Complete service repair manual for Hyster Lift Trucks H800-970E, H1050EH (D117), with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster Service Manual H800E-H970E, H1050EH (D117) workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

1453783 – Hyster Service Manual H800-970E, H1050EH (D117) .pdf

Total Pages: 883 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section | Part No. | SRM Number | Rev Date |

| FRAME | 1454304 | 0100 SRM 0692 | 12/02 |

| COOLING SYSTEM | 897934 | 0700 SRM 0626 | 11/01 |

| FOUR-SPEED PS TRANSMISSION – DESCR / OPER | 897948 | 1300 SRM 0634 | 11/03 |

| FOUR-SPEED PS TRANSMISSION – REPAIR | 897949 | 1300 SRM 0635 | 11/03 |

| DIFFERENTIAL | 910072 | 1400 SRM 0046 | 11/03 |

| PLANETARY GEAR AXLE | 910030 | 1400 SRM 0047 | 11/03 |

| STEERING AXLE | 910031 | 1600 SRM 0071 | 07/97 |

| STEERING SYSTEM | 897367 | 1600 SRM 0429 | 04/97 |

| OIL COOLED BRAKES | 1452928 | 1800 SRM 0678 | 09/03 |

| DISC BRAKES | 1453346 | 1800 SRM 0683 | 08/02 |

| ACCUMULATOR | 1529749 | 1800 SRM 1036 | 09/02 |

| PARKING BRAKE | 1531821 | 1800 SRM 1037 | 02/03 |

| SERVICE BRAKES (Later Units) | 1531822 | 1800 SRM 1038 | 11/03 |

| AUXILARY BRAKE CALIPER | 1531815 | 1800 SRM 1040 | 04/03 |

| HYDRAULIC GEAR PUMPS | 910091 | 1900 SRM 0097 | 10/03 |

| HYDRAULIC SYSTEM | 1452932 | 1900 SRM 0682 | 07/97 |

| HYDRAULIC PLATE (See SRM for S/N break) | 1513622 | 1900 SRM 1012 | 09/03 |

| HYDRAULIC SYSTEM (See SRM for S/N break) | 1514035 | 1900 SRM 1013 | 12/02 |

| TILT CYLINDERS | 910102 | 2100 SRM 0103 | 10/03 |

| INSTRUMENT PANEL INDICATORS and SENDERS | 910110 | 2200 SRM 0143 | 12/03 |

| ELECTRICAL SYSTEM | 1452929 | 2200 SRM 0679 | 11/03 |

| MAST | 897371 | 4000 SRM 0432 | 03/97 |

| EXTENDABLE CONTAINER ATTACHMENT | 910457 | 5000 SRM 0265 | 11/97 |

| FIXED CONTAINER ATTACHMENT | 910466 | 5000 SRM 0266 | 11/97 |

| EXTENDABLE CONTAINER ATTACHMENT (ELME) | 1462736 | 5000 SRM 0723 | 11/99 |

| INCH (SAE) and METRIC FASTENERS | 910442 | 8000 SRM 0231 | 03/03 |

| DIAGRAMS | 1452553 | 8000 SRM 0676 | 08/02 |

| PERIODIC MAINTENANCE | 1452927 | 8000 SRM 0677 | 10/03 |

| CAPACITIES and SPECIFICATIONS | 1452930 | 8000 SRM 0680 | 12/02 |

| ASSEMBLY GUIDE | 1526432 | 8000 SRM 1041 | 07/02 |

| For service and repair information on Cummins engines | |||

| see a dealer for Cummins engines. | |||

| PART NO. 1453783 | |||

| Rev. 12/03 | |||

Diagrams…2

Safety Precautions Maintenance and Repair…3

hyster-1452927-10-03-srm0677…26

toc…26

Periodic Maintenance…26

Safety Precautions Maintenance and Repair…27

General…32

Serial Number Data…32

How to Move Disabled Lift Truck…32

How to Tow Lift Truck…33

How to Put Lift Truck on Blocks…33

How to Raise Drive Tires…33

How to Raise Steering Tires…34

Maintenance Schedule…35

Maintenance Procedures Every 8 Hours or Daily…48

How to Make Checks With Engine Stopped…48

Tires and Wheels…48

Forks…48

Adjust…49

Remove…49

Low Mount Forks, Install…49

High Mount Forks, Install…49

Inspection of Forks, Mast, and Lift Chains…49

Precleaner for Air Filter…50

Air Filter…50

Safety Labels…51

Operator Restraint System…52

Steering Column Latch…52

Fuel, Oil, or Coolant Leak Check…52

Drive Belt…52

Engine Oil…52

Cooling System…54

Hydraulic System Oil…54

Hydraulic Oil Filters…55

Hydraulic Filter…55

Battery…56

Splash Fuses…56

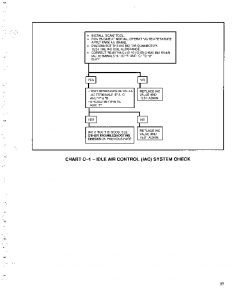

How to Make Checks With Engine Running…57

Engine Fault Codes…57

Gauges, Lights, Horn, Fuses, and Relays…63

Engine Oil Pressure…63

Electrical System…63

Transmission Oil…63

Steering System…64

Service Brakes…64

Parking Brake…64

Fuel System…64

Primary Fuel Filter…64

Control Levers and Pedals…64

Lift System Operation…65

Attachments…65

How to Add Fuel to Lift Truck…65

Maintenance Procedures Every 250 Hours or Each Month…66

Engine Oil and Filter…66

Oil Filter for Oil Cooled Brakes…66

Transmission…66

Coolant Filter…66

Lift Chains…67

Drive Shaft…67

Steering Axle Tie Rod Pins…67

Drive Axle and Differential…67

Heater Air Filter…67

Wheel Nuts…67

Mast Pivots, Sliding Surfaces…67

Sideshift Carriage…67

Fork Guides…67

Tilt Cylinder Pins…67

Shift Control Lever…67

Dedicated Carriage and Container Attachments…68

Maintenance Procedures Every 500 Hours or 2 Months…68

Forks…68

Lift Chains…68

Idle Speed…69

Governed Speed…69

Hydraulic Tank Breather…69

Maintenance Procedures Every 1000 Hours or 6 Months…69

Steer Wheel Bearing Nut…69

Change Transmission Oil…70

Fuel Filter…70

Chain Sheaves…70

Mast and Carriage Load Rollers…70

General Lubrication…70

Injection Pump Timing…70

Valve Adjustments…70

Steering Axle Kingpins…70

Disc Brake Assemblies…71

Clean…71

Inspect…71

Maintenance Procedures Every 2000 Hours or Yearly…73

Change Hydraulic Oil and Filters…73

Cooling System…73

Change Drive Axle and Differential Oil…74

Change Grease in Hub Bearings of Steer Wheels…74

Steering Axle Pivots…74

PCV Valve…74

Safety Procedures When Working Near Mast…74

Lift and Tilt System Leaks Check…76

Lift System…76

Tilt System…76

Pneumatic Tires and Wheels…77

Remove Wheels From Lift Truck…77

Remove Tire From Wheel…77

Remove Tire From Five-Piece Wheel…78

Install Tire on Wheel…79

Install Tire on Five-Piece Wheel…80

Add Air Pressure to Tires…81

Install Wheels on Lift Truck…82

tables…26

Table 1. Maintenance Schedule…35

Table 2. Maintenance Schedule, Container Attachment Until Mid 19…43

Table 3. Maintenance Schedule, Dedicated Container Attachment Af…44

Table 4. Maintenance Schedule, Fork Mounted Container Attachment…45

Table 5. Maintenance Schedule, Gantry Container Attachment After…46

Table 6. Error Code Descriptions…57

Table 7. Steer Wheel Nut Torque Specifications…69

hyster-1452928-09-03-srm0678…86

toc…86

Oil-Cooled Brakes…86

Safety Precautions Maintenance and Repair…87

General…90

Description…90

D117…91

E008…91

Description and Operation…94

D117…94

E008…94

Accumulator Charge Valve…95

Pressure Reducing Valves…97

Brake Pedal Valves…98

Operation…98

Operation (D117 E 01550, and After) (E008 Wet Brakes)…98

Parking Brake…99

Service Brakes…99

Auxiliary Brake (D117 only)…99

Pressure Switch Replacement…100

Accumulator Charge Valve Repair…100

Remove…100

Disassemble…100

Clean and Inspect…102

Assemble…102

Install…103

Adjust…103

Accumulator…103

Relay Valve Repair…103

Remove…103

Disassemble…104

Clean and Inspect…104

Assemble…104

Install…104

Shuttle Valve Repair…105

Remove…105

Disassemble…105

Clean and Inspect…105

Assemble…105

Install…105

Brake Pedal Valves (Treadle Valves) Repair…106

Remove…106

Clean and Inspect…106

Install…106

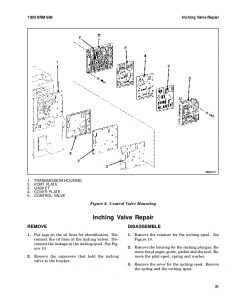

Inching Valve Repair…110

Remove…110

Disassemble…110

Clean and Inspect…110

Assemble…110

Install…112

Brake System Air Removal…112

Troubleshooting…113

tables…86

Table 1. Accumulator Charge Valve Pressures…95

Table 2. Brake Treadle Settings…98

hyster-1452929-11-03-srm0679…130

toc…130

Electrical System/Lights…130

Safety Precautions Maintenance and Repair…131

General…134

Alternator…134

Description…134

Remove and Disassemble…135

Clean…135

Inspect, Test, and Repair…135

Rotor…135

Rectifiers and Diode Set…136

To Test Rectifier With Ohmmeter:…136

To Test Rectifier With Test Lamp:…137

To Test Diode Set:…137

Drive End Frame…137

Brush End Frame…137

Brushes and Brush Holder Assembly…137

Stator…137

Assemble and Install…137

Meters, Senders, and Switches…138

General…138

Troubleshooting…138

hyster-1452930-12-02-srm0680…150

toc…150

Capacities and Specifications…150

Safety Precautions Maintenance and Repair…151

Counterweights Weights…154

Container Attachment Weights…154

Carriage Weights…154

Vehicle Weights…154

Capacities…155

Electrical System…155

Engine Specifications…155

Mast Weights…156

Lifting and Lowering Speeds…156

Tires…157

Forks…157

Hydraulic System Specifications…157

Torque Specifications…159

Control Valves…159

Electrical System…159

Counterweight…159

Drive Axle…159

Disc Brakes…159

Drive Shaft…159

Differential…159

Transmission…159

Torque Converter…160

Steering…160

Wheel Nuts…160

Carriages (All)…160

Disc Brakes…212

Safety Precautions Maintenance and Repair…213

General…216

Description and Operation…216

Accumulator Charge Valve…218

Pressure Reducing Valves…220

Brake Pedal Valves…220

Operation…220

Parking Brake…221

Service Brakes…221

Auxiliary Brake…222

Pressure Switch Replacement…222

Accumulator Charge Valve Repair…222

Remove…222

Disassemble…222

Clean and Inspect…224

Assemble…224

Install…225

Adjust…225

Accumulator…225

Pressure Reducing Valves Repair…225

Remove and Disassemble…225

Clean and Inspect…225

Assemble and Install…226

Relay Valve Repair…227

Remove and Disassemble…227

Clean and Inspect…227

Assemble…227

Install…228

Shuttle and Sequence Valves Repair…228

Remove and Disassemble…228

Clean and Inspect…228

Assemble and Install…228

Brake Pedal Valves (Treadle Valves) Repair…229

Remove and Disassemble…229

Clean and Inspect…229

Assemble and Install…229

Inching Valve Repair…233

Remove…233

Disassemble…233

Clean and Inspect…233

Assemble…233

Install…233

Service Brake Calipers Repair…235

Remove…235

Disassemble…235

Clean…237

Inspect…237

Assemble…238

Install…239

Brake System Air Removal…240

Troubleshooting…241

hyster-1454304-12-02-srm0692…252

toc…252

Frame…252

Safety Precautions Maintenance and Repair…253

General…256

Description…256

Counterweight Repair…257

Remove…257

Install…257

Fenders Repair…258

Remove…258

Install…258

Hood and Ballast Cover…258

Hood…258

Remove…258

Install…258

Ballast…258

Remove…258

Install…258

Floor Plates and Covers…262

Hydraulic Tank Repair…263

Remove…263

Repair…263

Small Leaks…263

Large Leaks…263

Clean…263

Steam Method…265

Chemical Solution Method…265

Other Methods of Preparation for Repair…265

Install…265

Fuel Tank Repair…266

Remove…266

Repair…266

Install…266

Radiator Repair…267

Remove…267

Clean…268

Install…269

Engine Repair…270

Remove…270

Install…273

Operator Compartment Repair…274

General…274

Remove…279

Install…280

Gauges and Switches Repair…280

Window Wipers Repair…281

Single Arm Wipers…281

Double Arm Wipers…281

Window Washer Motor/Pumps…281

Fuse Panel…282

Heater Assembly Repair…283

Remove…283

Heater Control Panel Assembly…283

Blower and Core Assemblies…283

Install…283

Door Handle Assembly…286

Door Retainer Assemblies…286

Window Replacement…287

Front and Rear Windows…287

Lower Door Windows…288

Upper Door (Slider) Windows…288

Top Window…288

Operator Restraint System Repair…289

Label Replacement…289

Description and Operation…323

Hydraulic Oil Supply…323

D117…323

E008…323

Manifold, Section 1 of Hydraulic Plate…323

Two-Spool and Single-Spool Main Control Valves, Section 2 and 3 …325

Flow Amplifier, Section 4 of Hydraulic Plate…325

Return Manifold, Section 5 of Hydraulic Plate…325

Hydraulic Filter…329

Relay Valve (D117 Only)…329

Manual Override (E008 Only)…329

Main Manifold Repair…330

General…330

Valves and Pressure Switches…331

Main Control Valves Repair…333

Single Spool and Two Spool…333

Flow Amplifier Repair…333

Hydraulic Hose Repair…333

Torque Values…333

Measurements and Adjustments…334

Measurements…334

Adjustments…334

Table 1. Accumulator Charge Valve Pressures…324

Table 2. Brake Treadle Settings…324

Table 3. Pressure Settings…335

Hydraulic System…348

Safety Precautions Maintenance and Repair…349

General…354

Description and Operation…354

Hydraulic Plate…354

Main Control Valves…355

Remote Control Valve…355

Lift Manifold…355

Accumulator Charge Valve…356

Directional Control Valve…356

Carriage Solenoid Valves…356

Heat Exchanger System…356

Steering Control System…356

Brake System…357

Lift and Lower Circuit…357

Description…357

Operation…357

Lift Circuit, Normal Speed (Heavy Load)…360

Lift Circuit, High Speed (Light Load)…360

Lowering…360

Lowering Control Valves…360

Repairs…361

General…361

Hydraulic Plate, Remove…361

Remote Control Valve…361

Remove…361

Disassemble…362

Clean and Inspect…363

Assemble…363

Install…363

Main Control Valves…363

Remove…363

Disassemble…363

Clean and Inspect…365

Assemble…365

Install…365

Lift Manifold…365

Remove…365

Clean and Inspect…366

Assemble and Install…366

Checks and Adjustments…367

Pilot Relief Pressure, Check…367

Main Control Valves Relief Pressure, Check…367

Lift Manifold, Check…368

Remote Control Valve, Adjust…368

Tilt Control Circuit…368

Description…368

Operation…369

Tilt Spool…369

Relief Valves in Main Control Valve…369

Relief Valves, Tilt Lock…371

Repairs…371

General…371

Main Control Valve (Two-Spool), Replace…371

Relief Valves, Tilt Lock, Disassemble…372

Clean and Inspect…372

Checks and Adjustments…372

Main Control Valve Relief Pressure, Check…372

Attachment Circuit Valves…373

General…373

Directional Control Valve…373

Carriage Solenoid Valve…373

Repairs…373

Directional Control Valve…373

Remove…373

Disassemble…374

Clean and Inspect…376

Assemble…376

Install…376

Return Control Valves…376

Carriage Solenoid Valve…377

Remove…377

Disassemble…378

Clean and Inspect…378

Assemble…378

Install…378

Checks and Adjustments…378

Other Hydraulic Components…379

Description and Operation…379

Accumulator Charge Valves…379

Relief Valve in Accumulator Charge Circuit…379

Relief Valves in Steering and Lift Circuits…379

Reducer Valve…379

Over Lowering Interrupt…379

Lift Interrupt…379

Hydraulic Filter…380

Checks and Adjustments…380

Relief Valves, Check and Adjust…380

Pilot Pressure, Check…381

Torque Specifications…381

Main Control Valves…381

Remote Control Valves…381

Attachment Control Valve…381

Carriage Solenoid Valve…381

Specifications…381

Hydraulic Pumps Output at 2286 rpm (Governed Speed – No Load)…381

Relief Valves (Approximate Operating Pressures)…382

Check Port Pressures…382

Main Hydraulic Filters…382

Tank Capacity…382

Troubleshooting…383

Lift and Lower Circuit…383

Tilt Circuit…385

Attachment Circuit Valves…387

Attachment Control Valve…388

Carriage Solenoid Valve…389

Other Hydraulic Components…389

Accumulator Circuit…389

2.1 MPa ( 300 psi) Pilot Circuit…390

Park Brake Circuit…390

tables…348

Table 1. Accumulator Charge Valve Pressures…356

Table 2. Brake Treadle Settings…357

hyster-1526432-07-02-srm1041…400

toc…400

Assembly Guide…400

Safety Precautions Maintenance and Repair…401

List of All Special Tools and Equipment Needed for the Assembly…404

General Considerations Before Starting the Job…404

Preparation of the Components Before Assembly…405

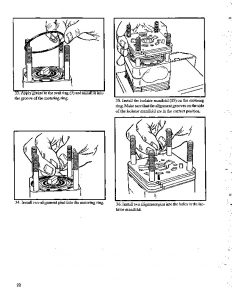

Installation and Checking of the Wheels…406

Installation of the Cab…411

Installation of the Mast…411

Installation of Carriage Equipped With Forks…419

Installation of the Dedicated Carriage…419

Installation of the Gantry…420

Connection of the Hoses and Cables to the Carriages…421

Harness Installation Instructions…423

Installation of the Forks…425

Low-Mounted Forks…425

Installation of the Low-Mount Quick-Disconnect Type Forks…425

Installation of the Low-Mount Pin-Mounted Forks…427

High-Mounted Forks…428

Installation of the High-Mount Quick-Disconnect Forks…428

Installation of the High-Mount Pin-Mounted Forks…429

Installation of the Container Attachment on Forks…430

Installation of the Container Attachment on the Dedicated Carria…432

Installation of the Container Attachment on the Gantry…433

Lights Installation…434

General Procedures After Assembly…435

Accumulator…438

Safety Precautions Maintenance and Repair…439

General…442

Description and Operation…442

Accumulator Maintenance…442

Precharge Check…442

Precharge Filling…442

Remove…443

Disassemble…444

Clean…445

Inspect…445

Repair…445

Assemble…445

Replace…445

Auxiliary Brake Caliper…448

Safety Precautions Maintenance and Repair…449

General…452

Description and Operation…452

Auxiliary Brake Caliper Repair…453

Brake Linings…453

Remove…453

Clean and Inspect…453

Install…454

Auxiliary Caliper…454

Remove…454

Disassemble…455

Caliper…455

Piston Subassembly…456

Clean…457

Inspect…458

Caliper…458

Rotor…458

Piston Return Spring…458

Piston Assembly Return Spring Force and Built-In Clearance…459

Piston Assembly Adjuster Grip Force…460

Grip Force Adjuster Grip Assembly…462

Assemble…463

Piston Subassembly…463

Caliper…464

Install…464

Bleed Brakes…465

Adjust…465

Troubleshooting…466

tables…448

Table 1. Rotor Wear Limits…458

Parking Brake…470

Safety Precautions Maintenance and Repair…471

General…474

Description and Operation…474

Parking Brake Caliper Repair…475

Release Brake Manually…475

Hydraulic Pressure Available…475

Hydraulic Pressure not Available…475

Remove…475

Disassemble…476

Clean…478

Inspect…478

Linings…478

Disc…478

Caliper Parts…479

Assemble…479

Install…481

Bleed Brakes…481

Adjust…482

Test…482

Specifications…483

Troubleshooting…483

tables…470

Table 1. Disc Wear Limits…479

Table 2. Torque Requirements…483

Table 3. Wear Limits…483

Table 4. Lining to Disc Clearance…483

hyster-1531822-11-03-srm1038…488

toc…488

Service Brake…488

Safety Precautions Maintenance and Repair…489

General…492

Description and Operation…492

Repair…493

Remove…493

Brake Assembly…493

Spindle and Brake Cover…496

Disassemble…497

Clean…499

Ground and Polished Parts…499

Parts With Rough Finish…499

Wet Disc Brake and Axle Assembly…499

Inspect…499

Face Seals…499

Disc…500

Wear Limits…500

Replace…500

Parts…500

Assemble…500

Brake Housings…500

Install…503

Hub Oil Seals…503

Double Seals…503

Single Seal…503

Spindle and Brake Cover…504

Brake Housing…506

Specifications…509

Brake Coolant…512

Coolant Change Intervals…512

Break-In…512

Normal Maintenance…512

Hydraulic Fluid…512

Troubleshooting…512

tables…488

Table 1. FRICTION DISC…500

Table 2. STATIONARY DISC…500

Table 3. Wheel Hub and Brake Housing Torque Chart…509

Table 4. Brake Housing Cover Torque Chart…511

Cooling System…574

Safety Precautions Maintenance and Repair…575

General…578

Description…579

Radiator…579

Radiator Cap…579

Thermostat…579

Water Pump…580

Fan and Fan Shroud…580

Cooling System Checks…580

Radiator…580

Thermostat…580

Water Pump…581

Exhaust Leaks…581

Fan and Fan Shroud…581

Radiator Cleaning…581

Drain…581

Clean…581

Fill…582

Troubleshooting…583

hyster-897948-11-03-srm0634…586

toc…586

Four-Speed Powershift Transmission…586

Safety Precautions Maintenance and Repair…587

General…590

Automatic Powershift Control…591

Transmission Control System…591

Transmission Control Lever…591

Mechanical Description and Operation…593

General…593

Torque Converter…593

Description…593

Operation…593

Clutch Assemblies…593

Description…593

Operation…594

Transmission Operation in Neutral…597

Input Shaft, Forward Shaft, and Clutch Assembly…597

Description…597

Operation…597

Reverse, Second-Speed, and First-Speed Shaft and Clutch Assembli…601

Description…601

Operation…601

Third-Speed Shaft, Gear, and Clutch Assembly…601

Description…601

Operation…601

Fourth-Speed Shaft and Clutch…601

Description…601

Operation…602

Output Shaft…602

Description…602

Operation…602

Hydraulic Description and Operation…602

Sump, Filter, and Pump…602

Transmission Charge Pump…602

Pressure Regulator Valve…602

Relief Valve…602

Transmission Control Valve…603

Solenoid Valves…604

Direction Spools…604

Range Spools…604

Modulator Valves…604

tables…586

Table 1. Gear, Solenoid, and Clutch Selections…594

hyster-897949-11-03-srm0635…610

toc…610

Four-Speed Powershift Transmission…610

Safety Precautions Maintenance and Repair…611

General…614

Torque Converter Repair…615

Torque Converter, Remove…615

Torque Converter, Disassemble…615

Clean and Inspect…615

Torque Converter, Assemble…615

Torque Converter (Turbine) Housing, Disassemble…618

Relief Valve for Lube Pressure, Disassemble and Assemble…618

Oil Sealing Rings Sleeve, Replace…618

Torque Converter Housing, Assemble…619

Torque Converter, Install…619

Transmission Repair…619

Remove, Transmission Only…619

Remove, Transmission and Engine Assembly…620

Transmission, Disassemble…621

Output Shaft, Disassemble and Assemble…622

Fourth-Speed Shaft, Disassemble and Assemble…623

Third-Speed Shaft, Disassemble and Assemble…624

Forward Shaft and Clutch, Disassemble and Assemble…627

Reverse and Second-Speed Shaft and Clutch, Disassemble and Assem…629

First-Speed Shaft and Clutch, Disassemble and Assemble…631

Input Shaft, Disassemble and Assemble…633

Speed Sensor, Install…633

Transmission, Clean and Inspect…635

Transmission, Assemble…635

Control Valve…637

Clean and Inspect…637

Assemble and Install…637

Install, Transmission …638

Install, Transmission and Engine Assembly…638

Clean Oil System of Transmission after Major Repair…639

Automatic Powershift Control (APC 100)…639

Functional Description…639

Fuses…642

Transmission Control Lever…642

First-Speed Shaft Bearings Adjustment…645

Torque Converter Stall Speed Check…648

Transmission Oil Pressures Check…648

Clutch Pressures Check…648

Torque Converter (Torque Converter Regulator) Oil Pressure Check…648

Troubleshooting…650

Transmission Controller (APC 100)…651

tables…610

Table 1. Flange Nut Torque…635

Table 2. APC 100 Control Module (Pin Connections)…641

Table 3. Hobbs Gear Selector Connections…644

Table 4. Example Torque Values at Dimensions Shown…646

Table 5. Transmission Pressures…649

hyster-910030-11-03-srm0047…658

toc…658

Planetary Gear Axle…658

Safety Precautions Maintenance and Repair…659

General…662

Description…662

Operation…663

Planetary Gear Axle Repair…664

Remove…664

Disassemble…664

Planetary Axle, Disassemble…667

Assemble and Install…671

Planetary Axle, Assemble…672

Torque Specifications…677

Troubleshooting…680

tables…658

Table 1. Axle-to-Frame Fasteners…671

Table 2. Standard Torque Values for Axle Fasteners…677

Table 3. Drive Wheel Nut Torque…677

Description…704

Differential Repair…704

Remove…704

Differential Carrier From Axle Housing, Remove…704

Differential and Ring Gear From Differential Carrier, Remove…708

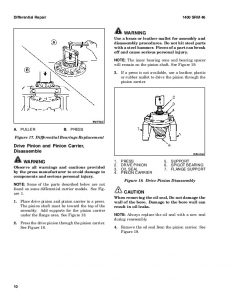

Drive Pinion and Pinion Carrier From Differential Carrier, Remov…710

Disassemble…711

Differential and Ring Gear Assembly, Disassemble…711

Drive Pinion and Pinion Carrier, Disassemble…713

Clean and Inspect…715

Assemble…716

Pinion, Bearings, and Pinion Carrier, Assemble…716

Pinion Bearings, Adjust Preload…717

Press Method…717

Yoke or Flange Method…717

Triple-Lip Seal, Install…718

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion)…719

Differential and Ring Gear, Assemble…721

Differential Gears Rotating Torque, Check…724

Differential and Ring Gear Assembly, Install…725

Differential Bearings, Preload Adjust…726

Ring Gear, Runout Check…727

Ring Gear Backlash, Adjust…727

Gear Set, Tooth Contact Pattern Check…729

Thrust Screw, Install and Adjust…731

Install…732

Differential Assembly Into Axle Housing, Install…732

Specifications…734

Troubleshooting…738

tables…700

Table 1. Ring Gear Backlash Adjustment Specifications…728

Table 2. Ring and Pinion Tooth Contact Adjustment…730

Table 3. General Specifications…734

Table 4. Rivet Installation Pressure…734

Table 5. Pinion Adjustment…734

Table 6. Pinion Preload Pressure…735

Table 7. Torque Specifications…736

Table 8. Torque Specifications for Metric Hardware…737

Table 9. Torque Specifications for Metric (Fine) Hardware…737

hyster-910091-10-03-srm0097…742

toc…742

Hydraulic Gear Pumps…742

Safety Precautions Maintenance and Repair…743

Description…746

Operation…747

Flow Control Valve…747

Relief Valve…748

Hydraulic Gear Pump Repair…748

Remove…748

Disassemble…749

Clean…749

Inspect…750

Assemble…753

Install…755

Pump Output Check…755

Method No. 1…755

Method No. 2…756

Hydraulic System Air Check…757

Troubleshooting…758

hyster-910102-10-03-srm0103…764

toc…764

Tilt Cylinders…764

Safety Precautions Maintenance and Repair…765

General…768

Description…768

Tilt Cylinder Repair…768

Remove…768

Disassemble…768

Clean…768

Assemble…769

Tilt Cylinders With O-Ring or Single-Lip Seals…769

Tilt Cylinders for XM and XMS Models…770

Tilt Cylinders for H700-800A and Early Model H700-920B…771

Install…772

Tilt Cylinders Using Chevron Packing…773

Install…774

Tilt Cylinder Leak Check…776

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…777

Torque Specifications…778

Piston Rod Nut…778

Retainer…779

Troubleshooting…781

tables…764

Table 1. Movement Rates (Maximum) for Tilt Cylinders…777

hyster-910110-12-03-srm0143…784

toc…784

Instrument Panel Indicators and Senders…784

Safety Precautions Maintenance and Repair…785

General…788

Description…789

Steering Column Gauges, Meters, and Indicators…789

LED Display Panel…789

Battery Discharge Indicators…789

Brush Wear Indicators…796

Motor Temperature Indicators…796

LX Series Display Panel…798

Hourmeter Functions…798

Battery Indicator Function…799

Status Code Function…800

ZX Series Display Panels…800

Display Panel…800

Basic Display Panels…800

Performance Display…803

Brush Wear Indicators…806

Adjustments – General…807

Replacement – General Information…807

Meter Replacement…808

Sender Replacement…809

Fuel Level Sender…809

Pressure and Temperature Sender…809

ITW Display Panel Replacement…810

Remove…810

Column Mount Display Panel (EV-100/200ZX Motor Controllers) Repl…811

Remove…811

Display Panel Assembly, Replace…811

Indicator LEDs…812

Battery Indicators…812

Digital Display (Performance Display Panel Only)…812

Status Code or Performance Level Switches and Indicator LEDs (Pe…812

Basic Display Panel, Replace Parts…812

Performance Display Panel, Replace Parts…814

Dash Mount Display Panel (EV100/200ZX Motor Controllers) Replace…815

Remove and Replace…815

Specifications…815

Meter Specifications…815

Sender Specifications…816

Troubleshooting…816

Meter…816

hyster-910442-03-03-srm0231…820

toc…820

Metric and Inch (SAE) Fasteners…820

Safety Precautions Maintenance and Repair…821

General…824

Threaded Fasteners…824

Nomenclature, Threads…824

Strength Identification…825

Cotter (Split) Pins…825

Fastener Torque Tables…830

Conversion Table…832

tables…820

Table 1. Bolts and Screws…826

Table 2. Studs and Nuts…827

Table 3. Torque Nuts…828

Table 4. Torque Nuts With Nylon Insert…829

Table 5. Torque Values for Metric Fasteners*…830

Table 6. Torque Values for Inch Fasteners*…831

Table 7. Conversion Table for Metric and English units…832

Table 8. Cotter Pin Dimensional Data…833

Hyster H800-970E, H1050EH (D117) Repair Service Manual