Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavators PC78MR, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Hydraulic Excavators PC78MR workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM030601 – Hydraulic Excavator PC78MR-6 Shop Manual.pdf

SEBM030604 – Hydraulic Excavator PC78MR-6 Shop Manual.pdf

TEN00032-00 – Hydraulic Excavator GALEO PC78MR-6 Operation & Maintenance Manual.pdf

TEN00074-00 – Hydraulic Excavator GALEO PC78MR-6 Operation & Maintenance Manual.pdf

TEN00202-00 – Hydraulic Excavator GALEO PC78MR-6 Operation & Maintenance Manual.pdf

TEN00288-00 – Hydraulic Excavator PC78MR-6 Operation & Maintenance Manual.pdf

Total Pages: 2,361 pages

File Format: PDF

Language: English

SEBM030601 – Hydraulic Excavator PC78MR-6 Shop Manual….2

SEBM030604 – Hydraulic Excavator PC78MR-6 Shop Manual….594

COVER….594

CONTENTS….595

SAFETY….599

SAFETY NOTICE….599

FOREWARD….601

GENERAL….601

HOW TO READ THE SHOP MANUAL….602

HOISTING INSTRUCTIONS….603

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER….604

COATING MATERIALS….606

STANDARD TIGHTENING TORQUE….608

ELECTRIC WIRE CODE….611

CONVERSION TABLE….612

UNITS….618

01 GENERAL….620

SPECIFICATION DIMENSIONS DRAWING….621

WORKING RANGE DRAWING….623

SPECIFICATIONS….624

WEIGHT TABLE….627

LIST OF LUBRICANTS AND COOLANT….629

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD….631

PTO ….632

COOLING SYSTEM….633

POWER TRAIN SYSTEM….634

SWING CIRCLE….635

SWING MACHINERY….636

TRACK FRAME AND IDLER CUSHION….638

IDLER….640

TRACK ROLLER….641

CARRIER ROLLER….643

SPROCKET….644

TRACK SHOE….645

ARRANGEMENT OF HYDRAULIC COMPONENTS….650

HYDRAULIC TANK AND OIL FILTER….651

CENTER SWIVEL JOINT….652

TRAVEL MOTOR….653

WORK EQUIPMENT CYLINDER….661

SOLENOID VALVE….665

SOLENOID VALVE (FOR EU SPEC.)….673

ACCUMULATOR FOR PPC….677

MULTI-CONTROL VALVE….678

ACCUMULATOR FOR BRAKER….679

HYDRAULIC PUMP….680

CONTROL VALVE….694

CLSS….706

SWING MOTOR….738

WORK EQUIPMENT AND SWING PPC VALVE….746

TRAVEL PPC VALVE….752

BOOM SWING PPC VALVE, BLADE PPC VALVE….756

BOOM HYDRAULIC ANTI-BURST VALVE (FOR EU SPEC)….760

WORK EQUIPMENT….766

DIMENSIONS OF EACH PART OF WORK EQUIPMENT….768

AIR CONDITIONER PIPING (OPTIONAL)….772

ELECTRIC CONTROL SYSTEM….773

SYSTEM COMPONENTS….793

MONITOR SYSTEM….802

SENSORS….807

20 TESTING AND ADJUSTING….810

STANDARD VALUE TABLE FOR ENGINE….811

STANARD VALUE TABLE FOR CHASSIS….812

STANDARD VALUE TABLE FOR ELECTRIC PARTS….820

TESTING AND ADJUSTING….826

LIST OF DEVICES FOR TESTING, ADJUSTING, AND TROUBLESHOOTING….827

MEASURING ENGINE SPEED….828

MEASURING EXHAUST GAS COLOR….829

ADJUSTING VALVE CLEARANCE….830

MEASURING COMPRESSION PRESSURE….831

MEASURING BLOW-BY PRESSURE….832

TESTING AND ADJUSTING FUEL INJECTION TIMING….833

MEASURING ENGINE OIL PRESSURE….837

ADJUSTING ENGINE STOP SOLENOID….838

ADJUSTING FUEL CONTROL LINKAGE….840

ADJUSTING ENGINE SPEED SENSOR….842

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS….843

MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE….846

ADJUSTING PC VALVE….848

TESTING TVC-EPC SOLENOID OUTPUT PRESSURE….848

MEASURING CONTROL CIRCUIT PRESSURE….849

MEASURING PPC VALVE OUTPUT PRESSURE….850

TESTING SOLENOID VALVE OUTPUT PRESSURE….851

ADJUSTING WORK EQUIPMENT VALVE AND SWING PPC VALVE….853

TESTING TRAVEL DEVIATION….854

TESTING PARTS WHICH CAN CAUSE HYDRAULIC DRIFT OF WORK EQUIPMENT….856

MEASURING OIL LEAKAGE FROM SWING AND TRAVEL MOTORS….857

RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT….858

TESTING CLEARANCE OF SWING CIRCLE BEARING….859

TESTING AND ADJUSTING TRACK SHOE TENSION….860

BLEEDING AIR FROM HYDRAULIC CIRCUIT….861

REPLACEMENT PROCEDURE OF POTENTIOMETERS….863

PROCEDURE FOR TESTING DIODE….864

TROUBLESHOOTING….866

POINTS TO REMEMBER WHEN TROUBLESHOOTING….867

SEQUENCE OF EVENTS IN TROUBLESHOOTING….868

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE….869

CHECKS BEFORE TROUBLESHOOTING….877

TYPE AND LOCATION OF CONNECTORS….879

CONNECTOR ARRANGEMENT DIAGRAM….881

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS….884

EXPLANATION OF FUNCTIONS OF ELECTRIC SYSTEM CONTROL MECHANISM….907

DISPLAY AND SPECIAL FUNCTIONS OF MONITOR PANEL….908

TVC VALVE CURRENT ADJUSTMENT TABLE….919

METHOD OF USING JUDGEMENT TABLE….920

HOW TO READ FLOW OF TROUBLESHOOTING….922

CONTENTS AND PROCEDURE OF TROUBLESHOOTING….924

TROUBLESHOOTING OF ENGINE (S MODE)….925

METHOD OF USING TROUBLESHOOTING CHART….926

S-1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)….930

S-2 ENGINE DOES NOT START….932

1) ENGINE DOES NOT TURN….932

2) ENGINE TURNS BUT NO EXHAUST SMOKE COMES OUT (FUEL IS NOT BEING INJECTED)….933

3) EXHAUST SMOKE COMES OUT BUT ENGINE DOES NOT START (FUEL IS BEING INJECTED)….934

S-3 ENGINE DOES NOT PICK UP SMOOTHLY (FOLLOW UP IS POOR)….935

S-4 ENGINE STOPS DURING OPERATIONS….936

S-5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)….937

S-6 ENGINE LACKS OUTPUT (OR LACKS POWER)….938

S-7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)….939

S-8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)….940

S-9 OIL BECOMES CONTAMINATED QUICKLY….941

S-10 FUEL CONSUMPTION IS EXCESSIVE….942

S-11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN….943

S-12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)….944

S-13 OIL LEVEL RISES (WATER, FUEL IN OIL)….945

S-14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)….946

S-15 ABNORMAL NOISE IS MADE….947

S-16 VIBRATION IS EXCESSIVE….948

TROUBLESHOOTING OF COMMUNICATION SYSTEM (N MODE)….949

N-1 DEFECTIVE COMMUNICATION….950

TROUBLESHOOTING FOR CONTROLLER (GOVERNOR CONTROL SYSTEM) (E MODE)….951

PRECAUTIONS FOR TROUBLESHOOTING FOR CONTROLLER (GOVERNOR CONTROL SYSTEM)….952

ACTION TAKEN BY CONTROLLER WHEN TROUBLE OCCURS AND PROBLEMS ON MACHINE….954

JUDGEMENT TABLE FOR CONTROLLER (GOVERNOR CONTROL SYSTEM) AND ENGINE….956

E-1 CONTROLLER POWER SUPPLY IS DEFECTIVE (LED OF CONTROLLER IS TURNED OFF)….958

E-2 [E323] (SHORT CIRCUIT IN ACCELERATOR RELAY SYSTEM) IS DISPLAYED….959

E-3 [E325] (SHORT CIRCUIT IN DECELERATOR RELAY SYSTEM) IS DISPLAYED….960

E-4 [E328] (STALL OF MOTOR) IS DISPLAYED….961

E-5 [E227] (TROUBLE IN ENGINE SPEED SENSOR) IS DISPLAYED….963

E-6 ONE TOUCH SLOW DOWN MECHANISM DOES NOT WORK….964

E-7 ENGINE DOES NOT START….965

a) [E304] SHORT CIRCUIT IN ENGINE STOP SOLENOID RELAY SYSTEM IS DISPLAYED….965

b) [E314] DISCONNECTION IN ENGINE STOP SOLENOID RELAY SYSTEM IS DISPLAYED….965

c) ENGINE STOP SOLENOID SYSTEM….966

d) STARTING SYSTEM….968

E-8 ENGINE DOES NOT STOP….972

TROUBLESHOOTING FOR CONTROLLER PUMP CONTROL SYSTEM (C MODE)….973

PRECAUTIONS FOR TROUBLESHOOTING FOR CONTROLLER (PUMP CONTROL SYSTEM)….974

ACTION TAKEN BY CONTROLLER WHEN TROUBLE OCCURS AND PROBLEMS ON MACHINE….976

JUDGEMENT TABLE FOR CONTROLLER (PUMP CONTROL SYSTEM) AND HYDRAULIC EQUIPMENT….980

ELECTRIC CIRCUIT DIAGRAM OF C MODE SYSTEM (FOR STD. SPEC)….982

ELECTRIC CIRCUIT DIAGRAM OF C MODE SYSTEM (FOR EU SPEC)….984

C-1 [E232], C-2 [E233] TROUBLE IN TVC-EPC SOLENOID SYSTEM….986

C-3 [E203], C-4 [E213] TROUBLE IN SWING HOLDING BRAKE SOLENOID SYSTEM….987

C-5 [E206], C-6 [E216] TROUBLE IN 2ND TRAVEL SPEED SELECTION SOLENOID SYSTEM….988

C-7 [E411] TROUBLE IN BOOM SWING ANGLE SENSOR CORRECTION….989

C-8 [E251] TROUBLE IN BOOM BOTTOM PRESSURE SENSOR (OVERLOAD SENSOR) SYSTEM (FOR EU SPEC)….990

C-9 [E258] SHORT CIRCUIT IN 5V SYSTEM OF SENSOR POWER SUPPLY (FOR EU SPEC)….990

C-9 [E258] SHORT CIRCUIT IN 5V SYSTEM OF SENSOR POWER SUPPLY (FOR STD SPEC)….991

C-10 [E412], C-11 [E413] TROUBLE IN BOOM SWING ANGLE SENSOR SYSTEM….992

C-12 [E451] SHORT CIRCUIT IN BOOM SWING LEFT STOP EPC SOLENOID SYSTEM IS DISPLAYED….993

C-13 [E452] DISCONNECTION IN BOOM SWING LEFT STOP EPC SOLENOID SYSTEM IS DISPLAYED….994

C-14 [E453] SHORT CIRCUIT IN BOOM SWING RIGHT STOP EPC SOLENOID SYSTEM IS DISPLAYED….995

C-15 [E454] DISCONNECTION IN BOOM SWING RIGHT STOP EPC SOLENOID SYSTEM IS DISPLAYED….996

C-16 BOOM SWING LEFTT END CUSHION DOES NOT WORK AT ALL OR NORMALLY….997

C-17 BOOM SWING RIGHT END CUSHION DOES NOT WORK AT ALL OR NORMALLY….999

C-18 WORK EQUIPMENT STILL MOVES AFTER WORK EQUIPMENT LOCK LEVER IS SET TO LOCK….1001

C-19 MACHINE DOES NOT SWING….1002

C-20 TRAVEL SPEED DOES NOT RISE….1003

C-21 TROUBLE IN CONTROLLER POWER SUPPLY (LED OF CONTROLLER IS TURNED OFF)….1003

TROUBLESHOOTING FOR CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE)….1004

F-1 BIT PATTERN 1023-(4) SWING PRESSURE SWITCH DOES NOT LIGHT UP….1005

F-2 BIT PATTERN 1023-(3) TRAVEL PRESSURE SWITCH DOES NOT LIGHT UP….1006

F-3 BIT PATTERN 1023-(6) BOOM RAISE PRESSURE SWITCH DOES NOT LIGHT UP….1007

F-4 BIT PATTERN 1023-(5) ARM IN PRESSURE SWITCH DOES NOT LIGHT UP….1008

F-5 BIT PATTERN 1026-(1) DECELERATION SWITCH OF LEFT KNOB DOES NOT LIGHT UP….1009

F-6 BIT PATTERN 1026-(4) 2ND TRAVEL SPEED SELECTION SWITCH (PEDAL) DOES NOT LIGHT UP….1010

F-7 BIT PATTERN 1021-(3) COMPRESSOR SIGNAL DOES NOT LIGHT UP….1011

TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)….1012

TABLE OF HYDRAULIC FAILURE MODES AND THEIR CAUSES….1015

H-1 SPEED OR POWER OF 2 OR MORE SYSTEMS OF WORK EQUIPMENT (BOOM, ARM, BUCKET) TRAVEL, SWING, AND BLADE IS LOW….1017

a) SPEED OR POWER OF WORK EQUIPMENT (INCLUDING BLADE), TRAVEL, AND SWING SYSTEMS IS LOW….1017

b) SPEED OR POWER OF ALL WORK EQUIPMENT (EXCLUDING BLADE) AND TRAVEL IS LOW….1018

c) SPEED OR POWER OF SWING AND BLADE IS LOW….1018

d) SPEED OR POWER OF TRAVEL AND BLADE IS LOW….1019

e) SPEED OR POWER OF ALL WORK EQUIPMENT (EXCLUDING BLADE) IS LOW….1019

f) SPEED OR POWER OF TRAVEL AND SWING IS LOW….1019

H-2 ENGINE SPEED LOWERS EXTREMELY OR ENGINE STALLS….1020

H-3 2 OR MORE SYSTEMS OF WORK EQUIPMENT (BOOM, ARM, BUCKET), TRAVEL, SWING, AND BLADE DO NOT MOVE….1022

a) ALL WORK EQUIPMENT (INCLUDING BLADE), TRAVEL, AND SWING SYSTEMS DO NOT MOVE….1022

b) ALL WORK EQUIPMENT (EXCLUDING BLADE) AND TRAVEL SYSTEMS DO NOT MOVE….1023

c) SWING AND BLADE SYSTEMS DO NOT MOVE….1023

d) TRAVEL AND BLADE SYSTEMS DO NOT MOVE….1024

e) ALL WORK EQUIPMENT (EXCLUDING BLADE) DOES NOT MOVE….1024

H-4 ABNORMAL SOUND COMES OUT (FROM AROUND PUMP)….1025

H-5 FINE CONTROLLABILITY OR RESPONSE IS LOW….1026

H-6 HYDRAULIC DRIFT IS LARGE (ALL WORK EQUIPMENT AND BLADE)….1027

H-7 BOOM SPEED OR POWER IS LOW (OTHER WORK EQUIPMENT IS NORMAL)….1028

a) BOOM RAISE SPEED OR POWER IS LOW….1028

b) BOOM LOWER SPEED OR POWER IS LOW….1029

H-8 ARM SPEED OR POWER IS LOW (OTHER WORK EQUIPMENT IS NORMAL)….1030

a) ARM IN SPEED OR POWER IS LOW….1030

b) ARM OUT SPEED OR POWER IS LOW….1031

H-9 BUCKET SPEED OR POWER IS LOW (OTHER WORK EQUIPMENT IS NORMAL)….1032

a) BUCKET CURL SPEED OR POWER IS LOW….1032

b) BUCKET DUMP SPEED OR POWER IS LOW….1033

H-10 BOOM SWING SPEED OR POWER IS LOW (OTHER WORK EQUIPMENT IS NORMAL)….1034

a) SWING LEFT SPEED OR POWER IS LOW….1034

b) SWING RIGHT SPEED OR POWER IS LOW….1035

H-11 BOOM DOES NOT MOVE….1036

a) BOOM DOES NOT RISE….1036

b) BOOM DOES NOT LOWER….1037

H-12 ARM DOES NOT MOVE….1038

a) ARM DOES NOT MOVE IN….1038

b) ARM DOES NOT MOVE OUT….1039

H-13 BUCKET DOES NOT MOVE….1040

a) BUCKET DOES NOT CURL….1040

b) BUCKET DOES NOT DUMP….1041

H-14 BOOM SWING DOES NOT MOVE….1042

a) BOOM SWING LEFT DOES NOT MOVE….1042

b) BOOM SWING RIGHT DOES NOT MOVE….1043

H-15 HYDRAULIC DRIFT OF BOOM IS LARGE….1044

H-16 HYDRAULIC DRIFT OF ARM IS LARGE….1044

H-17 HYDRAULIC DRIFT OF BUCKET IS LARGE….1045

H-18 HYDRAULIC DRIFT OF SWING IS LARGE….1045

a) HYDRAULIC DRIFT OF SWING TO LEFT IS LARGE….1045

b) HYDRAULIC DRIFT OF SWING TO RIGHT IS LARGE….1045

H-19 TIME LAG IS LARGE (WHEN ENGINE SPEED IS LOW)….1046

H-20 PART LOADED MORE MOVES SLOWER IN COMPOUND OPERATION OF WORK EQUIPMENT….1046

H-21 BOOM RAISE SPEED IS LOW IN COMPOUND OPERATION OF SWING AND BOOM RAISE….1047

H-22 TRAVEL SPEED LOWERS EXTREMELY IN COMPOUND OPERATION OF TRAVEL AND BOOM RAISE….1047

H-23 SPEED IS LOW IN COMPOUND OPERATION OF WORK EQUIPMENT RELIEF AND SWING, WORK EQUIPMENT RELIEF AND OTHER WORK EQUIPMENT….1047

H-24 TRAVEL DEVIATION IS LARGE….1048

a) TRAVEL DEVIATION IS LARGE DURING ORDINARY TRAVEL….1048

b) TRAVEL DEVIATION IS LARGE WHEN MACHINE STARTS (BUT NORMAL DURING ORDINARY TRAVEL)….1049

H-25 TRAVEL DEVIATION IS LARGE IN COMPOUND OERATION OF TRAVEL AND SWING, TRAVEL AND WORK EQUIPMENT….1050

H-26 TRAVEL SPEED OR POWER IS LOW (WORK EQUIPMENT, SWING, AND BLADE OPERATIONS ARE NORMAL)….1051

H-27 MACHINE CANNOT BE STEERED SHARPLY OR STEERING FORCE IS INSUFFICIENT….1053

H-28 TRAVEL SPEED DOES NOT CHANGE AT ALL OR DOES NOT CHANGE QUICKLY….1054

H-29 MACHINE DOES NOT TRAVEL….1055

H-29 SUPPLEMENT….1056

H-30 OVERRUN OF TRAVEL IS LARGE….1057

H-31 TRAVEL HYDRAULIC DRIFT IS LARGE….1057

H-32 FINE CONTROLLABILITY OR RESPONSE IS LOW….1058

H-33 SWING SPEED OR POWER IS LOW (WORK EQUIPMENT, TRAVEL, AND BLADE OPERATIONS ARE NORMAL)….1059

H-34 MACHINE DOES NOT SWING (WORK EQUIPMENT, TRAVEL, AND BLADE OPERATIONS ARE NORMAL)….1061

a) SWING SPEED OR POWER IS LOW IN BOTH DIRECTIONS….1061

b) SWING SPEED OR POWER IS LOW IN EITHER DIRECTION….1062

H-35 SWING ACCELERATION IS LOW….1063

a) SWING ACCELERATION IS LOW IN BOTH DIRECTIONS….1063

b) SWING ACCELERATION IS LOW IN EITHER DIRECTION….1063

H-36 OVERRUN OF SWING IS LARGE….1064

a) OVERRUN OF SWING IS LARGE IN BOTH DIRECTIONS….1064

b) OVERRUN OF SWING IS LARGE IN EITHER DIRECTION….1064

H-37 LARGE SHOCK IS MADE WHEN MACHINE STOPS SWINGING….1065

H-38 LARGE ABNORMAL SOUND IS MADE WHEN MACHINE STOPS SWINGING….1065

H-39 SWING HYDRAULIC DRIFT IS LARGE….1066

H-40 FINE CONTROLLABILITY OR RESPONSE OF SWING IS LOW….1067

H-41 BLADE SPEED OR POWER IS LOW (WORK EQUIPMENT, TRAVEL, AND SWING OPERATIONS ARE NORMAL)….1068

H-42 BLADE DOES NOT MOVE (WORK EQUIPMENT, TRAVEL, AND SWING OPERATIONS ARE NORMAL)….1069

a) BLADE DOES NOT RISE….1069

b) BLADE DOES NOT LOWER….1070

H-43 HYDRAULIC DRIFT OF BLADE IS LARGE….1071

H-44 FINE CONTROLLABILITY OR RESPONSE OF BLADE IS LOW….1072

TROUBLESHOOTING FOR MACHINE MONITOR SYSTEM (M MODE)….1074

ACTION TAKEN BY CONTROLLER WHEN TROUBLE OCCURS AND PROBLEMS ON MACHINE….1075

ELECTRIC CIRCUIT DIAGRAM OF M MODE SYSTEM….1077

M-1 [E101] (ERROR HISTORY DATA ARE ABNORMAL) IS DISPLAYED….1079

M-2 [E108] (ENGINE COOLANT TEMPERATURE IS 105 DEGREES C) IS DISPLAYED….1080

M-3 [E112] (WIPER FORWARD OUTPUT IS SHORTED) IS DISPLAYED….1080

M-4 [E113] (WIPER REVERSE OUTPUT IS SHORTED) IS DISPLAYED….1080

M-5 [E114] (CONTACT WITH WASHER OUTPUT OF 24V) IS DISPLAYED….1080

M-6 [E115] (WIPER DOES NOT START WIPING IN 10 SECONDS) IS DISPLAYED….1080

M-7 [E116] (WIPER IS NOT RETRACTED IN 10 SECONDS) IS DISPLAYED….1080

M-8 MONITOR PANEL SEGMENTS DO NOT LIGHT UP AT ALL FOR 3 SECONDS AFTER STARTING SWITCH IS TURNED ON….1081

a) MONITOR PANEL SEGMENTS DO NOT LIGHT UP AT ALL….1081

b) SOME MONITOR PANEL SEGMENTS DO NOT LIGHT UP….1081

M-9 WHEN STARTING SWITCH IS SET TO ON POSITION, ALL MONITOR PANEL SEGMENTS LIGHT UP BUT DO NOT GO OFF….1083

M-10 WHILE PREHEATING IS NOT EXECUTED, "PREHEATER MONITOR" LIGHTS UP….1083

M-11 WHEN STARTING SWITCH IS SET TO ON POSITION AND ENGINE IS STARTED, BASIC CHECK ITEMS FLASH….1084

a) ALTERNATOR SYSTEM….1084

b) ENGINE OIL SYSTEM….1085

M-12 WHEN STARTING SWITCH IS SET TO ON POSITION (BUT ENGINE IS STOPPED), CAUTION ITEMS (EXCLUDING BATTERY AND ENGINE OIL) FLASH….1086

a) ALTERNATOR SYSTEM….1086

b) ENGINE OIL PRESSURE SENSOR SYSTEM….1087

M-13 WHEN STARTING SWITCH IS SET TO ON POSITION AND ENGINE IS STARTED, CAUTION ITEMS AND EMERGENCY STOP ITEMS FLASH (WHEN THERE IS NOT ABNORMALITY IN INSPECTION ITEMS AND ENGINE BEFORE TROUBLESHOOTING, HOWEVER)….1088

a) "ENGINE OIL" FLASHES….1088

b) "CHARGE LEVEL" FLASHES….1088

c) "COOLANT TEMPERATURE" FLASHES….1089

d) "FUEL LEVEL" FLASHES….1090

M-14 WHEN STARTING SWITCH IS SET TO ON POSITION (BUT ENGINE IS STOPPED), BUZZER DOES NOT SOUND FOR 1 SECOND WHILE CAUTION ITEM IS FLASHING, BUZZER DOES NOT SOUND….1091

M-15 MONITOR PLANE LAMP FOR NIGHTTIME IS NOT TURNED ON (LC DISPLAY IS NORMAL)….1092

M-16 COOLANT TEMPERATURE GAUGE DOES NOT RISE….1093

M-17 COOLANT TEMPERATURE GAUGE IS NOT DISPLAYED (GAUGE DOES NOT RISE TO 1ST LINE DURING OPERATION)….1093

M-18 FUEL LEVEL GAUGE ALWAYS DISPLAYS FULL….1094

M-19 FUEL LEVEL GAUGE IS NOT DISPLAYED….1094

M-20 WHILE ENGINE IS RUNNING, SERVICE METER DOES NOT ADVANCE….1095

M-21 TROUBLE IN FUEL LEVEL SENSOR….1096

M-22 TROUBLE IN COOLANT TEMPERATURE SENSOR….1097

M-23 WIPER DOES NOT OPERATE OR OPERATES WHILE WIPER SWITCH IS TURNED OFF….1098

a) WIPER DOES NOT OPERATE….1098

b) WIPER OPERATES WHILE WIPER SWITCH IS TURNED OFF….1098

M-24 WASHER MOTOR DOES NOT OPERATE OR OPERATES WHILE WASHER SWITCH IS TURNED OFF….1101

a) WASHER MOTOR DOES NOT OPERATE….1101

b) WASHER OPERATES WHILE WIPER SWITCH IS TURNED OFF….1101

30 DISASSEMBLY AND ASSEMBLY….1104

METHOD OF USING MANUAL….1105

PRECAUTIONS WHEN CARRYING OUT OPERATION….1106

SPECIAL TOOL LIST….1110

COUNTERWEIGHT ….1116

REMOVAL AND INSTALLATION….1116

INJECTION PUMP ….1117

REMOVAL….1117

INSTALLATION….1118

CYLINDER HEAD….1119

REMOVAL….1119

INSTALLATION….1122

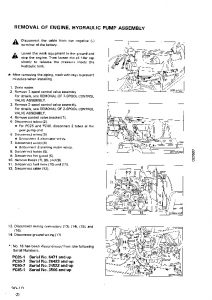

MAIN PUMP….1123

REMOVAL….1123

INSTALLATION….1124

CONTROL PUMP….1124

REMOVAL AND INSTALLATION….1124

ENGINE AND MAIN PUMP….1125

REMOVAL….1125

INSTALLATION….1127

HYDRAULIC OIL COOLER….1128

REMOVAL AND INSTALLATION….1128

RADIATOR ….1128

REMOVAL….1128

INSTALLATION….1129

SWING MOTOR AND SWING MACHINERY….1130

REMOVAL AND INSTALLATION….1130

SWING MACHINERY….1131

DISASSEMBLY….1131

ASSEMBLY….1133

SWING MOTOR ….1137

REMOVAL AND INSTALLATION….1137

CENTER SWIVEL JOINT….1137

REMOVAL….1137

INSTALLATION….1138

DISASSEMBLY AND ASSEMBLY….1139

CONTROL VALVE….1140

REMOVAL AND INSTALLATION….1140

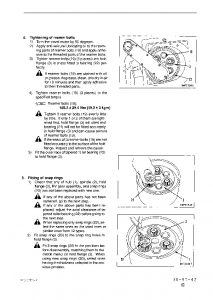

ASSEMBLY….1141

WORK EQUIPMENT PPC VALVE….1142

ASSEMBLY….1142

TRAVEL PPC VALVE ….1143

ASSEMBLY….1143

HYDRAULIC TANK ….1145

REMOVAL AND INSTALLATION….1145

FUEL TANK….1146

REMOVAL….1146

INSTALLATION….1147

CONTROLLER….1149

REMOVAL AND INSTALLATION….1149

MONITOR PANEL….1150

REMOVAL AND INSTALLATION….1150

AIR CONDITIONER UNIT….1150

REMOVAL….1150

INSTALLATION….1151

OPERATOR'S CAB….1152

REMOVAL AND INSTALLATION….1152

FLOOR FRAME ….1153

REMOVAL….1153

INSTALLATION….1154

REVOLVING FRAME….1155

REMOVAL AND INSTALLATION….1155

SWING CIRCLE….1156

REMOVAL AND INSTALLATION….1156

WORK EQUIPMENT ….1157

REMOVAL….1157

INSTALLATION….1158

SWING BRACKET….1159

REMOVAL….1159

INSTALLATION….1160

STEEL SHOE, RUBBER PAD SHOE, ROAD LINER….1161

EXPANSION AND INSTALLATION….1161

RUBBER SHOE ….1162

REMOVAL AND INSTALLATION….1162

FINAL DRIVE ….1162

REMOVAL….1162

INSTALLATION….1163

IDLER ….1163

ASSEMBLY….1163

RECOIL SPRING….1165

DISASSEMBLY….1165

ASSEMBLY….1166

TRACK ROLLER….1167

DISASSEMBLY….1167

ASSEMBLY….1168

HYDRAULIC CYLINDER….1170

DISASSEMBLY….1170

ASSEMBLY….1172

90 OTHERS….1174

HYDRAULIC CIRCUIT DIAGRAM (FOR STD SPEC)….1175

HYDRAULIC CIRCUIT DIAGRAM (FOR EU SPEC)….1176

ELECTRICAL CIRCUIT DIAGRAM (FOR STD SPEC) (1/2)….1177

ELECTRICAL CIRCUIT DIAGRAM (FOR STD SPEC) (2/2)….1178

ELECTRICAL CIRCUIT DIAGRAM (FOR EU SPEC) (1/2)….1179

ELECTRICAL CIRCUIT DIAGRAM (FOR EU SPEC) (2/2)….1180

ELECTRICAL CIRCUIT DIAGRAM (FOR NORWAY SPEC.) (1/2)….1181

ELECTRICAL CIRCUIT DIAGRAM (FOR NORWAY SPEC.) (2/2)….1182

TEN00032-00 – Hydraulic Excavator GALEO PC78MR-6 Operation & Maintenance Manual….1183

COVER….1183

FOREWORD….1184

FOREWORD….1185

SAFETY INFORMATION….1188

INTRODUCTION….1190

DIRECTIONS OF MACHINE….1190

PRODUCT INFORMATION….1191

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE….1191

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION….1191

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION….1192

SERVICE METER LOCATION….1192

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR….1193

CONTENTS….1194

SAFETY….1198

SAFETY INFORMATION….1199

SAFETY LABELS….1201

LOCATION OF SAFETY LABELS….1202

SAFETY LABELS….1203

SAFETY INFORMATION….1210

SAFETY RULES….1210

IF ABNORMALITIES ARE FOUND….1210

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS….1210

FIRE EXTINGUISHER AND FIRST AID KIT….1210

SAFETY EQUIPMENT….1210

KEEP MACHINE CLEAN….1211

KEEP OPERATOR'S COMPARTMENT CLEAN….1211

LEAVING OPERATOR'S SEAT WITH LOCK….1211

HANDRAILS AND STEPS….1212

MOUNTING AND DISMOUNTING….1212

NO PERSONS ON ATTACHMENTS….1212

DO NOT GET CAUGHT IN ARTICULATED PORTION….1212

BURN PREVENTION….1213

FIRE PREVENTION AND EXPLOSION PREVENTION….1213

ACTION IF FIRE OCCURS….1214

WINDSHIELD WASHER FLUID….1214

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION….1214

ATTACHMENT INSTALLATION….1215

ATTACHMENT COMBINATIONS….1215

CAB WINDOW GLASSES….1215

UNAUTHORIZED MODIFICATIONS….1215

SAFETY AT JOBSITE….1215

WORKING ON LOOSE GROUND….1216

DISTANCE TO HIGH VOLTAGE CABLES….1216

ENSURE GOOD VISIBILITY….1216

VENTILATION FOR ENCLOSED AREA….1217

SIGNALMAN'S SIGNAL AND SIGNS….1217

EMERGENCY EXIT FROM OPERATOR'S CAB….1217

ASBESTOS DUST HAZARD PREVENTION….1217

SAFETY MACHINE OPERATION….1218

STARTING ENGINE….1218

CHECKS BEFORE STARTING ENGINE….1218

SAFETY RULES FOR STARTING ENGINE….1219

STARTING ENGINE IN COLD WEATHER….1219

OPERATION….1220

CHECKS BEFORE OPERATION….1220

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS….1220

SAFETY RULES FOR TRAVELING….1221

TRAVELING ON SLOPES….1222

OPERATIONS ON SLOPES….1223

PROHIBITED OPERATIONS….1223

OPERATIONS ON SNOW….1224

PARKING MACHINE….1225

TRANSPORTATION….1226

LOADING AND UNLOADING….1226

SHIPPING THE MACHINE….1226

BATTERY….1227

BATTERY HAZARD PREVENTION….1227

STARTING ENGINE WITH BOOSTER CABLES….1228

TOWING….1229

SAFETY RULES FOR TOWING….1229

LIFTING OBJECTS WITH BUCKET….1230

SAFETY RULES FOR LIFTING OBJECTS….1230

SAFETY MAINTENANCE INFORMATION….1231

WARNING TAG….1231

KEEP WORK PLACE CLEAN AND TIDY….1231

APPOINT LEADER WHEN WORKING WITH OTHERS….1231

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE….1231

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING….1232

PROPER TOOLS….1233

ACCUMULATOR….1233

PERSONNEL….1233

ATTACHMENTS….1233

WORK UNDER THE MACHINE….1234

NOISE….1234

WHEN USING HAMMER….1234

WELDING WORKS….1234

REMOVING BATTERY TERMINALS….1234

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION….1235

DO NOT DISASSEMBLE RECOIL SPRINGS….1235

SAFETY RULES FOR HIGH-PRESSURE OIL….1235

SAFETY HANDLING HIGH-PRESSURE HOSES….1235

WASTE MATERIALS….1236

AIR CONDITIONER MAINTENANCE….1236

COMPRESSED AIR….1236

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS….1236

OPERATION….1238

MACHINE VIEW ILLUSTRATIONS….1239

OVERALL MACHINE VIEW….1239

CONTROLS AND GAUGES….1240

DETAILED CONTROLS AND GAUGES….1241

MONITORING SYSTEM….1241

SWITCHES….1252

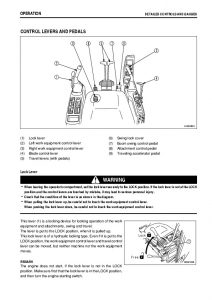

CONTROL LEVERS AND PEDALS….1257

SUN ROOF….1263

WINDSHIELD….1264

SLIDING DOOR….1269

EMERGENCY ESCAPE HAMMER….1269

CAP WITH LOCK….1271

ENGINE HOOD….1272

MUD COVER….1273

BATTERY INSPECTION COVER….1274

FUSE….1275

FUSIBLE LINK….1276

AUXILIARY ELECTRIC POWER….1276

CONTROLLERS….1276

AIR CONDITIONER CONTROLS….1277

HEATER AND DEFROSTER CONTROLS….1283

RADIO….1288

OPERATION MANUAL STORAGE….1293

TOOL BOX….1293

GREASE PUMP HOLDER….1293

ASHTRAY….1293

FIRE EXTINGUISHER….1294

MACHINE OPERATIONS AND CONTROLS….1295

BEFORE STARTING ENGINE….1295

STARTING ENGINE….1311

AFTER STARTING ENGINE….1316

STOPPING THE ENGINE….1319

CHECK AFTER SHUT OFF ENGINE….1319

MACHINE OPERATION….1320

STEERING THE MACHINE….1324

SWINGING….1326

WORK EQUIPMENT CONTROLS AND OPERATIONS….1327

WORKING MODE….1329

PROHIBITED OPERATIONS….1330

GENERAL OPERATION INFORMATION….1332

TRAVELING ON SLOPES….1334

ESCAPE FROM MUD….1336

RECOMMENDED APPLICATIONS….1337

MACHINE READY FOR ATTACHMENT….1339

BUCKET REPLACEMENT AND INVERSION….1345

PARKING MACHINE….1347

MACHINE INSPECTION AFTER DAILY WORK….1348

LOCKING….1348

ROAD LINERS AND RUBBER SHOES….1349

TRANSPORTATION….1354

TRANSPORTATION PROCEDURE….1354

LOADING AND UNLOADING WITH TRAILER….1354

LIFTING MACHINE….1360

COLD WEATHER OPERATION….1362

COLD WEATHER OPERATION INFORMATION….1362

AFTER DAILY WORK COMPLETION….1364

AFTER COLD WEATHER SEASON….1364

LONG TERM STORAGE….1365

BEFORE STORAGE….1365

DURING STORAGE….1365

AFTER STORAGE….1365

TROUBLES AND ACTIONS….1366

RUNNING OUT OF FUEL….1366

PHENOMENA THAT ARE NOT FAILURES….1366

TOWING THE MACHINE….1367

SEVERE JOB CONDITION….1367

DISCHARGED BATTERY….1368

HOW TO LOWER WORK EQUIPMENT WHEN ENGINE STOPS DUE TO ABNORMALITY….1373

OTHER TROUBLE….1374

MAINTENANCE….1380

MAINTENANCE INFORMATION….1381

OUTLINE OF SERVICE….1383

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….1383

ELECTRIC SYSTEM MAINTENANCE….1386

WEAR PARTS….1387

WEAR PARTS LIST….1387

RECOMMENDED FUEL, COOLANT, AND LUBRICANT….1388

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE….1389

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN….1390

TIGHTENING TORQUE SPECIFICATIONS….1391

TIGHTENING TORQUE LIST….1391

SAFETY CRITICAL PARTS….1392

SAFETY CRITICAL PARTS LIST….1392

MAINTENANCE SCHEDULE….1393

MAINTENANCE SCHEDULE CHART….1393

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER….1394

MAINTENANCE PROCEDURE….1395

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)….1395

REPLACE FUEL FILTER CARTRIDGE….1440

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE….1441

WHEN REQUIRED….1396

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT….1396

CLEAN INSIDE OF COOLING SYSTEM….1400

REPLACE WATER SEPARATOR ELEMENT….1403

CLEAN FUEL TANK….1404

CHECK AND TIGHTEN TRACK SHOE BOLTS….1405

CHECK AND ADJUST TRACK TENSION….1406

CHECK ROAD LINERS OR RUBBER SHOES….1408

CHECK AND ADJUST RUBBER SHOE TENSION….1410

REPLACE ROAD LINERS….1411

REPLACE RUBBER SHOES….1412

CHANGE STEEL SHOES OR ROAD LINER TO RUBBER SHOES….1414

REPLACE BUCKET TEETH (VERTICAL PIN TYPE)….1415

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)….1418

ADJUST BUCKET CLEARANCE….1419

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID….1420

CHECK AND ADJUST AIR CONDITIONER….1421

CHECK, CLEAN AND LUBRICATE CAB SLIDE DOOR RAIL AND ROLLER….1422

REPLACE BREAKER CIRCUIT ADDITIONAL OIL FILTER ELEMENT….1423

WASH WASHABLE FLOOR….1424

BLEEDING AIR FROM HYDRAULIC SYSTEM….1426

CHECK BEFORE STARTING….1429

EVERY 50 HOURS MAINTENANCE….1430

DRAIN WATER FROM FUEL TANK….1430

EVERY 100 HOURS MAINTENANCE….1431

LUBRICATING….1431

EVERY 250 HOURS MAINTENANCE….1432

LUBRICATING….1432

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL….1434

CHECK LEVEL OF BATTERY ELECTROLYTE….1435

CHECK AND ADJUST COOLING FAN BELT TENSION….1437

CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST….1439

EVERY 500 HOURS MAINTENANCE….1440

REPLACE FUEL FILTER CARTRIDGE….1440

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE….1441

CLEAN AIR CONDITIONER FRESH/RECIRC FILTERS….1442

CLEAN, CHECK RADIATOR FINS, OIL COOLER FINS AND CONDENSER FINS….1444

LUBRICATE SWING CIRCLE….1446

CHECK SWING PINION GREASE LEVEL, ADD GREASE….1446

EVERY 1000 HOURS MAINTENANCE….1447

REPLACE HYDRAULIC OIL FILTER ELEMENT….1447

CHANGE OIL IN SWING MACHINERY CASE….1449

CHANGE OIL IN FINAL DRIVE CASE….1450

EVERY 2000 HOURS MAINTENANCE….1451

CHECK PTO GEAR CASE, ADD OIL….1451

CLEAN, CHECK TURBOCHARGER….1451

CHECK ALTERNATOR, STARTING MOTOR….1451

CHECK ENGINE VALVE CLEARANCE, ADJUST….1451

EVERY 4000 HOURS MAINTENANCE….1452

CHECK WATER PUMP….1452

EVERY 5000 HOURS MAINTENANCE….1453

CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER….1453

SPECIFICATIONS….1456

SPECIFICATIONS….1457

ATTACHMENTS, OPTIONS….1460

ATTACHMENTS AND OPTIONS – GENERAL INFORMATION….1461

SAFETY FIRST….1461

ATTACHMENT INSTALLATION….1462

BUCKET WITH HOOK….1463

HOOK CONDITION….1463

PROHIBITED OPERATIONS….1463

METHOD FOR REMOVING AND INSTALLING EXTRA….1464

CHANGING MACHINE CONTROL PATTERN (IF PATTERN CHANGE….1466

CONTROL PATTERN CHANGE PROCEDURE….1466

MACHINE CONTROL PATTERNS….1467

ATTACHMENT GUIDE….1468

OTHER ATTACHMENTS….1468

ATTACHMENT COMBINATIONS….1469

SELECTION OF TRACK SHOES….1470

RECOMMENDED ATTACHMENT OPERATIONS….1471

HYDRAULIC BREAKER….1471

INDEX….1476

TEN00074-00 – Hydraulic Excavator GALEO PC78MR-6 Operation & Maintenance Manual….1480

COVER….1480

FOREWORD….1481

FOREWORD….1482

SAFETY INFORMATION….1485

INTRODUCTION….1487

DIRECTIONS OF MACHINE….1487

PRODUCT INFORMATION….1488

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE….1488

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION….1488

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION….1489

SERVICE METER LOCATION….1489

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR….1490

CONTENTS….1491

SAFETY….1495

SAFETY INFORMATION….1496

SAFETY LABELS….1498

LOCATION OF SAFETY LABELS….1499

SAFETY LABELS….1500

SAFETY INFORMATION….1507

SAFETY RULES….1507

IF PROBLEMS ARE FOUND….1507

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS….1507

FIRE EXTINGUISHER AND FIRST AID KIT….1507

SAFETY EQUIPMENT….1507

KEEP MACHINE CLEAN….1508

KEEP OPERATOR'S COMPARTMENT CLEAN….1508

LEAVING OPERATOR'S SEAT WITH LOCK….1508

HANDRAILS AND STEPS….1509

MOUNTING AND DISMOUNTING….1509

NO PERSONS ON ATTACHMENTS….1509

DO NOT GET CAUGHT IN ARTICULATED PORTION….1509

BURN PREVENTION….1510

FIRE PREVENTION AND EXPLOSION PREVENTION….1510

ACTION IF FIRE OCCURS….1511

WINDSHIELD WASHER FLUID….1511

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION….1511

ATTACHMENT INSTALLATION….1512

ATTACHMENT COMBINATIONS….1512

CAB WINDOW GLASSES….1512

UNAUTHORIZED MODIFICATIONS….1512

SAFETY AT JOBSITE….1512

WORKING ON LOOSE GROUND….1513

DISTANCE TO HIGH VOLTAGE CABLES….1513

ENSURE GOOD VISIBILITY….1513

VENTILATION FOR ENCLOSED AREA….1514

SIGNALMAN'S SIGNAL AND SIGNS….1514

EMERGENCY EXIT FROM OPERATOR'S CAB….1514

ASBESTOS DUST HAZARD PREVENTION….1514

SAFETY MACHINE OPERATION….1515

STARTING ENGINE….1515

CHECKS BEFORE STARTING ENGINE….1515

SAFETY RULES FOR STARTING ENGINE….1516

STARTING ENGINE IN COLD WEATHER….1516

OPERATION….1517

CHECKS BEFORE OPERATION….1517

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS….1517

SAFETY RULES FOR TRAVELING….1518

TRAVELING ON SLOPES….1519

OPERATIONS ON SLOPES….1520

PROHIBITED OPERATIONS….1520

OPERATIONS ON SNOW….1521

PARKING MACHINE….1522

TRANSPORTATION….1523

LOADING AND UNLOADING….1523

SHIPPING THE MACHINE….1523

BATTERY….1524

BATTERY HAZARD PREVENTION….1524

STARTING ENGINE WITH BOOSTER CABLES….1525

TOWING….1526

SAFETY RULES FOR TOWING….1526

LIFTING OBJECTS WITH BUCKET….1527

SAFETY RULES FOR LIFTING OBJECTS….1527

SAFETY MAINTENANCE INFORMATION….1528

WARNING TAG….1528

KEEP WORK PLACE CLEAN AND TIDY….1528

APPOINT LEADER WHEN WORKING WITH OTHERS….1528

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE….1528

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING….1529

PROPER TOOLS….1530

ACCUMULATOR….1530

PERSONNEL….1530

ATTACHMENTS….1530

WORK UNDER THE MACHINE….1531

NOISE….1531

WHEN USING HAMMER….1531

WELDING WORKS….1531

REMOVING BATTERY TERMINALS….1531

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION….1532

DO NOT DISASSEMBLE RECOIL SPRINGS….1532

SAFETY RULES FOR HIGH-PRESSURE OIL….1532

SAFETY HANDLING HIGH-PRESSURE HOSES….1532

WASTE MATERIALS….1533

AIR CONDITIONER MAINTENANCE….1533

COMPRESSED AIR….1533

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS….1533

OPERATION….1535

MACHINE VIEW ILLUSTRATIONS….1536

OVERALL MACHINE VIEW….1536

CONTROLS AND GAUGES….1537

DETAILED CONTROLS AND GAUGES….1538

MONITORING SYSTEM….1538

SWITCHES….1548

CONTROL LEVERS AND PEDALS….1553

SUN ROOF….1558

WINDSHIELD….1559

SLIDING DOOR….1564

EMERGENCY ESCAPE HAMMER….1564

CAP WITH LOCK….1566

ENGINE HOOD….1567

MUD COVER….1568

BATTERY INSPECTION COVER….1569

FUSE….1570

FUSIBLE LINK….1571

AUXILIARY ELECTRIC POWER….1571

CONTROLLERS….1571

AIR CONDITIONER CONTROLS….1572

HEATER AND DEFROSTER CONTROLS….1578

RADIO….1583

OPERATION MANUAL STORAGE….1588

TOOL BOX….1588

GREASE PUMP HOLDER….1588

ASHTRAY….1588

FIRE EXTINGUISHER….1589

MACHINE OPERATIONS AND CONTROLS….1590

BEFORE STARTING ENGINE….1590

STARTING ENGINE….1606

AFTER STARTING ENGINE….1611

STOPPING THE ENGINE….1614

CHECK AFTER SHUT OFF ENGINE….1614

MACHINE OPERATION….1615

STEERING THE MACHINE….1619

SWINGING….1621

WORK EQUIPMENT CONTROLS AND OPERATIONS….1622

WORKING MODE….1624

PROHIBITED OPERATIONS….1625

GENERAL OPERATION INFORMATION….1627

TRAVELING ON SLOPES….1629

ESCAPE FROM MUD….1631

RECOMMENDED APPLICATIONS….1632

MACHINE READY FOR ATTACHMENT….1634

BUCKET REPLACEMENT AND INVERSION….1640

PARKING MACHINE….1642

MACHINE INSPECTION AFTER DAILY WORK….1643

LOCKING….1643

ROAD LINERS AND RUBBER SHOES….1644

TRANSPORTATION….1649

TRANSPORTATION PROCEDURE….1649

LOADING AND UNLOADING WITH TRAILER….1649

LIFTING MACHINE….1655

COLD WEATHER OPERATION….1657

COLD WEATHER OPERATION INFORMATION….1657

AFTER DAILY WORK COMPLETION….1659

AFTER COLD WEATHER SEASON….1659

LONG TERM STORAGE….1660

BEFORE STORAGE….1660

DURING STORAGE….1660

AFTER STORAGE….1660

TROUBLES AND ACTIONS….1661

RUNNING OUT OF FUEL….1661

PHENOMENA THAT ARE NOT FAILURES….1661

TOWING THE MACHINE….1662

SEVERE JOB CONDITION….1662

DISCHARGED BATTERY….1663

HOW TO LOWER WORK EQUIPMENT WHEN ENGINE STOPS DUE TO ABNORMALITY….1668

OTHER TROUBLE….1669

MAINTENANCE….1675

MAINTENANCE INFORMATION….1676

OUTLINE OF SERVICE….1678

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….1678

ELECTRIC SYSTEM MAINTENANCE….1681

WEAR PARTS….1682

WEAR PARTS LIST….1682

RECOMMENDED FUEL, COOLANT, AND LUBRICANT….1683

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE….1684

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL….1685

TIGHTENING TORQUE SPECIFICATIONS….1686

TIGHTENING TORQUE LIST….1686

SAFETY CRITICAL PARTS….1687

SAFETY CRITICAL PARTS LIST….1687

MAINTENANCE SCHEDULE….1688

MAINTENANCE SCHEDULE CHART….1688

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER….1689

MAINTENANCE PROCEDURE….1690

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)….1690

REPLACE FUEL FILTER CARTRIDGE….1735

CHANGE OIL IN ENGINE OIL PAN, REPLACE OIL FILTER CARTRIDGE….1736

WHEN REQUIRED….1691

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT….1691

CLEAN INSIDE OF COOLING SYSTEM….1695

REPLACE WATER SEPARATOR ELEMENT….1698

CLEAN FUEL TANK….1699

CHECK AND TIGHTEN TRACK SHOE BOLTS….1700

CHECK AND ADJUST TRACK TENSION….1701

CHECK ROAD LINERS OR RUBBER SHOES….1703

CHECK AND ADJUST RUBBER SHOE TENSION….1705

REPLACE ROAD LINERS….1706

REPLACE RUBBER SHOES….1707

CHANGE STEEL SHOES OR ROAD LINER TO RUBBER SHOES….1709

REPLACE BUCKET TEETH (VERTICAL PIN TYPE)….1710

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)….1713

ADJUST BUCKET CLEARANCE….1714

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID….1715

CHECK AND ADJUST AIR CONDITIONER….1716

CHECK, CLEAN AND LUBRICATE CAB SLIDE DOOR RAIL AND ROLLER….1717

REPLACE BREAKER CIRCUIT ADDITIONAL OIL FILTER ELEMENT….1718

WASH WASHABLE FLOOR….1719

BLEEDING AIR FROM HYDRAULIC SYSTEM….1721

CHECK BEFORE STARTING….1724

EVERY 50 HOURS MAINTENANCE….1725

DRAIN WATER FROM FUEL TANK….1725

EVERY 100 HOURS MAINTENANCE….1726

LUBRICATING….1726

EVERY 250 HOURS MAINTENANCE….1727

LUBRICATING….1727

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL….1729

CHECK LEVEL OF BATTERY ELECTROLYTE….1730

CHECK AND ADJUST COOLING FAN BELT TENSION….1732

CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST….1734

EVERY 500 HOURS MAINTENANCE….1735

REPLACE FUEL FILTER CARTRIDGE….1735

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE….1736

CLEAN AIR CONDITIONER FRESH/RECIRC FILTERS….1737

CLEAN, CHECK RADIATOR FINS, OIL COOLER FINS AND CONDENSER FINS….1739

LUBRICATE SWING CIRCLE….1741

CHECK SWING PINION GREASE LEVEL, ADD GREASE….1741

EVERY 1000 HOURS MAINTENANCE….1742

REPLACE HYDRAULIC OIL FILTER ELEMENT….1742

CHANGE OIL IN SWING MACHINERY CASE….1744

CHANGE OIL IN FINAL DRIVE CASE….1745

EVERY 2000 HOURS MAINTENANCE….1746

CHECK PTO GEAR CASE, ADD OIL….1746

CLEAN, CHECK TURBOCHARGER….1746

CHECK ALTERNATOR, STARTING MOTOR….1746

EVERY 4000 HOURS MAINTENANCE….1747

CHECK WATER PUMP….1747

EVERY 5000 HOURS MAINTENANCE….1748

CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER….1748

SPECIFICATIONS….1751

SPECIFICATIONS….1752

ATTACHMENTS, OPTIONS….1755

ATTACHMENTS AND OPTIONS – GENERAL INFORMATION….1756

SAFETY FIRST….1756

ATTACHMENT INSTALLATION….1757

BUCKET WITH HOOK….1758

HOOK CONDITION….1758

PROHIBITED OPERATIONS….1758

METHOD FOR REMOVING AND INSTALLING EXTRA COUNTERWEIGHT….1759

CHANGING MACHINE CONTROL PATTERN (IF PATTERN CHANGE VALVE EQUIPPED)….1761

CONTROL PATTERN CHANGE PROCEDURE….1761

MACHINE CONTROL PATTERNS….1762

ATTACHMENT GUIDE….1763

OTHER ATTACHMENTS….1763

ATTACHMENT COMBINATIONS….1764

SELECTION OF TRACK SHOES….1765

RECOMMENDED ATTACHMENT OPERATIONS….1766

HYDRAULIC BREAKER….1766

INDEX….1771

TEN00202-00 – Hydraulic Excavator GALEO PC78MR-6 Operation & Maintenance Manual….1775

COVER….1775

FOREWORD….1776

FOREWORD….1777

SAFETY INFORMATION….1780

INTRODUCTION….1782

DIRECTIONS OF MACHINE….1782

PRODUCT INFORMATION….1783

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE….1783

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION….1783

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION….1784

SERVICE METER LOCATION….1784

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR….1785

CONTENTS….1786

SAFETY….1789

SAFETY INFORMATION….1790

SAFETY LABELS….1792

LOCATION OF SAFETY LABELS….1793

SAFETY LABELS….1794

SAFETY INFORMATION….1801

SAFETY RULES….1801

IF PROBLEMS ARE FOUND….1801

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS….1801

FIRE EXTINGUISHER AND FIRST AID KIT….1801

SAFETY EQUIPMENT….1801

KEEP MACHINE CLEAN….1802

KEEP OPERATOR'S COMPARTMENT CLEAN….1802

LEAVING OPERATOR'S SEAT WITH LOCK….1802

HANDRAILS AND STEPS….1803

MOUNTING AND DISMOUNTING….1803

NO PERSONS ON ATTACHMENTS….1803

DO NOT GET CAUGHT IN ARTICULATED PORTION….1803

BURN PREVENTION….1804

FIRE PREVENTION AND EXPLOSION PREVENTION….1804

ACTION IF FIRE OCCURS….1805

WINDSHIELD WASHER FLUID….1805

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION….1805

ATTACHMENT INSTALLATION….1806

ATTACHMENT COMBINATIONS….1806

CAB WINDOW GLASSES….1806

UNAUTHORIZED MODIFICATIONS….1806

SAFETY AT JOBSITE….1806

WORKING ON LOOSE GROUND….1807

DISTANCE TO HIGH VOLTAGE CABLES….1807

ENSURE GOOD VISIBILITY….1807

VENTILATION FOR ENCLOSED AREA….1808

SIGNALMAN'S SIGNAL AND SIGNS….1808

EMERGENCY EXIT FROM OPERATOR'S CAB….1808

ASBESTOS DUST HAZARD PREVENTION….1808

SAFETY MACHINE OPERATION….1809

STARTING ENGINE….1809

CHECKS BEFORE STARTING ENGINE….1809

SAFETY RULES FOR STARTING ENGINE….1810

STARTING ENGINE IN COLD WEATHER….1810

OPERATION….1811

CHECKS BEFORE OPERATION….1811

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS….1811

SAFETY RULES FOR TRAVELING….1812

TRAVELING ON SLOPES….1813

OPERATIONS ON SLOPES….1814

PROHIBITED OPERATIONS….1814

OPERATIONS ON SNOW….1815

PARKING MACHINE….1816

TRANSPORTATION….1817

LOADING AND UNLOADING….1817

SHIPPING THE MACHINE….1817

BATTERY….1818

BATTERY HAZARD PREVENTION….1818

STARTING ENGINE WITH BOOSTER CABLES….1819

TOWING….1820

SAFETY RULES FOR TOWING….1820

LIFTING OBJECTS WITH BUCKET….1821

SAFETY RULES FOR LIFTING OBJECTS….1821

SAFETY MAINTENANCE INFORMATION….1822

WARNING TAG….1822

KEEP WORK PLACE CLEAN AND TIDY….1822

APPOINT LEADER WHEN WORKING WITH OTHERS….1822

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE….1822

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING….1823

PROPER TOOLS….1824

ACCUMULATOR….1824

PERSONNEL….1824

ATTACHMENTS….1824

WORK UNDER THE MACHINE….1825

NOISE….1825

WHEN USING HAMMER….1825

WELDING WORKS….1825

REMOVING BATTERY TERMINALS….1825

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION….1826

DO NOT DISASSEMBLE RECOIL SPRINGS….1826

SAFETY RULES FOR HIGH-PRESSURE OIL….1826

SAFETY HANDLING HIGH-PRESSURE HOSES….1826

WASTE MATERIALS….1827

AIR CONDITIONER MAINTENANCE….1827

COMPRESSED AIR….1827

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS….1827

OPERATION….1828

MACHINE VIEW ILLUSTRATIONS….1829

OVERALL MACHINE VIEW….1829

CONTROLS AND GAUGES….1830

DETAILED CONTROLS AND GAUGES….1831

MONITORING SYSTEM….1831

SWITCHES….1841

CONTROL LEVERS AND PEDALS….1846

SUN ROOF….1851

WINDSHIELD….1852

SLIDING DOOR….1857

EMERGENCY ESCAPE HAMMER….1857

CAP WITH LOCK….1859

ENGINE HOOD….1860

MUD COVER….1861

BATTERY INSPECTION COVER….1862

FUSE….1863

FUSIBLE LINK….1864

AUXILIARY ELECTRIC POWER….1864

CONTROLLERS….1864

AIR CONDITIONER CONTROLS….1865

HEATER AND DEFROSTER CONTROLS….1871

RADIO….1876

OPERATION MANUAL STORAGE….1881

TOOL BOX….1881

GREASE PUMP HOLDER….1881

ASHTRAY….1881

FIRE EXTINGUISHER….1882

MACHINE OPERATIONS AND CONTROLS….1883

BEFORE STARTING ENGINE….1883

STARTING ENGINE….1899

AFTER STARTING ENGINE….1904

STOPPING THE ENGINE….1907

CHECK AFTER SHUT OFF ENGINE….1907

MACHINE OPERATION….1908

STEERING THE MACHINE….1912

SWINGING….1914

WORK EQUIPMENT CONTROLS AND OPERATIONS….1915

WORKING MODE….1917

PROHIBITED OPERATIONS….1918

GENERAL OPERATION INFORMATION….1920

TRAVELING ON SLOPES….1922

ESCAPE FROM MUD….1924

RECOMMENDED APPLICATIONS….1925

MACHINE READY FOR ATTACHMENT….1927

BUCKET REPLACEMENT AND INVERSION….1933

PARKING MACHINE….1936

MACHINE INSPECTION AFTER DAILY WORK….1937

LOCKING….1937

ROAD LINERS AND RUBBER SHOES….1938

TRANSPORTATION….1943

TRANSPORTATION PROCEDURE….1943

LOADING AND UNLOADING WITH TRAILER….1943

LIFTING MACHINE….1949

COLD WEATHER OPERATION….1951

COLD WEATHER OPERATION INFORMATION….1951

AFTER DAILY WORK COMPLETION….1953

AFTER COLD WEATHER SEASON….1953

LONG TERM STORAGE….1954

BEFORE STORAGE….1954

DURING STORAGE….1954

AFTER STORAGE….1954

TROUBLES AND ACTIONS….1955

RUNNING OUT OF FUEL….1955

PHENOMENA THAT ARE NOT FAILURES….1955

TOWING THE MACHINE….1956

SEVERE JOB CONDITION….1956

DISCHARGED BATTERY….1957

HOW TO LOWER WORK EQUIPMENT WHEN ENGINE STOPS DUE TO ABNORMALITY….1962

OTHER TROUBLE….1963

MAINTENANCE….1968

MAINTENANCE INFORMATION….1969

OUTLINE OF SERVICE….1971

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….1971

ELECTRIC SYSTEM MAINTENANCE….1975

WEAR PARTS….1976

WEAR PARTS LIST….1976

RECOMMENDED FUEL, COOLANT, AND LUBRICANT….1977

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE….1978

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL….1979

TIGHTENING TORQUE SPECIFICATIONS….1980

TIGHTENING TORQUE LIST….1980

SAFETY CRITICAL PARTS….1981

SAFETY CRITICAL PARTS LIST….1981

MAINTENANCE SCHEDULE….1982

MAINTENANCE SCHEDULE CHART….1982

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER….1983

MAINTENANCE PROCEDURE….1984

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)….1984

WHEN REQUIRED….1985

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT….1985

CLEAN INSIDE OF COOLING SYSTEM….1989

REPLACE WATER SEPARATOR ELEMENT….1992

CLEAN FUEL TANK….1993

CHECK AND TIGHTEN TRACK SHOE BOLTS….1994

CHECK AND ADJUST TRACK TENSION….1995

CHECK ROAD LINERS OR RUBBER SHOES….1997

CHECK AND ADJUST RUBBER SHOE TENSION….1999

REPLACE ROAD LINERS….2000

REPLACE RUBBER SHOES….2001

CHANGE STEEL SHOES OR ROAD LINER TO RUBBER SHOES….2003

REPLACE BUCKET TEETH (VERTICAL PIN TYPE)….2004

REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)….2007

ADJUST BUCKET CLEARANCE….2008

CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID….2009

CHECK AND MAINTENANCE AIR CONDITIONER….2010

CHECK, CLEAN AND LUBRICATE CAB SLIDE DOOR RAIL AND ROLLER….2011

REPLACE BREAKER CIRCUIT ADDITIONAL OIL FILTER ELEMENT….2012

WASH WASHABLE FLOOR….2013

BLEEDING AIR FROM HYDRAULIC SYSTEM….2015

CHECK BEFORE STARTING….2018

EVERY 50 HOURS MAINTENANCE….2019

DRAIN WATER FROM FUEL TANK….2019

EVERY 100 HOURS MAINTENANCE….2020

LUBRICATING….2020

CHECK SWING MACHINERY CASE OIL, ADD OIL….2021

EVERY 250 HOURS MAINTENANCE….2022

LUBRICATING….2022

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL….2024

CHECK LEVEL OF BATTERY ELECTROLYTE….2025

CHECK AND ADJUST COOLING FAN BELT TENSION….2027

CHECK AIR CONDITIONER COMPRESSOR BELT TENSION, ADJUST….2029

EVERY 500 HOURS MAINTENANCE….2030

REPLACE FUEL FILTER CARTRIDGE….2030

CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE….2031

CLEAN AIR CONDITIONER FRESH/RECIRC FILTERS….2032

CLEAN, CHECK RADIATOR FINS, OIL COOLER FINS AND CONDENSER FINS….2034

LUBRICATE SWING CIRCLE….2036

CHECK SWING PINION GREASE LEVEL, ADD GREASE….2036

EVERY 1000 HOURS MAINTENANCE….2037

REPLACE HYDRAULIC OIL FILTER ELEMENT….2037

CHANGE OIL IN SWING MACHINERY CASE….2039

GREASE SWING MACHINERY BEARING….2040

CHANGE OIL IN FINAL DRIVE CASE….2041

EVERY 2000 HOURS MAINTENANCE….2042

CHECK PTO GEAR CASE, ADD OIL….2042

CLEAN, CHECK TURBOCHARGER….2042

CHECK ALTERNATOR, STARTING MOTOR….2042

CHECK ENGINE VALVE CLEARANCE, ADJUST….2042

EVERY 4000 HOURS MAINTENANCE….2043

CHECK WATER PUMP….2043

EVERY 5000 HOURS MAINTENANCE….2044

CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER….2044

SPECIFICATIONS….2046

SPECIFICATIONS….2047

ATTACHMENTS, OPTIONS….2049

ATTACHMENTS AND OPTIONS – GENERAL INFORMATION….2050

SAFETY FIRST….2050

ATTACHMENT INSTALLATION….2051

BUCKET WITH HOOK….2052

HOOK CONDITION….2052

PROHIBITED OPERATIONS….2052

METHOD FOR REMOVING AND INSTALLING EXTRA COUNTERWEIGHT….2053

CHANGING MACHINE CONTROL PATTERN (IF PATTERN CHANGE VALVE EQUIPPED)….2055

CONTROL PATTERN CHANGE PROCEDURE….2055

MACHINE CONTROL PATTERNS….2056

ATTACHMENT GUIDE….2057

OTHER ATTACHMENTS….2057

ATTACHMENT COMBINATIONS….2058

SELECTION OF TRACK SHOES….2059

RECOMMENDED ATTACHMENT OPERATIONS….2060

HYDRAULIC BREAKER….2060

INDEX….2065

TEN00288-00 – Hydraulic Excavator PC78MR-6 Operation & Maintenance Manual….2069

COVER….2070

FOREWORD….2070

FOREWORD….2071

SAFETY INFORMATION….2072

INTRODUCTION….2074

DIRECTIONS OF MACHINE….2074

PRODUCT INFORMATION….2075

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE….2075

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION….2075

ADDITIONAL ENGINE SERIAL NO. PLATE….2076

SERVICE METER LOCATION….2076

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR….2076

CONTENTS….2077

SAFETY….2080

SAFETY….2081

SAFETY LABELS….2083

LOCATION OF SAFETY LABELS….2084

SAFETY LABELS….2085

GENERAL PRECAUTIONS….2092

SAFETY MACHINE OPERATION….2100

STARTING ENGINE….2100

OPERATION….2102

TRANSPORTATION….2108

BATTERY….2109

TOWING….2111

LIFTING OBJECTS WITH BUCKET….2112

SAFETY MAINTENANCE INFORMATION….2113

OPERATION….2120

MACHINE VIEW ILLUSTRATIONS….2121

OVERALL MACHINE VIEW….2121

CONTROLS AND GAUGES….2122

DETAILED CONTROLS AND GAUGES….2123

MONITORING SYSTEM….2123

SWITCHES….2133

CONTROL LEVERS AND PEDALS….2138

SUN ROOF….2143

WINDSHIELD….2144

SLIDING DOOR….2149

EMERGENCY ESCAPE HAMMER….2149

CAP WITH LOCK….2151

ENGINE HOOD….2152

MUD COVER….2153

BATTERY INSPECTION COVER….2154

FUSE….2155

FUSIBLE LINK….2156

AUXILIARY ELECTRIC POWER….2156

CONTROLLERS….2156

AIR CONDITIONER CONTROLS….2157

HEATER AND DEFROSTER CONTROLS….2163

RADIO….2168

OPERATION MANUAL STORAGE….2173

TOOL BOX….2173

GREASE PUMP HOLDER….2173

ASHTRAY….2173

FIRE EXTINGUISHER….2174

MACHINE OPERATIONS AND CONTROLS….2175

BEFORE STARTING ENGINE….2175

STARTING ENGINE….2191

AFTER STARTING ENGINE….2196

STOPPING THE ENGINE….2199

CHECK AFTER SHUT OFF ENGINE….2199

MACHINE OPERATION….2200

STEERING THE MACHINE….2204

SWINGING….2206

WORK EQUIPMENT CONTROLS AND OPERATIONS….2207

WORKING MODE….2209

PROHIBITED OPERATIONS….2210

GENERAL OPERATION INFORMATION….2212

TRAVELING ON SLOPES….2214

ESCAPE FROM MUD….2216

RECOMMENDED APPLICATIONS….2217

MACHINE READY FOR ATTACHMENT….2219

BUCKET REPLACEMENT AND INVERSION….2225

PARKING MACHINE….2228

MACHINE INSPECTION AFTER DAILY WORK….2229

LOCKING….2229

ROAD LINERS AND RUBBER SHOES….2230

TRANSPORTATION….2235

TRANSPORTATION PROCEDURE….2235

LOADING AND UNLOADING WITH TRAILER….2235

LIFTING MACHINE….2241

COLD WEATHER OPERATION….2243

COLD WEATHER OPERATION INFORMATION….2243

AFTER DAILY WORK COMPLETION….2245

AFTER COLD WEATHER SEASON….2245

LONG TERM STORAGE….2246

BEFORE STORAGE….2246

DURING STORAGE….2246

AFTER STORAGE….2246

TROUBLES AND ACTIONS….2247

RUNNING OUT OF FUEL….2247

PHENOMENA THAT ARE NOT FAILURES….2247

TOWING THE MACHINE….2248

SEVERE JOB CONDITION….2248

DISCHARGED BATTERY….2249

HOW TO LOWER WORK EQUIPMENT WHEN ENGINE STOPS DUE TO ABNORMALITY….2254

OTHER TROUBLE….2255

MAINTENANCE….2260

MAINTENANCE INFORMATION….2261

OUTLINE OF SERVICE….2263

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….2263

ELECTRIC SYSTEM MAINTENANCE….2267

WEAR PARTS….2268

WEAR PARTS LIST….2268

RECOMMENDED FUEL, COOLANT, AND LUBRICANT….2269

USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE….2270

RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL….2271

TIGHTENING TORQUE SPECIFICATIONS….2272

TIGHTENING TORQUE LIST….2272

SAFETY CRITICAL PARTS….2273

SAFETY CRITICAL PARTS LIST….2273

MAINTENANCE SCHEDULE….2274

MAINTENANCE SCHEDULE CHART….2274

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER….2275

MAINTENANCE PROCEDURE….2276

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)….2276

WHEN REQUIRED….2277

CHECK BEFORE STARTING….2310

EVERY 50 HOURS MAINTENANCE….2311

EVERY 100 HOURS MAINTENANCE….2312

EVERY 250 HOURS MAINTENANCE….2314

EVERY 500 HOURS MAINTENANCE….2322

EVERY 1000 HOURS MAINTENANCE….2329

EVERY 2000 HOURS MAINTENANCE….2334

EVERY 4000 HOURS MAINTENANCE….2335

EVERY 5000 HOURS MAINTENANCE….2336

SPECIFICATIONS….2338

SPECIFICATIONS….2339

ATTACHMENTS, OPTIONS….2342

ATTACHMENTS AND OPTIONS – GENERAL INFORMATION….2343

SAFETY FIRST….2343

ATTACHMENT INSTALLATION….2344

BUCKET WITH HOOK….2345

HOOK CONDITION….2345

PROHIBITED OPERATIONS….2345

METHOD FOR REMOVING AND INSTALLING EXTRA COUNTERWEIGHT….2346

CHANGING MACHINE CONTROL PATTERN (IF PATTERN CHANGE VALVE EQUIPPED)….2348

CONTROL PATTERN CHANGE PROCEDURE….2348

MACHINE CONTROL PATTERNS….2349

ATTACHMENT GUIDE….2350

OTHER ATTACHMENTS….2350

ATTACHMENT COMBINATIONS….2351

SELECTION OF TRACK SHOES….2352

RECOMMENDED ATTACHMENT OPERATIONS….2353

HYDRAULIC BREAKER….2353

INDEX….2358

Komatsu Hydraulic Excavators PC78MR Repair Service Manuals