Complete service repair manual for Hyster H440-700F/FS (E008) Forklifts Trucks, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster H440-700F/FS (E008) workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

897414 – Hyster H440-700F/FS (E008) Service Manual.pdf

Total Pages: 803 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section |

Part No.

|

SRM Number | Rev Date |

| FRAME |

897455

|

0100 SRM 0486 | 05/92 |

| FRAME – TIER 2 EMISSIONS ENGINE |

1529748

|

0100 SRM 1042 | 09/02 |

| COOLING SYSTEM |

897934

|

0700 SRM 0626 | 11/01 |

| THREE-SPEED PS TRANSMISSION – DESCR / OPER |

897240

|

1300 SRM 0375 | 11/01 |

| THREE-SPEED PS TRANSMISSION – REPAIR |

897241

|

1300 SRM 0376 | 09/97 |

| DIFFERENTIAL |

910072

|

1400 SRM 0046 | 11/03 |

| PLANETARY GEAR AXLE |

910030

|

1400 SRM 0047 | 11/03 |

| STEERING AXLE |

910031

|

1600 SRM 0071 | 07/97 |

| STEERING SYSTEM |

897367

|

1600 SRM 0429 | 04/97 |

| BRAKE SYSTEM |

897433

|

1800 SRM 0472 | 04/92 |

| ACCUMULATOR |

1529749

|

1800 SRM 1036 | 09/02 |

| PARKING BRAKE |

1531821

|

1800 SRM 1037 | 02/03 |

| SERVICE BRAKES (Later Units) |

1531822

|

1800 SRM 1308 | 11/03 |

| AUXILARY BRAKE CALIPER |

1531815

|

1800 SRM 1040 | 04/03 |

| HYDRAULIC GEAR PUMPS |

910091

|

1900 SRM 0097 | 10/03 |

| HYDRAULIC SYSTEM |

897463

|

1900 SRM 0492 | 03/03 |

| TILT CYLINDERS |

910102

|

2100 SRM 0103 | 10/03 |

| ALTERNATOR |

899784

|

2200 SRM 0002 | 10/03 |

| STARTER |

910107

|

2200 SRM 0106 | 02/01 |

| INSTRUMENT PANEL INDICATORS and SENDERS |

910110

|

2200 SRM 0143 | 12/03 |

| MAST |

897462

|

4000 SRM 0491 | 04/92 |

| EXTENDABLE CONTAINER ATTACHMENT |

910457

|

5000 SRM 0265 | 11/97 |

| FIXED CONTAINER ATTACHMENT |

910466

|

5000 SRM 0266 | 11/97 |

| INCH (SAE) and METRIC FASTENERS |

910442

|

8000 SRM 0231 | 03/03 |

| PERIODIC MAINTENANCE |

897456

|

8000 SRM 0487 | 10/03 |

| DIAGRAMS |

897457

|

8000 SRM 0488 | 02/97 |

| CAPACITIES and SPECIFICATIONS |

897458

|

8000 SRM 0489 | 02/02 |

| PERIODIC MAINTENANCE – TIER 2 EMISSION |

1523596

|

8000 SRM 1023 | 09/03 |

| DIAGRAMS – TIER 2 EMISSION |

1524437

|

8000 SRM 1035 | 09/03 |

| For service and repair information on Cummins diesel engines, | |||

| see a dealer for Cummins diesel engines. | |||

| PART NO. 897452 | |||

| REV. 12/03 | |||

Periodic Maintenance…..2

Safety Precautions Maintenance and Repair…..3

General…..6

Serial Number Data…..6

How to Move Disabled Truck…..6

How to Tow Lift Truck…..7

How to Put Lift Truck on Blocks…..7

How to Raise Drive Tires…..7

How to Raise Steering Tires…..8

Maintenance Schedule…..9

Maintenance Procedures Every 8 Hours or Daily…..15

How to Make Checks With Engine Stopped…..15

Hydraulic System Oil…..15

Engine Oil…..15

Drive Belt…..16

Cooling System…..16

Battery…..17

Splash Fuses…..17

Air Filter…..18

Fuel System…..18

Fuel Filter/Water Separator…..18

Tires and Wheels…..19

Forks…..19

Adjust…..19

Remove…..19

Low Mount Fork, Install…..20

High Mount Fork, Install…..20

Forks, Mast, and Lift Chains Inspection…..20

Safety Labels…..21

Operator Restraint System…..21

How to Make Checks With Engine Running…..22

Engine Fault Codes…..22

Gauges, Lights, Horn, Fuses, Control Levers, and Pedals…..28

Transmission Oil…..28

Lift System Operation…..29

Attachments…..29

Hydraulic Oil Filters…..29

Brakes…..30

Steering System…..30

Maintenance Procedures Every 250 Hours or 2 Months…..30

Engine Oil and Filter…..30

Drive Shaft…..30

Steering Axle…..30

Mast…..30

Lift Chains…..31

Wear Check…..31

Lubrication…..31

Adjust…..32

Forks…..32

Wheel Nuts…..32

Hydraulic Tank Breathers…..32

Air Filter, Heater…..32

Drive Axle and Differential…..32

Container Attachments…..32

Drive Belt…..32

Maintenance Procedures Every 500 Hours or 4 Months…..33

Transmission Oil Filter…..33

Fuel Filter/Water Separator…..33

Coolant Filter…..33

Maintenance Procedures Every 1000 Hours or 6 Months…..33

Steer Wheel Bearing Nut…..33

Transmission Oil…..34

Mast…..34

Other Lubrication…..34

Engine Speeds…..35

Idle Speed…..35

Governed Speed…..35

Maintenance Procedures Every 2000 Hours or Yearly…..35

Hydraulic System…..35

Steer Wheel Bearings…..35

Drive Wheel Bearings…..35

Differential and Drive Axle…..35

Brakes…..36

Tilt Cab Operation…..36

Raise Cab…..36

Lower Cab…..36

System Air Removal…..37

Safety Procedures When Working Near Mast…..38

Lift and Tilt System Leaks Check…..39

Lift System…..39

Tilt System…..40

Wheel and Tire Replacement…..40

Remove Wheels From Lift Truck…..40

Remove Tire From Wheel…..41

Install Tire on Wheel…..42

Add Air to Tires…..44

Wheels, Install…..45

tables…..2

Table 1. Maintenance Schedule…..9

Table 2. Maintenance Schedule, Container Attachments…..14

Table 3. Error Code Descriptions…..23

Table 4. Steer Wheel Nut Torque Specifications…..34

hyster-1524437-09-03-srm1035…..48

toc…..48

Diagrams…..48

Safety Precautions Maintenance and Repair…..49

hyster-1529748-09-02-srm1042…..68

toc…..68

Frame…..68

Safety Precautions Maintenance and Repair…..69

General…..72

Description…..72

Counterweight Repair…..72

Remove…..72

Install…..73

Fenders Repair…..73

Remove…..73

Install…..74

Hood Repair…..74

Remove…..74

Install…..74

Hydraulic Tank Repair…..76

Remove…..76

Repair…..77

Small Leaks…..77

Large Leaks…..77

Clean…..77

Steam Method…..77

Chemical Solution Method…..77

Other Methods of Preparation for Repair…..78

Install…..78

Fuel Tank Repair…..78

Remove…..78

Repair…..79

Install…..79

Oil Cooler…..79

Remove…..79

Clean…..79

Install…..80

Radiator Repair…..80

Remove…..80

Clean…..80

Install…..80

Engine Repair…..82

Remove…..82

Install…..84

Operator Compartment and Cab…..85

General…..85

Remove…..85

Install…..89

Repairs…..89

Gauges and Switches…..89

Window Wipers…..90

Window Washer Motor/Pumps…..90

Heater Assembly…..91

Heater Control Panel Assembly, Remove…..91

Blower and Core Assemblies, Remove…..92

Install…..92

Fuse Panel…..92

Operator Restraint System…..92

Door Handle Assembly…..93

Door Retainer Assemblies…..93

Window Replacement…..94

Front and Rear Windows…..95

Lower Door Windows…..96

Upper Door (Slider) Windows…..96

Tilt Cab Repair…..96

General…..96

Repairs…..98

Tilt Cylinder…..98

Latch…..98

Pump…..98

Label Replacement…..101

tables…..68

Table 1. Material Specifications for Cab Windows…..94

hyster-1529749-09-02-srm1036…..106

toc…..106

Accumulator…..106

Safety Precautions Maintenance and Repair…..107

General…..110

Description and Operation…..110

Accumulator Maintenance…..110

Precharge Check…..110

Precharge Filling…..110

Remove…..111

Disassemble…..112

Clean…..113

Inspect…..113

Repair…..113

Assemble…..113

Replace…..113

hyster-1531815-04-03-srm1040…..116

toc…..116

Auxiliary Brake Caliper…..116

Safety Precautions Maintenance and Repair…..117

General…..120

Description and Operation…..120

Auxiliary Brake Caliper Repair…..121

Brake Linings…..121

Remove…..121

Clean and Inspect…..121

Install…..122

Auxiliary Caliper…..122

Remove…..122

Disassemble…..123

Caliper…..123

Piston Subassembly…..124

Clean…..125

Inspect…..126

Caliper…..126

Rotor…..126

Piston Return Spring…..126

Piston Assembly Return Spring Force and Built-In Clearance…..127

Piston Assembly Adjuster Grip Force…..128

Grip Force Adjuster Grip Assembly…..130

Assemble…..131

Piston Subassembly…..131

Caliper…..132

Install…..132

Bleed Brakes…..133

Adjust…..133

Troubleshooting…..134

tables…..116

Table 1. Rotor Wear Limits…..126

hyster-1531821-02-03-srm1037…..138

toc…..138

Parking Brake…..138

Safety Precautions Maintenance and Repair…..139

General…..142

Description and Operation…..142

Parking Brake Caliper Repair…..143

Release Brake Manually…..143

Hydraulic Pressure Available…..143

Hydraulic Pressure not Available…..143

Remove…..143

Disassemble…..144

Clean…..146

Inspect…..146

Linings…..146

Disc…..146

Caliper Parts…..147

Assemble…..147

Install…..149

Bleed Brakes…..149

Adjust…..150

Test…..150

Specifications…..151

Troubleshooting…..151

tables…..138

Table 1. Disc Wear Limits…..147

Table 2. Torque Requirements…..151

Table 3. Wear Limits…..151

Table 4. Lining to Disc Clearance…..151

hyster-1531822-11-03-srm1038…..156

toc…..156

Service Brake…..156

Safety Precautions Maintenance and Repair…..157

General…..160

Description and Operation…..160

Repair…..161

Remove…..161

Brake Assembly…..161

Spindle and Brake Cover…..164

Disassemble…..165

Clean…..167

Ground and Polished Parts…..167

Parts With Rough Finish…..167

Wet Disc Brake and Axle Assembly…..167

Inspect…..167

Face Seals…..167

Disc…..168

Wear Limits…..168

Replace…..168

Parts…..168

Assemble…..168

Brake Housings…..168

Install…..171

Hub Oil Seals…..171

Double Seals…..171

Single Seal…..171

Spindle and Brake Cover…..172

Brake Housing…..174

Specifications…..177

Brake Coolant…..180

Coolant Change Intervals…..180

Break-In…..180

Normal Maintenance…..180

Hydraulic Fluid…..180

Troubleshooting…..180

tables…..156

Table 1. FRICTION DISC…..168

Table 2. STATIONARY DISC…..168

Table 3. Wheel Hub and Brake Housing Torque Chart…..177

Table 4. Brake Housing Cover Torque Chart…..179

hyster-897240-11-01-srm0375…..186

toc…..186

Three-Speed Powershift Transmission…..186

Safety Precautions Maintenance and Repair…..187

General…..190

Mechanical Description…..191

General…..191

Torque Converter…..191

Description…..191

Operation…..191

Clutch Assemblies…..191

Description…..191

Operation…..191

Forward Shaft…..193

Reverse Shaft…..194

First Speed Shaft…..194

Output Shaft…..194

Hydraulic Operation…..196

Sump, Filter, and Pump…..196

Shift Control Valve…..196

Solenoid Valves…..196

Inching Spool…..196

Direction Spools…..196

Range Spools…..199

Modulator Valve and Manifold Block…..199

Operation…..199

Transmission Control System H17.00-32.00C (H370-700C)…..202

Transmission Control System H20.00-32.00F (H440-700F) (without a…..202

Transmission Control System H20.00-32.00F (with auto shift APC 1…..208

Gear Selector…..208

Automatic Powershift Control…..209

Bypass Box and Bypass Plug…..210

Hydraulic Circuits…..210

Cooling and Lubrication…..210

Operation of Transmission, Neutral…..210

Operation of Transmission, Forward – First…..210

Operation of Transmission, Reverse – First…..210

Operation of Transmission, Forward – Second…..213

Operation of Transmission, Forward – Third – Inching…..214

Safety Precautions Maintenance and Repair…..369

General…..372

Serial Number Data…..372

How to Move Disabled Lift Truck…..372

How to Tow Lift Truck…..373

How to Put Lift Truck on Blocks…..373

How to Raise Drive Tires…..373

How to Raise Steering Tires…..374

Maintenance Schedule…..375

Maintenance Procedures Every 8 Hours or Daily…..379

How to Make Checks With Engine Stopped…..379

Hydraulic System Oil…..379

Engine Oil…..380

Drive Belt…..380

Cooling System…..381

Battery…..381

Air Filter…..381

Fuel System…..382

Water Separator (Fuel Filter)…..382

Tires and Wheels…..383

Forks…..383

Adjust…..383

Remove…..383

Low Mount Fork, Install…..384

High Mount Fork, Install…..384

Forks, Mast, and Lift Chains, Inspect…..384

Safety Labels…..385

Operator Restraint System…..385

How to Make Checks With Engine Running…..386

Gauges, Lights, Horn, Fuses, Control Levers, and Pedals…..386

Transmission Oil…..387

Lift System Operation…..387

Attachments…..387

Hydraulic Oil Filters…..387

Brakes…..388

Steering System…..388

Maintenance Procedures Every 250 Hours or 2 Months…..388

Engine Oil and Filter…..388

Drive Shaft…..388

Steering Axle…..388

Mast…..389

Lift Chains…..389

Wear Check…..389

Lubrication…..390

Adjustments…..390

Forks…..390

Wheel Nuts…..390

Hydraulic Tank Breathers…..390

Air Filter, Heater…..390

Drive Axle and Differential…..390

Container Attachments…..390

Drive Belt…..391

Maintenance Procedures Every 500 Hours or 4 Months…..391

Transmission Oil Filter…..391

Fuel Filters…..391

Coolant Filter…..391

Maintenance Procedures Every 1000 Hours or 6 Months…..393

Steer Wheel Bearing Nut…..393

Transmission Oil…..394

Mast…..394

Other Lubrication…..394

Fuel System…..394

Idle Speed…..394

Governed Speed…..394

Maintenance Procedures Every 2000 Hours or Yearly…..395

Hydraulic System…..395

Steer Wheel Bearings…..395

Drive Wheel Bearings…..395

Differential and Drive Axle…..395

Brakes…..396

Tilt Cab Operation…..396

Raise Cab…..396

Lower Cab…..396

Fuel System Air Removal…..397

Safety Procedures When Working Near Mast…..397

Lift and Tilt System Leaks Check…..399

Lift System…..399

Tilt System…..399

Wheels and Tires…..400

Remove Wheels From Lift Truck…..400

Remove Tire From Wheel…..401

Install Wheel in Tire…..402

Install Tire on Wheel…..403

Add Air to Tires…..404

Install Wheels…..405

tables…..368

Table 1. Maintenance Schedule…..375

Table 2. Maintenance Schedule, Container Attachments…..379

Table 3. Steer Wheel Nut Torque Specifications…..393

Safety Precautions Maintenance and Repair…..425

Lift Truck Weights…..428

Container Attachment Weights…..428

Mast Speeds…..429

Engine Specifications…..429

Specifications…..430

Capacities…..430

Electrical System…..430

Transmission Pressures…..431

Tires…..432

Torque Specifications…..432

Brake System…..432

Container Attachment…..432

Differential…..432

Drive Line and Axle…..432

Engine…..432

Frame…..433

Hydraulic System Selector Valve…..433

Mast and Carriages…..433

Steering…..433

Torque Converter…..434

Transmission…..434

Hydraulic System…..466

Safety Precautions Maintenance and Repair…..467

General…..472

Description and Operation…..472

Hydraulic Module…..472

Main Control Valves…..472

Remote Control Valve…..472

Lift Manifold…..473

Accumulator Charge Valve…..473

Relief Valve and Pressure Reducing Valves…..473

Directional Control Valve…..473

Return Control Solenoid Valves…..473

Carriage Solenoid Valves…..473

Heat Exchanger System…..473

Steering Control System…..474

Brake System…..474

Lift and Lower Circuit…..474

Description…..474

Operation…..475

Lift Circuit, Normal Speed (Heavy Load)…..477

Lift Circuit, High Speed (Light Load)…..477

Two-Speed Cartridge…..477

Lowering…..478

Lowering Control Valves…..478

Repairs…..478

General…..478

Hydraulic Module, Remove…..478

Hydraulic Module, Install…..479

Remote Control Valve…..479

Remove…..479

Disassemble…..479

Clean and Inspect…..480

Assemble…..480

Install…..482

Adjust…..482

Main Control Valves…..482

Remove…..482

Disassemble…..482

Clean and Inspect…..484

Assemble…..484

Install…..484

Lift Manifold…..485

Remove…..485

Clean and Inspect…..485

Assemble and Install…..485

Checks and Adjustments…..486

Pilot Pressure, Check…..486

Main Control Valves Relief Pressure, Check…..487

Two-Speed Cartridge, Check…..487

Tilt Control Circuit…..487

Description…..487

Operation…..488

Tilt Spool…..488

Relief Valves in Main Control Valve…..488

Relief Valves, Tilt Lock…..489

Repairs…..489

General…..489

Relief Valves, Tilt Lock, Disassemble…..489

Clean and Inspect…..490

Checks and Adjustments…..490

Main Control Valve Relief Pressure, Check…..490

Flow Control Valves Repair…..490

Description…..490

Accumulator Charge Valve…..490

Relief Valves…..492

Pressure Reduction Valves…..492

Repairs…..492

Accumulator Charge Valve…..492

Relief Valve…..492

Pressure Reduction Valves…..493

Checks and Adjustments…..493

Relief Valves, Check and Adjust…..493

Pressure Reduction Valves Check…..493

Solenoid Valves Repair…..494

Description…..494

Directional Control Valve, Carriage/Attachment…..494

Repairs…..495

Directional Control Valve, Carriage/Attachment…..495

Remove…..495

Disassemble…..495

Clean and Inspect…..497

Assemble…..497

Install…..499

Return Control Solenoid Valves…..499

Remove…..499

Install…..500

Return Control Solenoid…..500

Remove…..500

Install…..500

Carriage Solenoid Valves…..501

Remove…..501

Disassemble…..502

Clean and Inspect…..502

Assemble…..502

Install…..502

Over Lowering Interrupt…..502

Lift Interrupt…..502

Checks and Adjustments…..503

Torque Specifications…..503

Control Valves…..503

Remote Control Valve…..503

Control Valve, Carriage/Attachment…..503

Carriage Solenoid Valve…..503

Specifications…..503

Hydraulic Pump Output at 2500 rpm and 13.8 MPa ( 2000 psi)…..503

Pressure Reduction Valves…..503

Relief Pressures at 2500 rpm…..503

Main Hydraulic Filters…..504

Tank Capacity…..504

Troubleshooting…..504

Control Valves…..504

Remote Control Valve…..507

Flow Control Valves…..507

Accumulator Charge Valve and Accumulator…..507

Pressure Reduction Valve 2.1 MPa ( 300 psi)…..507

Pressure Reduction Valve 10.3 MPa ( 1500 psi)…..508

Solenoid Valves…..509

Control Valve for Carriage and Attachment…..509

tables…..466

Table 1. Accumulator Charge Valve Pressures…..473

hyster-897934-11-01-srm0626…..524

toc…..524

Cooling System…..524

Safety Precautions Maintenance and Repair…..525

General…..528

Description…..529

Radiator…..529

Radiator Cap…..529

Thermostat…..529

Water Pump…..530

Fan and Fan Shroud…..530

Cooling System Checks…..530

Radiator…..530

Thermostat…..530

Water Pump…..531

Exhaust Leaks…..531

Fan and Fan Shroud…..531

Radiator Cleaning…..531

Drain…..531

Clean…..531

Fill…..532

Troubleshooting…..533

hyster-899784-10-03-srm0002…..536

toc…..536

Alternator with Regulator…..536

Safety Precautions Maintenance and Repair…..537

General…..540

Description…..540

Alternator Repair…..542

Alternator Type A…..542

Remove and Disassemble…..542

Clean…..543

Assemble…..544

Install…..544

Alternator Type B…..547

Remove and Disassemble…..547

Clean…..547

Assemble…..548

Install…..549

General Check and Adjustment…..550

Low Output Check (Type A or Type B)…..550

High Output Check (Type A or Type B)…..552

Brushes Circuit Check…..553

Delco Alternators…..553

Motorola Alternators…..554

Diodes Check…..555

Diode Bridge Check…..555

Delco and Leece-Neville Alternators…..555

Motorola Alternators…..555

Rotor Field Winding Check…..556

Stator Windings Check…..557

Voltage Regulator Check…..557

Troubleshooting…..557

hyster-910030-11-03-srm0047…..562

toc…..562

Planetary Gear Axle…..562

Safety Precautions Maintenance and Repair…..563

General…..566

Description…..566

Operation…..567

Planetary Gear Axle Repair…..568

Remove…..568

Disassemble…..568

Planetary Axle, Disassemble…..571

Assemble and Install…..575

Planetary Axle, Assemble…..576

Torque Specifications…..581

Troubleshooting…..584

tables…..562

Table 1. Axle-to-Frame Fasteners…..575

Table 2. Standard Torque Values for Axle Fasteners…..581

Table 3. Drive Wheel Nut Torque…..581

Differential…..604

Safety Precautions Maintenance and Repair…..605

General…..608

Description…..608

Differential Repair…..608

Remove…..608

Differential Carrier From Axle Housing, Remove…..608

Differential and Ring Gear From Differential Carrier, Remove…..612

Drive Pinion and Pinion Carrier From Differential Carrier, Remov…..614

Disassemble…..615

Differential and Ring Gear Assembly, Disassemble…..615

Drive Pinion and Pinion Carrier, Disassemble…..617

Clean and Inspect…..619

Assemble…..620

Pinion, Bearings, and Pinion Carrier, Assemble…..620

Pinion Bearings, Adjust Preload…..621

Press Method…..621

Yoke or Flange Method…..621

Triple-Lip Seal, Install…..622

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion)…..623

Differential and Ring Gear, Assemble…..625

Differential Gears Rotating Torque, Check…..628

Differential and Ring Gear Assembly, Install…..629

Differential Bearings, Preload Adjust…..630

Ring Gear, Runout Check…..631

Ring Gear Backlash, Adjust…..631

Gear Set, Tooth Contact Pattern Check…..633

Thrust Screw, Install and Adjust…..635

Install…..636

Differential Assembly Into Axle Housing, Install…..636

Specifications…..638

Troubleshooting…..642

tables…..604

Table 1. Ring Gear Backlash Adjustment Specifications…..632

Table 2. Ring and Pinion Tooth Contact Adjustment…..634

Table 3. General Specifications…..638

Table 4. Rivet Installation Pressure…..638

Table 5. Pinion Adjustment…..638

Table 6. Pinion Preload Pressure…..639

Table 7. Torque Specifications…..640

Table 8. Torque Specifications for Metric Hardware…..641

Table 9. Torque Specifications for Metric (Fine) Hardware…..641

hyster-910091-10-03-srm0097…..646

toc…..646

Hydraulic Gear Pumps…..646

Safety Precautions Maintenance and Repair…..647

Description…..650

Operation…..651

Flow Control Valve…..651

Relief Valve…..652

Hydraulic Gear Pump Repair…..652

Remove…..652

Disassemble…..653

Clean…..653

Inspect…..654

Assemble…..657

Install…..659

Pump Output Check…..659

Method No. 1…..659

Method No. 2…..660

Hydraulic System Air Check…..661

Troubleshooting…..662

hyster-910102-10-03-srm0103…..668

toc…..668

Tilt Cylinders…..668

Safety Precautions Maintenance and Repair…..669

General…..672

Description…..672

Tilt Cylinder Repair…..672

Remove…..672

Disassemble…..672

Clean…..672

Assemble…..673

Tilt Cylinders With O-Ring or Single-Lip Seals…..673

Tilt Cylinders for XM and XMS Models…..674

Tilt Cylinders for H700-800A and Early Model H700-920B…..675

Install…..676

Tilt Cylinders Using Chevron Packing…..677

Install…..678

Tilt Cylinder Leak Check…..680

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…..681

Torque Specifications…..682

Piston Rod Nut…..682

Retainer…..683

Troubleshooting…..685

tables…..668

Table 1. Movement Rates (Maximum) for Tilt Cylinders…..681

hyster-910107-02-01-srm0106…..688

toc…..688

Starter…..688

Safety Precautions Maintenance and Repair…..689

General…..692

Description and Operation…..692

Starter Repair…..694

Remove…..694

Disassemble…..694

Clean…..695

Assemble…..695

Install…..696

General Checks and Adjustments…..696

Troubleshooting…..699

hyster-910110-12-03-srm0143…..704

toc…..704

Instrument Panel Indicators and Senders…..704

Safety Precautions Maintenance and Repair…..705

General…..708

Description…..709

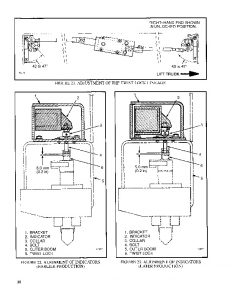

Steering Column Gauges, Meters, and Indicators…..709

LED Display Panel…..709

Battery Discharge Indicators…..709

Brush Wear Indicators…..716

Motor Temperature Indicators…..716

LX Series Display Panel…..718

Hourmeter Functions…..718

Battery Indicator Function…..719

Status Code Function…..720

ZX Series Display Panels…..720

Display Panel…..720

Basic Display Panels…..720

Performance Display…..723

Brush Wear Indicators…..726

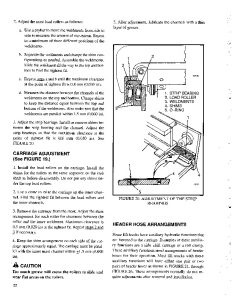

Adjustments – General…..727

Replacement – General Information…..727

Meter Replacement…..728

Sender Replacement…..729

Fuel Level Sender…..729

Pressure and Temperature Sender…..729

ITW Display Panel Replacement…..730

Remove…..730

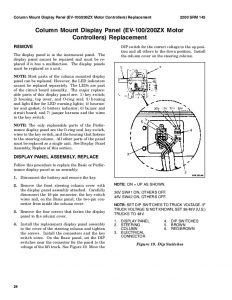

Column Mount Display Panel (EV-100/200ZX Motor Controllers) Repl…..731

Remove…..731

Display Panel Assembly, Replace…..731

Indicator LEDs…..732

Battery Indicators…..732

Digital Display (Performance Display Panel Only)…..732

Status Code or Performance Level Switches and Indicator LEDs (Pe…..732

Basic Display Panel, Replace Parts…..732

Performance Display Panel, Replace Parts…..734

Dash Mount Display Panel (EV100/200ZX Motor Controllers) Replace…..735

Remove and Replace…..735

Specifications…..735

Meter Specifications…..735

Sender Specifications…..736

Troubleshooting…..736

Meter…..736

hyster-910442-03-03-srm0231…..740

Metric and Inch (SAE) Fasteners…..740

General…..744

Threaded Fasteners…..744

Nomenclature, Threads…..744

Strength Identification…..745

Cotter (Split) Pins…..745

Fastener Torque Tables…..750

Conversion Table…..752

tables…..740

Table 1. Bolts and Screws…..746

Table 2. Studs and Nuts…..747

Table 3. Torque Nuts…..748

Table 4. Torque Nuts With Nylon Insert…..749

Table 5. Torque Values for Metric Fasteners*…..750

Table 6. Torque Values for Inch Fasteners*…..751

Table 7. Conversion Table for Metric and English units…..752

Table 8. Cotter Pin Dimensional Data…..753

Hyster H440-700F/FS (E008) Repair Service Manual