Complete factory shop manual including electrical wiring diagrams for Komatsu SK714-5, SK815-5, SK815-5 turbo, SK815-5N, SK815-5NA Skid-Steer Loader. It’s the same service manual used by dealers that guaranteed to be fully functional and intact without any missing page to save your precious time.

This Komatsu Skid-Steer Loaders SK714-5, SK815-5, SK815-5 turbo, SK815-5N, SK815-5NA repair manual (including maintenance, overhaul, disassembling & assembling, adjustment, tune-up, operation, inspecting, diagnostic & troubleshooting…) is divided into different sections. Each section covers a specific component or system with detailed illustrations. A table of contents is placed at the beginning of each section. Pages are easily found by category, and each page is expandable for great detail. The printer-ready PDF documents work like a charm on all kinds of devices.

CEAM016102 – Skid Steer Loader SK815-5N, SK815-5NA Operation & Maintenance Manual.pdf

CEBM015901 – Skid Steer Loader SK815-5N, SK815-5NA Shop Manual.pdf

WEAM003300 – Skid Steer Loader SK714-5 Operation & Maintenance Manual.pdf

WEAM003301 – Skid Steer Loader SK714-5 Operation & Maintenance Manual.pdf

WEAM003303 – Skid Steer Loader SK714-5 Operation & Maintenance Manual.pdf

WEAM003403 – Skid Steer Loader SK815-5 Operation & Maintenance Manual.pdf

WEAM003502 – Skid Steer Loader SK714-5 Operation & Maintenance Manual.pdf

WEAM003503 – Skid Steer Loader SK714-5 Operation & Maintenance Manual.pdf

WEAM003602 – Skid Steer Loader SK815-5 Operation & Maintenance Manual.pdf

WEAM003603 – Skid Steer Loader SK815-5 Operation & Maintenance Manual.pdf

WEAM005002 – Skid Steer Loader SK815-5 Turbo Operation & Maintenance Manual.pdf

WEAM005300 – Skid Steer Loader SK815-5 turbo Operation & Maintenance Manual.pdf

WEAM005301 – Skid Steer Loader SK815-5 turbo Operation & Maintenance Manual.pdf

WEBM003400 – Skid Steer Loader SK714-5, SK815-5 Shop Manual.pdf

WEBM005500 – Skid Steer Loader SK714-5, SK815-5, SK815-5 turbo Shop Manual.pdf

WEBM005501 – Skid Steer Loader SK714-5, SK815-5, SK815-5 turbo Shop Manual.pdf

WEBM005600 – Skid Steer Loader SK714-5, SK815-5, SK815-5 turbo Shop Manual.pdf

CEAM016102 – Skid Steer Loader SK815-5N, SK815-5NA Operation & Maintenance Manual…3

COVER…3

INTRODUCTION…5

FOREWORD…6

SAFETY INFORMATION…7

Directions Of Machine…8

APPROVED AND NON APPROVED USES…9

Approved…9

Non Approved…9

PRODUCT INFORMATION…10

Main Features…10

Break In Period…10

Synthetic Biodegradable Oil Types…10

PRODUCT IDENTIFICATION…11

Machine Serial Number…11

Machine Identification Plate and Product Identification Number (PIN)…11

Engine Serial Number And Emission Plate…11

Travel Reduction Gear Serial Number…12

Cab Serial Number…12

Excavator Identification Plate (if installed)…12

Serial Numbers and Distributor Information…13

TABLE OF CONTENTS…14

SAFETY…21

SAFETY LABELS…22

Safety Label Using Both Words And Pictorial Message…22

Hazard Panel…22

Avoidance Panel…22

SAFETY AND WARNING DECALS…23

PICTOGRAMS AND RELEVANT MEANINGS…32

Danger In The Work Area…32

Do Not Open The Hood…32

Consult The Manual…32

Hydraulic Oil Fill…32

Biological Hydraulic Oil Fill…33

Refuelling…33

Engine Lubricating Oil Filter…33

Fuel Filter…33

Engine Air Suction Filter…33

Engine Coolant…33

Engine Coolant Pressure…34

Hydraulic Oil Level…34

Hydraulic Oil Filter…34

Electric Outlet…34

Anchorage Point…34

Emergency Exit…35

Lifting Point…35

GENERAL PRECAUTIONS…36

Safety Rules…36

If Abnormalities Are Found…36

Clothing And Personal Protective Items…36

Fire Extinguisher And First Aid Kit…36

Safety Features…37

Keep Machine Clean…37

Inside Operator's Compartment…37

Leaving Operator’s Seat…37

CHECKING THE REAR-VIEW MIRRORS (if installed)…39

Mounting And Dismounting…40

Prevention Of Burns…40

Hot Coolant…40

High Temperature Oil…40

Fire Prevention…41

Fire Caused By Fuel Or Oil…41

Fire Caused By Accumulation Of Flammable Material…41

Fire Coming From Electric Wiring…41

Fire Coming From Hydraulic Line…41

Explosion Caused By Lighting Equipment…41

Action If Fire Occurs…42

Window Washer Liquid…42

Precautions When Using ROPS (Roll Over Protective Structure)…42

Precautions For Attachments…42

Unauthorized Modification…42

Safety At Work Site…43

Working On Loose Ground…43

Do Not Go Close To High-voltage Cables…43

Ensure Good Visibility…44

Ventilation For Enclosed Areas…44

Checking Signalman's Signals And Signs…44

Emergency Exit From Operator's Cab…44

Be Careful About Asbestos Dust…45

Seat Belt Inspection…46

PRECAUTIONS FOR OPERATION…47

Starting Engine…47

Checks Before Starting Engine…47

Precautions When Starting…47

Precautions In Cold Areas…48

Hydraulic Oil Travel Circuit Warm-Up…48

Operation…49

Precautions When Traveling In Forward Or Reverse…49

Precautions When Traveling…50

Working On Slopes…50

Prohibited Operations…52

Precautions When Operating…53

Operate Carefully On Snow…54

Parking The Machine…54

Precautions For Emergency Recovery…56

Transportation…57

Loading And Unloading…57

Shipping…57

BATTERY…58

Battery Hazard Prevention…58

Starting With Booster Cables…59

STOP ENGINE BEFORE PERFORMING MAINTENANCE…60

Two Workers For Maintenance When Engine Is Running…61

Proper Tools…62

Personnel…62

Attachments…62

Work Under The Machine…62

Noise…63

Precautions When Using Hammer…63

Repair Welding…63

Removing Battery Terminal…63

Precautions With High-pressure Oil…63

Handling High-pressure Hoses…63

Waste Materials…64

Compressed Air…64

Periodic Replacement Of Safety Critical Parts…64

PRECAUTIONS WITH TIRES…65

Handling Tires…65

Precautions When Storing Tires…65

SAFETY LOCKS…66

Loader Locks…66

OPERATION…69

GENERAL VIEWS…70

Front General View…70

Rear General View…71

Cab Inside General View…72

INSTRUMENTS AND CONTROLS…74

Instruments…74

Warning Lights…76

Switches And Push Buttons…81

Electrical Accessories…86

Machine Controls…88

Safety Bars…90

ISO PATTERN CONTROL SYSTEM…91

Servo Control Lever (Travel And Steering)…91

Right Servo Control Lever (Loader Arm And Bucket)…93

OPTIONAL PATTERN CONTROL SYSTEM…95

Right Servo Control Lever (Right Wheel Travel And Bucket Folding)…97

Auxiliary Hydraulic Kit Control Pedal (If Installed)…100

Foot Accelerator…101

Hand Accelerator…101

Parking Brake…102

Equipment Control Locking Lever (If Installed)…102

Standard Flow Hydraulic System Control (2 Lines)…103

"High Flow" Hydraulic System Control (3 Lines) (If Installed)…104

Instruments And Controls Super Flow” Hydraulic System Control(5 Lines) (If Installed)…105

Speed Increase Control…106

Floating Device Control (If Installed)…106

Instruments And Controls Pattern Shifting Control (If Installed)…107

Stabilizer Control (If Installed)…108

Left Stabilizer Control (If Installed)…108

Optional…108

FUSES AND RELAYS…109

Machine Function Fuses…109

Main Fuse…110

Relays…111

GUARDS AND DRIVER’S SEAT…113

Engine Hood…113

Rear Panel…114

Cab…115

Raising The Cab…116

Standard Seat…118

Cushioned Seat…118

Safety Belt…119

Seat Safety Switch…119

Emergency Exit…120

Technical Documentation Case…121

Fire Extinguisher…121

First Aid Kit…121

USE OF THE MACHINE…122

Checks Before Starting The Engine…122

Visual Checks…122

Daily Checks…122

Operational Checks…123

Starting The Engine…124

Starting With Warm Engine Or In Temperate Climates…124

Starting With Cold Engine Or In Cold Climates…125

Warming The Engine…126

Heating The Hydraulic Oil…126

How To Move The Machine (Iso Pattern Control System)…126

Steering (Changing Direction)…128

How To Move The Machine (Optional Pattern Control System)…130

Steering (Changing Direction)…132

Moving On Slopes…134

Maximum Immersion Depth…135

PARKING THE MACHINE…136

Parking On Level Ground…136

Parking On Slopes…137

STOPPING THE ENGINE…138

TRANSPORTING THE MACHINE ON OTHER VEHICLES…139

Loading And Unloading The Machine…139

Transport…140

HOW TO LIFT THE MACHINE…141

PRECAUTIONS TO BE TAKEN IN THE COLD SEASON…142

Fuel And Lubricants…142

Coolant…142

Battery…143

Other Precautions…143

Precautions To Be Taken At The End Of Work…143

PRECAUTIONS TO BE TAKEN IN THE WARM SEASON…144

USING THE WORK EQUIPMENT…145

Lowering The Equipment In Case Of Machine Failure…145

Organizing The Work Area…146

Loading Material On Heaps And On Level Surfaces…147

Loading Material On Slopes…148

Digging Method…149

Changing the Bucket or Attachment with Standard Quick Coupler…151

Removing the Bucket or Attachment…152

Installing the Bucket or Attachment…153

Checking Position of Locking Pins…154

LONG PERIODS OF INACTIVITY…155

Before The Period Of Inactivity…155

During The Period Of Inactivity…156

After The Period Of Inactivity…156

TROUBLESHOOTING…157

How To Remove The Machine…157

If The Fuel Has Been Completely Depleted…157

If The Battery Is Depleted…158

Starting With Booster Cables…159

Other Troubles…160

Electric Circuit…160

Hydraulic System…160

Engine…161

HYDROSTATIC TRANSMISSION…162

MAINTENANCE…163

GUIDE TO MAINTENANCE…164

MAINTENANCE NOTES…165

Notes Regarding The Engine…165

Engine Oil…165

Coolant…165

Fuel…166

Notes Regarding The Hydraulic System…166

Notes Regarding The Electrical System…166

Notes Regarding Lubrication…167

Parts Subject To Wear That Periodically Need Changing…167

FUEL, COOLANT AND LUBRICANTS…168

Approved Synthetic Biodegradable Lubricants Type Hees…170

DRIVING TORQUES FOR SCREWS AND NUTS…171

Standard Driving Torques…171

Specific Driving Torques…171

LUBRICATION…172

Lubrication Diagram…172

PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY…173

Critical Parts For Safety…174

Operator's Safety…179

MAINTENANCE PLAN…180

MAINTENANCE PROCEDURE…181

Checks Before Starting…181

Various Checks…181

Checking The Coolant Level…181

Checking The Fuel Level…182

Checking The Engine Oil Level…183

Checking The Oil Level In The Hydraulic Circuit…184

Checking The Water Separator For Sediments And Water…185

Checking The Wiring System…185

When Required…186

Checking, Cleaning Or Changing The Air Cleaner Cartridge…186

Tire Rotation…187

Draining The Fuel Tank…188

Releasing The Parking Brake…189

Checking The Battery Charge Level…190

Maintenance After First 50 Hours Of Operation…191

Maintenance Every 50 Hours Of Operation…191

Checking The Tire Pressure…191

Checking The Coolant Level In The Radiator…191

Maintenance After First 250 Hours Of Operation…192

Maintenance Every 250 Hours Of Operation…192

Adjusting The Fan Belt Tension…192

Checking The Gearing Chain Tension…193

Adjusting The Chains…194

Cleaning The Outside Of The Radiators…195

Checking The Wheel Nut Driving Torque…195

Checking The Oil Level In The Final Transmissions…196

Lubricating The Joints…197

Changing The Engine Oil…198

Changing The Engine Oil Filter…199

Maintenance After First 500 Hours Of Operation (Only For Machines Filled With Synthetic Biodegradable Oil Type Hees)…200

Maintenance Every 500 Hours Of Operation…200

Changing The Fuel Filter…200

Changing The Hydraulic Oil Drain Filter…202

Cleaning The Water Separator…203

Draining The Hydraulic Oil Tank (Only For Machines Filled With Synthetic Biodegradable Oil Type Hees)…204

Maintenance Every 1000 Hours Of Operation…205

Changing The Oil In The Final Transmission…205

Changing The Hydraulic System Oil And Cleaning The Suction Filter…206

Checking And Adjusting The Engine Valve Clearance…207

Maintenance Every 2000 Hours Of Operation…208

Changing The Coolant…208

Changing The Suction Filter…209

Checking The Alternator and The Starter…210

SPECIFICATIONS…211

TECHNICAL DATA…212

Standard Machine Overall Dimensions…212

Technical Characteristics…214

OPTIONS, ATTACHMENTS…215

AUTHORIZED OPTIONAL EQUIPMENT…216

Precautions Regarding Safety…216

Precautions Regarding The Installation Of Equipment…216

Characteristics Of The Standard Machine Optional Equipment…217

Characteristics Of The Optional Equipment Of The Machine Version With Super-flow Hydraulic System…218

CHANGING THE AUTHORIZED EQUIPMENT…219

Connecting The Excavator…219

Connecting The Hydraulic Circuit…220

Connecting The Return Circuit With Direct Drainage Into The Tank…222

Preparing The Machine For The Use Of The Excavator…223

Using The Machine With The Excavator…223

PALLET FORKS…224

Changing The Operating Pattern…225

How To Change The Operating Pattern…227

HAND & FOOT CONTROL SYSTEM…228

Machine Controls…228

Travel And Steering Control Levers…229

Work Equipment Control Pedals (Loader Arm And Bucket)…231

Auxiliary Hydraulic Kit Control…234

How To Move The Machine (Hand & Foot Control System)…237

Steering (Changing Direction)…238

CEBM015901 – Skid Steer Loader SK815-5N, SK815-5NA Shop Manual…241

COVER…241

FOREWORD…242

CONTENTS…242

SAFETY…247

SAFETY NOTICE…247

IMPORTANT SAFETY NOTICE…247

GENERAL PRECAUTIONS…247

PREPARATIONS FOR WORK…247

PRECAUTIONS DURING WORK…248

GENERAL…249

HOW TO READ THE SHOP MANUAL…250

VOLUMES…250

DISTRIBUTION AND UPDATING…250

FILING METHOD…250

REVISED EDITION MARK…250

REVISIONS…250

SYMBOLS…250

HOISTING INSTRUCTIONS…251

HOISTING…251

WIRE ROPES…251

PUSH PULL COUPLER…252

TYPE 1…252

DISCONNECTION…252

CONNECTION…252

TYPE 2…253

DISCONNECTION…253

CONNECTION…253

TYPE 3…254

DISCONNECTION…254

CONNECTION…254

COATING MATERIALS…255

SPECIFIC DRIVING TORQUE…257

STANDARD TIGHTENING TORQUE…258

STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS…258

TIGHTENING TORQUE OF HOSE NUTS…259

TIGHTENING TORQUE OF SPLIT FLANGE BOLTS…259

TIGHTENING TORQUE FOR FLARED NUTS…259

TABLE OF TIGHTENING TORQUES FOR O-RING BOSS PIPING JOINTS…260

TABLE OF TIGHTENING TORQUES FOR O-RING BOSS PLUGS…260

TIGHTENING TORQUE TABLE FOR HOSES (TAPER SEAL TYPE AND FACE SEAL TYPE)…260

ELECTRIC WIRE CODE…261

CLASSIFICATION BY THICKNESS…261

CLASSIFICATION BY COLOR AND CODE…261

CONVERSION TABLES…262

METHOD OF USING THE CONVERSION TABLE…262

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD…269

PTO…271

Maintenance Standard…272

POWER TRAIN…273

Maintenance Standard…274

FINAL DRIVE…278

Maintenance Standard…280

Description…281

Hydraulic Motor…281

Function…281

Operation…281

Flushing Relief Valve…284

Reduction Gearing…285

Function…285

Operating Principle…285

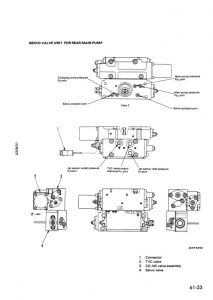

HYDRAULIC PUMP…286

HST Pump LPV40 + 40 (Standard Flow)…286

HST Pump LPV40 + 40 (High Flow)…288

HST Pump LPV40 + 40 (Standard Flow and High Flow)…290

Operation…291

Maintenance Standards…294

SAFETY VALVES…295

Suction Safety Valve Action…295

Charge Safety Valve Action…298

Charge Pump…300

ANTI ENGINE-STALL VALVE (AS VALVE)…301

Maintenance Standards…303

CONTROL VALVES…305

Standard 3-Spool Valve Port Location…305

Valve Sectional Views…306

Super High-Flow 4-Spool Valve Port Location…308

Valve Sectional Views…309

Maintenance Standards…312

Standard 3-spool…312

Super High Flow 4-Spool…316

CLSS (CLOSED CENTER LOAD SENSING SYSTEM)…323

Pressure Compensation Control…323

System Series Circuit Operation…326

Self Leveling Function…327

System In Series-Parallel Circuit Operation…328

Pressure Compensation Valve…330

Dividing Function…331

SOLENOID VALVE…332

Valve Group ST1…332

Valve Group ST2…333

ACCUMULATOR…334

PATTERN CHANGE VALVE (OPTIONAL)…335

Operation…337

Pattern ISO…337

Pattern Optional…337

Maintenance Standards…338

R.H. PPC VALVE (STANDARD)…339

Equipment Control…339

Maintenance Standards…343

R.H. PPC VALVE (PATTERN CHANGE) (OPTIONAL)…345

Equipment and Travel Control…345

L.H. PPC VALVE (STANDARD)…349

Travel Control…349

Maintenance Standards…353

L.H. PPC VALVE PATTERN CHANGE (OPTIONAL)…355

Equipment and Travel Control…355

Maintenance Standards…359

PATTERN CHANGE VALVE (OPTIONAL)…361

Maintenance Standard…361

CYLINDERS…362

Boom…362

Bucket…362

Maintenance Standards…363

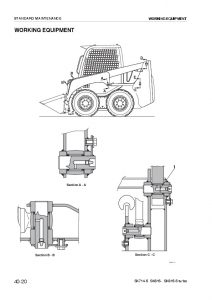

WORKING EQUIPMENT…364

20 STANDARD VALUE TABLES…367

STANDARD SERVICE VALUE TABLE…368

Standard Value Table…369

Engine…369

Chassis…370

30 TESTING AND ADJUSTING…375

SPECIAL TOOLS…377

T-ADAPTER PROCEDURES AND KITS…378

ENGINE COMPONENTS…379

Measuring Exhaust Smoke…379

Measuring Exhaust Temperature…379

Measuring Crankcase Pressure…379

Measuring Boost Pressure…379

Measuring Fuel Pressure…379

Bleeding Air From Fuel System…379

Adjusting Engine Stop Solenoid…379

Checking The Engine Speed…380

Adjusting Valve Clearance (SK815-5NA)…381

Adjusting Valve Clearance (SK815-5N)…382

Zero setting…382

Adjustment…382

Measuring Compression Pressure (SK815-5NA)…384

Measuring Compression Pressure (SK815-5N)…385

Control and Adjustment of Fan Belt Tension…386

Checking the Tension…386

Adjusting the Belt Tension…386

Control and Adjustment of the Injection Timing…387

Checking Engine Oil Pressure…389

Adjusting the Stroke of Accelerator Cables…390

ADJUSTING PPC VALVE DRIVE PRESSURES…391

Disassembly and Regulation…391

Assembly…392

Adjustment of the PPC Valve Clearances…393

ADJUSTING SERVO-CONTROL SAFETY SENSOR…394

GEAR CHAIN TENSION…395

Test…395

Adjustment…395

HYDRAULIC CIRCUITS…396

HYDRAULIC PUMP…397

VALVE CALIBRATION…398

HST Valve Calibration…398

AS Valve Calibration…398

Pressure Adjustment at Low Idling…398

Pressure Adjustment at Working Pressure…399

Travel Deviation Check…400

Checking the Deviation…400

Adjusting the Deviation…401

CONTROL VALVE…402

SERVO-CONTROL POWER SUPPLY…404

RELIEVING HYDRAULIC PRESSURE…406

Elimination of Pressures From the Hydraulic Circuits…406

Elimination of Pressure in the Tank…406

Pressurizing the Tank…406

BLEEDING HYDRAULIC CIRCUITS…407

Sequence for Bleeding the Air…407

Bleeding Air From The Pump…407

Bleeding Air From The Cylinders…408

Bleeding Air From Any Optional Equipment…408

50 DISASSEMBLY AND ASSEMBLY…409

HOW TO READ THIS MANUAL…412

Removal And Installation Of Assemblies…412

Special Tools…412

Removal…412

Installation…412

Disassembly and Assembly of Assemblies…414

Special Tools…414

Disassembly…414

Assembly…414

PRECAUTIONS DURING OPERATION…415

Precautions for Disassembly Operation…415

Precautions for Assembly Operation…416

Precautions for Completing Disassembly and Assembly Operations…416

Other Precautions…417

CONNECTOR REPAIR PROCEDURES…418

Stripping Insulation…418

Wire Inspection…418

Contact Terminal Removal (HD30 Type)…419

Crimping Contact Terminal (HD30 Type)…420

Insertion Of Contact Terminal (HD30 Type)…421

Contact Terminal Removal (DT Type)…422

Striping Insulation…423

Crimping Contact Terminal (DT Type)…424

Insertion Of Contact Terminal (DT Type)…425

ENGINE HOOD ASSEMBLY…426

Removal…426

Installation…426

ENGINE ASSEMBLY…427

Removal…427

Installation…430

Valve Cover (SK815-5NA)…431

Removal…431

Installation…431

Valve Cover (SK815-5N turbo)…432

Removal…432

Installation…433

Nozzle (SK815-5NA)…434

Removal…434

Installation…434

Nozzle (SK815-5N turbo)…435

Removal…435

Installation…435

Injector Pump…436

Removal…436

Installation…438

Cylinder Head (SK815-5NA)…439

Removal…439

Installation…441

Cylinder Head (SK815-5N turbo)…442

Removal…442

Installation…444

Water Pump…445

Removal…445

Installation…445

Starting Motor…446

Removal…446

Installation…446

Turbocharger…447

Removal…447

Installation…448

Alternator…449

Removal…449

Installation…449

CAB…450

Tilting The Cab…450

Lowering The Cab…452

Removing the Cab…453

Installing the Cab…455

BATTERY…456

Removal…456

Installation…456

AIR CLEANER ASSEMBLY…457

Removal…457

Installation…457

MUFFLER (SK815-5NA)…458

Removal…458

Installation…458

MUFFLER (SK815-5N turbo)…459

Removal…459

Installation…459

RADIATOR ASSEMBLY…460

Removal…460

Installation…461

FUEL TANK…462

Removal…462

Installation…463

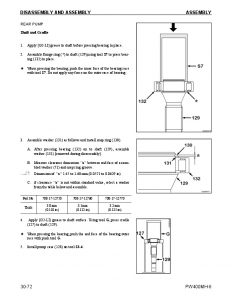

HYDRAULIC PUMP…464

Removal…464

Installation…466

GEAR PUMP…467

Removal…467

Installation…467

ENGINE PUMP COUPLING…468

Removal…468

Installation…468

CONTROL VALVE…469

Removal…469

Installation…469

PPC VALVES…470

Removal…470

Installation…470

WHEEL HUB…471

Removal…471

Installation…472

Disassembly…473

Assembly…474

FINAL DRIVE ASSEMBLY…475

Removal…475

Installation…476

CYLINDER ASSEMBLIES…477

Lift Cylinder Assembly…477

Removal…477

Installation…477

Bucket Cylinder Assembly…478

Removal…478

Installation…479

Disassembly of Cylinders…480

Assembly of the Cylinders…482

Assembly of the Cylinder Head…482

Piston Assembly…483

Piston Rod Assembly…483

Cylinder Assembly…484

WORK EQUIPMENT SYSTEM…486

Removal…486

Installation…488

WORKING EQUIPMENT SUPPORT FRAME…489

Removal…489

Installation…489

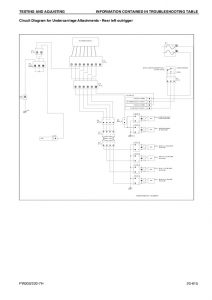

90 DIAGRAMS AND SCHEMATICS…491

ELECTRICAL DIAGRAMS…493

Engine Line (1/2)…493

Engine Line (2/2)…494

Frame Line Standard (1/2)…495

Frame Line Standard (2/2)…496

Frame Line Optional (1/2)…497

Frame Line Optional (2/2)…498

Cabin Line Standard (1/4)…499

Cabin Line Standard (2/4)…500

Cabin Line Standard (3/4)…501

Cabin Line Standard (4/4)…502

Cabin Line Optional (1/6)…503

Cabin Line Optional (2/6)…504

Cabin Line Optional (3/6)…505

Cabin Line Optional (4/6)…506

Cabin Line Optional (5/6)…507

Cabin Line Optional (6/6)…508

Top-Cabin Light Line Standard (1/2)…509

Top-Cabin Light Line Standard (2/2)…510

Top-Cabin Light Line Homologation (1/2)…511

Top-Cabin Light Line Homologation (2/2)…512

Standard (1/5)…513

Standard (2/5)…514

Standard (3/5)…515

Standard (4/5)…516

Standard (5/5)…517

Optional (1/7)…518

Optional (2/7)…519

Optional (3/7)…520

Optional (4/7)…522

Optional (5/7)…523

Optional (6/7)…524

Optional (7/7)…525

HYDRAULIC DIAGRAMS…526

Standard…526

High-Flow…527

Road Homologation…528

WEAM003300 – Skid Steer Loader SK714-5 Operation & Maintenance Manual…529

1.1 FOREWORD…531

1.2 INFORMATION ON SAFETY…532

1.3 INTRODUCTION…534

1.3.1 INTENDED USES…534

1.3.2 IMPROPER OR UNAUTHORIZED USES…534

1.3.3 MAIN CHARACTERISTICS…535

1.3.4 RUNNING-IN…535

1.4 PRODUCT IDENTIFICATION…536

1.4.1 MACHINE SERIAL NUMBER…536

1.4.2 MACHINE IDENTIFICATION PLATE…536

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE…537

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER…537

1.4.5 CAB SERIAL NUMBER…538

1.4.6 EXCAVATOR IDENTIFICATION PLATE (if installed)…538

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS…539

TABLE OF CONTENTS…540

1.1 FOREWORD 1…540

1.2 INFORMATION ON SAFETY 2…540

1.3 INTRODUCTION 4…540

1.3.1 INTENDED USES 4…540

1.3.2 IMPROPER OR UNAUTHORIZED USES 4…540

1.3.3 MAIN CHARACTERISTICS 5…540

1.3.4 RUNNING-IN 5…540

1.4 PRODUCT IDENTIFICATION 6…540

1.4.1 MACHINE SERIAL NUMBER 6…540

1.4.2 MACHINE IDENTIFICATION PLATE 6…540

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE 7…540

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER 7…540

1.4.5 CAB SERIAL NUMBER 8…540

1.4.6 EXCAVATOR IDENTIFICATION PLATE (if installed) 8…540

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS 9…540

2.1 SAFETY, NOISE AND VIBRATION PLATES 18…540

2.1.1 POSITION OF THE SAFETY PLATES 18…540

2.1.1.1 SAFETY PLATES 18…540

2.1.1.2 SAFETY PLATES FOR MACHINES WITH EXCAVATOR 20…540

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS 22…540

2.1.3 POSITION OF THE NOISE PLATES 26…540

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED 26…540

2.2 GENERAL PRECAUTIONS 27…540

2.2.1 GENERAL SAFETY RULES 27…540

2.2.2 SAFETY DEVICES AND GUARDS 27…540

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS 27…540

2.2.4 UNAUTHORIZED MODIFICATIONS 28…540

2.2.5 LEAVING THE OPERATORS SEAT 28…540

2.2.6 GETTING ON AND OFF THE MACHINE 29…540

2.2.7 CHECKING THE REAR-VIEW MIRRORS (if installed) 29…540

2.2.8 PREVENTING FIRES DUE TO FUEL AND OIL 30…540

2.2.9 PREVENTING BURNS 30…540

2.2.10 PREVENTING DAMAGE DUE TO ASBESTOS POWDER 31…540

2.2.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT 31…540

2.2.12 FIRE EXTINGUISHERS AND FIRST AID KIT 32…540

2.2.13 PRECAUTIONS CONCERNING THE CAB STRUCTURE 32…540

2.2.14 PRECAUTIONS CONCERNING THE EQUIPMENT 32…540

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE 33…540

2.3.1 SAFETY ON THE WORK SITE 33…540

2.3.2 FIRE PREVENTION 33…540

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB 33…540

2.3.4 ROOM VENTILATION 34…540

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS (if installed) 34…540

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS – CHECKING THE WINDSHIELD WIPER BLADES (if i…540

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING 35…541

2.4.1 STARTING THE ENGINE 35…541

2.4.2 RULES TO BE FOLLOWED WHEN TRAVELLING ON ROADS 35…541

2.4.3 CHECKS FOR TRAVELLING IN REVERSE 36…541

2.4.4 MOVING THE MACHINE 37…541

2.4.5 WORKING ON SLOPES 37…541

2.4.6 PREVENTING ELECTROCUTION 39…541

2.4.7 VISIBILITY 40…541

2.4.8 WORKING ON ICY OR SNOW-COVERED SURFACES 40…541

2.4.9 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT 40…541

2.4.10 WORKING ON LOOSE GROUND 40…541

2.4.11 PARKING THE MACHINE 41…541

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES 42…541

2.5.1 LOADING AND UNLOADING THE MACHINE 42…541

2.5.2 THE ROUTE 42…541

2.6 BATTERY 43…541

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES 43…541

2.6.2 STARTING WITH BOOSTER CABLES 43…541

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY 44…541

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE 46…541

2.8.1 WARNING PLATES 46…541

2.8.2 TOOLS 46…541

2.8.3 PERSONNEL 47…541

2.8.4 EQUIPMENT 47…541

2.8.5 WORKING UNDER THE MACHINE 47…541

2.8.6 KEEPING THE MACHINE CLEAN 47…541

2.8.7 USE OF THE ENGINE DURING MAINTENANCE 48…541

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY 48…541

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION 48…541

2.8.10 RULES FOR REFUELLING AND ADDING OIL 49…541

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR 49…541

2.8.12 USING LAMPS 49…541

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR 50…541

2.8.14 PRECAUTIONS CONCERNING THE STARTER 50…541

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES 51…541

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS 51…541

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES 51…541

2.8.18 COOLING FAN AND FAN BELT 52…541

2.8.19 WASTE MATERIALS 52…541

2.8.20 PRECAUTIONS TO BE TAKEN WHEN INFLATING THE TYRES 52…541

2.8.21 PRECAUTIONS TO BE TAKEN WHEN USING THE SYNTHETIC BIODEGRADABLE OIL TYPE «HEES» 53…541

3.1 SAFETY LOCKS 56…542

3.1.1 LOADER LOCKS 56…542

3.1.2 EXCAVATOR LOCKS (if installed) 58…542

3.1.3 ASPHALT CUTTER LOCKS (if installed) 60…542

3.2 GENERAL VIEWS 61…542

3.2.1 FRONT GENERAL VIEW 61…542

3.2.2 REAR GENERAL VIEW 62…542

3.2.3 CAB INSIDE GENERAL VIEW 63…542

3.3 INSTRUMENTS AND CONTROLS 65…542

3.3.1 INSTRUMENTS 65…542

3.3.2 WARNING LIGHTS 67…542

3.3.3 SWITCHES UND PUSH BUTTONS 72…542

3.3.4 ELECTRICAL ACCESSORIES 77…542

3.3.5 MACHINE CONTROLS 78…542

3.4 FUSES AND RELAYS 96…542

3.4.1 MACHINE FUNCTION FUSES 96…542

3.4.2 MAIN FUSE 97…542

3.4.3 RELAYS 98…542

3.5 GUARDS AND DRIVER’S SEAT 100…542

3.5.1 ENGINE HOOD 100…542

3.5.2 REAR PANEL 101…542

3.5.3 CAB 102…542

3.5.3.1 RAISING THE CAB 103…542

3.5.4 STANDARD SEAT 105…542

3.5.5 CUSHIONED SEAT 105…542

3.5.6 SAFETY BELT 106…542

3.5.7 EMERGENCY EXIT 106…542

3.5.8 TECHNICAL DOCUMENTATION CASE 107…542

3.5.9 FIRE EXTINGUISHER 107…542

3.5.10 FIRST AID KIT 107…542

3.6 USE OF THE MACHINE 109…542

3.6.1 CHECKS BEFORE STARTING THE ENGINE 109…542

3.6.1.1 VISUAL CHECKS 109…542

3.6.1.2 DAILY CHECKS 109…542

3.6.1.3 OPERATIONAL CHECKS 110…542

3.6.2 STARTING THE ENGINE 111…542

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES 111…542

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES 112…542

3.6.3 WARMING THE ENGINE 113…542

3.6.4 HEATING THE HYDRAULIC OIL 113…542

3.6.5 HOW TO MOVE THE MACHINE (ISO PATTERN CONTROL SYSTEM) 113…542

3.6.5.1 STEERING (CHANGING DIRECTION) 115…542

3.6.6 HOW TO MOVE THE MACHINE (OPTIONAL PATTERN CONTROL SYSTEM) 117…542

3.6.6.1 STEERING (CHANGING DIRECTION) 119…542

3.6.7 MOVING ON SLOPES 121…542

3.6.8 MAXIMUM IMMERSION DEPTH 122…542

3.7 PARKING THE MACHINE 123…543

3.7.1 PARKING ON LEVEL GROUND 123…543

3.7.2 PARKING ON SLOPES 124…543

3.8 STOPPING THE ENGINE 125…543

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES 126…543

3.9.1 LOADING AND UNLOADING THE MACHINE 126…543

3.9.2 TRANSPORT 127…543

3.10 HOW TO LIFT THE MACHINE 128…543

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON 129…543

3.11.1 FUEL AND LUBRICANTS 129…543

3.11.2 COOLANT 129…543

3.11.3 BATTERY 130…543

3.11.4 OTHER PRECAUTIONS 130…543

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK 130…543

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON 131…543

3.13 USING THE WORK EQUIPMENT 132…543

3.13.1 LOWERING THE EQUIPMENT IN CASE OF MACHINE FAILURE 132…543

3.13.2 ORGANIZING THE WORK AREA 133…543

3.13.3 LOADING MATERIAL ON HEAPS AND ON LEVEL SURFACES 134…543

3.13.4 LOADING MATERIAL ON SLOPES 135…543

3.13.5 DIGGING METHOD 136…543

3.13.6 CHANGING THE BUCKET WITH STANDARD RAPID COUPLING 137…543

3.13.6.1 RELEASING THE BUCKET 138…543

3.13.6.2 COUPLING THE BUCKET 138…543

3.13.7 CHANGING THE BUCKET WITH OPTIONAL RAPID COUPLING 140…543

3.13.7.1 RELEASING THE BUCKET 141…543

3.13.7.2 COUPLING THE BUCKET 141…543

3.14 LONG PERIODS OF INACTIVITY 143…543

3.14.1 BEFORE THE PERIOD OF INACTIVITY 143…543

3.14.2 DURING THE PERIOD OF INACTIVITY 144…543

3.14.3 AFTER THE PERIOD OF INACTIVITY 144…543

3.15 TROUBLESHOOTING 145…543

3.15.1 HOW TO REMOVE THE MACHINE 145…543

3.15.2 IF THE FUEL HAS BEEN COMPLETELY DEPLETED 145…543

3.15.3 IF THE BATTERY IS DEPLETED 146…543

3.15.3.1 STARTING WITH BOOSTER CABLES 147…543

3.15.4 OTHER TROUBLES 148…543

3.15.4.1 ELECTRICAL CIRCUIT 148…543

3.15.4.2 HYDRAULIC SYSTEM 149…543

3.15.4.3 ENGINE 150…543

3.15.4.4 HYDROSTATIC TRANSMISSION 151…543

4.1 GUIDE TO MAINTENANCE 154…544

4.2 MAINTENANCE NOTES 156…544

4.2.1 NOTES REGARDING THE ENGINE 156…544

4.2.1.1 ENGINE OIL 156…544

4.2.1.2 COOLANT 156…544

4.2.1.3 FUEL 157…544

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM 157…544

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM 158…544

4.2.4 NOTES REGARDING LUBRICATION 158…544

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING 159…544

4.3 FUEL, COOLANT AND LUBRICANTS 160…544

4.3.1 HOMOLOGATED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES 162…544

4.4 DRIVING TORQUES FOR SCREWS AND NUTS 163…544

4.4.1 STANDARD DRIVING TORQUES 163…544

4.4.2 SPECIFIC DRIVING TORQUES 163…544

4.5 LUBRICATION 164…544

4.5.1 LUBRICATION DIAGRAM 164…544

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY 165…544

4.6.1 CRITICAL PARTS FOR SAFETY 166…544

4.7 MAINTENANCE PLAN 172…544

4.7.1 WHEN REQUIRED 175…544

4.7.1.a CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE 175…544

4.7.1.b TYRE ROTATION 176…544

4.7.1.c WASHING THE COOLING CIRCUIT 177…544

4.7.1.d DRAINING THE FUEL TANK 178…544

4.7.1.e RELEASING THE PARKING BRAKE 179…544

4.7.2 CHECKS BEFORE STARTING 180…544

4.7.2.a VARIOUS CHECKS 180…544

4.7.2.b CHECKING THE COOLANT LEVEL 180…544

4.7.2.c CHECKING THE FUEL LEVEL 181…544

4.7.2.d CHECKING THE ENGINE OIL LEVEL 182…544

4.7.2.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT 183…544

4.7.2.f CHECKING THE FUEL FILTER FOR SEDIMENTS AND WATER 184…544

4.7.2.g CHECKING THE WIRING SYSTEM 184…544

4.7.3 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION 185…544

4.7.4 MAINTENANCE EVERY 50 HOURS OF OPERATION 185…544

4.7.4.a CHECKING THE TYRE PRESSURE 185…544

4.7.4.b CHECKING THE COOLANT LEVEL IN THE RADIATOR 185…544

4.7.5 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION 186…544

4.7.6 MAINTENANCE EVERY 250 HOURS OF OPERATION 186…544

4.7.6.a ADJUSTING THE FAN BELT TENSION 186…544

4.7.6.b CHECKING THE BATTERY ELECTROLYTE LEVEL 187…544

4.7.6.c CHECKING THE GEARING CHAIN TENSION 188…544

4.7.6.d CLEANING THE OUTSIDE OF THE RADIATORS 189…544

4.7.6.e CHECKING THE WHEEL NUT DRIVING TORQUE 190…544

4.7.6.f CHECKING THE OIL LEVEL IN THE FINAL TRANSMISSIONS 190…544

4.7.6.g LUBRICATING THE JOINTS 191…544

4.7.6.h CHANGING THE ENGINE OIL 192…544

4.7.6.j CHANGING THE ENGINE OIL FILTER 193…544

4.7.7 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines filled with synthetic…545

4.7.8 MAINTENANCE EVERY 500 HOURS OF OPERATION 194…545

4.7.8.a CHANGING THE FUEL FILTER 194…545

4.7.8.b CHANGING THE HYDRAULIC OIL DRAIN FILTER 196…545

4.7.8.c CHANGING THE FUEL PUMP PRECLEANER 197…545

4.7.8.d DRAINING THE HYDRAULIC OIL TANK (Only for machines filled with synthetic biodegradable oi…545

4.7.9 MAINTENANCE EVERY 1000 HOURS OF OPERATION 200…545

4.7.9.a CHANGING THE OIL IN THE FINAL TRANSMISSION 200…545

4.7.9.b CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER 201…545

4.7.9.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE 203…545

4.7.10 MAINTENANCE EVERY 2000 HOURS OF OPERATION 204…545

4.7.10.a CHANGING THE COOLANT 204…545

4.7.10.b CHANGING THE SUCTION FILTER 206…545

4.7.10.c CHECKING THE ALTERNATOR AND THE STARTER 207…545

5.1 TECHNICAL DATA 210…545

5.1.1 STANDARD MACHINE OVERALL DIMENSIONS 210…545

5.1.2 MACHINE OVERALL DIMENSIONS WITH OPTIONAL EQUIPMENT 212…545

5.1.3 TECHNICAL CHARACTERISTICS 214…545

6.1 AUTHORIZED OPTIONAL EQUIPMENT 218…545

6.1.1 PRECAUTIONS REGARDING SAFETY 218…545

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT 219…545

6.1.3 CHARACTERISTICS OF THE STANDARD MACHINE OPTIONAL EQUIPMENT 220…545

6.1.4 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT OF THE MACHINE VERSION WITH HIGH-FLOW HYDRAULIC S…545

6.2 CHANGING THE AUTHORIZED EQUIPMENT 222…545

6.2.1 CONNECTING THE EXCAVATOR 222…545

6.2.2 CONNECTING THE HYDRAULIC CIRCUIT 223…545

6.2.3 CONNECTING THE RETURN CIRCUIT WITH DIRECT DRAINAGE INTO THE TANK 225…545

6.2.4 PREPARING THE MACHINE FOR THE USE OF THE EXCAVATOR 226…545

6.2.5 USING THE MACHINE WITH THE EXCAVATOR 226…545

6.3 PALLET FORKS 227…545

2.1 SAFETY, NOISE AND VIBRATION PLATES…548

2.1.1 POSITION OF THE SAFETY PLATES…548

2.1.1.1 SAFETY PLATES…548

2.1.1.2 SAFETY PLATES FOR MACHINES WITH EXCAVATOR…550

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS…552

2.1.3 POSITION OF THE NOISE PLATES…556

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED…556

2.2 GENERAL PRECAUTIONS…557

2.2.1 GENERAL SAFETY RULES…557

2.2.2 SAFETY DEVICES AND GUARDS…557

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS…557

2.2.4 UNAUTHORIZED MODIFICATIONS…558

2.2.5 LEAVING THE OPERATORS SEAT…558

2.2.6 GETTING ON AND OFF THE MACHINE…559

2.2.7 CHECKING THE REAR-VIEW MIRRORS (if installed)…559

2.2.8 PREVENTING FIRES DUE TO FUEL AND OIL…560

2.2.9 PREVENTING BURNS…560

2.2.10 PREVENTING DAMAGE DUE TO ASBESTOS POWDER…561

2.2.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…561

2.2.12 FIRE EXTINGUISHERS AND FIRST AID KIT…562

2.2.13 PRECAUTIONS CONCERNING THE CAB STRUCTURE…562

2.2.14 PRECAUTIONS CONCERNING THE EQUIPMENT…562

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE…563

2.3.1 SAFETY ON THE WORK SITE…563

2.3.2 FIRE PREVENTION…563

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB…563

2.3.4 ROOM VENTILATION…564

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS (if installed)…564

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS – CHECKING THE WINDSHIELD WIPER BLADES (if i…564

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING…565

2.4.1 STARTING THE ENGINE…565

2.4.2 RULES TO BE FOLLOWED WHEN TRAVELLING ON ROADS…565

2.4.3 CHECKS FOR TRAVELLING IN REVERSE…566

2.4.4 MOVING THE MACHINE…567

2.4.5 WORKING ON SLOPES…567

2.4.6 PREVENTING ELECTROCUTION…569

2.4.7 VISIBILITY…570

2.4.8 WORKING ON ICY OR SNOW-COVERED SURFACES…570

2.4.9 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…570

2.4.10 WORKING ON LOOSE GROUND…570

2.4.11 PARKING THE MACHINE…571

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES…572

2.5.1 LOADING AND UNLOADING THE MACHINE…572

2.5.2 THE ROUTE…572

2.6 BATTERY…573

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES…573

2.6.2 STARTING WITH BOOSTER CABLES…573

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY…574

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE…576

2.8.1 WARNING PLATES…576

2.8.2 TOOLS…576

2.8.3 PERSONNEL…577

2.8.4 EQUIPMENT…577

2.8.5 WORKING UNDER THE MACHINE…577

2.8.6 KEEPING THE MACHINE CLEAN…577

2.8.7 USE OF THE ENGINE DURING MAINTENANCE…578

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY…578

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION…578

2.8.10 RULES FOR REFUELLING AND ADDING OIL…579

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR…579

2.8.12 USING LAMPS…579

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR…580

2.8.14 PRECAUTIONS CONCERNING THE STARTER…580

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES…581

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS…581

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES…581

2.8.18 COOLING FAN AND FAN BELT…582

2.8.19 WASTE MATERIALS…582

2.8.20 PRECAUTIONS TO BE TAKEN WHEN INFLATING THE TYRES…582

2.8.21 PRECAUTIONS TO BE TAKEN WHEN USING THE SYNTHETIC BIODEGRADABLE OIL TYPE «HEES»…583

3.1 SAFETY LOCKS…586

3.1.1 LOADER LOCKS…586

3.1.2 EXCAVATOR LOCKS (if installed)…588

3.1.3 ASPHALT CUTTER LOCKS (if installed)…590

3.2 GENERAL VIEWS…591

3.2.1 FRONT GENERAL VIEW…591

3.2.2 REAR GENERAL VIEW…592

3.2.3 CAB INSIDE GENERAL VIEW…593

3.3 INSTRUMENTS AND CONTROLS…595

3.3.1 INSTRUMENTS…595

3.3.2 WARNING LIGHTS…597

3.3.3 SWITCHES UND PUSH BUTTONS…602

3.3.4 ELECTRICAL ACCESSORIES…607

3.3.5 MACHINE CONTROLS…608

3.4 FUSES AND RELAYS…626

3.4.1 MACHINE FUNCTION FUSES…626

STANDARD VERSION…626

VERSION WITH OPTIONALS…627

3.4.2 MAIN FUSE…627

3.4.3 RELAYS…628

3.5 GUARDS AND DRIVER’S SEAT…630

3.5.1 ENGINE HOOD…630

3.5.2 REAR PANEL…631

3.5.3 CAB…632

3.5.3.1 RAISING THE CAB…633

3.5.4 STANDARD SEAT…635

3.5.5 CUSHIONED SEAT…635

3.5.6 SAFETY BELT…636

3.5.7 EMERGENCY EXIT…636

3.5.8 TECHNICAL DOCUMENTATION CASE…637

3.5.9 FIRE EXTINGUISHER…637

3.5.10 FIRST AID KIT…637

3.6 USE OF THE MACHINE…639

3.6.1 CHECKS BEFORE STARTING THE ENGINE…639

3.6.1.1 VISUAL CHECKS…639

3.6.1.2 DAILY CHECKS…639

3.6.1.3 OPERATIONAL CHECKS…640

3.6.2 STARTING THE ENGINE…641

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES…641

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES…642

3.6.3 WARMING THE ENGINE…643

3.6.4 HEATING THE HYDRAULIC OIL…643

3.6.5 HOW TO MOVE THE MACHINE (ISO PATTERN CONTROL SYSTEM)…643

3.6.5.1 STEERING (CHANGING DIRECTION)…645

3.6.6 HOW TO MOVE THE MACHINE (OPTIONAL PATTERN CONTROL SYSTEM)…647

3.6.6.1 STEERING (CHANGING DIRECTION)…649

3.6.7 MOVING ON SLOPES…651

3.6.8 MAXIMUM IMMERSION DEPTH…652

3.7 PARKING THE MACHINE…653

3.7.1 PARKING ON LEVEL GROUND…653

3.7.2 PARKING ON SLOPES…654

3.8 STOPPING THE ENGINE…655

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES…656

3.9.1 LOADING AND UNLOADING THE MACHINE…656

3.9.2 TRANSPORT…657

3.10 HOW TO LIFT THE MACHINE…658

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON…659

3.11.1 FUEL AND LUBRICANTS…659

3.11.2 COOLANT…659

3.11.3 BATTERY…660

3.11.4 OTHER PRECAUTIONS…660

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK…660

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON…661

3.13 USING THE WORK EQUIPMENT…662

3.13.1 LOWERING THE EQUIPMENT IN CASE OF MACHINE FAILURE…662

3.13.2 ORGANIZING THE WORK AREA…663

3.13.3 LOADING MATERIAL ON HEAPS AND ON LEVEL SURFACES…664

3.13.4 LOADING MATERIAL ON SLOPES…665

3.13.5 DIGGING METHOD…666

3.13.6 CHANGING THE BUCKET WITH STANDARD RAPID COUPLING…667

3.13.6.1 RELEASING THE BUCKET…668

3.13.6.2 COUPLING THE BUCKET…668

3.13.7 CHANGING THE BUCKET WITH OPTIONAL RAPID COUPLING…670

3.13.7.1 RELEASING THE BUCKET…671

3.13.7.2 COUPLING THE BUCKET…671

3.14 LONG PERIODS OF INACTIVITY…673

3.14.1 BEFORE THE PERIOD OF INACTIVITY…673

3.14.2 DURING THE PERIOD OF INACTIVITY…674

3.14.3 AFTER THE PERIOD OF INACTIVITY…674

3.15 TROUBLESHOOTING…675

3.15.1 HOW TO REMOVE THE MACHINE…675

3.15.2 IF THE FUEL HAS BEEN COMPLETELY DEPLETED…675

3.15.3 IF THE BATTERY IS DEPLETED…676

3.15.3.1 STARTING WITH BOOSTER CABLES…677

3.15.4 OTHER TROUBLES…678

3.15.4.1 ELECTRICAL CIRCUIT…678

3.15.4.2 HYDRAULIC SYSTEM…679

3.15.4.3 ENGINE…680

3.15.4.4 HYDROSTATIC TRANSMISSION…681

4.1 GUIDE TO MAINTENANCE…684

4.2 MAINTENANCE NOTES…686

4.2.1 NOTES REGARDING THE ENGINE…686

4.2.1.1 ENGINE OIL…686

4.2.1.2 COOLANT…686

4.2.1.3 FUEL…687

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM…687

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM…688

4.2.4 NOTES REGARDING LUBRICATION…688

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING…689

4.3 FUEL, COOLANT AND LUBRICANTS…690

4.3.1 HOMOLOGATED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES…692

4.4 DRIVING TORQUES FOR SCREWS AND NUTS…693

4.4.1 STANDARD DRIVING TORQUES…693

4.4.2 SPECIFIC DRIVING TORQUES…693

4.5 LUBRICATION…694

4.5.1 LUBRICATION DIAGRAM…694

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY…695

4.6.1 CRITICAL PARTS FOR SAFETY…696

FUEL SUPPLY SYSTEM…696

STANDARD HYDRAULIC SYSTEM…697

HIGH-FLOW HYDRAULIC SYSTEM…699

OPERATORíS SAFETY…701

4.7 MAINTENANCE PLAN…702

4.7.1 WHEN REQUIRED…705

4.7.1.a CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE…705

4.7.1.b TYRE ROTATION…706

4.7.1.c WASHING THE COOLING CIRCUIT…707

4.7.1.d DRAINING THE FUEL TANK…708

4.7.1.e RELEASING THE PARKING BRAKE…709

4.7.2 CHECKS BEFORE STARTING…710

4.7.2.a VARIOUS CHECKS…710

4.7.2.b CHECKING THE COOLANT LEVEL…710

4.7.2.c CHECKING THE FUEL LEVEL…711

4.7.2.d CHECKING THE ENGINE OIL LEVEL…712

4.7.2.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT…713

4.7.2.f CHECKING THE FUEL FILTER FOR SEDIMENTS AND WATER…714

4.7.2.g CHECKING THE WIRING SYSTEM…714

4.7.3 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION…715

4.7.4 MAINTENANCE EVERY 50 HOURS OF OPERATION…715

4.7.4.a CHECKING THE TYRE PRESSURE…715

4.7.4.b CHECKING THE COOLANT LEVEL IN THE RADIATOR…715

4.7.5 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION…716

4.7.6 MAINTENANCE EVERY 250 HOURS OF OPERATION…716

4.7.6.a ADJUSTING THE FAN BELT TENSION…716

4.7.6.b CHECKING THE BATTERY ELECTROLYTE LEVEL…717

4.7.6.c CHECKING THE GEARING CHAIN TENSION…718

4.7.6.d CLEANING THE OUTSIDE OF THE RADIATORS…719

4.7.6.e CHECKING THE WHEEL NUT DRIVING TORQUE…720

4.7.6.f CHECKING THE OIL LEVEL IN THE FINAL TRANSMISSIONS…720

4.7.6.g LUBRICATING THE JOINTS…721

4.7.6.h CHANGING THE ENGINE OIL…722

4.7.6.j CHANGING THE ENGINE OIL FILTER…723

4.7.7 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines filled with synthetic…724

4.7.8 MAINTENANCE EVERY 500 HOURS OF OPERATION…724

4.7.8.a CHANGING THE FUEL FILTER…724

4.7.8.b CHANGING THE HYDRAULIC OIL DRAIN FILTER…726

4.7.8.c CHANGING THE FUEL PUMP PRECLEANER…727

4.7.8.d DRAINING THE HYDRAULIC OIL TANK (Only for machines filled with synthetic biodegradable oi…728

4.7.9 MAINTENANCE EVERY 1000 HOURS OF OPERATION…730

4.7.9.a CHANGING THE OIL IN THE FINAL TRANSMISSION…730

4.7.9.b CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER…731

4.7.9.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE…733

4.7.10 MAINTENANCE EVERY 2000 HOURS OF OPERATION…734

4.7.10.a CHANGING THE COOLANT…734

4.7.10.b CHANGING THE SUCTION FILTER…736

4.7.10.c CHECKING THE ALTERNATOR AND THE STARTER…737

5.1 TECHNICAL DATA…740

5.1.1 STANDARD MACHINE OVERALL DIMENSIONS…740

5.1.2 MACHINE OVERALL DIMENSIONS WITH OPTIONAL EQUIPMENT…742

5.1.3 TECHNICAL CHARACTERISTICS…744

6.1 AUTHORIZED OPTIONAL EQUIPMENT…748

6.1.1 PRECAUTIONS REGARDING SAFETY…748

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT…749

6.1.3 CHARACTERISTICS OF THE STANDARD MACHINE OPTIONAL EQUIPMENT…750

6.1.4 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT OF THE MACHINE VERSION WITH HIGH-FLOW HYDRAULIC S…751

6.2 CHANGING THE AUTHORIZED EQUIPMENT…752

6.2.1 CONNECTING THE EXCAVATOR…752

6.2.2 CONNECTING THE HYDRAULIC CIRCUIT…753

6.2.3 CONNECTING THE RETURN CIRCUIT WITH DIRECT DRAINAGE INTO THE TANK…755

6.2.4 PREPARING THE MACHINE FOR THE USE OF THE EXCAVATOR…756

6.2.5 USING THE MACHINE WITH THE EXCAVATOR…756

6.3 PALLET FORKS…757

WEAM003301 – Skid Steer Loader SK714-5 Operation & Maintenance Manual…759

1.1 FOREWORD…761

1.2 INFORMATION ON SAFETY…762

1.3 INTRODUCTION…764

1.3.1 INTENDED USES…764

1.3.2 IMPROPER OR UNAUTHORIZED USES…764

1.3.3 MAIN CHARACTERISTICS…765

1.3.4 RUNNING-IN…765

1.4 PRODUCT IDENTIFICATION…766

1.4.1 MACHINE SERIAL NUMBER…766

1.4.2 MACHINE IDENTIFICATION PLATE…766

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE…767

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER…767

1.4.5 CAB SERIAL NUMBER…768

1.4.6 EXCAVATOR IDENTIFICATION PLATE (if installed)…768

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS…769

TABLE OF CONTENTS…770

2.1 SAFETY, NOISE AND VIBRATION PLATES…778

2.1.1 POSITION OF THE SAFETY PLATES…778

2.1.1.1 SAFETY PLATES…778

2.1.1.2 SAFETY PLATES FOR MACHINES WITH EXCAVATOR…780

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS…782

2.1.3 POSITION OF THE NOISE PLATES…786

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED…786

2.2 GENERAL PRECAUTIONS…787

2.2.1 GENERAL SAFETY RULES…787

2.2.2 SAFETY DEVICES AND GUARDS…787

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS…787

2.2.4 UNAUTHORIZED MODIFICATIONS…788

2.2.5 LEAVING THE OPERATORS SEAT…788

2.2.6 GETTING ON AND OFF THE MACHINE…789

2.2.7 CHECKING THE REAR-VIEW MIRRORS (if installed)…789

2.2.8 PREVENTING FIRES DUE TO FUEL AND OIL…790

2.2.9 PREVENTING BURNS…790

2.2.10 PREVENTING DAMAGE DUE TO ASBESTOS POWDER…791

2.2.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…791

2.2.12 FIRE EXTINGUISHERS AND FIRST AID KIT…792

2.2.13 PRECAUTIONS CONCERNING THE CAB STRUCTURE…792

2.2.14 PRECAUTIONS CONCERNING THE EQUIPMENT…792

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE…793

2.3.1 SAFETY ON THE WORK SITE…793

2.3.2 FIRE PREVENTION…793

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB…793

2.3.4 ROOM VENTILATION…794

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS (if installed)…794

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS – CHECKING THE WINDSHIELD WIPER BLADES (if i…794

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING…795

2.4.1 STARTING THE ENGINE…795

2.4.2 RULES TO BE FOLLOWED WHEN TRAVELLING ON ROADS…795

2.4.3 CHECKS FOR TRAVELLING IN REVERSE…796

2.4.4 MOVING THE MACHINE…797

2.4.5 WORKING ON SLOPES…797

2.4.6 PREVENTING ELECTROCUTION…799

2.4.7 VISIBILITY…800

2.4.8 WORKING ON ICY OR SNOW-COVERED SURFACES…800

2.4.9 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…800

2.4.10 WORKING ON LOOSE GROUND…800

2.4.11 PARKING THE MACHINE…801

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES…802

2.5.1 LOADING AND UNLOADING THE MACHINE…802

2.5.2 THE ROUTE…802

2.6 BATTERY…803

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES…803

2.6.2 STARTING WITH BOOSTER CABLES…803

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY…804

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE…806

2.8.1 WARNING PLATES…806

2.8.2 TOOLS…806

2.8.3 PERSONNEL…807

2.8.4 EQUIPMENT…807

2.8.5 WORKING UNDER THE MACHINE…807

2.8.6 KEEPING THE MACHINE CLEAN…807

2.8.7 USE OF THE ENGINE DURING MAINTENANCE…808

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY…808

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION…808

2.8.10 RULES FOR REFUELLING AND ADDING OIL…809

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR…809

2.8.12 USING LAMPS…809

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR…810

2.8.14 PRECAUTIONS CONCERNING THE STARTER…810

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES…811

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS…811

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES…811

2.8.18 COOLING FAN AND FAN BELT…812

2.8.19 WASTE MATERIALS…812

2.8.20 PRECAUTIONS TO BE TAKEN WHEN INFLATING THE TYRES…812

2.8.21 PRECAUTIONS TO BE TAKEN WHEN USING THE SYNTHETIC BIODEGRADABLE OIL TYPE «HEES»…813

3.1 SAFETY LOCKS…816

3.1.1 LOADER LOCKS…816

3.1.2 EXCAVATOR LOCKS (if installed)…818

3.1.3 ASPHALT CUTTER LOCKS (if installed)…820

3.2 GENERAL VIEWS…821

3.2.1 FRONT GENERAL VIEW…821

3.2.2 REAR GENERAL VIEW…822

3.2.3 CAB INSIDE GENERAL VIEW…823

3.3 INSTRUMENTS AND CONTROLS…825

3.3.1 INSTRUMENTS…825

3.3.2 WARNING LIGHTS…827

3.3.3 SWITCHES UND PUSH BUTTONS…832

3.3.4 ELECTRICAL ACCESSORIES…837

3.3.5 MACHINE CONTROLS…839

ISO PATTERN CONTROL SYSTEM…842

OPTIONAL PATTERN CONTROL SYSTEM…846

3.4 FUSES AND RELAYS…857

3.4.1 MACHINE FUNCTION FUSES…857

STANDARD VERSION…857

VERSION WITH OPTIONALS…858

3.4.2 MAIN FUSE…858

3.4.3 RELAYS…859

3.5 GUARDS AND DRIVER’S SEAT…861

3.5.1 ENGINE HOOD…861

3.5.2 REAR PANEL…862

3.5.3 CAB…863

3.5.3.1 RAISING THE CAB…864

3.5.4 STANDARD SEAT…866

3.5.5 CUSHIONED SEAT…866

3.5.6 SAFETY BELT…867

3.5.7 EMERGENCY EXIT…867

3.5.8 TECHNICAL DOCUMENTATION CASE…868

3.5.9 FIRE EXTINGUISHER…868

3.5.10 FIRST AID KIT…868

3.6 USE OF THE MACHINE…869

3.6.1 CHECKS BEFORE STARTING THE ENGINE…869

3.6.1.1 VISUAL CHECKS…869

3.6.1.2 DAILY CHECKS…869

3.6.1.3 OPERATIONAL CHECKS…870

3.6.2 STARTING THE ENGINE…871

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES…871

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES…872

3.6.3 WARMING THE ENGINE…873

3.6.4 HEATING THE HYDRAULIC OIL…873

3.6.5 HOW TO MOVE THE MACHINE (ISO PATTERN CONTROL SYSTEM)…873

3.6.5.1 STEERING (CHANGING DIRECTION)…875

3.6.6 HOW TO MOVE THE MACHINE (OPTIONAL PATTERN CONTROL SYSTEM)…877

3.6.6.1 STEERING (CHANGING DIRECTION)…879

3.6.7 MOVING ON SLOPES…881

3.6.8 MAXIMUM IMMERSION DEPTH…882

3.7 PARKING THE MACHINE…883

3.7.1 PARKING ON LEVEL GROUND…883

3.7.2 PARKING ON SLOPES…884

3.8 STOPPING THE ENGINE…885

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES…886

3.9.1 LOADING AND UNLOADING THE MACHINE…886

3.9.2 TRANSPORT…887

3.10 HOW TO LIFT THE MACHINE…888

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON…889

3.11.1 FUEL AND LUBRICANTS…889

3.11.2 COOLANT…889

3.11.3 BATTERY…890

3.11.4 OTHER PRECAUTIONS…890

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK…890

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON…891

3.13 USING THE WORK EQUIPMENT…892

3.13.1 LOWERING THE EQUIPMENT IN CASE OF MACHINE FAILURE…892

3.13.2 ORGANIZING THE WORK AREA…893

3.13.3 LOADING MATERIAL ON HEAPS AND ON LEVEL SURFACES…894

3.13.4 LOADING MATERIAL ON SLOPES…895

3.13.5 DIGGING METHOD…896

3.13.6 CHANGING THE BUCKET WITH STANDARD RAPID COUPLING…897

3.13.6.1 RELEASING THE BUCKET…898

3.13.6.2 COUPLING THE BUCKET…898

3.13.7 CHANGING THE BUCKET WITH OPTIONAL RAPID COUPLING…900

3.13.7.1 RELEASING THE BUCKET…901

3.13.7.2 COUPLING THE BUCKET…901

3.13.7.3 CHECKING THE POSITION OF THE LOCKING PINS…902

3.13.7.4 ADJUSTING THE LOCKING PINS…903

3.14 LONG PERIODS OF INACTIVITY…904

3.14.1 BEFORE THE PERIOD OF INACTIVITY…904

3.14.2 DURING THE PERIOD OF INACTIVITY…905

3.14.3 AFTER THE PERIOD OF INACTIVITY…905

3.15 TROUBLESHOOTING…906

3.15.1 HOW TO REMOVE THE MACHINE…906

3.15.2 IF THE FUEL HAS BEEN COMPLETELY DEPLETED…906

3.15.3 IF THE BATTERY IS DEPLETED…907

3.15.3.1 STARTING WITH BOOSTER CABLES…908

3.15.4 OTHER TROUBLES…909

3.15.4.1 ELECTRICAL CIRCUIT…909

3.15.4.2 HYDRAULIC SYSTEM…910

3.15.4.3 ENGINE…911

3.15.4.4 HYDROSTATIC TRANSMISSION…912

4.1 GUIDE TO MAINTENANCE…916

4.2 MAINTENANCE NOTES…918

4.2.1 NOTES REGARDING THE ENGINE…918

4.2.1.1 ENGINE OIL…918

4.2.1.2 COOLANT…918

4.2.1.3 FUEL…919

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM…919

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM…920

4.2.4 NOTES REGARDING LUBRICATION…920

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING…921

4.3 FUEL, COOLANT AND LUBRICANTS…922

4.3.1 HOMOLOGATED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES…924

4.4 DRIVING TORQUES FOR SCREWS AND NUTS…925

4.4.1 STANDARD DRIVING TORQUES…925

4.4.2 SPECIFIC DRIVING TORQUES…925

4.5 LUBRICATION…926

4.5.1 LUBRICATION DIAGRAM…926

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY…927

4.6.1 CRITICAL PARTS FOR SAFETY…928

FUEL SUPPLY SYSTEM…928

STANDARD HYDRAULIC SYSTEM…929

HIGH-FLOW HYDRAULIC SYSTEM…931

OPERATORíS SAFETY…933

4.7 MAINTENANCE PLAN…934

4.7.1 WHEN REQUIRED…937

4.7.1.a CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE…937

4.7.1.b TYRE ROTATION…938

4.7.1.c DRAINING THE FUEL TANK…939

4.7.1.d RELEASING THE PARKING BRAKE…940

4.7.2 CHECKS BEFORE STARTING…941

4.7.2.a VARIOUS CHECKS…941

4.7.2.b CHECKING THE COOLANT LEVEL…941

4.7.2.c CHECKING THE FUEL LEVEL…942

4.7.2.d CHECKING THE ENGINE OIL LEVEL…943

4.7.2.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT…944

4.7.2.f CHECKING THE FUEL FILTER FOR SEDIMENTS AND WATER…945

4.7.2.g CHECKING THE WIRING SYSTEM…945

4.7.3 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION…946

4.7.4 MAINTENANCE EVERY 50 HOURS OF OPERATION…946

4.7.4.a CHECKING THE TYRE PRESSURE…946

4.7.4.b CHECKING THE COOLANT LEVEL IN THE RADIATOR…946

4.7.5 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION…947

4.7.6 MAINTENANCE EVERY 250 HOURS OF OPERATION…947

4.7.6.a ADJUSTING THE FAN BELT TENSION…947

4.7.6.b CHECKING THE BATTERY ELECTROLYTE LEVEL…948

4.7.6.c CHECKING THE GEARING CHAIN TENSION…949

ADJUSTING THE CHAINS…950

4.7.6.d CLEANING THE OUTSIDE OF THE RADIATORS…951

4.7.6.e CHECKING THE WHEEL NUT DRIVING TORQUE…951

4.7.6.f CHECKING THE OIL LEVEL IN THE FINAL TRANSMISSIONS…952

4.7.6.g LUBRICATING THE JOINTS…953

EQUIPMENT LUBRICATION POINTS…953

4.7.6.h CHANGING THE ENGINE OIL…954

4.7.6.j CHANGING THE ENGINE OIL FILTER…955

4.7.7 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines filled with synthetic…956

4.7.8 MAINTENANCE EVERY 500 HOURS OF OPERATION…956

4.7.8.a CHANGING THE FUEL FILTER…956

4.7.8.b CHANGING THE HYDRAULIC OIL DRAIN FILTER…958

4.7.8.c CHANGING THE FUEL PUMP PRECLEANER…959

4.7.8.d DRAINING THE HYDRAULIC OIL TANK (Only for machines filled with synthetic biodegradable oi…960

4.7.9 MAINTENANCE EVERY 1000 HOURS OF OPERATION…962

4.7.9.a CHANGING THE OIL IN THE FINAL TRANSMISSION…962

4.7.9.b CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER…963

4.7.9.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE…965

4.7.10 MAINTENANCE EVERY 2000 HOURS OF OPERATION…966

4.7.10.a CHANGING THE COOLANT…966

4.7.10.b CHANGING THE SUCTION FILTER…968

4.7.10.c CHECKING THE ALTERNATOR AND THE STARTER…969

5.1 TECHNICAL DATA…972

5.1.1 STANDARD MACHINE OVERALL DIMENSIONS…972

OVERALL DIMENSIONS WITH STANDARD BUCKET L 1550 AND TYRES (10×16.5)…972

OVERALL DIMENSIONS WITH BUCKET L 1460 AND TYRES (7.00×16.5)…973

OVERALL DIMENSIONS WITH BUCKET L 1730 AND TYRES (10×16.5)…973

5.1.2 MACHINE OVERALL DIMENSIONS WITH OPTIONAL EQUIPMENT…974

MACHINE OVERALL DIMENSIONS WITH EXCAVATOR (E30)…974

MACHINE OVERALL DIMENSIONS WITH ASPHALT CUTTER…975

5.1.3 TECHNICAL CHARACTERISTICS…976

6.1 AUTHORIZED OPTIONAL EQUIPMENT…980

6.1.1 PRECAUTIONS REGARDING SAFETY…980

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT…981

6.1.3 CHARACTERISTICS OF THE STANDARD MACHINE OPTIONAL EQUIPMENT…982

6.1.4 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT OF THE MACHINE VERSION WITH HIGH-FLOW HYDRAULIC S…983

6.2 CHANGING THE AUTHORIZED EQUIPMENT…984

6.2.1 CONNECTING THE EXCAVATOR…984

6.2.2 CONNECTING THE HYDRAULIC CIRCUIT…985

6.2.3 CONNECTING THE RETURN CIRCUIT WITH DIRECT DRAINAGE INTO THE TANK…987

6.2.4 PREPARING THE MACHINE FOR THE USE OF THE EXCAVATOR…988

6.2.5 USING THE MACHINE WITH THE EXCAVATOR…988

6.3 PALLET FORKS…989

WEAM003303 – Skid Steer Loader SK714-5 Operation & Maintenance Manual…991

1.1 FOREWORD…993

1.2 INFORMATION ON SAFETY…994

1.3 INTRODUCTION…996

1.3.1 INTENDED USES…996

1.3.2 IMPROPER OR UNAUTHORIZED USES…996

1.3.3 MAIN CHARACTERISTICS…996

1.3.4 RUNNING-IN…997

1.4 PRODUCT IDENTIFICATION…998

1.4.1 MACHINE SERIAL NUMBER…998

1.4.2 MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)…998

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE…999

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER…999

1.4.5 CAB SERIAL NUMBER…999

1.4.6 EXCAVATOR IDENTIFICATION PLATE (if installed)…999

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS…1000

TABLE OF CONTENTS…1001

2.1 SAFETY, NOISE AND VIBRATION PLATES…1008

2.1.1 POSITION OF THE SAFETY PLATES…1008

2.1.1.1 SAFETY PLATES…1008

2.1.1.2 SAFETY PLATES FOR MACHINES WITH EXCAVATOR…1010

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS…1012

2.1.3 POSITION OF THE NOISE PLATES…1015

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED…1015

2.2 GENERAL PRECAUTIONS…1016

2.2.1 GENERAL SAFETY RULES…1016

2.2.2 SAFETY DEVICES AND GUARDS…1016

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS…1016

2.2.4 UNAUTHORIZED MODIFICATIONS…1017

2.2.5 LEAVING THE OPERATORS SEAT…1017

2.2.6 GETTING ON AND OFF THE MACHINE…1018

2.2.7 CHECKING THE REAR-VIEW MIRRORS (if installed)…1018

2.2.8 PREVENTING FIRES DUE TO FUEL AND OIL…1019

2.2.9 PREVENTING BURNS…1019

2.2.10 PREVENTING DAMAGE DUE TO ASBESTOS POWDER…1020

2.2.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…1020

2.2.12 FIRE EXTINGUISHERS AND FIRST AID KIT…1021

2.2.13 PRECAUTIONS CONCERNING THE CAB STRUCTURE…1021

2.2.14 PRECAUTIONS CONCERNING THE EQUIPMENT…1021

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE…1022

2.3.1 SAFETY ON THE WORK SITE…1022

2.3.2 FIRE PREVENTION…1022

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB…1022

2.3.4 ROOM VENTILATION…1023

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS (if installed)…1023

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS – CHECKING THE WINDSHIELD WIPER BLADES (if installed)…1023

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING…1024

2.4.1 STARTING THE ENGINE…1024

2.4.2 RULES TO BE FOLLOWED WHEN TRAVELLING ON ROADS…1024

2.4.3 CHECKS FOR TRAVELLING IN REVERSE…1025

2.4.4 MOVING THE MACHINE…1026

2.4.5 WORKING ON SLOPES…1026

2.4.6 PREVENTING ELECTROCUTION…1028

2.4.7 VISIBILITY…1029

2.4.8 WORKING ON ICY OR SNOW-COVERED SURFACES…1029

2.4.9 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…1029

2.4.10 WORKING ON LOOSE GROUND…1029

2.4.11 PARKING THE MACHINE…1030

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES…1031

2.5.1 LOADING AND UNLOADING THE MACHINE…1031

2.5.2 THE ROUTE…1031

2.6 BATTERY…1032

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES…1032

2.6.2 STARTING WITH BOOSTER CABLES…1032

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY…1033

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE…1035

2.8.1 WARNING PLATES…1035

2.8.2 TOOLS…1035

2.8.3 PERSONNEL…1036

2.8.4 EQUIPMENT…1036

2.8.5 WORKING UNDER THE MACHINE…1036

2.8.6 KEEPING THE MACHINE CLEAN…1036

2.8.7 USE OF THE ENGINE DURING MAINTENANCE…1037

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY…1037

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION…1037

2.8.10 RULES FOR REFUELLING AND ADDING OIL…1038

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR…1038

2.8.12 USING LAMPS…1038

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR…1039

2.8.14 PRECAUTIONS CONCERNING THE STARTER…1039

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES…1040

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS…1040

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES…1040

2.8.18 COOLING FAN AND FAN BELT…1041

2.8.19 WASTE MATERIALS…1041

2.8.20 PRECAUTIONS TO BE TAKEN WHEN INFLATING THE TYRES…1041

2.8.21 PRECAUTIONS TO BE TAKEN WHEN USING THE SYNTHETIC BIODEGRADABLE OIL TYPE «HEES»…1042

3.1 SAFETY LOCKS…1044

3.1.1 LOADER LOCKS…1044

3.1.2 EXCAVATOR LOCKS (if installed)…1046

3.1.3 ASPHALT CUTTER LOCKS (if installed)…1048

3.2 GENERAL VIEWS…1049

3.2.1 FRONT GENERAL VIEW…1049

3.2.2 REAR GENERAL VIEW…1050

3.2.3 CAB INSIDE GENERAL VIEW…1051

3.3 INSTRUMENTS AND CONTROLS…1053

3.3.1 INSTRUMENTS…1053

3.3.2 WARNING LIGHTS…1055

3.3.3 SWITCHES UND PUSH BUTTONS…1060

3.3.4 ELECTRICAL ACCESSORIES…1065

3.3.5 MACHINE CONTROLS…1067

3.4 FUSES AND RELAYS…1086

3.4.1 MACHINE FUNCTION FUSES…1086

3.4.2 MAIN FUSE…1087

3.4.3 RELAYS…1088

3.5 GUARDS AND DRIVER’S SEAT…1090

3.5.1 ENGINE HOOD…1090

3.5.2 REAR PANEL…1091

3.5.3 CAB…1092

3.5.3.1 RAISING THE CAB…1093

3.5.4 STANDARD SEAT…1095

3.5.5 CUSHIONED SEAT…1095

3.5.6 SAFETY BELT…1096

3.5.7 EMERGENCY EXIT…1096

3.5.8 TECHNICAL DOCUMENTATION CASE…1097

3.5.9 FIRE EXTINGUISHER…1097

3.5.10 FIRST AID KIT…1097

3.6 USE OF THE MACHINE…1098

3.6.1 CHECKS BEFORE STARTING THE ENGINE…1098

3.6.1.1 VISUAL CHECKS…1098

3.6.1.2 OPERATIONAL CHECKS…1099

3.6.2 STARTING THE ENGINE…1100

3.6.2.1 STARTING WITH WARM ENGINE OR IN TEMPERATE CLIMATES…1100

3.6.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES…1101

3.6.3 WARMING THE ENGINE…1102

3.6.4 HEATING THE HYDRAULIC OIL…1102

3.6.5 HOW TO MOVE THE MACHINE (ISO PATTERN CONTROL SYSTEMERN)…1102

3.6.5.1 STEERING (CHANGING DIRECTION)…1104

3.6.6 HOW TO MOVE THE MACHINE (OPTIONAL PATTERN CONTROL SYSTEM)…1106

3.6.6.1 STEERING (CHANGING DIRECTION)…1108

3.6.7 MOVING ON SLOPES…1110

3.6.8 MAXIMUM IMMERSION DEPTH…1111

3.7 PARKING THE MACHINE…1112

3.7.1 PARKING ON LEVEL GROUND…1112

3.7.2 PARKING ON SLOPES…1113

3.8 STOPPING THE ENGINE…1114

3.9 TRANSPORTING THE MACHINE ON OTHER VEHICLES…1115

3.9.1 LOADING AND UNLOADING THE MACHINE…1115

3.9.2 TRANSPORT…1116

3.10 HOW TO LIFT THE MACHINE…1117

3.11 PRECAUTIONS TO BE TAKEN IN THE COLD SEASON…1118

3.11.1 FUEL AND LUBRICANTS…1118

3.11.2 COOLANT…1118

3.11.3 BATTERY…1119

3.11.4 OTHER PRECAUTIONS…1119

3.11.5 PRECAUTIONS TO BE TAKEN AT THE END OF WORK…1119

3.12 PRECAUTIONS TO BE TAKEN IN THE WARM SEASON…1120

3.13 USING THE WORK EQUIPMENT…1121

3.13.1 LOWERING THE EQUIPMENT IN CASE OF MACHINE FAILURE…1121

3.13.2 ORGANIZING THE WORK ARE…1122

3.13.3 LOADING MATERIAL ON HEAPS AND ON LEVEL SURFACES…1123

3.13.4 LOADING MATERIAL ON SLOPES…1124

3.13.5 DIGGING METHOD…1125

3.13.6 CHANGING THE BUCKET OR THE EQUIPMENT WITH STANDARD RAPID COUPLING…1126

3.13.6.1 RELEASING THE BUCKET…1127

3.13.6.2 COUPLING THE BUCKET…1127

3.13.7 CHANGING THE BUCKET OR THE EQUIPMENT WITH OPTIONAL RAPID COUPLING…1129

3.13.7.1 REMOVING THE BUCKET OR THE EQUIPMENT…1130

3.13.7.2 CONNECTING THE BUCKET…1131

3.13.7.3 CHECKING THE POSITION OF THE LOCKING PINS…1132

3.13.7.4 ADJUSTING THE LOCKING PINS…1133

3.14 LONG PERIODS OF INACTIVITY…1134

3.14.1 BEFORE THE PERIOD OF INACTIVITY…1134

3.14.2 DURING THE PERIOD OF INACTIVITY…1135

3.14.3 AFTER THE PERIOD OF INACTIVITY…1135

3.15 TROUBLESHOOTING…1136

3.15.1 HOW TO REMOVE THE MACHINE…1136

3.15.2 IF THE FUEL HAS BEEN COMPLETELY DEPLETED…1136

3.15.3 IF THE BATTERY IS DEPLETED…1137

3.15.3.1 STARTING WITH BOOSTER CABLES…1138

3.15.4 OTHER TROUBLES…1139

3.15.4.1 ELECTRICAL CIRCUIT…1139

3.15.4.2 HYDRAULIC SYSTEM…1139

3.15.4.3 ENGINE…1140

3.15.4.4 TRASMISSIONE IDROSTATICA…1141

4.1 GUIDE TO MAINTENANCE…1144

4.2 MAINTENANCE NOTES…1146

4.2.1 NOTES REGARDING THE ENGINE…1146

4.2.1.1 ENGINE OIL…1146

4.2.1.2 COOLANT…1146

4.2.1.3 FUEL…1147

4.2.2 NOTES REGARDING THE HYDRAULIC SYSTEM…1147

4.2.3 NOTES REGARDING THE ELECTRICAL SYSTEM…1147

4.2.4 NOTES REGARDING LUBRICATION…1148

4.2.5 PARTS SUBJECT TO WEAR THAT PERIODICALLY NEED CHANGING…1148

4.3 FUEL, COOLANT AND LUBRICANTS…1149

4.3.1 HOMOLOGATED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES…1151

4.4 DRIVING TORQUES FOR SCREWS AND NUTS…1152

4.4.1 STANDARD DRIVING TORQUES…1152

4.4.2 SPECIFIC DRIVING TORQUES…1152

4.5 LUBRICATION…1153

4.5.1 LUBRICATION DIAGRAM…1153

4.6 PERIODICAL CHANGE OF THE COMPONENTS CONNECTED WITH SAFETY…1154

4.6.1 CRITICAL PARTS FOR SAFETY…1155

4.7 MAINTENANCE PLAN…1161

4.8 MAINTENANCE PROCEDURE…1163

4.8.1 WHEN REQUIRED…1163

4.8.1.a CHECKING, CLEANING OR CHANGING THE AIR CLEANER CARTRIDGE…1163

4.8.1.b TYRE ROTATION…1164

4.8.1.c DRAINING THE FUEL TANK…1165

4.8.1.d RELEASING THE PARKING BRAKE…1166

4.8.1.e CHECKING THE BATTERY CHARGE LEVEL…1167

4.8.2 CHECKS BEFORE STARTING…1168

4.8.2.a VARIOUS CHECKS…1168

4.8.2.b CHECKING THE COOLANT LEVEL…1168

4.8.2.c CHECKING THE FUEL LEVEL…1169

4.8.2.d CHECKING THE ENGINE OIL LEVE…1170

4.8.2.e CHECKING THE OIL LEVEL IN THE HYDRAULIC CIRCUIT…1171

4.8.2.f CHECKING THE WATER SEPARATOR FOR SEDIMENTS AND WATER…1172

4.8.2.g CHECKING THE WIRING SYSTEM…1172

4.8.3 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION…1173

4.8.4 MAINTENANCE EVERY 50 HOURS OF OPERATION…1173

4.8.4.a CHECKING THE TYRE PRESSURE…1173

4.8.4.b CHECKING THE COOLANT LEVEL IN THE RADIATOR…1173

4.8.5 MAINTENANCE AFTER THE FIRST 250 HOURS OF OPERATION…1174

4.8.6 MAINTENANCE EVERY 250 HOURS OF OPERATION…1174

4.8.6.a ADJUSTING THE FAN BELT TENSION…1174

4.8.6.b CHECKING THE GEARING CHAIN TENSION…1175

4.8.6.c CLEANING THE OUTSIDE OF THE RADIATORS…1177

4.8.6.d CHECKING THE WHEEL NUT DRIVING TORQUE…1177

4.8.6.e CHECKING THE OIL LEVEL IN THE FINAL TRANSMISSIONS…1178

4.8.6.f LUBRICATING THE JOINTS…1179

4.8.6.g CHANGING THE ENGINE OI…1180

4.8.6.h CHANGING THE ENGINE OIL FILTER…1181

4.8.7 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION (Only for machines filled with synthetic biodegradable oil type HEES)…1182

4.8.8 MAINTENANCE EVERY 500 HOURS OF OPERATION…1182

4.8.8.a CHANGING THE FUEL FILTER…1182

4.8.8.b CHANGING THE HYDRAULIC OIL DRAIN FILTER…1184

4.8.8.c CLEANING THE WATER SEPARATOR…1185

4.8.8.d DRAINING THE HYDRAULIC OIL TANK (Only for machines filled with synthetic biodegradable oil type HEES)…1186

4.8.9 MAINTENANCE EVERY 1000 HOURS OF OPERATION…1187

4.8.9.a CHANGING THE OIL IN THE FINAL TRANSMISSION…1187

4.8.9.b CHANGING THE HYDRAULIC SYSTEM OIL AND CLEANING THE SUCTION FILTER…1188

4.8.9.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE…1189

4.8.10 MANUTENZIONE OGNI 2000 ORE…1190

4.8.10.a CHANGING THE COOLANT…1190

4.8.10.b CHANGING THE SUCTION FILTER…1191

4.8.10.c CHECKING THE ALTERNATOR AND THE STARTER…1192

5.1 TECHNICAL DATA…1194

5.1.1 STANDARD MACHINE OVERALL DIMENSIONS…1194

5.1.2 MACHINE OVERALL DIMENSIONS WITH OPTIONAL EQUIPMENT…1196

5.1.3 TECHNICAL CHARACTERISTICS…1197

6.1 AUTHORIZED OPTIONAL EQUIPMENT…1200

6.1.1 PRECAUTIONS REGARDING SAFETY…1200

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT…1201

6.1.3 CHARACTERISTICS OF THE STANDARD MACHINE OPTIONAL EQUIPMENT…1202

6.1.4 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT OF THE MACHINE VERSION WITH HIGH-FLOW HYDRAULIC SYSTEM…1203

6.2 CHANGING THE AUTHORIZED EQUIPMENT…1204

6.2.1 CONNECTING THE EXCAVATOR…1204

6.2.2 CONNECTING THE HYDRAULIC CIRCUIT…1205

6.2.3 CONNECTING THE RETURN CIRCUIT WITH DIRECT DRAINAGE INTO THE TANK…1206

6.2.4 PREPARING THE MACHINE FOR THE USE OF THE EXCAVATOR…1207

6.2.5 USING THE MACHINE WITH THE EXCAVATOR…1207

6.3 PALLET FORKS…1208

6.4 CHANGING THE OPERATING PATTERN…1209

6.4.1 HOW TO CHANGE THE OPERATING PATTERN…1211

6.5 HAND & FOOT CONTROL SYSTEM…1212

6.5.1 MACHINE CONTROLS…1212

6.5.1.1 TRAVEL AND STEERING CONTROL LEVERS…1213

6.5.1.2 WORK EQUIPMENT CONTROL PEDALS (LOADER ARM AND BUCKET)…1215

6.5.1.3 AUXILIARY HYDRAULIC KIT CONTROL…1218

6.5.2 HOW TO MOVE THE MACHINE (HAND & FOOT CONTROL SYSTEM)…1221

6.5.2.1 STEERING (CHANGING DIRECTION)…1223

WEAM003403 – Skid Steer Loader SK815-5 Operation & Maintenance Manual…1227

1.1 FOREWORD…1229

1.2 INFORMATION ON SAFETY…1230

1.3 INTRODUCTION…1232

1.3.1 INTENDED USES…1232

1.3.2 IMPROPER OR UNAUTHORIZED USES…1232

1.3.3 MAIN CHARACTERISTICS…1232

1.3.4 RUNNING-IN…1233

1.4 PRODUCT IDENTIFICATION…1234

1.4.1 MACHINE SERIAL NUMBER…1234

1.4.2 MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)…1234

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE…1235

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER…1235

1.4.5 CAB SERIAL NUMBER…1235

1.4.6 EXCAVATOR IDENTIFICATION PLATE (if installed)…1235

1.4.7 SERIAL NUMBERS AND DEALER’S ADDRESS…1236

TABLE OF CONTENTS…1237

2.1 SAFETY, NOISE AND VIBRATION PLATES…1244

2.1.1 POSITION OF THE SAFETY PLATES…1244

2.1.1.1 SAFETY PLATES…1244

2.1.1.2 SAFETY PLATES FOR MACHINES WITH EXCAVATOR…1246

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS…1248

2.1.3 POSITION OF THE NOISE PLATES…1251

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED…1251

2.2 GENERAL PRECAUTIONS…1252

2.2.1 GENERAL SAFETY RULES…1252

2.2.2 SAFETY DEVICES AND GUARDS…1252

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS…1252

2.2.4 UNAUTHORIZED MODIFICATIONS…1253

2.2.5 LEAVING THE OPERATORS SEAT…1253

2.2.6 GETTING ON AND OFF THE MACHINE…1254

2.2.7 CHECKING THE REAR-VIEW MIRRORS (if installed)…1254

2.2.8 PREVENTING FIRES DUE TO FUEL AND OIL…1255

2.2.9 PREVENTING BURNS…1255

2.2.10 PREVENTING DAMAGE DUE TO ASBESTOS POWDER…1256

2.2.11 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…1256

2.2.12 FIRE EXTINGUISHERS AND FIRST AID KIT…1257

2.2.13 PRECAUTIONS CONCERNING THE CAB STRUCTURE…1257

2.2.14 PRECAUTIONS CONCERNING THE EQUIPMENT…1257

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE…1258

2.3.1 SAFETY ON THE WORK SITE…1258

2.3.2 FIRE PREVENTION…1258

2.3.3 PRECAUTIONS TO BE TAKEN FOR THE OPERATOR'S CAB…1258

2.3.4 ROOM VENTILATION…1259

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS (if installed)…1259

2.3.6 CLEANING THE WINDOWS AND THE REAR-VIEW MIRRORS – CHECKING THE WINDSHIELD WIPER BLADES (if installed)…1259

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING…1260

2.4.1 STARTING THE ENGINE…1260

2.4.2 RULES TO BE FOLLOWED WHEN TRAVELLING ON ROADS…1260

2.4.3 CHECKS FOR TRAVELLING IN REVERSE…1261

2.4.4 MOVING THE MACHINE…1262

2.4.5 WORKING ON SLOPES…1262

2.4.6 PREVENTING ELECTROCUTION…1264

2.4.7 VISIBILITY…1265

2.4.8 WORKING ON ICY OR SNOW-COVERED SURFACES…1265

2.4.9 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT…1265

2.4.10 WORKING ON LOOSE GROUND…1265

2.4.11 PARKING THE MACHINE…1266

2.5 TRANSPORTING THE MACHINE ON OTHER VEHICLES…1267

2.5.1 LOADING AND UNLOADING THE MACHINE…1267

2.5.2 THE ROUTE…1267

2.6 BATTERY…1268

2.6.1 SAFETY PRECAUTIONS FOR WORK ON BATTERIES…1268

2.6.2 STARTING WITH BOOSTER CABLES…1268

2.7 PRECAUTIONS FOR EMERGENCY RECOVERY…1269

2.8 PRECAUTIONS TO BE TAKEN DURING MAINTENANCE…1271

2.8.1 WARNING PLATES…1271

2.8.2 TOOLS…1271

2.8.3 PERSONNEL…1272

2.8.4 EQUIPMENT…1272

2.8.5 WORKING UNDER THE MACHINE…1272

2.8.6 KEEPING THE MACHINE CLEAN…1272

2.8.7 USE OF THE ENGINE DURING MAINTENANCE…1273

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY…1273

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION…1273

2.8.10 RULES FOR REFUELLING AND ADDING OIL…1274

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR…1274

2.8.12 USING LAMPS…1274

2.8.13 PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR…1275

2.8.14 PRECAUTIONS CONCERNING THE STARTER…1275

2.8.15 PRECAUTIONS CONCERNING HIGH-PRESSURE HOSES…1276

2.8.16 PRECAUTIONS TO BE TAKEN WHEN WORKING ON HIGH-PRESSURE SYSTEMS…1276

2.8.17 PRECAUTIONS FOR MAINTENANCE WORK INVOLVING HIGH TEMPERATURES AND PRESSURES…1276

2.8.18 COOLING FAN AND FAN BELT…1277

2.8.19 WASTE MATERIALS…1277

2.8.20 PRECAUTIONS TO BE TAKEN WHEN INFLATING THE TYRES…1277