Complete service manual for Daewoo Solar 340LC-V Excavator, with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Daewoo Solar 340LC-V Excavator workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

Solar 340LC-V Operation and Maintenance Manual 022-00025E Serial Number 1001 and Up.pdf

SENS34LV0001 – Daewoo Solar 340LC-V Shop Manual.pdf

S340 ELECTRICAL SHEMATIC 2.pdf

S340-ELECTR. SHEMATIC 1.pdf

Total Pages: 601 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

To the Operator of a Daewoo Excavator .. 3

General Safety Essentials .. 5

Location of Safety Labels … 5

Summary of Safety Precautions for Lifting in Digging Mode .. 6

Work-site Precautions .. 7

Operation.. 9

Equipment .. 14

Maintenance… 18

Shipping and Transportation… 21

Lifting With Sling… 21

S340 ELECTRICAL SHEMATIC 2…2

S340-ELECTR. SHEMATIC 1…3

SENS34LV0001 – Daewoo Solar 340LC-V Shop Manual…4

Safety…4

Track Excavator Safety…5

To the Operator of a Daewoo Excavator…7

General Safety Essentials…9

Location of Safety Labels…9

Summary of Safety Precautions for Lifting in Digging Mode…10

Work Site Precautions…11

Operation…13

Equipment…18

Maintenance…22

Shipping and Transportation…25

Lifting with Sling…25

Specifications…27

Specifications for Solar 340LC-V…28

General Description…30

Component Locations…31

General Dimensions…34

Working Range…35

General Specifications…37

Engine Performance Curves (Per KS-R1004 Standard)…39

Approximate Weight of Workload Materials…41

Performance Tests…44

Excavator Performance Standards…45

General Maintenance…50

General Maintenance Procedures …51

Welding Precautions and Guidelines…53

Hydraulic System – General Precautions…54

Maintenance Service and Repair Procedure…55

Hydraulic System Cleanliness and Oil Leaks…56

Cleaning and Inspection…57

Standard Torques…65

Torque Values for Standard Metric Fasteners…67

Torque Values for Standard U.S. Fasteners…68

Type 8 Phosphate Coated Hardware…70

Torque Values for Hose Clamps…71

Torque Values for Split Flanges…72

Torque Wrench Extension Tools…73

Upper Structure…77

Cab…78

Removal…80

Installation…83

Counterweight…86

General…88

Removal…90

Installation…91

Fuel Tank…92

General Description…94

Removal…97

Installation…101

Start-up Procedures…103

Fuel Transfer Pump…104

General Description…106

Troubleshooting…107

Replacement of Rotor and Vane…107

Replacement of Rear Cover…108

Replacement of Armature…109

Swing Bearing…110

Swing Bearing Maintenance…112

Swing Reduction Gear…116

General Description…118

Special Tools and Materials…121

Troubleshooting, Testing and Adjustment…124

Removal…125

Disassembly…126

Cleaning and Inspection (Wear Limits and Tolerances)…130

Reassembly…131

Installation…136

Start-up Procedures…137

Lower Structure and Chassis…138

Track Assembly…139

General Description…141

Track Tension…141

Cleaning and Inspection (Wear Limits and Tolerances)…143

Track Shoes and Links…147

Front Idler Roller…149

Lower Roller…153

Upper Roller…157

Track Spring and Adjusting Cylinder…162

Engine and Drive Train…165

Air-conditioner…166

Refrigerant Circulation…168

Control Panel…170

Control Specifications…171

Temperature Level Control and Display…172

Air Discharge According To Path Selection…173

Air-conditioning System Circuit Diagram…175

Troubleshooting…177

Refrigerant System Repairs…180

Drive Coupling (Main Pump)…188

Drive Coupling…190

Special Tools…191

Drive Coupling Installation…193

Hydraulics…198

Hydraulic System Troubleshooting, Testing and Adjustment…199

Hydraulic System – General Notes…202

Hydraulic Schematic…203

Operation of Working Components…204

Procedural Troubleshooting Baseline Recommendations…209

Pilot Pressure…210

Power Mode Valve…211

Swing Priority Valve…212

Pressure Up Valve…213

Pump Input Power Control…215

Flow Meter and Flow Meter Kit Installation and Testing…218

Swing System Troubleshooting…220

Troubleshooting – Swing Gearbox…222

Troubleshooting – Hydraulic Problems…223

Troubleshooting – Control Valve…225

Troubleshooting – Travel Control Valve…226

Troubleshooting – Joystick Control Valve…227

Accumulator…229

General Description…231

Center Joint (Swivel)…233

General Description…235

Troubleshooting, Testing and Adjustment…237

Disassembly…238

Reassembly…238

Cylinders…241

General Description…243

Special Tools and Materials…246

Disassembly…250

Reassembly…256

Swing Motor…261

General Description…263

Special Tools and Materials…269

Disassembly…271

Cleaning and Inspection (Wear Limits and Tolerances)…276

Reassembly…278

Travel Motor (With Gearbox)…283

General Description…285

Special Tools and Materials…300

Troubleshooting, Testing and Adjustment…303

Disassembly…307

Cleaning and Inspection (Wear Limits and Tolerances)…318

Reassembly…322

Installation…340

Main Pump (Rexroth)…343

Sectional View…345

General Repair Guidelines…347

Seal Kits and Sub-assemblies…348

Sealing The Drive Shaft…353

Gear Pump Sealing…356

Remove The Control Housing…357

Control Module…361

Removing The Controller…363

Valve Plate With Valves…365

Remove The Rotary Groups…366

Remove The Intermediate Wheel…369

Remove Auxiliary Drive…372

Inspection Hints…374

Re-fitting The Rotary Group…379

Pump Assembly…380

Hydraulic Component – Measurement "D"…383

Fit Control Housing…388

Assembly of The Intermediate Wheel…391

Fit The Gear Pump…392

Fit The Cover / Auxiliary Drive…393

Assembly Guidelines for Tightening Torques…394

Main Control Valve (Kayaba)…397

General Description…399

Trobleshooting, Testing and Adjustement…433

Disassembly…436

Cleaning and Inspection (Wear Limits and Tolerances)…442

Reassembly…443

Installation…450

Start-up Procedures…450

Pilot Control Valve (Work Lever/Joystick)…451

General Description…453

Removal…456

Disassembly…459

Cleaning and Inspection (Wear Limits and Tolerances)…463

Reassembly…464

Installation…469

Start-up Procedures…470

Travel Control Valve (With Damper)…471

General Description…473

Troubleshooting, Testomg amd Adjustment…478

Removal…479

Disassembly…481

Cleaning and Inspection (Wear Lmits and Tolerances)…487

Reassembly…488

Installation…493

Start-up Procedures…494

Hydraulic Schematic (S340LC-V)…495

General Description…497

Solar 340LC-V…498

Electrical System…501

Electrical System…502

Troubleshooting – Electrical System…505

Overview…506

Electric Supply System…507

Engine Starting Circuit…508

Engine Preheating System…510

Engine Stop System…511

Charging System…514

Monitoring System…515

Operation…519

Warning and Indicator Lights…521

Initial Operation…523

Mode Select Switch…524

Graphic Information Area Display…525

Main Menu…527

Special Menu…529

Electronic Hydraulic Control System (e-EPOS)…543

Power Mode Control…545

Power Mode Control – Circuit Diagram…549

Trenching Mode Control…551

Trenching Mode Control – Circuit Diagram…553

Engine Control System…554

Engine Control Motor…555

Engine Control Dial…556

Engine Control Circuit Diagram…558

Automatic Deceleration Control (Auto Idle Control)…559

Engine Overheat Protection System…560

Power Boost Mode…561

Automatic Travel Speed Control…563

Engine Control Device – Adjustment…565

Self-diagnostic Function…568

Engine Throttle Controller…570

Wiper System…571

Lighting System…573

Overload Warning Device…575

Electrical Schematic (S340LC-V)…576

General Description…578

Solar 340LC-V…579

Attachments…582

Boom and Arm…583

Front Attachment Pin Specifications…585

Front Attachment – Removal and Installation…586

Installation…589

Start-up Procedures…590

Bucket…591

Bucket Tooth Inspection and Replacement…593

Bucket O-ring Replacement…596

Bucket Shimming Procdures…598

Bucket Attachment, Removal and Reversal…599

Solar 340LC-V Operation and Maintenance Manual 022-00025E Serial Number 1001 and Up…601

Safety…607

To the Operator of a Daewoo Excavator…607

Learn the Signal Words Used with the Safety Alert Symbol…609

Location of Safety Labels…610

1. Warnings for operation, inspection and maintenance (190-00688, 190-00092)…611

2. Warnings for high voltage (190-00689, 190-00096)…611

3. Warnings when opening a front window (190-00690, 190-00093)…611

4. warnings for a high pressure cylinder (190-00122)…612

5. Warnings when adjusting track tension (2190-3386A, 190-00521)…612

6. WARNINGs FOR LEAVING OPERATOR’S SEAT (190-00693, 190-00094)…613

7. Warnings for batteries maintenance (2190-2533A, 190-00100)…613

8. Warnings for high temperature hydraulic oil (190-00691, 190-00097)…614

9. Warnings for hot Coolant (190-00692, 190-00097)…614

10. Warnings for handling an accumulator (190-00703, 190-00099)…614

11. WARNINGS FOR ROTATING PARTS (190-00694, 190-00095, 190-00557)…615

12. Warning tag – used when inspection and maintenance (190-00695, 190-00098)…615

13. warning for a hot surface (19000648)…616

14. caution for hood (190-00522)…616

15. keep out of the swing area (2190-3379, 190-00090)…616

16. Warnings for front attachments (190-00652)…617

Summary of Safety Precautions for Lifting in Digging Mode…618

Unauthorized Modifications…619

General Hazard Information…619

Safety Rules…619

Safety Features…619

Inside Operator's Compartment…620

Clothing and Personal Protective Items…620

Mounting and Dismounting…621

Fuel, Oil and Hydraulic Fluid Fire Hazards…622

Precautions When Handling Fluids at High Temperature…622

Asbestos dust hazard prevention…623

Injury from Work Equipment…623

Fire Extinguisher and First Aid Kit…624

Protection from Falling or Flying Objects…624

Attachment Precautions…625

Accumulator…625

Indoor Ventilation…626

Emergency Exit…626

Before Starting Engine…627

Work Site Precautions…627

Checks Before Starting Engine…628

Engine Starting…629

Before Operating Machine…629

Machine Operation…630

When Swinging or Changing Direction of Travel…630

Travel Precautions…630

Traveling on Slopes…631

Prohibited Operations…632

Precautions for Operation…632

Avoid High-voltage Cables…633

Operate Carefully on Snow, Ice and in Very Cold Temperatures…633

Operations on Slopes…634

Parking Machine…634

Never Let Anyone Ride on Attachment…634

Maintenance…635

Warning Tag…635

Clean Before Inspection or Maintenance…635

Proper Tools…636

Use of Lighting…636

Fire Prevention and Explosion Prevention…636

Burn Prevention…637

Welding Repairs…638

Precautions for Removal, Installation, and Storage of Attachments…638

Precautions when Working on Machine…639

Lock Inspection Covers…639

Crushing Prevention and Cutting Prevention…639

Track Tension Adjustments Require Caution…640

Supports and Blocking for Work Equipment…640

Action When Abnormally Is Found During Inspection…641

Precautions with High Pressure Line, Tubes and Hoses…641

Waste Materials…642

Battery…643

Battery Hazard Prevention…643

Boost Starting or Charging Engine Batteries…644

Towing…645

Precautions When Towing…645

Shipping and Transportation…646

Obey State and Local Over-the-Road Regulations…646

Excavator Rated Lift Capacity Tables…647

Operating Controls…653

Component Locations…654

Operator’s Area…656

Operational Controls and Panels…657

1. Starter Switch…658

2. Engine Speed Control Dial…658

3. light Switch…659

4. Wiper Switch…659

5. Windshield Washer Switch…660

6. Travel Speed Selection Switch…660

7. Stereo On/Off Switch…661

8. Cab Work Light Switch (Optional)…661

9. Warning Light Switch (Optional)…661

10. Travel/Swing Alarm Switch (Optional)…662

11. Overload Warning Switch (Optional)…662

12. Heater and Air Conditioner Control Panel…663

13. Cigar Lighter…663

14. Power Socket for 12 Volt…663

15. Horn Switch (Left-hand Work Lever (Joystick))…664

16. Booster Switch (Right-Hand work lever (Joystick))…664

17. Breaker Switch (Right-Hand Work Lever (Joystick))…664

18. Instrument Panel…664

19. Safety Lever…665

Instrument Panel…666

Functional check…667

1. Engine Coolant Temperature Gauge…667

2. Fuel Gauge…667

3. Multifunction Gauge and Graphic Information Area…668

4. Digital Clock…668

5. Hour Meter…668

6. Charge Warning Light…669

7. Engine Oil Pressure Warning Light…669

8. Coolant Temperature Warning Light…669

9. Preheating Completion Light…670

10. Work Light Indicator Light…670

11. Overload Warning Light (Optional)…670

Multifunction Gauge and Graphic Information…671

Communication Indicator…671

Communication Error Warning…672

1. Engine Speed…672

2. Battery Voltage…672

3. Front Hydraulic Pump Pressure…673

4. Rear Hydraulic Pump Pressure…673

5. Abnormal State Warning of Filters…674

Mode Selection Buttons…675

1. Power Mode Selection Button…675

2. Trenching Mode Selection Button…676

3. Auto Idle Selection Button…676

4. Display Selection Button…677

Setting Method for Main Menu…678

Main Menu…678

Language…679

Set Clock…679

Filter / Oil Info…680

Heater and Air Conditioner Control Panel…682

Location of Controls and Vents…682

Operation Panel…683

1. Fan and Air-conditioner Switch…683

2. Fan Speed Selection Switches…684

3. Temperature Control Switch…684

4. Air Outlet Selection Switch…685

5. Ventilation Selection Switch…686

Memory Function of Used Mode…686

Additional Operating Instructions…686

Stereo…687

Security and Area Code Setting…687

Order to Set Up Security and Area Code…687

Front Panel…688

1. Power/Volume Control Knob…688

2. Sound Mode Selection Button…688

3. Band Selection Switch…689

4. Tuning Up/Down…689

5 & 6. Auto Memory and Preset Scan Button / Preset Station Button…690

7. Tape Slot…690

8. Tape Ejection Button…690

9. Cassette and Program Buttons…691

10. Security Warning LED…691

11. Scan…691

12. LCD…692

Care of Stereo…692

Fuse Boxes…694

Miscellaneous Electrical Devices…695

1. Cab Light…695

2. Pilot Cutoff Switch…695

3. Circuit Breaker…695

4. Fusible Link…696

Seat Adjustment…697

1. Forward / Backward Adjustment (Figure 83)…697

2. Adjusting the Seat's Tilt and Seat Height (Figure 83)…697

3. Weight Adjustment (Figure 83)…697

4. Adjusting Reclining (Figure 83)…697

5. Moving the Total Seat Setting Forward/Backward (Figure 83)…698

6. Angle Adjustment of Armrest (Figure 84)…698

7. Headrest (Figure 84)…698

Seat Belt…699

Seat Belt Locking and Unlocking…699

Ceiling Cover…700

Opening the Ceiling Cover…700

Closing the Ceiling Cover…700

Front Windows…701

Front Upper Window…701

Front Bottom Window…703

Door Side Latch…704

Miscellaneous Access Covers and Doors…705

Side Door…705

Battery Box Door…705

Engine Cover…705

Cab Storage Compartments…706

Ashtray…706

Emergency Glass Breaking Tool…707

Operation…709

To Handle a New Excavator…709

Lubrication and filters…709

Starting and Stopping the Engine…710

Inspection Before Starting Engine…710

Operational Checks Before Starting Engine…710

Engine Start…712

Cold Weather Starting…714

Starting Engine With a Booster Cable…716

Hydraulic System Warm-up…718

Hydraulic System Warm-Up – Cold Weather…719

Engine Shut Down…720

Check and Confirmation After Stopping Engine…721

Safety Lever…722

Travel…723

Automatic Travel Speed Control…723

General Travel Instructions…724

Travel Control Lever Operation…726

Operating Instructions…728

Engine Speed Control…728

Mode Selection…730

Work Levers (ISO Style)…732

Operating Precautions…733

Working in Water…737

Parking Excavator…738

Towing Procedure…739

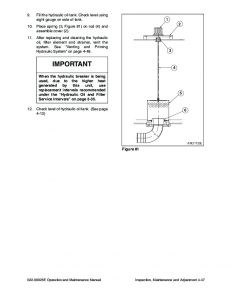

Hydraulic Breaker…740

Selection of Hydraulic Breaker…740

Hydraulic Hoses and Tubing for Breaker…740

Hydraulic Breaker Operation…740

To activate breaker;…742

Hydraulic Oil and Filter Service Intervals…743

Operating Techniques…744

Lifting…744

Operation Under Unusual Conditions…746

Operation In Extreme Cold…746

Operation In Extreme Heat…746

Operation In Dusty Or Sandy Areas…747

Operation In Rainy or Humid Conditions…748

Operation In Salt Water Areas…748

Operation at High Altitudes…748

Inspection, Maintenance and Adjustment…749

Serial Numbers…750

Safety Precautions…750

Preliminary Work Machine Setup for Maintenance…751

Table of Recommended Lubricants…753

Fluid Capacities…755

Lubrication and Service Chart…755

Maintenance Intervals…758

10 Hour / Daily Service…758

50 Hour / Weekly Service…758

250 Hour / Monthly Service…758

500 Hour / 3 Month Service…759

1000 Hour / 6 Month service…759

2000 Hour / Yearly Service…759

4000 Hour / Biennial Service…759

10 Hour / Daily Service…760

Grease Boom, Arm and Front Attachment Pins (for first 100 hours)…760

Check Engine Oil Level…760

Check Level of Hydraulic Oil Tank…761

Check for Leaks in the Hydraulic System…762

Check Fuel Level…763

Check for Leaks in the Fuel System…763

Check Water Separator and Drain Water As Required…764

Check Oil Level of Swing Reduction Device…765

Clean Dust Net in Front of Oil Cooler…766

Check Cooling System and Refill As Required…766

Check Level of Window Washer Liquid…767

Inspect the Bucket Teeth and Side Cutters for Signs of Wear…767

Inspect Engine Fan Blade…767

Check Air Intake System…768

Inspect Seat Belt for Proper Operation…768

Inspect the Structure for Cracks and Faulty Welds…768

Check the Operation of All Switches…768

Check the Operation of All Exterior Lights, Horn and Control Console Indicator and Monitor Lights…768

Start Engine, Check Starting Ability, and Observe Exhaust Color at Start-up and at Normal Operati….769

Check Operation of All Controls…769

50 Hour / Weekly Service…770

Perform All 10 Hour / Daily Service Checks…770

Grease Boom, Arm and Front Attachment Pins…770

Grease Swing Bearing…772

Drain Water and Sediment from Fuel Filter…773

Drain Water and Sediment from Fuel Tank…773

Check Engine Fan Belt for Cracks, Wear and Correct Tension (After First 50 Hours)…773

Change Engine Oil and Filter (After First 50 Hours)…773

Inspect the Track Assemblies for Proper Tension and Loose, Worn or Damaged Parts (Links, Shoes, R….773

250 Hour / Monthly Service…774

Perform All 10 hour / daily and 50 Operating Hour Service Checks…774

Change Swing Reduction Device Oil (Drain and Refill After First 250 Hours)…774

Clean Outer Element of Two Stage Air Cleaner…774

Check Engine Fan Belt Tension…775

Check Engine Fan Belt Wear…776

Change Engine Oil and Filter…777

Check Oil Level In Travel Reduction Device (One on Each Side of Unit)…778

Change Oil in Travel Reduction Device (One on Each Side of Unit) (After First 250 Hours)…778

Replace Full Flow Hydraulic Oil Filter (After First 250 Hours)…778

Change Pilot Filter (After First 250 Hours)…778

Inspect Pins and Bushings of the Front End Attachments for Signs of Wear…778

Check the Fluid Levels in the Batteries and the Battery Charge Levels…778

Inspect for Any Loose or Missing Nuts and Bolts…778

Inspect Fuel System Hose Clamps…778

500 Hour / 3 Month Service…779

Perform All Daily (10 Hour), 50, and 250 Operating Hour Service Checks…779

Grease Swing Gear and Pinion…779

Replace Full Flow Hydraulic Oil Filter…780

Change Pilot Filter…781

Clean Air Conditioning Filter…782

Clean Radiator, Oil Cooler, Intercooler and Air Conditioner Condenser Core…783

Replace Outer and Inner Air Cleaner Elements…784

Change Fuel Filter…785

1000 Hour / 6 Month Service…787

Perform All Daily (10 Hour), 50, 250 and 500 Operating Hour Service Checks…787

Grease Swing Reduction Device…787

Change Swing Reduction Device Oil…787

Change Oil in Travel Reduction Device (One on Each Side of Unit)…788

Change Radiator Coolant…789

Clean Fuel Injection Priming Pump Strainer…790

Check Air Conditioner Refrigerant…791

Check and Adjust Engine **…792

2000 Hour / Yearly Service…793

Perform All Daily, 50, 250, 500 and 1,000 Operating Hour Service Checks…793

Check Alternator and Starter**…793

Check All Rubber Anti-vibration Shock Mounts…793

Perform and Record the Results of the Cycle Time Tests…793

Inspect Machine to Check for Cracked or Broken Welds or other Structural Damage…793

Check, Adjust Valve Clearance **…793

Check Head Bolt Torques…793

Hydraulic Oil Exchange and Suction Strainer Cleaning…793

4000 Hour / Biennial Service…796

Major Parts – Periodic Replacement…796

Venting and Priming Hydraulic System…797

Main System Pump…797

Hydraulic Cylinders…797

Swing Motor…798

Air Release of Travel Motor…798

General Venting…798

Handling of Accumulator…799

Fuel Transfer Pump (Option)…800

Electrical System…802

Battery…802

Fuses…804

Air Conditioning System…806

Check Control Panel…806

Check Air Conditioner Hoses…806

Check Condenser…806

Check Magnetic Clutch…806

Check Belt Tension…806

Bucket…807

Bucket Tooth Replacement…807

Bucket O-ring Replacement…808

Bucket Shimming Procedures…810

New Bucket Installation…810

Shimming Procedures for Installed Bucket…810

Track Tension…811

Bolt and Nut Inspection…813

Maintenance in Special Conditions…814

Long Term Storage…815

Transportation…817

Loading and Unloading…817

Lifting With Sling…820

Troubleshooting…821

Engine…821

Hydraulic System…822

Swing System…823

Travel System…824

Electrical System…824

Specification…827

Standard Specification…827

Overall Dimensions…828

Working Range…829

Approximate Weight of Workload Materials…830

Index…833

Daewoo Solar 340LC-V Excavator Repair Service Manual