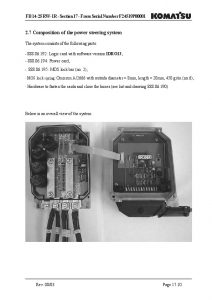

Complete service repair manual with Electrical Wiring Diagrams for Komatsu GD530A, GD530AW, GD530A-2, GD530AW-2, GD530A-2BY, GD530A-2CY, GD530AW-2BY, GD530AW-2CY, GD650A, GD650AW, GD650A-2, GD650AW-2, GD650A-2BY, GD650A-2CY, GD650AW-2BY, GD650AW-2CY, GD670A, GD670AW, GD670A-2, GD670AW-2, GD670A-2BY, GD670A-2CY, GD670AW-2BY, GD670AW-2CY Motor Graders , with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Motor Graders GD530A,AW & GD650A,AW & GD670A,AW & GD530A(W)-2 & GD650A(W)-2 & GD670A(W)-2 & GD530A(W)-2B(C)Y & GD650A(W)-2B(C)Y & GD670A(W)-2B(C)Y workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 3,764 pages

File Format: PDF

Language: English

CEBMG65194 – Motor Grader GD530A,AW & GD650A,AW & GD670A,AW Shop Manual.pdf

CEBM003902 – Motor Grader GD530A(W)-2 & GD650A(W)-2 & GD670A(W)-2 Shop Manual.pdf

CEBM009900 – Motor Grader GD530A(W)-2B(C)Y & GD650A(W)-2B(C)Y & GD670A(W)-2B(C)Y Shop Manual.pdf

CEAM009700 – Motor Grader GD530A(W)-2B(C)Y & GD650A(W)-2B(C)Y & GD670A(W)-2B(C)Y Operation & Maintenance Manual.pdf

CEAMG65040 – Motor Grader GD530A(W)-2 & GD650A(W)-2 & GD670A(W)-2 Operation & Maintenance Manual.pdf

CEAM003900 – Motor Grader with Emissionized Engine GD530A-2EY,AW-2EY & GD650A-2EY,AW-2EY & GD670A-2EY,AW-2EY Operation & Maintenance Manual.pdf

MAIN SECTIONS

COVER…1

CONTENTS…2

FOREWORD…8

SAFETY…5

SAFETY NOTICE…5

IMPORTANT SAFETY NOTICE…5

GENERAL PRECAUTIONS…5

PREPARATIONS FOR WORK…5

PRECAUTIONS DURING WORK…6

GENERAL…7

HOW TO READ THE SHOP MANUAL…8

VOLUMES…8

DISTRIBUTION AND UPDATING…8

FILING METHOD…8

REVISED EDITION MARK…8

REVISIONS…8

SYMBOLS…8

HOISTING INSTRUCTIONS…9

HOISTING…9

WIRE ROPES…9

COATING MATERIALS…10

STANDARD TIGHTENING TORQUE…12

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS…12

TIGHTENING TORQUE OF HOSE NUTS…13

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS…13

TIGHTENING TORQUE FOR FLARED NUTS…13

ELECTRIC WIRE CODE…14

CLASSIFICATION BY THICKNESS…14

CLASSIFICATION BY COLOR AND CODE…14

CONVERSION TABLES…15

METHOD OF USING THE CONVERSION TABLE…15

01 GENERAL…21

GENERAL ASSEMBLY DRAWING…22

GD530…22

GD650/670…22

FUEL, COOLANT, AND LUBRICANTS…23

ACCORDING TO AMBIENT TEMPERATURE…23

PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS…23

ENGINE OIL SPECIFICATIONS…25

NORMAL OPERATION…25

ARCTIC OPERATION…25

TRANSMISSION, TORQUE CONVERTER AND OIL COOLER, TANDEM DRIVE CASES, FRONT-WHEEL-DRIVE GEAR CASE, I…26

REAR-DRIVE AXLE AND CIRCLE DRIVE BRAKE HOUSING OIL SPECIFICATIONS…26

DIESEL FUEL SPECIFICATIONS…26

COOLANT SPECIFICATIONS…27

GENERAL…27

WATER…27

ANTIFREEZE…27

SUPPLEMENTAL COOLANT ADDITIVES…29

MAINTENANCE OF SUPPLEMENTAL COOLANT ADDITIVES…29

COOLANT TESTING FOR CONDITIONER CONCENTRATION…29

REPLENISHING COOLANT CONDITIONER…29

SUPPLEMENTAL COOLANT ADDITIVE MAINTENANCE GUIDE…30

COOLING SYSTEM TEST KIT…32

CIRCLE DRIVE GEAR CASE OIL SPECIFICATIONS (HDTF)…32

10 STRUCTURE AND FUNCTION…33

STEERING (ORBITROL) CONTROL VALVE…36

TRANSMISSION POWER SHIFT…38

TRANSMISSION SHIFTER…38

RECOMMENDED LUBRICANT AND FILTER CHANGE INTERVALS…41

GENERAL LOCATION OF COMPONENTS…43

ALL-WHEEL-DRIVE PUMP…44

ROTARY GROUP…46

EP2 HYDRAULIC CONTROL…48

INTERPRETATION OF TYPE CODES…50

CIRCLE REVERSE MOTOR…52

CIRCLE REVERSE GEAR CASE MOTOR…52

CIRCLE REVERSE MOTOR…54

STEERING AND BRAKE PUMP…56

STEERING AND BRAKE PUMP MOUNT…56

STEERING AND BRAKE PUMP…58

SPECIFICATIONS…59

AWD HYDRAULIC MOTOR…60

SPECIFICATIONS…62

HYDRAULIC OIL SWIVEL BLOCK…63

FOUR WAY…63

CONTROL VALVE MANIFOLDS…64

OPTIONAL CONTROL LEVER (SCARIFIER)…66

OPTIONAL CONTROL LEVERS (AUXILIARY)…68

CONTROL VALVES – L.H. BANK…70

CONTROL VALVES – R.H. BANK…72

VALVE SECTION…74

MAIN SYSTEM PUMP MOUNT…76

MAIN SYSTEM PUMP…78

AWD HIC VALVE…80

SOLENOID VALVE CARTRIDGE…84

ACCUMULATOR…85

SPECIFICATIONS…86

BRAKE SYSTEM ACCUMULATORS…87

DRAWBAR LIFT AND DRAWBAR SIDE SHIFT ACCUMULATORS…87

HYDRAULIC SYSTEM OVERVIEW…88

STANDARD GRADER…88

MAIN HYDRAULIC CIRCUIT…89

STEERING AND BRAKE HYDRAULIC CIRCUIT (INCLUDES LOCK PIN)…89

STANDARD GRADER WITH ALL WHEEL DRIVE (AWD)…90

MAIN HYDRAULIC CIRCUIT…91

ALL WHEEL DRIVE CIRCUIT…91

STEERING AND BRAKE HYDRAULIC CIRCUIT (INCLUDES LOCK PIN)…91

MAIN HYDRAULIC CIRCUIT…92

SPOOL VALVE POSITIONS…97

NEUTRAL (CENTER)…97

PULLED (PRESSURIZED "B" PORT)…98

PUSHED (PRESSURIZED "A" PORT)…99

MAIN SYSTEM CONTROL VALVES…101

SCARIFIER…101

RIGHT AND LEFT BLADE LIFT…102

FLOAT VALVE…104

BLADE SHIFT…104

CIRCLE REVERSE MOTOR…105

MOLDBOARD TILT…106

ARTICULATION…107

CIRCLE SIDE SHIFT…108

LEANING WHEEL…110

OPTIONAL FLOAT VALVE…111

STEERING AND BRAKE CIRCUIT…112

ALL-WHEEL-DRIVE CIRCUIT…115

NORMAL MODE…116

AGGRESSIVE MODE…118

HYDRAULIC OPERATION…119

ELECTRICAL OPERATION…122

AWD CONTROLLER PROGRAMMING…124

LOCK/UNLOCK DIFFERENTIAL PUMP…126

CIRCLE REVERSE SLIP CLUTCH…128

CIRCLE REVERSE GEAR CASE…130

WITHOUT SLIP CLUTCH…130

WITH SLIP CLUTCH…132

MOTOR INSTALLATION…134

TANDEM CASE…136

LOCATION…136

DESCRIPTION…136

NONPLANETARY FINAL DRIVE…136

PLANETARY FINAL DRIVE…138

FINAL DRIVE IDENTIFICATION…140

PART NUMBER TAG…140

TANDEM CASE MEASUREMENT…140

SPECIFICATIONS…141

AWD GEARBOX ASSEMBLY…141

AWD GEARBOX…142

FRONT AXLE ASSEMBLY…144

NON ALL-WHEEL-DRIVE FRONT AXLE…144

AWD FRONT AXLE…146

FINAL DRIVE ASSEMBLY…148

FINAL DRIVE WITHOUT PLANETARY REDUCTION…148

FINAL DRIVE WITH PLANETARY REDUCTION…150

NO-SPIN DIFFERENTIAL CASE ASSEMBLY…152

LOCK/UNLOCK DIFFERENTIAL CASE ASSEMBLY…154

INPUT QUILL ASSEMBLY…156

BRAKES…158

NO-SPIN DIFFERENTIAL BEARING QUILLS…160

LOCK/UNLOCK DIFFERENTIAL BEARING QUILLS…162

LOCK/UNLOCK DIFFERENTIAL ASSEMBLY…164

LOCK/UNLOCK DIFFERENTIAL CASE OIL LINE…166

NO-SPIN DIFFERENTIAL ASSEMBLY…168

NO-SPIN DIFFERENTIAL…170

PLANETARY ASSEMBLY AND RING GEAR…172

NONPLANETARY FINAL DRIVE CROSS SECTION…174

PLANETARY REDUCTION FINAL DRIVE CROSS SECTION…175

MICO PARKING BRAKE…176

MICO PARKING BRAKE INSTALLATION…177

PARKING BRAKE CALIPER…178

MICO BRAKE VALVE…180

BRAKE PEDAL LINKAGE…180

HYDRAULIC BRAKE LINES – WITHOUT AWD…182

HYDRAULIC BRAKE LINES – WITH AWD…184

BRAKE VALVE…186

TILT STEERING CONSOLE…188

EXPLODED VIEW OF TILT STEERING CONSOLE…190

20 TESTING, ADJUSTING AND TROUBLESHOOTING…193

STANDARD VALUE TABLES…197

TABLE OF JUDGEMENT STANDARD VALUE…197

ENGINE IN CHASSIS…198

CHASSIS…200

TOOL LIST…206

TRANSMISSION POWER SHIFT…207

TRANSMISSION SHIFTER…207

VOLTAGE AND ELECTRICAL POWER REQUIREMENTS…209

CLUTCH SOLENOID VALVE REQUIREMENTS…210

PRESSURE AND FLOW CHECKS…210

FLOW RATES…210

SETTING THE CLUTCH PRESSURE…211

FLYWHEEL DIMENSIONAL CHECKS…211

FLYWHEEL DIMENSIONS…212

CHECKING FOR THE CORRECT PILOT SLEEVE LENGTH…213

AWD PUMP…214

REXROTH…214

DIAGNOSTIC PORTS…214

CIRCLE REVERSE MOTOR…215

TESTS AND ADJUSTMENTS…215

STEERING AND BRAKE PUMP…216

PROCEDURE…216

STARTUP PROCEDURE…217

AWD HYDRAULIC MOTOR…218

FOUR-WAY SWIVEL BLOCK…218

FRONT AXLE AND GEARBOX…219

FRONT WHEEL ALIGNMENT AND TURNING RADIUS ADJUSTMENT…219

HYDRAULIC CYLINDERS…221

PRESSURE TESTING HYDRAULIC CYLINDERS…221

BALL AND SOCKET SHIMMING ADJUSTMENT…221

ACCUMULATORS…222

PRECHARGE…222

TESTS AND ADJUSTMENTS…222

PROCEDURE FOR ACCUMULATORS UP TO 3000 psi…223

PROCEDURE FOR ACCUMULATORS UP TO 5000 psi…224

HYDRAULIC CIRCUITS…225

RELIEVING ACCUMULATOR PRESSURE…226

SETTING RELIEF VALVES…226

GENERAL DIAGNOSIS PROCEDURE…227

HEAT PROBLEMS…227

SPECIAL TOOLS…228

HYDRAULIC PRESSURE TESTS…228

QUICK-REFERENCE PRESSURE CHART…229

MAIN HYDRAULIC SYSTEM SPECIFICATIONS…230

TEST PORT LOCATIONS…230

TEST PROCEDURE: LOW-PRESSURE STANDBY…231

TEST PROCEDURE: HIGH-PRESSURE STANDBY…232

STEERING AND BRAKE SYSTEM PRESSURE TEST…233

STEERING AND BRAKE SYSTEM SPECIFICATION…233

TEST PORT LOCATION…233

TEST PROCEDURE…233

AWD SYSTEM TEST…234

AWD SYSTEM FUNCTIONAL TEST…235

AWD HYDRAULIC SYSTEM PRESSURE TEST…238

ALL-WHEEL-DRIVE PUMP…239

ADJUSTMENT…239

RELIEF VALVES…241

HYDRAULIC CENTERING ADJUSTMENT PROCEDURE…244

MECHANICAL CENTERING ADJUSTMENT PROCEDURE…246

AWD HYDRAULIC SYSTEM FILTERING PROCEDURE…247

AWD ELECTRICAL SYSTEM TESTS…248

LOCK/UNLOCK DIFFERENTIAL RELIEF VALVE…257

REAR AXLE COOLING SYSTEM…257

FINAL DRIVE ASSEMBLY…258

WITH NoSPIN AND LOCK/UNLOCK DIFFERENTIAL…258

NO SPIN TEST…258

BRAKE DISC INSPECTION…259

TANDEM CASE…260

TANDEM CHAIN WEAR LIMITS…260

SPECIFICATIONS…260

PROCEDURE…260

SPROCKET WEAR (NON-PLANETARY ONLY)…262

OIL…262

SINGLE AND DOUBLE STRAND CHAINS…262

ROAD TEST…262

CIRCLE ADJUSTMENT…264

FOUR SHOES…264

VERTICAL ADJUSTMENT…265

PINION ADJUSTMENT…266

CIRCLE REVERSE SLIP CLUTCH…268

CIRCLE ADJUSTMENT…268

SLIP CLUTCH ADJUSTMENT…269

ENGINE AND TRANSMISSION GEAR RANGE TEST…270

PARKING BRAKE CALIPER…271

PERROT PARKING BRAKE ADJUSTMENT…271

BRAKE PRESSURE WARNING SWITCHES…271

LOW BRAKE PRESSURE WARNING SWITCH…272

PARKING BRAKE PRESSURE SWITCH…272

BLEEDING THE CALIPER?S…273

MICO PARKING BRAKE ADJUSTMENT…274

BRAKE VALVES…275

MICO BRAKE VALVE…275

BRAKE PEDAL BUMPER ADJUSTMENT…275

BRAKE PEDAL FREE HEIGHT…275

BRAKE PEDAL STOP…276

PRESSURE TEST…277

TROUBLESHOOTING…279

HYDRAULIC CIRCUITS…281

PROBLEMS…281

Problem 1. Test lamp does not light…281

Problem 2. Test lamp blinks green when in reverse…282

Problem 3. Test lamp blinks red…283

Problem 4. No change between the normal mode and aggressive mode…283

Problem 5. System appears to lack power…284

Problem 6. Wheels turn when in neutral…284

Problem 7. Wheels don't turn either direction…285

Problem 8. Wheels do not turn forward…286

Problem 9. Wheels do not turn in reverse…287

Problem 10. Wheels do not stop…287

RIGHT AND LEFT CONTROL VALVE…288

MOLDBOARD TILT CYLINDER…290

BLADE SHIFT CYLINDER…290

HYDRAULIC CYLINDERS…290

CIRCLE REVERSE MOTOR…291

AWD PUMP…292

AWD HYDRAULIC MOTOR…296

STEERING AND BRAKE PUMP…297

CONTROL VALVE MANIFOLDS…298

MAIN SYSTEM PUMP…299

TRANSMISSION POWER SHIFT…301

TRANSMISSION SHIFTER…301

TANDEM CASE…305

SINGLE AND DOUBLE STRAND CHAINS…305

FINAL DRIVE ASSEMBLY…306

WITH NoSPIN AND LOCK/UNLOCK DIFFERENTIAL…306

PARKING BRAKE CALIPER…307

PREDELIVERY PROCEDURES…311

CHECKS AND ADJUSTMENTS…311

FAN BELT TENSION…311

AIR CLEANER SYSTEM…311

AIR INDUCTION PRESSURE CHECK…312

SERVICE INDICATOR SAFETY FILTER…313

RADIATOR HOSES…314

FUEL LINES AND FITTINGS…315

WATER TRAP…315

TRANSMISSION FLUID LEVEL…315

TRANSMISSION FILL PLUG…315

HYDRAULIC OIL TANK LEVEL…315

HYDRAULIC OIL AND FUEL TANK FILL POINT…316

TANDEM CASE OIL LEVEL…316

TANDEM CASE BREATHER/FILL POINT…316

CIRCLE REVERSE OIL LEVEL…316

CIRCLE REVERSE FILL POINT…317

REAR AXLE OIL LEVEL…317

REAR AXLE OIL FILL POINT…317

FUEL TANK DRAIN PLUG…317

GREASE ZERKS…318

MOLDBOARD SLIDE RAILS…318

CONTROL LEVER LINKAGES…318

CONTROL VALVE LINKAGES…318

OIL LEVEL – AWD FRONT WHEEL GEAR…319

ENGINE OIL LEVEL AND FILL POINT…319

BATTERY WATER LEVEL…319

ENGINE COOLANT…319

ENGINE SPEED TABLE…320

ENGINE SPEED CHECK PROCEDURE…321

THROTTLE ADJUSTMENT PROCEDURE…322

HYDRAULIC PRESSURE TESTS…325

QUICK-REFERENCE PRESSURE CHART…326

MAIN HYDRAULIC SYSTEM SPECIFICATIONs…327

TEST PORT LOCATIONS…327

TEST PROCEDURE: Low-Pressure Standby…328

TEST PROCEDURE: High-Pressure Standby…329

STEERING AND BRAKE SYSTEM PRESSURE TEST…330

STEERING AND BRAKE SYSTEM SPECIFICATION…330

TEST PORT LOCATION…330

TEST PROCEDURE…330

AWD HYDRAULIC SYSTEM PRESSURE TEST…331

AWD SYSTEM SPECIFICATION…331

TEST PORT LOCATIONS…331

TEST PROCEDURE…332

CLUTCH PACK PRESSURE CHECK…333

TIRES AND RIMS…334

TIRE INFLATION…334

TIRE PRESSURES…334

RIM CENTERING…334

CONTROL VALVE OPERATION…336

CONTROL LEVERS – RIGHT BANK…336

CONTROL LEVERS – LEFT BANK…337

OPTIONAL EQUIPMENT…339

LIGHTING…339

WARNING LIGHTS…339

YARD TEST…339

BRAKE VALVES…340

MICO BRAKE VALVE…340

PARKING BRAKE CALIPER…343

PERROT PARKING BRAKE ADJUSTMENT…343

MICO PARKING BRAKE ADJUSTMENT…344

30 DISASSEMBLY AND ASSEMBLY…345

METHOD OF USING MANUAL…353

PRECAUTIONS DURING OPERATION…354

PRECAUTIONS WHEN CARRYING OUT REMOVAL WORK…354

PRECAUTIONS WHEN CLEANING AND INSPECTING…355

PRECAUTIONS WHEN CARRYING OUT INSTALLATION WORK…356

PRECAUTIONS WHEN COMPLETING THE OPERATIONS…356

OTHER PRECAUTIONS…357

SPECIAL TOOL LIST…358

SKETCHES OF SPECIAL TOOLS…359

TRANSMISSION…359

CHANNEL SUPPORT TOOL…359

CLUTCH PACK REMOVAL TOOL…360

CLUTCH SPRING COMPRESSION TOOL…361

CIRCLE REVERSE MOTOR (PARKER)…362

SPECIAL BEARING MANDREL TOOL…362

CIRCLE REVERSE MOTOR (CHAR-LYNN)…363

ASSEMBLY BULLET TOOL…363

SEAL BULLET TOOL…363

SEAL INSTALLATION TOOL…364

HYDRAULIC MOTOR…365

SHAFT BEARING REMOVAL / INSTALLATION TOOL…365

HOUSING BEARING RACE REMOVAL TOOL…366

BEARING RACE INSTALLATION TOOL…366

SHAFT SEAL DRIVER TOOL…367

HYDRAULIC OIL SWIVEL BLOCK – 4 WAY…368

SWIVEL BLOCK SEAL TOOL…368

CIRCLE REVERSE SLIP CLUTCH…369

CIRCLE SLIP CLUTCH GAUGE TOOL…369

TANDEM CASE…370

WHEEL KNOCKER TOOL…370

AXLE LIFTING TOOL…370

AXLE ROLLING TORQUE TOOL…371

SPREADER BAR AND CHAINS…371

AWD – GEARBOX ASSEMBLY…373

SEAL INSTALLATION TOOL…373

AWD – MOTOR (VICKERS-EATON)…374

SPECIAL SHAFT BEARING REMOVAL AND INSTALLATION TOOLS…374

HOUSING BEARING RACE REMOVAL TOOL…374

SPECIAL BEARING RACE INSTALLATION TOOL…375

SHAFT SEAL DRIVER…375

FINAL DRIVE ASSEMBLY…376

SPREADER BAR AND CHAINS…376

DIFFERENTIAL BACKLASH TOOL (DR08-111)…377

ARTICULATION JOINT…379

REMOVAL…380

DISASSEMBLY…384

ASSEMBLY…386

INSTALLATION…389

ENGINE HOOD, FRONT & REAR COWLING…392

REMOVAL…392

INSTALLATION…395

FUEL TANK AND HYDRAULIC TANK…398

REMOVAL…398

INSTALLATION…399

TRANSMISSION SHIFTER…400

REMOVAL…400

INSTALLATION…400

TRANSMISSION POWER SHIFT…401

REMOVAL…401

DISASSEMBLY…404

FRONT COVER DISASSEMBLY…406

MAIN CASE DISASSEMBLY…408

TORQUE CONVERTER DISASSEMBLY…410

CLUTCH PACK 1 AND 5 DISASSEMBLY (FIRST STAGE)…412

CLUTCH PACK 2 AND 6 DISASSEMBLY (SECOND STAGE)…414

CLUTCH PACK 3 AND 4 DISASSEMBLY (THIRD STAGE)…416

CONTROL VALVE DISASSEMBLY…418

REASSEMBLY…420

FRONT COVER REASSEMBLY…420

TORQUE CONVERTER ASSEMBLY…424

CLUTCH PACK 1 AND 5 REASSEMBLY (FIRST STAGE)…426

CLUTCH PACK 2 AND 6 REASSEMBLY (SECOND STAGE)…429

CLUTCH PACK 3 AND 4 REASSEMBLY (THIRD STAGE)…432

CONTROL VALVE ASSEMBLY…436

MAIN CASE REASSEMBLY…437

TRANSMISSION/TORQUE CONVERTER REASSEMBLY…440

INSTALLING THE CONVERTER INTO THE TRANSMISSION…442

TRANSFER CASE…443

DISASSEMBLY…443

ASSEMBLY…445

INSTALLATION…448

SERVICING THE MACHINE AFTER A TRANSMISSION OVERHAUL…452

STARTUP PROCEDURE…452

ALL WHEEL DRIVE (AWD)…452

ALL-WHEEL-DRIVE PUMP…453

REMOVAL…453

SHAFT SEAL (IN-WARRANTY SERVICE)…455

CHARGE PUMP (IN-WARRANTY SERVICE)…456

CONTROL PISTON COVER (IN-WARRANTY SERVICE)…457

LEFT COVER…457

RIGHT COVER…458

REPLACING THE VALVES (IN-WARRANTY SERVICE)…459

BOOST PRESSURE VALVE…459

RELIEF VALVE…459

PRESSURE CUT-OFF VALVE…459

CONTROL DEVICE (IN-WARRANTY SERVICE)…460

REGULATOR VALVE (IN-WARRANTY SERVICE)…461

REBUILDING THE PUMP (OUT-OF-WARRANTY SERVICE)…462

TORQUE VALUES…479

TIGHTENING TORQUES FOR SHAFT BOLTS (METRIC ISO STANDARD THREAD)…479

TIGHTENING TORQUES FOR LOCKING SCREWS VSTI (METRIC ISO FINE THREAD)…479

TIGHTENING TORQUE FOR SEAL LOCK NUTS VSTI (METRIC ISO STANDARD THREAD)…480

TIGHTENING TORQUES FOR CROSS-SLOTTED LENS HEAD SCREWS DIN 7985 (METRIC ISO STANDARD THREAD)…480

INSTALLATION…481

CIRCLE REVERSE MOTOR…482

CHAR-LYNN (MACHINE S/N 202309 TO 203192)…482

REMOVAL…482

DISASSEMBLY…482

ASSEMBLY…484

INSTALLATION…486

PARKER (MACHINE S/N 203193 AND UP)…488

EXPLODED ASSEMBLY VIEW…488

REMOVAL…490

DISASSEMBLY…490

ASSEMBLY…499

ONE PIECE STATOR CONSTRUCTION…508

FINAL CHECKS…509

INSTALLATION…509

STEERING (ORBITOL) VALVE…510

REMOVAL…510

DISASSEMBLY…510

ASSEMBLY…515

INSTALLATION…519

STEERING AND BRAKE PUMP…520

REMOVAL…520

DISASSEMBLY…521

ASSEMBLY…524

INSTALLATION…526

HYDRAULIC MOTOR…527

REMOVAL…527

DISASSEMBLY…528

SPECIAL INSPECTION AREAS…532

ASSEMBLY…534

INSTALLATION…537

4-WAY SWIVAL VALVE BLOCK…538

REMOVAL…538

DISASSEMBLY…539

ASSEMBLY…540

INSTALLATION…542

CONTROL VALVE MANIFOLDS…544

REMOVAL…544

DISASSEMBLY…547

CONTROL VALVE BANK…547

VALVE SECTION…549

VALVE SECTION IDENTIFICATION…550

ASSEMBLY…551

VALVE SECTION…551

CONTROL VALVE BANK…552

INSTALLATION…553

MAIN SYSTEM PUMP…555

REMOVAL…555

DISASSEMBLY…556

ASSEMBLY…562

INSTALLATION…568

HYDRAULIC INTEGRATED CIRCUIT VALVE…569

REMOVAL…569

DISASSEMBLY…570

HIC VALVE…570

SOLENOID CARTRIDGE DISASSEMBLY…571

ASSEMBLY…572

SOLENOID CARTRIDGE REASSEMBLY…572

HIC VALVE…573

INSTALLATION…574

HYDRAULIC CYLINDERS…575

BALL AND SOCKET SHIMMING ADJUSTMENT…575

SPECIAL TORQUES…576

CLEANING AND INSPECTION…576

STEERING CYLINDERS…577

REMOVAL…577

DISASSEMBLY…578

ASSEMBLY…579

INSTALLATION…580

LEANING WHEEL CYLINDER…581

REMOVAL…581

DISASSEMBLY…582

ASSEMBLY…583

INSTALLATION…584

MOLDBOARD TILT CYLINDERS…585

REMOVAL…585

DISASSEMBLY…586

ASSEMBLY…587

INSTALLATION…588

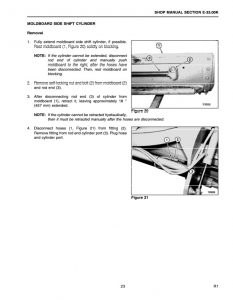

MOLDBOARD SIDE SHIFT CYLINDER…589

REMOVAL…589

DISASSEMBLY…590

ASSEMBLY…590

INSTALLATION…591

DRAWBAR SIDE SHIFT CYLINDER (R.H. BLADE SUSPENSION ONLY)…592

REMOVAL…592

DISASSEMBLY…593

ASSEMBLY…594

INSTALLATION…595

DRAWBAR SIDE SHIFT CYLINDER (R.H. & L.H. BIAS BLADE SUSPENSION)…596

REMOVAL…596

DISASSEMBLY…596

ASSEMBLY…598

INSTALLATION…599

DRAWBAR LIFT CYLINDERS (R.H. BLADE SUSPENSION ONLY)…600

REMOVAL…600

DISASSEMBLY…601

ASSEMBLY…602

INSTALLATION…603

DRAWBAR LIFT CYLINDERS (R.H. & L.H. BIAS BLADE SUSPENSION ONLY)…604

REMOVAL…604

TRUNNION BUSHING REPLACEMENT…605

DISASSEMBLY…606

ASSEMBLY…607

INSTALLATION…608

SCARIFIER CYLINDERS…610

REMOVAL…610

DISASSEMBLY…611

ASSEMBLY…612

INSTALLATION…613

LOCK PIN CYLINDER (R.H. & L.H. BIAS BLADE SUSPENSION ONLY)…615

REMOVAL…615

DISASSEMBLY…616

ASSEMBLY…617

INSTALLATION…618

ARTICULATION CYLINDERS…619

REMOVAL…619

DISASSEMBLY…620

ASSEMBLY…621

INSTALLATION…622

ACCUMULATORS…623

MAINTENANCE…623

CHECKING THE PRECHARGE…623

ACCUMULATORS WITH PARKER VALVE P/N 5323640000…624

ACCUMULATORS WITH PARKER VALVE P/N 6124330000…624

REMOVAL (BRAKE SYSTEM)…625

REMOVAL (DRAWBAR LIFT AND DRAWBAR SIDE SHIFT)…626

DISASSEMBLY…627

REPAIR AND REPLACEMENT…628

ASSEMBLY…628

INSTALLATION (BRAKE SYSTEM)…629

INSTALLATION (DRAWBAR LIFT AND DRAWBAR SIDE SHIFT)…629

LOCK/UNLOCK DIFFERENTIAL PUMP…630

REMOVAL…630

DISASSEMBLY…631

REPAIR AND REPLACEMENT…632

REASSEMBLY…633

INSTALLATION…634

ADJUSTING DIFFERENTIAL PUMP BELT TENSION…635

V-BELT ADJUSTMENT…635

OPTIONAL V-BELT ADJUSTMENT…635

CIRCLE REVERSE SLIP CLUTCH…636

REMOVAL…636

GENERAL EXPLOSION VIEW…637

DISASSEMBLY…639

ASSEMBLY…641

INSTALLATION…646

RETROFITTING A STANDARD CIRCLE GEAR CASE WITH A SLIP CLUTCH…647

CIRCLE IDENTIFICATION…647

RETROFITTING INSTRUCTIONS…647

CIRCLE REVERSE GEAR CASE…649

DISASSEMBLY…649

ASSEMBLY…655

TANDEM CASE…663

SINGLE AND DOUBLE STRAND CHAINS…663

REMOVAL…663

DISASSEMBLY…667

ASSEMBLY…668

INSTALLATION…670

AWD – GEARBOX ASSEMBLY…673

TWO-PIECE SEAL INSTALLATION…673

REMOVAL…678

DISASSEMBLY…682

ASSEMBLY…689

INSTALLATION…698

AWD MOTOR (VICKERS/EATON)…703

REMOVAL…703

DISASSEMBLY…703

REMOVAL OF FRONT SHAFT BEARING…706

REPLACE ALL PARTS THAT DO NOT MEET THE FOLLOWING SPECIFICATIONS…706

ASSEMBLY…707

INSTALLATION…710

FRONT AXLE ASSEMBLY…711

REMOVAL…711

DISASSEMBLY…713

ASSEMBLY…717

INSTALLATION…724

FINAL DRIVE ASSEMBLY…727

NoSPIN AND LOCK/UNLOCK DIFFERENTIALS…727

PARKING BRAKE BLEEDING…727

FINAL DRIVE BRAKE BLEEDING…727

ROAD TESTING…728

REMOVAL…728

GENERAL DISASSEMBLY…733

DISASSEMBLY OF THE PLANETARY CARRIER…733

DISASSEMBLY OF THE NONPLANETARY CARRIER…737

DISASSEMBLY OF THE DIFFERENTIAL BRAKE PISTONS…740

DISASSEMBLY OF THE INPUT QUILL ASSEMBLY…741

DISASSEMBLY OF THE DIFFERENTIAL CASE WITH NoSPIN DIFFERENTIAL…743

DISASSEMBLY OF DIFFERENTIAL CASE WITH LOCK/UNLOCK DIFFERENTIAL…745

NoSPIN DIFFERENTIAL INSPECTION…751

LOCK/UNLOCK DIFFERENTIAL INSPECTION…751

PARKING BRAKE MOUNTING BRACKET…752

DIFFERENTIAL ASSEMBLY…753

NoSPIN DIFFERENTIAL CASE ASSEMBLY…754

LOCK/UNLOCK DIFFERENTIAL CASE ASSEMBLY…758

PINION GEAR ADJUSTMENTS…765

PINION GEAR CONE POINT ADJUSTMENT…765

PINION GEAR ENDPLAY ADJUSTMENT…767

PINION GEAR BACKLASH ADJUSTMENT…768

FINAL ASSEMBLY…771

ASSEMBLY OF THE DIFFERENTIAL BRAKE PISTONS…773

NONPLANETARY CARRIER ASSEMBLY…775

PLANETARY CARRIER ASSEMBLY…782

INSTALLATION…787

REPLACING 6C FLANGE DRIVE SHAFT WITH 7C FLANGE DRIVE SHAFT…788

CIRCLE TOOTH REBUILD…794

REBUILDING THE TEETH…794

MICO PARKING BRAKE CALIPER…795

REMOVAL…795

BRAKE LINING REPLACEMENT…797

DISASSEMBLY…797

ASSEMBLY…801

INSTALLATION…804

BRAKE VALVE…805

REMOVAL…805

DISASSEMBLY…808

ASSEMBLY…810

INSTALLATION…811

SEAT…813

GENERAL SPECIFICATIONS…813

COMPLETE ASSEMBLY…815

DISASSEMBLY…816

ASSEMBLY…818

LOWER SUSPENSION…819

DISASSEMBLY…820

INSPECTION AND REPAIR…822

ASSEMBLY…822

SEAT ADJUSTER…823

DISASSEMBLY…824

ASSEMBLY…824

TILT STEERING CONSOLE…825

DISASSEMBLY…825

ASSEMBLY…833

AIR CONDITIONING…842

AIR CONDITIONING SYSTEM ELECTRICAL DIAGRAM…842

AIR CONDITIONING SYSTEM DIAGRAM…843

AIR CONDITIONING COMPRESSOR…844

REMOVAL…844

INSTALLATION…844

COMPRESSOR CLUTCH SERVICE…845

RECEIVER/DRYER…850

SERVICE…850

REMOVAL…850

INSTALLATION…850

CONDENSER…851

REMOVAL…851

INSTALLATION…851

AIR CONDITIONER/HEATER UNIT…852

ELECTRICAL DIAGRAM…852

ASSEMBLY DIAGRAM…853

REMOVAL…855

INSTALLATION…855

ASSEMBLY…856

AIR CONDITIONING SYSTEM CHARGING PROCEDURE…879

CHECKING COMPRESSOR OIL LEVEL…881

40 MAINTENANCE STANDARD…883

FINAL DRIVE…884

NO SPIN DIFFERENTIAL CASE ASSEMBLY…885

NO SPIN DIFFERENTIAL ASSEMBLY…886

FINAL DRIVE AND TANDEMS…887

TANDEM DRIVE…888

BRAKE VALVE…889

STEERING CYLINDER…890

LEANING WHEEL CYLINDER…891

MOLDBOARD TILT CYLINDER…892

MOLDBOARD SIDE SHIFT…893

DRAWBAR SIDE SHIFT CYLINDER…894

DRAWBAR LIFT CYLINDER…895

SCARIFIER CYLINDER…896

ARTICULATION CYLINDER…897

RIPPER CYLINDER…898

LUG NUTS…899

FRONT AXLE…900

POWER TILT MOLDBOARD CARRIER…901

FRAME…902

DRAWBAR AND CIRCLE…903

DRAWBAR LIFT…904

ENGINE AND TRANSMISSION…905

DRIVE LINE…906

ALTERNATOR…907

CAB MOUNT…908

90 OTHER…909

ORIGINAL ELECTRICAL DIAGRAM (SHEET 1 OF 3)…911

ORIGINAL ELECTRICAL DIAGRAM (SHEET 2 OF 3)…913

ORIGINAL ELECTRICAL DIAGRAM (SHEET 3 OF 3)…915

REVISED ELECTRICAL DIAGRAM (SHEET 1 PART 1 OF 2)…917

REVISED ELECTRICAL DIAGRAM (SHEET 1 PART 2 OF 2)…919

REVISED ELECTRICAL DIAGRAM (SHEET 2)…921

800 TRANSMISSION WITH AWD DIAGRAM…923

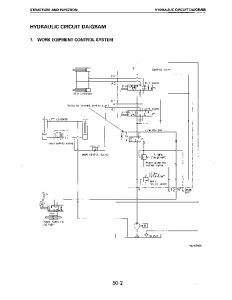

HYDRAULIC CIRCUIT DIAGRAM (SHEET 1 OF 2)…925

HYDRAULIC CIRCUIT DIAGRAM (SHEET 2 OF 2)…927

Komatsu GD530A,AW & GD650A,AW & GD670A,AW & GD530A(W)-2 & GD650A(W)-2 & GD670A(W)-2 & GD530A(W)-2B(C)Y & GD650A(W)-2B(C)Y & GD670A(W)-2B(C)Y Motor Graders Repair Service Manual + Operation & Maintenance Manual