Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC20MRX, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC20MRX-1 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM016602 – Hydraulic Excavator PC20MRX-1 Shop Manual.pdf

SEAM035202T – Hydraulic Excavator PC20MRx-1Operation & Maintenance Manual.pdf

SEAM035203 – Hydraulic Excavator PC20MRx-1 Operation & Maintenance Manual.pdf

Total Pages: 805 pages

File Format: PDF

Language: English

SEAM035202T – Hydraulic Excavator PC20MRx-1 Operation & Maintenance Manual…2

COVER…2

FOREWORD…3

FOREWORD…4

SAFETY INFORMATION…7

INTRODUCTION…9

DIRECTIONS OF MACHINE…9

PRODUCT INFORMATION…10

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION…10

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION…10

SERVICE METER LOCATION…11

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR…11

CONTENTS…12

SAFETY…15

SAFETY INFORMATION…16

WARNING LABELS AND PICTOGRAMS…18

WARNING LABELS AND PICTOGRAMS-LOCATION…18

WARNING LABELS AND PICTOGRAMS-ACTUAL…19

SAFETY INFORMATION…22

SAFETY RULES…22

IF ABNORMALITIES ARE FOUND…22

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS…22

FIRE EXTINGUISHER AND FIRST AID KIT…22

SAFETY EQUIPMENT…22

KEEP MACHINE CLEAN…23

KEEP OPERATOR'S COMPARTMENT CLEAN…23

LEAVING OPERATOR'S SEAT WITH LOCK…23

HANDRAILS AND STEPS…24

MOUNTING AND DISMOUNTING…24

NO PERSONS ON ATTACHMENTS…24

BURN PREVENTION…25

FIRE PREVENTION AND EXPLOSION PREVENTION…25

ACTION IF FIRE OCCURS…26

WINDSHIELD WASHER FLUID…26

FALLING OBJECTS,FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION…26

ATTACHMENT INSTALLATION…27

ATTACHMENT COMBINATIONS…27

CAB WIDOW GLASSES…27

UNAUTHORIZED MODIFICATIONS…27

SAFETY AT JOBSITE…27

WORKING ON LOOSE GROUND…27

DISTANCE TO HIGH VOLTAGE CABLES…28

ENSURE GOOD VISIBILITY…28

VENTILATION FOR ENCLOSED AREA…29

SIGNALMAN'S SIGNAL AND SIGNS…29

EMERGENCY EXIT FROM OPERATOR'S CAB…29

ASBESTOS DUST HAZARD PREVENTION…29

SAFETY MACHINE OPERATION…30

BEFORE STARTING ENGINE…30

CHECKS BEFORE STARTING ENGINE…30

SAFETY RULES FOR STARTING ENGINE…30

STARTING ENGINE IN COLD WEATHER…31

AFTER STARTING ENGINE…32

CHECKS AFTER STARTING ENGINE…32

SAFETY RULES FOR CHANGING MAHCINE DIRECTIONS…32

SAFETY RULES FOR TRAVELING…33

TRAVELING ON SLOPES…34

OPERATIONS ON SLOPES…35

PROHIBITED OPERATIONS…35

OPERATIONS ON SNOW…36

PARKING MACHINE…37

TRANSPORTATION…38

LOADING AND UNLOADING…38

SHIPPING THE MACHINE…38

BATTERY…39

BATTERY HAZARD PREVENTION…39

STARTING ENGINE WITH BOOSTER CABLES…40

TOWING…41

SAFETY RULES FOR TOWING…41

LIFTING OBJECTS WITH BUCKET…42

SAFETY RULES FOR LIFTING OBJECTS…42

SAFETY MAINTENANCE INFORMATION…43

WARING TAG…43

KEEP WORK PLACE CLEAN AND TIDY…43

APPOINT LEADER WHEN WORKING WITH OTHERS…43

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE…44

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING…45

PROPER TOOLS…45

PERSONNEL…45

ATTACHMENTS…46

WORK UNDER THE MACHINE…46

NOISE…46

WHEN USING HAMMER…46

WELDING WORKS…46

REMOVING BATTERY TERMINALS…47

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION…47

DO NOT DISASSEMBLE RECOIL SPRINGS…47

SAFETY RULES FOR HIGH-PRESSURE OIL…48

SAFETY HANDLING HIGH-PRESSURE HOSES…48

WASTE MATERIALS…48

AIR CONDITIONER MAINTENANCE…48

COMPRESSED AIR…49

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS…49

OPERATION…50

MACHINE VIEW ILLUSTRATIONS…51

OVERALL MACHINE VIEW…51

CONTROLS AND GAUGES…52

DETAILED CONTROLS AND GAUGES…53

MONITORING SYSTEM…53

SWITCHES…59

CONTROL LEVERS AND PEDALS…62

ENGINE HOOD…67

WINDSHIELD…69

SLIDING DOOR…72

EMERGENCY ESCAPE HAMMER…73

FUSE…74

BLOCK FUSE…74

COVER WITH LOCK…75

OPREATION MANUAL STORAGE…75

TOOL BOX…75

GREASE GUN HOLDER…76

MACHINE OPERATIONS AND CONTROLS…77

BEFORE STARTING ENGINE…77

STARTING ENGINE…89

AFTER STARTING ENGINE…92

STOPPING THE ENGINE…95

CHECK AFTER SHUT OFF ENGINE…95

MACHINE OPERATION…96

STEERING THE MACHINE…100

SWINGING…102

WORK EQUIPMENT CONTROLS AND OPERATIONS…103

PROHIBITED OPERATIONS…105

GENERAL OPERATION INFORMATION…108

TRAVELING ON SLOPES…109

ESCAPE FROM MUD…111

RECOMMENDED APPLICATIONS…111

BUCKET REPLACEMENT …114

PARKING MACHINE…115

MACHINE INSPECTION AFTER DAILY WORK…116

LOCKING…117

RUBBER SHOES (MACHINE WITH RUBBER SHOES ONLY)…118

TRANSPORTATION…122

TRANSPORTATION PROCEDURE…122

LOADING AND UNLOADING WITH TRAILER…122

LIFTING MACHINE…123

SHIPPING MACHINE INFORMATION…125

COLD WEATHER OPERATION…126

COLD WEATHER OPERATION INFORMATION…126

AFTER DAILY WORK COMPLETION…128

CAB HEATER IN COLD WEATHER…128

AFTER COLD WEATHER SEASON…128

LONG TERM STORAGE…129

BEFORE STORAGE…129

DURING STORAGE…129

AFTER STORAGE…129

STARTING MACHINE AFTER LONG-TERM STORAGE…130

TROUBLES AND ACTIONS…131

RUNNING OUT OF FUEL…131

PHENOMENA THAT ARE NOT FAILURES…131

TOWING THE MACHINE…132

SEVERE JOB CONDITION…132

DISCHARGED BATTERY…133

OTHER TROUBLE…137

MAINTENANCE…141

MAINTENANCE INFORMATION…142

LUBRICANTS, COOLANT AND FILTERS…144

OIL…144

ELECTRIC SYSTEM MAINTENANCE…145

WEAR PARTS…146

WEAR PARTS LIST…146

LUBRICANTS,FUEL AND COOLANT SPECIFICATIONS…147

PROPER SELECTION…147

TIGHTENING TORQUE SPECIFICATIONS…151

TIGHTENING TORQUE LIST…151

SAFETY CRITICAL PARTS…153

SAFETY CRITICAL PARTS LIST…153

MAINTENANCE SCHEDULE…154

MAINTENANCE SCHEDULE CHART…154

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER…155

MAINTENANCE PROCEDURE…156

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)…156

WHEN REQUIRED…157

AIR CLEANER ELEMENT-CHECK/CLEAN/REPLACE…157

COOLING SYSTEM COOLANT-CLEAN/CHANGE…159

BATTERY ELECTROLYTE LEVEL-CHECK…162

FUEL FILTER-CLEAN…163

TRACK TENSION (STEEL SHOES)-CHECK/ADJUST…164

RUBBER SHOES-CHECK…166

TRACK TENSION (RUBBER SHOES)-CHECK/ADJUST…168

RUBBER SHOES REPLACEMENT…170

BUCKET TEETH-CHECK/REPLACE…173

CAB SLIDE DOOR RAIL AND ROLLER-CHECK/CLEAN/LUBRICATE…175

FUEL TANK-DRAIN…176

CHECK BEFORE STARTING…177

EVERY 100 HOURS MAINTENANCE…178

LUBRICATING…178

EVERY 250 HOURS MAINTENANCE…179

ENGINE CRANKCASE OIL AND FILTER CARTRIDGE-CHANGE/REPLACE…179

FINAL DRIVE CASE OIL LEVEL-CHECK/ADD…180

HYDRAULIC OIL FILTER ELEMENT-REPLACE…180

COOLING FAN BELT TENSION-INSPECT/ADJUST…182

EVERY 500 HOURS MAINTENANCE…183

LUBRICATING…183

FUEL FILTER ELEMENT-REPLACE…184

RADIATOR CORE AND FINS-CHECK/CLEAN…186

FUEL FEED PUMP PRE-FILTER-REPLACE…186

EVERY 1000 HOURS MAINTENANCE…187

FINAL DRIVE CASE OIL-CHANGE…187

EVERY 2000 HOURS MAINTENANCE…188

HYDRAULIC OIL AND STRAINER-CHANGE/CLEAN…188

ALTERNATOR AND STARTING MOTOR-INSPECT…190

ENGINE VALVE CLEARANCES-INSPECT…190

SPECIFICATIONS…191

SPECIFICATIONS…192

ATTACHMENTS AND OPTIONS…194

ATTACHMENTS AND OPTIONS-GENERAL INFORMATION…195

SAFETY FIRST…195

ATTACHMENT INSTALLATION…196

BUCKET WITH HOOK…197

HOOK CONDITION…197

PROHIBITED OPERATIONS…197

RADIO…198

CONTROL PANEL…198

CONTROLS OF RADIO…201

CARE FOR RADIO…202

WINDSHIELD WASHER…203

WINDSHIELD WASHER OPERATION…203

WINDSHIELD WASHER FLUID LEVEL-CHECK/ADD…203

ATTACHMENT GUIDE…204

ATTACHMENT COMBINATIONS…204

HYDRAULIC BREAKER…205

INDEX…208

SEAM035203 – Hydraulic Excavator PC20MRx-1 Operation & Maintenance Manual…211

COVER…211

FOREWORD…212

FOREWORD…213

SAFETY INFORMATION…216

INTRODUCTION…218

DIRECTIONS OF MACHINE…218

PRODUCT INFORMATION…219

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION…219

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION…219

SERVICE METER LOCATION…220

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR…220

CONTENTS…221

SAFETY…224

SAFETY INFORMATION…225

WARNING LABELS AND PICTOGRAMS…227

WARNING LABELS AND PICTOGRAMS – LOCATION…227

WARNING LABELS AND PICTOGRAMS – ACTUAL…228

SAFETY INFORMATION…231

Asbestos Dust Hazard Prevention…238

Emergency Exit from Operator's Cab…238

Signalman's Signal and Signs…238

Ventilation for Enclosed Area…238

Ensure Good Visibility…237

Distance to High Voltage Cables…237

Safety at Jobsite…236

Unauthorized Modifications…236

Cab Widow Glasses…236

Attachment Combinations…236

Attachment Installation…236

Falling Objects, Flying Objects and Intruding Objects Prevention…235

Windshield Washer Fluid…235

Action If Fire Occurs…235

Fire Prevention and Explosion Prevention…234

Burn Prevention…234

No Persons on Attachments…233

Mounting and Dismounting…233

Handrails and Steps…233

Leaving Operator's Seat with Lock…232

Keep Operator's Compartment Clean…232

Keep Machine Clean…232

Safety Equipment…231

Fire Extinguisher and First Aid Kit…231

Working Wear and PersonaŁŁ Protective Items…231

If Abnormalities are Found…231

Safety Rules…231

SAFETY MACHINE OPERATION…239

BEFORE STARTING ENGINE…239

Checks Before Starting Engine…239

Safety Rules for Starting Engine…239

Starting Engine in Cold Weather…240

AFTER STARTING ENGINE…241

Checks After Starting Engine…241

Safety Rules for Changing Machine Directions…241

Safety Rules for Traveling…242

Traveling on Slopes…243

Operations on Slopes…244

Prohibited Operations…244

Operations on Snow…245

Parking Machine…246

TRANSPORTATION…247

Loading and Unloading…247

Shipping the Machine…247

BATTERY…248

Battery Hazard Prevention…248

Starting Engine with Booster Cables…249

TOWING…250

Safety Rules for Towing…250

LIFTING OBJECTS WITH BUCKET…251

Safety Rules for Lifting Objects…251

SAFETY MAINTENANCE INFORMATION…252

Warning Tag…252

Keep Work Place Clean and Tidy…252

Appoint Leader when Working with Others…252

Stop Engine Before Carrying Out Maintenance…253

Two Workers for Maintenance when Engine is Running…254

Proper Tools…254

Personnel…254

Attachments…255

Work Under the Machine…255

Noise…255

When Using Hammer…255

Welding Works…255

Removing Battery Terminals…256

Safety First when Using High-pressure Grease to Adjust Track Tension…256

Do Not Disassemble Recoil Springs…256

Safety Rules for High-pressure Oil…257

Safety Handling High-pressure Hoses…257

Waste Materials…257

Air Conditioner Maintenance…257

Compressed Air…258

Periodic Replacement of Safety Critical Parts…258

OPERATION…260

MACHINE VIEW ILLUSTRATIONS…261

OVERALL MACHINE VIEW…261

CONTROLS AND GAUGES…262

DETAILED CONTROLS AND GAUGES…263

MONITORING SYSTEM…263

SWITCHES…269

CONTROL LEVERS AND PEDALS…272

ENGINE HOOD…277

WINDSHIELD…279

SLIDING DOOR…282

EMERGENCY ESCAPE HAMMER…283

FUSE…284

BLOCK FUSE…284

COVER WITH LOCK…285

OPERATION MANUAL STORAGE…285

TOOL BOX…285

GREASE GUN HOLDER…286

MACHINE OPERATIONS AND CONTROLS…287

BEFORE STARTING ENGINE…287

STARTING ENGINE…299

AFTER STARTING ENGINE…302

STOPPING THE ENGINE…305

CHECK AFTER SHUT OFF ENGINE…305

MACHINE OPERATION…306

STEERING THE MACHINE…310

SWINGING…312

WORK EQUIPMENT CONTROLS AND OPERATIONS…313

PROHIBITED OPERATIONS…315

GENERAL OPERATION INFORMATION…318

TRAVELING ON SLOPES…319

ESCAPE FROM MUD…321

RECOMMENDED APPLICATIONS…321

BUCKET REPLACEMENT…324

PARKING MACHINE…325

MACHINE INSPECTION AFTER DAILY WORK…326

LOCKING…327

RUBBER SHOES (MACHINE WITH RUBBER SHOES ONLY)…328

TRANSPORTATION…332

TRANSPORTATION PROCEDURE…332

LOADING AND UNLOADING WITH TRAILER…332

LIFTING MACHINE…333

SHIPPING MACHINE INFORMATION…335

COLD WEATHER OPERATION…336

COLD WEATHER OPERATION INFORMATION…336

AFTER DAILY WORK COMPLETION…338

CAB HEATER IN COLD WEATHER…338

AFTER COLD WEATHER SEASON…338

LONG TERM STORAGE…339

BEFORE STORAGE…339

DURING STORAGE…339

AFTER STORAGE…339

STARTING MACHINE AFTER LONG-TERM STORAGE…340

TROUBLES AND ACTIONS…341

RUNNING OUT OF FUEL…341

PHENOMENA THAT ARE NOT FAILURES…341

TOWING THE MACHINE…342

SEVERE JOB CONDITION…342

DISCHARGED BATTERY…343

OTHER TROUBLE…347

MAINTENANCE…352

MAINTENANCE INFORMATION…353

LUBRICANTS, COOLANT AND FILTERS…355

OIL…355

ELECTRIC SYSTEM MAINTENANCE…356

WEAR PARTS…357

WEAR PARTS LIST…357

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS…358

PROPER SELECTION…358

TIGHTENING TORQUE SPECIFICATIONS…362

TIGHTENING TORQUE LIST…362

SAFETY CRITICAL PARTS…364

SAFETY CRITICAL PARTS LIST…364

MAINTENANCE SCHEDULE…365

MAINTENANCE SCHEDULE CHART…365

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER…366

MAINTENANCE PROCEDURE…367

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)…367

FUEL FILTER ELEMENT – REPLACE…395

ENGINE VALVE CLEARANCES – INSPECT…401

WHEN REQUIRED…368

AIR CLEANER ELEMENT – CHECK/CLEAN/REPLACE…368

COOLING SYSTEM COOLANT – CLEAN/ CHANGE…370

BATTERY ELECTROLYTE LEVEL – CHECK…373

FUEL FILTER – CLEAN…374

TRACK TENSION (STEEL SHOES)- CHECK/ADJUST…375

RUBBER SHOES – CHECK…377

TRACK TENSION (RUBBER SHOES)- CHECK/ADJUST…379

RUBBER SHOES REPLACEMENT…381

BUCKET TEETH – CHECK/REPLACE…384

CAB SLIDE DOOR RAIL AND ROLLER – CHECK/CLEAN/LUBRICATE…386

FUEL TANK – DRAIN…387

CHECK BEFORE STARTING…388

COOLING SYSTEM COOLANT – CLEAN/CHANGE…289

ENGINE CRANKCASE OIL LEVEL – CHECK/ADD…290

FUEL LEVEL – CHECK/REFILL…291

HYDRAULIC OIL LEVEL – CHECK/ADD…292

AIR CLEANER DUST INDICATOR – CHECK…293

FUEL FILTER – CHECK/CLEAN…293

ELECTRIC WIRING – INSPECT…294

HORN FUNCTION – CHECK…294

EVERY 100 HOURS MAINTENANCE…389

LUBRICATING…389

EVERY 250 HOURS MAINTENANCE…390

ENGINE CRANKCASE OIL AND FILTER CARTRIDGE – CHANGE/REPLACE…390

FINAL DRIVE CASE OIL LEVEL – CHECK/ADD…391

HYDRAULIC OIL FILTER ELEMENT – REPLACE…391

COOLING FAN BELT TENSION – INSPECT/ADJUST…393

EVERY 500 HOURS MAINTENANCE…394

LUBRICATING…394

FUEL FILTER ELEMENT – REPLACE…395

RADIATOR CORE AND FINS – CHECK/CLEAN…397

FUEL FEED PUMP PRE-FILTER – REPLACE…397

EVERY 1000 HOURS MAINTENANCE…398

FINAL DRIVE CASE OIL – CHANGE…398

EVERY 2000 HOURS MAINTENANCE…399

HYDRAULIC OIL AND STRAINER – CHANGE/CLEAN…399

ALTERNATOR AND STARTING MOTOR – INSPECT…401

ENGINE VALVE CLEARANCES – INSPECT…401

SPECIFICATIONS…402

SPECIFICATIONS…403

ATTACHMENT AND OPTIONS…406

ATTACHMENTS AND OPTIONS – GENERAL INFORAMTION…407

SAFETY FIRST…407

ATTACHMENT INSTALLATION…408

BUCKET WITH HOOK…409

HOOK CONDITION…409

PROHIBITED OPERATIONS…409

RADIO…410

CONTROL PANEL…410

CONTROLS OF RADIO…413

CARE FOR RADIO…414

WINDSHIELD WASHER…415

WINDSHIELD WASHER OPERATION…415

WINDSHIELD WASHER FLUID LEVEL – CHECK/ADD…415

ATTACHMENT GUIDE…416

ATTACHMENT COMBINATIONS…416

HYDRAULIC BREAKER…417

INDEX…420

SEBM016602 – Hydraulic Excavator PC20MRX-1 Shop Manual…424

COVER PAGE…424

CONTENTS…425

00 FOREWARD…425

SAFETY…428

FOREWARD…430

HOW TO READ THE SHOP MANUAL…425

HOISTING INSTRUCTIONS…432

METHOD OF DISASSEMBLING, CONNECTING PUSH-PULL TYPE COUPLER…433

COATING MATERIALS…435

STANDARD TIGHTENING TORQUE…437

ELECTRIC WIRE CODE…440

CONVERSION TABLE…441

01 GENERAL…447

GENERAL ASSEMBLY DRAWING…448

SPECIFICATIONS…450

WEIGHT TABLE…454

LIST OF LUBRICANT AND WATER…456

10 STRUCTURE AND FUNCTION…457

RADIATOR, OIL COOLER…458

ENGINE CONTROL…459

PTO…460

POWER TRAIN DIAGRAM…461

SWING CIRCLE…462

SWING MACHINERY…463

TRACK FRAME…464

RECOIL SPRING…465

TRACK SHOE…466

HYDRAULIC PIPING DRAWING…467

HYDRAULIC TANK…469

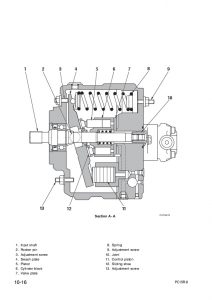

HYDRAULIC PUMP…470

CONTROL VALVE…490

CLSS…498

CENTER SWIVEL JOINT…527

SWING MOTOR…528

TRAVEL MOTOR…529

VALVE CONTROL…533

PPC VALVE…534

SOLENOID VALVE…541

WORK EQUIPMENT…543

ELECTRICAL WIRING DIAGRAM…544

MACHINE MONITOR SYSTEM…546

20 TESTING AND ADJUSTING…551

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS…552

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS…553

STANDARD VALUE TABLE FOR ELECTRICAL PARTS…561

TESTING AND ADJUSTING…563

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING…564

MEASURING ENGINE SPEED…565

MEASURING EXHAUST COLOR…566

ADJUSTING VALVE CLEARANCE…567

MEASURING COMPRESSION PRESSURE…568

TESTING AND ADJUSTING FUEL INJECTION TIMING…569

MEASURING ENGINE OIL PRESSURE…570

TESTING AND ADJUSTING FAN BELT TENSION…571

ADJUSTING FUEL CONTROL LEVER…572

TESTING AND ADJUSTING TRACK SHOE TENSION…573

MEASURING SPROCKET WEAR…574

TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT…575

TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE…577

ADJUSTING TCC VALVE…578

TESTING AND ADJUSTING CONTROL CIRCUIT PRESSURE…579

MEASURING SWING HOLDING BRAKE INLET PORT PRESSURE…580

ADJUSTING WORK EQUIPMENT, SWING PPC VALVE…580

TESTING AND ADJUSTING TRAVEL DEVIATION…581

MEASURING OIL LEAKAGE INSIDE WORK EQUIPMENT CYLINDER…582

RELEASING REMAINING PRESSURE FROM HYDRAULIC CIRCUIT…584

RELEASING REMAINING PRESSURE FROM HYDRAULIC TANK…584

PRESSURIZING HYDRAULIC TANK…584

BLEEDING AIR…585

TROUBLESHOOTING…587

POINTS TO REMEMBER WHEN TROUBLESHOOTING…588

SEQUENCE OF EVENTS IN TROUBLESHOOTING…589

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE…590

CHECKS BEFORE TROUBLESHOOTING…598

CONNECTOR TYPES AND MOUNTING LOCATIONS…599

CONNECTOR PIN ALLOCATION DRAWING…600

CONNECTION TABLE FOR CONNECTOR PIN NUMBERS…602

METHOD OF USING TROUBLESHOOTING CHARTS…609

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)…611

E-MODE RELATED ELECTRICAL CIRCUIT DIAGRAM…612

E-1 ENGINE DOES NOT START…614

A) WHEN STARTING MOTOR DOES NOT TURN (STARTING SYSTEM)…614

B) WHEN STARTING MOTOR TURNS (ENGINE STOP SOLENOID SYSTEM)…616

E-2 ENGINE DOES NOT STOP…618

E-3 WORK EQUIPMENT DOES NOT MOVE EVEN WHEN WORK EQUIPMENT LOCK IS CANCELED…619

E-4 WORK EQUIPMENT MOVES EVEN WHEN WORK EQUIPMENT LOCK LEVER IS LOCKED…620

E-5 TRAVEL SPEED DOES NOT INCREASE EVEN WHEN TRAVEL BOOST PEDAL IS DEPRESSED…621

E-6 TRAVEL SPEED DOES NOT DECREASE EVEN WHEN TRAVEL BOOST PEDAL IS RELEASED…622

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)…623

TABLE OF FAILURE MODES AND CAUSES…624

H-1 SPEEDS OF ALL WORK EQUIPMENT, SWING, TRAVEL ARE SLOW OR LACK POWER…626

H-2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS…627

H-3 NO WORK EQUIPMENT, TRAVEL, SWING MOVE…628

H-4 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)…628

H-5 FINE CONTROL ABILITY IS POOR OR RESPONSE IS POOR…629

H-6 BOOM IS SLOW OR LACKS POWER…630

H-7 ARM IS SLOW OR LACKS POWER…630

H-8 BUCKET IS SLOW OR LACKS POWER…631

H-9 BOOM SWING IS SLOW OR LACKS POWER…631

H-10 BLADE IS SLOW OR LACKS POWER…632

H-11 BOOM, ARM, BUCKET DO NOT MOVE (BOOM SWING, BLADE, TRAVEL AND SWING ARE NORMAL)…632

H-12 EXCESSIVE HYDRAULIC DRIFT (BOOM, ARM, BUCKET, BOOM SWING, BLADE)…633

A) BOOM…633

B) ARM, BUCKET, BOOM SWING…633

C) BLADE…633

H-13 EXCESSIVE TIME LAG (ENGINE AT LOW IDLING)…634

H-14 IN COMPOUND OPERATIONS, WORK EQUIPMENT WITH LARGER LOAD IS SLOW…634

H-15 TRAVEL DEVIATION…635

A) DEVIATION IN NORMAL TRAVEL…635

B) DEVIATION WHEN STARTING…635

H-16 TRAVEL SPEED IS SLOW OR LACKS POWER…636

H-17 STEERING DOES NOT TURN EASILY…636

H-18 TRAVEL SPEED DOES NOT SWITCH…637

H-19 TRAVEL DOES NOT MOVE (ONE SIDE ONLY)…637

H-20 SWING SPEED IS SLOW OR LACKS POWER…638

A) SPEED IS SLOW OR LACKS POWER IN BOTH DIRECTIONS…638

B) SPEED IS SLOW OR LACKS POWER IN ONE DIRECTION ONLY (LEFT OR RIGHT)…638

H-21 DOES NOT SWING…639

A) DOES NOT SWING IN EITHER DIRECTION…639

B) DOES NOT SWING IN ONE DIRECTION (LEFT OR RIGHT)…639

H-22 SWING ACCELERATION IS POOR…640

A) ACCELERATION IS POOR IN BOTH DIRECTIONS…640

B) ACCELERATION IS POOR IN ONE DIRECTION ONLY (LEFT OR RIGHT)…640

H-23 EXCESSIVE OVERRUN WHEN STOPPING SWING…641

A) OVERRUN WHEN STOPPING IS EXCESSIVE IN BOTH DIRECTIONS…641

B) OVERRUN WHEN STOPPING IS EXCESSIVE IN ONE DIRECTION ONLY (LEFT OR RIGHT)…641

H-24 EXCESSIVE SHOCK WHEN STOPPING SWING (IN ONE DIRECTION ONLY)…642

H-25 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING…642

H-26 EXCESSIVE HYDRAULIC DRIFT OF SWING…642

TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)…643

ELECTRICAL CIRCUIT DIAGRAM FOR M MODE RELATED PARTS…644

M-1 WHEN STARTING SWITCH IS TURNED ON, NO DISPLAY IS GIVEN…645

M-2 WHEN STARTING SWITCH IS TURNED ON, EVEN WHEN SELF CHECK IS COMPLETED (ALL LAMPS LIGHT UP FOR 3 SECONDS), LAMPS DO NOT GO…645

M-3 WHEN STARTING SWITCH IS TURNED ON, SOME SELF CHECK LAMPS DO NOT LIGHT UP FOR 3 SECONDS…646

A) NO GAUGE LAMPS LIGHT UP (FUEL, COOLANT TEMPERATURE)…646

B) CAUTION LAMPS (ENGINE OIL PRESSURE, BATTERY CHARGE), PILOT LAMP (PREHEATING) DO NOT LIGHT UP…646

M-4 DURING SELF CHECK (ALL LAMPS LIGHT UP FOR 3 SECONDS), EVEN IF STARTING SWITCH IS TURNED TO START, SELF CHECK IS NOT COMP…646

M-5 WHEN STARTING SWITCH IS ON (ENGINE STOPPED), ENGINE OIL PRESSURE CAUTION LAMP DOES NOT LIGHT UP…647

M-6 WHEN STARTING SWITCH IS TURNED ON (BEFORE STARTING ENGINE), CHARGE CAUTION LAMP DOES NOT LIGHT UP…648

M-7 WHEN STARTING SWITCH IS TURNED TO HEAT, PREHEATING PILOT LAMP DOES NOT LIGHT…649

M-8 WHEN ENGINE IS RUNNING, ENGINE OIL PRESSURE CAUTION LAMP LIGHTS UP…649

M-9 WHEN ENGINE IS RUNNING, CHARGE CAUTION LAMP LIGHTS UP…650

M-10 ABNORMALITY IN COOLANT TEMPERATURE GAUGE…652

A) LEVEL DOES NOT RISE FROM SEGMENT C…652

B) LEVEL DOES NOT GO DOWN FROM SEGMENT H, OR ALL SEGMENTS GO OUT…652

C) COOLANT TEMPERATURE DOES NOT MATCH GUAGE DISPLAY…653

M-11 ABNORMALITY IN FUEL GAUGE…654

A) LEVEL DOES NOT RISE FROM SEGMENT E OR ALL SEGMENTS GO OUT…654

B) LEVEL DOES NOT GO DOWN FROM SEGMENT F…654

C) FUEL LEVEL DOES NOT MATCH GAUGE DISPLAY…655

M-12 DEFECTIVE OPERATION OF ALARM BUZZER…656

A) BUZZER DOES NOT SOUND…656

B) BUZZER CONTINUES TO SOUND AND DOES NOT STOP…656

M-13 WHEN ENGINE IS RUNNING, SERVICE METER DOES NOT ADVANCE…657

A) WHEN CHARGE CAUTION LAMP DOES NOT LIGHT UP…657

B) WHEN CHARGE CAUTION LAMP LIGHTS UP…657

C) PILOT LAMP DOES NOT FLASH (SERVICE METER IS ACTUATED)…657

M-14 NIGHT LIGHTING DOES NOT LIGHT UP…658

A) GAUGE LIGHTING DOES NOT LIGHT UP…658

B) SERVICE METER LIGHTING DOES NOT LIGHT UP…658

30 DISASSEMBLY AND ASSEMBLY…659

METHOD OF USING MANUAL…661

PRECAUTION WHEN CARRYING OUT OPERATION…662

SPECIAL TOOL LIST…664

STARTING MOTOR…665

REMOVAL AND INSTALLATION…665

ALTERNATOR…666

REMOVAL AND INSTALLATION…666

FUEL INJECTION PUMP…667

REMOVAL…667

INSTALLATION…668

NOZZLE HOLDER…669

REMOVAL AND INSTALLATION…669

WATER PUMP…670

REMOVAL AND INSTALLATION…670

THERMOSTAT…671

REMOVAL AND INSTALLATION…671

ENGINE FRONT SEAL…672

REMOVAL AND INSTALLATION…672

ENGINE REAR SEAL…673

REMOVAL…673

INSTALLATION…674

CYLINDER HEAD…675

REMOVAL…675

INSTALLATION…676

RADIATOR…677

REMOVAL AND INSTALLATION…677

ENGINE AND HYDRAULIC PUMP …678

REMOVAL…678

INSTALLATION…681

FUEL TANK…682

REMOVAL AND INSTALLATION…682

DAMPER…683

REMOVAL AND INSTALLATION…683

CENTER SWIVEL JOINT…684

REMOVAL AND INSTALLATION…684

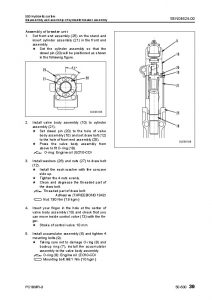

DISASSEMBLY AND ASSEMBLY…685

TRAVEL MOTOR…686

REMOVAL AND INSTALLATION…686

DISASSEMBLY AND ASSEMBLY OF TRAVEL MOTOR PHV190…687

SPROCKET…698

REMOVAL AND INSTALLATION…698

SWING MOTOR AND SWING MACHINERY…699

REMOVAL AND INSTALLATION…699

REVOLVING FRAME…700

REMOVAL…700

INSTALLATION…701

SWING CIRCLE…702

REMOVAL AND INSTALLATION…702

IDLER …703

REMOVAL AND INSTALLATION…703

DISASSEMBLY…704

ASSEMBLY…705

RECOIL SPRING…707

REMOVAL AND INSTALLATION…707

DISASSEMBLY AND ASSEMBLY…708

TRACK ROLLER…709

REMOVAL AND INSTALLATION…709

DISASSEMBLY …710

ASSEMBLY…711

RUBBER SHOE…712

REMOVAL AND INSTALLATION…712

HYDRAULIC TANK…713

REMOVAL AND INSTALLATION…713

HYDRAULIC OIL COOLER…714

REMOVAL AND INSTALLATION…714

HYDRAULIC PUMP…715

REMOVAL AND INSTALLATION…715

CONTROL VALVE…716

REMOVAL…716

INSTALLATION…718

DISASSEMBLY…719

ASSEMBLY…724

MAIN RELIEF VALVE…729

REMOVAL AND INSTALLATION…729

RIGHT/LEFT PPC VALVE…730

REMOVAL…730

INSTALLATION…731

PPC VALVE…732

DISASSEMBLY…732

ASSEMBLY…733

BOOM CYLINDER…734

REMOVAL…734

INSTALLATION…735

ARM CYLINDER…736

REMOVAL…736

INSTALLATION…737

BUCKET CYLINDER…738

REMOVAL…738

INSTALLATION…739

SWING CYLINDER…740

REMOVAL…740

INSTALLATION…741

BLADE CYLINDER…742

REMOVAL AND INSTALLATION…742

HYDRAULIC CYLINDER…743

DISASSEMBLY…743

ASSEMBLY…746

WORK EQUIPMENT…749

REMOVAL…749

INSTALLATION…750

BUCKET…751

REMOVAL AND INSTALLATION…751

QUICK BUCKET…752

REMOVAL AND INSTALLATION…752

ARM…753

REMOVAL…753

INSTALLATION…754

BUCKET AND ARM…755

REMOVAL…755

INSTALLATION…756

BOOM…757

REMOVAL…757

INSTALLATION…758

SWING BRACKET…759

REMOVAL…759

INSTALLATION…760

BLADE…761

REMOVAL AND INSTALLATION…761

SOLENOID VALVE…762

REMOVAL AND INSTALLATION…762

COUNTERWEIGHT…763

REMOVAL AND INSTALLATION…763

SEAT AND BRACKET…764

REMOVAL AND INSTALLATION…764

MONITOR…765

REMOVAL AND INSTALLATION…765

40 MAINTENANCE STANDARD…766

SWING CIRCLE…767

TRACK FRAME, RECOIL SPRING…768

IDLER…769

TRACK ROLLER…770

TRACK SHOE…771

HYDRAULIC PUMP…774

CONTROL PUMP…775

CONTROL VALVE…776

CENTER SWIVEL JOINT…782

TRAVEL MOTOR…783

PPC VALVE…784

HYDRAULIC CYLINDER…786

WORK EQUIPMENT…788

DIMENSION OF WORK EQUIPMENT…790

90 OTHERS…794

HYDRAULIC CIRCUIT DIAGRAM…795

ELECTRICAL CIRCUIT DIAGRAM…800

Komatsu Hydraulic Excavator PC20MRX Repair Service Manuals