Complete service repair manual with Electrical Wiring Diagrams for Komatsu Wheeled Excavator PW160-7E0, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Wheeled Excavator PW160-7E0 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

PRODUCT DETAILS:

Total Pages: 1,023 pages

File Format: PDF

Language: English

VEBM395100 – Wheeled Excavator PW160-7E0 Shop Manual.pdf

MAIN SECTIONS

VEBM395100 PW160-7E0…..1

SAFETY…..3

SAFETY NOTICE…..3

IMPORTANT SAFETY NOTICE…..3

GENERAL PRECAUTIONS…..3

PRECAUTIONS DURING WORK…..4

01 GENERAL…..21

SPECIFICATION DIMENSION DRAWINGS…..22

DIMENSIONS…..22

1 pIECE BOOM…..22

WORKING RANGES…..24

1 PIECE BOOM…..24

2 PIECE BOOM…..25

SPECIFICATIONS…..26

WEIGHT TABLE…..28

1 piece boom…..29

2 piece boom…..30

FUEL, COOLANT AND LUBRICANTS…..31

10 STRUCTURE, FUNCTION AND…..33

ENGINE RELATED PARTS…..34

RADIATOR . OIL COOLER . CHARGE AIR COOLER…..35

POWER TRAIN…..36

SWING CIRCLE…..38

SWING MACHINERY & MOTOR…..40

SWING MOTOR…..44

Operation of swing lock…..48

RELIEF VALVE PORTION…..49

Operation…..49

UNDERCARRIAGE…..50

TRANSMISSION…..52

ATT EPC VALVE ASSEMBLY…..55

QUICK COUPLER CONTROL VALVE…..56

TRAVEL MOTOR…..58

OPERATION OF TRAVEL MOTOR…..60

CLUTCH CONTROL CIRCUIT…..62

AXLE…..64

SUSPENSION LOCK CYLINDER…..68

BRAKING SYSTEM…..70

BRAKE/STEER PUMP…..72

PRIORITY VALVE…..73

POWER BRAKE VALVE…..74

SPECIFICATIONS…..74

FUNCTION…..75

ACCUMULATOR for brake system…..76

STEERING SYSTEM…..78

STEERING COLUMN…..79

ORBITROL VALVE…..80

HYDRAULIC EQUIPMENT LAYOUT DRAWINGS…..81

HYDRAULIC CIRCUIT DIAGRAM…..84

HYDRAULIC TANK…..85

HYDRAULIC PUMP…..86

HPV125…..86

LS VALVE…..91

PC VALVE…..91

LS(pc)-EPC VALVE…..104

PILOT PRESSURE CONTROL (PPC) SYSTEM…..107

CONTROL VALVE…..108

PW160-7E0…..108

CLSS…..118

OUTLINE OF CLSS…..118

CENTre SWIVEL JOINT…..139

TRAVEL PPC PEDAL…..140

WORK EQUIPMENT . SWING PPC VALVE…..142

SOLENOID VALVE MANIFOLD…..146

SOLENOID VALVE BLOCK…..147

2 Position 3 way valve…..147

2 Position 4 way valve…..149

attachment epc valve…..151

BOOM SAFETY VALVE…..154

HYDRAULIC CYLINDER…..157

BOOM CYLINDER…..157

ARM CYLINDER…..157

BUCKET CYLINDER…..157

ADJUST CYLINDER…..158

OUTRIGGER CYLINDER…..160

DOZER CYLINDER…..162

WORK EQUIPMENT…..164

Work Equipment…..165

1. DIMENSION OF ARM…..167

2. Dimension of bucket…..168

AIR CONDITIONER…..169

air conditioner piping…..169

ELECTRICAL WIRING DIAGRAM…..170

ELECTRICAL SYSTEM…..171

Engine Control…..171

Engine controller…..173

CN-CE01 (*: Never connect to NC as malfunctions and errors occur)…..174

CN-CE01 (*: Never connect to NC as malfunctions and errors occur)…..174

CN-CE02 (*: Never connect to NC as malfunctions and errors occur)…..175

CN-CE03(*: Never connect to NC as malfunctions and errors occur)…..175

Engine throttle and pump controller…..175

ELECTRONIC CONTROL SYSTEM…..178

machine control system diagram…..179

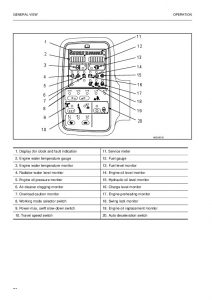

MACHINE MONITOR SYSTEM…..202

MONITOR PANEL…..204

LIQUID CRYSTAL MONITOR ADJUSTMENT SWITCH…..223

OVERLOAD WARNING DEVICE…..230

OUTLINE…..230

SENSOR…..231

1st ATTACHMENT CIRCUIT HYDRAULIC PERFORMANCE (MAIN…..240

TRAVEL SYSTEM…..242

TRAVEL CIRCUIT…..242

oPERATIONAL AND CONTROL FEATURES…..243

Operators Input via travel mode switch…..243

OVERRUN PROTECTION. This is dealt with through the action of the counterbalance spool in the motor control block.When the machin……243

STEERING SYSTEM…..264

Operating principles…..264

Dynamic Steering…..264

2 – stage principle…..264

SERVICE BRAKE AND SUSPENSION SYSTEM…..277

bRAKING SYSTEM…..277

operation…..280

KOMTRAX terminal system…..282

KOMTRAX terminal…..283

20 TESTING AND ADJUSTING…..285

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS…..286

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS…..287

Flow control characteristic of PC valve (STD)…..298

TESTING AND ADJUSTING…..299

Measuring engine speed…..300

Measuring intake air pressure (boost pressure)…..302

MEASUREMENT OF EXHAUST GAS COLOUR…..303

Adjusting valve clearance…..305

Measuring compression pressure…..307

MEASUREMENT OF BLOW-BY PRESSURE…..309

Measuring engine oil pressure…..310

CHECKING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION…..311

Replacing the fan belt…..312

Handling fuel system parts…..313

Releasing residual pressure from fuel system…..314

Measuring fuel pressure…..315

Measuring fuel discharge, return and leakage…..317

Bleeding air from fuel circuit…..321

Checking fuel circuit for leakage…..322

MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS…..323

INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWING AND TRAVEL…..324

INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE…..327

Procedure for pressure reducing adjustment…..328

INSPECTION AND ADJUSTMENT OF PUMP PC (Valve INLET) CONTROL OIL PRESSURE…..329

INSPECTION AND ADJUSTMENT OF PUMP LS valve CONTROL OIL PRESSURE…..332

MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE…..336

6 – Stage solenoid block…..338

4 – Stage solenoid block…..340

2 – Stage solenoid block…..341

MEASUREMENT OF PPC VALVE OUTPUT PRESSURE…..342

ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE…..344

Measuring and adjusting quick coupler control valve output pressure…..345

testing travel motor relief pressure…..346

adjusting travel motor relief pressure…..347

Testing propshaft speed…..348

TESTING TRANSMISSION CLUTCH CONTROL CIRCUIT…..349

INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT…..351

RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT…..353

MEASUREMENT OF OIL LEAKAGE AMOUNT…..354

AIR BLEEDING OF VARIOUS PARTS…..356

INSPECTION PROCEDURES FOR DIODE…..358

SPECIAL FUNCTION OF MONITOR PANEL…..359

OPERATION OF OPERATORS MENU AND DISPLAY (OUTLINE)…..361

TABLE FOR FAILURE CODE NO…..368

OPERATION AND DISPLAY OF SERVICE MENU…..371

Way of switching to Service Menu…..371

Table for Monitoring Items…..374

Procedure for turning on KOMTRAX terminal…..391

KOMTRAX terminal lamp indications…..394

Preparation work for troubleshooting of electrical system…..397

PM – Tune up service…..399

TROUBLESHOOTING…..403

POINTS TO REMEMBER WHEN TROUBLESHOOTING…..404

SEQUENCE OF EVENTS IN TROUBLESHOOTING…..405

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE…..406

CHECKS BEFORE TROUBLESHOOTING…..414

CLASSIFICATION AND STEPS FOR TROUBLESHOOTING…..415

Failure-looking Phenomenon and Troubleshooting No…..416

How to read electric wire code…..419

CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM…..422

CONNECTOR LOCATIONS…..430

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS…..451

TROUBLESHOOTING WHEN FAILURE CODE IS INDICATED…..485

Before carrying out troubleshooting when failure code is displayed…..487

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE…..488

Relative Electrical Circuit Diagram…..489

Failure code [CA111] EMC Critical Internal Failure…..490

Failure code [CA115] Engine Neutral and Backup Speed Sensor Error…..491

Failure code [CA122] Chg Air Press Sensor High Error…..492

Failure code [CA123] Chg Air Press Sensor Low Error…..494

Failure code [CA131] Throttle Sensor High Error…..496

Failure code [CA132] Throttle Sensor Low Error…..498

Failure code [CA144] Coolant Temp Sens High Error…..500

Failure code [CA145] Coolant Temp Sens Low Error…..502

Failure code [CA153] Chg Air Temp Sensor High Error…..504

Failure code [CA154] Chg Air Temp Sensor Low Error…..506

Failure code [CA155] Chg Air Temp High Speed Derate…..508

Failure code [CA187] Sens Supply 2 Volt Low Error…..510

Failure code [CA221] Ambient Press Sens High Error…..512

Failure code [CA222] Ambient Press Sens Low Error…..514

Failure code [CA227] Sens Supply 2 Volt High Error…..516

Failure code [CA238] Ne Speed Sens Supply Volt Error…..518

Failure code [CA271] IMV/PCV1 Short Error…..520

Failure code [CA272] IMV/PCV1 Open Error…..522

Failure code [CA322] Inj #1 (L#1) Open/Short Error…..524

Failure code [CA324] Inj #3 (L#3) Open/Short Error…..527

Failure code [CA331] Inj #2 (L#2) Open/Short Error…..530

Failure code [CA332] Inj #4 (L#4) Open/Short Error…..533

Failure code [CA342] Calibration Code Incompatibility…..536

Failure code [CA351] Injectors Drive Circuit Error…..537

Failure code [CA352] Sensor Supply 1 Volt Low Error…..540

Failure code [CA386] Sens Supply 1 Volt High Error…..542

Failure code [CA428] Water in Fuel Sensor High Error…..544

Failure code [CA429] Water in Fuel Sensor Low Error…..546

Failure code [CA435] Eng Oil Press Sw Error…..548

Failure code [CA441] Battery Voltage Low Error…..550

Failure code [CA442] Battery Voltage High Error…..553

Failure code [CA449] Rail Press Very High Error…..555

Failure code [CA451] Rail Press Sensor High Error…..556

Failure code [CA452] Rail Press Sensor Low Error…..558

Failure code [CA488] Chg Air Temp High Torque Derate…..560

Failure code [CA553] Rail Press High Error…..561

Failure code [CA559] Rail Press Low Error…..562

Failure code [CA689] Eng Ne Speed Sensor Error…..564

Failure code [CA731] Eng Bkup Speed Sens Phase Error…..567

Failure code [CA757] All Continuous Data Lost Error…..568

Failure code [CA778] Eng G Speed Sensor Error…..570

Failure code [CA1633] KOMNET Datalink Timeout Error…..574

Failure code [CA2185] Throttle Sensor Supply Voltage High Error…..576

Failure code [CA2186] Throttle Sensor Supply Voltage Low Error…..578

Failure code [CA2249] Rail Press Very Low Error…..580

Failure code [CA2311] IMV Solenoid Error…..582

Failure code [CA2555] Grid Htr Relay Volt High Error…..584

Failure code [CA2556] Grid Heater Relay Volt Low Error…..586

Failure Code [D110KB] (Short-circuiting in battery relay)…..588

Failure code [D862KA] GPS Antenna Disconnection…..590

Configuration diagram of KOMTRAX system…..590

Failure Code [DA22KK] (Abnormality in pump pressure sensor)…..592

Failure code [DA25KP] Press. Sensor Power Abnormality…..594

Failure code [DA2RMC] Pump Comm. Abnormality…..596

Failure Code [DA2SKQ] (Abnormality in inputting model code)…..598

Failure Code [DA2SKQ] (Abnormality in inputting model code)…..600

Failure code [DAFRMC] Monitor Comm. Abnormality…..602

Failure code [DDC3KZ] Outrigger Switch Select Abnormality…..604

Failure Code [DDP4KX] (Abnormality in travel PPC pressure switch)…..606

Failure Code [DDWCKZ] (Abnormality in travel direction control switch)…..608

Failure code [DFB1KZ] Service Lever Potentio 1 Abnormality…..610

Failure code [DFB2KZ] Service Lever Potentio 2 Abnormality…..613

Failure code [DFB3L8] Service Lever 1 Potentio Error…..616

Failure code [DFB4L8] Service Lever 2 Potentio Error…..617

Failure code [DGH2KB] Hydr Oil Sensor Short…..619

Failure Code [DH1OKS] (Abnormality in Pressure sensor power source)…..620

Failure code [DHPAMA] F Pump Press Sensor Abnormality…..622

Failure Code [DHS5KX] (Abnormality in travel PPC sensor)…..624

Failure Code [DHX1MA] (Abnormality in overload caution sensor)…..626

Failure Code [DLT4KA] (Disconnection in transmission speed sensor in pump controller system)…..628

Failure Code [DW27KA] (Disconnection in Transmission Clutch solenoid)…..630

Failure Code [DW27KB] (Short-circuiting in Transmission Clutch solenoid)…..632

Failure Code DW4AKA (Disconnection in suspension lock solenoid)…..634

Failure Code [DW4AKB] (Short circuiting in suspension lock solenoid)…..636

Failure Code [DW4CKA] (Disconnection in PPC lock solenoid)…..638

Failure code [DW4CKB] PPC Lock Sol. S/C…..640

Failure Code [DW4MKA] (Disconnection in Creep solenoid)…..642

Failure Code [DW4MKB] (Short-circuiting in Creep solenoid)…..644

Failure Code [DW44KA] (Disconnection of Travel F/R solenoid)…..646

Failure Code [DW44KB] (Short-circuiting of Travel F/R solenoid)…..648

Failure Code [DW45KA] (Disconnection in Swing Parking Brake solenoid)…..650

Failure code [DW45KB] Swing Brake Sol. S/C…..654

Failure Code [DW91KA] (Disconnection in Travel Neutral solenoid)…..656

Failure Code [DW91KB] (Short-circuiting in Travel Neutral Solenoid)…..658

Failure Code [DWK0KA] (Disconnection in 2-stage Relief solenoid)…..660

Failure Code [DWK0KB] (Short-circuiting in 2-Stage Relief Solenoid)…..662

Failure Code [DWK2KA] (Disconnection in 2-stage Back Pressure solenoid)…..664

Failure Code [DWK2KB] (Short circuiting in 2-stage back pressure solenoid)…..666

Failure Code [DXA0KA] (Disconnection in PC-EPC solenoid system)…..668

Failure Code [DXA0KB] (Short-circuiting in PC-EPC solenoid)…..670

Failure Code [DXE0KA] (Disconnection in LS-EPC solenoid system)…..672

Failure Code [DXE0KB] (Short-circuiting in LS-EPC solenoid)…..674

Failure code [DXE4KA] Service Current EPC1 Discon…..676

Failure code [DXE4KB] Service Current EPC1 Short…..678

Failure code [DXE7KA] Service Current EPC2 Discon…..680

Failure code [DXE7KB] Service Current EPC2 Short…..682

Failure code [DXE8KA] Service Current EPC3 Discon…..684

Failure code [DXE8KB] Service Current EPC3 Short…..686

Failure code [DXE9KA] Service Current EPC4 Discon…..688

Failure code [DXE9KB] Service Current EPC4 Short…..690

Failure code [DY20KA] Wiper Working Abnormality…..692

Failure code [DY20MA] Wiper Parking Abnormality…..694

Failure code [DY2CKB] Washer Drive S/C…..696

Failure code [DY2DKB] Wiper Drive (For) S/C…..698

Failure code [DY2EKB] Wiper Drive (Rev) S/C…..700

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E-MODE)…..703

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE…..704

E-1 Engine does not start (Engine does not rotate)…..706

E-5 Auto-decelerator does not work…..711

E-6 Auto engine warm-up device does not work…..713

E-7 Preheater does not operate…..714

E-8 All work equipment, swing and travel do not move…..716

E-9 One-touch Power Max Switch does not work…..718

E-10 No display in monitor panel at all…..719

E-11 Part of display on monitor panel is missing…..720

E-12 Monitor panel displays contents irrelevant to the model…..720

E-13 Fuel level monitor red lamp lights up while engine is running…..721

E-14 Engine coolant temperature gauge does not indicate normally…..722

E-15 Hydraulic oil temperature gauge does not display correctly…..724

E-16 Fuel gauge does not display correctly…..725

E-17 Swing lock monitor does not display correctly…..726

E-18 When the monitor switch is operated, no display appears…..728

E-19 Windshield wiper and window washer do not operate…..729

E-20 Alarm buzzer cannot be stopped…..731

E-21 "Boom/Stabiliser RAISE" is not correctly displayed in monitor function…..732

E-22 "Boom/Stabiliser LOWER" is not correctly displayed in monitor function…..733

E-23 "Arm DIGGING" is not correctly displayed in monitor function…..734

E-24 "Arm DUMPING" is not correctly displayed in monitor function…..735

E-25 "Bucket DIGGING" is not correctly displayed in monitor function…..736

E-26 "Bucket DUMPING" is not correctly displayed in monitor function…..737

E-27 "SWING" is not correctly displayed in monitor function…..738

E-28 "TRAVEL" is not correctly displayed in monitor function…..740

E-29 "2 Piece Boom" is not correctly displayed in monitor function…..742

E-30 Air Conditioner does not work…..744

E-31 Travel reverse alarm does not sound…..746

E-32 KOMTRAX system does not operate normally…..748

TROUBLESHOOTING OF ELECTRICAL SYSTEM (Error checking of items without Monitor codes)…..751

Relative Electrical Circuit Diagram…..753

Radio Cassette & Telephone Socket…..754

Electrical Circuit Diagram For Radio Cassette & Telephone Socket…..755

PPC Lock Circuit…..756

Circuit Diagram for PPC Lock Circuit…..757

Brake Light Circuit…..758

Circuit Diagram for Brake Light Circuit…..759

Undercarriage Attachments – Mode Selection…..760

Circuit Diagram for Undercarriage Attachments – Mode Selection…..761

Undercarriage Attachments – Front Left Outrigger…..762

Circuit Diagram for Undercarriage Attachments – Front Left Outrigger…..763

Undercarriage Attachments – Front Right Outrigger…..764

Circuit Diagram for Undercarriage Attachments – Front Right Outrigger…..765

Undercarriage Attachments – Rear Left Outrigger…..766

Undercarriage Attachments – Rear Right Outrigger…..768

Circuit Diagram for Undercarriage Attachments – Rear Right Outrigger…..769

Heated Seat Does Not Warm Up…..770

Circuit Diagram for the Heated Seat…..771

Suspension Lock…..772

Circuit Diagram for Suspension Lock…..773

Lower Wiper Does Not Work (Optional Fitment)…..774

Circuit Diagram for Lower Wiper…..775

Work Lights (Operator Cab Front Left)…..776

Work Lights (Operator Cab Front Right)…..777

Work Lights (Operator Cab Rear)…..778

Circuit Diagram for Work Lights…..779

Worklights (Boom, Arm & Counterweight)…..780

Circuit Diagram for Worklights (Boom & Counterweight)…..781

Cab and Counterweight Beacon Light…..782

Circuit Diagram for Cab & Counterweight Beacon Light…..783

Air Seat Compressor (Option – Air Suspension Seat)…..784

Circuit Diagram for Air Seat Compressor (Option – Air Suspension Seat)…..785

Operator Cab Interior Light…..786

Circuit Diagram for Operator Cab Interior Light…..787

Cigar Lighter…..788

Circuit Diagram for Cigar Lighter…..789

Park Brake (Not Activating)…..790

Circuit Diagram for Park Brake…..791

Park Brake (Displayed Symbol)…..792

Circuit Diagram for Park Brake…..793

RH PPC Lever Clamshell Roller Switch Pushed to the LH Position…..794

Circuit Diagram for Clamshell Control…..795

RH PPC Lever Clamshell Roller Switch Pushed to the RH Position…..796

Circuit Diagram for Clamshell Control…..797

RH PPC Lever Clamshell Roller Switched Pushed to the RH or LH…..798

Circuit Diagram for Clamshell Control…..799

Horns…..800

Circuit Diagram for Horn…..801

Swing Lock – Normal Operation…..802

Circuit Diagram for Swing Lock…..803

Swing Lock – Emergency Operation…..804

Circuit Diagram for Swing Lock – Emergency Operation…..805

Neutral Start (Engine)…..806

Neutral Start (Engine) contd (A)…..807

Neutral Start (Engine) contd (B)…..808

Neutral Start (Engine) contd (C)…..809

Circuit Diagram for Neutral Start (Engine)…..810

Emergency Travel Control – Forward…..811

Circuit Diagram for Travel Direction Control…..812

Emergency Travel Control – Neutral…..813

Circuit Diagram for Travel Direction Control…..814

Emergency Travel Control – Reverse…..815

Emergency Travel Control – Reverse contd…..816

Circuit Diagram for Travel Direction Control…..817

Driving Lights – Main Beam…..818

Circuit Diagram for Driving Lights…..819

Driving Lights – Main Beam Flash…..820

Circuit Diagram for Driving Lights…..821

Driving Lights – Main Beam Dipped…..822

Circuit Diagram for Driving Lights…..823

Driving Lights – Position Lights…..824

Circuit Diagram for Driving Lights…..825

Driving Lights – Position Lights contd (1) and (2)…..826

Circuit Diagram for Driving Lights…..827

Indicators – Right Hand…..828

Circuit Diagram for Indicators & Hazard Warning…..829

Indicators – Left Hand…..830

Circuit Diagram for Indicators & Hazard Warning…..831

Hazard Warning Lights…..832

Circuit Diagram for Indicators & Hazard Warning…..833

Hazard Warning Lights contd (A)…..834

Circuit Diagram for Indicators & Hazard Warning…..835

Swing Lock Proximity Switch…..836

Brake and Swing Lock Proximity Switches…..837

TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H-MODE)…..839

SYSTEM CHART FOR HYDRAULIC AND MECHANICAL SYSTEMS…..840

INFORMATION CONTAINED IN TROUBLESHOOTING TABLE…..844

Quick coupler…..863

30 DISASSEMBLY AND ASSEMBLY…..865

HOW TO READ THIS MANUAL…..869

REMOVAL AND INSTALLATION OF ASSEMBLIES…..869

DisassemblY and assemblY OF assemblIES…..870

SPECIAL TOOLS…..875

SKETCHES…..875

LIST OF TOOLS…..876

PRECAUTIONS WHEN PERFORMING OPERATION…..880

STARTING MOTOR ASSEMBLY…..882

FUEL Supply PUMP assembly…..883

FUEL INJECTOR ASSEMBLY…..886

FRONT OIL SEAL…..891

REAR OIL SEAL…..893

CYLINDER HEAD ASSEMBLY…..896

COMBINATION COOLER…..906

FUEL COOLER ASSEMBLY…..909

ENGINE AND HYDRAULIC PUMP ASSEMBLIES…..910

TRAVEL MOTOR ASSEMBLY…..917

TRAVEL MOTOR ASSEMBLY…..919

SWING MOTOR AND SWING MACHINERY ASSEMBLY…..923

SWING MACHINERY ASSEMBLY…..924

SWING MOTOR ASSEMBLY…..932

FRONT AXLE ASSEMBLY…..941

FRONT AXLE ASSEMBLY…..943

REAR AXLE AND TRANSMISSION ASSEMBLY…..992

REAR AXLE ASSEMBLY…..995

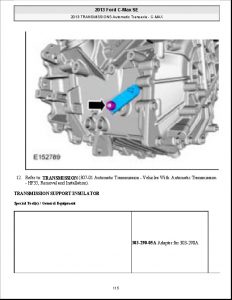

TRANSMISSION ASSEMBLY…..1025

PROPSHAFT ASSEMBLY…..1054

WHEEL ASSEMBLY…..1056

SUSPENSION LOCK CYLINDER ASSEMBLY…..1057

SUSPENSION LOCK CYLINDERS ASSEMBLY…..1058

OUTRIGGER ASSEMBLY…..1059

OUTRIGGER ASSEMBLY…..1060

DOZER BLADE…..1061

DOZER BLADE ASSEMBLY…..1062

SWING CIRCLE ASSEMBLY…..1063

REVOLVING FRAME ASSEMBLY…..1064

CENTRE SWIVEL JOINT ASSEMBLY…..1067

CENTRE SWIVEL JOINT ASSEMBLY…..1070

HYDRAULIC TANK ASSEMBLY…..1072

FUEL TANK ASSEMBLY…..1076

CONTROL VALVE ASSEMBLY…..1078

LS SEPARATION VALVE ASSEMBLY…..1082

PRESSURE COMPENSATION VALVE ASSEMBLY…..1083

MAIN RELIEF VALVE ASSEMBLY…..1084

LS CONTROL EPC VALVE ASSEMBLY…..1085

EPC SOLENOID VALVE ASSEMBLY…..1086

4 STATION PPC SOLENOID VALVE BLOCK ASSEMBLY…..1087

MANIFOLD BLOCK ASSEMBLY…..1089

OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT…..1090

WORK EQUIPMENT PPC VALVE ASSEMBLY…..1091

HYDRAULIC CYLINDER ASSEMBLY…..1092

MONOBOOM WORK EQUIPMENT ASSEMBLY…..1098

2 PIECE BOOM WORK EQUIPMENT ASSEMBLY…..1101

AIR CONDITIONER UNIT ASSEMBLY…..1104

COUNTERWEIGHT ASSEMBLY…..1108

OPERATOR CAB ASSEMBLY…..1110

MONITOR ASSEMBLY…..1113

GOVERNOR / PUMP CONTROLLER ASSEMBLY…..1114

KOMTRAX TERMINAL…..1115

ENGINE CONTROLLER…..1116

90 OTHERS…..1117

Mono boom…..1118

Two plece boom…..1119

Hydraulic circuit diagram 1/3…..1121

Hydraulic circuit diagram 2/3…..1123

Hydraulic circuit diagram 3/3…..1125

Electrical circuit diagram 1/7…..1127

Electrical circuit diagram 2/7…..1129

Electrical circuit diagram 3/7…..1131

Electrical circuit diagram 4/7…..1133

Electrical circuit diagram 5/7…..1135

Electrical circuit diagram 6/7…..1137

Electrical circuit diagram 7/7…..1139

Komatsu Wheeled Excavator PW160-7E0 Repair Service Manuals