Complete Operation Maintenance Manuals for Komatsu Crawler Dozers D50P-16, D50PL-16, D51EXi-22, D51PXi-22, D53A-17, D53P-17, D53A-17, D53P-17, with all the service information to maintain & operate.

KEAM019300 – Crawler Dozer D51EXi-22, D51PXi-22 Operation & Maintenance Manual (SN-B13500&up).pdf

SEAM13FC00 – Bulldozer D50P,PL-16 Operation & Maintenance Manual (SN68001&up).pdf

SEAM026300P – Bulldozer D53A,P-17 Operation & Maintenance Manual (SN82727&up).pdf

SEAM01341703 – Bulldozer D53A,P-17 Operation & Maintenance Manual (SN80001&up).pdf

PRODUCT DETAILS:

Total Pages: 613 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

FOREWORD

BEFORE READING THIS MANUAL . . .

SAFETY INFORMATION . . . .

INTRODUCTION . . .

USE OF MACHINE . . . .

DIRECTIONS OF MACHINE . . . .

PRODUCT IDENTIFICATION . . . .

PRODUCT IDENTIFICATION PLATE . . . .

ENGINE SERIAL NUMBER AND EMISSION LABEL . . .

SERIAL NUMBERS AND DEALER INFORMATION . . .

MODEL: D51EXi/PXi-22 . . . .

INTRODUCTION . . .

MACHINE FEATURES . . .

SAFETY

SAFETY AND WARNING DECALS . . . 1-2

LOCATION OF THE SAFETY DECALS . . . 1-3

GENERAL SAFETY RULES AND PRECAUTIONS . . . 1-8

GENERAL SAFETY RULES . . . 1-8

UNAUTHORIZED MODIFICATIONS . . . . 1-9

GENERAL SAFETY AT JOB SITE . . . 1-9

WORKING ON LOOSE GROUND . . . 1-9

SAFETY FEATURES . . . . 1-10

PERSONAL PROTECTIVE EQUIPMENT . . . 1-10

FIRE AND EXPLOSION PREVENTION . . . . 1-11

FIRE CAUSED BY FUEL OR OIL . . . . 1-11

FIRE CAUSED BY ACCUMULATION OF FLAMMABLE MATERIAL . . . 1-11

FIRE FROM ELECTRICAL SYSTEM . . . 1-12

FIRE FROM HYDRAULIC LINE . . . 1-12

WINDSHIELD WASHER FLUID . . . 1-12

ACTION IF FIRE OCCURS . . . 1-12

DUST HAZARDS . . . 1-12

BLAST ZONE HAZARD . . . 1-13

KEEP OPERATOR’S CAB CLEAN . . . 1-13

UNAUTHORIZED MODIFICATIONS . . . . 1-13

LEAVING OPERATOR’S COMPARTMENT . . . . 1-14

PARKING BRAKE AND EQUIPMENT LOCKS . . . 1-14

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE . . . . 1-15

WHEN STANDING UP FROM OPERATOR’S SEAT . . . 1-15

WHEN LEAVING MACHINE . . . . 1-15

MOUNTING AND DISMOUNTING . . . . 1-16

CRUSH OR PINCH POINT DANGERS . . . 1-16

FIRE EXTINGUISHER AND FIRST AID KIT . . . . 1-16

INSIDE OPERATOR’S COMPARTMENT . . . 1-17

PRECAUTIONS WHEN USING ROPS . . . . 1-17

PRECAUTIONS FOR OPERATION . . . .

IN COLD AREAS . . . .

PRECAUTIONS FOR BLADE AUTOMATIC CONTROL . . . .

PRECAUTIONS BEFORE STARTING OPERATIONS . . . .

PRE-OPERATIONAL CHECKS . . .

STARTING YOUR WORK OPERATIONS . . . .

WORK SITE HAZARDS . . .

AVOIDING DANGEROUS SITUATIONS . . .

HIGH VOLTAGE LINES . . .

RULES FOR ROAD TRAVEL . . . .

PRECAUTIONS WHEN TRAVELING . . . .

USING BRAKES . . . .

RULES FOR TRAVELING IN REVERSE . . .

TRAVELING ON ICY OR SNOW-COVERED SURFACES . . .

WORKING ON LOOSE OR UNSTABLE GROUND . . .

TRAVEL ON SLOPES . . .

PARKING THE MACHINE . . .

PRECAUTIONS DURING MAINTENANCE OPERATIONS . . .

WARNING TAGS . . .

EQUIPMENT STORAGE . . .

WORKING UNDER THE MACHINE . . .

USING DROP LAMPS . . .

KEEPING THE MACHINE CLEAN . . . .

KEEP WORKPLACE CLEAN AND TIDY . . .

APPOINT LEADER WHEN WORKING WITH OTHERS . . .

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE . . . .

RUNNING THE MACHINE DURING MAINTENANCE . . .

RULES FOR REFUELING THE MACHINE . . .

COOLING SYSTEM PRECAUTIONS . . . .

WORK UNDER THE MACHINE . . . .

PRECAUTIONS WHEN USING HAMMER . . . .

TURN THE BATTERY DISCONNECT SWITCH TO THE OFF POSITION . . . .

REPAIR WELDING . . .

ENGINE SYSTEM HIGH VOLTAGE . . .

BATTERY PRECAUTIONS . . . .

STARTING THE MACHINE . . . .

HIGH PRESSURE HOSES . . . .

HANDLING HIGH-PRESSURE HOSES . . . .

PRECAUTION FOR HIGH FUEL PRESSURE . . . .

HIGH TEMPERATURE AREAS . . .

ROTATING PARTS . . .

DISPOSAL OF WASTE MATERIALS . . . .

MERCURY CONTAINING COMPONENT(S) . . . .

USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION . . . .

DO NOT DISASSEMBLE RECOIL SPRING . . .

ACCUMULATOR AND GAS SPRING . . . .

CRITICAL PARTS . . . .

PRECAUTIONS FOR CHECK AND MAINTENANCE . . .

PRECAUTIONS FOR iB GNSS ANTENNA . . . .

TRANSPORTING THE MACHINE . . . . 1-37

LOADING AND SECURING THE MACHINE . . . 1-37

TOWING THE MACHINE . . . . 1-38

OPERATION

GENERAL VIEWS . . . . 2-2

VIEW OF MACHINE . . . 2-2

VIEW OF CONTROLS AND GAUGES . . . . 2-4

MACHINE MONITOR SYSTEM . . . . 2-6

MONITOR LAYOUT . . . 2-6

BASIC OPERATION OF MONITOR PANEL . . . 2-7

CHECK MONITOR SYSTEM . . . . 2-8

MONITOR CHECK ITEMS . . . 2-9

EMERGENCY ALERTS . . . . 2-9

ENGINE OIL PRESSURE CAUTION LAMP . . . 2-9

ENGINE COOLANT TEMPERATURE CAUTION LAMP . . . 2-10

HYDRAULIC OIL TEMPERATURE CAUTION LAMP . . . 2-10

HST CHARGE PRESSURE CAUTION LAMP . . . 2-10

CHARGE FILTER CLOG CAUTION LAMP . . . . 2-10

WARNING ALERTS . . . . 2-11

BATTERY CHARGE CAUTION LAMP . . . 2-11

AIR CLEANER CLOGGING CAUTION LAMP . . . 2-12

WATER IN FUEL LAMP . . . . 2-12

MAINTENANCE CAUTION LAMP . . . 2-12

CONSOLE CONTROL SWITCHES . . . 2-13

SWITCH LAYOUT VIEW . . . . 2-13

LAMP SWITCH . . . 2-13

BUZZER CANCEL SWITCH . . . 2-14

INFORMATION SWITCH . . . 2-14

HEATER SWITCH . . . 2-14

IGNITION SWITCH . . . . 2-15

HORN SWITCH . . . 2-16

WIPER SWITCH . . . 2-16

CAB LAMP SWITCH . . . 2-17

CIGARETTE LIGHTER . . . 2-17

ACCESSORY SOCKET . . . 2-17

METER DISPLAY . . . . 2-18

ENGINE COOLANT TEMPERATURE GAUGE . . . 2-18

HYDRAULIC OIL TEMPERATURE GAUGE . . . 2-19

DISPLAY PANEL (A) . . . . 2-19

FUEL LEVEL GAUGE . . . . 2-23

REVERSE TRAVEL SPEED SET SWITCH . . . 2-23

SHIFT MODE SWITCH . . . 2-23

ENGINE INTAKE AIR PRE-HEAT PILOT LAMP . . . 2-23

DISPLAY PANEL (B) . . . . 2-24

FAN ROTATION SELECTOR SWITCH . . . 2-25

FLOAT MODE MONITOR . . . . 2-25

WARNING LAMP VIEW . . . 2-26

WARNING LAMP (1) . . . .

USING FAILURE CODE DISPLAY . . .

USING MAINTENANCE MODE . . .

METHOD OF SELECTING EACH MODE . . . .

USING OIL AND FILTER MAINTENANCE MODE . . .

USING ADJUSTMENT MODE . . .

CONTROL LEVERS AND PEDALS . . .

LEVER LAYOUT VIEW . . . .

LOCK LEVERS . . .

JOYSTICK (STEERING, DIRECTIONAL AND GEAR . . .

SHIFT LEVER) . . . .

BLADE CONTROL LEVER . . .

ANGLING CONTROL . . . .

WORK EQUIPMENT LOCK LEVER . . . .

FUEL CONTROL DIAL . . .

DECELERATOR PEDAL . . . .

BRAKE PEDAL . . .

PARKING BRAKE LEVER . . . .

DOOR AND WINDOW SYSTEM . . .

DOOR – OPEN LOCK . . .

SASH GLASS INTERMEDIATE LOCK . . .

SAFETY LOCKS AND SECURITY . . .

DOOR LOCK . . . .

CAP, COVER WITH LOCK . . .

METHOD OF OPENING OR CLOSING HYDRAULIC TANK CAP . . . .

OPEN AND CLOSE FUEL FILLER PORT CAP . . . .

OPEN . . . .

CLOSE . . .

METHOD OF OPENING AND CLOSING COVER WITH LOCK . . . .

TO OPEN THE COVER (LOCKED COVER) . . . .

TO LOCK THE COVER . . .

LOCKABLE AREAS . . . .

SEAT POCKET . . . .

ADDITIONAL FEATURES AND ACCESSORIES . . .

AIR CONDITIONER AND FEET HEATER . . . .

GENERAL DESCRIPTION OF CONTROL PANEL . . . .

MODE SELECTOR SWITCH . . . .

BLOWER SPEED SELECTOR SWITCH . . .

TEMPERATURE CONTROL SWITCH . . . .

PRECAUTIONS WHEN USING AIR CONDITIONER . . . .

FEET HEATER . . . .

RADIO . . . .

EXPLANATION OF FEATURES . . .

POWER SWITCH/VOLUME . . .

AUTO-STORE/PRESET SCAN BUTTON . . . .

BASS CONTROL KNOB . . . .

TREBLE CONTROL KNOB . . .

LOUDNESS BUTTON . . . .

TIME/RADIO DISPLAY SELECTOR BUTTON . . .

TAPE EJECT BUTTON . . . 2-54

CASSETTE DOOR . . . 2-54

FAST FORWARD, REWIND BUTTONS . . . 2-54

PRESET BUTTONS . . . . 2-54

METAL TAPE BUTTON . . . . 2-55

MANUAL TUNING BUTTONS . . . . 2-55

SEEK TUNING BUTTONS . . . . 2-55

BAND SELECTOR BUTTON . . . . 2-55

METHOD OF OPERATION . . . . 2-56

LISTENING TO RADIO . . . 2-57

LISTENING TO A CASSETTE TAPE . . . . 2-57

REVERSING TAPE . . . . 2-58

PRECAUTION WHEN USING . . . 2-58

ASHTRAY . . . 2-59

LUNCH BOX HOLDER STRAP . . . 2-59

CUP HOLDER . . . 2-59

TOOL BOX . . . . 2-59

GREASE PUMP HOLDER . . . . 2-60

ELECTRICAL POWER ADAPTER . . . 2-60

BATTERY DISCONNECT SWITCH . . . . 2-61

FUSES . . . 2-62

FUSES . . . . 2-62

FUSE CAPACITIES AND CIRCUIT NAMES . . . 2-62

PRECAUTIONS BEFORE STARTING WORK OPERATIONS . . . 2-65

PRE-OPERATIONAL CHECKS . . . 2-65

WALK-AROUND CHECKS . . . 2-65

CHECKS BEFORE STARTING . . . 2-66

ADJUSTMENTS BEFORE OPERATION . . . 2-80

ADJUST ARMREST . . . . 2-81

FASTENING AND REMOVING SEAT BELT . . . 2-81

ADJUSTING MIRROR . . . . 2-82

OPERATIONS AND CHECKS BEFORE . . . 2-82

STARTING ENGINE . . . 2-82

STARTING THE ENGINE . . . . 2-84

NORMAL OR COLD START PROCEDURES . . . 2-84

COLD WEATHER STARTS . . . 2-85

OPERATIONS AND CHECKS AFTER STARTING ENGINE . . . . 2-89

BREAKING IN THE MACHINE . . . 2-89

WARMING UP ENGINE . . . . 2-89

STARTING IN COLD WEATHER . . . . 2-90

STOPPING THE ENGINE . . . . 2-92

MOVING, STEERING, STOPPING AND PARKING THE MACHINE . . . 2-93

PREPARATIONS FOR MOVING THE MACHINE . . . . 2-93

MOVING MACHINE FORWARD OR REVERSE . . . . 2-94

CHANGING SPEED RANGES . . . 2-96

STEERING THE MACHINE . . . . 2-98

NORMAL TURN . . . . 2-98

MAKING A LEFT OR RIGHT TURN . . . . 2-98

MAKING A PIVOT TURN . . . . 2-99

TURNING WHILE DESCENDING A SLOPE . . . 2-99

COUNTER-ROTATION TURN . . . 2-99

STOPPING THE MACHINE . . . 2-100

PARKING MACHINE . . . . 2-102

CHECK AFTER FINISHING WORK . . . 2-103

CHECK AFTER SHUTTING OFF ENGINE . . . . 2-103

STARTING YOUR WORK OPERATIONS . . . . 2-104

AVOIDING DANGEROUS SITUATIONS . . . . 2-104

HIGH VOLTAGE LINES . . . . 2-106

OPERATING THE MACHINE . . . 2-107

PAY ATTENTION TO GAUGES . . . . 2-107

PERMISSIBLE WATER DEPTH . . . 2-107

METHOD OF USING BRAKES . . . 2-107

WHEN TRAVELING UP OR DOWN HILLS . . . 2-107

PRECAUTIONS ON SLOPES . . . . 2-108

BE AWARE OF FUEL LEVEL . . . . 2-108

PRECAUTIONS WHEN ENGINE STOPS ON A SLOPES . . . . 2-108

ALWAYS KEEP THE DOORS CLOSED DURING OPERATIONS . . . 2-108

DO NOT MODIFY THE CAB GLASS IN ANY WAY . . . . 2-108

PRECAUTIONS FOR BLIND SPOTS CAUSED BY CAB STAYS . . . 2-108

CUTTING A GRADE . . . 2-109

DOZING . . . . 2-109

BACK GRADING A SURFACE . . . 2-109

CUTTING HARD OR FROZEN GROUND OR DITCHING . . . 2-110

FELLING TREES, REMOVING STUMPS . . . 2-110

SIDE-CUTTING OPERATIONS . . . 2-110

UNDERCARRIAGE CARE . . . . 2-111

OPERATION METHOD . . . . 2-111

INSPECTION AND ADJUSTMENT . . . . 2-111

INSPECTION AND REPAIR . . . 2-112

MEASURING LINK PITCH . . . 2-112

MEASURING HEIGHT OF GROUSER . . . 2-112

MEASURING OUTSIDE DIAMETER OF TRACK ROLLER . . . . 2-113

TRANSPORTING THE MACHINE . . . 2-114

LOADING OR UNLOADING A TRAILER . . . 2-114

PRE-TRANSPORTATION PROCEDURES . . . . 2-115

SECURING MACHINE . . . . 2-116

UNLOADING THE MACHINE . . . . 2-119

LIFTING THE MACHINE . . . 2-120

FOR BASE MACHINE . . . 2-120

FOR MACHINE EQUIPPED WITH RIPPER . . . 2-121

COLD WEATHER OPERATION . . . . 2-122

FUEL AND LUBRICANTS . . . . 2-122

COOLING SYSTEM COOLANT . . . . 2-122

BATTERY . . . . 2-123

PRECAUTIONS ON PARTICULAR JOBSITES . . . 2-124

DISCHARGED BATTERY . . . . 2-124

REMOVE AND INSTALL BATTERY . . . . 2-125

BATTERY CHARGES . . . 2-125

STARTING ENGINE WITH BOOSTER CABLES . . . 2-126

GENERAL TROUBLESHOOTING . . . 2-128

AFTER RUNNING OUT OF FUEL . . . . 2-128

TOWING THE MACHINE . . . 2-128

WHEN IT IS POSSIBLE TO START ENGINE . . . 2-129

WHEN ENGINE DOES NOT START . . . . 2-129

RELEASING THE BRAKES . . . . 2-129

CONNECTING PUMP TO MACHINE . . . . 2-130

AFTER TOWING MACHINE . . . . 2-132

ELECTRICAL SYSTEM PROBLEMS . . . 2-134

MONITOR PANEL . . . 2-135

CHASSIS PROBLEMS . . . . 2-136

ENGINE PROBLEMS . . . . 2-137

LONG TERM STORAGE . . . 2-138

BEFORE STORAGE . . . . 2-138

DURING STORAGE . . . 2-138

AFTER STORAGE . . . 2-138

MACHINES EQUIPPED WITH KOMTRAX SYSTEMS . . . . 2-139

BASIC PRECAUTIONS . . . 2-139

MAINTENANCE

MAINTENANCE INFORMATION . . .

SERVICE METER READING . . . .

KOMATSU GENUINE REPLACEMENT PARTS . . . .

KOMATSU GENUINE LUBRICANTS . . .

WINDSHIELD WASHER FLUID . . .

FRESH AND CLEAN LUBRICANTS . . . .

CHECK DRAINED OIL AND USED FILTER . . .

FUEL STRAINER . . . .

WELDING INSTRUCTIONS . . .

DO NOT DROP THINGS INSIDE MACHINE . . .

DUSTY JOBSITE . . . .

AVOID MIXING LUBRICANTS . . . .

HYDRAULIC SYSTEM – AIR BLEEDING . . .

HYDRAULIC HOSE INSTALLATION . . . .

CHECKS AFTER INSPECTION AND MAINTENANCE WORKS . . . .

LOCKING THE INSPECTION COVER . . . .

OPENING OR CLOSING RADIATOR GRILL . . .

LUBRICANTS, COOLANT AND FILTERS . . . .

OUTLINE OF SERVICE . . . .

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC . . . .

OIL . . .

FUEL . . .

COOLING SYSTEM COOLANT . . .

GREASE . . . .

CARRYING OUT KOWA (KOMATSU OIL WEAR ANALYSIS) . . . .

OIL AND FUEL STORAGE . . .

FILTERS . . . .

KEAM019300 – Crawler Dozer D51EXi-22, D51PXi-22 Operation & Maintenance Manual (SN-B13500&up)….2

FOREWORD….5

BEFORE READING THIS MANUAL….5

SAFETY INFORMATION….6

INTRODUCTION….7

USE OF MACHINE….7

DIRECTIONS OF MACHINE….7

PRODUCT IDENTIFICATION….8

PRODUCT IDENTIFICATION PLATE….8

ENGINE SERIAL NUMBER AND EMISSION LABEL….9

SERIAL NUMBERS AND DEALER INFORMATION….10

MODEL: D51EXi/PXi-22….10

INTRODUCTION….11

MACHINE FEATURES….11

CONTENTS….12

SAFETY….26

SAFETY AND WARNING DECALS….27

LOCATION OF THE SAFETY DECALS….28

GENERAL SAFETY RULES AND PRECAUTIONS….33

GENERAL SAFETY RULES….33

UNAUTHORIZED MODIFICATIONS….34

GENERAL SAFETY AT JOB SITE….34

WORKING ON LOOSE GROUND….34

SAFETY FEATURES….35

PERSONAL PROTECTIVE EQUIPMENT….35

FIRE AND EXPLOSION PREVENTION….36

FIRE CAUSED BY FUEL OR OIL….36

FIRE CAUSED BY ACCUMULATION OF FLAMMABLE MATERIAL….36

FIRE FROM ELECTRICAL SYSTEM….37

FIRE FROM HYDRAULIC LINE….37

WINDSHIELD WASHER FLUID….37

ACTION IF FIRE OCCURS….37

DUST HAZARDS….37

BLAST ZONE HAZARD….38

KEEP OPERATOR'S CAB CLEAN….38

UNAUTHORIZED MODIFICATIONS….38

LEAVING OPERATOR’S COMPARTMENT….39

PARKING BRAKE AND EQUIPMENT LOCKS….39

PRECAUTIONS WHEN GETTING ON OR OFF MACHINE….40

WHEN STANDING UP FROM OPERATOR'S SEAT….40

WHEN LEAVING MACHINE….40

MOUNTING AND DISMOUNTING….41

CRUSH OR PINCH POINT DANGERS….41

FIRE EXTINGUISHER AND FIRST AID KIT….41

INSIDE OPERATOR’S COMPARTMENT….42

PRECAUTIONS WHEN USING ROPS….42

PRECAUTIONS FOR OPERATION….42

IN COLD AREAS….42

PRECAUTIONS FOR BLADE AUTOMATIC CONTROL….43

PRECAUTIONS BEFORE STARTING OPERATIONS….44

PRE-OPERATIONAL CHECKS….44

STARTING YOUR WORK OPERATIONS….44

WORK SITE HAZARDS….44

AVOIDING DANGEROUS SITUATIONS….45

HIGH VOLTAGE LINES….47

RULES FOR ROAD TRAVEL….48

PRECAUTIONS WHEN TRAVELING….48

USING BRAKES….48

RULES FOR TRAVELING IN REVERSE….49

TRAVELING ON ICY OR SNOW-COVERED SURFACES….49

WORKING ON LOOSE OR UNSTABLE GROUND….49

TRAVEL ON SLOPES….49

PARKING THE MACHINE….50

PRECAUTIONS DURING MAINTENANCE OPERATIONS….51

WARNING TAGS….51

EQUIPMENT STORAGE….51

WORKING UNDER THE MACHINE….52

USING DROP LAMPS….52

KEEPING THE MACHINE CLEAN….52

KEEP WORKPLACE CLEAN AND TIDY….52

APPOINT LEADER WHEN WORKING WITH OTHERS….52

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE….53

RUNNING THE MACHINE DURING MAINTENANCE….54

RULES FOR REFUELING THE MACHINE….54

COOLING SYSTEM PRECAUTIONS….54

WORK UNDER THE MACHINE….54

PRECAUTIONS WHEN USING HAMMER….55

TURN THE BATTERY DISCONNECT SWITCH TO THE OFF POSITION….55

REPAIR WELDING….55

ENGINE SYSTEM HIGH VOLTAGE….55

BATTERY PRECAUTIONS….56

STARTING THE MACHINE….57

HIGH PRESSURE HOSES….57

HANDLING HIGH-PRESSURE HOSES….57

PRECAUTION FOR HIGH FUEL PRESSURE….58

HIGH TEMPERATURE AREAS….58

ROTATING PARTS….58

DISPOSAL OF WASTE MATERIALS….58

MERCURY CONTAINING COMPONENT(S)….58

USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION….59

DO NOT DISASSEMBLE RECOIL SPRING….59

ACCUMULATOR AND GAS SPRING….59

CRITICAL PARTS….60

PRECAUTIONS FOR CHECK AND MAINTENANCE….61

PRECAUTIONS FOR iB GNSS ANTENNA….61

TRANSPORTING THE MACHINE….62

LOADING AND SECURING THE MACHINE….62

TOWING THE MACHINE….63

OPERATION….66

GENERAL VIEWS….67

VIEW OF MACHINE….67

VIEW OF CONTROLS AND GAUGES….69

MACHINE MONITOR SYSTEM….71

MONITOR LAYOUT….71

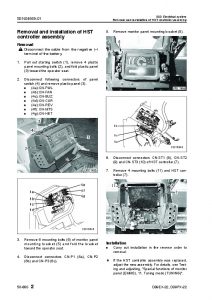

BASIC OPERATION OF MONITOR PANEL….72

CHECK MONITOR SYSTEM….73

MONITOR CHECK ITEMS….74

EMERGENCY ALERTS….74

ENGINE OIL PRESSURE CAUTION LAMP….74

ENGINE COOLANT TEMPERATURE CAUTION LAMP….75

HYDRAULIC OIL TEMPERATURE CAUTION LAMP….75

HST CHARGE PRESSURE CAUTION LAMP….75

CHARGE FILTER CLOG CAUTION LAMP….75

WARNING ALERTS….76

BATTERY CHARGE CAUTION LAMP….76

AIR CLEANER CLOGGING CAUTION LAMP….77

WATER IN FUEL LAMP….77

MAINTENANCE CAUTION LAMP….77

CONSOLE CONTROL SWITCHES….78

SWITCH LAYOUT VIEW….78

LAMP SWITCH….78

BUZZER CANCEL SWITCH….79

INFORMATION SWITCH….79

HEATER SWITCH….79

IGNITION SWITCH….80

HORN SWITCH….81

WIPER SWITCH….81

CAB LAMP SWITCH….82

CIGARETTE LIGHTER….82

ACCESSORY SOCKET….82

METER DISPLAY….83

ENGINE COOLANT TEMPERATURE GAUGE….83

HYDRAULIC OIL TEMPERATURE GAUGE….84

DISPLAY PANEL (A)….84

FUEL LEVEL GAUGE….88

REVERSE TRAVEL SPEED SET SWITCH….88

SHIFT MODE SWITCH….88

ENGINE INTAKE AIR PRE-HEAT PILOT LAMP….88

DISPLAY PANEL (B)….89

FAN ROTATION SELECTOR SWITCH….90

FLOAT MODE MONITOR….90

WARNING LAMP VIEW….91

WARNING LAMP (1)….91

USING FAILURE CODE DISPLAY….92

USING MAINTENANCE MODE….93

METHOD OF SELECTING EACH MODE….94

USING OIL AND FILTER MAINTENANCE MODE….95

USING ADJUSTMENT MODE….96

CONTROL LEVERS AND PEDALS….99

LEVER LAYOUT VIEW….99

LOCK LEVERS….99

JOYSTICK (STEERING, DIRECTIONAL AND GEAR….100

SHIFT LEVER)….100

BLADE CONTROL LEVER….101

ANGLING CONTROL….102

WORK EQUIPMENT LOCK LEVER….103

FUEL CONTROL DIAL….104

DECELERATOR PEDAL….105

BRAKE PEDAL….105

PARKING BRAKE LEVER….106

DOOR AND WINDOW SYSTEM….107

DOOR – OPEN LOCK….107

SASH GLASS INTERMEDIATE LOCK….107

SAFETY LOCKS AND SECURITY….108

DOOR LOCK….108

CAP, COVER WITH LOCK….108

METHOD OF OPENING OR CLOSING HYDRAULIC TANK CAP….109

OPEN AND CLOSE FUEL FILLER PORT CAP….110

OPEN….110

CLOSE….110

METHOD OF OPENING AND CLOSING COVER WITH LOCK….110

TO OPEN THE COVER (LOCKED COVER)….110

TO LOCK THE COVER….110

LOCKABLE AREAS….111

SEAT POCKET….111

ADDITIONAL FEATURES AND ACCESSORIES….112

AIR CONDITIONER AND FEET HEATER….112

GENERAL DESCRIPTION OF CONTROL PANEL….112

MODE SELECTOR SWITCH….112

BLOWER SPEED SELECTOR SWITCH….113

TEMPERATURE CONTROL SWITCH….113

PRECAUTIONS WHEN USING AIR CONDITIONER….114

FEET HEATER….115

RADIO….116

EXPLANATION OF FEATURES….116

POWER SWITCH/VOLUME….117

AUTO-STORE/PRESET SCAN BUTTON….117

BASS CONTROL KNOB….117

TREBLE CONTROL KNOB….118

LOUDNESS BUTTON….118

TIME/RADIO DISPLAY SELECTOR BUTTON….118

TAPE EJECT BUTTON….119

CASSETTE DOOR….119

FAST FORWARD, REWIND BUTTONS….119

PRESET BUTTONS….119

METAL TAPE BUTTON….120

MANUAL TUNING BUTTONS….120

SEEK TUNING BUTTONS….120

BAND SELECTOR BUTTON….120

METHOD OF OPERATION….121

LISTENING TO RADIO….122

LISTENING TO A CASSETTE TAPE….122

REVERSING TAPE….123

PRECAUTION WHEN USING….123

ASHTRAY….124

LUNCH BOX HOLDER STRAP….124

CUP HOLDER….124

TOOL BOX….124

GREASE PUMP HOLDER….125

ELECTRICAL POWER ADAPTER….125

BATTERY DISCONNECT SWITCH….126

FUSES….127

FUSES….127

FUSE CAPACITIES AND CIRCUIT NAMES….127

PRECAUTIONS BEFORE STARTING WORK OPERATIONS….130

PRE-OPERATIONAL CHECKS….130

WALK-AROUND CHECKS….130

CHECKS BEFORE STARTING….131

ADJUSTMENTS BEFORE OPERATION….145

ADJUST ARMREST….146

FASTENING AND REMOVING SEAT BELT….146

ADJUSTING MIRROR….147

OPERATIONS AND CHECKS BEFORE….147

STARTING ENGINE….147

STARTING THE ENGINE….149

NORMAL OR COLD START PROCEDURES….149

COLD WEATHER STARTS….150

OPERATIONS AND CHECKS AFTER STARTING ENGINE….154

BREAKING IN THE MACHINE….154

WARMING UP ENGINE….154

STARTING IN COLD WEATHER….155

STOPPING THE ENGINE….157

MOVING, STEERING, STOPPING AND PARKING THE MACHINE….158

PREPARATIONS FOR MOVING THE MACHINE….158

MOVING MACHINE FORWARD OR REVERSE….159

CHANGING SPEED RANGES….161

STEERING THE MACHINE….163

NORMAL TURN….163

MAKING A LEFT OR RIGHT TURN….163

MAKING A PIVOT TURN….164

TURNING WHILE DESCENDING A SLOPE….164

COUNTER-ROTATION TURN….164

STOPPING THE MACHINE….165

PARKING MACHINE….167

CHECK AFTER FINISHING WORK….168

CHECK AFTER SHUTTING OFF ENGINE….168

STARTING YOUR WORK OPERATIONS….169

AVOIDING DANGEROUS SITUATIONS….169

HIGH VOLTAGE LINES….171

OPERATING THE MACHINE….172

PAY ATTENTION TO GAUGES….172

PERMISSIBLE WATER DEPTH….172

METHOD OF USING BRAKES….172

WHEN TRAVELING UP OR DOWN HILLS….172

PRECAUTIONS ON SLOPES….173

BE AWARE OF FUEL LEVEL….173

PRECAUTIONS WHEN ENGINE STOPS ON A SLOPES….173

ALWAYS KEEP THE DOORS CLOSED DURING OPERATIONS….173

DO NOT MODIFY THE CAB GLASS IN ANY WAY….173

PRECAUTIONS FOR BLIND SPOTS CAUSED BY CAB STAYS….173

CUTTING A GRADE….174

DOZING….174

BACK GRADING A SURFACE….174

CUTTING HARD OR FROZEN GROUND OR DITCHING….175

FELLING TREES, REMOVING STUMPS….175

SIDE-CUTTING OPERATIONS….175

UNDERCARRIAGE CARE….176

OPERATION METHOD….176

INSPECTION AND ADJUSTMENT….176

INSPECTION AND REPAIR….177

MEASURING LINK PITCH….177

MEASURING HEIGHT OF GROUSER….177

MEASURING OUTSIDE DIAMETER OF TRACK ROLLER….178

TRANSPORTING THE MACHINE….179

LOADING OR UNLOADING A TRAILER….179

PRE-TRANSPORTATION PROCEDURES….180

SECURING MACHINE….181

UNLOADING THE MACHINE….184

LIFTING THE MACHINE….185

FOR BASE MACHINE….185

FOR MACHINE EQUIPPED WITH RIPPER….186

COLD WEATHER OPERATION….187

FUEL AND LUBRICANTS….187

COOLING SYSTEM COOLANT….187

BATTERY….188

PRECAUTIONS ON PARTICULAR JOBSITES….189

DISCHARGED BATTERY….189

REMOVE AND INSTALL BATTERY….190

BATTERY CHARGES….190

STARTING ENGINE WITH BOOSTER CABLES….191

GENERAL TROUBLESHOOTING….193

AFTER RUNNING OUT OF FUEL….193

TOWING THE MACHINE….193

WHEN IT IS POSSIBLE TO START ENGINE….194

WHEN ENGINE DOES NOT START….194

RELEASING THE BRAKES….194

CONNECTING PUMP TO MACHINE….195

AFTER TOWING MACHINE….197

ELECTRICAL SYSTEM PROBLEMS….199

MONITOR PANEL….200

CHASSIS PROBLEMS….201

ENGINE PROBLEMS….202

LONG TERM STORAGE….203

BEFORE STORAGE….203

DURING STORAGE….203

AFTER STORAGE….203

MACHINES EQUIPPED WITH KOMTRAX SYSTEMS….204

BASIC PRECAUTIONS….204

MAINTENANCE….206

MAINTENANCE INFORMATION….207

SERVICE METER READING….207

KOMATSU GENUINE REPLACEMENT PARTS….207

KOMATSU GENUINE LUBRICANTS….207

WINDSHIELD WASHER FLUID….207

FRESH AND CLEAN LUBRICANTS….207

CHECK DRAINED OIL AND USED FILTER….207

FUEL STRAINER….207

WELDING INSTRUCTIONS….207

DO NOT DROP THINGS INSIDE MACHINE….208

DUSTY JOBSITE….208

AVOID MIXING LUBRICANTS….208

HYDRAULIC SYSTEM – AIR BLEEDING….208

HYDRAULIC HOSE INSTALLATION….208

CHECKS AFTER INSPECTION AND MAINTENANCE WORKS….208

LOCKING THE INSPECTION COVER….209

OPENING OR CLOSING RADIATOR GRILL….209

LUBRICANTS, COOLANT AND FILTERS….211

OUTLINE OF SERVICE….211

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….211

OIL….211

FUEL….211

COOLING SYSTEM COOLANT….212

GREASE….212

CARRYING OUT KOWA (KOMATSU OIL WEAR ANALYSIS)….212

OIL AND FUEL STORAGE….213

FILTERS….213

ELECTRIC SYSTEM MAINTENANCE….214

HANDLING HYDRAULIC SYSTEM….214

WEAR PARTS LIST….215

RECOMMENDED FUEL, COOLANT, AND LUBRICANT….216

RECOMMENDED PRODUCTS OTHER THAN KOMATSU GENUINE OILS….218

LUBRICANT AND COOLANT SUPPLIER RECOMMENDATIONS….219

TIGHTENING TORQUE SPECIFICATIONS….221

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS….222

SAFETY RELATED CRITICAL PARTS….222

MAINTENANCE SCHEDULE….223

MAINTENANCE SCHEDULE CHART….223

WHEN REQUIRED….226

CLEANING THE MACHINE….226

CLEAN TIPS….226

CLEANING THROUGH ACCESS AREAS….226

CHECK ELECTRICAL INTAKE AIR HEATER….229

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT….229

CLEANING OR REPLACING OUTER ELEMENT….229

REPLACING INNER ELEMENT….231

CLEAN COOLING SYSTEM….233

FLUSHING THE COOLING SYSTEM….234

TRACK SYSTEM MAINTENANCE….237

CHECK AND TIGHTEN TRACK SHOE BOLTS….237

CHECKING AND ADJUSTING TRACK TENSION….237

IDLER GUIDE CLEARANCE….239

REVERSING OR REPLACING END BITS AND CUTTING EDGES….241

CHECKING IDLER OIL LEVEL….241

ADJUST PLAY IN CENTER BALL….242

ADJUST PLAY IN PITCH BALL….242

MECHANICAL PITCH ROD (ADJUSTABLE)….243

ADJUSTMENT….243

SPECIFICATIONS….243

ADJUSTMENT OF PITCH ANGLE….243

DOOR HINGES….244

CHECKING WINDOW WASHER FLUID LEVEL….245

MIXTURE RATIO OF PURE WASHER FLUID AND WATER….245

CHECKING AIR CONDITIONER….246

CHECK LEVEL OF REFRIGERANT….246

OPERATING AIR CONDITIONER OFF-SEASON….246

REPLACE WIPER BLADE….247

REPLACEMENT….247

RELEASING INTERNAL PRESSURE ON HYDRAULIC SYSTEM….248

BLEEDING AIR FROM HYDRAULIC SYSTEM….249

BLEEDING AIR FROM PUMP….249

BLEEDING AIR FROM CYLINDERS….249

CLEAN, CHECK RADIATOR FINS….250

CLEANING BY ROTATING COOLING FAN IN REVERSE DIRECTION….250

CLEANING WITH COMPRESSED AIR….252

CLEAN HYDRAULIC TANK BREATHER….254

CLEAN FUEL TANK BREATHER….254

INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)….255

REPLACE FUEL PRE-FILTER CARTRIDGE….255

INITIAL 500 HOURS SERVICE (ONLY AFTER THE FIRST 500 HOURS)….257

REPLACE MAIN FUEL FILTER CARTRIDGE….257

EVERY 50 HOURS MAINTENANCE….259

LUBRICATE….259

DRAINING SEDIMENT FROM FUEL TANK….261

EVERY 250 HOURS MAINTENANCE….262

CHECK OIL LEVEL IN FINAL DRIVE CASE….262

CHECKING FINAL DRIVE OIL LEVEL….262

LUBRICATING….262

CHECK LEVEL OF BATTERY ELECTROLYTE….264

CHECK BRAKE PERFORMANCE….265

AIR CONDITIONER AIR FILTER (FRESH/RECIRC FILTER)….267

EVERY 500 HOURS MAINTENANCE….268

REPLACE FUEL PRE-FILTER CARTRIDGE….268

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE….271

EVERY 1000 HOURS MAINTENANCE….273

CHANGE OIL IN FINAL DRIVE CASE….273

CHECK ALTERNATOR BELT TENSION….273

CHECK ALL TIGHTENING POINTS OF ENGINE INTAKE & EXHAUST PIPE CLAMPS….273

CHECK FOR LOOSE ROPS MOUNT BOLTS….274

REPLACE PRE AND MAIN FUEL FILTER CARTRIDGES….275

REPLACE BREATHER ELEMENT IN FUEL TANK….281

REPLACE BREATHER ELEMENT IN HYDRAULIC TANK….281

EVERY 2000 HOURS MAINTENANCE….282

CHANGE OIL IN HYDRAULIC TANK, REPLACE OIL FILTER CARTRIDGE….282

CHECK ALTERNATOR, STARTING MOTOR….284

CHECK ENGINE VALVE CLEARANCE, ADJUST….284

CHECK CHARGE PRESSURE ACCUMULATOR (CONTROL CIRCUIT)….284

FUNCTION OF ACCUMULATOR….284

CHECKING FUNCTION OF ACCUMULATOR….285

RELEASING PRESSURE IN HYDRAULIC CIRCUIT….285

CHECKING PIVOT SHAFT OIL LEVEL….286

EVERY 4000 HOURS MAINTENANCE….287

CHECK WATER PUMP….287

CHECK VIBRATION DAMPER….287

REPLACE ACCUMULATOR (FOR CONTROL CIRCUIT)….287

CHECK FOR LOOSENESS OF HIGH-PRESSURE CLAMP, HARDENING OF RUBBER….288

CHECK FOR MISSING FUEL SPRAY CAP, HARDENING OF RUBBER….289

SPECIFICATIONS….292

SPECIFICATIONS….293

OPERATING WEIGHT….293

MACHINE DIMENSIONS AND WEIGHTS….294

MACHINE SYSTEMS SPECIFICATIONS….295

ENGINE….295

TRANSMISSION….296

STEERING SYSTEM….296

SERVICE REFILL CAPACITIES….296

UNDERCARRIAGE….296

OPTIONAL ATTACHMENTS….298

AUTHORIZED OPTIONAL EQUIPMENT….299

BASIC PRECAUTIONS….299

AIR SUSPENSION SEAT….300

FORESTRY KIT….302

CABIN POLYCARBONATE PANEL FRONT….303

EQUIPPING FIRE EXTINGUISHER AND FIRST-AID KIT….304

HANDLING HYDRAULIC RIPPER….305

GENERAL VIEW….305

EXPLANATION OF COMPONENTS….306

RIPPER CONTROL LEVER….306

MAINTENANCE….310

EVERY 250 HOURS SERVICE….310

OPERATION….307

CHECK BEFORE STARTING ENGINE, ADJUST….307

PRECAUTIONS WHEN OPERATING….307

ADJUSTING POSTURE OF WORK EQUIPMENT….307

REPLACEMENT OF POINT….308

TROUBLESHOOTING….309

OTHER TROUBLE….309

iB OPERATION….312

HANDLING iB MONITOR….374

iB INDEX….440

SEAM01341703 – Bulldozer D53A,P-17 Operation & Maintenance Manual (SN80001&up)….444

COVER….444

FOREWORD….445

BREAKING IN YOUR NEW MACHINE….446

CONTENTS….447

SAFETY HINTS….448

GENERAL LOCATIONS AND SPECIFICATIONS….455

OPERATOR'S COMPARTMENT….456

INSTRUMENTS AND CONTROLS….458

CHECK BEFORE STARTING….469

OPERATING YOUR MACHINE….473

COLD WEATHER OPERATION….485

BULLDOZER'S WORK….490

BLADE OPERATION….492

BLADE ADJUSTMENT….495

REVERSING OF CUTTING EDGE AND REPLACEMENT OF END BIT….498

TIPS FOR LONGER UNDERCARRIAGE LIFE….499

HANDLING OF BATTERY….500

TRANSPORTATION….503

PERIODIC MAINTENANCE….504

PRECAUTIONS FOR MAINTENANCE….505

MAINTENANCE TABLE….508

EVERY 50 HOURS SERVICE….511

EVERY 250 HOURS SERVICE….512

EVERY 500 HOURS SERVICE….517

EVERY 1000 HOURS SERVICE….522

EVERY 2000 HOURS SERVICE….526

EVERY 4000 HOURS SERVICE….531

WHEN REQUIRED….532

ADJUSTMENT….542

TROUBLE SHOOTING GUIDE….546

STORAGE….549

SERVICE METER….551

MACHINE AND ENGINE SERIAL NUMBERS….552

FUEL,COOLANT AND LUBRICANTS….553

SEAM026300P – Bulldozer D53A,P-17 Operation & Maintenance Manual (SN82727&up)….558

COVER….558

FOREWORD….559

BREAKING IN YOUR NEW MACHINE….560

CONTENTS….561

SAFETY HINTS….562

POSITION FOR ATTACHING SAFETY LABELS….569

GENERAL LOCATIONS AND SPECIFICATIONS….573

OPERATOR'S COMPARTMENT….574

INSTRUMENTS AND CONTROLS….576

CHECK BEFORE STARTING….587

OPERATING YOUR MACHINE….591

COLD WEATHER OPERATION….603

BULLDOZER'S WORK….608

BLADE OPERATION….610

BLADE ADJUSTMENT….613

REVERSING OF CUTTING EDGE AND REPLACEMENT OF END BIT….616

TIPS FOR LONGER UNDERCARRIAGE LIFE….617

HANDLING OF BATTERY….618

TRANSPORTATION….621

PERIODIC MAINTENANCE….622

PRECAUTIONS FOR MAINTENANCE….623

MAINTENANCE TABLE….626

EVERY 50 HOURS SERVICE ….629

EVERY 250 HOURS SERVICE ….630

EVERY 500 HOURS SERVICE ….636

EVERY 1000 HOURS SERVICE ….641

EVERY 2000 HOURS SERVICE ….645

EVERY 4000 HOURS SERVICE ….650

WHEN REQUIRED….651

ADJUSTMENT….661

TROUBLE SHOOTING GUIDE….665

STORAGE….668

SERVICE METER….670

MACHINE AND ENGINE SERIAL NUMBERS….671

FUEL,COOLANT AND LUBRICANTS….672

SEAM13FC00 – Bulldozer D50P,PL-16 Operation & Maintenance Manual (SN68001&up)….677

COVER….677

FOREWORD….678

BREAKING IN YOUR NEW MACHINE….679

CONTENTS….680

SAFETY HINTS….681

GENERAL LOCATIONS….694

OPERATOR'S COMPARTMENT….696

INSTRUMENTS AND CONTROLS….698

CHECK BEFORE STARTING….705

OPERATING YOUR MACHINE….711

COLD WEATHER OPERATION….723

BULLDOZER'S WORK….728

BLADE OPERATION….730

BLADE ADJUSTMENT….732

REVERSING OF CUTTING EDGE AND REPLACEMENT OF END BIT….733

TIPS FOR LONGER UNDERCARRIAGE LIFE….734

TRANSPORTATION….735

MAINTENANCE….737

PERIODIC MAINTENANCE….738

PRECAUTIONS FOR MAINTENANCE….739

MAINTENANCE TABLE….745

EVERY 50 HOURS SERVICE….750

EVERY 250 HOURS SERVICE….751

EVERY 500 HOURS SERVICE….757

EVERY 1000 HOURS SERVICE….760

EVERY 2000 HOURS SERVICE….765

WHEN REQUIRED….772

ADJUSTMENT….776

TROUBLE SHOOTING GUIDE….782

STORAGE….786

SERVICE METER….788

MACHINE AND ENGINE SERIAL NUMBERS….789

WEAR PARTS….790

SPECIFICATIONS….791

FUEL AND LUBRICANTS….793

Komatsu Crawler Dozers D50-, D51-, D53- Operation Maintenance Manuals