Complete service repair manual for Hyster H360H, H400H, H450H (A214) & H400H-EC5, H450H-EC6 (A214) Lift Trucks, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster H360H, H400H, H450H (A214) & H400H-EC5, H450H-EC6 (A214) Lift Trucks workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

Total Pages: 620 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section |

Part No.

|

SRM Number | Rev Date |

| FRAME |

897984

|

0100 SRM 0656 | 07/02 |

| COOLING SYSTEM |

897934

|

0700 SRM 0626 | 11/01 |

| ZF THREE-SPEED PS TRANSMISSION |

897999

|

1300 SRM 0669 | 05/97 |

| DIFFERENTIAL |

910072

|

1400 SRM 0046 | 11/03 |

| PLANETARY DRIVE AXLE |

897985

|

1400 SRM 0657 | 05/97 |

| STEERING AXLE |

897986

|

1600 SRM 0658 | 03/97 |

| STEERING SYSTEM |

897993

|

1600 SRM 0671 | 09/03 |

| BRAKE SYSTEM |

897987

|

1800 SRM 0659 | 09/03 |

| ACCUMULATOR |

1529749

|

1800 SRM 1036 | 09/02 |

| PARKING BRAKE |

1531821

|

1800 SRM 1037 | 02/03 |

| HYDRAULIC SYSTEM |

897994

|

1900 SRM 0666 | 09/02 |

| TILT CYLINDERS |

910102

|

2100 SRM 0103 | 10/03 |

| INSTRUMENT PANEL INDICATORS and SENDERS |

910110

|

2200 SRM 0143 | 12/03 |

| MAST – FORK LIFT |

897988

|

4000 SRM 0660 | 04/97 |

| MAST – EMPTY CONTAINER HANDLER |

897989

|

4000 SRM 0661 | 02/04 |

| EMPTY CONTAINER HNDLG ATTACH ( 572,573,575,578 ) |

1509204

|

5000 SRM 0990 | 09/01 |

| INCH (SAE) and METRIC FASTENERS |

910442

|

8000 SRM 0231 | 03/03 |

| PERIODIC MAINTENANCE |

897990

|

8000 SRM 0662 | 05/97 |

| DIAGRAMS |

897991

|

8000 SRM 0663 | 08/02 |

| CAPACITIES and SPECIFICATIONS |

897992

|

8000 SRM 0664 | 08/02 |

| PERIODIC MAINTENANCE with TIER 2 EMISSION ENGINE |

1529752

|

8000 SRM 1043 | 12/03 |

| For service and repair information on Cummins diesel engines | |||

| see a dealer for Cummins diesel engines. | |||

| PART NO. 1452600 | |||

| Rev 02/04 | |||

A214 (H14.00-18.00XM-12, -12EC Europe)…2

897987-1800SRM0659-(09-2003)-UK-EN…4

toc…4

Brake System…4

Safety Precautions Maintenance and Repair…5

General…8

Description and Operation…8

Parking Brake…10

Brake Pedal Valves…11

Pilot Supply Valve Repair…11

Repairs…11

Checks and Adjustments…11

Accumulator Replacement…11

Oil Cooler…13

Remove…13

Clean…13

Install…13

Brake Pedal Components…13

Manifold…13

Shuttle Valve…14

Remove and Disassemble…14

Clean and Inspect…14

Assemble and Install…14

Brake Pedal Valves…15

Remove and Disassemble…15

Clean and Inspect…15

Assemble…15

Install…15

Parking Brake Valve Repair…17

Remove…17

Install…17

Parking Brake Caliper Repair…17

Brake System Air Removal…17

Service Brakes Air Removal…17

Troubleshooting…21

tables…4

Table 1. Hydraulic System Check Ports…20

996-0…32

996-1…146

996-10…206

996-11…216

996-12…220

996-13…224

996-14…227

996-16…265

996-2…271

996-3…293

996-4…301

996-5…306

996-6…362

996-7…381

996-8…397

996-9…411

996-c…417

996-e…421

996-front…431

996-i…435

996-l…449

996-x…454

ACCUMULATOR…458

toc…458

Brake Accumulator…458

Safety Precautions Maintenance and Repair…459

General…462

Description and Operation…462

Accumulator Maintenance…462

Precharge Check…462

Precharge Filling…463

Remove…464

Disassemble…464

Clean…466

Inspect…466

Repair…466

Assemble…466

Replace…466

tables…458

Table 1. Accumulator Pressures…463

BRAKE SYSTEM…470

toc…470

Brake System…470

Safety Precautions Maintenance and Repair…471

General…474

Description and Operation…474

Parking Brake…476

Brake Pedal Valves…477

Pilot Supply Valve Repair…477

Repairs…477

Checks and Adjustments…477

Accumulator Replacement…477

Oil Cooler…479

Remove…479

Clean…479

Install…479

Brake Pedal Components…479

Manifold…479

Shuttle Valve…480

Remove and Disassemble…480

Clean and Inspect…480

Assemble and Install…480

Brake Pedal Valves…481

Remove and Disassemble…481

Clean and Inspect…481

Assemble…481

Install…481

Parking Brake Valve Repair…483

Remove…483

Install…483

Parking Brake Caliper Repair…483

Brake System Air Removal…483

Service Brakes Air Removal…483

Troubleshooting…487

tables…470

Table 1. Hydraulic System Check Ports…486

CAPACITIES AND SPECIFICATIONS…498

toc…498

Capacities and Specifications…498

Safety Precautions Maintenance and Repair…499

Lift Truck Weights…502

Container Attachment Weights…503

Engine Specifications…503

Capacities…504

Hydraulic System…504

Steering…505

Electrical System…505

Mast Speeds…506

Tire Sizes…506

Transmission Pressures…507

Torque Specifications…508

Container Attachment…508

Drive Line and Axle…508

Engine…508

Frame…508

Mast…508

Steering…508

Transmission…508

tables…498

Table 1. Basic Truck as Counterweighted for Standard Pin Fork Op…502

Table 2. Basic Truck as Counterweighted for Quick Disconnect Hoo…502

CONTAINER HANDLING ATTACHMENT…512

EMPTY CONTAINER ATTACHMENT…512

GENERAL…512

DESCRIPTION…512

OPERATION…512

Selector Valves…512

Side-Shift Circuit…513

Extend/Retract Circuit…513

Lock Pin Circuit…513

REPAIRS…516

CARRIAGE…516

Removal…516

Disassembly…516

Assembly…516

Installation…517

CONTAINER ATTACHMENT…517

Removal…517

Disassembly…517

Cleaning and Inspection…518

Assembly…518

Installation…518

SIDE-SHIFT CYLINDER…518

Removal…518

Disassembly…519

Cleaning and Inspection…519

Assembly…519

Installation…519

EXTENSION CYLINDERS…520

Removal…520

Disassembly…520

Cleaning and Inspection…520

Assembly…521

Installation…521

END BEAMS…522

Removal…522

Disassembly…522

Cleaning and Inspection…522

Assembly…522

LOCK PIN CYLINDER…523

Removal…523

Disassembly…523

Cleaning and Inspection…523

Assembly…523

OPERATOR CONTROLS…524

Repairs…524

CHECKS AND ADJUSTMENTS…531

CHECK AND ADJUST THE END BEAM SWITHCES…531

CHECK THE LOCK PINS…531

LIFT CHAIN ADJUSTMENTS…531

CARRIAGE ADJUSTMENTS…531

CHECK AND ADJUST THE WIDTH OF THE ATTACHMENT…532

TROUBLESHOOTING…533

COOLING SYSTEM…535

toc…535

Cooling System…535

Safety Precautions Maintenance and Repair…536

General…539

Description…540

Radiator…540

Radiator Cap…540

Thermostat…540

Water Pump…541

Fan and Fan Shroud…541

Cooling System Checks…541

Radiator…541

Thermostat…541

Water Pump…542

Exhaust Leaks…542

Fan and Fan Shroud…542

Radiator Cleaning…542

Drain…542

Clean…542

Fill…543

Troubleshooting…544

DIAGRAMS…547

toc…547

Diagrams…547

Safety Precautions Maintenance and Repair…548

DIFFERENTIAL…597

toc…597

Differential…597

Safety Precautions Maintenance and Repair…598

General…601

Description…601

Differential Repair…602

Remove…602

Differential Carrier From Axle Housing, Remove…602

Differential and Ring Gear From Differential Carrier, Remove…604

Drive Pinion and Pinion Carrier From Differential Carrier, Remov…606

Disassemble…607

Differential and Ring Gear Assembly, Disassemble…607

Drive Pinion and Pinion Carrier, Disassemble…609

Clean and Inspect…612

Assemble…613

Pinion, Bearings, and Pinion Carrier, Assemble…613

Pinion Bearings, Adjust Preload…613

Press Method…613

Yoke or Flange Method…614

Triple-Lip Seal, Install…615

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion)…616

Differential and Ring Gear, Assemble…618

Differential Gears Rotating Torque, Check…620

Differential and Ring Gear Assembly, Install…621

Differential Bearings, Preload Adjust…623

Ring Gear, Runout Check…624

Ring Gear Backlash, Adjust…624

Gear Set, Tooth Contact Pattern Check…626

Thrust Screw, Install and Adjust…629

Install…629

Differential Assembly Into Axle Housing, Install…629

Specifications…631

Troubleshooting…636

tables…597

Table 1. Ring Gear Backlash Adjustment Specifications…626

Table 2. Ring and Pinion Tooth Contact Adjustment…627

Table 3. General Specifications…631

Table 4. Rivet Installation Pressure…631

Table 5. Pinion Adjustment…632

Table 6. Pinion Preload Pressure…632

Table 7. Torque Specifications…633

Table 8. Torque Specifications for Metric Hardware…634

Table 9. Torque Specifications for Metric (Fine) Hardware…635

EMPTY CONTAINER HANDLING ATTACHMENT…639

toc…639

Empty Container Handling Attachment…639

Safety Precautions Maintenance and Repair…640

General…643

Description…643

Operation…653

General…653

Selector Valves…653

Sideshift Circuit…653

Extend and Retract Circuit…653

Twist Lock Circuit and Control…653

Model 572 – Double Horizontally Mounted…653

Model 573 – Horizontally Mounted…654

Model 578 – Vertically Mounted…654

Lifting Hooks…654

Model 575…654

Indicator Lights and LEDs…654

Lift Interrupt and Override…655

Overlowering Interrupt and Override…655

Second Container Detection Sensor (Model 572 Only)…656

Carriage and Attachment Repair…656

Remove…656

Attachment Without Carriage Repair…657

Remove…657

Sideshift Cylinders Repair…657

Remove…657

Disassemble…657

Assemble…658

Extension Cylinders Repair…658

Remove…658

Disassemble…658

Clean and Inspect…659

Assemble…659

Install…659

Floating End Beams Repair…660

Remove…660

Install…660

Hose Replacement In End Beams…660

Twist Locks Repair for Model 572 and 573…660

Remove…660

Model 573…660

Model 572…660

Disassemble…661

Clean and Inspect…661

Assemble…661

Hook Replacement for Model 575…662

Inspect…662

Remove…662

Install…662

Twist Locks Repair for Model 578…663

Disassemble…663

Clean and Inspect…663

Assemble…663

Extension Beams Repair…664

LH and RH Extension Beam, Remove…664

Slave Beam, Remove…664

Clean and Inspect…665

Assemble…665

Bleed the System…666

Valve Assembly…666

Slide Pad Replacement…667

Adjustments…667

Twist Lock Angle Adjustment…667

Model 578 Only…667

LOCKED/NOT LOCKED Sensors Adjustment…668

Model 573…668

Model 578…668

Seated Sensor Adjustment…668

Model 572 and 573…668

Model 578…669

Overlowering Protection Sensor Adjustment (Models 572, 573, and …669

Torque Chart…670

Maintenance…670

Additional Attachment Maintenance…673

Interface Boxes With LED Indicators…674

Models 572, 573, 575, and 578: Interface Box With LED Indicators…674

Models 573 and 578: Two Additional Interface Boxes With LED Indi…674

Model 572…675

Troubleshooting…675

tables…639

Table 1. Torque Chart…670

Table 2. Maintenance Schedule…671

EXTENDABLE CONTAINER ATTACHMENT (ELME) 580 SERIES…705

toc…705

Extendable Container Attachment (Elme)…705

Safety Precautions Maintenance and Repair…706

General…711

Description…711

Operation…715

General…715

Optional Powered Pile Slope…715

Sideshift…716

Extend and Retract Circuit…717

Container locking Model 582…719

Sequence Valve…719

Pilot Check Valve…720

Container Locking Model 583…721

Container Locking Model 584…721

Container Locking Model 585…722

Container Locking Models 586, 588, and 589…722

Electrical System…724

Indicator Lights…724

Flashing Indicator Lights…725

Automatic Locking…725

Lift Interrupt and Override…725

Overlowering Interrupt and Override…725

Second Container Detection Sensor (Model 582 Only)…726

Carriage and Attachment Removal…726

Carriage…726

Spreader…727

Sideshift Cylinder Removal and Installation…727

Remove…727

Install…727

Extension Cylinder Removal and Installation…728

Remove…728

Upper, Right-Hand…728

Lower, Left-Hand…728

Install…728

Floating End Beams Repair…729

Remove…729

Install…729

Hose, Replace…730

Twist Lock Repair for Model 582…731

Remove…731

Upper Twist Lock…731

Lower Twist Lock…731

Disassemble…732

Clean and Inspect…732

Assemble…733

Install…733

Hook Repair for Model 584 and 585…733

Remove…733

Inspect…733

Install…733

Side Clamp Replacement for Model 584…734

Remove…734

Install…735

Twist Lock Repair for Models 586, 588, and 589…735

Disassemble…735

Clean and Inspect…735

Assemble…736

Extension Beam Repair…737

Remove…737

Inspect…737

Assemble…738

Cylinder Repair…739

Extension Cylinder…739

Disassemble…739

Clean and Inspect…739

Assemble…739

Guide for Extension Cylinder…740

Remove…740

Install…740

Sideshift Cylinder, Powered Pile Slope Cylinder, Retract Cylinde…740

Disassemble…740

Assemble…740

Wear Pad Replacement…741

General…741

Floating End Beam Wear Pads…741

Upper Wear Pads…741

Lower Wear Pads…741

Main Frame Wear Pads at Large (Right-Hand) Extension Beam…741

Main Frame Wear Pads at Small (Left-Hand) Extension Beam…741

Guide for Extension Cylinder…742

Large Extension Beam Internal Wear Pads…743

Spreader Frame…743

Upper Wear Pads…743

Lower Wear Pads…743

Powered Pile Slope Carriage…743

Upper Wear Pads…743

Lower Wear Pads…743

Adjustments…743

Twist Lock Angle Adjustment…743

Model 586, 588 and 589…743

LOCKED/NOT LOCKED Sensors Adjustment…744

Model 582…744

Model 586, 588 and 589…744

Side Clamp Open/Closed Sensor Adjustment (Model 584)…744

Hook in Sensor Adjustment (Model 584)…744

Seated Sensor Adjustment…745

Model 582…745

Model 586, 588 and 589…745

Overlowering Protection Sensor Adjustment (All 580 Models)…745

Schematics…746

tables…705

Table 1. Elme Schematic Overview…746

FRAME…833

toc…833

Frame…833

Safety Precautions Maintenance and Repair…834

General…837

Description…837

Counterweights…837

Remove…837

Center Counterweight…837

Counterweight…837

Fender Counterweight…837

Install…839

Hood and Air Filter Repair…839

Remove…839

Install…839

Hydraulic Tank Repair…842

Remove…842

Repairs, All Units…842

Small Leaks…842

Large Leaks…842

Clean…843

Steam Method…843

Chemical Solution Method…843

Other Methods of Preparation for Repair…844

Install…844

Fuel Tank Repair…844

Remove…844

Repair…844

Install…845

Radiator Repair…845

Remove…845

Install…845

Engine and Transmission Repair…848

Remove…848

Install…849

Operator Compartment Repair…850

General…850

Remove…852

Install…854

Window Wipers…854

Window Washer Motors and Pumps…854

Heater Control Panel Assembly…855

Blower and Core Assemblies…856

Remove…856

Install…856

Window Replacement…858

Front and Rear Windows…859

Lower Door Windows…860

Upper Door (Sliding) Windows…860

Top Window…860

Operator Restraint System…860

Oil Cooler…861

Remove…861

Clean…861

Install…861

Label Replacement…862

Painting Instructions…865

tables…833

Table 1. Counterweights…839

Table 2. Cab Windows Material Specifications…858

HYDRAULIC SYSTEM…869

toc…869

Hydraulic System…869

Safety Precautions Maintenance and Repair…870

General…873

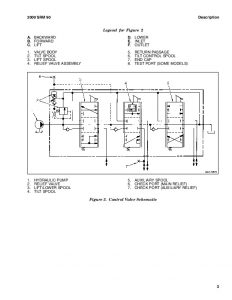

Description and Operation…873

Main Control Valve…874

Remote Control Valve…874

Pilot Supply Valve…875

Auxiliary Control Valve…875

Selector Valves…875

Steering System…875

Main Control Valve Repair…875

Description…875

Lifting…877

Lowering…877

Tilt Spool…877

Priority Valve…877

Relief Valves…877

Repairs…877

Remove…877

Disassemble…878

Clean and Inspect…878

Assemble…878

Install…878

Checks and Adjustments…880

Relief Pressures Check…880

Remote Control Valve Repair…880

Description…880

Operation…880

Repairs…882

Remove…882

Disassemble…882

Clean and Inspect…884

Assemble…884

Install…885

Adjust…885

Pilot Supply Valve Repair…885

Description and Operation…885

Repairs…886

Checks and Adjustments…886

Relief Valve, Check and Adjust…886

Pressure Reduction Valves, Check…886

Auxiliary Control Valve Repair…888

Description and Operation…888

Repairs…888

Remove…888

Disassemble…888

Clean and Inspect…889

Assemble…889

Install…890

Check and Adjust…890

Hydraulic Pump Repair…890

General…890

Repairs…890

Specifications…892

Troubleshooting…900

Main Control Valve…900

Remote Control valve…901

Pilot Supply Valve…902

Accumulator Charge Valve and Accumulator…902

Pressure Reduction Valves…902

Auxiliary Control Valve…903

tables…869

Table 1. Hydraulic System Check Ports…892

INSTRUMENT PANEL INDICATORS AND SENDERS…907

toc…907

Instrument Panel Indicators and Senders…907

Safety Precautions Maintenance and Repair…908

General…911

Description…912

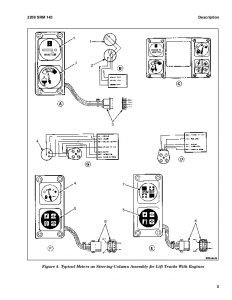

Steering Column Gauges, Meters, and Indicators…912

LED Display Panel…912

Battery Discharge Indicators…912

Brush Wear Indicators…918

Motor Temperature Indicators…918

LX Series Display Panel…920

Hourmeter Functions…921

Battery Indicator Function…921

Status Code Function…921

ZX Series Display Panels…923

Display Panel…923

Basic Display Panels…923

Performance Display…925

Brush Wear Indicators…929

Adjustments – General…929

Replacement – General Information…929

Meter Replacement…930

Sender Replacement…931

Fuel Level Sender…931

Pressure and Temperature Sender…931

Seat Sensor, Operator Presence System (OPS)…932

Remove…932

Install…932

Operator Presence System Module Replacement…932

Remove…933

Install…934

ITW Display Panel Replacement…935

Remove…935

Column Mount Display Panel (EV-100/200ZX Motor Controllers) Repl…935

Remove…935

Display Panel Assembly, Replace…935

Indicator LEDs…936

Battery Indicators…936

Digital Display (Performance Display Panel Only)…936

Status Code or Performance Level Switches and Indicator LEDs (Pe…937

Basic Display Panel, Replace Parts…937

Performance Display Panel, Replace Parts…939

Dash Mount Display Panel (EV100/200ZX Motor Controllers) Replace…939

Remove and Replace…939

Specifications…940

Meter Specifications…940

Sender Specifications…940

Troubleshooting…941

Meter…941

Troubleshooting for Operator Presence System…942

tables…907

Table 1. Troubleshooting Procedure for Operator Presence Module…942

LIFT CYLINDERS (OLD MAST)…947

toc…947

Lift Cylinders…947

Safety Precautions Maintenance and Repair…948

Safety Procedures When Working Near Mast…951

General…955

Description…955

Lowering Control Valve…955

Cylinders (General)…958

Cylinders (H520-620B, H700-800A)…958

Retainer, Install…958

Cylinders (H360-460B)…960

Cylinders (Two-Speed)…962

Lift Cylinder Repair…964

Lift Cylinder Removal Without Removing Mast…964

Standard Masts With Main Lift Cylinder Fastened to Crossmember o…964

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to…964

Masts That Have Two Cylinders, Main Lift Cylinder and Free-Lift …964

Disassemble…966

Assemble…966

Lift Cylinder Installation in Mast…968

Standard Masts With Main Lift Cylinder Fastened to Crossmember o…968

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to…968

Chevron-Style Packing…968

Chevron-Style Packing Installation on Piston…969

Chevron-Style Packing Installation in Packing Gland…971

Lift Cylinders for VISTA® Masts…972

Description…972

Lowering Control Valve…972

Remove…974

Disassemble…975

Assemble…976

Install…977

Main Lift Cylinders…977

Free-Lift Cylinder…977

Lift System Leak Check…978

Specifications…979

Troubleshooting…980

tables…947

Table 1. Lift Trucks with Two-Speed Lift Cylinders…963

Table 2. Cylinder Retainer Torque Specifications and Weight Guid…979

MAST-EMPTY CONTAINER HANDLER…983

toc…983

Mast…983

Safety Precautions Maintenance and Repair…984

Safety Procedures When Working Near Mast…987

General…988

Description…988

Operation…989

Control Valve, Carriage/Attachment…990

Tilt Cylinders Repair (A214 Only)…990

Remove…990

Disassemble…990

Clean and Inspect…990

Assemble…991

Install…991

Mast Repair…992

Remove…992

Disassemble…993

Clean and Inspect…994

Assemble…994

Install…997

Lift Cylinders Repair…999

Description…999

Remove…1000

Disassemble…1000

Clean and Inspect…1000

Assemble…1000

Install…1000

Mast Operation Check…1002

Lift and Tilt System Leaks Check…1002

Lift System…1002

Tilt System…1002

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment…1003

Lift Chain Adjustments…1004

Mast Adjustments…1005

Bearing Blocks…1005

Wear Plates…1005

Carriage Adjustment…1007

Troubleshooting…1007

tables…983

Table 1. Mast Weights…992

Table 2. Allowable Mast Movement from Internal Leakage (Hydrauli…1003

MAST-FORK LIFT TRUCK…1011

toc…1011

Mast…1011

Safety Precautions Maintenance and Repair…1012

General…1015

Description…1015

Operation…1015

Control Valve, Carriage/Attachment…1016

Selector Valve…1016

Safety Procedures When Working Near Mast…1017

Carriage Repair…1019

Remove…1019

Disassemble…1019

Assemble…1021

Install…1021

Selector Valve…1022

Remove and Disassemble…1022

Clean and Inspect…1022

Assemble…1022

Install…1022

Tilt Cylinders Repair…1023

Remove…1023

Disassemble…1023

Clean…1024

Assemble…1024

Install…1025

Mast Repair…1025

Remove…1025

Disassemble…1028

Clean and Inspect…1028

Assemble…1030

Install…1031

Lift Cylinders Repair…1033

Description and Operation…1033

Remove…1034

Disassemble…1034

Clean and Inspect…1034

Assemble…1034

Install…1036

Mast Operation Check…1037

Lift and Tilt System Leaks Check…1037

Lift System…1037

Tilt System…1037

Tilt Cylinder Stroke and Backward Tilt Angle Adjustments…1039

Carriage Adjustments…1040

Lift Chain Adjustments…1040

Bearing Blocks…1040

Mast Adjustments…1040

Bearing Blocks…1040

Wear Plates…1040

Troubleshooting…1042

tables…1011

Table 1. Lift Height and Mast Weights…1027

Table 2. Allowable Mast Movement from Internal Leakage [Hydrauli…1038

Table 3. Allowable Mast Movement from Internal Leakage [Hydrauli…1038

METRIC AND INCH (SAE) FASTENERS…1047

toc…1047

Metric and Inch (SAE) Fasteners…1047

Safety Precautions Maintenance and Repair…1048

General…1051

Threaded Fasteners…1051

Nomenclature, Threads…1051

Strength Identification…1052

Cotter (Split) Pins…1052

Fastener Torque Tables…1057

Conversion Table…1059

tables…1047

Table 1. Bolts and Screws…1053

Table 2. Studs and Nuts…1054

Table 3. Torque Nuts…1055

Table 4. Torque Nuts With Nylon Insert…1056

Table 5. Torque Values for Metric Fasteners*…1057

Table 6. Torque Values for Inch Fasteners*…1058

Table 7. Conversion Table for Metric and English Units…1059

Table 8. Cotter Pin Dimensional Data…1060

Table 9. Cotter Pin Dimensional Data…1061

Table 10. Cotter Pin Dimensional Data…1062

Table 11. Cotter Pin Dimensional Data…1064

PARKING BRAKE…1069

toc…1069

Parking Brake…1069

Safety Precautions Maintenance and Repair…1070

General…1073

Description and Operation…1073

Parking Brake Caliper Repair…1074

Release Brake Manually…1074

Hydraulic Pressure Available…1074

Hydraulic Pressure not Available…1074

Remove…1074

Disassemble…1075

Clean…1077

Inspect…1077

Linings…1077

Disc…1077

Caliper Parts…1078

Assemble…1078

Install…1079

Bleed Brakes…1080

Adjust…1081

Test…1081

Specifications…1082

Troubleshooting…1082

tables…1069

Table 1. Disc Wear Limits…1078

Table 2. Torque Requirements…1082

Table 3. Wear Limits…1082

Table 4. Lining to Disc Clearance…1082

PERIODIC MAINTENANCE-TIER II EMISSION ENGINE…1087

toc…1087

Periodic Maintenance…1087

Safety Precautions Maintenance and Repair…1088

General…1093

Serial Number Data…1093

How to Move Disabled Lift Truck…1093

How to Tow Lift Truck…1094

How to Put Lift Truck on Blocks…1094

How to Raise Drive Tires…1095

How to Raise Steering Tires…1095

Maintenance Schedule…1096

Empty Container Attachment Maintenance…1102

Maintenance Procedures Every 8 Hours or Daily…1104

How to Make Checks With Engine Stopped…1104

Safety Labels…1104

Forks…1104

Adjust…1104

Remove…1104

Install…1105

Forks, Mast, and Lift Chains, Inspect…1105

Operator Restraint System…1106

Steering Column Latch…1107

Tires and Wheels…1107

Air Filter…1107

Fuel, Oil, or Coolant Leak Check…1108

Air Intake Piping…1108

Cooling Fan…1109

Crankcase Breather Tube…1109

Cooling System…1109

Drive Belt…1110

Battery…1110

Engine Oil…1111

Hydraulic System Oil…1112

Sealed Fuses…1112

How to Make Checks With Engine Running…1112

Engine Fault Codes…1112

Gauges, Lights, Horn, Fuses, and Relays…1118

Engine Oil Pressure…1119

Transmission Oil…1119

Electrical System…1119

Steering System…1119

Service Brakes…1119

Parking Brake…1119

Fuel System…1119

Fuel Filter/Water Separator…1120

Control Levers and Pedals…1120

Lift System Operation…1120

Attachments…1120

Maintenance Procedures Every 250 Hours Or Monthly…1121

Empty Container Attachment…1121

Maintenance Procedures Every 250 Hours or 2 Months…1121

Lift Chains…1121

Wear Check…1121

Lubrication…1121

Adjust…1121

H14.00-20.00XM (H360-450H)…1123

H16.00-18.00XM-12EC (H400-450H-EC)…1123

Drive Shaft…1123

Steering Axle…1123

Wheel Nuts…1123

Differential…1123

Planetary Drive Axle…1124

Hydraulic Tank Breather…1124

Heater Air Filter…1124

Mast…1124

Maintenance Procedures Every 500 Hours or 3 Months…1125

Empty Container Attachment…1125

Maintenance Procedures Every 500 Hours or 6 Months…1125

Engine Oil and Filter…1125

Fuel Filter/Water Separator…1125

Fuel Pump…1125

Maintenance Procedures Every 1000 Hours or 6 Months…1126

General Lubrication…1126

Steering Axle…1126

Accumulator…1126

Mast…1126

Differential and Planetary Drive Axles…1126

Transmission Oil and Filter…1126

Forks, Wear and Damage Check…1126

Maintenance Procedures Every 1000 Hours or Annually…1127

Coolant Fan Belt Tensioner…1127

Belt Driven Fan Hub…1128

Valve Adjustment…1128

Maintenance Procedures Every 2000 Hours or Annually…1130

Hydraulic System…1130

Hydraulic Oil Filter Change…1130

Hydraulic Oil Change…1130

Steer Wheel Bearings…1130

Brakes…1131

Maintenance Procedures Every 2000 Hours or 2 Years…1131

Rubber Vibration Damper…1131

Engine Coolant…1131

Maintenance Procedures Every 5000 Hours…1132

Empty Container Attachment…1132

System Air Removal…1132

Lift and Tilt System Leaks Check…1133

Welding Repairs…1133

Safety Procedures When Working Near Mast…1134

Tire and Wheel Replacement…1135

Pneumatic Tires and Wheels…1135

Remove Wheels From Lift Truck…1135

Remove Tire From Wheel…1136

Install Tire on Wheel…1137

Install Tire on Wheel Procedures…1138

Add Air Pressure to Tires…1139

Wheels, Install…1140

Solid Rubber Tires…1141

Remove Wheels From Lift Truck…1141

Remove Tire From Wheel…1141

Install Tire on Wheel…1142

Wheels, Install…1143

tables…1087

Table 1. Daily Inspections − Condition Check…1096

Table 2. Daily Inspections − Fluid Level Check…1097

Table 3. Daily Inspections − Checks With the Engine Running…1098

Table 4. First Inspection After First 100 Hours of Operation…1099

Table 5. Periodic Maintenance Schedule − Inspect and Adjust…1099

Table 6. Periodic Maintenance Schedule − Lubricate…1100

Table 7. Periodic Maintenance Schedule − Change…1101

Table 8. Empty Container Attachment Maintenance − Inspect and …1103

Table 9. Empty Container Attachment Maintenance − Lubricate…1103

Table 10. Empty Container Attachment Maintenance − Change…1104

Table 11. Error Code Descriptions…1113

Table 12. Nominal Valve Clearance…1129

PERIODIC MAINTENANCE…1147

PERIODIC MAINTENANCE…1147

GENERAL…1147

Serial Number Data…1147

HOW TO MOVE A DISABLED LIFT TRUCK…1147

How to Tow the Lift Truck…1148

HOW TO PUT A LIFT TRUCK ON BLOCKS …1148

How to Raise the Drive Tires…1148

How to Raise the Steering Tires…1148

MAINTENANCE SCHEDULE…1149

MAINTENANCE SCHEDULE, EMPTY CONTAINER ATTACHMENT…1152

MAINTENANCE PROCEDURES…1153

EVERY 8 HOURS OR DAILY…1153

HOW TO MAKE THE CHECKS WITH THE ENGINE STOPPED…1153

Tires and Wheels…1153

Forks…1153

Forks, Adjustment…1153

Forks, Removal…1154

Forks, Installation…1154

Inspection of Forks, Mast and Lift Chains…1154

Safety Labels…1155

Operator Restraint System…1155

Steering Column Latch…1156

Check For Fuel, Oil Or Coolant Leaks…1156

Drive Belt…1156

Engine Oil…1156

Water Separator…1156

Cooling System…1157

Hydraulic System Oil…1157

Battery…1157

Air Filter…1158

HOW TO MAKE THE CHECKS WITH THE ENGINE RUNNING…1158

Gauges, Lights, Horn and Fuses And Relays…1159

Engine Oil Pressure…1159

Cooling System…1159

Electrical System…1159

Transmission Oil…1159

Steering System…1160

Service Brakes…1160

Parking Brakes…1160

Fuel System…1160

Control Levers and Pedals…1160

Lift System Operation…1160

Attachments…1161

EVERY 250 HOURS OR TWO MONTHS…1161

LIFT CHAINS, LUBRICATION…1161

LIFT CHAINS, ADJUSTMENT…1161

H14.00-20.00XM…1161

H18.00-20.00XM-12EC (H400-450H-EC)…1161

DRIVE SHAFT…1161

STEERING AXLE…1161

WHEEL NUTS…1162

DIFFERENTIAL…1162

DRIVE AXLE PLANETARIES…1162

ENGINE OIL AND FILTER…1162

FUEL FILTERS…1162

HYDRAULIC TANK BREATHER…1163

AIR FILTER, HEATER…1163

MAST…1163

EMPTY CONTAINER ATTACHMENT…1163

FORKS, CHECK FOR WEAR AND DAMAGE…1163

LIFT CHAINS, CHECK FOR WEAR…1164

FUEL SYSTEM…1164

EVERY 1000 HOURS OR SIX MONTHS…1164

GENERAL LUBRICATION…1164

STEERING AXLE…1164

MAST…1164

TRANSMISSION OIL AND FILTER…1165

BRAKE SYSTEM OIL FILTER…1165

EVERY 2000 HOURS OR YEARLY…1165

HYDRAULIC SYSTEM…1165

Change the Hydraulic Oil Filter…1165

Change the Hydraulic Oil…1165

DIFFERENTIAL AND DRIVE AXLE PLANETARIES…1165

EMPTY CONTAINER ATTACHMENT…1166

STEER WHEEL BEARINGS…1166

BRAKES…1166

GENERAL PROCEDURES…1167

CHECK FOR LEAKS IN THE LIFT AND TILT SYSTEM…1167

WELDING REPAIRS…1167

SAFETY PROCEDURES WHEN WORKING NEAR THE MAST…1168

TIRES AND WHEELS…1169

PNEUMATIC TIRES AND WHEELS…1169

Remove The Wheels From The Lift Truck…1169

Remove the Tire from the Wheel…1169

Install the Tire on the Wheel…1170

Add Air Pressure To The Tires…1171

Install The Wheels…1171

SOLID RUBBER TIRES…1171

Remove The Wheels From The Lift Truck…1171

Remove the Tire from the Wheel…1171

Install the Tire on the Wheel…1173

Install The Wheels…1173

PLANETARY DRIVE AXLE…1174

toc…1174

Planetary Drive Axle…1174

Safety Precautions Maintenance and Repair…1175

General…1178

Description…1179

Drive Axle Repair…1179

Remove…1179

Install…1181

Planetary Gear and Service Brake Repair…1182

Disassemble…1183

Assemble…1188

Axle Hardware Torque…1195

Troubleshooting…1196

tables…1174

Table 1. Approximate Weights of Axle Parts…1180

STEERING AXLE…1200

toc…1200

Steering Axle…1200

Safety Precautions Maintenance and Repair…1201

General…1204

Description…1204

Steering Axle Repair…1204

Remove…1204

Install…1205

Wheels and Hubs Repair…1206

Remove and Disassemble…1206

Clean…1206

Assemble and Install…1206

Spindles and Bearings Repair…1207

Remove…1207

Clean…1207

Assemble and Install…1207

Steering Cylinder Repair…1208

Remove and Disassemble…1208

Clean and Inspect…1208

Assemble and Install…1209

Troubleshooting…1211

STEERING SYSTEM…1214

toc…1214

Steering System…1214

Safety Precautions Maintenance and Repair…1215

General…1218

Description…1218

Steering Wheel and Column Assembly Repair…1220

General…1220

Steering Wheel and Horn…1220

Remove…1220

Install…1220

Steering Control Unit Repair…1222

Description…1222

Operation…1222

Load Sensing Steering…1222

Remove…1223

Disassemble…1223

Clean…1226

Assemble and Install…1226

Steering System Air Removal…1232

Steering Relief Pressure Check…1233

Troubleshooting…1235

tables…1214

Table 1. Hydraulic System Check Ports…1234

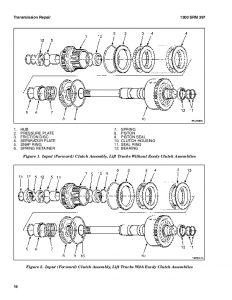

THREE-SPEED POWERSHIFT TRANSMISSION (ZF)…1240

ZF TRANSMISSION REPAIR…1240

GENERAL…1240

TORQUE CONVERTER…1240

Removal…1240

Installation…1240

TRANSMISSION…1240

Removal…1240

Disassembly…1240

Cleaning and Inspection…1248

Assembly…1248

Installation…1257

CONTROL VALVE…1257

Removal And Disassembly…1257

Cleaning and Inspection…1257

Assembly…1258

Installation…1258

INCHING VALVE…1260

Removal…1260

Disassembly…1260

Cleaning and Inspection…1260

Assembly…1261

Installation…1261

TRANSMISSION CONTROL LEVER…1261

TRANSMISSION DISPLAY…1261

Fault Codes…1261

CHECKS AND ADJUSTMENTS…1262

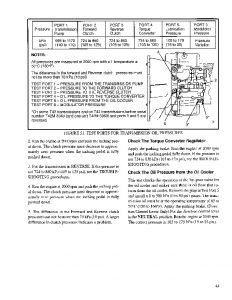

CHECK THE STALL SPEED OF THE TORQUE CONVERTER…1262

CHECK THE OIL PRESSURE OF THE TRANSMISSION…1262

Check the Main Regulator…1262

Check the Clutch Pressure…1262

Check The Oil Pressure For The Torque Converter …1262

TRANSMISSION PRESSURES…1263

CHECK AND ADJUST THE INCHING LINKAGE…1263

TROUBLESHOOTING…1265

TILT CYLINDERS…1270

toc…1270

Tilt Cylinders…1270

Safety Precautions Maintenance and Repair…1271

General…1274

Description…1274

Tilt Cylinder Repair…1274

Remove…1274

Disassemble…1274

Clean…1274

Assemble…1274

Tilt Cylinders With O-Ring or Single-Lip Seals…1274

Tilt Cylinders for XM and XMS Models…1276

Tilt Cylinders for XL, XLS, and XL 3 Models…1277

Tilt Cylinders for H700-800A and Early Model H700-920B…1279

Install…1280

Tilt Cylinders Using Chevron Packing…1280

Install…1281

Tilt Cylinder Leak Check…1283

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…1285

Torque Specifications…1285

Piston Rod Nut…1285

Retainer…1286

Troubleshooting…1288

tables…1270

Table 1. Movement Rates (Maximum) for Tilt Cylinders…1284

A214 (H360-450H)…1292

ACCUMULATOR…1293

toc…1293

Brake Accumulator…1293

Safety Precautions Maintenance and Repair…1294

General…1297

Description and Operation…1297

Accumulator Maintenance…1297

Precharge Check…1297

Precharge Filling…1298

Remove…1299

Disassemble…1299

Clean…1301

Inspect…1301

Repair…1301

Assemble…1301

Replace…1301

tables…1293

Table 1. Accumulator Pressures…1298

BRAKE SYSTEM…1305

toc…1305

Brake System…1305

Safety Precautions Maintenance and Repair…1306

General…1309

Description and Operation…1309

Parking Brake…1311

Brake Pedal Valves…1312

Pilot Supply Valve Repair…1312

Repairs…1312

Checks and Adjustments…1312

Accumulator Replacement…1312

Oil Cooler…1314

Remove…1314

Clean…1314

Install…1314

Brake Pedal Components…1314

Manifold…1314

Shuttle Valve…1315

Remove and Disassemble…1315

Clean and Inspect…1315

Assemble and Install…1315

Brake Pedal Valves…1316

Remove and Disassemble…1316

Clean and Inspect…1316

Assemble…1316

Install…1316

Parking Brake Valve Repair…1318

Remove…1318

Install…1318

Parking Brake Caliper Repair…1318

Brake System Air Removal…1318

Service Brakes Air Removal…1318

Troubleshooting…1322

tables…1305

Table 1. Hydraulic System Check Ports…1321

CAPACITIES AND SPECIFICATIONS…1333

toc…1333

Capacities and Specifications…1333

Safety Precautions Maintenance and Repair…1334

Lift Truck Weights…1337

Container Attachment Weights…1338

Engine Specifications…1338

Capacities…1339

Hydraulic System…1339

Steering…1340

Electrical System…1340

Mast Speeds…1341

Tire Sizes…1341

Transmission Pressures…1342

Torque Specifications…1343

Container Attachment…1343

Drive Line and Axle…1343

Engine…1343

Frame…1343

Mast…1343

Steering…1343

Transmission…1343

tables…1333

Table 1. Basic Truck as Counterweighted for Standard Pin Fork Op…1337

Table 2. Basic Truck as Counterweighted for Quick Disconnect Hoo…1337

COOLING SYSTEM…1347

toc…1347

Cooling System…1347

Safety Precautions Maintenance and Repair…1348

General…1351

Description…1352

Radiator…1352

Radiator Cap…1352

Thermostat…1352

Water Pump…1353

Fan and Fan Shroud…1353

Cooling System Checks…1353

Radiator…1353

Thermostat…1353

Water Pump…1354

Exhaust Leaks…1354

Fan and Fan Shroud…1354

Radiator Cleaning…1354

Drain…1354

Clean…1354

Fill…1355

Troubleshooting…1356

DIAGRAMS…1359

toc…1359

Diagrams…1359

Safety Precautions Maintenance and Repair…1360

DIFFERENTIAL…1409

toc…1409

Differential…1409

Safety Precautions Maintenance and Repair…1410

General…1413

Description…1413

Differential Repair…1414

Remove…1414

Differential Carrier From Axle Housing, Remove…1414

Differential and Ring Gear From Differential Carrier, Remove…1416

Drive Pinion and Pinion Carrier From Differential Carrier, Remov…1418

Disassemble…1419

Differential and Ring Gear Assembly, Disassemble…1419

Drive Pinion and Pinion Carrier, Disassemble…1421

Clean and Inspect…1424

Assemble…1425

Pinion, Bearings, and Pinion Carrier, Assemble…1425

Pinion Bearings, Adjust Preload…1425

Press Method…1425

Yoke or Flange Method…1426

Triple-Lip Seal, Install…1427

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion)…1428

Differential and Ring Gear, Assemble…1430

Differential Gears Rotating Torque, Check…1432

Differential and Ring Gear Assembly, Install…1433

Differential Bearings, Preload Adjust…1435

Ring Gear, Runout Check…1436

Ring Gear Backlash, Adjust…1436

Gear Set, Tooth Contact Pattern Check…1438

Thrust Screw, Install and Adjust…1441

Install…1441

Differential Assembly Into Axle Housing, Install…1441

Specifications…1443

Troubleshooting…1448

tables…1409

Table 1. Ring Gear Backlash Adjustment Specifications…1438

Table 2. Ring and Pinion Tooth Contact Adjustment…1439

Table 3. General Specifications…1443

Table 4. Rivet Installation Pressure…1443

Table 5. Pinion Adjustment…1444

Table 6. Pinion Preload Pressure…1444

Table 7. Torque Specifications…1445

Table 8. Torque Specifications for Metric Hardware…1446

Table 9. Torque Specifications for Metric (Fine) Hardware…1447

EMPTY CONTAINER HANDLING ATTACHMENT…1451

toc…1451

Empty Container Handling Attachment…1451

Safety Precautions Maintenance and Repair…1452

General…1455

Description…1455

Operation…1466

General…1466

Selector Valves…1466

Sideshift Circuit…1466

Extend and Retract Circuit…1466

Twist Lock Circuit and Control…1466

Model 572 – Double Horizontally Mounted…1466

Model 573 – Horizontally Mounted…1467

Model 578 – Vertically Mounted…1467

Lifting Hooks…1467

Model 575…1467

Indicator Lights and LEDs…1467

Lift Interrupt and Override…1468

Overlowering Interrupt and Override…1468

Second Container Detection Sensor (Model 572 Only)…1469

Carriage and Attachment Repair…1469

Remove…1469

Attachment Without Carriage Repair…1470

Remove…1470

Sideshift Cylinders Repair…1470

Remove…1470

Disassemble…1470

Assemble…1471

Extension Cylinders Repair…1471

Remove…1471

Disassemble…1471

Clean and Inspect…1472

Assemble…1472

Install…1472

Floating End Beams Repair…1473

Remove…1473

Install…1473

Hose Replacement In End Beams…1473

Twist Locks Repair for Model 572 and 573…1473

Remove…1473

Model 573…1473

Model 572…1473

Disassemble…1474

Clean and Inspect…1474

Assemble…1474

Hook Replacement for Model 575…1475

Inspect…1475

Remove…1475

Install…1475

Twist Locks Repair for Model 578…1476

Disassemble…1476

Clean and Inspect…1476

Assemble…1476

Extension Beams Repair…1477

LH and RH Extension Beam, Remove…1477

Slave Beam, Remove…1477

Clean and Inspect…1478

Assemble…1478

Bleed the System…1479

Valve Assembly…1479

Slide Pad Replacement…1480

Adjustments…1480

Twist Lock Angle Adjustment…1480

Model 578 Only…1480

LOCKED/NOT LOCKED Sensors Adjustment…1481

Model 573…1481

Model 578…1481

Seated Sensor Adjustment…1481

Model 572 and 573…1481

Model 578…1482

Overlowering Protection Sensor Adjustment (Models 572, 573, and …1482

Torque Chart…1483

Maintenance…1483

Additional Attachment Maintenance…1486

Interface Boxes With LED Indicators…1487

Models 572, 573, 575, and 578: Interface Box With LED Indicators…1487

Models 573 and 578: Two Additional Interface Boxes With LED Indi…1487

Model 572…1488

Troubleshooting…1488

tables…1451

Table 1. Torque Chart…1483

Table 2. Maintenance Schedule…1484

EXTENDABLE CONTAINER ATTACHMENT (ELME) 580 SERIES…1519

toc…1519

Extendable Container Attachment (Elme)…1519

Safety Precautions Maintenance and Repair…1520

General…1525

Description…1525

Operation…1529

General…1529

Optional Powered Pile Slope…1529

Sideshift…1530

Extend and Retract Circuit…1531

Container locking Model 582…1533

Sequence Valve…1533

Pilot Check Valve…1534

Container Locking Model 583…1535

Container Locking Model 584…1535

Container Locking Model 585…1536

Container Locking Models 586, 588, and 589…1536

Electrical System…1538

Indicator Lights…1538

Flashing Indicator Lights…1539

Automatic Locking…1539

Lift Interrupt and Override…1539

Overlowering Interrupt and Override…1539

Second Container Detection Sensor (Model 582 Only)…1540

Carriage and Attachment Removal…1540

Carriage…1540

Spreader…1541

Sideshift Cylinder Removal and Installation…1541

Remove…1541

Install…1541

Extension Cylinder Removal and Installation…1542

Remove…1542

Upper, Right-Hand…1542

Lower, Left-Hand…1542

Install…1542

Floating End Beams Repair…1543

Remove…1543

Install…1543

Hose, Replace…1544

Twist Lock Repair for Model 582…1545

Remove…1545

Upper Twist Lock…1545

Lower Twist Lock…1545

Disassemble…1546

Clean and Inspect…1546

Assemble…1547

Install…1547

Hook Repair for Model 584 and 585…1547

Remove…1547

Inspect…1547

Install…1547

Side Clamp Replacement for Model 584…1548

Remove…1548

Install…1549

Twist Lock Repair for Models 586, 588, and 589…1549

Disassemble…1549

Clean and Inspect…1549

Assemble…1550

Extension Beam Repair…1551

Remove…1551

Inspect…1551

Assemble…1552

Cylinder Repair…1553

Extension Cylinder…1553

Disassemble…1553

Clean and Inspect…1553

Assemble…1553

Guide for Extension Cylinder…1554

Remove…1554

Install…1554

Sideshift Cylinder, Powered Pile Slope Cylinder, Retract Cylinde…1554

Disassemble…1554

Assemble…1554

Wear Pad Replacement…1555

General…1555

Floating End Beam Wear Pads…1555

Upper Wear Pads…1555

Lower Wear Pads…1555

Main Frame Wear Pads at Large (Right-Hand) Extension Beam…1555

Main Frame Wear Pads at Small (Left-Hand) Extension Beam…1555

Guide for Extension Cylinder…1556

Large Extension Beam Internal Wear Pads…1557

Spreader Frame…1557

Upper Wear Pads…1557

Lower Wear Pads…1557

Powered Pile Slope Carriage…1557

Upper Wear Pads…1557

Lower Wear Pads…1557

Adjustments…1557

Twist Lock Angle Adjustment…1557

Model 586, 588 and 589…1557

LOCKED/NOT LOCKED Sensors Adjustment…1558

Model 582…1558

Model 586, 588 and 589…1558

Side Clamp Open/Closed Sensor Adjustment (Model 584)…1558

Hook in Sensor Adjustment (Model 584)…1558

Seated Sensor Adjustment…1559

Model 582…1559

Model 586, 588 and 589…1559

Overlowering Protection Sensor Adjustment (All 580 Models)…1559

Schematics…1560

tables…1519

Table 1. Elme Schematic Overview…1560

FRAME…1647

toc…1647

Frame…1647

Safety Precautions Maintenance and Repair…1648

General…1651

Description…1651

Counterweights…1651

Remove…1651

Center Counterweight…1651

Counterweight…1651

Fender Counterweight…1651

Install…1653

Hood and Air Filter Repair…1653

Remove…1653

Install…1653

Hydraulic Tank Repair…1656

Remove…1656

Repairs, All Units…1656

Small Leaks…1656

Large Leaks…1656

Clean…1657

Steam Method…1657

Chemical Solution Method…1657

Other Methods of Preparation for Repair…1658

Install…1658

Fuel Tank Repair…1658

Remove…1658

Repair…1658

Install…1659

Radiator Repair…1659

Remove…1659

Install…1659

Engine and Transmission Repair…1662

Remove…1662

Install…1663

Operator Compartment Repair…1664

General…1664

Remove…1666

Install…1668

Window Wipers…1668

Window Washer Motors and Pumps…1668

Heater Control Panel Assembly…1669

Blower and Core Assemblies…1670

Remove…1670

Install…1670

Window Replacement…1672

Front and Rear Windows…1673

Lower Door Windows…1674

Upper Door (Sliding) Windows…1674

Top Window…1674

Operator Restraint System…1674

Oil Cooler…1675

Remove…1675

Clean…1675

Install…1675

Label Replacement…1676

Painting Instructions…1679

tables…1647

Table 1. Counterweights…1653

Table 2. Cab Windows Material Specifications…1672

HYDRAULIC SYSTEM…1683

toc…1683

Hydraulic System…1683

Safety Precautions Maintenance and Repair…1684

General…1687

Description and Operation…1687

Main Control Valve…1688

Remote Control Valve…1688

Pilot Supply Valve…1689

Auxiliary Control Valve…1689

Selector Valves…1689

Steering System…1689

Main Control Valve Repair…1689

Description…1689

Lifting…1691

Lowering…1691

Tilt Spool…1691

Priority Valve…1691

Relief Valves…1691

Repairs…1691

Remove…1691

Disassemble…1692

Clean and Inspect…1692

Assemble…1692

Install…1692

Checks and Adjustments…1694

Relief Pressures Check…1694

Remote Control Valve Repair…1694

Description…1694

Operation…1694

Repairs…1696

Remove…1696

Disassemble…1696

Clean and Inspect…1698

Assemble…1698

Install…1699

Adjust…1699

Pilot Supply Valve Repair…1699

Description and Operation…1699

Repairs…1700

Checks and Adjustments…1700

Relief Valve, Check and Adjust…1700

Pressure Reduction Valves, Check…1700

Auxiliary Control Valve Repair…1702

Description and Operation…1702

Repairs…1702

Remove…1702

Disassemble…1702

Clean and Inspect…1703

Assemble…1703

Install…1704

Check and Adjust…1704

Hydraulic Pump Repair…1704

General…1704

Repairs…1704

Specifications…1706

Troubleshooting…1714

Main Control Valve…1714

Remote Control valve…1715

Pilot Supply Valve…1716

Accumulator Charge Valve and Accumulator…1716

Pressure Reduction Valves…1716

Auxiliary Control Valve…1717

tables…1683

Table 1. Hydraulic System Check Ports…1706

INSTRUMENT PANEL INDICATORS AND SENDERS…1721

toc…1721

Instrument Panel Indicators and Senders…1721

Safety Precautions Maintenance and Repair…1722

General…1725

Description…1726

Steering Column Gauges, Meters, and Indicators…1726

LED Display Panel…1726

Battery Discharge Indicators…1726

Brush Wear Indicators…1732

Motor Temperature Indicators…1732

LX Series Display Panel…1734

Hourmeter Functions…1735

Battery Indicator Function…1735

Status Code Function…1735

ZX Series Display Panels…1737

Display Panel…1737

Basic Display Panels…1737

Performance Display…1739

Brush Wear Indicators…1743

Adjustments – General…1743

Replacement – General Information…1743

Meter Replacement…1744

Sender Replacement…1745

Fuel Level Sender…1745

Pressure and Temperature Sender…1745

Seat Sensor, Operator Presence System (OPS)…1746

Remove…1746

Install…1746

Operator Presence System Module Replacement…1746

Remove…1747

Install…1748

ITW Display Panel Replacement…1749

Remove…1749

Column Mount Display Panel (EV-100/200ZX Motor Controllers) Repl…1749

Remove…1749

Display Panel Assembly, Replace…1749

Indicator LEDs…1750

Battery Indicators…1750

Digital Display (Performance Display Panel Only)…1750

Status Code or Performance Level Switches and Indicator LEDs (Pe…1751

Basic Display Panel, Replace Parts…1751

Performance Display Panel, Replace Parts…1753

Dash Mount Display Panel (EV100/200ZX Motor Controllers) Replace…1753

Remove and Replace…1753

Specifications…1754

Meter Specifications…1754

Sender Specifications…1754

Troubleshooting…1755

Meter…1755

Troubleshooting for Operator Presence System…1756

tables…1721

Table 1. Troubleshooting Procedure for Operator Presence Module…1756

MAST-EMPTY CONTAINER HANDLER…1761

toc…1761

Mast…1761

Safety Precautions Maintenance and Repair…1762

Safety Procedures When Working Near Mast…1765

General…1766

Description…1766

Operation…1767

Control Valve, Carriage/Attachment…1768

Tilt Cylinders Repair (A214 Only)…1768

Remove…1768

Disassemble…1768

Clean and Inspect…1768

Assemble…1769

Install…1769

Mast Repair…1770

Remove…1770

Disassemble…1771

Clean and Inspect…1772

Assemble…1772

Install…1775

Lift Cylinders Repair…1777

Description…1777

Remove…1778

Disassemble…1778

Clean and Inspect…1778

Assemble…1778

Install…1778

Mast Operation Check…1780

Lift and Tilt System Leaks Check…1780

Lift System…1780

Tilt System…1780

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment…1781

Lift Chain Adjustments…1782

Mast Adjustments…1783

Bearing Blocks…1783

Wear Plates…1783

Carriage Adjustment…1785

Troubleshooting…1785

tables…1761

Table 1. Mast Weights…1770

Table 2. Allowable Mast Movement from Internal Leakage (Hydrauli…1781

MAST-FORK LIFT TRUCK…1789

toc…1789

Mast…1789

Safety Precautions Maintenance and Repair…1790

General…1793

Description…1793

Operation…1793

Control Valve, Carriage/Attachment…1794

Selector Valve…1794

Safety Procedures When Working Near Mast…1795

Carriage Repair…1797

Remove…1797

Disassemble…1797

Assemble…1799

Install…1799

Selector Valve…1800

Remove and Disassemble…1800

Clean and Inspect…1800

Assemble…1800

Install…1800

Tilt Cylinders Repair…1801

Remove…1801

Disassemble…1801

Clean…1802

Assemble…1802

Install…1803

Mast Repair…1803

Remove…1803

Disassemble…1806

Clean and Inspect…1806

Assemble…1808

Install…1809

Lift Cylinders Repair…1811

Description and Operation…1811

Remove…1812

Disassemble…1812

Clean and Inspect…1812

Assemble…1812

Install…1814

Mast Operation Check…1815

Lift and Tilt System Leaks Check…1815

Lift System…1815

Tilt System…1815

Tilt Cylinder Stroke and Backward Tilt Angle Adjustments…1817

Carriage Adjustments…1818

Lift Chain Adjustments…1818

Bearing Blocks…1818

Mast Adjustments…1818

Bearing Blocks…1818

Wear Plates…1818

Troubleshooting…1820

tables…1789

Table 1. Lift Height and Mast Weights…1805

Table 2. Allowable Mast Movement from Internal Leakage [Hydrauli…1816

Table 3. Allowable Mast Movement from Internal Leakage [Hydrauli…1816

METRIC AND INCH (SAE) FASTENERS…1825

toc…1825

Metric and Inch (SAE) Fasteners…1825

Safety Precautions Maintenance and Repair…1826

General…1829

Threaded Fasteners…1829

Nomenclature, Threads…1829

Strength Identification…1830

Cotter (Split) Pins…1830

Fastener Torque Tables…1835

Conversion Table…1837

tables…1825

Table 1. Bolts and Screws…1831

Table 2. Studs and Nuts…1832

Table 3. Torque Nuts…1833

Table 4. Torque Nuts With Nylon Insert…1834

Table 5. Torque Values for Metric Fasteners*…1835

Table 6. Torque Values for Inch Fasteners*…1836

Table 7. Conversion Table for Metric and English Units…1837

Table 8. Cotter Pin Dimensional Data…1838

Table 9. Cotter Pin Dimensional Data…1839

Table 10. Cotter Pin Dimensional Data…1840

Table 11. Cotter Pin Dimensional Data…1842

PARKING BRAKE…1847

toc…1847

Parking Brake…1847

Safety Precautions Maintenance and Repair…1848

General…1851

Description and Operation…1851

Parking Brake Caliper Repair…1852

Release Brake Manually…1852

Hydraulic Pressure Available…1852

Hydraulic Pressure not Available…1852

Remove…1852

Disassemble…1853

Clean…1855

Inspect…1855

Linings…1855

Disc…1855

Caliper Parts…1856

Assemble…1856

Install…1857

Bleed Brakes…1858

Adjust…1859

Test…1859

Specifications…1860

Troubleshooting…1860

tables…1847

Table 1. Disc Wear Limits…1856

Table 2. Torque Requirements…1860

Table 3. Wear Limits…1860

Table 4. Lining to Disc Clearance…1860

PERIODIC MAINTENANCE,…1865

toc…1865

Periodic Maintenance…1865

Safety Precautions Maintenance and Repair…1866

General…1871

Serial Number Data…1871

How to Move Disabled Lift Truck…1871

How to Tow Lift Truck…1872

How to Put Lift Truck on Blocks…1872

How to Raise Drive Tires…1873

How to Raise Steering Tires…1873

Maintenance Schedule…1874

Empty Container Attachment Maintenance…1880

Maintenance Procedures Every 8 Hours or Daily…1882

How to Make Checks With Engine Stopped…1882

Safety Labels…1882

Forks…1882

Adjust…1882

Remove…1882

Install…1883

Forks, Mast, and Lift Chains, Inspect…1883

Operator Restraint System…1884

Steering Column Latch…1885

Tires and Wheels…1885

Air Filter…1885

Fuel, Oil, or Coolant Leak Check…1886

Air Intake Piping…1886

Cooling Fan…1887

Crankcase Breather Tube…1887

Cooling System…1887

Drive Belt…1888

Battery…1888

Engine Oil…1889

Hydraulic System Oil…1890

Sealed Fuses…1890

How to Make Checks With Engine Running…1890

Engine Fault Codes…1890

Gauges, Lights, Horn, Fuses, and Relays…1896

Engine Oil Pressure…1897

Transmission Oil…1897

Electrical System…1897

Steering System…1897

Service Brakes…1897

Parking Brake…1897

Fuel System…1897

Fuel Filter/Water Separator…1898

Control Levers and Pedals…1898

Lift System Operation…1898

Attachments…1898

Maintenance Procedures Every 250 Hours Or Monthly…1899

Empty Container Attachment…1899

Maintenance Procedures Every 250 Hours or 2 Months…1899

Lift Chains…1899

Wear Check…1899

Lubrication…1899

Adjust…1899

H14.00-20.00XM (H360-450H)…1901

H16.00-18.00XM-12EC (H400-450H-EC)…1901

Drive Shaft…1901

Steering Axle…1901

Wheel Nuts…1901

Differential…1901

Planetary Drive Axle…1902

Hydraulic Tank Breather…1902

Heater Air Filter…1902

Mast…1902

Maintenance Procedures Every 500 Hours or 3 Months…1903

Empty Container Attachment…1903

Maintenance Procedures Every 500 Hours or 6 Months…1903

Engine Oil and Filter…1903

Fuel Filter/Water Separator…1903

Fuel Pump…1903

Maintenance Procedures Every 1000 Hours or 6 Months…1904

General Lubrication…1904

Steering Axle…1904

Accumulator…1904

Mast…1904

Differential and Planetary Drive Axles…1904

Transmission Oil and Filter…1904

Forks, Wear and Damage Check…1904

Maintenance Procedures Every 1000 Hours or Annually…1905

Coolant Fan Belt Tensioner…1905

Belt Driven Fan Hub…1906

Valve Adjustment…1906

Maintenance Procedures Every 2000 Hours or Annually…1908

Hydraulic System…1908

Hydraulic Oil Filter Change…1908

Hydraulic Oil Change…1908

Steer Wheel Bearings…1908

Brakes…1909

Maintenance Procedures Every 2000 Hours or 2 Years…1909

Rubber Vibration Damper…1909

Engine Coolant…1909

Maintenance Procedures Every 5000 Hours…1910

Empty Container Attachment…1910

System Air Removal…1910

Lift and Tilt System Leaks Check…1911

Welding Repairs…1911

Safety Procedures When Working Near Mast…1912

Tire and Wheel Replacement…1913

Pneumatic Tires and Wheels…1913

Remove Wheels From Lift Truck…1913

Remove Tire From Wheel…1914

Install Tire on Wheel…1915

Install Tire on Wheel Procedures…1916

Add Air Pressure to Tires…1917

Wheels, Install…1918

Solid Rubber Tires…1919

Remove Wheels From Lift Truck…1919

Remove Tire From Wheel…1919

Install Tire on Wheel…1920

Wheels, Install…1921

tables…1865

Table 1. Daily Inspections − Condition Check…1874

Table 2. Daily Inspections − Fluid Level Check…1875

Table 3. Daily Inspections − Checks With the Engine Running…1876

Table 4. First Inspection After First 100 Hours of Operation…1877

Table 5. Periodic Maintenance Schedule − Inspect and Adjust…1877

Table 6. Periodic Maintenance Schedule − Lubricate…1878

Table 7. Periodic Maintenance Schedule − Change…1879

Table 8. Empty Container Attachment Maintenance − Inspect and …1881

Table 9. Empty Container Attachment Maintenance − Lubricate…1881

Table 10. Empty Container Attachment Maintenance − Change…1882

Table 11. Error Code Descriptions…1891

Table 12. Nominal Valve Clearance…1907

PERIODIC MAINTENANCE…1925

…1925

…1926

…1927

…1928

…1929

…1930

…1931

…1932

…1933

…1934

…1935

…1936

…1937

…1938

…1939

…1940

…1941

…1942

…1943

…1944

…1945

…1946

…1947

…1948

…1949

…1950

…1951

…1952

…1953

…1954

…1955

…1956

PLANETARY DRIVE AXLE…1957

toc…1957

Planetary Drive Axle…1957

Safety Precautions Maintenance and Repair…1958

General…1961

Description…1962

Drive Axle Repair…1962

Remove…1962

Install…1964

Planetary Gear and Service Brake Repair…1965

Disassemble…1966

Assemble…1971

Axle Hardware Torque…1978

Troubleshooting…1979

tables…1957

Table 1. Approximate Weights of Axle Parts…1963

STEERING AXLE…1983

toc…1983

Steering Axle…1983

Safety Precautions Maintenance and Repair…1984

General…1987

Description…1987

Steering Axle Repair…1987

Remove…1987

Install…1988

Wheels and Hubs Repair…1989

Remove and Disassemble…1989

Clean…1989

Assemble and Install…1989

Spindles and Bearings Repair…1990

Remove…1990

Clean…1990

Assemble and Install…1990

Steering Cylinder Repair…1991

Remove and Disassemble…1991

Clean and Inspect…1991

Assemble and Install…1992

Troubleshooting…1994

STEERING SYSTEM…1997

toc…1997

Steering System…1997

Safety Precautions Maintenance and Repair…1998

General…2001

Description…2001

Steering Wheel and Column Assembly Repair…2003

General…2003

Steering Wheel and Horn…2003

Remove…2003

Install…2003

Steering Control Unit Repair…2005

Description…2005

Operation…2005

Load Sensing Steering…2005

Remove…2006

Disassemble…2006

Clean…2009

Assemble and Install…2009

Steering System Air Removal…2015

Steering Relief Pressure Check…2016

Troubleshooting…2018

tables…1997

Table 1. Hydraulic System Check Ports…2017

THREE-SPEED POWERSHIFT TRANSMISSION (ZF)…2023

toc…2023

ZF Three-Speed Powershift Transmission…2023

Safety Precautions Maintenance and Repair…2024

General…2027

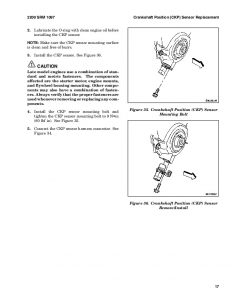

Torque Converter Repair…2027

Remove…2027

Install…2027

Transmission Repair…2027

Remove…2027

Disassemble…2031

Clean and Inspect…2037

Assemble…2038

Install…2054

Control Valve Repair…2055

Remove and Disassemble…2055

Clean and Inspect…2056

Assemble…2056

Install…2056

Inching Valve Repair…2057

Remove…2057

Disassemble…2057

Clean and Inspect…2058

Assemble…2058

Install…2059

Transmission Control Lever Repair…2059

Transmission Display Repair…2059

Fault Codes…2059

Torque Converter Stall Speed Check…2060

Transmission Oil Pressure Check…2061

Main Regulator Check…2061

Clutch Pressure Check…2061

Oil Pressure Check for Torque Converter (Torque Converter Regula…2061

Transmission Pressures…2061

Inching Linkage Check and Adjust…2062

Troubleshooting…2064

tables…2023

Table 1. Clutch Pack Specifications…2053

Table 2. Transmission Display Fault Codes…2059

Table 3. Transmission Pressures/Check Ports…2061

TILT CYLINDERS…2075

toc…2075

Tilt Cylinders…2075

Safety Precautions Maintenance and Repair…2076

General…2079

Description…2079

Tilt Cylinder Repair…2079

Remove…2079

Disassemble…2079

Clean…2079

Assemble…2079

Tilt Cylinders With O-Ring or Single-Lip Seals…2079

Tilt Cylinders for XM and XMS Models…2081

Tilt Cylinders for XL, XLS, and XL 3 Models…2082

Tilt Cylinders for H700-800A and Early Model H700-920B…2084

Install…2085

Tilt Cylinders Using Chevron Packing…2085

Install…2086

Tilt Cylinder Leak Check…2088

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…2090

Torque Specifications…2090

Piston Rod Nut…2090

Retainer…2091

Troubleshooting…2093

tables…2075

Table 1. Movement Rates (Maximum) for Tilt Cylinders…2089

Hyster H360H, H400H, H450H (A214) & H400H-EC5, H450H-EC6 (A214) Repair Service Manual