Complete service repair manual with Electrical Wiring Diagrams for Komatsu Forklift Truck FG10-17, FG14-17, FG15-17, FG18-17, FG15H-17, FG18H-17, FD15-17, FD18-17, with all the technical information to maintain, diagnose, repair, rebuild like professional mechanics.

Komatsu Forklift Truck FG10_14_15_18-17, FG15H_18H-17, FD15_18-17 workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

BEA17E1-01 – Komatsu Forklift Truck FG10_14_15_18-17, FG15H_18H-17, FD15_18-17 Shop Manual.pdf

PRODUCT DETAILS:

Total Pages: 275 pages

File Format: PDF

Language: English

MAIN SECTIONS

Title Page — BEA17E1-01…1

Section Index…5

01. General and Specifications…7

Specifications…8

Periodic Replacement of Consumable Parts…15

Safety Items for Maintenance…16

Standard Tightening Torque for Bolts…24

Standard Tightening Torque for Pipe Joints…25

10. Testing and Adjusting…27

Service Data (Gasoline Engine Lift Truck)…28

Service Data (Diesel Engine Lift Truck)…30

Gasoline Engine…32

Diesel Engine…34

Air Cleaner…36

Method of Adjusting Ignition Timing…37

Method of Adjusting Fuel Injection Timing…38

Measuring Method for Compression…39

Adjustment Method of Valve Clearance…40

Tightening Torque for Cylinder Mounting Bolts…41

Differential Case…42

TORQFLOW Transmission Case (TORQFLOW Truck Only)…43

Hydraulic Tank…44

Measuring Hydraulic Drift of Lift Cylinder, Tilt Cylinder…45

Adjusting the Clutch/Brake Pedal (Clutch Type Truck Only)…46

Adjusting Inching/Brake Pedal (TORQFLOW Type Truck)…47

Adjusting Accelerator Pedal (H15, H20-II Engine)…48

Adjusting Accelerator Pedal (4D92E Engine)…49

Adjusting Parking Brake Lever…50

Bleeding Air…51

Adjusting Spring-Up Angle of Steering Column…53

(Fuel-Lubricants) Gasoline Engine Lift Truck…54

(Fuel-Lubricants) Diesel Engine Lift Truck…55

Check Items for Each Equipment…57

20. Removal and Installation…81

Overall Assembly and Disassembly Drawing…82

Engine Mounting Bolt…84

Weight Table…85

Mast…86

Lift Cylinder…88

Engine…90

Clutch or Torque Converter, Transmission and Front Axle…95

Rear Axle, Power Steering…100

Wheel Brake…103

30. Disassembly and Assembly…107

Clutch…108

Clutch Master Cylinder…112

Clutch Release Cylinder…113

Clutch Transmission…119

Torque Converter…129

TORQFLOW Transmission…154

Differential…167

Front Axle…173

Wheel Brake…175

Brake Master Cylinder…178

Combination Switch…186

Steering Gear Box…190

Power Steering Cylinder…200

Steering Axle…202

Lift Cylinder…206

Tilt Cylinder…208

Control Valve…209

Hydraulic Pump…211

Mast…221

Fork Carriage…223

40. Maintenance Standard…225

Clutch Release Cylinder…227

Clutch…228

Clutch Transmission…230

Torque Converter…232

TORQFLOW Transmission…234

Differential…236

Wheel Brake…237

Brake Master Cylinder…238

Steering Axle…240

Power Steering Cylinder…241

Lift Cylinder…242

Tilt Cylinder…243

Contol Valve…244

Mast, Fork Carriage…246

50. Structure and Function…247

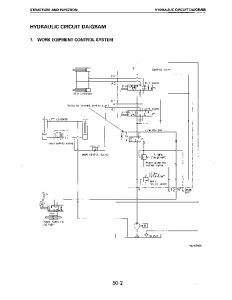

Hydraulic Circuit Diagram…248

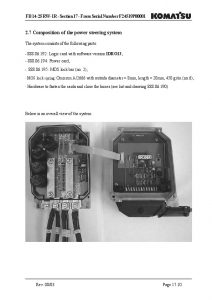

Electrical Circuit Diagram…250

Mast Assembly Drawing…252

Fork Carriage Assembly Drawing…253

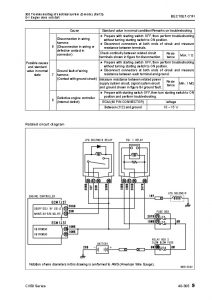

60. Troubleshooting…255

4D92E Diesel Engine…256

Torque Converter…261

Hydraulic Pump…263

70. Conversion Tables…265

Millimeters to Inches…266

Inches to Millimeters…266

Cubic Meters to Cubic Yards…267

Cubic Yards to Cubic Meters…267

Liter to U.S. Gallon…268

U.S. Gallon to Liter…268

Liter to U.K. Gallon…269

U.K. Gallon to Liter…269

Kilogram to Pound…270

Pound to Kilogram…270

Kg/cm (squared) / lb.in. (squared)…271

kgm to ft.lb…272

Temperature…273

Komatsu Forklift Truck FG10-17, FG14-17, FG15-17, FG18-17, FG15H-17, FG18H-17, FD15-17, FD18-17 Repair Service Manual (BEA17E101)