Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC75R, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC75R-2 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

WEBM004000 – Hydraulic Excavator PC75R-2 Shop Manual.pdf

WEAM002800A – Hydraulic Excavator PC75R-2 Operation & Maintenance Manual.pdf

WEAM002801 – Hydraulic Excavator PC75R-2 Operation & Maintenance Manual.pdf

WEAM003900 – Hydraulic Excavator PC75R-2 Operation & Maintenance Manual.pdf

Total Pages: 1,040 pages

File Format: PDF

Language: English

WEAM002800A – Hydraulic Excavator PC75R-2 Operation & Maintenance Manual….2

COVER….2

1.1 FOREWORD….5

1.2 INFORMATION ON SAFETY….6

1.3 INTRODUCTION….8

1.3.1 INTENDED USES….8

1.3.2 IMPROPER OR UNAUTHORIZED USE….8

1.3.3 MAIN CHARACTERISTICS….9

1.3.4 RUNNING-IN….9

1.4 PRODUCT IDENTIFICATION….10

1.4.1 MACHINE SERIAL NUMBER….10

1.4.2 MACHINE IDENTIFICATION PLATE….10

1.4.3 ENGINE SERIAL NUMBER AND EMISSION LABEL….11

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER….11

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER….12

1.4.6 CAB SERIAL NUMBER….12

1.4.7 SERIAL NUMBERS AND DEALER'S ADDRESS….13

CONTENTS….14

SAFETY AND ACCIDENT PREVENTION….21

2.1 SAFETY PLATES….22

2.1.1 POSITION OF THE SAFETY PLATES….22

2.1.2 POSITION OF THE PICTOGRAMS….38

2.1.3 PICTOGRAMS AND RELEVENT MEANINGS….39

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED….41

2.2 GENERAL PRECAUTIONS….42

2.2.1 GENERAL SAFETY RULES….42

2.2.2 SAFETY DEVICES AND GUARDS….42

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS….42

2.2.4 UNAUTHORIZED MODIFICATIONS….43

2.2.5 LEAVING THE OPERATOR'S SEAT….43

2.2.6 GETTING ON AND OFF THE MACHINE….44

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL….44

2.2.8 PREVENTING BURNS….45

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER….45

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….46

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT….46

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE….46

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT….46

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE….47

2.3.1 SAFETY ON THE WORK SITE….47

2.3.2 FIRE PREVENTION….47

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB….47

2.3.4 ROOM VENTILATION….48

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS….48

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS-CHECKING THE WINDSHIELD WIPER BLADES….48

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING….49

2.4.1 STARTING THE ENGINE….49

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE….49

2.4.3 CHECKS FOR TRAVELLING IN REVERSE….49

2.4.4 MOVING THE MACHINE….50

2.4.5 MOVING THE SLOPES….51

2.4.6 WORKING ON SLOPES….52

2.4.7 UNAUTHORIZED OPERATIONS….52

2.4.8 PREVENTING ELECTROCUTION….53

2.4.9 VISIBILITY….54

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES….54

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….54

2.4.12 WORKING ON LOOSE GROUND….54

2.4.13 PARKING THE MACHINE….55

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES….56

2.5.1 LOADING AND UNLOADING THE MACHINE….56

2.5.2 SHIPPING….56

2.6 BATTERY….57

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES….57

2.6.2 STARTING WITH BOOSTER CABLES….57

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY….58

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE….59

2.8.1 WARNING PLATES….59

2.8.2 TOOLS….59

2.8.3 PERSONNEL….60

2.8.4 EQUIPMENT….60

2.8.5 WORKING UNDER THE MACHINE….60

2.8.6 KEEPING THE MACHINE CLEAN….60

2.8.7 USE OF THE ENGINE DURING MAINTENANCE….61

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY….61

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION….61

2.8.10 RULES FOR REFUELLING AND ADDING OIL….62

2.8.11 CHECKING THE COOLAND LEVEL IN THE RADIATOR….62

2.8.12 USING LAMPS….62

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR….63

2.8.14 PRECAUTIONS CONCERNING THE STARTER….63

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES….64

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS….64

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES….64

2.8.18 COOLING FAN AND FAN BELT….65

2.8.19 WASTE MATERIALS….65

DESCRIPTION AND USE OF THE MACHINE….67

3.1 SAFETY LOCKS….68

3.1.1 MACHINE LOCKS….68

3.2 GENERAL VIEWS….69

3.2.1 FRONT GENERAL VIEW (MONOBOOM)….69

3.2.2 FRONT GENERAL VIEW (TWO-PIECE BOOM)….70

3.2.3 CAB INSIDE GENERAL VIEW….71

3.3 INSTRUMENTS AND CONTROLS….73

3.3.1 INSTRUMENTS, WARNING LIGHTS AND PUSH BUTTONS….73

3.3.2 MACHINE CONTROLS….82

3.4 FUSES AND RELAYS….93

3.4.1 CENTRAL UNIT FUSES AND RELAYS….93

3.4.1.1 CENTRAL UNIT FUSES….94

3.4.1.2 CENTRAL UNIT RELAYS….95

3.4.2 ENGINE LINE FUSES AND RELAYS….96

3.4.2.1 ENGINE LINE FUSES….96

3.4.2.2 ENGINE LINE RELAYS….97

3.5 GAURDS AND DRIVER'S SEAT….98

3.5.1 ENGINE HOOD….98

3.5.2 SIDE COVER….98

3.5.3 CAB….99

3.5.4 VENTILATION AND HEATING….103

3.5.5 SEAT….104

3.5.6 SAFETY BELT….105

3.5.7 EMERGENCY EXIT….105

3.5.8 TECHNICAL DOCUMENTATION CASE….106

3.5.9 FIRE EXTINGUISHER….106

3.5.10 FIRST AID KIT….106

3.6 USE OF THE MACHINE….107

3.6.1 CHECKS BEFORE STARTING THE ENGINE….107

3.6.1.1 VISUAL CHECKS….107

3.6.1.2 DAILY CHECKS….107

3.6.1.3 OPERATIONAL CHECKS….108

3.6.2 STARTING THE ENGINE….109

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES….109

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES….110

3.6.3 WARMING THE ENGINE….111

3.6.4 HEATING THE HYDRAULIC OIL….111

3.6.5 HOW TO MOVE THE MACHINE….111

3.6.5.1 STEERING (CHANGING DIRECTION)….113

3.6.5.2 MOVING ON SLOPES….114

3.6.5.3 MAXIMUM IMMERSION DEPTH….115

3.7 PARKING THE MACHINE….116

3.7.1 PARKING ON LEVEL GROUND….116

3.7.2 PARKING ON SLOPES….117

3.8 STOPPING THE ENGINE….118

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES….119

3.9.1 LOADING AND UNLOADING THE MACHINE….119

3.9.2 TRANSPORT….120

3.10 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON….121

3.10.1 FUEL AND LUBRICANTS….121

3.10.2 COOLANT….121

3.10.3 BATTERY….122

3.10.4 OTHER PRECAUTIONS….122

3.10.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK….122

3.11 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON….123

3.12 USING THE WORK EQUIPMENT….124

3.12.1 ORGANIZING THE WORK AREA….124

3.12.2 POSITIONING THE BUCKET ACCORDING T OTHE WORK TO BE CARRIED OUT….124

3.12.3 POSITIONING THE MACHINE FOR DIGGING OPERATIONS….125

3.12.4 DIGGING METHOD….126

3.12.5 CHANGING THE BUCKET….127

3.13 LONG PERIODS OF INACTIVITY….128

3.13.1 BEFORE THE PERIOD OF INACTIVITY….128

3.13.2 DURING THE PERIOD OF INACTIVITY….129

3.13.3 AFTER THE PERIOD OF INACTIVITY….129

3.14 TROUBLESHOOTING….130

3.14.1 HOW TO REMOVE THE MACHINE….130

3.14.2 IF THE FUEL HAS BEEN COMPLETELY DEPLETED….130

3.14.3 IF THE BATTERY IS DEPLETED….131

3.14.3.1 STARTING WITH BOOSTER CABLES….132

3.14.4 OTHER TROUBLES….133

3.14.4.1 ELECTRICAL CIRCUIT….133

3.14.4.2 HYDRAULIC SYSTEM….134

3.14.4.3 ENGINE….135

MAINTENANCE….137

4.1 GUIDE TO MAINTENANCE….138

4.2 MAINTENANCE NOTES….140

4.2.1 NOTES REGARDING THE ENGINE….140

4.2.1.1 ENGINE OIL….140

4.2.1.2 COOLANT….140

4.2.1.3 FUEL….141

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM….141

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM….142

4.2.4 NOTES REGARDING LUBRICATION….142

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING….143

4.3 FUEL, COOLANT AND LUBRICANTS….144

4.4 NUT AND BOLT TIGHTENING TORQUES….148

4.4.1 STANDARD TIGHTENING TORQUES….148

4.4.2 SPECIFIC TIGHTENING TORQUES….148

4.5 LUBRICATION….149

4.5.1 LUBRICATION DIAGRAM….149

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY….150

4.6.1 CRITICAL PARTS FOR SAFETY….151

4.7 MAINTENANCE PLAN….154

4.7.1 WHEN REQUIRED….157

4.7.1.a CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE….157

4.7.1.b CHECKING AND CLEANING THE CAB AIR FILTER….158

4.7.1.c WASHING THE COOLING CIRCUIT….159

4.7.1.d CLEANING THE WATER SEPARATOR….160

4.7.1.e CHECKING THE STEEL TRACK TENSION….161

4.7.1.f CHECKING THE SHOE FASTENING….163

4.7.1.g CHECKING THE RUBBER TRACKS….164

4.7.1.h CHECKING THE RUBBER TRACK TENSION….166

4.7.1.i CHANGING THE RUBBER TRACK….168

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER….170

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER….170

4.7.2.b CHANGING THE HYDRAULIC OIL….170

4.7.3 CHECKS BEFORE STARTING….171

4.7.3.a VARIOUS CHECKS….171

4.7.3.b CHECKING THE COOLANT LEVEL….171

4.7.3.c CHECKING THE FUEL LEVEL….172

4.7.3.d CHECKING THE ENGINE OIL LEVEL….172

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT….173

4.7.3.f. DRAINING THE WATER SEPARATOR….174

4.7.4 MAINTENANCE EVERY 10 HOURS OF OPERATION….175

4.7.4.a LUBRICATING THE JOINTS….175

4.7.5 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION….178

4.7.6 MAINTENANCE EVERY 50 HOURS OF OPERATION….178

4.7.6.a CHECKING THE RADIATOR FLUID LEVEL….178

4.7.6.b LUBRICATING THE SWING JOINT….178

4.7.6.c CHECKING THE ELECTRICAL SYSTEM….179

4.7.7 MAINTENANCE EVERY 100 HOURS OF OPERATION….180

4.7.7.a LUBRICATING THE BALL-BEARING RING….180

4.7.8 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION….181

4.7.9 MAINTENANCE EVERY 250 HOURS OF OPERATION….181

4.7.9.a ADJUSTING THE FAN BELT TENSION….181

4.7.9.b CHECKING THE BATTERY ELECTROLYTE LEVEL….182

4.7.9.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS….183

4.7.9.d CHECKING THE OIL LEVEL IN THE SWING REDUCTION GEAR….183

4.7.10 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION….184

4.7.11 MAINTENANCE EVERY 500 HOURS OF OPERATION….184

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL FILTER….184

4.7.11.b CHANGING THE SERVO CONTROL FILTER….185

4.7.11.c CHANGING THE ENGINE OIL….186

4.7.11.d CHANGING THE ENGINE OIL FILTER….187

4.7.11.e CHANGING THE FUEL FILTER….188

4.7.11.f DRAINING THE FUEL TANK….189

4.7.11.g CLEANING THE OUTSIDE OF THE RADIATORS….189

4.7.11.h CHECKING THE BALL-BEARING RING PINION LUBRICANT LEVEL….190

4.7.12 MAINTENANCE EVERY 1000 HOURS OF OPERATION….191

4.7.12.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS….191

4.7.12.b CHANGING THE OIL IN THE SWING REDUCTION GEAR….192

4.7.12.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE….192

4.7.13 MAINTENANCE EVERY 2000 HOURS OF OPERATION….193

4.7.13.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER….193

4.7.13.b CHANGING THE COOLANT….196

4.7.13.c CHANGING THE BALL-BEARING RING PINION LUBRICANT….197

4.7.13.d CHECKING THE ALTERNATOR AND THE STARTER….197

TECHNICAL DATA….199

5.1 TECHNICAL DATA….200

5.1.1 STANDARD OVERALL DIMENSIONS….200

5.1.2 TECHNICAL CHARACTERISTICS….201

5.1.3 LIFTING CAPACITIES….202

5.1.3.1 LIFTING CAPACITY TABLE….202

5.1.3.2 LIFTING CAPACITY WITH RAISED BLADE….203

5.1.3.3 LIFTING CAPACITY WITH LOWERED BLADE….204

AUTHORIZED OPTIONAL EQUIPMENT….205

6.1 AUTHORIZED OPTIONAL EQUIPMENT….206

6.1.1 PRECAUTIONS REGARDING SAFETY….206

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT….207

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT….208

6.2 APPARNGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER….209

6.2.1 DESCRIPTION AND OPERATION….209

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED….209

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER….213

6.2.3.1 INSTALLING THE HAMMER….213

6.2.3.2 REMOVING THE HAMMER….214

6.2.4 MAINTENANCE….214

6.3 CLAMSHELL BUCKET….215

6.3.1 DESCRIPTION AND OPERATION….215

6.3.2 INSTALLING THE CLAMSHELL BUCKET….216

6.3.3 MAINTENANCE….218

WEAM002801 – Hydraulic Excavator PC75R-2 Operation & Maintenance Manual….220

COVER….220

1.1 FOREWARD….221

1.2 INFORMATION ON SAFETY….222

1.3 INTRODUCTION….224

1.3.1 INTENDED USES….224

1.3.2 IMPROPER OR UNAUTHORIZED USE….224

1.3.3 MAIN CHARACTERISTICS….225

1.3.4 RUNNING-IN….225

1.4 PRODUCT IDENTIFICATION….226

1.4.1 MACHINE SERIAL NUBER….226

1.4.2 MACHINE IDENTIFICATION PLATE….226

1.4.3 ENGINE SERIAL NUMBER AND EMISSION LABEL….227

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER….227

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER….228

1.4.6 CAB SERIAL NUMBER….228

1.4.7 SERIAL NUMBERS AND DEALER'S ADDRESS….229

CONTENTS….230

SAFETY AND ACCIDENT PREVENTION….237

2.1 SAFETY PLATES….238

2.1.1 POSITION OF THE SAFETY PLATES….238

2.1.2 POSITION OF THE PICTOGRAMS….254

2.1.3 PICTOGRAMS AND RELEVANT MEANINGS….255

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED….257

2.2 GENERAL PRECAUTIONS….258

2.2.1 GENERAL SAFETY RULES….258

2.2.2 SAFETY DEVICES AND GUARDS….258

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS….258

2.2.4 UNAUTHORIZED MODIFICATIONS….259

2.2.5 LEAVING THE OPERATOR'S SEAT….259

2.2.6 GETTING ON AND OFF THE MACHINE….260

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL….260

2.2.8 PREVENTING BURNS….261

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER….261

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….262

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT….262

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE….262

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT….262

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE….263

2.3.1 SAFETY ON THE WORK SITE….263

2.3.2 FIRE PREVENTION….263

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB….263

2.3.4 ROOM VENTILATION….264

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS….264

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS – CHECKING THE WINDSHIELD WIPER BLADES….264

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING….265

2.4.1 STARTING THE ENGINE….265

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE….265

2.4.3 CHECKS FOR TRAVELLING IN REVERSE….265

2.4.4 MOVING THE MACHINE….266

2.4.5 MOVING ON SLOPES….267

2.4.6 WORKING ON SLOPES….268

2.4.7 UNAUTHORIZED OPERATIONS….268

2.4.8 PREVENTING ELECTROCUTION….269

2.4.9 VISIBILITY….270

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES….270

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….270

2.4.12 WORKING ON LOOSE GROUND….270

2.4.13 PARKING THE MACHINE….271

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES….272

2.5.1 LOADING AND UNLOADING THE MACHINE….272

2.5.2 SHIPPING….272

2.6 BATTERY….273

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES….273

2.6.2 STARTING WITH BOOSTER CABLES….273

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY….274

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE….275

2.8.1 WARNING PLATES….275

2.8.2 TOOLS….275

2.8.3 PERSONNEL….276

2.8.4 EQUIPMENT….276

2.8.5 WORKING UNDER THE MACHINE….276

2.8.6 KEEPING THE MACHINE CLEAN….276

2.8.7 USE OF THE ENGINE DURING MAINTENANCE….277

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY….277

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION….277

2.8.10 RULES FOR REFUELLING AND ADDING OIL….278

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR….278

2.8.12 USING LAMPS….278

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR….279

2.8.14 PRECAUTIONS CONCERNING THE STARTER….279

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES….280

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS….280

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES….280

2.8.18 COOLING FAN AND FAN BELT….281

2.8.19 WASTE MATERIALS….281

2.8.20 PRECAUTIONS FOR THE USE OF THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES….281

THE MACHINE AND ITS OPERATIONS….283

3.1 SAFETY LOCKS….284

3.1.1 MACHINE LOCKS….284

3.2 GENERAL VIEWS….285

3.2.1 FRONT GENERAL VIEW (MONOBOOM)….285

3.2.2 FRONT GENERAL VIEW (TWO-PIECE BOOM)….286

3.2.3 CAB INSIDE GENERAL VIEW….287

3.3 INSTRUMENTS AND CONTROLS….289

3.3.1 INSTRUMENTS….289

3.3.2 WARNING LIGHTS….291

3.3.3 SWITCHES AND PUSH BUTTONS….293

3.3.4 ELECTRICAL ACCESSORIES….300

3.3.5 MACHINE CONTROLS….302

3.4 FUSES AND RELAYS….313

3.4.1 CENTRAL UNIT FUSES AND RELAYS….313

3.4.1.1 CENTAL UNIT FUSES….314

3.4.1.2 CENTRAL UNIT RELAYS….315

3.4.2 ENGINE LINE FUSES AND RELAYS….316

3.4.2.1 ENGINE LINE FUSES….316

3.4.2.2 ENGINE LINE RELAYS….317

3.5 GUARDS AND DRIVER'S SEAT….318

3.5.1 ENGINE HOOD….318

3.5.2 SIDE COVER….318

3.5.3 CAB….319

3.5.4 VENTILATION AND HEATING….323

3.5.5 SEAT….324

3.5.6 SAFETY BELT….325

3.5.7 EMERGENCY EXIT….325

3.5.8 TECHNICAL DOCUMENTATION CASE….326

3.5.9 FIRE EXTINGUISHER….326

3.5.10 FIRST AID KIT….326

3.6 USE OF THE MACHINE….327

3.6.1 CHECKS BEFORE STARTING THE ENGINE….327

3.6.1.1 VISUAL CHECKS….327

3.6.1.2 DAILY CHECKS….327

3.6.1.3 OPERATIONAL CHECKS….328

3.6.2 STARTING THE ENGINE….329

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES….329

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES….330

3.6.3 WARMING THE ENGINE….331

3.6.4 HEATING THE HYDRAULIC OIL….331

3.6.5 HOW TO MOVE THE MACHINE….331

3.6.5.1 STEERING (CHANGING DIRECTION)….333

3.6.5.2 MOVING ON SLOPES….334

3.6.5.3 MAXIMUM IMMERSION DEPTH….335

3.7 PARKING THE MACHINE….336

3.7.1 PARKING ON LEVEL GROUND….336

3.7.2 PARKING ON SLOPES….337

3.8 STOPPING THE ENGINE….338

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES….339

3.9.1 LOADING AND UNLOADING THE MACHINE….339

3.9.2 TRANSPORT….340

3.10 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON….341

3.10.1 FUEL AND LUBRICANTS….341

3.10.2 COOLANT….341

3.10.3 BATTERY….342

3.10.4 OTHER PRECAUTIONS….342

3.10.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK….342

3.11 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON….343

3.12 USING THE WORK EQUIPMENT….344

3.12.1 ORGANIZING THE WORK AREA….344

3.12.2 POSITIONING THE BUCKET ACCORDING TO THE WORK TO BE CARRIED OUT….344

3.12.3 POSITIONING THE MACHINE FOR DIGGING OPERATIONS….345

3.12.4 DIGGING METHOD….346

3.12.5 CHANGING THE BUCKET….347

3.13 LONG PERIODS OF INACTIVITY….348

3.13.1 BEFORE THE PERIOD OF INACTIVITY….348

3.13.2 DURING THE PERIOD OF INACTIVITY….349

3.13.3 AFTER THE PERIOD OF INACTIVITY….349

3.14 TROUBLESHOOTING….350

3.14.1 HOW TO REMOVE THE MACHINE….350

3.14.2 IF THE FUEL HAS BEEN COMPLETELY DEPLETED….350

3.14.3 IF THE BATTERY IS DEPLETED….351

3.14.3.1 STARTING WITH BOOSTER CABLES….352

3.14.4 OTHER TROUBLES….353

3.14.4.1 ELECTRICAL CIRCUIT….353

3.14.4.2 HYDRAULIC SYSTEM….354

3.14.4.3 ENGINE….355

MAINTENANCE….357

4.1 GUIDE TO MAINTENANCE….358

4.2 MAINTENANCE NOTES….360

4.2.1 NOTES REGARDING THE ENGINE….360

4.2.1.1 ENGINE OIL….360

4.2.1.2 COOLANT….360

4.2.1.3 FUEL….361

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM….361

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM….362

4.2.4 NOTES REGARDING LUBRICATION….362

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING….363

4.3 FUEL, COOLANT AND LUBRICANTS….364

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS….368

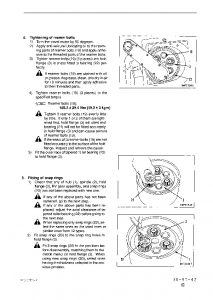

4.4 NUT AND BOLT TIGHTENING TORQUES….369

4.4.1 STANDARD TIGHTENING TORQUES….369

4.4.2 SPECIFIC TIGHTENING TORQUES….369

4.5 LUBRICATION….370

4.5.1 LUBRICATION DIAGRAM….370

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY….371

4.6.1 CRITICAL PARTS FOR SAFETY….372

4.7 MAINTENANCE PLAN….375

4.7.1 WHEN REQUIRED….378

4.7.1.a CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE….378

4.7.1 b CHECKING AND CLEANING THE CAB AIR FILTER….379

4.7.1.c WASHING THE COOLING CIRCUIT….380

4.7.1 d CLEANING THE WATER SEPARATOR….381

4.7.1.e CHECKING THE STEEL TRACK TENSION….382

4.7.1.f CHECKING THE SHOE FASTENING….384

4.7.1.g CHECKING THE RUBBER TRACKS….385

4.7.1.h CHECKING THE RUBBER TRACK TENSION….387

4.7.1.j CHANGING THE RUBBER TRACK….389

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER….391

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER….391

4.7.2.b CHANGING THE HYDRAULIC OIL….391

4.7.3 CHECKS BEFORE STARTING….392

4.7.3.a VARIOUS CHECKS….392

4.7.3.b CHECKING THE COOLANT LEVEL….392

4.7.3.c CHECKING THE FUEL LEVEL….393

4.7.3.d CHECKING THE ENGINE OIL LEVEL….393

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT….394

4.7.3.f DRAINING THE WATER SEPARATOR….395

4.7.4 MAINTENANCE EVERY 10 HOURS OF OPERATION….396

4.7.4.a LUBRICATING THE JOINTS….396

4.7.5 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (ONLY FOR MACHINES IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES….399

4.7.6 MAINTENANCE EVERY 50 HOURS OF OPERATION….399

4.7.6.a CHECKING THE RADIATOR FLUID LEVEL….399

4.7.6.b LUBRICATING THE SWING JOINT….399

4.7.6.c CHECKING THE ELECTRICAL SYSTEM….400

4.7.7 MAINTENANCE EVERY 100 HOURS OF OPERATION….401

4.7.7.a LUBRICATING THE BALL-BEARING RING….401

4.7.8 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION….402

4.7.9 MAINTENANCE EVERY 250 HOURS OF OPERATION….402

4.7.9.a ADJUSTING THE FAN BELT TENSION….402

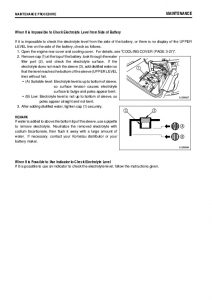

4.7.9.b CHECKING THE BATTERY ELECTROLYTE LEVEL….403

4.7.9.c CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS….404

4.7.9.d CHECKING THE OIL LEVEL IN THE SWING REDUCTION GEAR….404

4.7.10 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION….405

4.7.11 MAINTENANCE EVERY 500 HOURS OF OPERATION….405

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL FILTER….405

4.7.11.b CHANGING THE SERVO CONTROL FILTER….407

4.7.11.c CHANGING THE ENGINE OIL….408

4.7.11.d CHANGING THE ENGINE OIL FILTER….409

4.7.11.e CHANGING THE FUEL FILTER….410

4.7.11.f DRAINING THE FUEL TANK….411

4.7.11.g CLEANING THE OUTSIDE OF THE RADIATORS….411

4.7.11.h CHECKING THE BALL-BEARING RING PINION LUBIRCANT LEVEL….412

4.7.11.j DRAINING THE HYDRAULIC OIL TANK (ONLY FOR MACHINES IN WHICH THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES IS USED)….412

4.7.12 MAINTENANCE EVERY 1000 HOURS OF OPERATION….414

4.7.12.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS….414

4.7.12.b CHANGING THE OIL IN THE SWING REDUCTION GEAR….415

4.7.12.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE….415

4.7.13 MAINTENANCE EVERY 2000 HOURS OF OPERATION….416

4.7.13.a CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER….416

4.7.13.b CHANGING THE COOLANT….419

4.7.13.c CHANGING THE BALL-BEARING RING PINION LUBRICANT….420

4.7.13.d CHECKING THE ALTERNATOR AND THE STARTER….420

TECHNICAL SPECIFICATIONS….421

5.1 TECHNICAL DATA….422

5.1.1 STANDARD OVERALL DIMENSIONS….422

5.1.2 TECHNICAL CHARACTERISTICS….423

5.1.3 LIFTING CHARACTERISTICS….424

5.1.3.1 LIFTING CAPACITY TABLE….424

5.1.3.2 LIFTING CAPACITY WITH RAISED BLADE….425

5.1.3.3 LIFTING CAPACITY WITH LOWERED BLADE….426

AUTHORIZED OPTIONAL EQUIPMENT….427

6.1 AUTHORIZED OPTIONAL EQUIPMENT….428

6.1.1 PRECAUTIONS REGARDING SAFETY….428

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT….429

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT….430

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER….431

6.2.1 DESCRIPTION AND OPERATION….431

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED….431

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER….435

6.2.3.1 INSTALLING THE HAMMER….435

6.2.3.2 REMOVING THE HAMMER….436

6.2.4 MAINTENANCE….436

6.3 CLAMSHELL BUCKET….437

6.3.1 DESRIPTION AND OPERATION….437

6.3.2 INSTALLING THE CLAMSHELL BUCKET….438

6.3.3 MAINTENANCE….440

WEAM003900 – Hydraulic Excavator PC75R-2 Operation & Maintenance Manual….441

COVER….441

1.1 FOREWORD….443

1.2 INFORMATION ON SAFETY….444

1.3 INTRODUCTION….446

1.3.1 INTENDED USES….446

1.3.2 IMPROPER OR UNAUTHORIZED USE….446

1.3.3 MAIN CHARACTERISTICS….447

1.3.4 RUNNING-IN….447

1.4 PRODUCT IDENTIFICATION….448

1.4.1 MACHINE SERIAL NUMBER….448

1.4.2 MACHINE IDENTIFICATION PLATE….448

1.4.3 ENGINE SERIAL NUMBER AND EMISSION LABEL….449

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER….449

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER….450

1.4.6 CAB SERIAL NUMBER….450

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS….451

CONTENTS….452

SAFETY AND ACCIDENT PREVENTION….459

2.1 SAFETY PLATES….460

2.1.1 POSITION OF THE SAFETY PLATES….460

2.1.2 POSITION OF THE PICTOGRAMS….476

2.1.3 PICTOGRAMS AND RELEVANT MEANINGS….477

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED….479

2.2 GENERAL PRECAUTIONS….480

2.2.1 GENERAL SAFETY RULES….480

2.2.2 SAFETY DEVICES AND GUARDS….480

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS….480

2.2.4 UNAUTHORIZED MODIFICATIONS….481

2.2.5 LEAVING THE OPERATOR’S SEAT….481

2.2.6 GETTING ON AND OFF THE MACHINE….482

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL….482

2.2.8 PREVENTING BURNS….483

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER….483

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….484

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT….484

2.2.12 PRECAUTIONS CONCERNING THE CAB STRUCTURE….484

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT….484

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE….485

2.3.1 SAFETY ON THE WORK SITE….485

2.3.2 FIRE PREVENTION….485

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB….485

2.3.4 ROOM VENTILATION….486

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS….486

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS – CHECKING THE WINDSHIELD WIPER BLADES….486

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING….487

2.4.1 STARTING THE ENGINE….487

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE….487

2.4.3 CHECKS FOR TRAVELLING IN REVERSE….487

2.4.4 MOVING THE MACHINE….488

2.4.5 MOVING ON SLOPES….489

2.4.6 WORKING ON SLOPES….490

2.4.7 UNAUTHORIZED OPERATIONS….490

2.4.8 PREVENTING ELECTROCUTION….491

2.4.9 VISIBILITY….492

2.4.10 WORKING ON ICY OR SNOW-COVERED SURFACES….492

2.4.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT….492

2.4.12 WORKING ON LOOSE GROUND….492

2.4.13 PARKING THE MACHINE….493

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES….494

2.5.1 LOADING AND UNLOADING THE MACHINE….494

2.5.2 SHIPPING….494

2.6 BATTERY….495

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES….495

2.6.2 STARTING WITH BOOSTER CABLES….495

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY….496

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE….497

2.8.1 WARNING PLATES….497

2.8.2 TOOLS….497

2.8.3 PERSONNEL….498

2.8.4 EQUIPMENT….498

2.8.5 WORKING UNDER THE MACHINE….498

2.8.6 KEEPING THE MACHINE CLEAN….498

2.8.7 USE OF THE ENGINE DURING MAINTENANCE….499

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY….499

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION….499

2.8.10 RULES FOR REFUELLING AND ADDING OIL….500

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR….500

2.8.12 USING LAMPS….500

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR….501

2.8.14 PRECAUTIONS CONCERNING THE STARTER….501

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES….502

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS….502

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES….502

2.8.18 COOLING FAN AND FAN BELT….503

2.8.19 WASTE MATERIALS….503

2.8.20 PRECAUTIONS FOR THE USE OF THE synthetic biodegradable oil type HEES….503

THE MACHINE AND ITS OPERATIONS….505

3.1 SAFETY LOCKS….506

3.1.1 MACHINE LOCKS….506

3.2 GENERAL VIEWS….507

3.2.1 FRONT GENERAL VIEW (MONOBOOM)….507

3.2.2 FRONT GENERAL VIEW (TWO-PIECE BOOM)….508

3.2.3 CAB INSIDE GENERAL VIEW….509

3.3 INSTRUMENTS AND CONTROLS….511

3.3.1 INSTRUMENTS….511

3.3.2 WARNING LIGHTS….513

3.3.3 SWITCHES AND PUSH BUTTONS….515

3.3.4 ELECTRICAL ACCESSORIES….523

3.3.5 MACHINE CONTROLS….525

3.4 FUSES AND RELAYS….536

3.4.1 CENTRAL UNIT FUSES AND RELAYS….536

3.4.1.1 CENTRAL UNIT FUSES….537

3.4.1.2 CENTRAL UNIT RELAYS….538

3.4.2 ENGINE LINE FUSES AND RELAYS….539

3.4.2.1 ENGINE LINE FUSES….539

3.4.2.2 ENGINE LINE RELAYS….540

3.4.3 FUSES AND RELAYS OF THE AIR CONDITIONING SYSTEM (if provided)….541

3.5 GUARDS AND DRIVER’S SEAT….543

3.5.1 ENGINE HOOD….543

3.5.2 SIDE COVER….543

3.5.3 CAB….544

3.5.4 VENTILATION AND HEATING….548

3.5.5 AIR CONDITIONER (if provided)….549

3.5.6 SEAT….551

3.5.7 SAFETY BELT….552

3.5.8 EMERGENCY EXIT….552

3.5.9 TECHNICAL DOCUMENTATION CASE….553

3.5.10 FIRE EXTINGUISHER….553

3.5.11 FIRST AID KIT….553

3.6 USE OF THE MACHINE….555

3.6.1 CHECKS BEFORE STARTING THE ENGINE….555

3.6.1.1 VISUAL CHECKS….555

3.6.1.2 DAILY CHECKS….555

3.6.1.3 OPERATIONAL CHECKS….556

3.6.2 STARTING THE ENGINE….557

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES….557

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES….558

3.6.3 WARMING THE ENGINE….559

3.6.4 HEATING THE HYDRAULIC OIL….559

3.6.5 HOW TO MOVE THE MACHINE….559

3.6.5.1 STEERING (CHANGING DIRECTION)….561

3.6.5.2 MOVING ON SLOPES….562

3.6.5.3 MAXIMUM IMMERSION DEPTH….563

3.7 PARKING THE MACHINE….564

3.7.1 PARKING ON LEVEL GROUND….564

3.7.2 PARKING ON SLOPES….565

3.8 STOPPING THE ENGINE….566

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES….567

3.9.1 LOADING AND UNLOADING THE MACHINE….567

3.9.2 TRANSPORT….568

3.10 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON….569

3.10.1 FUEL AND LUBRICANTS….569

3.10.2 COOLANT….569

3.10.3 BATTERY….570

3.10.4 OTHER PRECAUTIONS….570

3.10.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK….570

3.11 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON….571

3.12 USING THE WORK EQUIPMENT….572

3.12.1 ORGANIZING THE WORK AREA….572

3.12.2 POSITIONING THE BUCKET ACCORDING TO THE WORK TO BE CARRIED OUT….572

3.12.3 POSITIONING THE MACHINE FOR DIGGING OPERATIONS….573

3.12.4 DIGGING METHOD….574

3.12.5 CHANGING THE BUCKET….575

3.13 LONG PERIODS OF INACTIVITY….576

3.13.1 BEFORE THE PERIOD OF INACTIVITY….576

3.13.2 DURING THE PERIOD OF INACTIVITY….577

3.13.3 AFTER THE PERIOD OF INACTIVITY….577

3.14 TROUBLESHOOTING….578

3.14.1 HOW TO REMOVE THE MACHINE….578

3.14.2 IF THE FUEL HAS BEEN COMPLETELY DEPLETED….578

3.14.3 IF THE BATTERY IS DEPLETED….579

3.14.3.1 STARTING WITH BOOSTER CABLES….580

3.14.4 OTHER TROUBLES….581

3.14.4.1 ELECTRICAL CIRCUIT….581

3.14.4.2 HYDRAULIC SYSTEM….582

3.14.4.3 ENGINE….583

MAINTENANCE….585

4.1 GUIDE TO MAINTENANCE….586

4.2 MAINTENANCE NOTES….588

4.2.1 NOTES REGARDING THE ENGINE….588

4.2.1.1 ENGINE OIL….588

4.2.1.2 COOLANT….588

4.2.1.3 FUEL….589

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM….589

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM….590

4.2.4 NOTES REGARDING LUBRICATION….590

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING….591

4.3 FUEL, COOLANT AND LUBRICANTS….592

4.3.1 HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS….596

4.4 NUT AND BOLT TIGHTENING TORQUES….597

4.4.1 STANDARD TIGHTENING TORQUES….597

4.4.2 SPECIFIC TIGHTENING TORQUES….597

4.5 LUBRICATION….598

4.5.1 LUBRICATION DIAGRAM….598

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY….599

4.6.1 CRITICAL PARTS FOR SAFETY….600

4.7 MAINTENANCE PLAN….603

4.7.1 WHEN REQUIRED….607

4.7.1.a CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE….607

4.7.1.b CHECKING AND CLEANING THE CAB AIR FILTER….609

4.7.1.c CHECKING AND CLEANING THE AIR RECIRCULATION FILTER (only for machines equipped with air c….610

4.7.1.d CLEANING THE WATER SEPARATOR….611

4.7.1.e CHECKING THE STEEL TRACK TENSION….612

4.7.1.f CHECKING THE SHOE FASTENING….614

4.7.1.g CHECKING THE RUBBER TRACKS….615

4.7.1.h CHECKING THE RUBBER TRACK TENSION….617

4.7.1.j CHANGING THE RUBBER TRACK….619

4.7.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE DEMOLITION HAMMER….621

4.7.2.a CHANGING THE HYDRAULIC OIL FILTER….621

4.7.2.b CHANGING THE HYDRAULIC OIL….621

4.7.3 CHECKS BEFORE STARTING….622

4.7.3.a VARIOUS CHECKS….622

4.7.3.b CHECKING THE COOLANT LEVEL….622

4.7.3.c CHECKING THE FUEL LEVEL….623

4.7.3.d CHECKING THE ENGINE OIL LEVEL….623

4.7.3.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT….624

4.7.3.f DRAINING THE WATER SEPARATOR….625

4.7.4 MAINTENANCE EVERY 10 HOURS OF OPERATION….626

4.7.4.a LUBRICATING THE JOINTS….626

4.7.5 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION (Only for machines in which the synthetic….629

4.7.6 MAINTENANCE EVERY 50 HOURS OF OPERATION….629

4.7.6.a CHECKING THE RADIATOR FLUID LEVEL….629

4.7.6.b LUBRICATING THE SWING JOINT….629

4.7.6.c CHECKING THE ELECTRICAL SYSTEM….630

4.7.7 MAINTENANCE EVERY 100 HOURS OF OPERATION….631

4.7.7.a LUBRICATING THE BALL-BEARING RING….631

4.7.8 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION….632

4.7.9 MAINTENANCE EVERY 250 HOURS OF OPERATION….632

4.7.9.a ADJUSTING THE FAN BELT TENSION….632

4.7.9.b ADJUSTING THE TENSION OF THE A/C COMPRESSOR BELT (only for machines equipped with air con….633

4.7.9.c CHECKING THE BATTERY ELECTROLYTE LEVEL….634

4.7.9.d CHECKING THE OIL LEVEL IN THE TRAVEL REDUCTION GEARS….635

4.7.9.e CHECKING THE OIL LEVEL IN THE SWING REDUCTION GEAR….635

4.7.10 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines in which the synthet….636

4.7.11 MAINTENANCE EVERY 500 HOURS OF OPERATION….636

4.7.11.a CHANGING THE HYDRAULIC SYSTEM OIL FILTER….636

4.7.11.b CHANGING THE SERVO CONTROL FILTER….638

4.7.11.c CHANGING THE ENGINE OIL….639

4.7.11.d CHANGING THE ENGINE OIL FILTER….640

4.7.11.e CHANGING THE FUEL FILTER….641

4.7.11.f DRAINING THE FUEL TANK….642

4.7.11.g CLEANING THE OUTSIDE OF THE RADIATORS….642

4.7.11.h CLEANING THE OUTSIDE OF THE A/C CONDENSER (only for machines equipped with air conditioner)….643

4.7.11.j CHECKING THE BALL-BEARING RING PINION LUBRICANT LEVEL….644

4.7.11.k DRAINING THE HYDRAULIC OIL TANK (Only for machines in which the synthetic biodegradable ….644

4.7.12 MAINTENANCE EVERY 1000 HOURS OF OPERATION….646

4.7.12.a CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE….646

4.7.13 MAINTENANCE EVERY 2000 HOURS OF OPERATION….647

4.7.13.a CHANGING THE OIL IN THE TRAVEL REDUCTION GEARS….647

4.7.13.b CHANGING THE OIL IN THE SWING REDUCTION GEAR….648

4.7.13.c CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER….649

4.7.13.d CHANGING THE COOLANT….652

4.7.13.e CHANGING THE BALL-BEARING RING PINION LUBRICANT….653

4.7.13.f CHECKING THE ALTERNATOR AND THE STARTER….653

4.7.13.g CHECKING THE A/C COOLING GAS QUANTITY (only for machines equipped with air conditioner)….654

4.7.14 MAINTENANCE EVERY 4000 HOURS OF OPERATION….655

4.7.14.a CHANGING THE A/C DEHYDRATOR FILTER (only for machines equipped with air conditioner)….655

4.7.14.b CHECKING THE CORRECT OPERATION OF THE A/C COMPRESSOR (only for machines equipped with ai….655

TECHNICAL SPECIFICATIONS….657

5.1 TECHNICAL DATA….658

5.1.1 STANDARD OVERALL DIMENSIONS….658

5.1.2 TECHNICAL CHARACTERISTICS….659

5.1.3 LIFTING CAPACITIES….660

5.1.3.1 LIFTING CAPACITY TABLE….660

5.1.3.2 LIFTING CAPACITY WITH RAISED BLADE….661

5.1.3.3 LIFTING CAPACITY WITH LOWERED BLADE….662

AUTHORIZED OPTIONAL EQUIPMENT….663

6.1 AUTHORIZED OPTIONAL EQUIPMENT….664

6.1.1 PRECAUTIONS REGARDING SAFETY….664

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT….665

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT….666

6.2 ARRANGEMENT FOR THE INSTALLATION OF THE DEMOLITION HAMMER….667

6.2.1 DESCRIPTION AND OPERATION….667

6.2.2 USE OF THE DEMOLITION HAMMER AND RULES TO BE OBSERVED….667

6.2.3 INSTALLING AND REMOVING THE DEMOLITION HAMMER….671

6.2.3.1 INSTALLING THE HAMMER….671

6.2.3.2 REMOVING THE HAMMER….672

6.2.4 MAINTENANCE….672

6.3 CLAMSHELL BUCKET….673

6.3.1 DESCRIPTION AND OPERATION….673

6.3.2 INSTALLING THE CLAMSHELL BUCKET….674

6.3.3 MAINTENANCE….676

WEBM004000 – Hydraulic Excavator PC75R-2 Shop Manual….677

COVER….677

CONTENTS….679

LIST OF REVISED PAGES….681

SAFETY….683

FOREWORD….685

HOW TO READ THE SHOP MANUAL….686

HOISTING INSTRUCTIONS….687

STANDARD TIGHTENING TORQUE….688

COATING MATERIALS….690

ELECTRIC WIRE CODE….691

WEIGHT TABLE….692

TABLE OF OIL COOLANT QUANTITIES….693

10. STRUCTURE AND FUNCTION….697

P.T.O….698

POWER TRAIN….699

TRACK FRAME….701

IDLER AND RECOIL SPRING….702

CARRIER ROLLER….703

TRACK ROLLER….703

TRACK SHOE….704

SWING CIRCLE….705

SWING MACHINERY….706

HYDRAULIC CIRCUIT DIAGRAM (STANDARD)….707

HYDRAULIC CIRCUIT DIAGRAM (2-PIECE BOOM)….709

HYDRAULIC PUMP….710

9-SPOOL CONTROL VALVE (STANDARD)….736

10-SPOOL CONTROL VALVE (STANDARD+2-PIECE BOOM)….738

SWING MOTOR….766

CENTER SWIVEL JOINT….770

TRAVEL MOTOR….772

PARKING BRAKE….774

BRAKE VALVE….775

TRAVEL MOTOR….777

REDUCTION GEAR….779

CYLINDERS….780

SERVOCONTROL FEED UNIT….782

ACCUMULATOR….787

PPC VALVE (WORK EQUIPMENT)….788

PPC VALVE (BLADE, BOOM SWING, 2-PIECE BOOM)….792

TRAVEL PPC VALVE….796

BOOM AND ARM SAFETY VALVE….801

BLADE SAFETY VALVE….802

2-PIECE BOOM SAFETY VALVE….803

OVERLOAD SENSOR SWITCH….804

SOLENOID VALVE….805

ELECTRICAL DIAGRAM (1/3)….807

ELECTRICAL DIAGRAM (2/3)….809

ELECTRICAL DIAGRAM (3/3)….811

20. TESTING AND ADJUSTING….815

NORMAL OR STANDARD TECHNICAL DATA….816

SPECIAL TOOLS….833

MEASURING THE ENGINE SPEED….835

ADJUSTING VALVE CLEARANCE….836

MEASURING COMPRESSION PRESSURE….837

TESTING AND ADJUSTING FUEL INJECTION TIMING….838

TESTING AND ADJUSTING FAN BELT TENSION….840

ADJUSTING THE STROKE OF THE ACCELERATOR LEVER….841

ADJUSTING PPC VALVE CLEARANCE….842

ADJUSTING THE SAFETY MICROSWITCH….843

MEASURING THE SWING CIRCLE AXIAL CLEARANCE….844

TESTING AND ADJUSTING TRACK-SHOE TENSION….845

AIR BLEEDING FROM HYDRAULIC CIRCUITS….846

RELEASING RESIDUAL PRESSURE FROM THE CIRCUITS….849

CHECKING AND REGULATING PRESSURE IN THE HYDRAULIC CIRCUITS….850

TESTING AND SETTING OF MAIN VALVES….851

ADJUSTING PC VALVE….853

MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE….854

CHECKING AND ADJUSTING PRESSURES IN THE SERVOCONTROL FEED UNIT….856

MEASURING PUMPS DELIVERY AND FLOW CONTROL STARTING POINT PUMP P1….857

MEASURING TRAVEL DEVIATION….859

ADJUSTING THE MAXIMUM SPEED OF THE TRAVEL MOTORS….860

MEASURING INNER OIL LEAKAGE OF TRAVEL MOTOR….861

ADJUSTING BOOM AND ARM SAFETY VALVES….862

ADJUSTING 2nd BOOM SAFETY VALVES….863

MEASURING AND SETTING OF PRESSURE SWITCH SIGNAL OVERLOAD OPERATION….864

MEASUREMENT OF INTERNAL OIL LEAKAGES IN THE SWING MOTOR….865

CHECKING FOR LEAKAGES INSIDE THE SWIVEL JOINT….866

ANALYSIS OF THE CAUSES OF HYDRAULIC DRIFTS….868

30. DISASSEMBLY AND ASSEMBLY….877

HOW TO READ THE MANUAL….879

PRECAUTIONS TO BE TAKEN WHEN WORKING….880

SPECIAL TOOLS….881

STARTER MOTOR….883

REMOVAL AND INSTALLATION….883

ALTERNATOR….884

REMOVAL AND INSTALLATION….884

INJECTION PUMP….885

REMOVAL….885

INSTALLATION….888

NOZZLE HOLDER….889

REMOVAL AND INSTALLATION….889

CYLINDER HEAD….890

REMOVAL….890

INSTALLATION….892

SEAT….893

REMOVAL AND INSTALLATION….893

CABIN….894

REMOVAL AND INSTALLATION….894

ENGINE HOOD….895

REMOVAL AND INSTALLATION….895

FRONT HOOD….896

REMOVAL AND INSTALLATION….896

HEATING FAN….897

REMOVAL AND INSTALLATION….897

RADIATOR….898

REMOVAL….898

INSTALLATION….899

FUEL TANK….900

REMOVAL….900

INSTALLATION….901

HYDRAULIC OIL TANK….902

REMOVAL AND INSTALLATION….902

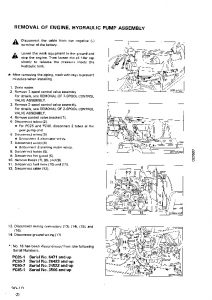

ENGINE-PUMP GROUP….903

REMOVAL….903

INSTALLATION….906

PUMP GROUP….907

REMOVAL….907

INSTALLATION….908

ENGINE-PUMP COUPLING JOINT….909

REMOVAL AND INSTALLATION….909

MAIN PUMP INPUT SHAFT OIL SEAL….910

REMOVAL AND INSTALLATION….910

GEAR PUMP….911

REMOVAL AND INSTALLATION….911

SWIVEL JOINT….912

REMOVAL AND INSTALLATION….912

SWING MOTOR….913

REMOVAL AND INSTALLATION….913

SWING MACHINERY….914

REMOVAL AND INSTALLATION….914

DISASSEMBLY….915

ASSEMBLY….918

CONTROL VALVE….921

REMOVAL AND INSTALLATION….921

REVOLVING FRAME….922

REMOVAL….922

INSTALLATION….923

COUNTERWEIGHT….924

REMOVAL AND INSTALLATION….924

SWING CIRCLE….925

REMOVAL AND INSTALLATION….925

TRACK SHOES….926

REMOVAL AND INSTALLATION….926

SPROCKET ASSEMBLY….927

REMOVAL AND INSTALLATION….927

TRAVEL GEAR MOTOR….928

REMOVAL AND INSTALLATION….928

DISASSEMBLY….929

ASSEMBLY….944

BALL BEARING PRELOAD….959

ADJUSTING….959

AXIAL CLEARANCE ON TAPERED ROLLER BEARINGS….960

ADJUSTING….960

IDLER AND RECOIL SPRING ASSEMBLY….961

REMOVAL AND INSTALLATION….961

IDLER….962

DISASSEMBLY AND ASSEMBLY….962

RECOIL SPRING GROUP AND CYLINDER….963

DISASSEMBLY AND ASSEMBLY….963

TRACK ROLLER….964

REMOVAL AND INSTALLATION….964

CARRIER ROLLER….965

REMOVAL AND INSTALLATION….965

R.H. PPC VALVE (BOOM-BUCKET)….966

REMOVAL….966

INSTALLATION….967

L.H. PPC VALVE (ARM-SWING)….968

REMOVAL….968

INSTALLATION….969

BLADE PPC VALVE….970

REMOVAL AND INSTALLATION….970

TRAVEL PEDAL CONTROL….971

REMOVAL AND INSTALLATION….971

1st BOOM SWING PEDAL CONTROL….972

REMOVAL AND INSTALLATION….972

BOOM CYLINDER (FOR 1-PIECE BOOM)….973

REMOVAL AND INSTALLATION….973

BOOM CYLINDER (FOR 2-PIECE BOOM)….974

REMOVAL….974

INSTALLATION….975

2nd BOOM CYLINDERS….976

REMOVAL….976

INSTALLATION….977

ARM CYLINDER….978

REMOVAL AND INSTALLATION….978

BUCKET CYLINDER….979

REMOVAL AND INSTALLATION….979

BOOM SWING CYLINDER….980

REMOVAL AND INSTALLATION….980

BLADE CYLINDER….981

REMOVAL AND INSTALLATION….981

WORK EQUIPMENT CYLINDERS….982

DISASSEMBLY….982

ASSEMBLY….983

WORK EQUIPMENT (FOR 1-PIECE BOOM)….987

REMOVAL AND INSTALLATION….987

WORK EQUIPMENT (FOR 2-PIECE BOOM)….988

REMOVAL….988

INSTALLATION….989

BUCKET….990

REMOVAL AND INSTALLATION….990

ARM….991

REMOVAL….991

INSTALLATION….993

2nd BOOM….994

REMOVAL….994

INSTALLATION….995

BOOM (FOR 1-PIECE BOOM)….996

REMOVAL AND INSTALLATION….996

1st BOOM….997

REMOVAL….997

INSTALLATION….998

SWING BRACKET….999

REMOVAL AND INSTALLATION….999

BLADE….1000

REMOVAL AND INSTALLATION….1000

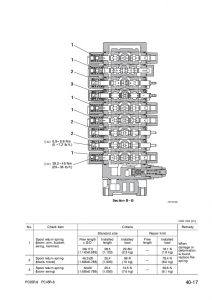

40. MAINTENANCE STANDARD….1003

P.T.O….1004

SWING CIRCLE….1005

TRACK FRAME….1006

IDLER….1007

CARRIER ROLLER….1008

TRACK ROLLER….1009

TRACK SHOE….1010

SPROCKET….1011

SWING MACHINERY….1012

HYDRAULIC PUMP….1013

CONTROL VALVE….1014

SWING MOTOR….1024

SWIVEL JOINT….1025

TRAVEL MOTOR….1026

SERVOCONTROL FEED UNIT….1028

TRAVEL PPC VALVE….1029

PPC VALVE….1030

BLADE SAFETY VALVE….1032

CYLINDERS….1034

WORK EQUIPMENT (1-PIECE BOOM)….1036

WORK EQUIPMENT (2-PIECE BOOM)….1038

Komatsu Hydraulic Excavator PC75R Repair Service Manuals