning and Inspection…1057

Assembly…1058

TWIST LOCKS…1061

Disassembly…1061

Assembly…1061

CHECKS AND ADJUSTMENTS…1066

ADJUST THE WIDTH OF THE ATTACHMENT…1066

CHECK THE PRESSURE OF THE RELIEF VALVES…1068

TROUBLESHOOTING…1069

5000266…1071

INTRODUCTION…1071

GENERAL…1071

DESCRIPTION…1071

OPERATION…1071

Slew Circuit…1074

Twist Lock Circuit…1071

REPAIRS…1075

CONTAINER ATTACHMENT…1075

Removal …1075

Installation…1075

HYDRAULIC VALVES…1075

Disassembly…1075

Cleaning and Inspection…1075

Assembly…1075

Installation…1075

FORK ROLLERS…1078

Removal and Disassembly…1078

Cleaning and Inspection…1078

Removal…1078

Assembly and Installation…1078

SLEW CYLINDERS…1078

Removal…1078

Disassembly…1078

Assembly…1078

Installation…1078

TWIST LOCKS…1079

Disassembly…1079

Assembly…1080

CHECKS AND ADJUSTMENTS…1085

CHECK THE PRESSURE OF THE RELIEF VALVES…1085

TROUBLESHOOTING…1086

600269…1088

INTRODUCTION…1088

General…1088

Description…1088

CYLINDER HEAD AND VALVE MECHANISM…1088

Cylinder Head…1088

Valve Mechanism…1090

LUBRICATION SYSTEM…1093

Oil Pump…1093

Idler Gear for the Oil Pump…1094

Relief Valve for Oil Pressure…1094

Relief Valve for Cold Oil…1095

Oil Cooler…1095

Control Valve for the Piston Cooling Jets…1096

Piston Cooling Jets…1096

TIMING GEARS AND CAMSHAFT…1097

Timing Gear Case…1097

Camshaft Gear…1097

Camshaft…1098

Camshaft Idler Gear…1098

CRANKSHAFT…1099

Removal…1099

Repair…1100

Installation…1100

PISTON AND CONNECTING RODS…1102

Removal…1102

Repairs…1102

Installation…1103

CYLINDER LINERS…1105

Removal and Installation…1105

FLYWHEEL AND FLYWHEEL HOUSING…1106

Removal…1106

Repairs…1106

Installation…1106

FUEL SYSTEM…1107

Fuel Pump…1107

Fuel Injection Pump…1108

Fuel Injectors…1109

TURBOCHARGER…1109

Removal…1109

Disassembly…1109

Cleaning and Inspection…1110

Assembly…1110

COOLING SYSTEM…1111

Water Pump…1111

AIR COMPRESSOR…1112

Removal…1112

Disassembly…1112

Inspection…1113

Assembly…1113

Installation…1114

CHECKS AND ADJUSTMENTS…1114

Removing Air from the Fuel System…1114

Timing the Fuel Injection Pump…1115

Adjusting the Clearance of the Valves…1116

Adjusting the Idle Speed…1117

Adjusting the Stall Device…1117

TROUBLESHOOTING…1118

SPECIFICATIONS…1119

700626…1124

General…1126

Description…1127

Radiator…1127

Radiator Cap…1127

Thermostat…1127

Water Pump…1128

Fan and Fan Shroud…1128

Cooling System Checks…1128

Radiator…1128

Thermostat…1128

Water Pump…1129

Exhaust Leaks…1129

Fan and Fan Shroud…1129

Radiator Cleaning…1129

Drain…1129

Clean…1129

Fill…1130

Troubleshooting…1131

8000231…1133

General…1135

Nomenclature, Threads…1135

Strength Identification…1136

Fastener Torque Tables…1140

Conversion Table…1142

8000271…1144

INTRODUCTION…1144

General…1144

Maintenance Schedule…1144

MAINTENANCE PROCEDURES…1147

Every 8 Hours or Daily…1147

Checks With The Engine Stopped…1147

Checks With The Engine Running…1150

Every 150 Hours or Monthly…1152

Every 350 Hours or Monthly…1155

Every 2000 Hours or Yearly…1156

8000276…1161

FIGURE 1. HYDRAULIC SYSTEM SCHEMATIC EARLY MODEL H16.00-30.00C (H360-650C)…1161

FIGURE 2. HYDRAULIC SYSTEM SCHEMATIC LATE MODEL H17.00-32.00C (H370-700C)…1163

FIGURE 3. ELECTRICAL SYSTEM SCHEMATIC EARLY MODEL H16.00-30.00C (H360-650C)…1165

FIGURE 4. ELECTRICAL SYSTEM SCHEMATIC LATE MODEL H17.00-32.00C (H370-700C)…1167

FIGURE 5. ELECTRICAL SYSTEM SCHEMATIC U.S. LIGHT SYSTEM…1169

FIGURE 6. ELETRICAL SYSTEM SCHEMATIC EUROPEAN LIGHT SYSTEM…1170

FIGURE 7. ELECTRICAL SYSTEM SCHEMATIC CAB…1171

FIGURE 8. ELECTRICAL SYSTEM SCHEMATIC CONTAINER ATTACHMENT…1172

8000277…1173

8000440…1179

INTRODUCTION…1179

General…1179

Welding Repairs…1179

How to Move a Disabled Lift Truck…1179

How to Put a Lift Truck on Blocks…1180

MAINTENANCE SCHEDULE…1181

MAINTENANCE PROCEDURES…1184

EVERY 8 HOURS OR DAILY…1184

How To Make Checks with the Engine Stopped…1184

Hydraulic Sytem Oil…1184

Air Filter…1185

Engine Oil…1185

Battery…1185

Cooling System…1186

Fuel System…1186

Drive Belts…1186

Upright, Forks and Lift Chains…1186

Tires and Wheels…1188

Operator Restraint System…1189

How To Make Checks With The Engine Running…1189

Guages, Lights, Horn, Fuses, Control Levers and Pedals…1190

Transmission Oil…1190

Lift System Operation…1190

Attachment…1190

Hydraulic Oil Filters…1190

Brakes…1191

Steering System…1191

EVERY 150 HOURS OR MONTHLY…1191

Engine Oil and Filters…1191

Fuel Filters…1191

Drive Shafts…1191

Steering Axle…1191

Brake Fluid Reservoir…1191

Shafts for Brake Actuators…1192

Brake Actuator Arms…1192

Air Tanks…1192

Upright…1192

Lift Chains…1192

Wheel Nuts…1193

Steer Wheel Hubs…1193

Drive Axle and Differential…1193

Hydraulic Tank Breather…1194

Container Attachments…1194

EVERY 350 HOURS OR TWO MONTHS…1194

Upright Pivots…1194

Fork Pins and Fork Guides…1194

Forks…1194

Lift Chains…1194

Drive Belts…1195

Other Lubrication…1195

Fuel Sytem…1195

EVERY 500 HOURS…1196

Transmission Oil Filter…1196

EVERY 1000 HOURS…1196

Transmission oil…1196

EVERY 2000 HOURS OR YEARLY…1196

Hydraulic System…1196

Differential and Drive Axle…1196

Drive Wheel Bearings…1197

Service Brakes…1197

GENERAL PROCEDURES…1197

Check the Lift and Tilt System…1197

Remove Air From The Perkins Diesel Fuel System…1198

REPAIR OF TIRES AND WHEELS…1199

Remove Wheels from the Lift Truck…1199

Remove the Wheel from the Tire…1200

Install the Wheel in the Tire…1200

Add Air to the Tires…1201

Install the Wheels…1202

8000446…1204

myManual[2]…1210

INTRODUCTION…1210

General…1210

Description…1212

Operation…1212

REPAIRS…1213

Removal…1213

Disassembly…1213

Inspection…1218

Assembly…1218

Installation…1218

CHECKS AND ADJUSTMENTS…1224

TROUBLESHOOTING…1225

Hyster H360-650C (C008) & H370-700C (C008) Service Repair Manual