Complete service repair manual with Electrical Wiring Diagrams for Komatsu Forklift FBRJ-2R, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Forklift FBRJ-2R workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

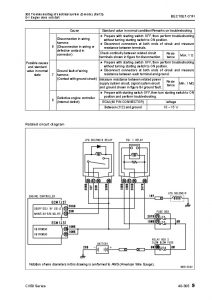

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

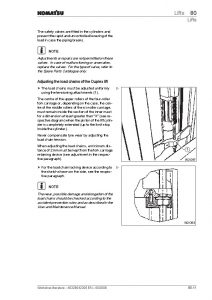

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

8054 349 – Komatsu Forklift FBRJ-2R Workshop Manual.pdf

PRODUCT DETAILS:

Total Pages: 390 pages

File Format: PDF

Language: English

MAIN SECTIONS

Guide to chapters…4

Guide to components…6

Contents…7

Chapter 1 – Chapter 6…7

Chapter 7 – Chapter 9…8

Chapter 9 – Chapter 11…9

Chapter 11- Chapter 12…10

Chapter 12 – Chapter 13…11

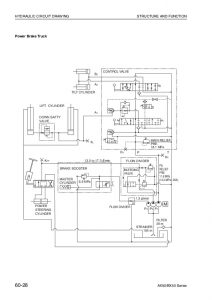

Chapter 14 – Chapter 20…12

Chapter 21 – Chapter 27…13

Chapter 28 – Chapter 38…14

Chapter 38 – Chapter 39…15

Chapter 40 – Chapter 41…16

Chapter 1 Vehicle data…17

Chapter 2 Drive motor…21

Chapter 3 Drive wheel…35

Chapter 4 Gear…36

Chapter 5 Electro-magnetic parking brake…39

Chapter 6 Generator service brake…46

Chapter 7 Hydraulic/mechanical service brake…47

Chapter 8 Brake deceleration…59

Chapter 9 Steering…61

Chapter 10 Electronic components…89

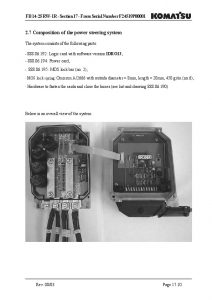

Chapter 11 FPS…95

Chapter 12 LAS-Module…126

Chapter 13 Converters…155

Chapter 14 Display…174

Chapter 15 CAN-Bus…189

Chapter 16 Supply and emergency-stopcircuit…198

Chapter 18 Single-lever potentiometer…199

Chapter 19 Inductive proximity switches…201

Chapter 20 Travel transducer…202

Chapter 21 DC/DC Converter…204

Chapter 22 Height measuring system…205

Chapter 23 Foot pedal adjustment…210

Chapter 24 Hydraulic functions…211

Chapter 25 Chassis valve block…216

Chapter 26 Reach carriage valve block…223

Chapter 27 Additional hydraulics valve block…227

Chapter 28 Line break protection…228

Chapter 29 Lowering brake valve…230

Chapter 30 Load holding valve…231

Chapter 33 Hydraulic pump…232

Chapter 34 Tank indicator…233

Chapter 35 Tank…234

Chapter 36 Runback filter…235

Chapter 37 Lubrication plan…236

Chapter 38 Servicesoftware…239

Chapter 39 Error codes…320

Chapter 40 WINFLASH…345

Chapter 41 Height preselection…366

Komatsu Forklift Truck FBRJ-2R Repair Service Manual