Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

UEN00084-07 – Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Shop Manual.pdf

UEN00084 – Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Shop Manual.pdf

SEAM02050307 – Hydraulic Excavator PC200-3, PC210-3, PC220-3, PC240-3, PC280-3 Operation & Maintenance Manual.pdf

UEAM004904 – Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Operation & Maintenance Manual.pdf

UEAM004912 – Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Operation & Maintenance Manual.pdf

PRODUCT DETAILS:

Total Pages: 3,330 pages

File Format: PDF

Language: English

SEAM02050307 – Hydraulic Excavator PC200-3, PC210-3, PC220-3, PC240-3, PC280-3 Operation & Maintenance Manual…2

UEAM004904 – Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Operation & Maintenance Manual…83

FOREWORD…85

FOREWORD…86

SAFETY INFORMATION…87

NOISE (PC210,210LC,210NLC, PC230NHD)…89

NOISE (PC240LC,240NLC)…90

Vibration levels…91

Guide to Reduce Vibration Levels on Machine…91

INTRODUCTION…93

DIRECTIONS OF MACHINE…93

BREAKING-IN THE NEW MACHINE…94

PRODUCT INFORMATION…95

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…95

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION…95

SERVICE METER LOCATION…96

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…96

MACHINE SERIAL PLATES…97

STANDARD SERIAL PLATE…97

FOREWORD…98

SAFETY…98

OPERATION…100

MAINTENANCE…102

SPECIFICATIONS…104

ATTACHMENTS AND OPTIONS…105

SUPER LONG FRONT BOOM AND ARM PC210/240-8…107

INDEX…108

COLOPHON…108

SAFETY…109

SAFETY INFORMATION…110

SAFETY LABELS…112

LOCATION OF SAFETY LABELS…112

SAFETY LABELS…113

SAFETY INFORMATION…120

SAFETY RULES…120

IF PROBLEMS ARE FOUND…120

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS…120

FIRE EXTINGUISHER AND FIRST AID KIT…120

SAFETY EQUIPMENT…121

KEEP MACHINE CLEAN…121

KEEP OPERATOR'S COMPARTMENT CLEAN…121

LEAVING OPERATOR'S SEAT WITH LOCK…121

HANDRAILS AND STEPS…122

MOUNTING AND DISMOUNTING…123

NO PERSONS ON ATTACHMENTS…123

DO NOT GET CAUGHT IN ARTICULATED PORTION…123

BURN PREVENTION…123

ACTION IF FIRE OCCURS…125

WINDSHIELD WASHER FLUID…125

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION…125

ATTACHMENT INSTALLATION…125

ATTACHMENT COMBINATIONS…126

CAB WINDOW GLASSES…126

UNAUTHORIZED MODIFICATIONS…126

SAFETY AT JOBSITE…126

WORKING ON LOOSE GROUND…126

DISTANCE TO HIGH VOLTAGE CABLES…127

ENSURE GOOD VISIBILITY…127

VENTILATION FOR ENCLOSED AREA…128

SIGNALMAN'S SIGNAL AND SIGNS…128

EMERGENCY EXIT FROM OPERATOR'S CAB…128

ELECTROMAGNETIC INTERFERENCE…128

ASBESTOS DUST HAZARD PREVENTION…129

SAFETY MACHINE OPERATION…130

STARTING ENGINE…130

CHECKS BEFORE STARTING ENGINE…130

SAFETY RULES FOR STARTING ENGINE…131

STARTING ENGINE IN COLD WEATHER…131

OPERATION…132

CHECKS BEFORE OPERATION…132

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS…132

SAFETY RULES FOR TRAVELLING…133

TRAVELLING ON SLOPES…134

OPERATIONS ON SLOPES…135

PROHIBITED OPERATIONS…135

OPERATIONS ON SNOW…137

PARKING MACHINE…137

TRANSPORTATION…138

LOADING AND UNLOADING…138

SHIPPING THE MACHINE…139

BATTERY…140

STARTING ENGINE WITH BOOSTER CABLES…141

TOWING…142

SAFETY RULES FOR TOWING…142

LIFTING OBJECTS WITH BUCKET…143

SAFETY RULES FOR LIFTING OBJECTS…143

SAFETY MAINTENANCE INFORMATION…144

WARNING TAG…144

KEEP WORK PLACE CLEAN AND TIDY…144

APPOINT LEADER WHEN WORKING WITH OTHERS…144

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE…145

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING…146

PROPER TOOLS…146

ACCUMULATOR…147

HANDLING GAS SPRING…147

PERSONNEL…148

ATTACHMENTS…148

WORK UNDER THE MACHINE…148

NOISE…149

WHEN USING HAMMER…149

WELDING WORKS…149

REMOVING BATTERY TERMINALS…149

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION…150

DO NOT DISASSEMBLE RECOIL SPRINGS…150

SAFETY RULES FOR HIGH-PRESSURE OIL…150

OPERATION…153

MACHINE VIEW ILLUSTRATIONS…154

OVERALL MACHINE VIEW…154

CONTROLS AND GAUGES…155

DETAILED CONTROLS AND GAUGES…156

MONITORING SYSTEM…156

Basic Operation of Machine Monitor…157

Basic Check Monitors…161

Caution Monitors…163

Emergency Monitors…166

Meter Display Portion…168

Monitor Switches Portion…175

Handling Function Switches…184

SWITCHES…220

CONTROL LEVERS AND PEDALS…225

CEILING WINDOW…228

WINDSHIELD…228

EMERGENCY ESCAPE HAMMER…234

DOOR LOCK…234

CAP WITH LOCK…235

DRINK BOX…237

MAGAZINE BOX…237

ASHTRAY…237

AIR CONDITIONER CONTROLS…238

Air Conditioner Control Panel…238

Method of Operation…243

Use Air Conditioner with Care…250

Air Conditioner Maintenance…250

RADIO…251

Control Panel…251

Controls of Radio…253

Use Radio with Care…255

Space for radio cassette…255

AUXILIARY ELECTRIC POWER…256

24V power source…256

12V power source…256

FUSE…257

FUSIBLE LINK…258

CONTROLLER…258

TOOL BOX…258

GREASE GUN HOLDER…258

MACHINE OPERATIONS AND CONTROLS…259

BEFORE STARTING ENGINE…259

Walk-around Checks…259

REFUELLING PUMP…260

Checks Before Starting…261

Adjustment…268

Seat Belt…272

Operations Before Starting Engine…273

STARTING ENGINE…275

AFTER STARTING ENGINE…278

Warming Up Engine…279

Warming Up Hydraulic Equipment…281

Operation After Completion Of Warming-Up Operation…287

STOPPING THE ENGINE…289

MACHINE OPERATION…290

Preparations for Moving the Machine…290

Moving Machine Forward…291

Moving Machine Backward…292

Stopping Machine…293

STEERING THE MACHINE…294

Steering…294

SWINGING…296

WORK EQUIPMENT CONTROLS AND OPERATIONS…297

WORKING MODE…299

PROHIBITED OPERATIONS…301

GENERAL OPERATION INFORMATION…303

TRAVELLING ON SLOPES…305

ESCAPE FROM MUD…307

Track on One Side Stuck…307

Tracks on Both Sides Stuck…307

RECOMMENDED APPLICATIONS…308

Backhoe Work…308

Shovel Work…308

Ditching Work…308

Loading Work…309

BUCKET REPLACEMENT AND INVERSION…310

Replacement…310

Inversion…312

PARKING MACHINE…313

CHECK AFTER SHUT OFF ENGINE…315

MACHINE INSPECTION AFTER DAILY WORK…315

LOCKING…315

TRANSPORTATION…316

TRANSPORTATION PROCEDURE…316

SPECIAL TRANSPORTATION INSTRUCTIONS FOR PC210NLC-8 AND PC230NHD-8…316

LOADING AND UNLOADING WITH TRAILER…318

Loading…319

Securing Machine…322

Unloading…326

LIFTING MACHINE…328

COLD WEATHER OPERATION…330

COLD WEATHER OPERATION INFORMATION…330

Fuel and Lubricants…330

Cooling System Coolant…330

Battery…331

AFTER DAILY WORK COMPLETION…332

AFTER COLD WEATHER SEASON…332

LONG TERM STORAGE…333

BEFORE STORAGE…333

DURING STORAGE…333

AFTER STORAGE…334

STARTING MACHINE AFTER LONG-TERM STORAGE…334

TROUBLES AND ACTIONS…335

RUNNING OUT OF FUEL…335

PHENOMENA THAT ARE NOT FAILURES…335

TOWING THE MACHINE…336

LIGHTWEIGHT TOWING HOLE…337

SEVERE JOB CONDITION…337

DISCHARGED BATTERY…338

Battery Removal and Installation…338

Battery Charges…339

Starting Engine with Booster Cables…340

OTHER TROUBLE…342

Electrical System…342

Chassis…343

Engine…344

Electronic Control System…346

Point of Contact to Telephone when Error Occurs…346

MAINTENANCE…347

MAINTENANCE INFORMATION…348

OUTLINE OF SERVICE…351

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC…351

OIL…351

FUEL…352

COOLANT AND WATER FOR DILUTION…352

GREASE…353

CARRYING OUT KOWA (Komatsu Oil Wear Analysis)…353

STORING OIL AND FUEL…354

FILTERS…354

EXPLANATION OF LUBRICATION CHART DECAL…355

ELECTRIC SYSTEM MAINTENANCE…357

WEAR PARTS…358

WEAR PARTS LIST…358

RECOMMENDED FUEL, COOLANT, AND LUBRICANT…359

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…361

TIGHTENING TORQUE SPECIFICATIONS…362

TIGHTENING TORQUE LIST…362

SAFETY CRITICAL PARTS…363

SAFETY CRITICAL PARTS LIST…363

MAINTENANCE SCHEDULE…364

MAINTENANCE SCHEDULE CHART…364

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER…366

MAINTENANCE PROCEDURE…367

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)…367

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)…367

WHEN REQUIRED…368

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT…368

CLEAN INSIDE OF COOLING SYSTEM…373

CHECK AND TIGHTEN TRACK SHOE BOLTS…376

CHECK AND ADJUST TRACK TENSION…377

REPLACE BUCKET TEETH (VERTICAL PIN TYPE)…379

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)…382

ADJUST BUCKET CLEARANCE…383

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID…384

CHECK AND MAINTENANCE AIR CONDITIONER…385

WASH WASHABLE FLOOR…386

BLEEDING AIR FROM HYDRAULIC SYSTEM…389

CHECK BEFORE STARTING…391

EVERY 100 HOURS MAINTENANCE…392

LUBRICATING…392

EVERY 250 HOURS MAINTENANCE…394

CHECK LEVEL OF BATTERY ELECTROLYTE…394

CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST…396

EVERY 500 HOURS MAINTENANCE…397

LUBRICATING…397

LUBRICATE SWING CIRCLE…398

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE…399

REPLACE FUEL PRE-FILTER CARTRIDGE…401

CHECK SWING PINION GREASE LEVEL, ADD GREASE…403

CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS, AFTERCOOLER FINS, FUEL COOLER FINS, AND CONDENSER FINS (ONLY MACHINES EQUIPPED WITH AIR CONDITIONER)…404

CLEAN AIR CONDITIONER FRESH/RECIRC FILTERS…406

REPLACE BREATHER ELEMENT IN HYDRAULIC TANK…407

CHECK OIL LEVEL IN SWING MACHINERY CASE, ADD OIL…408

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL…409

EVERY 1000 HOURS MAINTENANCE…410

REPLACE HYDRAULIC OIL FILTER ELEMENT…410

CHANGE OIL IN SWING MACHINERY CASE…411

CHECK OIL LEVEL IN DAMPER CASE, ADD OIL…412

REPLACE FUEL MAIN FILTER CARTRIDGE…413

CHECK ALL TIGHTENING POINTS OF ENGINE EXHAUST PIPE CLAMPS…414

REPLACE CORROSION RESISTOR CARTRIDGE…415

CHECK FAN BELT TENSION AND REPLACE FAN BELT…415

CHECK NITROGEN GAS CHARGE PRESSURE IN ACCUMULATOR (for breaker)…415

EVERY 2000 HOURS MAINTENANCE…416

CHANGE OIL IN FINAL DRIVE CASE…416

CLEAN HYDRAULIC TANK STRAINER…417

CHECKING CHARGE PRESSURE OF NITROGEN GAS IN ACCUMULATOR (FOR CONTROL CIRCUIT)…418

CHECK ALTERNATOR, STARTING MOTOR…421

CHECK ENGINE VALVE CLEARANCE, ADJUST…421

EVERY 4000 HOURS MAINTENANCE…422

CHECK WATER PUMP…422

CHECK VIBRATION DAMPER…422

REPLACE ACCUMULATOR (FOR CONTROL CIRCUIT)…423

CHECK FOR LOOSENESS OF HIGH-PRESSURE PIPING CLAMP, HARDENING OF RUBBER…424

CHECK FOR MISSING FUEL SPRAY PREVENTION CAP, HARDENING OF RUBBER…424

CHECK OPERATING CONDITION OF COMPRESSOR…425

EVERY 5000 HOURS MAINTENANCE…426

CHANGE OIL IN HYDRAULIC TANK…426

EVERY 8000 HOURS MAINTENANCE…427

REPLACE FUEL SPRAY PREVENTION CAP…427

REPLACE HIGH-PRESSURE PIPING CLAMP…427

SPECIFICATIONS…429

SPECIFICATIONS…430

MONOBOOM WORKING RANGE…432

PC210-8 WORKING RANGE (2-PIECE BOOM)…434

PC230-8 WORKING RANGE (2-PIECE BOOM)…434

PC240-8 WORKING RANGE (2-PIECE BOOM)…434

EXPLANATION OF LIFTING CAPACITY CHART PC210, PC210LC, PC210NLC, PC230NHD-8…436

PC210-8…437

PC210LC-8…438

PC210NLC-8…439

PC230NHD-8…440

EXPLANATION OF LIFTING CAPACITY CHART PC240LC, PC240NLC-8…441

PC240LC-8…442

PC240NLC-8…443

EXPLANATION OF LIFTING CAPACITY CHART PC210, PC210LC, PC210NLC-8, pc230nhd-8 2 PIECE BOOM…444

PC210-8…445

PC210LC-8…446

PC210NLC-8…447

PC230NHD-8…448

EXPLANATION OF LIFTING CAPACITY CHART (PC240LC,NLC-8 2 PIECE BOOM)…449

PC240LC-8, PC240NLC-8 2 PIECE BOOM…450

ATTACHMENTS AND OPTIONS…453

GENERAL PRECAUTIONS FOR SAFETY…454

PRECAUTIONS WHEN SELECTING…454

READ THE INSTRUCTION MANUAL THOROUGHLY…454

PRECAUTIONS WHEN REMOVING OR INSTALLING…454

PRECAUTIONS WHEN USING…455

HYDRAULIC QUICK COUPLER PIPING…456

LOCATIONS…456

OPERATION…457

BUCKET WITH HOOK…459

HOOK CONDITION…459

PROHIBITED OPERATIONS…459

MACHINE READY FOR ATTACHMENT…460

LOCATIONS…460

HYDRAULIC CIRCUIT…465

Switching Hydraulic Circuit…465

Adjusting Oil Flow…465

Switching Between Breaker and General Attachment…465

Hydraulic Circuit Connection…466

Oil Flow Path…467

Replace Additional Breaker Filter Element…468

Replace Additional Breaker Pilot Filter Element…470

ATTACHMENT REMOVAL AND INSTALLATION…472

Attachment Removal…472

Attachment Installation…474

ATTACHMENT OPERATIONS…476

When Using Breaker…476

When Using General Attachment Such as Crusher…478

LONG TERM STORAGE…479

SPECIFICATIONS…479

ATTACHMENT GUIDE…480

COMBINATIONS OF WORK EQUIPMENT…480

SELECTION OF TRACK SHOES…483

METHOD OF SELECTING SHOES…483

SELECTION OF BUCKET TEETH…484

METHOD OF SELECTING TEETH…484

STANDARDS FOR SELECTING VERTICAL PIN TYPE AND HORIZONTAL PIN TYPE TEETH…484

HANDLING OF RUBBER PAD SHOE AND ROAD LINER…485

Working Environment…485

Working Conditions…485

Storage and Maintenance…486

Extent of Damage to Rubber…486

Check Road Liner…486

Replace Road Liner…486

TRAPEZOIDAL BUCKET…487

HANDLING EXTENSION ARM…488

HANDLING CLAMSHELL BUCKET…489

CONTROLS (AUXILIARY HYDRAULIC CIRCUITS)…490

CRUSHER CONTROL PEDAL FOR OPENING AND CLOSING…491

CRUSHER CONTROL PEDAL FOR ROTATION…492

RECOMMENDED ATTACHMENT OPERATIONS…493

HYDRAULIC BREAKER…493

PC210/230-8 2-PC BOOM…498

FEATURES OF 2-PIECE BOOM & ARM…498

OPERATION…498

BEFORE STORAGE POSTURE WHEN LEAVING MACHINE…500

Lifting…500

TESTING AND ADJUSTING…501

PERODIC MAINTENANCE…501

TRANSPORTATION…502

LUBRICATING…503

Every 500 Hours…503

PC240-8 2-PC BOOM…504

FEATURES OF 2-PIECE BOOM & ARM…504

OPERATION…505

TESTING AND ADJUSTING…507

TRANSPORTATION…508

PC240-8 STRAIGHT BOOM…509

GENERAL VIEW OF MACHINE…509

CAUTION ITEMS…509

CONTROL (AUXILIARY HYDRAULIC CIRCUITS)…510

CRUSHER CONTROL PEDAL FOR OPENING AND CLOSING…511

CRUSHER CONTROL BUTTON FOR ROTATION…512

CEILING WINDOW WIPER SWITCH (3)…513

WORKING RANGE (PC 240 STRAIGHT BOOM)…514

TRANSPORTATION (Straight Boom equipment)…515

HANDLING MACHINES EQUIPPED WITH KOMTRAX…516

BASIC PRECAUTIONS…516

SUPER LONG FRONT BOOM AND ARM PC210/240-8…517

OPERATION INSTRUCTION FOR SUPER LONG FRONT BOOM AND ARM…518

WORKING MODES…519

CHECKS BEFORE STARTING…520

USING SUPER LONG FRONT…521

METHOD OF WORK…522

WHEN TRAVELLING…522

CONTROL LEVERS, PEDALS…523

‘WEEDCUTTER’ MACHINE CONTROL LEVERS, PEDALS…526

RIGHT CONTROL LEVER BUTTONS (5 & 6)…526

LEFT WORK EQUIPMENT CONTROL LEVER (7 & 8)…527

ATTACHMENT FLOW SELECTOR (9)…528

TRANSPORT & STORAGE OF SUPER LONG FRONT MACHINE…529

INSTALLATION OF SUPPORTING LINK…529

TRANSPORTATION OF SUPER LONG FRONT MACHINE…530

WORKING RANGE OF SUPER LONG FRONT…531

LIFTING CAPACITY PC210 LC 15 m SUPER LONG FRONT…532

LIFTING CAPACITY PC210 NLC 15 m SUPER LONG FRONT…533

LIFTING CAPACITY PC240 LC 18 m SUPER LONG FRONT…534

LIFTING CAPACITY PC240 NLC 18 m SUPER LONG FRONT…535

MAINTENANCE…536

SPECIAL SERVICE REQUIREMENTS FOR SUPER LONG FRONT WORK EQUIPMENT…536

EVERY 50 HOURS SERVICE…537

LUBRICATING…537

EVERY 100 HOURS SERVICE…538

LUBRICATING…538

INDEX…541

Numerics…543

<A>…543

<B>…543

<C>…543

<D>…543

<E>…543

<F>…543

<G>…543

<H>…543

<I>…543

<K>…543

<L>…543

<M>…543

<N>…544

<O>…544

<P>…544

<R>…544

<S>…544

<T>…544

<V>…544

<W>…544

<Y>…544

COLOPHON…545

UEAM004912 – Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Operation & Maintenance Manual…547

FOREWORD…549

FOREWORD…550

SAFETY INFORMATION…551

NOISE (PC210,210LC,210NLC, PC230NHD)…553

NOISE (PC240LC,240NLC)…554

Vibration levels…555

Guide to Reduce Vibration Levels on Machine…555

INTRODUCTION…557

DIRECTIONS OF MACHINE…557

OPERATOR PROTECTIVE STRUCTURE…557

VISIBILITY FOR OPERATOR…557

BREAKING-IN THE NEW MACHINE…558

PRODUCT INFORMATION…559

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE…559

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION…559

SERVICE METER LOCATION…560

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR…560

MACHINE SERIAL PLATES…561

SERIAL PLATE (WHERE FITTED)…561

DECLARATION OF CONFORMITY…562

FOREWORD…563

SAFETY…563

OPERATION…565

MAINTENANCE…568

SPECIFICATIONS…570

ATTACHMENTS AND OPTIONS…571

SUPER LONG FRONT BOOM AND ARM PC210/240-8…573

PC240LC/NLC-8 HIGH REACH DEMOLITION…573

INDEX…574

COLOPHON…574

SAFETY…575

SAFETY INFORMATION…576

SAFETY LABELS…578

LOCATION OF SAFETY LABELS…578

SAFETY LABELS…579

SAFETY INFORMATION…590

SAFETY RULES…590

IF PROBLEMS ARE FOUND…590

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS…590

FIRE EXTINGUISHER AND FIRST AID KIT…590

SAFETY EQUIPMENT…591

KEEP MACHINE CLEAN…591

KEEP OPERATOR'S COMPARTMENT CLEAN…591

LEAVING OPERATOR'S SEAT WITH LOCK…591

HANDRAILS AND STEPS…592

MOUNTING AND DISMOUNTING…593

LIFTING OF PERSONNEL PROHIBITED…593

NO PERSONS ON ATTACHMENTS…593

DO NOT GET CAUGHT IN ARTICULATED PORTION…593

BURN PREVENTION…593

ACTION IF FIRE OCCURS…595

WINDSHIELD WASHER FLUID…595

PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES…595

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION…596

ACTIONS IN THE EVENT OF DAMAGE TO SAFETY STRUCTURES…597

ATTACHMENT INSTALLATION…597

ATTACHMENT COMBINATIONS…597

CAB WINDOW GLASSES…597

UNAUTHORIZED MODIFICATIONS…597

SAFETY AT JOBSITE…598

WORKING ON LOOSE GROUND…598

DISTANCE TO HIGH VOLTAGE CABLES…598

ENSURE GOOD VISIBILITY…599

VENTILATION FOR ENCLOSED AREA…600

SIGNALMAN'S SIGNAL AND SIGNS…600

EMERGENCY EXIT FROM OPERATOR'S CAB…600

ELECTROMAGNETIC INTERFERENCE…600

ASBESTOS DUST HAZARD PREVENTION…601

SAFETY MACHINE OPERATION…602

STARTING ENGINE…602

CHECKS BEFORE STARTING ENGINE…602

SAFETY RULES FOR STARTING ENGINE…603

STARTING ENGINE IN COLD WEATHER…603

OPERATION…604

CHECKS BEFORE OPERATION…604

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS…604

SAFETY RULES FOR TRAVELLING…605

TRAVELLING ON SLOPES…606

OPERATIONS ON SLOPES…607

PROHIBITED OPERATIONS…607

OPERATIONS ON SNOW…609

PARKING MACHINE…609

TRANSPORTATION…610

LOADING AND UNLOADING…610

SHIPPING THE MACHINE…611

Turn off the battery disconnect switch to the OFF position…612

BATTERY…612

STARTING ENGINE WITH BOOSTER CABLES…613

TOWING…614

SAFETY RULES FOR TOWING…614

LIFTING OBJECTS WITH BUCKET LINK LIFTING DEVICE (OPTIONAL EQUIPMENT)…615

SAFETY RULES FOR LIFTING OBJECTS…615

LIFTING OBJECTS WITH BUCKET…617

SAFETY RULES FOR LIFTING OBJECTS…617

SAFETY MAINTENANCE INFORMATION…618

WARNING TAG…618

KEEP WORK PLACE CLEAN AND TIDY…618

STABILITY…618

GUARDS…618

END OF SERVICE LIFE…618

APPOINT LEADER WHEN WORKING WITH OTHERS…619

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE…619

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING…620

PROPER TOOLS…620

ACCUMULATOR…621

HANDLING GAS SPRING…621

PERSONNEL…622

ATTACHMENTS…622

WORK UNDER THE MACHINE…622

NOISE…623

WHEN USING HAMMER…623

WELDING WORKS…623

REMOVING BATTERY CABLES (for machines not fitted with battery disconnect switch only)…623

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION…624

DO NOT DISASSEMBLE RECOIL SPRINGS…624

SAFETY RULES FOR HIGH-PRESSURE OIL…624

OPERATION…627

MACHINE VIEW ILLUSTRATIONS…629

OVERALL MACHINE VIEW…629

CONTROLS AND GAUGES…630

DETAILED CONTROLS AND GAUGES…632

MONITORING SYSTEM…632

Basic Operation of Machine Monitor…633

Basic Check Monitors…637

Caution Monitors…639

Emergency Monitors…642

Meter Display Portion…644

Monitor Switches Portion…651

Handling Function Switches…660

Attachment 2 Setting…682

SWITCHES…700

Quick Coupler Switches…704

DIESEL PARTICULATE FILTER (DPF) MONITOR…706

CONTROL LEVERS AND PEDALS…708

CEILING WINDOW…711

WINDSHIELD…711

EMERGENCY ESCAPE HAMMER…717

DOOR LOCK…717

CAP WITH LOCK…718

DRINK BOX…720

MAGAZINE BOX…720

ASHTRAY…720

AIR CONDITIONER CONTROLS…721

Air Conditioner Control Panel…721

Method of Operation…726

Use Air Conditioner with Care…733

Air Conditioner Maintenance…733

Battery Disconnect Switch…734

RADIO…735

Control Panel…735

Controls of Radio…737

Use Radio with Care…739

Space for radio cassette…739

AUXILIARY ELECTRIC POWER…740

24V power source…740

12V power source…740

FUSE…741

FUSIBLE LINK…742

CONTROLLER…742

TOOL BOX…742

GREASE GUN HOLDER…743

MACHINE OPERATIONS AND CONTROLS…744

BEFORE STARTING ENGINE…744

Walk-around Checks…744

REFUELLING PUMP…746

Checks Before Starting…748

Adjustment…755

Seat Belt…761

Operations Before Starting Engine…762

STARTING ENGINE…765

AFTER STARTING ENGINE…768

Warming Up Engine…769

Warming Up Hydraulic Equipment…771

Operation After Completion Of Warming-Up Operation…777

STOPPING THE ENGINE…779

MACHINE OPERATION…780

Preparations for Moving the Machine…780

Moving Machine Forward…781

Moving Machine Backward…782

Stopping Machine…783

STEERING THE MACHINE…784

Steering…784

SWINGING…786

WORK EQUIPMENT CONTROLS AND OPERATIONS…787

WORKING MODE…789

PROHIBITED OPERATIONS…791

GENERAL OPERATION INFORMATION…793

TRAVELLING ON SLOPES…795

ESCAPE FROM MUD…797

Track on One Side Stuck…797

Tracks on Both Sides Stuck…797

RECOMMENDED APPLICATIONS…798

Backhoe Work…798

Shovel Work…798

Ditching Work…798

Loading Work…799

BUCKET REPLACEMENT AND INVERSION…800

Replacement…800

Inversion…802

PARKING MACHINE…803

CHECK AFTER SHUT OFF ENGINE…805

MACHINE INSPECTION AFTER DAILY WORK…805

LOCKING…805

TRANSPORTATION…806

TRANSPORTATION PROCEDURE…806

SPECIAL TRANSPORTATION INSTRUCTIONS FOR PC210NLC-8 AND PC230NHD-8…806

LOADING AND UNLOADING WITH TRAILER…808

Loading…809

Securing Machine…812

Unloading…817

LIFTING MACHINE…819

COLD WEATHER OPERATION…821

COLD WEATHER OPERATION INFORMATION…821

Fuel and Lubricants…821

Cooling System Coolant…821

Battery…822

AFTER DAILY WORK COMPLETION…823

AFTER COLD WEATHER SEASON…823

LONG TERM STORAGE…824

BEFORE STORAGE…824

DURING STORAGE…825

AFTER STORAGE…826

STARTING MACHINE AFTER LONG-TERM STORAGE…826

TROUBLES AND ACTIONS…827

RUNNING OUT OF FUEL…827

PHENOMENA THAT ARE NOT FAILURES…827

TOWING THE MACHINE…828

LIGHTWEIGHT TOWING HOLE…829

SEVERE JOB CONDITION…829

DISCHARGED BATTERY…830

Battery Removal and Installation…830

Battery Charges…831

Starting Engine with Booster Cables…832

OTHER TROUBLE…835

Electrical System…835

Chassis…836

Engine…837

Electronic Control System…839

Point of Contact to Telephone when Error Occurs…839

MAINTENANCE…841

MAINTENANCE INFORMATION…842

OUTLINE OF SERVICE…845

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC…845

OIL…845

FUEL…846

COOLANT AND WATER FOR DILUTION…846

GREASE…847

CARRYING OUT KOWA (Komatsu Oil Wear Analysis)…848

STORING OIL AND FUEL…849

FILTERS…849

EXPLANATION OF LUBRICATION CHART DECAL…850

ELECTRIC SYSTEM MAINTENANCE…852

WEAR PARTS…853

WEAR PARTS LIST…853

RECOMMENDED FUEL, COOLANT AND LUBRICANT…854

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL…856

TIGHTENING TORQUE SPECIFICATIONS…857

TIGHTENING TORQUE LIST…857

SAFETY CRITICAL PARTS…858

SAFETY CRITICAL PARTS LIST…858

MAINTENANCE SCHEDULE…859

MAINTENANCE SCHEDULE CHART…859

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER…861

MAINTENANCE PROCEDURE…862

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)…862

INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)…862

WHEN REQUIRED…863

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT…863

CLEAN INSIDE OF COOLING SYSTEM…868

COOLANT DENSITY TABLE…869

CHECK AND TIGHTEN TRACK SHOE BOLTS…871

CHECK AND ADJUST TRACK TENSION…872

REPLACE BUCKET TEETH (VERTICAL PIN TYPE)…874

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)…877

ADJUST BUCKET CLEARANCE…878

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID…879

CHECK AND MAINTENANCE AIR CONDITIONER…880

WASH WASHABLE FLOOR…881

BLEEDING AIR FROM HYDRAULIC SYSTEM…884

CHECK AND TIGHTEN DIESEL PARTICULATE FILTER CLAMPS…886

CHECK BEFORE STARTING…887

EVERY 100 HOURS MAINTENANCE…888

LUBRICATING (MANUAL GREASE SYSTEMS)…888

EVERY 250 HOURS MAINTENANCE…890

CHECK LEVEL OF BATTERY ELECTROLYTE…890

CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST…892

EVERY 500 HOURS MAINTENANCE…893

LUBRICATING (MANUAL GREASE SYSTEMS)…893

LUBRICATE SWING CIRCLE (MANUAL GREASE SYSTEMS)…894

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE…895

REPLACE FUEL PRE-FILTER CARTRIDGE…897

CHECK SWING PINION GREASE LEVEL, ADD GREASE…899

CLEAN AND INSPECT RADIATOR FINS, OIL COOLER FINS, AFTERCOOLER FINS, FUEL COOLER FINS, AND CONDENSER FINS (ONLY MACHINES EQUIPPED WITH AIR CONDITIONER)…900

CLEAN AIR CONDITIONER FRESH/RECIRC FILTERS…902

REPLACE BREATHER ELEMENT IN HYDRAULIC TANK…903

CHECK OIL LEVEL IN SWING MACHINERY CASE, ADD OIL…904

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL…905

EVERY 1000 HOURS MAINTENANCE…906

REPLACE HYDRAULIC OIL FILTER ELEMENT…906

REPLACE PILOT FILTER ELEMENT…907

Replace Additional Breaker Filter Element…909

CHANGE OIL IN SWING MACHINERY CASE…911

CHECK OIL LEVEL IN DAMPER CASE, ADD OIL…912

REPLACE FUEL MAIN FILTER CARTRIDGE…913

CHECK ALL TIGHTENING POINTS OF ENGINE EXHAUST PIPE CLAMPS…914

CHECK FAN BELT TENSION AND REPLACE FAN BELT…914

CHECK NITROGEN GAS CHARGE PRESSURE IN ACCUMULATOR (for breaker)…914

CLEAN DIESEL PARTICULATE FILTER…915

EVERY 2000 HOURS MAINTENANCE…918

CHANGE OIL IN FINAL DRIVE CASE…918

CLEAN HYDRAULIC TANK STRAINER…919

CHECKING CHARGE PRESSURE OF NITROGEN GAS IN ACCUMULATOR (FOR CONTROL CIRCUIT)…920

CHECK ALTERNATOR, STARTING MOTOR…923

CHECK ENGINE VALVE CLEARANCE, ADJUST…923

EVERY 4000 HOURS MAINTENANCE…924

CHECK WATER PUMP…924

CHECK VIBRATION DAMPER…924

REPLACE ACCUMULATOR (FOR CONTROL CIRCUIT)…925

CHECK FOR LOOSENESS OF HIGH-PRESSURE PIPING CLAMP, HARDENING OF RUBBER…926

CHECK FOR MISSING FUEL SPRAY PREVENTION CAP, HARDENING OF RUBBER…926

CHECK OPERATING CONDITION OF COMPRESSOR…927

EVERY 5000 HOURS MAINTENANCE…928

CHANGE OIL IN HYDRAULIC TANK…928

EVERY 8000 HOURS MAINTENANCE…929

REPLACE FUEL SPRAY PREVENTION CAP…929

REPLACE HIGH-PRESSURE PIPING CLAMP…929

AUTOMATIC GREASE SYSTEM…930

Filling the grease reservoir…931

Method of filling grease reservoir…932

Recommended Komatsu pumps for filling grease reservoir…932

Indication on the in-cab display…933

Tests…934

Maintenance…934

END OF SERVICE LIFE…935

SPECIFICATIONS…937

SPECIFICATIONS…938

MONOBOOM WORKING RANGE…940

PC210-8 WORKING RANGE (2-PIECE BOOM)…942

PC230-8 WORKING RANGE (2-PIECE BOOM)…942

PC240-8 WORKING RANGE (2-PIECE BOOM)…942

EXPLANATION OF LIFTING CAPACITY CHART PC210, PC210LC, PC210NLC, PC230NHD-8 1-PIECE BOOM…944

PC210-8…945

PC210LC-8…946

PC210NLC-8…947

PC230NHD-8…948

EXPLANATION OF LIFTING CAPACITY CHART PC240LC, PC240NLC-8 1-PIECE BOOM…949

PC240LC-8…950

PC240NLC-8…951

EXPLANATION OF LIFTING CAPACITY CHART PC210, PC210LC, PC210NLC, PC230NHD-8 2 PIECE BOOM…952

PC210-8…953

PC210LC-8…954

PC210NLC-8…955

PC230NHD-8…956

EXPLANATION OF LIFTING CAPACITY CHART (PC240LC,NLC-8 2 PIECE BOOM)…957

PC240LC-8, PC240NLC-8 2 PIECE BOOM…958

ATTACHMENTS AND OPTIONS…961

GENERAL PRECAUTIONS FOR SAFETY…962

PRECAUTIONS WHEN SELECTING…962

READ THE INSTRUCTION MANUAL THOROUGHLY…962

PRECAUTIONS WHEN REMOVING OR INSTALLING…962

PRECAUTIONS WHEN USING…963

SPECIFICATIONS…964

ARM/PIN INFORMATION – PC210/230/240-8…964

HYDRAULIC QUICK COUPLER PIPING…965

LOCATIONS…965

OPERATION…966

BUCKET WITH HOOK…968

HOOK CONDITION…968

PROHIBITED OPERATIONS…968

MACHINE READY FOR ATTACHMENT…969

LOCATIONS…969

HYDRAULIC CIRCUIT…975

Switching Hydraulic Circuit…975

Adjusting Oil Flow…975

Switching Between Breaker and General Attachment…975

Hydraulic Circuit Connection…976

Oil Flow Path…977

ATTACHMENT REMOVAL AND INSTALLATION…978

Attachment Removal…978

Attachment Installation…980

ATTACHMENT OPERATIONS…982

Operation When Using Breaker…982

Operation When Using General Attachment 1 (e.g. Crusher)…985

Operation When Using Attachment 2 (e.g clamshell rotation, crusher rotation)…987

LONG TERM STORAGE…987

ATTACHMENT GUIDE…988

COMBINATIONS OF WORK EQUIPMENT…988

SELECTION OF TRACK SHOES…991

METHOD OF SELECTING SHOES…991

SELECTION OF BUCKET TEETH…992

METHOD OF SELECTING TEETH…992

STANDARDS FOR SELECTING VERTICAL PIN TYPE AND HORIZONTAL PIN TYPE TEETH…992

HANDLING OF RUBBER PAD SHOE AND ROAD LINER…993

Working Environment…993

Working Conditions…993

Storage and Maintenance…994

Extent of Damage to Rubber…994

Check Road Liner…994

Replace Road Liner…994

TRAPEZOIDAL BUCKET…995

HANDLING EXTENSION ARM…996

HANDLING CLAMSHELL BUCKET…997

RECOMMENDED ATTACHMENT OPERATIONS…998

HYDRAULIC BREAKER…998

PC210/230-8 2-PC BOOM…1003

FEATURES OF 2-PIECE BOOM & ARM…1003

OPERATION…1003

BEFORE STORAGE POSTURE WHEN LEAVING MACHINE…1005

Lifting…1005

TESTING AND ADJUSTING…1006

PERODIC MAINTENANCE…1006

TRANSPORTATION…1007

LUBRICATING (MANUAL GREASE SYSTEM)…1008

Every 500 Hours…1008

PC240-8 2-PC BOOM…1009

FEATURES OF 2-PIECE BOOM & ARM…1009

OPERATION…1010

TESTING AND ADJUSTING…1012

TRANSPORTATION…1013

PC240-8 STRAIGHT BOOM…1014

GENERAL VIEW OF MACHINE…1014

CAUTION ITEMS…1014

WORKING RANGE (PC 240 STRAIGHT BOOM)…1015

TRANSPORTATION (Straight Boom equipment)…1016

HANDLING MACHINES EQUIPPED WITH KOMTRAX…1017

BASIC PRECAUTIONS…1017

SUPER LONG FRONT BOOM AND ARM PC210/240-8…1019

OPERATION INSTRUCTION FOR SUPER LONG FRONT BOOM AND ARM…1020

WORKING MODES…1021

CHECKS BEFORE STARTING…1022

USING SUPER LONG FRONT…1023

METHOD OF WORK PC210LC-8 (15m), PC210NLC-8 (15m)…1024

WHEN TRAVELLING…1024

METHOD OF WORK PC240LC-8 (18m), PC240NLC-8 (18m)…1025

WHEN TRAVELLING…1025

CONTROL LEVERS, PEDALS…1026

TRANSPORT & STORAGE OF SUPER LONG FRONT MACHINE…1029

INSTALLATION OF SUPPORTING LINK…1029

TRANSPORTATION OF SUPER LONG FRONT MACHINE…1030

WORKING RANGE OF SUPER LONG FRONT…1031

LIFTING CAPACITY PC210 LC 15 m SUPER LONG FRONT…1032

LIFTING CAPACITY PC210 NLC 15 m SUPER LONG FRONT…1033

LIFTING CAPACITY PC240 LC 18 m SUPER LONG FRONT…1034

LIFTING CAPACITY PC240 NLC 18 m SUPER LONG FRONT…1035

MAINTENANCE…1036

SPECIAL SERVICE REQUIREMENTS FOR SUPER LONG FRONT WORK EQUIPMENT…1036

EVERY 50 HOURS SERVICE…1037

LUBRICATING (MANUAL GREASE SYSTEM)…1037

EVERY 100 HOURS SERVICE…1038

LUBRICATING (MANUAL GREASE SYSTEM)…1038

PC240LC/NLC-8 HIGH REACH DEMOLITION…1041

GENERAL VIEW OF MACHINE…1042

CAUTION ITEMS…1043

TRAVEL POSTURE…1043

OPERATION INSTRUCTIONS…1044

WORK EQUIPMENT CONTROL LEVERS…1044

ATTACHMENT ROTATION (with auto-deceleration)…1045

CRUSHER CONTROL FOR OPENING AND CLOSING…1046

MACHINE OPERATIONS AND CONTROLS…1047

BEFORE STARTING ENGINE…1047

PROHIBITION OF WORK AT THE STROKE END OF A CYLINDER…1051

Confirmation and inspection before and after work…1051

PROHIBITION OF WORK WITH HYDRAULIC BREAKER…1051

PROHIBITION OF WORK WITH DIGGING ATTACHMENT…1051

WORKING RANGE AND USING RANGE OF BOOM…1052

POSTURE WHEN LEAVING MACHINE…1053

SPECIFICATIONS…1054

GROUND PRESSURE TABLE…1054

WORKING RANGE…1054

TRANSPORT DIMENSIONS…1055

INDEX…1057

Numerics…1059

<A>…1059

<B>…1059

<C>…1059

<D>…1059

<E>…1059

<F>…1059

<G>…1059

<H>…1059

<I>…1059

<K>…1059

<L>…1059

<M>…1059

<N>…1060

<O>…1060

<P>…1060

<R>…1060

<S>…1060

<T>…1060

<V>…1060

<W>…1061

<Y>…1061

COLOPHON…1063

UEN00084 – Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Shop Manual…1065

00 Index and foreword…1067

Index…1067

Organization list of the shop manual…1068

Table of contents…1070

00 Index and foreword…1079

Foreword and general information…1079

Foreword and general information…1080

Safety notice…1080

How to read the shop manual…1084

Explanation of terms for maintenance standard…1086

Handling electric equipment and hydraulic component…1088

How to read electric wire code…1096

Method of disassembling and connecting push-pull type coupler…1099

Standard tightening torque table…1102

Conversion table…1106

01 Specification…1113

Specification and technical data…1113

Specification and technical data…1114

Specification dimension drawings…1114

Working range diagram…1115

Specifications…1116

Weight table…1120

Table of fuel, coolant and lubricants…1124

10 Structure, function and maintenance standard…1127

Engine and cooling system…1127

Engine and cooling system…1128

Engine related parts…1128

Radiator, oil cooler, aftercooler and fuel cooler…1129

10 Structure, function and maintenance standard…1131

Power train…1131

Power train…1132

Power train…1132

Final drive…1134

Swing machinery…1136

Swing circle…1140

10 Structure, function and maintenance standard…1143

Undercarriage and frame…1143

Undercarriage and frame…1144

Track frame and recoil spring…1144

Idler…1146

Carrier roller…1148

Track roller…1149

Track shoe…1150

10 Structure, function and maintenance standard…1157

Hydraulic system, Part 1…1157

Hydraulic system, Part 1…1158

Hydraulic equipment layout drawing…1158

Hydraulic tank and filter…1160

Hydraulic pump…1161

Hydraulic pump…1162

Pilot oil filter…1185

10 Structure, function and maintenance standard…1187

Hydraulic system, Part 2…1187

Hydraulic system, Part 2…1188

Control valve…1188

CLSS…1201

Functions and operation by valve…1206

Hydraulic drift prevention valve…1232

10 Structure, function and maintenance standard…1245

Hydraulic system, Part 3…1245

Hydraulic system, Part 3…1247

Swing motor…1247

Center swivel joint…1256

Travel motor…1259

PPC valve…1270

Valve control…1292

Solenoid valve…1294

PPC Accumulator…1296

Return oil filter…1297

Attachment circuit selector valve…1298

Hydraulic cylinder…1300

10 Structure, function and maintenance standard…1305

Work equipment…1305

Work equipment…1306

Dimensions of components…1306

10 Structure, function and maintenance standard…1313

Cab and its attachments…1313

Cab and its attachments…1314

Air conditioner piping…1314

10 Structure, function and maintenance standard…1317

Electrical system…1317

Electrical system…1318

Engine control…1318

Electrical control system…1326

Monitor system…1346

Sensor…1373

KOMTRAX terminal system…1376

20 Standard value table…1379

Standard service value table…1379

Standard service value table…1380

Standard value table for engine related parts…1380

Standard value table for chassis related parts…1382

30 Testing and adjusting…1401

Testing and adjusting, Part 1…1401

Testing and adjusting, Part 1…1403

Tools for testing, adjusting, and troubleshooting…1403

Measuring engine speed…1406

Measuring intake air pressure (boost pressure)…1407

Checking exhaust gas color…1408

Adjusting valve clearance…1409

Measuring compression pressure…1411

Measuring blow-by pressure…1413

Measuring engine oil pressure…1414

Handling fuel system parts…1415

Releasing residual pressure from fuel system…1415

Measuring fuel pressure…1416

Measuring fuel return rate and leakage…1418

Bleeding air from fuel circuit…1420

Checking fuel circuit for leakage…1422

Checking and adjusting air conditioner compressor belt tension…1423

Measuring swing circle bearing clearance…1424

Checking and adjusting track shoe tension…1425

Measuring and adjusting oil pressure in work equipment, swing, and travel circuits…1427

Measuring control circuit basic pressure…1431

Measuring and adjusting oil pressure in pump PC control circuit…1432

Measuring and adjusting oil pressure in pump LS control circuit…1436

Measuring solenoid valve output pressure…1442

Measuring PPC valve output pressure…1445

Adjusting play of work equipment and swing PPC valves…1447

Checking parts which cause hydraulic drift of work equipment…1448

Releasing residual pressure from hydraulic circuit…1450

Measuring oil leakage…1451

Bleeding air from each part…1454

Checking cab tipping stopper…1457

Adjusting mirrors…1458

30 Testing and adjusting…1461

Testing and adjusting, Part 2…1461

Testing and adjusting, Part 2…1462

Special functions of machine monitor…1462

30 Testing and adjusting…1519

Testing and adjusting, Part 3…1519

Testing and adjusting, Part 3…1520

Handling high-voltage circuit of engine controller…1520

Preparation work for troubleshooting of electrical system…1521

Procedure for testing diodes…1525

Pm Clinic service…1527

Warning…1529

Pm Clinic service…1533

40 Troubleshooting…1541

General information on troubleshooting…1541

General information on troubleshooting…1542

Points to remember when troubleshooting…1542

Sequence of events in troubleshooting…1543

Check before troubleshooting…1544

Classification and procedures for troubleshooting…1545

How to read electric wire code…1549

Connection table for connector pin numbers…1552

T-boxes and T-adapters table…1575

40 Troubleshooting…1579

Troubleshooting by failure code (Display of code), Part 1…1579

Troubleshooting by failure code (Display of code), Part 1…1581

Failure codes table…1581

Before carrying out troubleshooting when failure code is displayed…1586

Information in troubleshooting table…1590

Failure code [989L00] Engine Controller Lock Caution 1…1592

Failure code [989M00] Engine Controller Lock Caution 2…1592

Failure code [989N00] Engine Controller Lock Caution 3…1593

Failure code [AA10NX] Air Cleaner Clogging…1593

Failure code [AB00KE] Charge Voltage Low…1594

Failure code [B@BAZG] Eng Oil Press. Low…1596

Failure code [B@BAZK] Eng Oil Level Low…1596

Failure code [B@BCNS] Eng Water Overheat…1597

Failure code [B@BCZK] Eng Water Level Low…1597

Failure code [B@HANS] Hydr Oil Overheat…1598

Failure code [CA111] EMC Critical Internal Failure…1598

Failure code [CA115] Eng Ne and Bkup Speed Sens Error…1599

Failure code [CA122] Chg Air Press Sensor High Error…1600

Failure code [CA123] Chg Air Press Sensor Low Error…1602

Failure code [CA131] Throttle Sensor High Error…1604

Failure code [CA132] Throttle Sensor Low Error…1606

Failure code [CA144] Coolant Temp Sens High Error…1608

Failure code [CA145] Coolant Temp Sens Low Error…1610

Failure code [CA153] Chg Air Temp Sensor High Error…1612

Failure code [CA154] Chg Air Temp Sensor Low Error…1614

Failure code [CA155] Chg Air Temp High Speed Derate…1616

Failure code [CA187] Sens Supply 2 Volt Low Error…1618

Failure code [CA221] Ambient Press Sens High Error…1620

Failure code [CA222] Ambient Press Sens Low Error…1622

Failure code [CA227] Sens Supply 2 Volt High Error…1624

Failure code [CA234] Eng Overspeed…1625

Failure code [CA238] Ne Speed Sens Supply Volt Error…1626

Failure code [CA271] IMV/PCV1 Short Error…1627

Failure code [CA272] IMV/PCV1 Open Error…1628

Failure code [CA322] Inj #1 (L#1) Open/Short Error…1630

Failure code [CA323] Inj #5 (L#5) Open/Short Error…1632

Failure code [CA324] Inj #3 (L#3) Open/Short Error…1634

Failure code [CA325] Inj #6 (L#6) Open/Short Error…1636

Failure code [CA331] Inj #2 (L#2) Open/Short Error…1638

Failure code [CA332] Inj #4 (L#4) Open/Short Error…1640

40 Troubleshooting…1643

Troubleshooting by failure code (Display of code), Part 2…1643

Troubleshooting by failure code (Display of code), Part 2…1645

Failure code [CA342] Calibration Code Incompatibility…1645

Failure code [CA351] Injectors Drive Circuit Error…1646

Failure code [CA352] Sens Supply 1 Volt Low Error…1648

Failure code [CA386] Sens Supply 1 Volt High Error…1650

Failure code [CA428] Water in Fuel Sensor High Error…1652

Failure code [CA429] Water in Fuel Sensor Low Error…1654

Failure code [CA435] Eng Oil Press Sw Error…1656

Failure code [CA441] Battery Voltage Low Error…1657

Failure code [CA442] Battery Voltage High Error…1660

Failure code [CA449] Rail Press Very High Error…1662

Failure code [CA451] Rail Press Sensor High Error…1664

Failure code [CA452] Rail Press Sensor Low Error…1666

Failure code [CA488] Chg Air Temp High Torque Derate…1668

Failure code [CA553] Rail Press High Error…1668

Failure code [CA559] Rail Press Low Error…1669

Failure code [CA689] Eng Ne Speed Sensor Error…1670

Failure code [CA731] Eng Bkup Speed Sens Phase Error…1672

Failure code [CA757] All Continuous Data Lost Error…1674

Failure code [CA778] Eng Bkup Speed Sensor Error…1676

Failure code [CA1633] KOMNET Datalink Timeout Error…1678

Failure code [CA2185] Throt Sens Sup Volt High Error…1680

Failure code [CA2186] Throt Sens Sup Volt Low Error…1681

Failure code [CA2249] Rail Press Very Low Error…1682

Failure code [CA2311] IMV Solenoid Error…1684

Failure code [CA2555] Grid Htr Relay Volt High Error…1686

Failure code [CA2556] Grid Htr Relay Volt Low Error…1688

Failure code [D19JKZ] Personal Code Relay Abnormality…1690

Failure code [D862KA] GPS Antenna Discon…1692

Failure code [DA25KP] 5V Sensor 1 Power Abnormality…1693

Failure code [DA29KQ] Model Selection Abnormality…1700

40 Troubleshooting…1705

Troubleshooting by failure code (Display of code), Part 3…1705

Troubleshooting by failure code (Display of code), Part 3…1708

Failure code [DA2RMC] CAN Discon (Pump Con Detected)…1708

Failure code [DAFGMC] GPS Module Error…1710

Failure code [DAFRMC] CAN Discon (Monitor Detected)…1712

Failure code [DGH2KB] Hydr Oil Sensor Short…1714

Failure code [DHPAMA] F Pump Press Sensor Abnormality…1716

Failure code [DHPBMA] R Pump Press Sensor Abnormality…1718

Failure code [DHS3MA] Arm Curl PPC Press Sensor Abnormality…1720

Failure code [DHS4MA] Bucket Curl PPC Press Sensor Abnormality…1722

Failure code [DHS8MA] Boom Raise PPC Press Sensor Abnormality…1724

Failure code [DHSAMA] Swing RH PPC Press Sensor Abnormality…1726

Failure code [DHSBMA] Swing LH PPC Press Sensor Abnormality…1728

Failure code [DHSDMA] Bucket Dump PPC Press Sensor Abnormality…1730

Failure code [DHX1MA] Overload Sensor Abnormality (Analog)…1732

Failure code [DW43KA] Travel Speed Sol Discon…1734

Failure code [DW43KB] Travel Speed Sol Short…1736

Failure code [DW45KA] Swing Brake Sol Discon…1738

Failure code [DW45KB] Swing Brake Sol Short…1740

Failure code [DW91KA] Travel Junction Sol Discon…1742

Failure code [DW91KB] Travel Junction Sol Short…1744

Failure code [DWA2KA] Service Sol Discon…1746

Failure code [DWA2KB] Service Sol Short…1747

Failure code [DWK0KA] 2-stage Relief Sol Discon…1748

Failure code [DWK0KB] 2-stage Relief Sol Short…1750

40 Troubleshooting…1753

Troubleshooting by failure code (Display of code), Part 4…1753

Troubleshooting by failure code (Display of code), Part 4…1756

Failure code [DXA8KA] PC-EPC (F) Sol Discon…1756

Failure code [DXA8KB] PC-EPC (F) Sol Short…1758

Failure code [DXA9KA] PC-EPC (R) Sol Discon…1760

Failure code [DXA9KB] PC-EPC (R) Sol Short…1762

Failure code [DXE0KA] LS-EPC Sol Discon…1764

Failure code [DXE0KB] LS-EPC Sol Short…1766

Failure code [DXE4KA] Service Current EPC Discon…1768

Failure code [DXE4KB] Service Current EPC Short…1770

Failure code [DXE5KA] Merge-divider Main Sol Discon…1772

Failure code [DXE5KB] Merge-divider Main Sol Short…1774

Failure code [DXE6KA] Merge-divider LS Sol Discon…1776

Failure code [DXE6KB] Merge-divider LS Sol Short…1778

Failure code [DY20KA] Wiper Working Abnormality…1780

Failure code [DY20MA] Wiper Parking Abnormality…1782

Failure code [DY2CKA] Washer Drive Discon…1784

Failure code [DY2CKB] Washer Drive Short…1786

Failure code [DY2DKB] Wiper Drive (For) Short…1788

Failure code [DY2EKB] Wiper Drive (Rev) Short…1790

40 Troubleshooting…1793

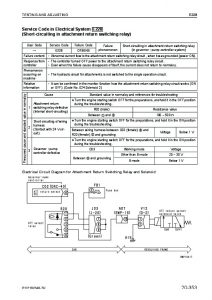

Troubleshooting of electrical system (E-mode)…1793

Troubleshooting of electrical system (E-mode)…1795

Before carrying out troubleshooting of electrical system…1795

Information in troubleshooting table…1797

E-1 When starting switch turned ON, machine monitor displays nothing…1798

E-2 When starting switch turned ON (before starting engine), basic check item lights up…1800

E-3 Engine does not start (Engine does not turn)…1803

E-4 Preheater does not operate…1806

E-5 Automatic warm-up system does not operate (in cold season)…1808

E-6 All work equipment, swing, and travel mechanism do not move or cannot be locked…1810

E-7 Precaution lights up while engine is running…1812

E-8 Emergency stop item lights up while engine is running…1817

E-9 Engine coolant temperature gauge does not indicate normally…1818

E-10 Hydraulic oil temperature gauge does not indicate normally…1819

E-11 Fuel level gauge does not indicate normally…1821

E-12 Contents of display by machine monitor are different from applicable machine…1823

E-13 Machine monitor does not display some items…1823

E-14 Function switch does not work…1823

E-15 Auto-decelerator does not operate normally…1824

E-16 Working mode does not change…1825

E-17 Travel speed does not change…1826

E-18 Alarm buzzer cannot be stopped…1827

E-19 Windshield wiper and window washer do not operate…1828

E-20 Power maximizing function does not operate normally…1830

E-21 Swing holding brake does not operate normally…1832

E-22 Travel alarm does not sound or does not stop sounding…1834

E-23 Air conditioner does not operate normally (including air conditioner abnormality record)…1836

E-24 When starting switch is turned OFF, service meter is not displayed…1848

E-25 Machine monitor cannot be set in service mode…1848

E-26 Monitoring function does not display lever control signal normally…1849

E-27 KOMTRAX system does not operate normally…1858

40 Troubleshooting…1861

Troubleshooting of hydraulic and mechanical system (H-mode)…1861

Troubleshooting of hydraulic and mechanical system (H-mode)…1864

System diagram of hydraulic and mechanical system…1864

Information in troubleshooting table…1866

H-1 Speed or power of whole work equipment, swing, and travel is low…1867

H-2 Engine speed lowers extremely or engine stalls…1869

H-3 Work equipment, swing, and travel systems do not work…1870

H-4 Abnormal sound comes out from around hydraulic pump…1870

H-5 Auto-decelerator does not operate…1871

H-6 Fine control performance or response is low…1871

H-7 Speed or power of boom is low…1872

H-8 Speed or power of arm is low…1873

H-9 Speed or power of bucket is low…1874

H-10 Work equipment does not move singly…1874

H-11 Hydraulic drift of work equipment is large…1875

H-12 Time lag of work equipment is large…1877

H-13 When part of work equipment is relieved singly, other parts of work equipment move…1877

H-14 Power maximizing function does not work…1878

H-15 In compound operation of work equipment, speed of part loaded more is low…1878

H-16 When machine swings and raises boom simultaneously, boom rising speed is low…1879

H-17 When machine swings and travels simultaneously, travel speed lowers largely…1879

H-18 Machine deviates during travel…1880

H-19 Travel speed is low…1881

H-20 Machine is not steered well or steering power is low…1882

H-21 Travel speed does not change or travel speed is low/high…1883

H-22 Travel system does not move (only one side)…1884

H-23 Upper structure does not swing…1885

H-24 Swing acceleration or swing speed is low…1887

H-25 Upper structure overruns remarkably when it stops swinging…1888

H-26 Large shock is made when upper structure stops swinging…1889

H-27 Large sound is made when upper structure stops swinging…1889

H-28 Hydraulic drift of swing is large…1890

H-29 Attachment circuit is not changed…1891

H-30 Oil flow in attachment circuit cannot be controlled…1891

40 Troubleshooting…1893

Troubleshooting of engine (S-mode)…1893

Troubleshooting of engine (S-mode)…1895

Method of using troubleshooting chart…1895

S-1 Starting performance is poor…1898

S-2 Engine does not start…1899

S-3 Engine does not pick up smoothly…1902

S-4 Engine stops during operations…1903

S-5 Engine does not rotate smoothly…1904

S-6 Engine lack output (or lacks power)…1905

S-7 Exhaust smoke is black (incomplete combustion)…1906

S-8 Oil consumption is excessive (or exhaust smoke is blue)…1907

S-9 Oil becomes contaminated quickly…1908

S-10 Fuel consumption is excessive…1909

S-11 Oil is in coolant (or coolant spurts back or coolant level goes down)…1910

S-12 Oil pressure drops…1911

S-13 Oil level rises (Entry of coolant/fuel)…1912

S-14 Coolant temperature becomes too high (overheating)…1913

S-15 Abnormal noise is made…1914

S-16 Vibration is excessive…1915

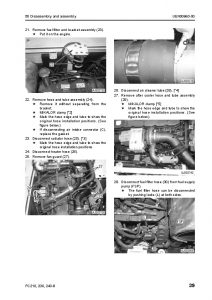

50 Disassembly and assembly…1917

Disassembly and assembly related information…1917

Disassembly and assembly related information…1918

How to read this manual…1918

List of adhesives…1920

Special tool list…1923

Sketches of special tools…1928

50 Disassembly and assembly…1933

Engine cooling related…1933

Engine cooling related…1934

Removal and installation of fuel supply pump assembly…1934

Removal and installation of fuel injector assembly…1936

Removal and installation of engine front seal…1943

Removal and installation of engine rear seal…1946

Removal and installation of cylinder head assembly…1949

Removal and installation of radiator assembly…1961

Removal and installation of assembly hydraulic oil cooler assembly…1964

Removal and installation of aftercooler assembly…1966

Removal and installation of fuel cooler assembly…1968

Removal and installation of engine and hydraulic pump assemblies…1969

50 Disassembly and assembly…1981

Power train…1981

Power train…1982

Removal and installation of final drive assembly…1982

Disassembly and assembly of final drive assembly…1984

Removal and installation of swing motor and swing machinery assembly…2000

Disassembly and assembly of swing motor and swing machinery assembly…2002

Removal and installation of swing circle assembly…2012

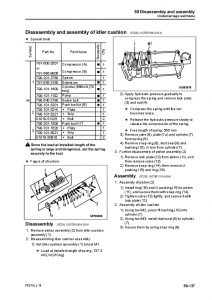

50 Disassembly and assembly…2015

Under carriage and frame…2015

Under carriage and frame…2016

Disassembly and assembly of carrier roller…2016

Disassembly and assembly of track roller assembly…2019

Disassembly and assembly of idler assembly…2021

Disassembly and assembly of recoil spring…2024

Removal and installation of sprocket…2026

Expansion and installation of track shoe assembly…2027

Removal and installation of revolving frame assembly…2029

Removal and installation of counterweight assembly…2031

50 Disassembly and assembly…2033

Hydraulic system…2033

Hydraulic system…2034

Removal and installation of center swivel joint assembly…2034

Disassembly and assembly of center swivel joint assembly…2036

Removal and installation of hydraulic tank assembly…2037

Removal and installation of control valve assembly…2040

Disassembly and assembly of control valve assembly…2045

Removal and installation of hydraulic pump assembly…2049

Removal and installation of oil seal in hydraulic pump input shaft…2054

Disassembly and assembly of work equipment PPC valve assembly…2055

Disassembly and assembly of travel PPC valve assembly…2056

Disassembly and assembly of hydraulic cylinder assembly…2057

50 Disassembly and assembly…2065

Work equipment…2065

Work equipment…2066

Removal and installation of the work equipment assembly…2066

50 Disassembly and assembly…2071

Cab related…2071

Cab related…2072

Removal and installation of operator's cab assembly…2072

Removal and installation of operator cab glass (stuck glass)…2075

Removal and installation of front window assembly…2085

Removal and installation of floor frame assembly…2092

50 Disassembly and assembly…2097

Electric components…2097

Electric components…2098

Removal and installation of air conditioner unit assembly…2098

Removal and installation of KOMTRAX communication modem assembly…2101

Removal and installation of monitor assembly…2102

Removal and installation of pump controller assembly…2104

Removal and installation of engine controller assembly…2105

90 Diagrams and drawings…2107

Hydraulic diagrams and drawings…2107

Hydraulic diagrams and drawings…2109

Hydraulic circuit diagram…2109

90 Diagrams and drawings…2113

Electrical diagrams and drawings…2113

Electrical diagrams and drawings…2115

Electrical circuit diagram (1/5)…2115

Electrical circuit diagram (2/5)…2117

Electrical circuit diagram (3/5)…2119

Electrical circuit diagram (4/5)…2121

Electrical circuit diagram (5/5)…2123

UEN00084-07 – Hydraulic Excavator PC210-8, PC210LC-8, PC210NLC-8, PC230NHD-8, PC240LC-8, PC240NLC-8 Shop Manual…2127

00 Index and foreword…2129

Index…2129

Organization list of the shop manual…2130

Table of contents…2132

00 Index and foreword…2143

Foreword and general information…2143

Foreword and general information…2144

Safety notice…2144

How to read the shop manual…2148

Explanation of terms for maintenance standard…2150

Handling electric equipment and hydraulic component…2152

How to read electric wire code…2160

Method of disassembling and connecting push-pull type coupler…2163

Standard tightening torque table…2166

Conversion table…2170

01 Specification…2177

Specification and technical data…2177

Specification and technical data…2178

Specification dimension drawings…2178

Working range diagram…2179

Specifications…2180

Weight table…2184

Table of fuel, coolant and lubricants…2188

10 Structure, function and maintenance standard…2191

Engine and cooling system…2191

Engine and cooling system…2192

Engine related parts…2192

Radiator, oil cooler, aftercooler and fuel cooler…2193

Diesel Particulate Filter…2194

Diesel Particulate Filter – Component Parts…2195

System Description…2196

Regeneration…2196

10 Structure, function and maintenance standard…2199

Power train…2199

Power train…2200

Power train…2200

Final drive…2202

Swing machinery…2204

Swing circle…2208

10 Structure, function and maintenance standard…2211

Undercarriage and frame…2211

Undercarriage and frame…2212

Track frame and recoil spring…2212

Idler…2214

Carrier roller…2216

Track roller…2217

Track shoe…2218

10 Structure, function and maintenance standard…2225

Hydraulic system, Part 1…2225

Hydraulic system, Part 1…2226

Hydraulic equipment layout drawing…2226

Hydraulic tank and filter…2228

Hydraulic pump…2229

Hydraulic pump…2230

Pilot oil filter…2253

10 Structure, function and maintenance standard…2255

Hydraulic system, Part 2…2255

Hydraulic system, Part 2…2256

Control valve…2256

CLSS…2269

Functions and operation by valve…2274

Hydraulic drift prevention valve…2300

10 Structure, function and maintenance standard…2313

Hydraulic system, Part 3…2313

Hydraulic system, Part 3…2315

Swing motor…2315

Centre swivel joint…2324

Travel motor…2327

PPC valve…2338

Valve control…2358

ATT EPC Valve Assembly…2360

Solenoid valve…2362

PPC Accumulator…2364

Return oil filter…2365

Attachment circuit selector valve…2366

Quick coupler control valve – For PC210 K50001 ~ K51094, PC230 K50001 ~ K50113 and PC240 K50001~K50303…2368

Quick coupler control valve – For PC210 K51095 – K53243, PC230 K50114 – K50286 and PC240 K50304 – K51093.)…2370

Quick coupler control valve – For PC210 K53424 and up, PC230 K50287 and up and PC240 K51094 and up…2372

Hydraulic cylinder…2374

10 Structure, function and maintenance standard…2379

Work equipment…2379

Work equipment…2380

Dimensions of components…2380

10 Structure, function and maintenance standard…2387

Cab and its attachments…2387

Cab and its attachments…2388

Air conditioner piping…2388

10 Structure, function and maintenance standard…2391

Electrical system…2391

Electrical system…2392

Engine control…2392

Electrical control system…2400

Monitor system…2426

Sensor…2457

PPC Levers…2460

KOMTRAX terminal system…2462

10 Structure, function and maintenance standard…2465

Auto Grease system…2465

Outline of Auto Grease System…2466

20 Standard value table…2481

Standard service value table…2481

Standard service value table…2482

Standard value table for engine related parts…2482

Standard value table for chassis related parts…2484

30 Testing and adjusting…2503

Testing and adjusting, Part 1…2503

Testing and adjusting, Part 1…2505

Tools for testing, adjusting, and troubleshooting…2505

Measuring engine speed…2508

Measuring intake air pressure (boost pressure)…2509

Checking exhaust gas colour…2510

Adjusting valve clearance…2511

Measuring compression pressure…2513

Measuring blow-by pressure…2515

Measuring engine oil pressure…2516

Handling fuel system parts…2517

Releasing residual pressure from fuel system…2517

Measuring fuel pressure…2518

Measuring fuel return rate and leakage…2520

Bleeding air from fuel circuit…2522

Checking fuel circuit for leakage…2524

Checking and adjusting air conditioner compressor belt tension…2525

Measuring swing circle bearing clearance…2526

Checking and adjusting track shoe tension…2527

Measuring and adjusting oil pressure in work equipment, swing, and travel circuits…2529

Measuring control circuit basic pressure…2533

Measuring and adjusting oil pressure in pump PC control circuit…2534

Measuring and adjusting oil pressure in pump LS control circuit…2538

Measuring solenoid valve output pressure…2544

Measuring PPC valve output pressure…2547

Adjusting play of work equipment and swing PPC valves…2549

Measuring and adjusting quick coupler control valve output pressure – For PC210 K50001 – K53423, PC230 K50001 – K50286 and PC240 K50001 – K51093…2550

Measuring and adjusting quick coupler control valve output pressure – For PC210 K53424 and up, PC230 K50287 and up and PC240 K51094 and up…2551

Checking parts which cause hydraulic drift of work equipment…2552

Releasing residual pressure from hydraulic circuit…2554

Measuring oil leakage…2555

Bleeding air from each part…2558

Checking cab tipping stopper…2561

Adjusting mirrors…2562

Adjusting mirrors…2564

30 Testing and adjusting…2567

Testing and adjusting, Part 2…2567

Testing and adjusting, Part 2…2568

Special functions of machine monitor…2568

30 Testing and adjusting…2633

Testing and adjusting, Part 3…2633

Testing and adjusting, Part 3…2634

Handling high-voltage circuit of engine controller…2634

Preparation work for troubleshooting of electrical system…2635

Procedure for testing diodes…2639

Pm Clinic service…2641

Warning…2643

Pm Clinic service…2647

40 Troubleshooting…2655

General information on troubleshooting…2655

General information on troubleshooting…2656

Points to remember when troubleshooting…2656

Sequence of events in troubleshooting…2657

Check before troubleshooting…2658

Classification and procedures for troubleshooting…2659

How to read electric wire code…2663

Connection table for connector pin numbers…2666

T-boxes and T-adapters table…2697

40 Troubleshooting…2703

Troubleshooting by failure code (Display of code), Part 1…2703

Troubleshooting by failure code (Display of code), Part 1…2705

Failure codes table…2705

Before carrying out troubleshooting when failure code is displayed…2710

Before carrying out troubleshooting when failure code is displayed…2711

Information in troubleshooting table…2716

Failure code [989L00] Engine Controller Lock Caution 1…2718

Failure code [989M00] Engine Controller Lock Caution 2…2718

Failure code [989N00] Engine Controller Lock Caution 3…2719

Failure code [AA10NX] Air Cleaner Clogging…2719

Failure code [AB00KE] Charge Voltage Low…2720

Failure code [B@BAZG] Eng Oil Press. Low…2722

Failure code [B@BAZK] Eng Oil Level Low…2722

Failure code [B@BCNS] Eng Water Overheat…2723

Failure code [B@BCZK] Eng Water Level Low…2723

Failure code [B@HANS] Hydr Oil Overheat…2724

Failure code [CA111] EMC Critical Internal Failure…2724

Failure code [CA115] Eng Ne and Bkup Speed Sens Error…2725

Failure code [CA122] Chg Air Press Sensor High Error…2726

Failure code [CA123] Chg Air Press Sensor Low Error…2728

Failure code [CA131] Throttle Sensor High Error…2730

Failure code [CA132] Throttle Sensor Low Error…2732

Failure code [CA144] Coolant Temp Sens High Error…2734

Failure code [CA145] Coolant Temp Sens Low Error…2736

Failure code [CA153] Chg Air Temp Sensor High Error…2738

Failure code [CA154] Chg Air Temp Sensor Low Error…2740

Failure code [CA155] Chg Air Temp High Speed Derate…2742

Failure code [CA187] Sens Supply 2 Volt Low Error…2744

Failure code [CA221] Ambient Press Sens High Error…2746

Failure code [CA222] Ambient Press Sens Low Error…2748

Failure code [CA227] Sens Supply 2 Volt High Error…2750

Failure code [CA234] Eng Overspeed…2751

Failure code [CA238] Ne Speed Sens Supply Volt Error…2752

Failure code [CA271] IMV/PCV1 Short Error…2753

Failure code [CA272] IMV/PCV1 Open Error…2754

Failure code [CA322] Inj #1 (L#1) Open/Short Error…2756

Failure code [CA323] Inj #5 (L#5) Open/Short Error…2758

Failure code [CA324] Inj #3 (L#3) Open/Short Error…2760

Failure code [CA325] Inj #6 (L#6) Open/Short Error…2762

Failure code [CA331] Inj #2 (L#2) Open/Short Error…2764

Failure code [CA332] Inj #4 (L#4) Open/Short Error…2766

40 Troubleshooting…2769

Troubleshooting by failure code (Display of code), Part 2…2769

Troubleshooting by failure code (Display of code), Part 2…2771

Failure code [CA342] Calibration Code Incompatibility…2771

Failure code [CA351] Injectors Drive Circuit Error…2772

Failure code [CA352] Sens Supply 1 Volt Low Error…2774

Failure code [CA386] Sens Supply 1 Volt High Error…2776

Failure code [CA428] Water in Fuel Sensor High Error…2778

Failure code [CA429] Water in Fuel Sensor Low Error…2780

Failure code [CA435] Eng Oil Press Sw Error…2782

Failure code [CA441] Battery Voltage Low Error…2783

Failure code [CA442] Battery Voltage High Error…2786

Failure code [CA449] Rail Press Very High Error…2788

Failure code [CA451] Rail Press Sensor High Error…2790

Failure code [CA452] Rail Press Sensor Low Error…2792

Failure code [CA488] Chg Air Temp High Torque Derate…2794

Failure code [CA553] Rail Press High Error…2794

Failure code [CA559] Rail Press Low Error…2795

Failure code [CA689] Eng Ne Speed Sensor Error…2796

Failure code [CA731] Eng Bkup Speed Sens Phase Error…2798

Failure code [CA757] All Continuous Data Lost Error…2800

Failure code [CA778] Eng Bkup Speed Sensor Error…2802

Failure code [CA1633] KOMNET Datalink Timeout Error…2804

Failure code [CA2185] Throt Sens Sup Volt High Error…2806

Failure code [CA2186] Throt Sens Sup Volt Low Error…2807

Failure code [CA2249] Rail Press Very Low Error…2808

Failure code [CA2311] IMV Solenoid Error…2810

Failure code [CA2555] Grid Htr Relay Volt High Error…2812

Failure code [CA2556] Grid Htr Relay Volt Low Error…2814

Failure code [D19JKZ] Personal Code Relay Abnormality…2816

Failure code [D862KA] GPS Antenna Discon…2818

Failure code [DA25KP] 5V Sensor 1 Power Abnormality…2819

Failure code [DA29KQ] Model Selection Abnormality…2826

40 Troubleshooting…2831

Troubleshooting by failure code (Display of code), Part 3…2831

Troubleshooting by failure code (Display of code), Part 3…2834

Failure code [DA2RMC] CAN Discon (Pump Con Detected)…2834

Failure code [DAFGMC] GPS Module Error…2836

Failure code [DAFRMC] CAN Discon (Monitor Detected)…2838

Failure code [DGH2KB] Hydr Oil Sensor Short…2840

Failure code [DHPAMA] F Pump Press Sensor Abnormality…2842

Failure code [DHPBMA] R Pump Press Sensor Abnormality…2844

Failure code [DHS3MA] Arm Curl PPC Press Sensor Abnormality…2846

Failure code [DHS4MA] Bucket Curl PPC Press Sensor Abnormality…2848

Failure code [DHS8MA] Boom Raise PPC Press Sensor Abnormality…2850

Failure code [DHSAMA] Swing RH PPC Press Sensor Abnormality…2852

Failure code [DHSBMA] Swing LH PPC Press Sensor Abnormality…2854

Failure code [DHSDMA] Bucket Dump PPC Press Sensor Abnormality…2856

Failure code [DHX1MA] Overload Sensor Abnormality (Analog)…2858

Failure code [DW43KA] Travel Speed Sol Discon…2860

Failure code [DW43KB] Travel Speed Sol Short…2862

Failure code [DW45KA] Swing Brake Sol Discon…2864

Failure code [DW45KB] Swing Brake Sol Short…2866

Failure code [DW91KA] Travel Junction Sol Discon…2868

Failure code [DW91KB] Travel Junction Sol Short…2870

Failure code [DWA2KA] Service Sol Discon…2872

Failure code [DWA2KB] Service Sol Short…2873

Failure code [DWK0KA] 2-stage Relief Sol Discon…2874

Failure code [DWK0KB] 2-stage Relief Sol Short…2876

40 Troubleshooting…2879

Troubleshooting by failure code (Display of code), Part 4…2879

Troubleshooting by failure code (Display of code), Part 4…2881

Failure code [DXA8KA] PC-EPC (F) Sol Discon…2881

Failure code [DXA8KB] PC-EPC (F) Sol Short…2883

Failure code [DXA9KA] PC-EPC (R) Sol Discon…2885

Failure code [DXA9KB] PC-EPC (R) Sol Short…2887

Failure code [DXE0KA] LS-EPC Sol Discon…2889

Failure code [DXE0KB] LS-EPC Sol Short…2891

Failure code [DXE4KA] Service Current EPC Discon…2893

Failure code [DXE4KB] Service Current EPC Short…2895

Failure code [DXE5KA] Merge-divider Main Sol Discon…2897

Failure code [DXE5KB] Merge-divider Main Sol Short…2899

Failure code [DXE6KA] Merge-divider LS Sol Discon…2901

Failure code [DXE6KB] Merge-divider LS Sol Short…2903

Failure code [DY20KA] Wiper Working Abnormality…2905

Failure code [DY20MA] Wiper Parking Abnormality…2907

Failure code [DY2CKA] Washer Drive Discon…2909

Failure code [DY2CKB] Washer Drive Short…2911

Failure code [DY2DKB] Wiper Drive (For) Short…2913

Failure code [DY2EKB] Wiper Drive (Rev) Short…2915

Failure code [DXEAKA] Service Current EPC1 Discon…2917

Failure code [DXEAKB] Service Current EPC1 Short…2918

Failure code [DXE7KA] Service Current EPC2 Discon…2919

Failure code [DXE7KB] Service Current EPC2 Short…2920

Failure code [DXE8KA] Service Current EPC3 Discon…2921

Failure code [DXE8KB] Service Current EPC3 Short…2922

Failure code [DXE9KA] Service Current EPC4 Discon…2923

Failure code [DXE9KB] Service Current EPC4 Short…2924

Failure code [DFB1KZ] Service Lever Potentio 1 Abnormality…2927

Failure code [DFB2KZ] Service Lever Potentio 2 Abnormality…2929

Failure code [DFB5KZ] Service Lever Sub Potentio 1 Abnormality…2931

Failure code [DFB6KZ] Service Lever Sub Potentio 2 Abnormality…2933

Failure code [DFB3L8] Service Lever 1 Potentio Error…2935

Failure code [DFB4L8] Service Lever 2 Potentio Error…2936

40 Troubleshooting…2939

Troubleshooting of electrical system (E-mode)…2939

Troubleshooting of electrical system (E-mode)…2941

Before carrying out troubleshooting of electrical system…2941

Troubleshooting of electrical system (E-mode)…2942

Information in troubleshooting table…2945

E-1 When starting switch turned ON, machine monitor displays nothing…2946

E-2 When starting switch turned ON (before starting engine), basic check item lights up…2948

E-3 Engine does not start (Engine does not turn)…2951

E-4 Preheater does not operate…2954

E-5 Automatic warm-up system does not operate (in cold season)…2956

E-6 All work equipment, swing, and travel mechanism do not move or cannot be locked…2958

E-7 Precaution lights up while engine is running…2960

E-8 Emergency stop item lights up while engine is running…2965

E-9 Engine coolant temperature gauge does not indicate normally…2966

E-10 Hydraulic oil temperature gauge does not indicate normally…2967

E-11 Fuel level gauge does not indicate normally…2969

E-12 Contents of display by machine monitor are different from applicable machine…2971

E-13 Machine monitor does not display some items…2971

E-14 Function switch does not work…2971

E-15 Auto-decelerator does not operate normally…2972

E-16 Working mode does not change…2973

E-17 Travel speed does not change…2974

E-18 Alarm buzzer cannot be stopped…2975

E-18 Alarm buzzer cannot be stopped…2976

E-19 Windshield wiper and window washer do not operate…2978

E-20 Power maximising function does not operate normally…2980

E-20 Power maximising function does not operate normally…2982

E-21 Swing holding brake does not operate normally…2984

E-22 Travel alarm does not sound or does not stop sounding…2986

E-23 Air conditioner does not operate normally (including air conditioner abnormality record)…2988

E-24 When starting switch is turned OFF, service meter is not displayed…3000

E-25 Machine monitor cannot be set in service mode…3000

E-26 Monitoring function does not display lever control signal normally…3001

E-27 KOMTRAX system does not operate normally…3010

40 Troubleshooting…3013

Troubleshooting of hydraulic and mechanical system (H-mode)…3013

Troubleshooting of hydraulic and mechanical system (H-mode)…3016

System diagram of hydraulic and mechanical system…3016

Information in troubleshooting table…3018

H-1 Speed or power of whole work equipment, swing, and travel is low…3019

H-2 Engine speed lowers extremely or engine stalls…3021

H-3 Work equipment, swing, and travel systems do not work…3022

H-4 Abnormal sound comes out from around hydraulic pump…3022

H-5 Auto-decelerator does not operate…3023

H-6 Fine control performance or response is low…3023

H-7 Speed or power of boom is low…3024

H-8 Speed or power of arm is low…3025

H-9 Speed or power of bucket is low…3026

H-10 Work equipment does not move singly…3026

H-11 Hydraulic drift of work equipment is large…3027

H-12 Time lag of work equipment is large…3029

H-13 When part of work equipment is relieved singly, other parts of work equipment move…3029

H-14 Power maximizing function does not work…3030

H-15 In compound operation of work equipment, speed of part loaded more is low…3030

H-16 When machine swings and raises boom simultaneously, boom rising speed is low…3031

H-17 When machine swings and travels simultaneously, travel speed lowers largely…3031

H-18 Machine deviates during travel…3032

H-19 Travel speed is low…3033

H-20 Machine is not steered well or steering power is low…3034

H-21 Travel speed does not change or travel speed is low/high…3035

H-22 Travel system does not move (only one side)…3036

H-23 Upper structure does not swing…3037

H-24 Swing acceleration or swing speed is low…3039

H-25 Upper structure overruns remarkably when it stops swinging…3040

H-26 Large shock is made when upper structure stops swinging…3041

H-27 Large sound is made when upper structure stops swinging…3041

H-28 Hydraulic drift of swing is large…3042

H-29 Attachment circuit is not changed…3043

H-30 Oil flow in attachment circuit cannot be controlled…3043

Quick coupler…3044

Quick coupler…3046

Quick coupler…3048

40 Troubleshooting…3053

Troubleshooting of engine (S-mode)…3053

Troubleshooting of engine (S-mode)…3055

Method of using troubleshooting chart…3055

S-1 Starting performance is poor…3058

S-2 Engine does not start…3059