Complete service repair manual with Electrical Wiring Diagrams for Komatsu Hydraulic Excavator PC09-1, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Hydraulic Excavator PC09-1 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

SEBM026105 – Hydraulic Excavator PC09-1 Shop Manual.pdf

SEAM044501T – Hydraulic Excavator GALEO PC09-1 Operation & Maintenance Manual.pdf

SEAM044502 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual.pdf

TEN00062-04 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual.pdf

TEN00555-00 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual.pdf

Total Pages: 1,027 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

SEAM044501T – Hydraulic Excavator GALEO PC09-1 Operation & Maintenance Manual….2

COVER….2

FOREWORD….3

FOREWORD….4

SAFETY INFORMATION….7

INTRODUCTION….9

DIRECTIONS OF MACHINE….9

PRODUCT INFORMATION….10

MACHINE SERIAL NUMBER PLATE AND ITS LOCATION….10

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION….10

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION….11

SERVICE METER LOCATION….11

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR….12

CONTENTS….13

SAFETY….16

SAFETY INFORMATION….17

SAFETY LABELS….19

LOCATION OF SAFETY LABELS….19

SAFETY LABELS….20

SAFETY INFORMATION….23

SAFETY RULES….23

IF ABNORMALITIES ARE FOUND….23

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS….23

FIRE EXTINGUISHER AND FIRST AID KIT….23

SAFETY EQUIPMENT….23

KEEP MACHINE CLEAN….24

OPERATOR'S SEAT EQUIPMENT….24

LEAVING OPERATOR'S SEAT WITH LOCK….24

HANDRAILS AND STEPS….25

MOUNTING AND DISMOUNTING….25

NO PERSONS ON ATTACHMENTS….25

BURN PREVENTION….26

FIRE PREVENTION AND EXPLOSION PREVENTION….27

ACTION IF FIRE OCCURS….27

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION….28

ATTACHMENT INSTALLATION….28

ATTACHMENT COMBINATIONS….28

UNAUTHORIZED MODIFICATIONS….28

SAFETY AT JOBSITE….29

WORKING ON LOOSE GROUND….29

DISTANCE TO HIGH VOLTAGE CABLES….29

ENSURE GOOD VISIBILITY….30

VENTILATION FOR ENCLOSED AREA….30

SIGNALMAN'S SIGNAL AND SIGNS….30

ASBESTOS DUST HAZARD PREVENTION….30

SAFETY MACHINE OPERATION….31

STARTING ENGINE….31

CHECKS BEFORE STARTING ENGINE….31

SAFETY RULES FOR STARTING ENGINE….31

SAFETY ENGINE IN COLD WEATHER….31

OPERATION….32

CHECKS BEFORE OPERATION….32

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS….32

SAFETY RULES FOR TRAVELING….33

TRAVELING ON SLOPES….34

OPERATIONS ON SLOPES….35

PROHIBITED OPERATIONS….35

OPERATIONS ON SNOW….37

PARKING MACHINE….37

TRANSPORTATION….39

LOADING AND UNLOADING….39

SHIPPING THE MACHINE….39

BATTERY….40

BATTERY HAZARD PREVENTION….40

STARTING ENGINE WITH BOOSTER CABLES….41

TOWING….42

SAFETY RULES FOR TOWING….42

LIFTING OBJECTS WITH BUCKET….43

SAFETY RULES FOR LIFTING OBJECTS….43

SAFETY MAINTENANCE INFORMATION….44

WARNING TAG….44

KEEP WORK PLACE CLEAN AND TIDY….44

APPOINT LEADER WHEN WORKING WITH OTHERS….44

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE….45

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING….46

PROPER TOOLS….46

PERSONNEL….46

ATTACHMENTS….47

WORK UNDER THE MACHINE….47

NOISE….47

WHEN USING HAMMER….47

WELDING WORKS….47

REMOVING BATTERY TERMINALS….48

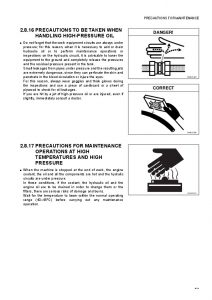

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION….48

SAFETY RULES FOR HIGH-PRESSURE OIL….48

SAFETY HANDLING HIGH-PRESSURE HOSES….49

WASTE MATERIALS….49

COMPRESSED AIR….49

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS….49

OPERATION….50

MACHINE VIEW ILLUSTRATIONS….51

OVERALL MACHINE VIEW….51

CONTROLS AND GAUGES….52

DETAILED CONTROLS AND GAUGES….53

METERS,LAMPS….53

SWITCHES….55

CONTROL LEVERS AND PEDALS….57

VARIABLE BLADE….64

ENGINE HOOD….64

FUSE….65

BLOCK FUSE….65

OPERATION MANUAL STORAGE….66

MACHINE OPERATIONS AND CONTROLS….67

BEFORE STARTING ENGINE….67

STARTING ENGINE….78

AFTER STARTING ENGINE….81

STOPPING THE ENGINE….84

CHECK AFTER SHUT OFF ENGINE….84

MACHINE OPERATION….85

STEERING THE MACHINE….89

SWINGING….91

WORK EQUIPMENT CONTROLS AND OPERATIONS….92

PROHIBITED OPERATIONS….94

GENERAL OPERATION INFORMATION….97

TRAVELING ON SLOPES….98

ESCAPE FROM MUD….100

WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR….101

BUCKET REPLACEMENT….103

PARKING MACHINE….105

MACHINE INSPECTION AFTER DAILY WORK….106

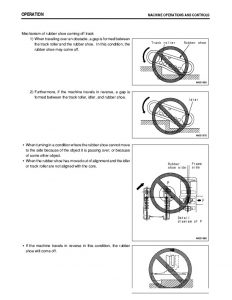

RUBBER SHOES(MACHINE WITH RUBBER SHOES ONLY)….107

TRANSPORTATION….112

TRANSPORTATION PROCEDURE….112

LOADING AND UNLOADING WITH TRAILER….112

LIFTING MACHINE….114

SHIPPING MACHINE INFORMATION….116

COLD WEATHER OPERATION….117

COLD WEATHER OPERATION INFORMATION….117

AFTER DAILY WORK COMPLETION….119

AFTER COLD WEATHER SEASON….119

LONG TERM STORAGE….120

BEFORE STORAGE….120

DURING STORAGE….120

AFTER STORAGE….120

STARTING MACHINE AFTER LONG-TERM STORAGE….120

TROUBLES AND ACTIONS….121

RUNNING OUT OF FUEL….121

PHENOMENA THAT ARE NOT FAILURES….121

TOWING THE MACHINE….122

SEVERE JOB CONDITION….122

DISCHARGED BATTERY….123

OTHER TROUBLE….127

MAINTENANCE….131

MAINTENANCE INFORMATION….132

LUBRICANTS, COOLANT AND FILTERS….134

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….134

ELECTRIC SYSTEM MAINTENANCE….136

WEAR PARTS….137

WEAR PARTS LIST….137

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS….138

PROPER SELECTION….138

TIGHTENING TORQUE SPECIFICATIONS….142

TIGHTENING TORQUE LIST….142

SAFETY CRITICAL PARTS….143

SAFETY CRITICAL PARTS LIST….143

MAINTENANCE SCHEDULE….144

MAINTENANCE SCHEDULE CHART….144

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER….145

MAINTENANCE SCHEDULE….146

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)….146

WHEN REQUIRED….147

CHECK,CLEAN AND REPLACE AIR CLEANER ELEMENT….147

CLEAN INSIDE OF COOLING SYSTEM….149

CHECK LEVEL OF BATTERY ELECTROLYTE….152

CHECK RUBBER SHOES….155

CHECK AND ADJUST RUBBER SHOE TENSION….157

REPLACE RUBBER SHOES….159

DRAIN WATER AND SEDIMENT FROM FUEL TANK….162

CHECKS BEFORE STARTING….163

EVERY 100 HOURS MAINTENANCE….164

LUBRICATING….164

EVERY 250 HOURS MAINTENANCE….165

LUBRICATING….165

REPLACE ENGINE OIL IN ENGINE OIL PAN….166

CHECK OIL LEVEL IN FINAL DRIVE CASE,ADD OIL….167

REPLACE HYDRAULIC OIL FILTER CARTRIDGE….168

CHECK AND ADJUST COOLINE FAN BELT TENSION….169

EVERY 500 HOURS MAINTENANCE….170

LUBRICATING….170

REPLACE ENGINE OIL FILTER CARTRIDGE….171

REPLACE FUEL FILTER ELEMENT….172

CLEAN AND INSPECT RADIATOR FINS AND OIL COOLER FINS….174

REPLACE FUEL FEED PUMP PRE-FILTER….175

EVERY 1000 HOURS MAINTENANCE….176

CHANGE OIL IN FINAL DRIVE CASE….176

EVERY 2000 HOURS MAINTENANCE….177

CHANGE OIL IN HYDRAULIC TANK,CLEAN STRAINER….177

CHECK ALTERNATOR,STARTING MOTOR….178

CHECK ENGINE VALVE CLEARANCE,ADJUST….178

SPECIFICATIONS….179

SPECIFICATIONS….180

ATTACHMENTS, OPTIONS….182

ATTACHMENTS AND OPTIONS-GENERAL INFORAMTION….183

SAFETY FIRST….183

ATTACHMENT INSTALLATION….184

BUCKET WITH HOOK….185

HOOK CONDITION….185

PROHIBITED OPERATIONS….185

ATTACHMENT GUIDE….186

ATTACHMENT COMBINATIONS….186

HANDLING ARM WITH BUILT-IN BREAKER….187

BUCKET POSTURE….187

REMOVING AND INSTALLING CHISEL….187

PROCEDURE FOR BREAKER OPERATIONS….188

PRECAUTIONS WHEN CARRYING OUT BREAKER OPERATIONS….189

STOWING CHISEL,DUMMY CHISEL….190

PRECAUTIONS WHEN CARRYING OUT BUCKET OPERATIONS….190

HANDLING DUMMY LINK….191

CHECK BEFORE STARTING….192

SPECIFICATIONS….193

HANDLING BUCKET COUPLER….194

PROCEDURE FOR REMOVING BUCKET….194

PROCEDURE FOR INSTALLING BUCKET….196

RECOMMENDED ATTACHMENT OPERATIONS….198

HYDRAULIC BREAKER….198

INDEX….202

SEAM044502 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual….205

COVER….205

FOREWARD….206

FOREWORD….207

SAFETY INFORMATION….210

INTRODUCTION….212

DIRECTIONS OF MACHINE….212

PRODUCT INFORMATION….213

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE….213

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION….213

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION….214

SERVICE METER LOCATION….214

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR….215

CONTENTS….216

SAFETY….220

SAFETY INFORMATION….221

SAFETY LABELS….223

LOCATION OF SAFETY LABELS….223

SAFETY LABELS….224

SAFETY INFORMATION….227

SAFETY RULES….227

IF ABNORMALITIES ARE FOUND….227

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS….227

FIRE EXTINGUISHER AND FIRST AID KIT….227

SAFETY EQUIPMENT….227

KEEP MACHINE CLEAN….228

OPERATOR'S SEAT EQUIPMENT….228

LEAVING OPERATOR'S SEAT WITH LOCK….228

HANDRAILS AND STEPS….229

MOUNTING AND DISMOUNTING….229

NO PERSONS ON ATTACHMENTS….229

BURN PREVENTION….230

FIRE PREVENTION AND EXPLOSION PREVENTION….231

ACTION IF FIRE OCCURS….231

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION….232

ATTACHMENT INSTALLATION….232

ATTACHMENT COMBINATIONS….232

UNAUTHORIZED MODIFICATIONS….232

SAFETY AT JOBSITE….233

WORKING ON LOOSE GROUND….233

DISTANCE TO HIGH VOLTAGE CABLES….233

ENSURE GOOD VISIBILITY….234

VENTILATION FOR ENCLOSED AREA….234

SIGNALMAN'S SIGNAL AND SIGNS….234

ASBESTOS DUST HAZARD PREVENTION….234

SAFETY MACHINE OPERATION….235

STARTING ENGINE….235

CHECKS BEFORE STARTING ENGINE….235

SAFETY RULES FOR STARTING ENGINE….235

STARTING ENGINE IN COLD WEATHER….235

OPERATION….236

CHECKS BEFORE OPERATION….236

SAFETY RULES FOR CHANGING MACHINE DIRECTIONS….236

SAFETY RULES FOR TRAVELING….237

TRAVELING ON SLOPES….238

OPERATIONS ON SLOPES ….239

PROHIBITED OPERATIONS….239

OPERATIONS ON SNOW….241

PARKING MACHINE….241

TRANSPORTATION….243

LOADING AND UNLOADING….243

SHIPPING THE MACHINE….243

BATTERY….244

BATTERY HAZARD PREVENTION….244

STARTING ENGINE WITH BOOSTER CABLES….245

TOWING….246

SAFETY RULES FOR TOWING….246

LIFTING OBJECTS WITH BUCKET….247

SAFETY RULES FOR LIFTING OBJECTS….247

SAFETY MAINTENANCE INFORMATION….248

WARNING TAG….248

KEEP WORK PLACE CLEAN AND TIDY….248

APPOINT LEADER WHEN WORKING WITH OTHERS….248

STOP ENGINE BEFORE CARRYING OUT MAINTENANCE….249

TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING….250

PROPER TOOLS….250

PERSONNEL….250

ATTACHMENTS….251

WORK UNDER THE MACHINE….251

NOISE….251

WHEN USING HAMMER….251

WELDING WORKS….251

REMOVING BATTERY TERMINALS….252

SAFETY FIRST WHEN USING HIGH-PRESSURE GREASE TO ADJUST TRACK TENSION….252

SAFETY RULES FOR HIGH-PRESSURE OIL….252

SAFETY HANDLING HIGH-PRESSURE HOSES….253

WASTE MATERIALS….253

COMPRESSED AIR….253

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS….253

OPERATION….254

MACHINE VIEW ILLUSTRATIONS….255

OVERALL MACHINE VIEW….255

CONTROLS AND GAUGES….256

DETAILED CONTROLS AND GAUGES….257

METERS,LAMPS….257

SWITCHES….259

CONTROL LEVERS AND PEDALS….261

VARIABLE BLADE….268

ENGINE HOOD….268

FUSE….269

BLOCK FUSE….269

OPERATION MANUAL STORAGE….270

MACHINE OPERATIONS AND CONTROLS….271

BEFORE STARTING ENGINE….271

STARTING ENGINE….282

AFTER STARTING ENGINE….285

STOPPING THE ENGINE….288

CHECK AFTER SHUT OFF ENGINE….288

MACHINE OPERATION….289

STEERING THE MACHINE….293

SWINGING….295

WORK EQUIPMENT CONTROLS AND OPERATIONS….296

PROHIBITED OPERATIONS….298

GENERAL OPERATION INFORMATION….301

TRAVELING ON SLOPES….302

ESCAPE FROM MUD….304

WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR….305

BUCKET REPLACEMENT….307

PARKING MACHINE….309

MACHINE INSPECTION AFTER DAILY WORK….310

RUBBER SHOES (MACHINE WITH RUBBER SHOES ONLY)….311

TRANSPORTATION….316

TRANSPORTATION PROCEDURE….316

LOADING AND UNLOADING WITH TRAILER….316

LIFTING MACHINE….318

SHIPPING MACHINE INFORMATION….320

COLD WEATHER OPERATION….321

COLD WEATHER OPERATION INFORMATION….321

AFTER DAILY WORK COMPLETION….323

AFTER COLD WEATHER SEASON….323

LONG TERM STORAGE….324

BEFORE STORAGE….324

DURING STORAGE….324

AFTER STORAGE….324

STARTING MACHINE AFTER LONG-TERM STORAGE….324

TROUBLES AND ACTIONS….325

RUNNING OUT OF FUEL….325

PHENOMENA THAT ARE NOT FAILURES….325

TOWING THE MACHINE….326

SEVERE JOB CONDITION….326

DISCHARGED BATTERY….327

OTHER TROUBLE….331

MAINTENANCE….336

MAINTENANCE INFORMATION….337

LUBRICANTS, COOLANT AND FILTERS….339

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….339

ELECTRIC SYSTEM MAINTENANCE….341

WEAR PARTS….342

WEAR PARTS LIST….342

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS….343

PROPER SELECTION….343

TIGHTENING TORQUE SPECIFICATIONS….347

TIGHTENING TORQUE LIST….347

SAFETY CRITICAL PARTS….348

SAFETY CRITICAL PARTS LIST….348

MAINTENANCE SCHEDULE….349

MAINTENANCE SCHEDULE CHART….349

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER….350

MAINTENANCE PROCEDURE….351

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)….351

REPLACE FUEL FILTER ELEMENT….376

REPLACE ENGINE OIL FILTER CARTRIDGE….375

CHECK ENGINE VALVE CLEARANCE, ADJUST….382

WHEN REQUIRED….352

CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT….352

CLEAN INSIDE OF COOLING SYSTEM….354

CHECK LEVEL OF BATTERY ELECTROLYTE….357

CHECK RUBBER SHOES….360

CHECK AND ADJUST RUBBER SHOE TENSION….362

REPLACE RUBBER SHOES….364

DRAIN WATER AND SEDIMENT FROM FUEL TANK….366

CHECK BEFORE STARTING….367

EVERY 100 HOURS MAINTENANCE….368

LUBRICATING….368

EVERY 250 HOURS MAINTENANCE….369

LUBRICATING….369

REPLACE ENGINE OIL IN ENGINE OIL PAN….370

CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL….371

REPLACE HYDRAULIC OIL FILTER CARTRIDGE….372

CHECK AND ADJUST COOLING FAN BELT TENSION….373

EVERY 500 HOURS MAINTENANCE….374

LUBRICATING….374

REPLACE ENGINE OIL FILTER CARTRIDGE….375

REPLACE FUEL FILTER ELEMENT….376

CLEAN AND INSPECT RADIATOR FINS AND OIL COOLER FINS….378

REPLACE FUEL FEED PUMP PRE-FILTER….379

EVERY 1000 HOURS MAINTENANCE….380

CHANGE OIL IN FINAL DRIVE CASE….380

EVERY 2000 HOURS MAINTENANCE….381

CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER….381

CHECK ALTERNATOR, STARTING MOTOR….382

CHECK ENGINE VALVE CLEARANCE, ADJUST….382

SPECIFICATIONS….384

SPECIFICATIONS….385

ATTACHMENTS, OPTIONS….388

ATTACHMENTS AND OPTIONS – GENERAL INFORMATION….389

SAFETY FIRST….389

ATTACHMENT INSTALLATION….390

BUCKET WITH HOOK….391

HOOK CONDITION….391

PROHIBITED OPERATIONS….391

ATTACHMENT GUIDE….392

ATTACHMENT COMBINATIONS….392

HANDLING ARM WITH BUILT-IN BREAKER….393

BUCKET POSTURE….393

REMOVING AND INSTALLING CHISEL….393

PROCEDURE FOR BREAKER OPERATIONS….394

PRECAUTIONS WHEN CARRYING OUT BREAKER OPERATIONS….395

STOWING CHISEL, DUMMY CHISEL….396

PRECAUTIONS WHEN CARRYING OUT BUCKET OPERATIONS….396

HANDLING DUMMY LINK….397

CHECK BEFORE STARTING….398

SPECIFICATIONS….399

HANDLING BUCKET COUPLER….400

PROCEDURE FOR REMOVING BUCKET….400

PROCEDURE FOR INSTALLING BUCKET….402

RECOMMENDED ATTACHMENT OPERATIONS….404

HYDRAULIC BREAKER….404

INDEX….408

SEBM026105 – Hydraulic Excavator PC09-1 Shop Manual….412

COVER….412

CONTENTS….413

01 GENERAL….436

GENERAL ASSEMBLY DRAWING….437

SPECIFICATIONS….438

WEIGHT TABLE….444

LIST OF LUBRICANT AND WATER….446

10 STRUCTURE, FUNCTION AND MAINTENANCE STANDARD….447

RADIATOR….448

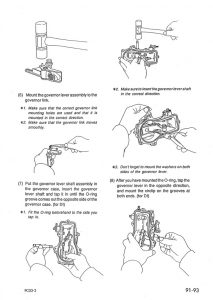

ENGINE CONTROL….450

PTO….452

POWER TRAIN DIAGRAM….453

SWING CIRCLE….454

TRACK FRAME….455

IDLER CUSHION….457

IDLER….458

TRACK ROLLER….459

TRACK SHOE….460

HYDRAULIC EQUIPMENT LAYOUT….461

VALVE CONTROL….462

HYDRAULIC TANK….463

HYDRAULIC PUMP….464

10-SPOOL CONTROL VALVE….466

CENTER SWIVEL JOINT….468

SWING MOTOR….469

TRAVEL MOTOR….470

HYDRAULIC CYLINDER….476

WORK EQUIPMENT….478

DIMENSION OF WORK EQUIPMENT….480

MACHINE MONITOR SYSTEM….484

20 TESTING AND ADJUSTING….486

STANDARD VALUE TABLE FOR ENGINE RELATED PARTS….487

STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS….489

TESTING AND ADJUSTING….497

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING….498

MEASUREMENT ENGINE SPEED….499

MASURING EXHAUST COLOR….501

ADJUSTMENT VALVE CLEARANCE….503

MEASURING COMPRESSION PRESSURE….504

MEASURING ENGINE OIL PRESSURE….505

INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING….506

ADJUSTMENT OF FUEL CONTROL CABLE….508

BLEEDING AIR FROM FUEL CIRCUIT….510

TESTING AND ADJUSTING ALTERNATOR FAN BELT TENSION….511

TESTING AND ADJUSTING TRACK SHOE TENSION….512

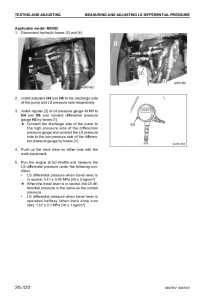

INSPECTION AND ADJUSTMENT OF HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING AND TRAVEL CIRCUITS….513

IDENTIFICATION OF SPOT CAUSING WORK EQUIPMENT HYDRAULIC DRIFT….516

MEASUREMENT OF OIL LEAK AMOUNT INSIDE WORK EQUIPMENT CYLINDER….517

BLEEDING AIR FROM HYDRAULIC CIRCUITS….517

PRESSURIZING HYDRAULIC TANK….518

TROUBLESHOOTING….519

POINTS TO REMEMBER WHEN TROUBLESHOOTING….520

SEQUENCE OF EVENTS IN TROUBLESHOOTING….521

POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE ….522

CHECKS BEFORE TROUBLESHOOTING….530

METHOD OF USING TROUBLESHOOTING….531

CONNECTOR MOUNTING LOCATIONS AND ELECTRICAL CIRCUITS….532

CONNECTOR PIN ALLOCATION DRAWING….533

ELECTRICAL CIRCUIT DIAGRAM FOR ENGINE START, STOP, PREHEATING AND CHARGING SYSTEMS (E CIRCUIT)….535

ELECTRICAL CIRCUIT DIAGRAM FOR PANEL SYSTEMS (P CIRCUIT)….536

CONNECTOR TABLE FOR CONNECTOR PIN NUMBERS….537

TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)….539

INFORMATION IN TROUBLESHOOTING TABLE….540

E-1 ENGINE DOES NOT START….541

E-2 ENGINE DOES NOT STOP….545

E-3 ENGINE OIL PRESSURE LAMP DOES NOT WORK PROPERLY….546

E-4 ENGINE COOLING WATER TEMPERATURE LAMP DOES NOT WORK PROPERLY….548

E-5 ENGINE PREHEATING SYSTEM DOES NOT WORK….550

E-6 SERVICE METER DOES NOT ADVANCE….552

E-7 HORN DOES NOT SOUND, OR DOES NOT STOP SOUNDING….553

E-8 WORKING LAMP DOES NOT LIGHT UP, OR DOES NOT GO OFF….555

TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H-MODE)….557

METHOD OF USING TROUBLESHOOTING CHARTS….558

H-1 ALL WORK EQUIPMENT, TRAVEL AND SWING SHOW SLOW SPEED OR LACK IN POWER….560

H-2 ENGINE RUNNING SPEED DROPS SHARPLY OR ENGINE STAALS.MOREOVER, ALL WORK EQUIPMENT, TRAVEL AND SWING DO NOT MOVE AT ALL OR MOVE EXTREMELY SLOWLY…..560

H-3 THERE IS NOISE FROM AROUND HYDRAULIC PUMP….561

H-4 CONTROL LEVERS AND PEDALS ARE HARD TO OPERATE….561

H-5 BOOM MOVES SLOWLY, LACKS IN POWER, HAS LONG TIME LAG AND BIG HYDRAULIC DRIFT….562

H-6 ARM MOVES SLOWLY, LACKS IN POWER, HAS LONG TIME LAG AND BIG HYDRAULIC DRIFT….562

H-7 BUCKET MOVES SLOWLY, LACKS IN POWER, HAS LONG TIME LAG AND BIG HYDRAULIC DRIFT….563

H-8 SWING IS SLOW, LACKS IN POWER AND HAS BIG HYDRAULIC DRIFT….563

H-9 BLADE MOVES SLOWLY, LACKS IN POWER, HAS LONG TIME LAG AND BIG HYDRAULIC DRIFT….563

H-10 MACHINE DEVIATES FROM TRAVEL PATH IN TRAVELING….564

a) THE MACHINE DEVIATES IN THE SAME DIRECTION BOTH IN FORWARD AND IN REVERSE DIRECTIONS ….564

b) THE DEVIATION DIRECTION CHANGES DEPENDING ON FORWARD OR REVERSE TRAVEL….564

H-11 NO POWER OR SLOW IN TRAVELING….566

H-12 UNDERCARRIAGE DOES NOT MOVE (ONE SIDE ONLY)….566

H-13 TRAVEL SPEED CANNOT BE CHANGED….567

H-14 UPPER STRUCTURE DOES NOT SWING….567

H-15 SWING SPEED IS SLOW OR ACCELERATION IS POOR….568

H-16 OVERRUN WHEN STOPPING WING IS BIG….568

H-17 THERE IS BIG SHOCK WHEN STOPPING SWING….569

H-18 THERE IS BIG NOISE WHEN STOPPING SWING….569

H-19 HYDRAULIC DRIFT OF SWING IS BIG….570

H-20 TROUBLESHOOTING OF HYDRAULIC BREAKER….571

30 DISASSEMBLY AND ASSEMBLY….572

METHOD OF USING MANUAL….573

PRECAUTIONS WHEN CARRYING OUT OPERATION….574

SPECIAL TOOL LIST….576

SWING MOTOR….577

REMOVAL AND INSTALLATION….577

CENTER SWIVEL JOINT….578

REMOVAL AND INSTALLATION….577

DISASSEMBLY AND ASSEMBLY….579

ENGINE AND HYDRAULIC PUMP….580

REMOVAL….580

INSTALLATION….583

REVOLVING FRAME….584

REMOVAL ….584

INSTALLATION….585

SWING CIRCLE….586

REMOVAL AND INSTALLATION….586

IDLER….587

ASSEMBLY….587

TRACK ROLLER….588

ASSEMBLY….588

RUBBER SHOE….588

REMOVAL AND INSTALLATION….588

CONTROL VALVE….589

ASSEMBLY….589

HYDRAULIC CYLINDER….590

ASSEMBLY….590

HYDRAULIC BREAKER….593

DISASSEMBLY….594

ASSEMBLY….597

90 OTHERS….601

HYDRAULIC CIRCUIT DIAGRAM….602

FIXED GAUGE TYPE (STD)….602

VARIABLE GAUGE TYPE (IF EQUIPPED)….603

ELECTRICAL CIRCUIT DIAGRAM….604

STANDERD SPECIFICATION….604

TRAVEL ALREM SPECIFICATION (IF EQUIPPED)….605

TEN00062-04 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual….606

COVER….606

FOREWORD….607

FOREWORD….608

SAFETY INFORMATION….611

INTRODUCTION….613

DIRECTIONS OF MACHINE….613

PRODUCT INFORMATION….614

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE….614

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION….614

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION….615

SERVICE METER LOCATION….615

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR….616

CONTENTS….617

SAFETY….621

SAFETY….622

SAFETY LABELS….624

LOCATION OF SAFETY LABELS….624

SAFETY LABELS….625

GENERAL PRECAUTIONS….628

SAFETY MACHINE OPERATION….636

STARTING ENGINE….636

OPERATION….637

TRANSPORTATION….644

BATTERY….645

TOWING….647

LIFTING OBJECTS WITH BUCKET….648

SAFETY MAINTENANCE INFORMATION….649

OPERATION….655

MACHINE VIEW ILLUSTRATIONS….656

OVERALL MACHINE VIEW….656

CONTROLS AND GAUGES….657

DETAILED CONTROLS AND GAUGES….658

METERS, LAMPS….658

SWITCHES….660

CONTROL LEVERS AND PEDALS….662

VARIABLE BLADE….669

ENGINE HOOD….669

FUSE….670

BLOCK FUSE….670

OPERATION MANUAL STORAGE….671

MACHINE OPERATIONS AND CONTROLS….672

BEFORE STARTING ENGINE….672

STARTING ENGINE….683

AFTER STARTING ENGINE….686

STOPPING THE ENGINE….689

CHECK AFTER SHUT OFF ENGINE….689

MACHINE OPERATION….690

STEERING THE MACHINE….694

SWINGING….696

WORK EQUIPMENT CONTROLS AND OPERATIONS….697

PROHIBITED OPERATIONS….699

GENERAL OPERATION INFORMATION….702

TRAVELING ON SLOPES….703

ESCAPE FROM MUD….705

WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR….706

BUCKET REPLACEMENT….708

PARKING MACHINE….710

MACHINE INSPECTION AFTER DAILY WORK….711

RUBBER SHOES (MACHINE WITH RUBBER SHOES ONLY)….712

TRANSPORTATION….717

TRANSPORTATION PROCEDURE….717

LOADING AND UNLOADING WITH TRAILER….717

LIFTING MACHINE….719

SHIPPING MACHINE INFORMATION….721

COLD WEATHER OPERATION….722

COLD WEATHER OPERATION INFORMATION….722

AFTER DAILY WORK COMPLETION….724

AFTER COLD WEATHER SEASON….724

LONG TERM STORAGE….725

BEFORE STORAGE….725

DURING STORAGE….725

AFTER STORAGE….725

STARTING MACHINE AFTER LONG-TERM STORAGE….725

TROUBLES AND ACTIONS….726

RUNNING OUT OF FUEL….726

PHENOMENA THAT ARE NOT FAILURES….726

TOWING THE MACHINE….727

SEVERE JOB CONDITION….727

DISCHARGED BATTERY….728

OTHER TROUBLE….732

MAINTENANCE….737

MAINTENANCE INFORMATION….738

OUTLINE OF SERVICE….740

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….740

ELECTRIC SYSTEM MAINTENANCE….743

WEAR PARTS….744

WEAR PARTS LIST….744

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS….745

PROPER SELECTION….745

TIGHTENING TORQUE SPECIFICATIONS….749

TIGHTENING TORQUE LIST….749

SAFETY CRITICAL PARTS….750

SAFETY CRITICAL PARTS LIST….750

MAINTENANCE SCHEDULE….751

MAINTENANCE SCHEDULE CHART….751

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER….752

MAINTENANCE PROCEDURE….753

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)….753

WHEN REQUIRED….754

CHECK BEFORE STARTING….769

EXPLANATION OF SYMBOLS FOR LUBRICATION STANDARD TABLE….769

EVERY 100 HOURS MAINTENANCE….770

EVERY 250 HOURS MAINTENANCE….771

EVERY 500 HOURS MAINTENANCE….776

EVERY 1000 HOURS MAINTENANCE….783

EVERY 2000 HOURS MAINTENANCE….784

SPECIFICATIONS….787

SPECIFICATIONS….788

ATTACHMENTS, OPTIONS….791

ATTACHMENTS AND OPTIONS – GENERAL INFORMATION….792

SAFETY FIRST….792

ATTACHMENT INSTALLATION….793

BUCKET WITH HOOK….794

HOOK CONDITION….794

PROHIBITED OPERATIONS….794

ATTACHMENT GUIDE….795

ATTACHMENT COMBINATIONS….795

HANDLING ARM WITH BUILT-IN BREAKER….796

BUCKET POSTURE….796

REMOVING AND INSTALLING CHISEL….796

PROCEDURE FOR BREAKER OPERATIONS….797

PRECAUTIONS WHEN CARRYING OUT BREAKER OPERATIONS….798

STOWING CHISEL, DUMMY CHISEL….799

PRECAUTIONS WHEN CARRYING OUT BUCKET OPERATIONS….799

HANDLING DUMMY LINK….800

CHECK BEFORE STARTING….801

SPECIFICATIONS….802

HANDLING BUCKET COUPLER….803

PROCEDURE FOR REMOVING BUCKET….803

PROCEDURE FOR INSTALLING BUCKET….805

HANDLING FOLDING TOPS CANOPY….807

RECOMMENDED ATTACHMENT OPERATIONS….809

HYDRAULIC BREAKER….809

INDEX….813

TEN00555-00 – Hydraulic Excavator PC09-1 Operation & Maintenance Manual….817

COVER….817

FOREWORD….818

FOREWORD….819

SAFETY INFORMATION….822

INTRODUCTION….824

DIRECTIONS OF MACHINE….824

PRODUCT INFORMATION….825

PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE….825

ENGINE SERIAL NUMBER PLATE AND ITS LOCATION….825

EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION….826

SERVICE METER LOCATION….826

YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR….827

CONTENTS….828

SAFETY….832

SAFETY….833

SAFETY LABELS….835

LOCATION OF SAFETY LABELS….835

SAFETY LABELS….836

GENERAL PRECAUTIONS….839

SAFETY MACHINE OPERATION….847

STARTING ENGINE….847

OPERATION….848

TRANSPORTATION….855

BATTERY….856

TOWING….858

LIFTING OBJECTS WITH BUCKET….859

SAFETY MAINTENANCE INFORMATION….860

OPERATION….866

MACHINE VIEW ILLUSTRATIONS….867

OVERALL MACHINE VIEW….867

CONTROLS AND GAUGES….868

DETAILED CONTROLS AND GAUGES….869

METERS, LAMPS….869

SWITCHES….871

CONTROL LEVERS AND PEDALS….873

VARIABLE BLADE….880

ENGINE HOOD….880

FUSE….881

BLOCK FUSE….881

OPERATION MANUAL STORAGE….882

MACHINE OPERATIONS AND CONTROLS….883

BEFORE STARTING ENGINE….883

STARTING ENGINE….894

AFTER STARTING ENGINE….897

STOPPING THE ENGINE….900

CHECK AFTER SHUT OFF ENGINE….900

MACHINE OPERATION….901

STEERING THE MACHINE….905

SWINGING….907

WORK EQUIPMENT CONTROLS AND OPERATIONS….908

PROHIBITED OPERATIONS….910

GENERAL OPERATION INFORMATION….913

TRAVELING ON SLOPES….914

ESCAPE FROM MUD….916

WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR….917

BUCKET REPLACEMENT….919

PARKING MACHINE….921

MACHINE INSPECTION AFTER DAILY WORK….922

RUBBER SHOES (MACHINE WITH RUBBER SHOES ONLY)….923

TRANSPORTATION….928

TRANSPORTATION PROCEDURE….928

LOADING AND UNLOADING WITH TRAILER….928

LIFTING MACHINE….930

SHIPPING MACHINE INFORMATION….932

COLD WEATHER OPERATION….933

COLD WEATHER OPERATION INFORMATION….933

AFTER DAILY WORK COMPLETION….935

AFTER COLD WEATHER SEASON….935

LONG TERM STORAGE….936

BEFORE STORAGE….936

DURING STORAGE….936

AFTER STORAGE….936

STARTING MACHINE AFTER LONG-TERM STORAGE….936

TROUBLES AND ACTIONS….937

RUNNING OUT OF FUEL….937

PHENOMENA THAT ARE NOT FAILURES….937

TOWING THE MACHINE….938

SEVERE JOB CONDITION….938

DISCHARGED BATTERY….939

OTHER TROUBLE….943

MAINTENANCE….948

MAINTENANCE INFORMATION….949

OUTLINE OF SERVICE….951

HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC….951

ELECTRIC SYSTEM MAINTENANCE….954

WEAR PARTS….955

WEAR PARTS LIST….955

LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS….956

PROPER SELECTION….956

TIGHTENING TORQUE SPECIFICATIONS….960

TIGHTENING TORQUE LIST….960

SAFETY CRITICAL PARTS….961

SAFETY CRITICAL PARTS LIST….961

MAINTENANCE SCHEDULE….962

MAINTENANCE SCHEDULE CHART….962

MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER….963

MAINTENANCE PROCEDURE….964

INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)….964

WHEN REQUIRED….965

CHECK BEFORE STARTING….980

EXPLANATION OF SYMBOLS FOR LUBRICATION STANDARD TABLE….980

EVERY 100 HOURS MAINTENANCE….981

EVERY 250 HOURS MAINTENANCE….982

EVERY 500 HOURS MAINTENANCE….987

EVERY 1000 HOURS MAINTENANCE….994

EVERY 2000 HOURS MAINTENANCE….995

SPECIFICATIONS….998

SPECIFICATIONS….999

ATTACHMENTS, OPTIONS….1002

ATTACHMENTS AND OPTIONS – GENERAL INFORMATION….1003

SAFETY FIRST….1003

ATTACHMENT INSTALLATION….1004

BUCKET WITH HOOK….1005

HOOK CONDITION….1005

PROHIBITED OPERATIONS….1005

ATTACHMENT GUIDE….1006

ATTACHMENT COMBINATIONS….1006

HANDLING ARM WITH BUILT-IN BREAKER….1007

BUCKET POSTURE….1007

REMOVING AND INSTALLING CHISEL….1007

PROCEDURE FOR BREAKER OPERATIONS….1008

PRECAUTIONS WHEN CARRYING OUT BREAKER OPERATIONS….1009

STOWING CHISEL, DUMMY CHISEL….1010

PRECAUTIONS WHEN CARRYING OUT BUCKET OPERATIONS….1010

HANDLING DUMMY LINK….1011

CHECK BEFORE STARTING….1012

SPECIFICATIONS….1013

HANDLING BUCKET COUPLER….1014

PROCEDURE FOR REMOVING BUCKET….1014

PROCEDURE FOR INSTALLING BUCKET….1016

HANDLING FOLDING TOPS CANOPY….1018

RECOMMENDED ATTACHMENT OPERATIONS….1020

HYDRAULIC BREAKER….1020

INDEX….1024

Komatsu Hydraulic Excavator PC09 Repair Service Manuals