INSTANT DOWNLOAD

Complete service repair manual with Electrical Wiring Diagrams for Komatsu 95 Series Diesel Engines, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu 95 Series Diesel Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBE61460114 – 95 Series Diesel Engine Shop Manual.pdf

SEBM018803 – 95-2 Series Diesel Engine Shop Manual.pdf

SEBM031001 – 95-3 Series Diesel Engines Shop Manual.pdf

SEN04408-00 – 95 Series Diesel Engine Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,422 pages

File Format: PDF

Language: English

MAIN SECTIONS

01 GENERAL ……. 01-1

11 STRUCTURE AND FUNCTION …. 11-1

12 TESTING AND ADJUSTING ….. 12-1

13 DISASSEMBLY AND ASSEMBLY …. 13-1

14 MAINTENANCE STANDARD ….. 14-1

15 REPAIR AND REPLACEMENT OF PARTS … 15-1

Complete service repair manual with Electrical Wiring Diagrams for Komatsu 95 Series Diesel Engines, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu 95 Series Diesel Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBE61460114 – 95 Series Diesel Engine Shop Manual.pdf

SEBM018803 – 95-2 Series Diesel Engine Shop Manual.pdf

SEBM031001 – 95-3 Series Diesel Engines Shop Manual.pdf

SEN04408-00 – 95 Series Diesel Engine Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,422 pages

File Format: PDF

Language: English

MAIN SECTIONS

01 GENERAL ……. 01-1

11 STRUCTURE AND FUNCTION …. 11-1

12 TESTING AND ADJUSTING ….. 12-1

13 DISASSEMBLY AND ASSEMBLY …. 13-1

14 MAINTENANCE STANDARD ….. 14-1

15 REPAIR AND REPLACEMENT OF PARTS … 15-1

SEBE61460114 – 95 Series Diesel Engine Shop Manual…………….2

CONTENTS…………….3

01 GENERAL …………….28

GENERAL VIEW …………….29

SPECIFICATIONS …………….31

GENERAL ASSEMBLY DRAWING …………….53

ENGINE PERFORMANCE CURVE …………….95

WEIGHT TABLE…………….155

11 STRUCTURE AND FUNCTION …………….158

GENERAL STRUCTURE …………….159

INTAKE AND EXHAUST SYSTEM …………….170

INTAKE AND EXHAUST SYSTEM…………….170

FTG AIR CLEANER…………….186

TURBOCHARGER…………….190

AFTER-COOLER…………….197

ENGINE BODY…………….199

CYLINDER HEAD…………….199

VALVE SYSTEM…………….219

CYLINDER BLOCK…………….227

CYLINDER LINER…………….233

MAIN CIRCULATION SYSTEM…………….235

TIMING GEAR…………….253

FLYWHEEL AND FLYWHEEL HOUSING…………….259

LUBRICATION SYSTEM…………….264

LUBRICATION SYSTEM CHART…………….264

OIL PUMP …………….270

OIL FILTER …………….271

OIL COOLER …………….273

FUEL SYSTEM …………….275

FUEL SYSTEM CHART …………….275

FUEL INJECTION PUMP …………….287

GOVERNOR…………….317

FEED PUMP…………….321

FUEL INJECTION NOZZLE …………….323

FUEL CUT SOLENOID …………….326

ENGINE STOP MOTOR …………….329

FUEL FILTER …………….334

WATER SEPARATOR …………….335

COOLING SYSTEM …………….336

COOLING SYSTEM CHART …………….336

WATER PUMP …………….339

CORROSION RESISTOR (OPTION) …………….342

THERMOSTAT AND FAN DRIVE …………….343

ELECTRICAL SYSTEM…………….353

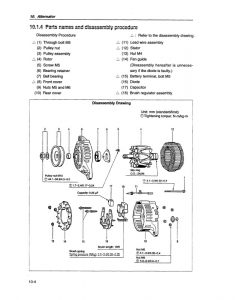

ALTERNATOR…………….353

STARTING MOTOR …………….362

ELECTRICAL INTAKE AIR HEATER …………….368

ACCESSORY…………….373

AIR COMPRESSOR…………….373

12 TESTING AND ADJUSTING…………….376

INTAKE AND EXHAUST SYSTEM…………….377

ADJUSTING VALVE CLEARANCE…………….377

MEASURING EXHAUST GAS COLOR…………….379

ENGINE BODY…………….380

MEASURING COMPRESSION PRESSURE…………….380

MEASURING BLOW-BY PRESSURE…………….381

ADJUSTING ENGINE SPEED SENSOR…………….382

FUEL SYSTEM…………….383

CHECKING AND ADJUSTING FUEL INJECTION TIMING…………….383

ADJUSTING GOVERNOR…………….393

TESTING AND ADJUSTING FUEL CUT SOLENOID…………….396

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE…………….401

ADJUSTING FUEL INJECTION PRESSURE…………….403

LUBRICATION SYSTEM…………….406

MEASURING OIL PRESSURE…………….406

MEASURING OIL TEMPERATURE…………….407

COOLING SYSTEM…………….408

MEASURING WATER TEMPERATURE…………….408

TESTING AND ADJUSTING FAN BELT TENSION…………….409

FUEL INJECTION PUMP CALIBRATION DATA…………….410

PERFORMANCE TEST…………….529

RUN-IN STANDARD…………….529

PERFORMANCE TEST CRITERIA…………….538

TESTING AND ADJUSTING TOOL LIST…………….559

TESTING AND ADJUSTING DATA…………….560

TROUBLESHOOTING…………….583

METHOD OF USING TROUBLESHOOTING TABLE…………….584

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………….588

S-1 Starting performance is poor (Starting always takes time) …………….589

S-2 Engine does not start…………….590

(1) Engine does not turn…………….590

(2) Engine turns but no exhaust gas comes out (Fuel is not being injected)…………….591

(3) Exhaust gas comes out but engine does not start (Fuel is being injected)…………….592

S-3 Engine does not pick up smoothly (Follow-up is poor) …………….593

S-4 Engine stops during operations …………….594

S-5 Engine does not rotate smoothly …………….595

S-6 Engine lacks output (no power) …………….596

S-7 Exhaust gas is black (incomplete combustion) …………….597

S-8 Oil consumption is excessive (or exhaust gas is blue)…………….598

S-9 Oil becomes contaminated quickly …………….599

S-10 Fuel consumption is excessive …………….600

S-11 Oil is in cooling water, or water spurts back, or water level …………….601

S-12 Oil pressure lamp lights up (drop in oil pressure) …………….602

S-13 Oil level rises…………….603

S-14 Water temperature becomes too high (overheating) …………….604

S-15 Abnormal noise is made…………….605

S-16 Vibration is excessive…………….606

S-17 Diagnosis of electronical governor by diagnosis display (electronical governor made by ZEXEL)…………….607

13 DISASSEMBLY AND ASSEMBLY…………….623

3D95S-W-1…………….624

GENERAL DISASSEMBLY…………….625

GENERAL ASSEMBLY …………….632

4D95S-1…………….645

GENERAL DISASSEMBLY…………….646

GENERAL ASSEMBLY …………….656

4D95L SERIES…………….672

GENERAL DISASSEMBLY…………….672

GENERAL ASSEMBLY…………….686

6D95L SERIES…………….708

GENERAL DISASSEMBLY…………….708

GENERAL ASSEMBLY…………….722

DISASSEMBLY AND ASSEMBLY OF AIR COMPRESSOR…………….746

14 MAINTENANCE STANDARD …………….753

TURBOCHARGER …………….754

CYLINDER HEAD …………….757

VALVE, VALVE GUIDE…………….762

ROCKER ARM SHAFT, PUSH ROD AND TAPPET…………….765

CYLINDER BLOCK …………….766

CRANKSHAFT …………….768

CAMSHAFT …………….772

TIMING GEAR (HELICAL GEAR) …………….778

FLYWHEEL AND FLYWHEEL HOUSING …………….783

PISTON, PISTON RING AND PISTON PIN…………….784

CONNECTING ROD …………….793

OIL PUMP …………….794

REGULATOR VALVE …………….796

WATER PUMP, THERMOSTAT …………….797

FUEL SYSTEM …………….800

15 REPAIR AND REPLACEMENT …………….803

CYLINDER HEAD SECTION…………….805

GRINDING CYLINDER HEAD MOUNTING SURFACE …………….805

REPLACING VALVE SEAT INSERT…………….806

REPLACING VALVE GUIDE …………….810

GRINDING VALVE …………….811

CYLINDER BLOCK SECTION…………….812

REPLACING CAM BUSHING …………….812

REPLACING GEARS…………….814

PROCEDURE FOR PRESSURE TEST …………….816

CYLINDER LINER (SPECIAL RESTORATION PART) …………….817

MACHINING DRAWING FOR CYLINDER BLOCK BORE …………….818

ADDITIONAL MACHINING OF CAM JOURNAL …………….819

GRINDING CRANKSHAFT …………….820

SEBM018803 – 95-2 Series Diesel Engine Shop Manual…………….822

COVER…………….822

CONTENTS…………….823

SAFETY…………….826

SAFETY NOTICE…………….826

FOREWORD…………….828

GENERAL…………….828

HOW TO READ THE SHOP MANUAL…………….829

HOISTING INSTRUCTIONS…………….830

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER…………….831

COATING MATERIALS…………….833

STANDARD TIGHTENING TORQUE…………….835

ELECTRIC WIRE CODE…………….838

CONVERSION TABLE…………….839

UNITS…………….845

01 GENERAL…………….846

APPLICABLE MACHINE…………….847

SPECIFICATIONS…………….848

WEIGHT TABLE…………….850

OVERALL DRAWING …………….851

ENGINE PERFORMANCE CURVE…………….854

11 STRUCTURE AND FUNCTION…………….857

GENERAL STRUCTURE…………….858

GENERAL STRUCTURE…………….858

INTAKE AND EXHAUST SYSTEM …………….860

INTAKE AND EXHAUST SYSTEM …………….860

AIR CLEANER…………….862

ENGINE BODY…………….864

CYLINDER HEAD…………….864

CYLINDER BLOCK…………….866

MAIN CIRCULATION SYSTEM…………….868

TIMING GEAR…………….870

VALVE SYSTEM …………….872

FLYWHEEL AND FLYWHEEL HOUSING…………….874

LUBRICATION SYSTEM …………….876

LUBRICATION SYSTEM CHART…………….876

OIL PUMP…………….877

OIL FILTER …………….878

OIL FILTER MOUNT…………….879

FUEL SYSTEM …………….881

FUEL SYSTEM CHART…………….881

FUEL INJECTION PUMP…………….882

FUEL INJECTION NOZZLE…………….884

FUEL FILTER…………….885

ENGINE CUT SOLENOID…………….886

COOLING SYSTEM…………….887

COOLING SYSTEM CHART…………….887

WATER PUMP…………….888

FAN DRIVE AND THERMOSTAT…………….889

ELECTRICAL SYSTEM …………….892

STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM…………….892

ALTERNATOR…………….893

STARTING MOTOR…………….894

ENGINE STARTING DEVICE…………….895

12 TESTING AND ADJUSTING…………….896

TESTING AND ADJUSTING…………….897

ADJUSTING VALVLE CLEARANCE…………….897

MEASURING COMPRESSION PRESSURE…………….899

ADJUSTING FUEL INJECTION PRESSURE…………….900

TESTING AND ADJUSTING FUEL INJECTION TIMING…………….901

ADJUSTING FUEL CUT SOLENOID…………….905

FUEL INJECTION PUMP CALIBRATION DATA…………….908

PERFORMANCE TEST …………….911

RUN-IN STANDARD…………….911

PERFORMANCE TEST CRITERIA …………….912

TROUBLESHOOTING…………….914

METHOD OF USING TROUBLESHOOTING CHARTS…………….915

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………….919

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………….920

S-2 ENGINE DOES NOT START…………….921

(1) ENGINE DOES NOT TURN…………….921

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)…………….922

(3) EXHAUST SMOKE COMES OUT, BUT ENGINE DOES NOT START (FUEL IS NOT BEING INJECTED)…………….923

S-3 ENGINE DOES NOT PICK UP SMOOTHLY…………….924

S-4 ENGINE STOPS DURING OPERATIONS…………….925

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…………….926

S-6 ENGINE LACK OUTPUT (NO POWER)…………….927

S-7 EXHAUST GAS IS BLACK…………….928

S-8 OIL CONSUMPTION IS EXCESSIVE, OR EXHAUST GAS IS BLUE…………….929

S-9 OIL BECOMES CONTAMINATED QUICKLY…………….930

S-10 FUEL CONSUMPTION IS EXCESSIVE…………….931

S-11 OIL IS IN COOLING WATER …………….932

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UPS (DROP IN OIL PRESSURE)…………….933

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL )…………….934

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)…………….935

S-15 ABNORMAL NOISE IS MADE…………….936

S-16 VIBRATION IS EXCESSIVE…………….937

TESTING AND ADJUSTING TOOL LIST…………….938

TESTING AND ADJUSTING DATA…………….939

13 DISASSEMBLY AND ASSEMBLY…………….941

SPECIAL TOOL LIST…………….942

OVERALL DISASSEMBLY OF 4D95LC-2…………….943

PREPARATORY WORK…………….944

1. ALTERNATOR, FAN PULLEY…………….944

2. STARTING MOTOR, ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK…………….945

3. WATER PUMP…………….945

4. FUEL INJECTION TUBE, GLOW PLUG…………….945

5. INJECTION NOZZLE…………….945

6. FUEL INJECTION PUMP…………….946

7. INTAKE MANIFOLD…………….946

8. EXHAUST MANIFOLD…………….946

9. HEAD COVER…………….946

10. ROCKER ARM…………….947

11. PUSH ROD, CYLINDER HEAD MOUNTING BOLT…………….947

12. CYLINDER HEAD COVER…………….947

13. PTO SHAFT…………….948

14. OIL PAN…………….949

15. OIL SUCTION PIPE…………….949

16. CRANKSHAFT PULLEY…………….949

17. GEAR CASE COVER…………….949

18. OIL PUMP, IDLER GEAR…………….950

19. CAMSHAFT ASSEMBLY…………….950

20. FLYWHEEL…………….950

21. FLYWHEEL HOUSING…………….951

22. PISTION, CONNECTING ROD ASSEMBLY…………….951

23. MAIN CAP…………….953

24. CRANKSHAFT…………….954

25. TAPPET…………….954

26.CYLINDER BLOCK ASSEMBLY…………….954

OVERALL ASSEMBLY…………….955

1. CYLINDER BLOCK ASSEMBLY…………….955

2. TAPPET…………….955

3. CRANKSHAFT…………….955

4. MAIN CAP…………….956

5. FLYWHEEL HOUSING…………….959

6. FLYWHEEL…………….960

7. CAMSHAFT ASSEMBLY…………….960

8. OIL PUMP, IDLER GEAR…………….961

9. GEAR CASE COVER…………….962

10. CRANKSHAFT PULLEY…………….962

11. OIL SUCTION PIPE…………….962

12. OIL PAN…………….963

13. PTO SHAFT…………….963

14. FUEL INJECTION PUMP…………….963

15. CYLINDER HEAD ASSEMBLY…………….964

16. ADJUSTMENT OF VALVE CLEARANCE…………….966

17. HEAD COVER…………….967

18. EXHAUST MANIFOLD…………….967

19. INTAKE MANIFOLD…………….967

20. INJECTION NOZZLE…………….967

21. FUEL INJECTION TUBE, GLOW PLUG…………….968

22. WATER PUMP…………….968

23. STARTING MOTOR. ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK…………….968

24. ALTERNATOR, FAN PULLEY…………….969

25. ENGINE ASSEMBLY…………….969

26. FAN, EXHAUST PIPE, MUFFLER, ENGINE OIL TUBES, BLOCK, COVER…………….970

14 MAINTENANCE STANDARD…………….971

CYLINDER HEAD…………….972

VALVE AND VALVE GUIDE…………….973

ROCKER ARM SHAFT, PUSH ROD AND TAPPET…………….974

CYLINDER BLOCK…………….975

CYLINDER…………….976

CRANKSHAFT…………….977

CAMSHAFT…………….978

TIMING GEAR…………….979

PISTION, PISTON RING AND PISTION PIN…………….980

CONNECTING ROD…………….981

FLYWHEEL AND FLYWHEEL HOUSING…………….982

OIL PUMP…………….983

REGULATOR VALVE…………….984

WATER PUMP AND THERMOSTAT…………….985

15 REPAIR AND REPLACEMENT OF PARTS…………….986

CYLINDER HEAD SECTION…………….987

GRINDING CYLINDER HEAD MOUNTING SURFACE…………….987

REPLACING VALVE GUIDE…………….988

GRINDING VALVE…………….989

CYLINDER BLOCK SECTION…………….990

REPLACING CAMSHAFT BUSHING…………….990

REPLACING CRANKSHAFT GEAR…………….992

REPLACING CAM GEAR…………….993

REPLACING FLYWHEEL RING GEAR…………….994

PROCEDURE FOR PRESSURE TEST …………….995

CYLINDER LINER (SPECIAL RESTORATION PART)…………….996

MACHINING DRAWING FOR CYLINDER BLOCK BORE…………….997

ADDITIONAL MACHINING OF CAM JOURNAL…………….998

GRINDING CRANKSHAFT…………….999

REPLACING CONNECTING ROD SMALL END BUSHING…………….1000

SEBM031001 – 95-3 Series Diesel Engines Shop Manual…………….1002

SAFETY …………….1006

SAFETY NOTICE …………….1006

FOREWORD …………….1008

GENERAL …………….1008

STANDARD TIGHTENING TORQUE …………….1015

CONVERSION TABLE …………….1019

SPECIFICATIONS …………….1031

OVERALL DRAWING …………….1037

GENERAL STRUCTURE …………….1047

INTAKE AND EXHAUST SYSTEM …………….1049

AIR CLEANER …………….1053

CYLINDER …………….1066

MAIN CIRCULATION SYSTEM …………….1067

CRANKSHAFT …………….1071

CONNECTING ROD …………….1075

TIMING GEAR …………….1081

CAMSHAFT …………….1087

ROCKER ARM SHAFT, PUSH ROD AND TAPPET …………….1088

OIL PUMP …………….1091

OIL FILTER …………….1098

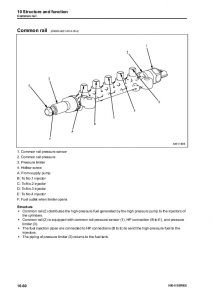

FUEL SYSTEM CHART …………….1100

FUEL INJECTION PUMP …………….1103

COOLING SYSTEM CHART …………….1114

WATER PUMP …………….1115

STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM …………….1121

ADJUSTING VALVE CLEARANCE …………….1129

MEASURING COMPRESSION PRESSURE …………….1131

ADJUSTING FUEL INJECTION PRESSURE ( CRACKING PRESSURE) …………….1132

PERFORMANCE TEST …………….1145

METHOD OF USING TROUBLESHOOTING CHARTS …………….1151

POINTS TO REMEMBER WHEN TROUBLESHOOTING …………….1155

TESTING AND ADJUSTING TOOL LIST …………….1174

SPECIAL TOOL LIST …………….1179

OVERALL DISASSEMBLY, ASSEMBLY …………….1180

DISASSEMBLY …………….1181

ASSEMBLY …………….1193

GRINDING CYLINDER HEAD MOUNTING SURFACE …………….1211

REPLACING VALVE GUIDE …………….1212

GRINDING VALVE …………….1213

REPLACING CAMSHAFT BUSHING …………….1214

REPLACING CRANKSHAFT GEAR …………….1216

REPLACING CAM GEAR …………….1217

REPLACING FLYWHEEL RING GEAR …………….1218

PROCEDURE FOR PRESSURE TEST …………….1219

CYLINDER LINER ( SPECIAL RESTORATION PART) …………….1220

MACHINING DRAWING FOR CYLINDER BLOCK BORE …………….1221

GRINDING CRANKSHAFT …………….1223

SEN04408-00 – 95 Series Diesel Engine Shop Manual…………….1226

SEN04408-00 WA65-6, WA70-6, WA80-6…………….1226

CONTENTS…………….1227

SAFETY…………….1227

FOREWORD…………….1229

01 GENERAL…………….1248

General…………….1249

General view…………….1251

4D95LWE-5…………….1251

S4D95LWE-5…………….1253

Specifications…………….1255

General assembly drawing…………….1257

4D95LWE-5 LEFT SIDE VIEW (WA65HH-6)…………….1257

4D95LWE-5 RIGHT SIDE VIEW (WA65HH-6)…………….1258

4D95LWE-5 FRONT VIEW (WA65HH-6)…………….1259

4D95LWE-5 REAR VIEW (WA65HH-6)…………….1260

S4D95LWE-5 LEFT SIDE VIEW (WA80HH-6)…………….1261

S4D95LWE-5 RIGHT SIDE VIEW (WA80HH-6)…………….1262

S4D95LWE-5 FRONT VIEW (WA80HH-6)…………….1263

S4D95LWE-5 REAR VIEW (WA80HH-6)…………….1264

DIMENSION TABLE…………….1265

Engine performance curve…………….1266

4D95LWE-5 [Applicable machine: WA65-HH-6]…………….1266

4D95LWE-5 [Applicable machine: WA70-HH-6]…………….1267

4D95LWE-5 [Applicable machine: WA80-HH-6]…………….1268

Weight table…………….1269

11 STRUCTURE AND FUNCTION…………….1270

General structure…………….1271

EXHAUST SYSTEM…………….1275

Turbocharger…………….1275

TD04L…………….1275

Outline of waste gate valve…………….1276

ENGINE BODY…………….1277

Cylinder head…………….1277

4D95LWE-5…………….1277

Cylinder head…………….1278

Head cover…………….1278

S4D95LWE-5…………….1279

Cylinder head…………….1280

Head cover…………….1280

Cylinder block…………….1281

Main moving parts…………….1283

Timing gear…………….1285

WITHOUT FRONT PTO TYPE (HELICAL GEAR)…………….1285

Front oil seal…………….1286

Valve system…………….1287

Flywheel and flywheel housing…………….1289

WITHOUT REAR PTO TYPE…………….1289

LUBRICATION SYSTEM…………….1291

Lubrication system chart…………….1291

Oil pump…………….1292

Specifications…………….1292

Oil pump…………….1292

Regulator valve…………….1292

Oil filter…………….1293

Relief valve…………….1293

FUEL SYSTEM…………….1294

Fuel system chart…………….1294

Fuel injection pump…………….1295

Fuel injection nozzle…………….1297

For direct fuel injection type…………….1297

For swirl chamber type…………….1297

Fuel injection nozzle…………….1297

COOLING STSTEM…………….1298

Cooling system chart…………….1298

Thermostat and fan drive…………….1299

THERMOSTAT (WITHOUT JIGGLE VALVE)…………….1301

ELECTRICAL SYSTEM…………….1302

Starting and charging system electrical circuit diagram…………….1302

Alternator…………….1303

ALTERNATOR WITH BUILT-IN REGULATOR (Open type, 90A)…………….1303

Starting motor…………….1305

For 2.2 kW…………….1305

Engine starting device…………….1306

GLOW PLUG (METAL 2-WIRE TYPE GLOW PLUG)…………….1306

1. Connector (round 8-pin), (Short 8-pin)…………….1307

2. Lead wire…………….1307

3. Case…………….1307

4. Bracket…………….1307

5. Label…………….1307

1. Water temperature sensor…………….1307

1. Glow relay…………….1307

2. Lead wire…………….1307

3. Connector (round 2-in)…………….1307

12 TESTING AND ADJUSTING…………….1308

Performance test…………….1309

Run-in standard…………….1309

Performance test criteria…………….1311

Testing and adjusting data…………….1313

Testing and adjusting tools list…………….1314

Intake and exhaust system…………….1315

Adjusting valve clearance…………….1315

Engine body…………….1317

Measuring compression pressure…………….1317

Measurement procedure…………….1317

Fuel system…………….1318

Adjusting fuel injection pressure (Cracking pressure)…………….1318

Shim data for adjusting injection pressure…………….1319

Testing and adjusting fuel injection timing…………….1320

Table of injection pumps using plunger with stepped lead…………….1325

Adjusting fuel injection rate…………….1326

Governor adjustment standard…………….1327

Troubleshooting…………….1330

Method of using troubleshooting charts…………….1331

Points on troubleshooting…………….1335

S-1 Starting performance is poor (Starting always takes time)…………….1336

S-2 Engine does not start…………….1337

1) Engine does not turn…………….1337

2) Engine turns but no exhaust gas comes out (Fuel is not being injected)…………….1338

3) Exhaust gas comes out but engine does not start (Fuel is being injected)…………….1339

S-3 Engine does not pick up smoothly (Follow-up is poor)…………….1340

S-4 Engine stops during operations…………….1341

S-5 Engine does not rotate smoothly…………….1342

S-6 Engine lacks output (no power)…………….1343

S-7 Exhaust gas is black (incomplete combustion)…………….1344

S-8 Oil consumption is excessive (or exhaust gas is blue)…………….1345

S-9 Oil becomes contaminated quickly…………….1346

S-10 Fuel consumption is excessive…………….1347

S-11 Oil is in coolant, or coolant spurts back, or coolant level goes down…………….1348

S-12 Oil pressure lamp lights up (drop in oil pressure)…………….1349

S-13 Oil level rises…………….1350

S-14 Coolant temperature becomes too high (overheating)…………….1351

S-15 Abnormal noise is made…………….1352

S-16 Vibration is excessive…………….1353

13 DISASSEMLY AND ASSEMBLY…………….1354

General disassembly…………….1355

Special tools…………….1355

General assembly…………….1367

Special tools…………….1367

14 MAINTENANCE STANDARD…………….1386

Turbocharger…………….1387

Cylinder head…………….1389

Valve, valve guide…………….1391

Rocker arm shaft, push rod and tappet…………….1392

Cylinder block…………….1393

Cylinder…………….1395

Crankshaft…………….1396

Camshaft…………….1397

Timing gear (Helical gear)…………….1399

Flywheel and flywheel housing…………….1400

Piston, piston ring and piston pin…………….1401

Connecting rod…………….1403

Regulator valve…………….1405

Water pump and thermostat…………….1406

15 REPAIR AND REPLACEMENT OF PARTS…………….1408

Grinding cylinder head mounting surface…………….1409

Replacing valve guide…………….1410

Special tools…………….1410

Grinding valve…………….1411

Special tool…………….1411

Replacing camshaft bushing…………….1412

Special tools…………….1412

Replacing crankshaft gear…………….1414

Testing and adjusting fuel injection timing…………….1415

Replacing flywheel ring gear…………….1416

Procedure for pressure test…………….1417

Special tools…………….1417

Cylinder liner…………….1418

(special restoration part)…………….1418

Cylinder liner…………….1418

Machining drawing for cylinder block bore…………….1419

Additional machining of cam journal…………….1420

Grinding crankshaft…………….1421

Applicable crankshaft…………….1421

Replacing connecting rod small end bushing…………….1422

Special tools…………….1422

Komatsu 95 Series Diesel Engine Repair Service Manuals

Complete service repair manual with Electrical Wiring Diagrams for Komatsu 95 Series Diesel Engines, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu 95 Series Diesel Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBE61460114 – 95 Series Diesel Engine Shop Manual.pdf

SEBM018803 – 95-2 Series Diesel Engine Shop Manual.pdf

SEBM031001 – 95-3 Series Diesel Engines Shop Manual.pdf

SEN04408-00 – 95 Series Diesel Engine Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,422 pages

File Format: PDF

Language: English

MAIN SECTIONS

01 GENERAL ……. 01-1

11 STRUCTURE AND FUNCTION …. 11-1

12 TESTING AND ADJUSTING ….. 12-1

13 DISASSEMBLY AND ASSEMBLY …. 13-1

14 MAINTENANCE STANDARD ….. 14-1

15 REPAIR AND REPLACEMENT OF PARTS … 15-1

SEBE61460114 – 95 Series Diesel Engine Shop Manual…………….2

CONTENTS…………….3

01 GENERAL …………….28

GENERAL VIEW …………….29

SPECIFICATIONS …………….31

GENERAL ASSEMBLY DRAWING …………….53

ENGINE PERFORMANCE CURVE …………….95

WEIGHT TABLE…………….155

11 STRUCTURE AND FUNCTION …………….158

GENERAL STRUCTURE …………….159

INTAKE AND EXHAUST SYSTEM …………….170

INTAKE AND EXHAUST SYSTEM…………….170

FTG AIR CLEANER…………….186

TURBOCHARGER…………….190

AFTER-COOLER…………….197

ENGINE BODY…………….199

CYLINDER HEAD…………….199

VALVE SYSTEM…………….219

CYLINDER BLOCK…………….227

CYLINDER LINER…………….233

MAIN CIRCULATION SYSTEM…………….235

TIMING GEAR…………….253

FLYWHEEL AND FLYWHEEL HOUSING…………….259

LUBRICATION SYSTEM…………….264

LUBRICATION SYSTEM CHART…………….264

OIL PUMP …………….270

OIL FILTER …………….271

OIL COOLER …………….273

FUEL SYSTEM …………….275

FUEL SYSTEM CHART …………….275

FUEL INJECTION PUMP …………….287

GOVERNOR…………….317

FEED PUMP…………….321

FUEL INJECTION NOZZLE …………….323

FUEL CUT SOLENOID …………….326

ENGINE STOP MOTOR …………….329

FUEL FILTER …………….334

WATER SEPARATOR …………….335

COOLING SYSTEM …………….336

COOLING SYSTEM CHART …………….336

WATER PUMP …………….339

CORROSION RESISTOR (OPTION) …………….342

THERMOSTAT AND FAN DRIVE …………….343

ELECTRICAL SYSTEM…………….353

ALTERNATOR…………….353

STARTING MOTOR …………….362

ELECTRICAL INTAKE AIR HEATER …………….368

ACCESSORY…………….373

AIR COMPRESSOR…………….373

12 TESTING AND ADJUSTING…………….376

INTAKE AND EXHAUST SYSTEM…………….377

ADJUSTING VALVE CLEARANCE…………….377

MEASURING EXHAUST GAS COLOR…………….379

ENGINE BODY…………….380

MEASURING COMPRESSION PRESSURE…………….380

MEASURING BLOW-BY PRESSURE…………….381

ADJUSTING ENGINE SPEED SENSOR…………….382

FUEL SYSTEM…………….383

CHECKING AND ADJUSTING FUEL INJECTION TIMING…………….383

ADJUSTING GOVERNOR…………….393

TESTING AND ADJUSTING FUEL CUT SOLENOID…………….396

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE…………….401

ADJUSTING FUEL INJECTION PRESSURE…………….403

LUBRICATION SYSTEM…………….406

MEASURING OIL PRESSURE…………….406

MEASURING OIL TEMPERATURE…………….407

COOLING SYSTEM…………….408

MEASURING WATER TEMPERATURE…………….408

TESTING AND ADJUSTING FAN BELT TENSION…………….409

FUEL INJECTION PUMP CALIBRATION DATA…………….410

PERFORMANCE TEST…………….529

RUN-IN STANDARD…………….529

PERFORMANCE TEST CRITERIA…………….538

TESTING AND ADJUSTING TOOL LIST…………….559

TESTING AND ADJUSTING DATA…………….560

TROUBLESHOOTING…………….583

METHOD OF USING TROUBLESHOOTING TABLE…………….584

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………….588

S-1 Starting performance is poor (Starting always takes time) …………….589

S-2 Engine does not start…………….590

(1) Engine does not turn…………….590

(2) Engine turns but no exhaust gas comes out (Fuel is not being injected)…………….591

(3) Exhaust gas comes out but engine does not start (Fuel is being injected)…………….592

S-3 Engine does not pick up smoothly (Follow-up is poor) …………….593

S-4 Engine stops during operations …………….594

S-5 Engine does not rotate smoothly …………….595

S-6 Engine lacks output (no power) …………….596

S-7 Exhaust gas is black (incomplete combustion) …………….597

S-8 Oil consumption is excessive (or exhaust gas is blue)…………….598

S-9 Oil becomes contaminated quickly …………….599

S-10 Fuel consumption is excessive …………….600

S-11 Oil is in cooling water, or water spurts back, or water level …………….601

S-12 Oil pressure lamp lights up (drop in oil pressure) …………….602

S-13 Oil level rises…………….603

S-14 Water temperature becomes too high (overheating) …………….604

S-15 Abnormal noise is made…………….605

S-16 Vibration is excessive…………….606

S-17 Diagnosis of electronical governor by diagnosis display (electronical governor made by ZEXEL)…………….607

13 DISASSEMBLY AND ASSEMBLY…………….623

3D95S-W-1…………….624

GENERAL DISASSEMBLY…………….625

GENERAL ASSEMBLY …………….632

4D95S-1…………….645

GENERAL DISASSEMBLY…………….646

GENERAL ASSEMBLY …………….656

4D95L SERIES…………….672

GENERAL DISASSEMBLY…………….672

GENERAL ASSEMBLY…………….686

6D95L SERIES…………….708

GENERAL DISASSEMBLY…………….708

GENERAL ASSEMBLY…………….722

DISASSEMBLY AND ASSEMBLY OF AIR COMPRESSOR…………….746

14 MAINTENANCE STANDARD …………….753

TURBOCHARGER …………….754

CYLINDER HEAD …………….757

VALVE, VALVE GUIDE…………….762

ROCKER ARM SHAFT, PUSH ROD AND TAPPET…………….765

CYLINDER BLOCK …………….766

CRANKSHAFT …………….768

CAMSHAFT …………….772

TIMING GEAR (HELICAL GEAR) …………….778

FLYWHEEL AND FLYWHEEL HOUSING …………….783

PISTON, PISTON RING AND PISTON PIN…………….784

CONNECTING ROD …………….793

OIL PUMP …………….794

REGULATOR VALVE …………….796

WATER PUMP, THERMOSTAT …………….797

FUEL SYSTEM …………….800

15 REPAIR AND REPLACEMENT …………….803

CYLINDER HEAD SECTION…………….805

GRINDING CYLINDER HEAD MOUNTING SURFACE …………….805

REPLACING VALVE SEAT INSERT…………….806

REPLACING VALVE GUIDE …………….810

GRINDING VALVE …………….811

CYLINDER BLOCK SECTION…………….812

REPLACING CAM BUSHING …………….812

REPLACING GEARS…………….814

PROCEDURE FOR PRESSURE TEST …………….816

CYLINDER LINER (SPECIAL RESTORATION PART) …………….817

MACHINING DRAWING FOR CYLINDER BLOCK BORE …………….818

ADDITIONAL MACHINING OF CAM JOURNAL …………….819

GRINDING CRANKSHAFT …………….820

SEBM018803 – 95-2 Series Diesel Engine Shop Manual…………….822

COVER…………….822

CONTENTS…………….823

SAFETY…………….826

SAFETY NOTICE…………….826

FOREWORD…………….828

GENERAL…………….828

HOW TO READ THE SHOP MANUAL…………….829

HOISTING INSTRUCTIONS…………….830

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER…………….831

COATING MATERIALS…………….833

STANDARD TIGHTENING TORQUE…………….835

ELECTRIC WIRE CODE…………….838

CONVERSION TABLE…………….839

UNITS…………….845

01 GENERAL…………….846

APPLICABLE MACHINE…………….847

SPECIFICATIONS…………….848

WEIGHT TABLE…………….850

OVERALL DRAWING …………….851

ENGINE PERFORMANCE CURVE…………….854

11 STRUCTURE AND FUNCTION…………….857

GENERAL STRUCTURE…………….858

GENERAL STRUCTURE…………….858

INTAKE AND EXHAUST SYSTEM …………….860

INTAKE AND EXHAUST SYSTEM …………….860

AIR CLEANER…………….862

ENGINE BODY…………….864

CYLINDER HEAD…………….864

CYLINDER BLOCK…………….866

MAIN CIRCULATION SYSTEM…………….868

TIMING GEAR…………….870

VALVE SYSTEM …………….872

FLYWHEEL AND FLYWHEEL HOUSING…………….874

LUBRICATION SYSTEM …………….876

LUBRICATION SYSTEM CHART…………….876

OIL PUMP…………….877

OIL FILTER …………….878

OIL FILTER MOUNT…………….879

FUEL SYSTEM …………….881

FUEL SYSTEM CHART…………….881

FUEL INJECTION PUMP…………….882

FUEL INJECTION NOZZLE…………….884

FUEL FILTER…………….885

ENGINE CUT SOLENOID…………….886

COOLING SYSTEM…………….887

COOLING SYSTEM CHART…………….887

WATER PUMP…………….888

FAN DRIVE AND THERMOSTAT…………….889

ELECTRICAL SYSTEM …………….892

STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM…………….892

ALTERNATOR…………….893

STARTING MOTOR…………….894

ENGINE STARTING DEVICE…………….895

12 TESTING AND ADJUSTING…………….896

TESTING AND ADJUSTING…………….897

ADJUSTING VALVLE CLEARANCE…………….897

MEASURING COMPRESSION PRESSURE…………….899

ADJUSTING FUEL INJECTION PRESSURE…………….900

TESTING AND ADJUSTING FUEL INJECTION TIMING…………….901

ADJUSTING FUEL CUT SOLENOID…………….905

FUEL INJECTION PUMP CALIBRATION DATA…………….908

PERFORMANCE TEST …………….911

RUN-IN STANDARD…………….911

PERFORMANCE TEST CRITERIA …………….912

TROUBLESHOOTING…………….914

METHOD OF USING TROUBLESHOOTING CHARTS…………….915

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………….919

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………….920

S-2 ENGINE DOES NOT START…………….921

(1) ENGINE DOES NOT TURN…………….921

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)…………….922

(3) EXHAUST SMOKE COMES OUT, BUT ENGINE DOES NOT START (FUEL IS NOT BEING INJECTED)…………….923

S-3 ENGINE DOES NOT PICK UP SMOOTHLY…………….924

S-4 ENGINE STOPS DURING OPERATIONS…………….925

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…………….926

S-6 ENGINE LACK OUTPUT (NO POWER)…………….927

S-7 EXHAUST GAS IS BLACK…………….928

S-8 OIL CONSUMPTION IS EXCESSIVE, OR EXHAUST GAS IS BLUE…………….929

S-9 OIL BECOMES CONTAMINATED QUICKLY…………….930

S-10 FUEL CONSUMPTION IS EXCESSIVE…………….931

S-11 OIL IS IN COOLING WATER …………….932

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UPS (DROP IN OIL PRESSURE)…………….933

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL )…………….934

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)…………….935

S-15 ABNORMAL NOISE IS MADE…………….936

S-16 VIBRATION IS EXCESSIVE…………….937

TESTING AND ADJUSTING TOOL LIST…………….938

TESTING AND ADJUSTING DATA…………….939

13 DISASSEMBLY AND ASSEMBLY…………….941

SPECIAL TOOL LIST…………….942

OVERALL DISASSEMBLY OF 4D95LC-2…………….943

PREPARATORY WORK…………….944

1. ALTERNATOR, FAN PULLEY…………….944

2. STARTING MOTOR, ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK…………….945

3. WATER PUMP…………….945

4. FUEL INJECTION TUBE, GLOW PLUG…………….945

5. INJECTION NOZZLE…………….945

6. FUEL INJECTION PUMP…………….946

7. INTAKE MANIFOLD…………….946

8. EXHAUST MANIFOLD…………….946

9. HEAD COVER…………….946

10. ROCKER ARM…………….947

11. PUSH ROD, CYLINDER HEAD MOUNTING BOLT…………….947

12. CYLINDER HEAD COVER…………….947

13. PTO SHAFT…………….948

14. OIL PAN…………….949

15. OIL SUCTION PIPE…………….949

16. CRANKSHAFT PULLEY…………….949

17. GEAR CASE COVER…………….949

18. OIL PUMP, IDLER GEAR…………….950

19. CAMSHAFT ASSEMBLY…………….950

20. FLYWHEEL…………….950

21. FLYWHEEL HOUSING…………….951

22. PISTION, CONNECTING ROD ASSEMBLY…………….951

23. MAIN CAP…………….953

24. CRANKSHAFT…………….954

25. TAPPET…………….954

26.CYLINDER BLOCK ASSEMBLY…………….954

OVERALL ASSEMBLY…………….955

1. CYLINDER BLOCK ASSEMBLY…………….955

2. TAPPET…………….955

3. CRANKSHAFT…………….955

4. MAIN CAP…………….956

5. FLYWHEEL HOUSING…………….959

6. FLYWHEEL…………….960

7. CAMSHAFT ASSEMBLY…………….960

8. OIL PUMP, IDLER GEAR…………….961

9. GEAR CASE COVER…………….962

10. CRANKSHAFT PULLEY…………….962

11. OIL SUCTION PIPE…………….962

12. OIL PAN…………….963

13. PTO SHAFT…………….963

14. FUEL INJECTION PUMP…………….963

15. CYLINDER HEAD ASSEMBLY…………….964

16. ADJUSTMENT OF VALVE CLEARANCE…………….966

17. HEAD COVER…………….967

18. EXHAUST MANIFOLD…………….967

19. INTAKE MANIFOLD…………….967

20. INJECTION NOZZLE…………….967

21. FUEL INJECTION TUBE, GLOW PLUG…………….968

22. WATER PUMP…………….968

23. STARTING MOTOR. ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK…………….968

24. ALTERNATOR, FAN PULLEY…………….969

25. ENGINE ASSEMBLY…………….969

26. FAN, EXHAUST PIPE, MUFFLER, ENGINE OIL TUBES, BLOCK, COVER…………….970

14 MAINTENANCE STANDARD…………….971

CYLINDER HEAD…………….972

VALVE AND VALVE GUIDE…………….973

ROCKER ARM SHAFT, PUSH ROD AND TAPPET…………….974

CYLINDER BLOCK…………….975

CYLINDER…………….976

CRANKSHAFT…………….977

CAMSHAFT…………….978

TIMING GEAR…………….979

PISTION, PISTON RING AND PISTION PIN…………….980

CONNECTING ROD…………….981

FLYWHEEL AND FLYWHEEL HOUSING…………….982

OIL PUMP…………….983

REGULATOR VALVE…………….984

WATER PUMP AND THERMOSTAT…………….985

15 REPAIR AND REPLACEMENT OF PARTS…………….986

CYLINDER HEAD SECTION…………….987

GRINDING CYLINDER HEAD MOUNTING SURFACE…………….987

REPLACING VALVE GUIDE…………….988

GRINDING VALVE…………….989

CYLINDER BLOCK SECTION…………….990

REPLACING CAMSHAFT BUSHING…………….990

REPLACING CRANKSHAFT GEAR…………….992

REPLACING CAM GEAR…………….993

REPLACING FLYWHEEL RING GEAR…………….994

PROCEDURE FOR PRESSURE TEST …………….995

CYLINDER LINER (SPECIAL RESTORATION PART)…………….996

MACHINING DRAWING FOR CYLINDER BLOCK BORE…………….997

ADDITIONAL MACHINING OF CAM JOURNAL…………….998

GRINDING CRANKSHAFT…………….999

REPLACING CONNECTING ROD SMALL END BUSHING…………….1000

SEBM031001 – 95-3 Series Diesel Engines Shop Manual…………….1002

SAFETY …………….1006

SAFETY NOTICE …………….1006

FOREWORD …………….1008

GENERAL …………….1008

STANDARD TIGHTENING TORQUE …………….1015

CONVERSION TABLE …………….1019

SPECIFICATIONS …………….1031

OVERALL DRAWING …………….1037

GENERAL STRUCTURE …………….1047

INTAKE AND EXHAUST SYSTEM …………….1049

AIR CLEANER …………….1053

CYLINDER …………….1066

MAIN CIRCULATION SYSTEM …………….1067

CRANKSHAFT …………….1071

CONNECTING ROD …………….1075

TIMING GEAR …………….1081

CAMSHAFT …………….1087

ROCKER ARM SHAFT, PUSH ROD AND TAPPET …………….1088

OIL PUMP …………….1091

OIL FILTER …………….1098

FUEL SYSTEM CHART …………….1100

FUEL INJECTION PUMP …………….1103

COOLING SYSTEM CHART …………….1114

WATER PUMP …………….1115

STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM …………….1121

ADJUSTING VALVE CLEARANCE …………….1129

MEASURING COMPRESSION PRESSURE …………….1131

ADJUSTING FUEL INJECTION PRESSURE ( CRACKING PRESSURE) …………….1132

PERFORMANCE TEST …………….1145

METHOD OF USING TROUBLESHOOTING CHARTS …………….1151

POINTS TO REMEMBER WHEN TROUBLESHOOTING …………….1155

TESTING AND ADJUSTING TOOL LIST …………….1174

SPECIAL TOOL LIST …………….1179

OVERALL DISASSEMBLY, ASSEMBLY …………….1180

DISASSEMBLY …………….1181

ASSEMBLY …………….1193

GRINDING CYLINDER HEAD MOUNTING SURFACE …………….1211

REPLACING VALVE GUIDE …………….1212

GRINDING VALVE …………….1213

REPLACING CAMSHAFT BUSHING …………….1214

REPLACING CRANKSHAFT GEAR …………….1216

REPLACING CAM GEAR …………….1217

REPLACING FLYWHEEL RING GEAR …………….1218

PROCEDURE FOR PRESSURE TEST …………….1219

CYLINDER LINER ( SPECIAL RESTORATION PART) …………….1220

MACHINING DRAWING FOR CYLINDER BLOCK BORE …………….1221

GRINDING CRANKSHAFT …………….1223

SEN04408-00 – 95 Series Diesel Engine Shop Manual…………….1226

SEN04408-00 WA65-6, WA70-6, WA80-6…………….1226

CONTENTS…………….1227

SAFETY…………….1227

FOREWORD…………….1229

01 GENERAL…………….1248

General…………….1249

General view…………….1251

4D95LWE-5…………….1251

S4D95LWE-5…………….1253

Specifications…………….1255

General assembly drawing…………….1257

4D95LWE-5 LEFT SIDE VIEW (WA65HH-6)…………….1257

4D95LWE-5 RIGHT SIDE VIEW (WA65HH-6)…………….1258

4D95LWE-5 FRONT VIEW (WA65HH-6)…………….1259

4D95LWE-5 REAR VIEW (WA65HH-6)…………….1260

S4D95LWE-5 LEFT SIDE VIEW (WA80HH-6)…………….1261

S4D95LWE-5 RIGHT SIDE VIEW (WA80HH-6)…………….1262

S4D95LWE-5 FRONT VIEW (WA80HH-6)…………….1263

S4D95LWE-5 REAR VIEW (WA80HH-6)…………….1264

DIMENSION TABLE…………….1265

Engine performance curve…………….1266

4D95LWE-5 [Applicable machine: WA65-HH-6]…………….1266

4D95LWE-5 [Applicable machine: WA70-HH-6]…………….1267

4D95LWE-5 [Applicable machine: WA80-HH-6]…………….1268

Weight table…………….1269

11 STRUCTURE AND FUNCTION…………….1270

General structure…………….1271

EXHAUST SYSTEM…………….1275

Turbocharger…………….1275

TD04L…………….1275

Outline of waste gate valve…………….1276

ENGINE BODY…………….1277

Cylinder head…………….1277

4D95LWE-5…………….1277

Cylinder head…………….1278

Head cover…………….1278

S4D95LWE-5…………….1279

Cylinder head…………….1280

Head cover…………….1280

Cylinder block…………….1281

Main moving parts…………….1283

Timing gear…………….1285

WITHOUT FRONT PTO TYPE (HELICAL GEAR)…………….1285

Front oil seal…………….1286

Valve system…………….1287

Flywheel and flywheel housing…………….1289

WITHOUT REAR PTO TYPE…………….1289

LUBRICATION SYSTEM…………….1291

Lubrication system chart…………….1291

Oil pump…………….1292

Specifications…………….1292

Oil pump…………….1292

Regulator valve…………….1292

Oil filter…………….1293

Relief valve…………….1293

FUEL SYSTEM…………….1294

Fuel system chart…………….1294

Fuel injection pump…………….1295

Fuel injection nozzle…………….1297

For direct fuel injection type…………….1297

For swirl chamber type…………….1297

Fuel injection nozzle…………….1297

COOLING STSTEM…………….1298

Cooling system chart…………….1298

Thermostat and fan drive…………….1299

THERMOSTAT (WITHOUT JIGGLE VALVE)…………….1301

ELECTRICAL SYSTEM…………….1302

Starting and charging system electrical circuit diagram…………….1302

Alternator…………….1303

ALTERNATOR WITH BUILT-IN REGULATOR (Open type, 90A)…………….1303

Starting motor…………….1305

For 2.2 kW…………….1305

Engine starting device…………….1306

GLOW PLUG (METAL 2-WIRE TYPE GLOW PLUG)…………….1306

1. Connector (round 8-pin), (Short 8-pin)…………….1307

2. Lead wire…………….1307

3. Case…………….1307

4. Bracket…………….1307

5. Label…………….1307

1. Water temperature sensor…………….1307

1. Glow relay…………….1307

2. Lead wire…………….1307

3. Connector (round 2-in)…………….1307

12 TESTING AND ADJUSTING…………….1308

Performance test…………….1309

Run-in standard…………….1309

Performance test criteria…………….1311

Testing and adjusting data…………….1313

Testing and adjusting tools list…………….1314

Intake and exhaust system…………….1315

Adjusting valve clearance…………….1315

Engine body…………….1317

Measuring compression pressure…………….1317

Measurement procedure…………….1317

Fuel system…………….1318

Adjusting fuel injection pressure (Cracking pressure)…………….1318

Shim data for adjusting injection pressure…………….1319

Testing and adjusting fuel injection timing…………….1320

Table of injection pumps using plunger with stepped lead…………….1325

Adjusting fuel injection rate…………….1326

Governor adjustment standard…………….1327

Troubleshooting…………….1330

Method of using troubleshooting charts…………….1331

Points on troubleshooting…………….1335

S-1 Starting performance is poor (Starting always takes time)…………….1336

S-2 Engine does not start…………….1337

1) Engine does not turn…………….1337

2) Engine turns but no exhaust gas comes out (Fuel is not being injected)…………….1338

3) Exhaust gas comes out but engine does not start (Fuel is being injected)…………….1339

S-3 Engine does not pick up smoothly (Follow-up is poor)…………….1340

S-4 Engine stops during operations…………….1341

S-5 Engine does not rotate smoothly…………….1342

S-6 Engine lacks output (no power)…………….1343

S-7 Exhaust gas is black (incomplete combustion)…………….1344

S-8 Oil consumption is excessive (or exhaust gas is blue)…………….1345

S-9 Oil becomes contaminated quickly…………….1346

S-10 Fuel consumption is excessive…………….1347

S-11 Oil is in coolant, or coolant spurts back, or coolant level goes down…………….1348

S-12 Oil pressure lamp lights up (drop in oil pressure)…………….1349

S-13 Oil level rises…………….1350

S-14 Coolant temperature becomes too high (overheating)…………….1351

S-15 Abnormal noise is made…………….1352

S-16 Vibration is excessive…………….1353

13 DISASSEMLY AND ASSEMBLY…………….1354

General disassembly…………….1355

Special tools…………….1355

General assembly…………….1367

Special tools…………….1367

14 MAINTENANCE STANDARD…………….1386

Turbocharger…………….1387

Cylinder head…………….1389

Valve, valve guide…………….1391

Rocker arm shaft, push rod and tappet…………….1392

Cylinder block…………….1393

Cylinder…………….1395

Crankshaft…………….1396

Camshaft…………….1397

Timing gear (Helical gear)…………….1399

Flywheel and flywheel housing…………….1400

Piston, piston ring and piston pin…………….1401

Connecting rod…………….1403

Regulator valve…………….1405

Water pump and thermostat…………….1406

15 REPAIR AND REPLACEMENT OF PARTS…………….1408

Grinding cylinder head mounting surface…………….1409

Replacing valve guide…………….1410

Special tools…………….1410

Grinding valve…………….1411

Special tool…………….1411

Replacing camshaft bushing…………….1412

Special tools…………….1412

Replacing crankshaft gear…………….1414

Testing and adjusting fuel injection timing…………….1415

Replacing flywheel ring gear…………….1416

Procedure for pressure test…………….1417

Special tools…………….1417

Cylinder liner…………….1418

(special restoration part)…………….1418

Cylinder liner…………….1418

Machining drawing for cylinder block bore…………….1419

Additional machining of cam journal…………….1420

Grinding crankshaft…………….1421

Applicable crankshaft…………….1421

Replacing connecting rod small end bushing…………….1422

Special tools…………….1422

Komatsu 95 Series Diesel Engine Repair Service Manuals

Complete service repair manual with Electrical Wiring Diagrams for Komatsu 95 Series Diesel Engines, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu 95 Series Diesel Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBE61460114 – 95 Series Diesel Engine Shop Manual.pdf

SEBM018803 – 95-2 Series Diesel Engine Shop Manual.pdf

SEBM031001 – 95-3 Series Diesel Engines Shop Manual.pdf

SEN04408-00 – 95 Series Diesel Engine Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,422 pages

File Format: PDF

Language: English

MAIN SECTIONS

01 GENERAL ……. 01-1

11 STRUCTURE AND FUNCTION …. 11-1

12 TESTING AND ADJUSTING ….. 12-1

13 DISASSEMBLY AND ASSEMBLY …. 13-1

14 MAINTENANCE STANDARD ….. 14-1

15 REPAIR AND REPLACEMENT OF PARTS … 15-1

SEBE61460114 – 95 Series Diesel Engine Shop Manual…………….2

CONTENTS…………….3

01 GENERAL …………….28

GENERAL VIEW …………….29

SPECIFICATIONS …………….31

GENERAL ASSEMBLY DRAWING …………….53

ENGINE PERFORMANCE CURVE …………….95

WEIGHT TABLE…………….155

11 STRUCTURE AND FUNCTION …………….158

GENERAL STRUCTURE …………….159

INTAKE AND EXHAUST SYSTEM …………….170

INTAKE AND EXHAUST SYSTEM…………….170

FTG AIR CLEANER…………….186

TURBOCHARGER…………….190

AFTER-COOLER…………….197

ENGINE BODY…………….199

CYLINDER HEAD…………….199

VALVE SYSTEM…………….219

CYLINDER BLOCK…………….227

CYLINDER LINER…………….233

MAIN CIRCULATION SYSTEM…………….235

TIMING GEAR…………….253

FLYWHEEL AND FLYWHEEL HOUSING…………….259

LUBRICATION SYSTEM…………….264

LUBRICATION SYSTEM CHART…………….264

OIL PUMP …………….270

OIL FILTER …………….271

OIL COOLER …………….273

FUEL SYSTEM …………….275

FUEL SYSTEM CHART …………….275

FUEL INJECTION PUMP …………….287

GOVERNOR…………….317

FEED PUMP…………….321

FUEL INJECTION NOZZLE …………….323

FUEL CUT SOLENOID …………….326

ENGINE STOP MOTOR …………….329

FUEL FILTER …………….334

WATER SEPARATOR …………….335

COOLING SYSTEM …………….336

COOLING SYSTEM CHART …………….336

WATER PUMP …………….339

CORROSION RESISTOR (OPTION) …………….342

THERMOSTAT AND FAN DRIVE …………….343

ELECTRICAL SYSTEM…………….353

ALTERNATOR…………….353

STARTING MOTOR …………….362

ELECTRICAL INTAKE AIR HEATER …………….368

ACCESSORY…………….373

AIR COMPRESSOR…………….373

12 TESTING AND ADJUSTING…………….376

INTAKE AND EXHAUST SYSTEM…………….377

ADJUSTING VALVE CLEARANCE…………….377

MEASURING EXHAUST GAS COLOR…………….379

ENGINE BODY…………….380

MEASURING COMPRESSION PRESSURE…………….380

MEASURING BLOW-BY PRESSURE…………….381

ADJUSTING ENGINE SPEED SENSOR…………….382

FUEL SYSTEM…………….383

CHECKING AND ADJUSTING FUEL INJECTION TIMING…………….383

ADJUSTING GOVERNOR…………….393

TESTING AND ADJUSTING FUEL CUT SOLENOID…………….396

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE…………….401

ADJUSTING FUEL INJECTION PRESSURE…………….403

LUBRICATION SYSTEM…………….406

MEASURING OIL PRESSURE…………….406

MEASURING OIL TEMPERATURE…………….407

COOLING SYSTEM…………….408

MEASURING WATER TEMPERATURE…………….408

TESTING AND ADJUSTING FAN BELT TENSION…………….409

FUEL INJECTION PUMP CALIBRATION DATA…………….410

PERFORMANCE TEST…………….529

RUN-IN STANDARD…………….529

PERFORMANCE TEST CRITERIA…………….538

TESTING AND ADJUSTING TOOL LIST…………….559

TESTING AND ADJUSTING DATA…………….560

TROUBLESHOOTING…………….583

METHOD OF USING TROUBLESHOOTING TABLE…………….584

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………….588

S-1 Starting performance is poor (Starting always takes time) …………….589

S-2 Engine does not start…………….590

(1) Engine does not turn…………….590

(2) Engine turns but no exhaust gas comes out (Fuel is not being injected)…………….591

(3) Exhaust gas comes out but engine does not start (Fuel is being injected)…………….592

S-3 Engine does not pick up smoothly (Follow-up is poor) …………….593

S-4 Engine stops during operations …………….594

S-5 Engine does not rotate smoothly …………….595

S-6 Engine lacks output (no power) …………….596

S-7 Exhaust gas is black (incomplete combustion) …………….597

S-8 Oil consumption is excessive (or exhaust gas is blue)…………….598

S-9 Oil becomes contaminated quickly …………….599

S-10 Fuel consumption is excessive …………….600

S-11 Oil is in cooling water, or water spurts back, or water level …………….601

S-12 Oil pressure lamp lights up (drop in oil pressure) …………….602

S-13 Oil level rises…………….603

S-14 Water temperature becomes too high (overheating) …………….604

S-15 Abnormal noise is made…………….605

S-16 Vibration is excessive…………….606

S-17 Diagnosis of electronical governor by diagnosis display (electronical governor made by ZEXEL)…………….607

13 DISASSEMBLY AND ASSEMBLY…………….623

3D95S-W-1…………….624

GENERAL DISASSEMBLY…………….625

GENERAL ASSEMBLY …………….632

4D95S-1…………….645

GENERAL DISASSEMBLY…………….646

GENERAL ASSEMBLY …………….656

4D95L SERIES…………….672

GENERAL DISASSEMBLY…………….672

GENERAL ASSEMBLY…………….686

6D95L SERIES…………….708

GENERAL DISASSEMBLY…………….708

GENERAL ASSEMBLY…………….722

DISASSEMBLY AND ASSEMBLY OF AIR COMPRESSOR…………….746

14 MAINTENANCE STANDARD …………….753

TURBOCHARGER …………….754

CYLINDER HEAD …………….757

VALVE, VALVE GUIDE…………….762

ROCKER ARM SHAFT, PUSH ROD AND TAPPET…………….765

CYLINDER BLOCK …………….766

CRANKSHAFT …………….768

CAMSHAFT …………….772

TIMING GEAR (HELICAL GEAR) …………….778

FLYWHEEL AND FLYWHEEL HOUSING …………….783

PISTON, PISTON RING AND PISTON PIN…………….784

CONNECTING ROD …………….793

OIL PUMP …………….794

REGULATOR VALVE …………….796

WATER PUMP, THERMOSTAT …………….797

FUEL SYSTEM …………….800

15 REPAIR AND REPLACEMENT …………….803

CYLINDER HEAD SECTION…………….805

GRINDING CYLINDER HEAD MOUNTING SURFACE …………….805

REPLACING VALVE SEAT INSERT…………….806

REPLACING VALVE GUIDE …………….810

GRINDING VALVE …………….811

CYLINDER BLOCK SECTION…………….812

REPLACING CAM BUSHING …………….812

REPLACING GEARS…………….814

PROCEDURE FOR PRESSURE TEST …………….816

CYLINDER LINER (SPECIAL RESTORATION PART) …………….817

MACHINING DRAWING FOR CYLINDER BLOCK BORE …………….818

ADDITIONAL MACHINING OF CAM JOURNAL …………….819

GRINDING CRANKSHAFT …………….820

SEBM018803 – 95-2 Series Diesel Engine Shop Manual…………….822

COVER…………….822

CONTENTS…………….823

SAFETY…………….826

SAFETY NOTICE…………….826

FOREWORD…………….828

GENERAL…………….828

HOW TO READ THE SHOP MANUAL…………….829

HOISTING INSTRUCTIONS…………….830

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER…………….831

COATING MATERIALS…………….833

STANDARD TIGHTENING TORQUE…………….835

ELECTRIC WIRE CODE…………….838

CONVERSION TABLE…………….839

UNITS…………….845

01 GENERAL…………….846

APPLICABLE MACHINE…………….847

SPECIFICATIONS…………….848

WEIGHT TABLE…………….850

OVERALL DRAWING …………….851

ENGINE PERFORMANCE CURVE…………….854

11 STRUCTURE AND FUNCTION…………….857

GENERAL STRUCTURE…………….858

GENERAL STRUCTURE…………….858

INTAKE AND EXHAUST SYSTEM …………….860

INTAKE AND EXHAUST SYSTEM …………….860

AIR CLEANER…………….862

ENGINE BODY…………….864

CYLINDER HEAD…………….864

CYLINDER BLOCK…………….866

MAIN CIRCULATION SYSTEM…………….868

TIMING GEAR…………….870

VALVE SYSTEM …………….872

FLYWHEEL AND FLYWHEEL HOUSING…………….874

LUBRICATION SYSTEM …………….876

LUBRICATION SYSTEM CHART…………….876

OIL PUMP…………….877

OIL FILTER …………….878

OIL FILTER MOUNT…………….879

FUEL SYSTEM …………….881

FUEL SYSTEM CHART…………….881

FUEL INJECTION PUMP…………….882

FUEL INJECTION NOZZLE…………….884

FUEL FILTER…………….885

ENGINE CUT SOLENOID…………….886

COOLING SYSTEM…………….887

COOLING SYSTEM CHART…………….887

WATER PUMP…………….888

FAN DRIVE AND THERMOSTAT…………….889

ELECTRICAL SYSTEM …………….892

STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM…………….892

ALTERNATOR…………….893

STARTING MOTOR…………….894

ENGINE STARTING DEVICE…………….895

12 TESTING AND ADJUSTING…………….896

TESTING AND ADJUSTING…………….897

ADJUSTING VALVLE CLEARANCE…………….897

MEASURING COMPRESSION PRESSURE…………….899

ADJUSTING FUEL INJECTION PRESSURE…………….900

TESTING AND ADJUSTING FUEL INJECTION TIMING…………….901

ADJUSTING FUEL CUT SOLENOID…………….905

FUEL INJECTION PUMP CALIBRATION DATA…………….908

PERFORMANCE TEST …………….911

RUN-IN STANDARD…………….911

PERFORMANCE TEST CRITERIA …………….912

TROUBLESHOOTING…………….914

METHOD OF USING TROUBLESHOOTING CHARTS…………….915

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………….919

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…………….920

S-2 ENGINE DOES NOT START…………….921

(1) ENGINE DOES NOT TURN…………….921

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)…………….922

(3) EXHAUST SMOKE COMES OUT, BUT ENGINE DOES NOT START (FUEL IS NOT BEING INJECTED)…………….923

S-3 ENGINE DOES NOT PICK UP SMOOTHLY…………….924

S-4 ENGINE STOPS DURING OPERATIONS…………….925

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…………….926

S-6 ENGINE LACK OUTPUT (NO POWER)…………….927

S-7 EXHAUST GAS IS BLACK…………….928

S-8 OIL CONSUMPTION IS EXCESSIVE, OR EXHAUST GAS IS BLUE…………….929

S-9 OIL BECOMES CONTAMINATED QUICKLY…………….930

S-10 FUEL CONSUMPTION IS EXCESSIVE…………….931

S-11 OIL IS IN COOLING WATER …………….932

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UPS (DROP IN OIL PRESSURE)…………….933

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL )…………….934

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)…………….935

S-15 ABNORMAL NOISE IS MADE…………….936

S-16 VIBRATION IS EXCESSIVE…………….937

TESTING AND ADJUSTING TOOL LIST…………….938

TESTING AND ADJUSTING DATA…………….939

13 DISASSEMBLY AND ASSEMBLY…………….941

SPECIAL TOOL LIST…………….942

OVERALL DISASSEMBLY OF 4D95LC-2…………….943

PREPARATORY WORK…………….944

1. ALTERNATOR, FAN PULLEY…………….944

2. STARTING MOTOR, ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK…………….945

3. WATER PUMP…………….945

4. FUEL INJECTION TUBE, GLOW PLUG…………….945

5. INJECTION NOZZLE…………….945

6. FUEL INJECTION PUMP…………….946

7. INTAKE MANIFOLD…………….946

8. EXHAUST MANIFOLD…………….946

9. HEAD COVER…………….946

10. ROCKER ARM…………….947

11. PUSH ROD, CYLINDER HEAD MOUNTING BOLT…………….947

12. CYLINDER HEAD COVER…………….947

13. PTO SHAFT…………….948

14. OIL PAN…………….949

15. OIL SUCTION PIPE…………….949

16. CRANKSHAFT PULLEY…………….949

17. GEAR CASE COVER…………….949

18. OIL PUMP, IDLER GEAR…………….950

19. CAMSHAFT ASSEMBLY…………….950

20. FLYWHEEL…………….950

21. FLYWHEEL HOUSING…………….951

22. PISTION, CONNECTING ROD ASSEMBLY…………….951

23. MAIN CAP…………….953

24. CRANKSHAFT…………….954

25. TAPPET…………….954

26.CYLINDER BLOCK ASSEMBLY…………….954

OVERALL ASSEMBLY…………….955

1. CYLINDER BLOCK ASSEMBLY…………….955

2. TAPPET…………….955

3. CRANKSHAFT…………….955

4. MAIN CAP…………….956

5. FLYWHEEL HOUSING…………….959

6. FLYWHEEL…………….960

7. CAMSHAFT ASSEMBLY…………….960

8. OIL PUMP, IDLER GEAR…………….961

9. GEAR CASE COVER…………….962

10. CRANKSHAFT PULLEY…………….962

11. OIL SUCTION PIPE…………….962

12. OIL PAN…………….963

13. PTO SHAFT…………….963

14. FUEL INJECTION PUMP…………….963

15. CYLINDER HEAD ASSEMBLY…………….964

16. ADJUSTMENT OF VALVE CLEARANCE…………….966

17. HEAD COVER…………….967

18. EXHAUST MANIFOLD…………….967

19. INTAKE MANIFOLD…………….967

20. INJECTION NOZZLE…………….967

21. FUEL INJECTION TUBE, GLOW PLUG…………….968

22. WATER PUMP…………….968

23. STARTING MOTOR. ENGINE STOP SOLENOID, FUEL AND OIL FILTERS, DIPSTICK…………….968

24. ALTERNATOR, FAN PULLEY…………….969

25. ENGINE ASSEMBLY…………….969

26. FAN, EXHAUST PIPE, MUFFLER, ENGINE OIL TUBES, BLOCK, COVER…………….970

14 MAINTENANCE STANDARD…………….971

CYLINDER HEAD…………….972

VALVE AND VALVE GUIDE…………….973

ROCKER ARM SHAFT, PUSH ROD AND TAPPET…………….974

CYLINDER BLOCK…………….975

CYLINDER…………….976

CRANKSHAFT…………….977

CAMSHAFT…………….978

TIMING GEAR…………….979

PISTION, PISTON RING AND PISTION PIN…………….980

CONNECTING ROD…………….981

FLYWHEEL AND FLYWHEEL HOUSING…………….982

OIL PUMP…………….983

REGULATOR VALVE…………….984

WATER PUMP AND THERMOSTAT…………….985

15 REPAIR AND REPLACEMENT OF PARTS…………….986

CYLINDER HEAD SECTION…………….987

GRINDING CYLINDER HEAD MOUNTING SURFACE…………….987

REPLACING VALVE GUIDE…………….988

GRINDING VALVE…………….989

CYLINDER BLOCK SECTION…………….990

REPLACING CAMSHAFT BUSHING…………….990

REPLACING CRANKSHAFT GEAR…………….992

REPLACING CAM GEAR…………….993

REPLACING FLYWHEEL RING GEAR…………….994

PROCEDURE FOR PRESSURE TEST …………….995

CYLINDER LINER (SPECIAL RESTORATION PART)…………….996

MACHINING DRAWING FOR CYLINDER BLOCK BORE…………….997

ADDITIONAL MACHINING OF CAM JOURNAL…………….998

GRINDING CRANKSHAFT…………….999

REPLACING CONNECTING ROD SMALL END BUSHING…………….1000

SEBM031001 – 95-3 Series Diesel Engines Shop Manual…………….1002

SAFETY …………….1006

SAFETY NOTICE …………….1006

FOREWORD …………….1008

GENERAL …………….1008

STANDARD TIGHTENING TORQUE …………….1015

CONVERSION TABLE …………….1019

SPECIFICATIONS …………….1031

OVERALL DRAWING …………….1037

GENERAL STRUCTURE …………….1047

INTAKE AND EXHAUST SYSTEM …………….1049

AIR CLEANER …………….1053

CYLINDER …………….1066

MAIN CIRCULATION SYSTEM …………….1067

CRANKSHAFT …………….1071

CONNECTING ROD …………….1075

TIMING GEAR …………….1081

CAMSHAFT …………….1087

ROCKER ARM SHAFT, PUSH ROD AND TAPPET …………….1088

OIL PUMP …………….1091

OIL FILTER …………….1098

FUEL SYSTEM CHART …………….1100

FUEL INJECTION PUMP …………….1103

COOLING SYSTEM CHART …………….1114

WATER PUMP …………….1115

STARTING AND CHARGING SYSTEM ELECTRICAL CIRCUIT DIAGRAM …………….1121

ADJUSTING VALVE CLEARANCE …………….1129

MEASURING COMPRESSION PRESSURE …………….1131

ADJUSTING FUEL INJECTION PRESSURE ( CRACKING PRESSURE) …………….1132

PERFORMANCE TEST …………….1145

METHOD OF USING TROUBLESHOOTING CHARTS …………….1151

POINTS TO REMEMBER WHEN TROUBLESHOOTING …………….1155

TESTING AND ADJUSTING TOOL LIST …………….1174

SPECIAL TOOL LIST …………….1179

OVERALL DISASSEMBLY, ASSEMBLY …………….1180

DISASSEMBLY …………….1181

ASSEMBLY …………….1193

GRINDING CYLINDER HEAD MOUNTING SURFACE …………….1211

REPLACING VALVE GUIDE …………….1212

GRINDING VALVE …………….1213

REPLACING CAMSHAFT BUSHING …………….1214

REPLACING CRANKSHAFT GEAR …………….1216

REPLACING CAM GEAR …………….1217

REPLACING FLYWHEEL RING GEAR …………….1218

PROCEDURE FOR PRESSURE TEST …………….1219

CYLINDER LINER ( SPECIAL RESTORATION PART) …………….1220

MACHINING DRAWING FOR CYLINDER BLOCK BORE …………….1221

GRINDING CRANKSHAFT …………….1223

SEN04408-00 – 95 Series Diesel Engine Shop Manual…………….1226

SEN04408-00 WA65-6, WA70-6, WA80-6…………….1226

CONTENTS…………….1227

SAFETY…………….1227

FOREWORD…………….1229

01 GENERAL…………….1248

General…………….1249

General view…………….1251

4D95LWE-5…………….1251

S4D95LWE-5…………….1253

Specifications…………….1255

General assembly drawing…………….1257

4D95LWE-5 LEFT SIDE VIEW (WA65HH-6)…………….1257

4D95LWE-5 RIGHT SIDE VIEW (WA65HH-6)…………….1258

4D95LWE-5 FRONT VIEW (WA65HH-6)…………….1259

4D95LWE-5 REAR VIEW (WA65HH-6)…………….1260

S4D95LWE-5 LEFT SIDE VIEW (WA80HH-6)…………….1261

S4D95LWE-5 RIGHT SIDE VIEW (WA80HH-6)…………….1262

S4D95LWE-5 FRONT VIEW (WA80HH-6)…………….1263

S4D95LWE-5 REAR VIEW (WA80HH-6)…………….1264

DIMENSION TABLE…………….1265

Engine performance curve…………….1266

4D95LWE-5 [Applicable machine: WA65-HH-6]…………….1266

4D95LWE-5 [Applicable machine: WA70-HH-6]…………….1267

4D95LWE-5 [Applicable machine: WA80-HH-6]…………….1268

Weight table…………….1269

11 STRUCTURE AND FUNCTION…………….1270

General structure…………….1271

EXHAUST SYSTEM…………….1275

Turbocharger…………….1275

TD04L…………….1275

Outline of waste gate valve…………….1276

ENGINE BODY…………….1277

Cylinder head…………….1277

4D95LWE-5…………….1277

Cylinder head…………….1278

Head cover…………….1278

S4D95LWE-5…………….1279

Cylinder head…………….1280

Head cover…………….1280

Cylinder block…………….1281

Main moving parts…………….1283

Timing gear…………….1285

WITHOUT FRONT PTO TYPE (HELICAL GEAR)…………….1285

Front oil seal…………….1286

Valve system…………….1287

Flywheel and flywheel housing…………….1289

WITHOUT REAR PTO TYPE…………….1289

LUBRICATION SYSTEM…………….1291

Lubrication system chart…………….1291

Oil pump…………….1292

Specifications…………….1292

Oil pump…………….1292

Regulator valve…………….1292

Oil filter…………….1293

Relief valve…………….1293

FUEL SYSTEM…………….1294

Fuel system chart…………….1294

Fuel injection pump…………….1295

Fuel injection nozzle…………….1297

For direct fuel injection type…………….1297

For swirl chamber type…………….1297

Fuel injection nozzle…………….1297

COOLING STSTEM…………….1298

Cooling system chart…………….1298

Thermostat and fan drive…………….1299

THERMOSTAT (WITHOUT JIGGLE VALVE)…………….1301

ELECTRICAL SYSTEM…………….1302

Starting and charging system electrical circuit diagram…………….1302

Alternator…………….1303

ALTERNATOR WITH BUILT-IN REGULATOR (Open type, 90A)…………….1303

Starting motor…………….1305

For 2.2 kW…………….1305

Engine starting device…………….1306

GLOW PLUG (METAL 2-WIRE TYPE GLOW PLUG)…………….1306

1. Connector (round 8-pin), (Short 8-pin)…………….1307

2. Lead wire…………….1307

3. Case…………….1307

4. Bracket…………….1307

5. Label…………….1307

1. Water temperature sensor…………….1307

1. Glow relay…………….1307

2. Lead wire…………….1307

3. Connector (round 2-in)…………….1307

12 TESTING AND ADJUSTING…………….1308

Performance test…………….1309

Run-in standard…………….1309

Performance test criteria…………….1311

Testing and adjusting data…………….1313

Testing and adjusting tools list…………….1314

Intake and exhaust system…………….1315

Adjusting valve clearance…………….1315

Engine body…………….1317

Measuring compression pressure…………….1317

Measurement procedure…………….1317

Fuel system…………….1318

Adjusting fuel injection pressure (Cracking pressure)…………….1318

Shim data for adjusting injection pressure…………….1319

Testing and adjusting fuel injection timing…………….1320

Table of injection pumps using plunger with stepped lead…………….1325

Adjusting fuel injection rate…………….1326

Governor adjustment standard…………….1327

Troubleshooting…………….1330

Method of using troubleshooting charts…………….1331

Points on troubleshooting…………….1335

S-1 Starting performance is poor (Starting always takes time)…………….1336

S-2 Engine does not start…………….1337

1) Engine does not turn…………….1337

2) Engine turns but no exhaust gas comes out (Fuel is not being injected)…………….1338

3) Exhaust gas comes out but engine does not start (Fuel is being injected)…………….1339

S-3 Engine does not pick up smoothly (Follow-up is poor)…………….1340

S-4 Engine stops during operations…………….1341

S-5 Engine does not rotate smoothly…………….1342

S-6 Engine lacks output (no power)…………….1343

S-7 Exhaust gas is black (incomplete combustion)…………….1344

S-8 Oil consumption is excessive (or exhaust gas is blue)…………….1345

S-9 Oil becomes contaminated quickly…………….1346

S-10 Fuel consumption is excessive…………….1347

S-11 Oil is in coolant, or coolant spurts back, or coolant level goes down…………….1348

S-12 Oil pressure lamp lights up (drop in oil pressure)…………….1349

S-13 Oil level rises…………….1350

S-14 Coolant temperature becomes too high (overheating)…………….1351

S-15 Abnormal noise is made…………….1352

S-16 Vibration is excessive…………….1353

13 DISASSEMLY AND ASSEMBLY…………….1354

General disassembly…………….1355

Special tools…………….1355

General assembly…………….1367

Special tools…………….1367

14 MAINTENANCE STANDARD…………….1386

Turbocharger…………….1387

Cylinder head…………….1389

Valve, valve guide…………….1391

Rocker arm shaft, push rod and tappet…………….1392

Cylinder block…………….1393

Cylinder…………….1395

Crankshaft…………….1396

Camshaft…………….1397

Timing gear (Helical gear)…………….1399

Flywheel and flywheel housing…………….1400

Piston, piston ring and piston pin…………….1401

Connecting rod…………….1403

Regulator valve…………….1405

Water pump and thermostat…………….1406

15 REPAIR AND REPLACEMENT OF PARTS…………….1408

Grinding cylinder head mounting surface…………….1409

Replacing valve guide…………….1410

Special tools…………….1410

Grinding valve…………….1411

Special tool…………….1411

Replacing camshaft bushing…………….1412

Special tools…………….1412

Replacing crankshaft gear…………….1414

Testing and adjusting fuel injection timing…………….1415

Replacing flywheel ring gear…………….1416

Procedure for pressure test…………….1417

Special tools…………….1417

Cylinder liner…………….1418

(special restoration part)…………….1418

Cylinder liner…………….1418

Machining drawing for cylinder block bore…………….1419

Additional machining of cam journal…………….1420

Grinding crankshaft…………….1421

Applicable crankshaft…………….1421

Replacing connecting rod small end bushing…………….1422

Special tools…………….1422

Komatsu 95 Series Diesel Engine Repair Service Manuals

Complete service repair manual with Electrical Wiring Diagrams for Komatsu 95 Series Diesel Engines, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu 95 Series Diesel Engines workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBE61460114 – 95 Series Diesel Engine Shop Manual.pdf

SEBM018803 – 95-2 Series Diesel Engine Shop Manual.pdf

SEBM031001 – 95-3 Series Diesel Engines Shop Manual.pdf

SEN04408-00 – 95 Series Diesel Engine Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,422 pages

File Format: PDF

Language: English

MAIN SECTIONS

01 GENERAL ……. 01-1

11 STRUCTURE AND FUNCTION …. 11-1

12 TESTING AND ADJUSTING ….. 12-1

13 DISASSEMBLY AND ASSEMBLY …. 13-1

14 MAINTENANCE STANDARD ….. 14-1

15 REPAIR AND REPLACEMENT OF PARTS … 15-1

SEBE61460114 – 95 Series Diesel Engine Shop Manual…………….2

CONTENTS…………….3

01 GENERAL …………….28

GENERAL VIEW …………….29

SPECIFICATIONS …………….31

GENERAL ASSEMBLY DRAWING …………….53

ENGINE PERFORMANCE CURVE …………….95

WEIGHT TABLE…………….155

11 STRUCTURE AND FUNCTION …………….158

GENERAL STRUCTURE …………….159

INTAKE AND EXHAUST SYSTEM …………….170

INTAKE AND EXHAUST SYSTEM…………….170

FTG AIR CLEANER…………….186

TURBOCHARGER…………….190

AFTER-COOLER…………….197

ENGINE BODY…………….199

CYLINDER HEAD…………….199

VALVE SYSTEM…………….219

CYLINDER BLOCK…………….227

CYLINDER LINER…………….233

MAIN CIRCULATION SYSTEM…………….235

TIMING GEAR…………….253

FLYWHEEL AND FLYWHEEL HOUSING…………….259

LUBRICATION SYSTEM…………….264

LUBRICATION SYSTEM CHART…………….264

OIL PUMP …………….270

OIL FILTER …………….271

OIL COOLER …………….273

FUEL SYSTEM …………….275

FUEL SYSTEM CHART …………….275

FUEL INJECTION PUMP …………….287

GOVERNOR…………….317

FEED PUMP…………….321

FUEL INJECTION NOZZLE …………….323

FUEL CUT SOLENOID …………….326

ENGINE STOP MOTOR …………….329

FUEL FILTER …………….334

WATER SEPARATOR …………….335

COOLING SYSTEM …………….336

COOLING SYSTEM CHART …………….336

WATER PUMP …………….339

CORROSION RESISTOR (OPTION) …………….342

THERMOSTAT AND FAN DRIVE …………….343

ELECTRICAL SYSTEM…………….353

ALTERNATOR…………….353

STARTING MOTOR …………….362

ELECTRICAL INTAKE AIR HEATER …………….368

ACCESSORY…………….373

AIR COMPRESSOR…………….373

12 TESTING AND ADJUSTING…………….376

INTAKE AND EXHAUST SYSTEM…………….377

ADJUSTING VALVE CLEARANCE…………….377

MEASURING EXHAUST GAS COLOR…………….379

ENGINE BODY…………….380

MEASURING COMPRESSION PRESSURE…………….380

MEASURING BLOW-BY PRESSURE…………….381

ADJUSTING ENGINE SPEED SENSOR…………….382

FUEL SYSTEM…………….383

CHECKING AND ADJUSTING FUEL INJECTION TIMING…………….383

ADJUSTING GOVERNOR…………….393

TESTING AND ADJUSTING FUEL CUT SOLENOID…………….396

PROCEDURE FOR ADJUSTING ENGINE STOP MOTOR CABLE…………….401

ADJUSTING FUEL INJECTION PRESSURE…………….403

LUBRICATION SYSTEM…………….406

MEASURING OIL PRESSURE…………….406

MEASURING OIL TEMPERATURE…………….407

COOLING SYSTEM…………….408

MEASURING WATER TEMPERATURE…………….408

TESTING AND ADJUSTING FAN BELT TENSION…………….409

FUEL INJECTION PUMP CALIBRATION DATA…………….410

PERFORMANCE TEST…………….529

RUN-IN STANDARD…………….529

PERFORMANCE TEST CRITERIA…………….538

TESTING AND ADJUSTING TOOL LIST…………….559

TESTING AND ADJUSTING DATA…………….560

TROUBLESHOOTING…………….583

METHOD OF USING TROUBLESHOOTING TABLE…………….584

POINTS TO REMEMBER WHEN TROUBLESHOOTING…………….588

S-1 Starting performance is poor (Starting always takes time) …………….589

S-2 Engine does not start…………….590

(1) Engine does not turn…………….590

(2) Engine turns but no exhaust gas comes out (Fuel is not being injected)…………….591

(3) Exhaust gas comes out but engine does not start (Fuel is being injected)…………….592

S-3 Engine does not pick up smoothly (Follow-up is poor) …………….593

S-4 Engine stops during operations …………….594

S-5 Engine does not rotate smoothly …………….595

S-6 Engine lacks output (no power) …………….596

S-7 Exhaust gas is black (incomplete combustion) …………….597

S-8 Oil consumption is excessive (or exhaust gas is blue)…………….598

S-9 Oil becomes contaminated quickly …………….599

S-10 Fuel consumption is excessive …………….600

S-11 Oil is in cooling water, or water spurts back, or water level …………….601

S-12 Oil pressure lamp lights up (drop in oil pressure) …………….602

S-13 Oil level rises…………….603

S-14 Water temperature becomes too high (overheating) …………….604

S-15 Abnormal noise is made…………….605

S-16 Vibration is excessive…………….606

S-17 Diagnosis of electronical governor by diagnosis display (electronical governor made by ZEXEL)…………….607

13 DISASSEMBLY AND ASSEMBLY…………….623

3D95S-W-1…………….624

GENERAL DISASSEMBLY…………….625

GENERAL ASSEMBLY …………….632

4D95S-1…………….645

GENERAL DISASSEMBLY…………….646

GENERAL ASSEMBLY …………….656

4D95L SERIES…………….672

GENERAL DISASSEMBLY…………….672

GENERAL ASSEMBLY…………….686

6D95L SERIES…………….708

GENERAL DISASSEMBLY…………….708

GENERAL ASSEMBLY…………….722

DISASSEMBLY AND ASSEMBLY OF AIR COMPRESSOR…………….746

14 MAINTENANCE STANDARD …………….753

TURBOCHARGER …………….754

CYLINDER HEAD …………….757

VALVE, VALVE GUIDE…………….762

ROCKER ARM SHAFT, PUSH ROD AND TAPPET…………….765

CYLINDER BLOCK …………….766

CRANKSHAFT …………….768

CAMSHAFT …………….772

TIMING GEAR (HELICAL GEAR) …………….778

FLYWHEEL AND FLYWHEEL HOUSING …………….783

PISTON, PISTON RING AND PISTON PIN…………….784

CONNECTING ROD …………….793

OIL PUMP …………….794

REGULATOR VALVE …………….796

WATER PUMP, THERMOSTAT …………….797

FUEL SYSTEM …………….800

15 REPAIR AND REPLACEMENT …………….803

CYLINDER HEAD SECTION…………….805

GRINDING CYLINDER HEAD MOUNTING SURFACE …………….805

REPLACING VALVE SEAT INSERT…………….806

REPLACING VALVE GUIDE …………….810

GRINDING VALVE …………….811

CYLINDER BLOCK SECTION…………….812

REPLACING CAM BUSHING …………….812

REPLACING GEARS…………….814

PROCEDURE FOR PRESSURE TEST …………….816

CYLINDER LINER (SPECIAL RESTORATION PART) …………….817

MACHINING DRAWING FOR CYLINDER BLOCK BORE …………….818

ADDITIONAL MACHINING OF CAM JOURNAL …………….819

GRINDING CRANKSHAFT …………….820

SEBM018803 – 95-2 Series Diesel Engine Shop Manual…………….822

COVER…………….822

CONTENTS…………….823

SAFETY…………….826

SAFETY NOTICE…………….826

FOREWORD…………….828

GENERAL…………….828

HOW TO READ THE SHOP MANUAL…………….829

HOISTING INSTRUCTIONS…………….830

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER…………….831

COATING MATERIALS…………….833

STANDARD TIGHTENING TORQUE…………….835