Complete service repair manual with Electrical Wiring Diagrams for Komatsu Dump Truck HD255, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Dump Truck HD255 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM00911 – Komatsu Dump Truck HD255-5 Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 613 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

COVER…1

CONTENTS…2

LIST OF REVISED PAGES…3

SAFETY…7

SAFETY NOTICE…7

FOREWORD…9

GENERAL…9

HOW TO READ THE SHOP MANUAL…10

HOISTING INSTRUCTIONS…11

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER…12

COATING MATERIALS…14

STANDARD TIGHTENING TORQUE…16

ELECTRIC WIRE CODE…19

CONVERSION TABLE…20

UNITS…26

01 GENERAL…27

DIMENSIONS…28

SPECIFICATIONS…30

WEIGHT TABLE…36

LIST OF LUBRICANTS AND COOLANT…37

10 STRUCTURE AND FUNCTION…39

RADIATOR, TORQUE CONVERTER AND BRAKE OIL COOLER, AND AFTERCOOLER…40

POWER TRAIN SKELETON…42

HYDRAULIC CIRCUIT DIAGRAM FOR TORQUE CONVERTER, TRANSMISSION, AND BRAKE COOLING…44

TORQUE CONVERTER…46

MAIN RELIEF VALVE…48

TORQUE CONVERTER VALVE…50

TRANSMISSION…55

TRANSMISSION VALVE…60

ECMV (ELECTRONIC CONTROL MODULATION VALVE)…61

FRONT AXLE…66

REAR AXLE…67

DIFFERENTIAL…68

FINAL DRIVE…69

FRONT BRAKE…70

REAR BRAKE…71

PARKING BRAKE…72

STEERING COLUMN…74

STEERING LINKAGE…76

DEMAND VALVE…77

CROSSOVER RELIEF VALVE…80

STEERING VALVE…81

FRONT SUSPENSION CYLINDER…82

REAR SUSPENSION CYLINDER…83

AIR GOVERNOR…84

SAFETY VALVE…86

CHECK VALVE…86

DOUBLE CHECK VALVE…87

HAND BRAKE VALVE (RETARDER CONTROL VALVE)…88

BRAKE VALVE…90

PARKING BRAKE CONTROL VAVLE…93

BRAKE RELAY VALVE…95

BRAKE RELAY VALVE (ACTS ALSO AS EMERGENCY RELAY)…97

PARKING BRAKE RELAY VALVE…104

PARKING BRAKE QUICK RELEASE VALVE…106

SPRING CYLINDER…107

SLACK ADJUSTER…108

FRONT BRAKE CHAMBER…109

REAR BRAKE CHAMBER…110

AIR DRIER (DRYING AGENT TYPE)…111

AIR SYSTEM DIAGRAM…113

HOIST VALVE…114

HOIST CYLINDER…115

AUTOMATIC SHIFT CONTROL SYSTEM…116

AUTOMATIC RETARDER VALVE…126

HORN VALVE…128

WIPER SWITCH…128

SENSORS, SWITCHES…129

METER LAMPS…140

20 TESTING AND ADJUSTING…151

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS…152

STANDARD VALUE TABLE FOR CHASSIS…155

STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM…163

TESTING AND ADJUSTING…175

TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING…176

SKETCHES OF SPECIAL TOOLS…178

ADJUSTING VALVE CLEARANCE…180

MEASURING COMPRESSION PRESSURE…182

MEASURING BLOW-BY…184

TESTING AND ADJUSTING ALTERNATOR BELT TENSION AND FAN BELT TENSION…186

TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION…187

MEASURING ENGINE SPEED…188

MEASURING ENGINE OIL PRESSURE…190

MEASURING BOOST PRESSURE…191

MEASURING EXHAUST GAS TEMPERATURE…192

MEASURING EXHAUST GAS COLOR…193

TESTING AND ADJUSTING FUEL INJECTION TIMING…194

BLEEDING AIR FROM FUEL INJECTION PUMP…196

HANDLING EQUIPMENT IN FUEL CIRCUIT…197

RELEASING REMAINING PRESSURE IN FUEL SYSTEM…197

MEASURING FUEL PRESSURE…198

BLEEDING AIR FROM FUEL CIRCUIT…199

REDUCED CYLINDER MODE OPERATION FOR ENGINE…201

CHECKING FOR LEAKAGE IN FUEL CIRCUIT…202

ADJUSTING ENGINE STOP MOTOR CABLE…203

ADJUSTING ACCELERATOR PEDAL…204

ADJUSTING ENGINE SPEED SENSOR…205

TESTING OIL PRESSURE OF TORQUE CONVERTER VALVE…206

TESTING TORQUE CONVERTER STALL SPEED…207

TESTING BRAKE PRESSURE…208

BLEEDING AIR FROM BRAKE CIRCUIT…209

TESTING AND ADJUSTING PARKING BRAKE PERFORMANCE…210

TESTING WEAR OF FRONT BRAKE PAD…211

TESTING WEAR OF REAR BRAKE DISC…212

TESTING AND ADJUSTING SUSPENSION CYLINDER…213

TESTING AND ADJUSTING AIR GOVERNOR SET PRESSURE…218

INSPECTION OF AIR DRIER (DESICCANT TYPE)…219

ADJUSTING HOIST LEVER LINKAGE…221

ADJUSTING BODY POSITIONER…222

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN STEERING, HOIST CIRCUIT…223

BLEEDING AIR FROM HYDRAULIC CYLINDER (STEERING CYLINDER)…226

EMERGENCY TRAVEL WHEN THERE IS FAILURE IN ELECTRICAL SYSTEM…227

METHOD FOR EMERGENCY ESCAPE WHEN THERE IS FAILURE IN ELECTRICAL SYSTEM…228

PROCEDURE FOR MOVING MACHINE WHEN TRANSMISSION VALVE FAILS…234

PROCEDURE FOR FLUSHING TORQUE CONVERTER, TRANSMISSION HYDRAULIC CIRCUIT…236

PM CLINIC CHECK SHEET…237

TROUBLESHOOTING…241

POINTS TO REMEMBER WHEN TROUBLESHOOTING…242

SEQUENCE OF EVENTS IN TROUBLESHOOTING…243

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE…244

CHECKS BEFORE TROUBLESHOOTING…252

TYPE OF CONNECTOR AND POSITION OF INSTALLATION (SERIAL NO. 1001-1200)…254

CONNECTOR PIN ARRANGEMENT DIAGRAM (SERIAL NO. 1001-1200)…258

TYPE OF CONNECTOR AND POSITION OF INSTALLATION (SERIAL NO. 1201-1599)…262

CONNECTOR PIN ARRANGEMENT DIAGRAM (SERIAL NO. 1201-1599)…266

TYPE OF CONNECTOR AND POSITION OF INSTALLATION (SERIAL NO. 1601 AND UP)…270

CONNECTOR PIN ARRANGEMENT DIAGRAM (SERIAL NO. 1601 AND UP)…274

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS …280

METHOD OF USING JUDGEMENT TABLE…303

METHOD OF USING TROUBLESHOOTING CHARTS…304

METHOD OF LED DISPLAY FOR TRANSMISSION CONTROLLER…306

HOW TO DELETE FAILURE CODES FOR TRANSMISSION CONTROLLER AND ENGINE CONTROLLER…310

ACTION TAKEN BY TRANSMISSION CONTROLLER AND PROBLEMS ON MACHINE…312

TROUBLESHOOTING OF ENGINE SYSTEM (D MODE)…361

METHOD OF USING TROUBLESHOOTING CHART…362

D-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…366

D-2 ENGINE DOES NOT START…367

(1) ENGINE DOES NOT TURN…367

(2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)…368

(3) EXHAUST SMOKE COMES OUT, BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)…369

D-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)…370

D-4 ENGINE STOPS DURING OPERATIONS…371

D-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…372

D-6 ENGINE LACKS OUTPUT (NO POWER)…373

D-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)…374

D-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)…375

D-9 OIL BECOMES CONTAMINATED QUICKLY…376

D-10 FUEL CONSUMPTION IS EXCESSIVE…377

D-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN…378

D-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)…379

D-13 OIL LEVEL RISES (WATER, FUEL IN OIL)…380

D-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)…381

D-15 ABNORMAL NOISE IS MADE…382

D-16 VIBRATION IS EXCESSIVE…383

TROUBLESHOOTING OF ENGINE SYSTEM (D MODE)…385

POINTS TO REMEMBER WHEN TROUBLESHOOTING…386

METHOD OF USING TROUBLESHOOTING CHARTS…387

D-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)…390

D-2 ENGINE DOES NOT START…391

D-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW-UP IS POOR)…394

D-4 ENGINE STOPS DURING OPERATIONS…395

D-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)…396

D-6 ENGINE LACKS OUTPUT (OR LACKS POWER)…397

D-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)…398

D-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)…399

D-9 OIL BECOMES CONTAMINATED QUICKLY…400

D-10 FUEL CONSUMPTION IS EXCESSIVE…401

D-11 OIL IS IN COOLING WATER (OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN)…402

D-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)…403

D-13 OIL LEVEL RISES (WATER, FUEL IN OIL)…404

D-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)…405

D-15 ABNORMAL NOISE IS MADE…406

D-16 VIBRATION IS EXCESSIVE…407

TROUBLESHOOTING OF ENGINE CONTROLLER SYSTEM (G MODE)…409

ERROR CODE DISPLAYS AND POINTS TO REMEMBER WHEN TROUBLESHOOTING…411

ACTION TAKEN BY CONTROLLER AND CONDITION OF MACHINE WHEN ERROR CODE IS DISPLAYED…414

ENGINE CONTROLLER RELATED JUDGEMENT TABLE…422

ELECTRICAL CIRCUIT DIAGRAM FOR ENGINE CONTROLLER SYSTEM…424

G-1 ERROR CODE [C01b] [ABNORMALITY IN NE REVOLUTION SENSOR SYSTEM]…426

G-2 ERROR CODE [C01C] [ABNORMALITY IN G REVOLUTION SENSOR SYSTEM]…427

G-3 ERROR CODE [C020] [ABNORMALITY IN MODEL SELECTION SYSTEM]…428

G-4 ERROR CODE [C022] [OVERRUN]…429

G-5 ERROR CODE [C023] [OVERHEAT]…429

G-6 ERROR CODE [C024] [DROP IN OIL PRESSURE]…430

G-7 ERROR CODE [C030] [ABNORMALITY IN IDLING VALIDATION SIGNAL SYSTEM]…431

G-8 ERROR CODE [C031] [ABNORMALITY IN ACCELERATOR SENSOR SYSTEM]…433

G-9 ERROR CODE [C034] [ABNORMALITY IN HIGH ENGINE COOLANT TEMPERATURE SENSOR SYSTEM]…435

G-10 ERROR CODE [C036] [ABNORMALITY IN OIL PRESSURE SWITCH SYSTEM]…436

G-11 ERROR CODE [C03C] [ABNORMALITY IN BOOST PRESSURE SENSOR SYSTEM]…438

G-12 ERROR CODE [C03d] [ABNORMALITY IN FUEL TEMPERATURE SENSOR SYSTEM]…439

G-13 ERROR CODE [C050] [ABNORMALITY IN PREHEATING RELAY CONNECTING POINT SYSTEM]…440

G-14 ERROR CODE [C051] [ABNORMALITY IN PREHEATING RELAY COIL SYSTEM]…441

G-15 ERROR CODE [C054] [SHORT CIRCUIT IN STARTING SWITCH C SYSTEM]…442

G-16 ERROR CODE [C056] [POWER SOURCE SYSTEM ABNORMALITY 1]…443

G-17 ERROR CODE [C057] [POWER SOURCE SYSTEM ABNORMALITY 2]…445

G-18 ERROR CODE [C05A] [ABNORMALITY IN FUEL INJECTION QUANTITY CONTROL SWITCH SIGNAL]…446

G-19 ERROR CODE [C06A] [ABNORMALITY IN LOW ENGINE COOLANT TEMPERATURE SENSOR SYSTEM]…446

G-20 ERROR CODE [C070] [EXCESS CURRENT IN FUEL SUPPLY PUMP PCV1 SYSTEM]…447

G-21 ERROR CODE [C071] [EXCESS CURRENT IN FUEL SUPPLY PUMP PCV2 SYSTEM]…448

G-22 ERROR CODE [C074] [DISCONNECTION IN FUEL SUPPLY PUMP PCV1 SYSTEM]…449

G-23 ERROR CODE [C075] [DISCONNECTION IN FUEL SUPPLY PUMP PCV2 SYSTEM]…450

G-24 ERROR CODE [C077] [ABNORMALITY IN COMMON RAIL FUEL PRESSURE SENSOR SYSTEM]…451

G-25 ERROR CODE [C079] [COMMON RAIL HIGH FUEL PRESSURE ABNORMALITY 1] ERROR CODE [C07A] [COMMON RAIL HIGH FUEL PRESSURE ABNORMALITY 2]…452

G-26 ERROR CODE [C07C] [FUEL SUPPLY PUMP NON-FORCE FEED 1] ERROR CODE [C07b] [FUEL SUPPLY PUMP NON-FORCE FEED 2]…453

G-27 ERROR CODE [C07d] [ABNORMALITY IN COMMON RAIL FUEL PRESSURE]…455

G-28 ERROR CODE [C080] [DEFECTIVE CONTROLLER]…455

G-29 ERROR CODE [C081] [DISCONNECTION IN NO.1 FUEL INJECTOR <A> SYSTEM]…456

G-30 ERROR CODE [C082] [DISCONNECTION IN NO.2 FUEL INJECTOR <E> SYSTEM]…457

G-31 ERROR CODE [C083] [DISCONNECTION IN NO.3 FUEL INJECTOR <C> SYSTEM]…458

G-32 ERROR CODE [C084] [DISCONNECTION IN NO.4 FUEL INJECTOR <F> SYSTEM]…459

G-33 ERROR CODE [C085] [DISCONNECTION IN NO.5 FUEL INJECTOR <B> SYSTEM]…460

G-34 ERROR CODE [C086] [DISCONNECTION IN NO.6 FUEL INJECTOR <D> SYSTEM]…461

G-35 ERROR CODE [C08A] [SHORT CIRCUIT IN NO.1 <A>, NO.2 <E>, NO.3 <C> FUEL INJECTOR SYSTEM]…462

G-36 ERROR CODE [C08b] [SHORT CIRCUIT IN NO.4 <F>, NO.5 <B>, NO.6 <D> FUEL INJECTOR SYSTEM]…465

TROUBLESHOOTING OF ENGINE ELECTRICAL SYSTEM FOR START/STOP SYSTEM (ENG MODE)…469

SERIAL NO.:1001-1599…470

ENG-1 ENGINE DOES NOT START (FUEL INJECTION PUMP STOP LEVER STAYS AT STOP POSITION)…470

ENG-2 ENGINE DOES NOT STOP (FUEL INJECTION PUMP STOP LEVER STAYS AT RUN POSITION)…477

SERIAL NO.:1601 AND UP…482

ENG-1 ENGINE DOES NOT START (STARTING MOTOR DOES NOT ROTATE)…482

ENG-2 ENGINE DOES NOT START OR IT HUNTS (RUNS ROUGH)…486

TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM (A MODE)…487

POINTS TO REMEMBER WHEN CARRYING OUT TROUBLESHOOTING OF TRANSMISSION CONTROLLER SYSTEM…489

JUDGMENT TABLE FOR TRANSMISSION CONTROLLER, TRANSMISSION RELATED PARTS…490

A-1 ABNORMALITY IN POWER SOURCE…492

a) [ ][DEFECTIVE CONTROLLER POWER SOURCE]IS DISPLAYED(ALL LEDS OFF)…492

b) [0.1](DROP IN VOLTAGE OF CONTROLLER)IS DISPLAYED…496

c) [0.2](DROP IN VOLTAGE OF SOLENOID)IS DISPLAYED…497

A-2 [0.3](NEUTRAL SAFETY)IS DISPLAYED…499

A-3 CONTROLLER SYSTEM…501

a) [ . ][ONLY DOT LIGHTS UP] OR [0.4](DATA ERROR)IS DISPLAYED…501

b) [0.5](DOUBLE ENGAGEMENT FOR CLUTCH)IS DISPLAYED…501

A-4 [0.6](DISCONNECTION,SHORT CIRCUIT,SHORT CIRCUIT WITH GROUND IN TRANSMISSION CUT RELAY)IS DISPLAYED…502

A-5 [0.8](DISCONNECTION,SHORT CIRCUIT,SHORT CIRCUIT WITH GROUND IN AUTOMATIC RETARDER SOLENOID)IS DISPLAYED…506

A-6 [0.9](DISCONNECTION,SHORT CIRCUIT,SHORT CIRCUIT WITH GROUND IN EXHAUST BRAKE SOLENOID)IS DISPLAYED…510

A-7 SPEED SENSOR SYSTEM…514

a) [1.0](DISCONNECTION IN ENGINE SPEED SENSOR) OR [6.0](DEFECTIVE OUTPUT OF ENGINE SPEED SENSOR)…514

b) [1.1](DISCONNECTION IN TRANSMISSION INPUT SHAFT SPEED SENSOR) OR [6.1](DEFECTIVE OUTPUT OF TRANSMISSION INPUT SHAFT SPEED SENSOR)…517

c) [1.2](DISCONNECTION IN TRANSMISSION INTERMEDIATE SHAFT SPEED SENSOR) OR [6.2](DEFECTIVE OUTPUT OF TRANSMISSION INTERMEDIATE SHAFT SPEED SENSOR)…518

d) [1.3](DISCONNECTION IN TRANSMISSION OUTPUT SHAFT SPEED SENSOR) OR [6.3](DEFECTIVE OUTPUT OF TRANSMISSION OUTPUT SHAFT SPEED SENSOR)…519

A-8 SLIPPING CLUTCH OR SPEED SENSOR SYSTEM…520

a) [2.1][DEFECTIVE LOCK-UP CLUTCH SYSTEM] IS DISPLAYED…520

b) [2.2][FAILURE IN HI CLUTCH OR INPUT SHAFT SPEED SENSOR SYSTEM] OR [2.3][FAILURE IN LO CLUTCH OR INPUT SHAFT SPEED SENSOR SYSTEM] IS DISPLAYED…520

c) [2.4][FAILURE IN 1ST CLUTCH OR OUTPUT SHAFT SPEED SENSOR SYSTEM] OR [2.5][FAILURE IN 2ND CLUTCH OR OUTPUT SHAFT SPEED SENSOR SYSTEM] OR [2.6][FAILURE IN 3RD CLUTCH OR OUTPUT SHAFT SPEED SENSOR SYSTEM] OR [2.8][FAILURE IN R CLUTCH OR OUTPUT SHAFT SPEED SENSOR SYSTEM] IS DISPLAYED…520

A-9 [A.1]ABNORMALITY IN MODEL SELECTION SIGNAL IS DISPLAYED…521

A-10 ABNORMALITY IN SHIFT LEVER SYSTEM…522

a) [0.7][SHORT CIRCUIT WITH 12V OUTPUT CIRCUIT] IS DISPLAYED…522

b) [1.5][SHORT CIRCUIT,SHORT CIRCUIT WITH GROUND IN LEVER SIGNAL SYSTEM] IS DISPLAYED…523

c) [1.6][DISCONNECTION IN LEVER SIGNAL SYSTEM] IS DISPLAYED…527

A-11 [A.1][DISCONNECTION IN ACCELERATOR SIGNAL,DEFECTIVE ADJUSTMENT,DISCONNECTED LINK] IS DISPLAYED…529

A-12 [1.9][SHORT CIRCUIT WITH GROUND IN TRANSMISSION VALVE OIL TEMPERATURE SENSOR] IS DISPLAYED…533

A-13 PRESSURE CONTROL VALVE SYSTEM…534

a) [3.1][DEFECTIVE LOCK-UP CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅰ] OR [3.2][DEFECTIVE HI CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅰ]…534

a) [3.3][DEFECTIVE LO CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅰ] OR [3.4][DEFECTIVE 1ST CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅰ]…534

a) [3.5][DEFECTIVE 2ND CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅰ] OR [3.6][DEFECTIVE 3RD CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅰ]…534

a) [3.8][DEFECTIVE R CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅰ] IS DISPLAYED…534

b) [4.1][DEFECTIVE LOCK-UP CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅱ] OR [4.2][DEFECTIVE HI CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅱ]…535

b) [4.3][DEFECTIVE LO CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅱ] OR [4.4][DEFECTIVE 1ST CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅱ]…535

b) [4.5][DEFECTIVE 2ND CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅱ] OR [4.6][DEFECTIVE 3RD CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅱ]…535

b) [4.8][DEFECTIVE R CLUTCH PRESSURE CONTROL VALVE SYSTEM Ⅱ] IS DISPLAYED…535

b1) CHECKING FILL SIGNAL SYSTEM…535

b2) CHECKING WHEN [4.2] OR [4.3] IS DISPLAYED…536

b3) CHECKING WHEN [4.4] OR [4.6] OR [4.8] IS DISPLAYED…536

A-14 FLOW DETECTION VALVE SYSTEM…537

[5.1][DISCONNECTION IN LOCK-UP CLUTCH FLOW CONTROL VALVE SYSTEM] OR [5.2][DISCONNECTION IN HI CLUTCH FLOW CONTROL VALVE SYSTEM]…537

[5.3][DISCONNECTION IN LO CLUTCH FLOW CONTROL VALVE SYSTEM] OR [5.4][DISCONNECTION IN 1ST CLUTCH FLOW CONTROL VALVE SYSTEM]…537

[5.5][DISCONNECTION IN 2ND CLUTCH FLOW CONTROL VALVE SYSTEM] OR [5.6][DISCONNECTION IN 3RD CLUTCH FLOW CONTROL VALVE SYSTEM]…537

[5.8][DISCONNECTION IN R CLUTCH FLOW CONTROL VALVE SYSTEM] IS DISPLAYED…537

A-15 PRESSURE CONTEOL SOLENOID SYSTEM…538

a) [7.1][SHORT CIRCUIT IN LOCK-UP CLUTCH PRESSURE CONTROL SOLENOID SYSTEM] OR [7.2][SHORT CIRCUIT IN HI CLUTCH PRESSURE CONTROL SOLENOID SYSTEM]…538

a) [7.3][SHORT CIRCUIT IN LO CLUTCH PRESSURE CONTROL SOLENOID SYSTEM] OR [7.4][SHORT CIRCUIT IN 1ST CLUTCH PRESSURE CONTROL SOLENOID SYSTEM]…538

a) [7.5][SHORT CIRCUIT IN 2ND CLUTCH PRESSURE CONTROL SOLENOID SYSTEM] OR [7.6][SHORT CIRCUIT IN 3RD CLUTCH PRESSURE CONTROL SOLENOID SYSTEM]…538

a) [7.8][SHORT CIRCUIT IN R CLUTCH PRESSURE CONTROL SOLENOID SYSTEM] IS DISPLAYED…538

b) [9.1][SHORT CIRCUIT IN LOCK-UP CLUTCH PRESSURE CONTROL SOLENOID SYSTEM] OR [9.2][SHORT CIRCUIT IN HI CLUTCH PRESSURE CONTROL SOLENOID SYSTEM]…540

b) [9.3][SHORT CIRCUIT IN LO CLUTCH PRESSURE CONTROL SOLENOID SYSTEM] OR [9.4][SHORT CIRCUIT IN 1ST CLUTCH PRESSURE CONTROL SOLENOID SYSTEM]…540

b) [9.5][SHORT CIRCUIT IN 2ND CLUTCH PRESSURE CONTROL SOLENOID SYSTEM] OR [9.6][SHORT CIRCUIT IN 3RD CLUTCH PRESSURE CONTROL SOLENOID SYSTEM]…540

b) [9.8][SHORT CIRCUIT IN R CLUTCH PRESSURE CONTROL SOLENOID SYSTEM] IS DISPLAYED…540

A-16 PRESSURE SENSOR SYSTEM…542

a) [8.1][DEFECTIVE OUTPUT OF TORQUE CONVERTER INLET PRESSURE SENSOR] OR [8.3][DEFECTIVE OUTPUT OF TORQUE CONVERTER INLET PRESSURE SENSOR] IS DISPLAYED…542

b) [8.2][DEFECTIVE OUTPUT OF TORQUE CONVERTER OUTLET PRESSURE SENSOR] OR [8.4][DEFECTIVE OUTPUT OF TORQUE CONVERTER OUTLET PRESSURE SENSOR] IS DISPLAYED…543

ELECTRICAL CIRCUIT DIAGRAM FOR A MODE SYSTEM…544

TROUBLESHOOTING FOR METER PANEL SYSTEM (E MODE)…557

E-1 WATER TEMPERATURE GAUGE GIVES NO DISPLAY OR GIVES ABNORMAL DISPLAY…558

a) GIVES NO DISPLAY…558

b) GIVES ABNORMAL DISPLAY…558

E-2 TORQUE CONVERTER OIL TEMPERATURE GAUGE GIVES NO DISPLAY OR GIVES ABNORMAL DISPLAY…560

a) GIVES NO DISPLAY…560

b) GIVES ABNORMAL DISPLAY…560

E-3 RETARDER OIL TEMPERATURE GAUGE GIVES NO DISPLAY OR GIVES ABNORMAL DISPLAY…562

a) GIVES NO DISPLAY…562

b) GIVES ABNORMAL DISPLAY…562

E-4 FUEL GAUGE GIVES NO DISPLAY OR GIVES ABNORMAL DISPLAY…564

a) GIVES NO DISPLAY…564

b) GIVES ABNORMAL DISPLAY…564

E-5 SERVICE METER DOES NOT MOVE (SERIAL NO.:1001-1599)…566

E-6 SERVICE METER AND TACHOMETOR DOES NOT MOVE (SERIAL NO.:1601 AND UP)…567

TROUBLESHOOTING FOR PILOT LAMP SYSTEM(F MODE)…569

F-1 ABNORMALITY IN LIGHTING UP OF RETARDER PILOT LAMP…570

F-2 ABNORMALITY IN LIGHTING UP OF PARKING BRAKE PILOT LAMP…576

F-3 ABNORMALITY IN LIGHTING UP OF FRONT BRAKE OIL LEVEL PILOT LAMP…582

F-4 ABNORMALITY IN LIGHTING UP OF REAR BRAKE CAUTION LAMP…588

F-5 ABNORMALITY IN LIGHTING UP OF ENGINE OIL PRESSURE PILOT LAMP…594

F-6 ABNORMALITY IN LIGHTING UP OF BATTERY CHARGE CAUTION LAMP…598

ELECTRICAL CIRCUIT DIAGRAM FOR F MODE SYSTEM…604

TROUBLESHOOTING OF AIR SYSTEM ON MACHINE AIR COMPRESSOR(C MODE)…607

TROUBLESHOOTING OF AIR SYSTEM ON MACHINE AIR COMPRESSOR…608

BASIC AIR CIRCUIT OF AIR COMPRESSOR…608

C-1 AIR PRESSURE DOES NOT RISE AT ALL…609

C-2 AIR PRESSURE DOES NOT RISE TO SPECIFIED PRESSURE RANGE(GREEN RANGE OF AIR GAUGE)…610

C-3 AIR PRESSURE RISES BUT CHARGING TAKES A LONG TIME…611

C-4 AIR BLOWS OUT FROM SAFETY VALVE…612

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEMS(H MODE)…613

METHOD OF USING MATRIX TROUBLESHOOTING TABLES…614

H-1 MACHINE DOES NOT START…616

H-2 MACHINE DOES NOT TRAVEL SMOOTHLY (MACHINE JERKS)…618

H-3 LOCK-UP CLUTCH CANNOT BE DISENGAGED (ENGINE STALLS)…618

H-4 EXCESSIVE SHOCK WHEN STARTING OR SHIFTING…619

H-5 TRANSMISSION DOES NOT SHIFT UP…619

H-6 MACHINE LACKS POWER OR SPEED WHEN TRAVELING…620

H-7 TIME LAG IS EXCESSIVE WHEN STARTING OR SHIFTING GEAR…626

H-8 TORQUE CONVERTER OIL TEMPERATURE IS HIGH…628

H-9 TORQUE CONVERTER OIL PRESSURE IS LOW…629

H-10 FRONT BRAKE IS INEFFECTIVE,OR EFFECTIVE ONLY ON ONE SIDE…630

H-11 REAR BRAKE IS INEFFECTIVE,OR EFFECTIVE ONLY ON ONE SIDE…631

H-12 STEERING WHEEL IS HEAVY…632

H-13 STEERING WHEEL DOES NOT WORK…633

H-14 STEERING WHEEL VIBRATES…633

H-15 HOIST CYLINDER LACKS LIFTING FORCE(LIFTING SPEED)…634

H-16 HOIST CYLINDER DOES NOT WORK…635

H-17 EXCESSIVE HYDRAULIC DRIFT OF DUMP BODY…636

TROUBLESHOOTING OF ARSC [AUTOMATIC RETARDER SPEED CONTROLLER] SYSTEM (R MODE)…637

OUTLINE…638

ELECTRICAL CIRCUIT DIAGRAM FOR ARSC (AUTOMATIC RETARDER SPEED CONTROLLER) SYSTEM…642

R-1 0.1 (ABNORMALITY IN POWER SOURCE VOLTAGE) IS DISPLAYED…644

R-2 1.0 (DISCONNECTION IN ENGINE SPEED SENSOR SYSTEM) IS DISPLAYED…645

R-3 1.3 (DISCONNECTION IN TRANSMISSION OUTPUT SHAFT SPEED SENSOR SYSTEM) IS DISPLAYED…646

R-4 1.5 (FAILURE IN RETARDER OIL TEMPERATURE SENSOR SYSTEM) IS DISPLAYED…647

R-5 1.7 (FAILURE IN ACCELERATOR SIGNAL SYSTEM) IS DISPLAYED…648

R-6 1.8 (FAILURE IN SUSPENSION PRESSURE SENSOR "LEFT" SYSTEM) IS DISPLAYED…649

R-7 1.9 (FAILURE IN SUSPENSION PRESSURE SENSOR "RIGHT" SYSTEM) IS DISPLAYED…650

R-8 4.2 (DISCONNECTION IN EXHAUST BRAKE SELECTOR SIGNAL SYSTEM) IS DISPLAYED…651

R-9 4.3 (DISCONNECTION IN ARSC CAUTION LAMP SYSTEM) IS DISPLAYED…652

R-10 4.4 (DISCONNECTION IN READY LAMP SYSTEM) IS DISPLAYED…653

R-11 4.5 (DISCONNECTION IN PANEL CAUTION AND BUZZER SYSTEM) IS DISPLAYED…654

R-12 5.2 (SHORT CIRCUIT WITH GROUND IN EXHAUST BRAKE SELECTOR SIGNAL OUTPUT SYSTEM) IS DISPLAYED…655

R-13 5.3 (SHORT CIRCUIT WITH GROUND IN ARSC CAUTION LAMP SYSTEM) IS DISPLAYED…656

R-14 5.4 (SHORT CIRCUIT WITH GROUND IN READY OUTPUT CIRCUIT SYSTEM) IS DISPLAYED…657

R-15 5.5 (SHORT CIRCUIT WITH GROUND IN PANEL CAUTION LAMP AND BUZZER OUTPUT SYSTEM) IS DISPLAYED…658

R-16 6.0 (FAILURE IN ENGINE SPEED SYSTEM) IS DISPLAYED…659

R-17 7.0 (DISCONNECTION IN TRAVEL SPEED DISPLAY UP OUTPUT SYSTEM) IS DISPLAYED…660

R-18 7.1 (DISCONNECTION IN TRAVEL SPEED DISPLAY DOWN OUTPUT SYSTEM) IS DISPLAYED…661

R-19 7.2 (DISCONNECTION IN TRAVEL SPEED DISPLAY CLEAR OUTPUT SYSTEM) IS DISPLAYED…662

R-20 7.3 (SHORT CIRCUIT WITH GROUND IN TRAVEL SPEED DISPLAY UP OUTPUT SYSTEM) IS DISPLAYED…663

R-21 7.4 (SHORT CIRCUIT WITH GROUND IN TRAVEL SPEED DISPLAY DOWN OUTPUT SYSTEM) IS DISPLAYED…664

R-22 7.5 (SHORT CIRCUIT WITH GROUND IN TRAVEL SPEED DISPLAY CLEAR OUTPUT SYSTEM) IS DISPLAYED…665

R-23 8.1 (SHORT CIRCUIT WITH GROUND IN PRESSURE CONTROL VALVE SYSTEM) IS DISPLAYED…666

R-24 8.3 (DISCONNECTION IN PRESSURE CONTROL VALVE SYSTEM) IS DISPLAYED…667

R-25 8.5 (FAILURE IN PRESSURE CONTROL VALVE (PRESSURE CONTROL VALVE REMAINS OPEN) IS DISPLAYED…668

R-26 8.7 (FAILURE IN PRESSURE CONTROL VALVE (PRESSURE CONTROL VALVE DOES NOT OPEN) IS DISPLAYED…669

R-27 8.9 (SHORT CIRCUIT WITH GROUND IN PRESSURE SWITCH VALVE SYSTEM) IS DISPLAYED…670

R-28 9.0 (DISCONNECTION IN PRESSURE SWITCH VALVE SYSTEM) IS DISPLAYED…671

R-29 9.1 (FAILURE IN PRESSURE SWITCH VALVE SYSTEM (REMAINS OPEN)) IS DISPLAYED…672

R-30 9.2 (FAILURE IN PRESSURE SWITCH VALVE SYSTEM (DOES NOT OPEN)) IS DISPLAYED…673

R-31 9.3 (DISCONNECTION IN SYSTEM SWITCH SYSTEM) IS DISPLAYED…674

R-32 9.4 (SHORT CIRCUIT WITH GROUND IN SYSTEM SWITCH SYSTEM) IS DISPLAYED…675

R-33 9.5 (DISCONNECTION, SHORT CIRCUIT WITH GROUND IN TRAVEL SPEED SETTING SWITCH SYSTEM) IS DISPLAYED…676

R-101 SET SPEED CANNOT BE SET…677

R-102 FAILURE CODE IS ALWAYS CLEARED (CONTROLLER DISPLAY WINDOW ALWAYS SHOWS "–") OR FAILURE CODE CANNOT BE CLEARED…680

R-103 EFFECT OF RETARDER IS TOO STRONG WHEN MACHINE IS EMPTY, OR TOO WEAK WHEN MACHINE IS LOADED (DOES NOT JUDGE LOADED/UNLOADED CONDITION PROPERLY)…681

R-104 ABNORMALITY APPEARS IN OTHER CONTROLLER…681

R-105 WHEN TRAVELING DOWNHILL, EVEN WHEN SET SPEED IS EXCEEDED, NO CONTROL IS CARRIED OUT…682

R-106 MONITOR LAMP (BUZZER) STAYS ON (OR OFF)…683

R-107 READY LAMP DOES NOT LIGHT UP (OR STAYS LIGHTED UP)…684

R-108 EXHAUST BRAKE DOES NOT WORK PROPERLY [EXHAUST BRAKE IS ACTUATED WHEN EXHAUST BRAKE SWITCH IS OFF; OR EXHAUST BRAKE IS NOT ACTUATED WHEN EXHAUST BRAKE SWITCH IS ON]…686

R-109 RETARDER LAMP DOES NOT LIGHT UP, OR STAYS LIGHTED UP…688

R-110 TRAVEL SPEED DISPLAY ALWAYS GIVES DISPLAY (OR DOES NOT GIVE ANY DISPLAY)…689

30 DISASSEMBLY AND ASSEMBLY…691

SPECIAL TOOL LIST…694

SKETCHES OF SPECIAL TOOLS…698

STARTING MOTOR…700

REMOVAL AND INSTALLATION…700

ALTERNATOR…701

REMOVAL AND INSTALLATION…701

ENGINE OIL COOLER…702

REMOVAL AND INSTALLATION…702

FUEL INJECTION PUMP…703

REMOVAL AND INSTALLATION…703

FUEL SUPPLY PUMP…704

REMOVAL…704

INSTALLATION…706

AIR COMPRESSOR…708

REMOVAL AND INSTALLATION…708

AIR CONDITIONER COMPRESSOR …710

REMOVAL AND INSTALLATION…710

AIR CONDITIONER CONDENSER…712

REMOVAL AND INSTALLATION…712

WATER PUMP…713

REMOVAL AND INSTALLATION…713

AFTERCOOLER CORE…714

REMOVAL AND INSTALLATION…714

EXHAUST BRAKE CYLINDER…715

REMOVAL AND INSTALLATION…715

TURBOCHARGER…716

REMOVAL AND INSTALLATION…716

NOZZLE HOLDER…717

REMOVAL AND INSTALLATION…717

FUEL INJECTOR…718

REMOVAL…718

INSTALLATION…720

NOZZLE TIP…722

REMOVAL…722

INSTALLATION…724

CYLINDER HEAD…726

REMOVAL…726

INSTALLATION…728

ENGINE FRONT SEAL…739

REMOVAL…739

INSTALLATION…740

ENGINE REAR SEAL…742

REMOVAL…742

INSTALLATION…743

ENGINE…746

REMOVAL…746

INSTALLATION…749

RADIATOR…754

REMOVAL…754

INSTALLATION…756

OIL COOLER…761

REMOVAL AND INSTALLATION…761

OUTPUT SHAFT…762

REMOVAL AND INSTALLATION…762

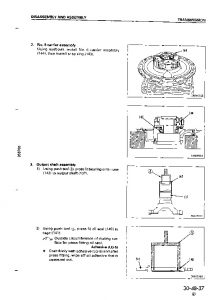

DISASSEMBLY…763

ASSEMBLY…765

TORQUE CONVERTER, TRANSMISSION…769

REMOVAL …769

INSTALLATION…771

DISCONNECTION…773

CONNECTION…774

TORQUE CONVERTER…775

DISASSEMBLY…775

ASSEMBLY…781

PTO…787

DISASSEMBLY…787

ASSEMBLY…788

TRANSMISSION…790

DISASSEMBLY…790

ASSEMBLY…808

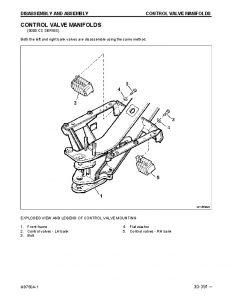

TRANSMISSION CONTROL VALVE (ECMV)…827

REMOVAL AND INSTALLATION…827

TRANSMISSION, MAIN RELIEF VALVE…828

REMOVAL AND INSTALLATION…828

DIFFERENTIAL…829

REMOVAL…829

INSTALLATION…830

DISASSEMBLY…831

ASSEMBLY…834

FRONT WHEEL…842

REMOVAL AND INSTALLATION…842

REAR WHEEL…843

REMOVAL AND INSTALLATION…843

FRONT BRAKE CALIPER PAD…844

REMOVAL AND INSTALLATION…844

FRONT BRAKE CALIPER…845

REMOVAL AND INSTALLATION…845

DISASSEMBLY…846

ASSEMBLY…847

FRONT WHEEL HUB…849

DISASSEMBLY…849

ASSEMBLY…850

FINAL DRIVE CARRIER…853

REMOVAL AND INSTALLATION…853

DISASSEMBLY AND ASSEMBLY…854

REAR WHEEL BRAKE …855

REMOVAL…855

INSTALLATION…857

REAR BRAKE…859

DISASSEMBLY…859

ASSEMBLY…861

FRONT SUSPENSION CYLINDER…864

REMOVAL…864

INSTALLATION…865

DISASSEMBLY…866

ASSEMBLY…867

REAR SUSPENSION CYLINDER…868

REMOVAL AND INSTALLATION…868

DISASSEMBLY…869

ASSEMBLY…870

AIR GOVERNOR…871

REMOVAL AND INSTALLATION…871

DISASSEMBLY AND ASSEMBLY…872

BRAKE VALVE…873

REMOVAL AND INSTALLATION…873

DISASSEMBLY…874

ASSEMBLY…876

PARKING BRAKE SPRING CYLINDER…878

REMOVAL AND INSTALLATION…878

PARKING BRAKE CHAMBER…879

DISASSEMBLY…879

ASSEMBLY…880

FRONT BRAKE CHAMBER…881

REMOVAL AND INSTALLATION…881

DISASSEMBLY…882

ASSEMBLY…884

REAR BRAKE CHAMBER…886

REMOVAL AND INSTALLATION…886

DISASSEMBLY…887

ASSEMBLY…891

SLACK ADJUSTER…894

REMOVAL AND INSTALLATION…894

DISASSEMBLY AND ASSEMBLY…895

AIR DRIER (DESICCANT TYPE)…896

REMOVAL AND INSTALLATION…896

DISASSEMBLY AND ASSEMBLY…897

TRANSMISSION CONTROL, RETARDER BRAKE COOLING PUMP AND HOIST, STEERING PUMP…914

REMOVAL AND INSTALLATION…914

EMERGENCY STEERING MOTOR PUMP…915

REMOVAL AND INSTALLATION…915

STEERING VALVE…916

REMOVAL AND INSTALLATION…916

DISASSEMBLY…917

ASSEMBLY…922

DEMAND VALVE…930

REMOVAL AND INSTALLATION…930

DISASSEMBLY AND ASSEMBLY…931

RELIEF VALVE…932

DISASSEMBLY AND ASSEMBLY…932

HOIST VALVE…933

REMOVAL AND INSTALLATION…933

DISASSEMBLY…934

ASSEMBLY…935

STEERING CYLINDER…936

REMOVAL AND INSTALLATION…936

DISASSEMBLY…937

ASSEMBLY…939

HOIST CYLINDER…941

REMOVAL AND INSTALLATION…941

DISASSEMBLY…942

ASSEMBLY…945

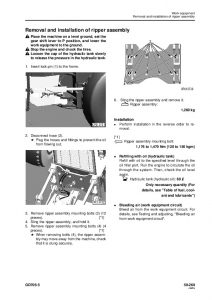

DUMP BODY…948

REMOVAL AND INSTALLATION…948

SHIM OF DUMP BODY…949

PROCEDURE FOR ADJUSTING…949

TRANSMISSION CONTROLLER…950

REMOVAL AND INSTALLATION…950

ENGINE CONTROLLER…951

REMOVAL AND INSTALLATION…951

SHIFT INDICATOR CONTROLLER…952

REMOVAL AND INSTALLATION…952

PARKING BRAKE SHOE…953

REMOVAL …953

INSTALLATION…954

40 MAINTENANCE STANDARD…955

DAMPER…957

TORQUE CONVERTER…958

TRANSMISSION…960

MAIN RELIEF VALVE…963

TRANSMISSION VALVE, ECMV…964

FRONT AXLE…965

DIFFERENTIAL…967

FINAL DRIVE…970

FRONT BRAKE…971

REAR BRAKE…972

PARKING BRAKE…974

REAR BRAKE CHAMBER…975

FRONT BRAKE CHAMBER…976

SLACK ADJUSTER…977

HYDRAULIC PUMP…978

STEERING, HOIST PUMP…979

STEERING CYLINDER…980

DEMAND VAVLE…981

CROSSOVER RELIEF VALVE…981

HOIST VALVE…982

HOIST CYLINDER…983

STEERING LINKAGE…984

REAR AXLE SUPPORT…985

FRONT SUSPENSION CYLINDER…986

REAR SUSPENSION CYLINDER…987

90 OTHERS…989

AIR CIRCUIT DIAGRAM (STANDARD SPECIFICATION SERIAL NO.:1001-1200)…991

AIR CIRCUIT DIAGRAM (STANDARD SPECIFICATION SERIAL NO.:1201-1600)…993

AIR CIRCUIT DIAGRAM (EMERGENCY BRAKE SPECIFICATION SERIAL NO.:1001-1200)…995

AIR CIRCUIT DIAGRAM (EMERGENCY BRAKE SPECIFICATION SERIAL NO.:1201-1600)…997

AIR CIRCUIT DIAGRAM (EMERGENCY BRAKE SPECIFICATION SERIAL NO.:1601 AND UP)…999

HYDRAULIC CIRCUIT DIAGRAM FOR TORQUE CONVERTER, TRANSMISSION, AND BRAKE COOLING…1001

STEERING, HOIST HYDRAULIC CIRCUIT DIAGRAM (SERIAL NO.:1001-1200)…1003

STEERING, HOIST HYDRAULIC CIRCUIT DIAGRAM (SERIAL NO.:1201 AND UP)…1005

ELECTRIC CIRCUIT DIAGRAM (1/2) (SERIAL NO.:1001-1200)…1007

ELECTRIC CIRCUIT DIAGRAM (2/2) (SERIAL NO.:1001-1200)…1009

ELECTRIC CIRCUIT DIAGRAM (1/2) (SERIAL NO.:1201-1600)…1011

ELECTRIC CIRCUIT DIAGRAM (2/2) (SERIAL NO.:1201-1600)…1013

ELECTRIC CIRCUIT DIAGRAM (1/4) (SERIAL NO.:1601-1685)…1015

ELECTRIC CIRCUIT DIAGRAM (2/4) (SERIAL NO.:1601-1685)…1017

ELECTRIC CIRCUIT DIAGRAM (3/4) (SERIAL NO.:1601-1685)…1019

ELECTRIC CIRCUIT DIAGRAM (4/4) (SERIAL NO.:1601-1685)…1021

ELECTRIC CIRCUIT DIAGRAM (1/4) (SERIAL NO.:1686 AND UP)…1023

ELECTRIC CIRCUIT DIAGRAM (2/4) (SERIAL NO.:1686 AND UP)…1025

ELECTRIC CIRCUIT DIAGRAM (3/4) (SERIAL NO.:1686 AND UP)…1027

ELECTRIC CIRCUIT DIAGRAM (4/4) (SERIAL NO.:1686 AND UP)…1029

ELECTRIC CIRCUIT DIAGRAM FOR TRANSMISSION CONTROLLER SYSTEM…1031

ELECTRIC CIRCUIT DIAGRAM OF AIR CONDITIONER (SERIAL NO.:1001-1200)…1033

ELECTRIC CIRCUIT DIAGRAM OF AIR CONDITIONER (SERIAL NO.: 1201 – 1600)…1034

ELECTRIC CIRCUIT DIAGRAM OF AIR CONDITIONER (SERIAL NO.: 1601 AND UP)…1035

Komatsu Dump Truck HD255 Repair Service Manual