Complete repair service manual for Daewoo/Doosan Solar S200W-V Excavators with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Daewoo Solar S200W-V Excavators workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

2023-7139E – Daewoo Solar S200W-V Shop Manual (Serial Number 0001 and Up).pdf

SHOP MAN.-TRAVEL MOTOR-MAIN PUMP.pdf

TENSOLRV0002 Solar V Model.pdf

TENSOLRV0004 Solar V Model.pdf

ELECTRIC SYSTEM OF SOLAR-V.pdf

Total Pages: 711 pages

File Format: PDF (bookmarked, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

Safety

Wheel Excavator Safety …S0102020

Specifications

Specifications for Solar 200W-V …S0202040

General Maintenance

General Maintenance Procedures …S0302000

Standard Torques …S0309000

Upper Structure

Cab …S0402020

Counterweight…S0403000

Fuel Tank…S0405070

Swing Bearing…S0407010

Swing Reduction Gearbox …S0408040

Lower Structure and Chassis

Ram Lock Valve Operation…S0503000

Engine and Drive Train

Front Axle …S0602100

Transmission, Final Drive and Rear Axle …S0602110

Air-Conditioner…S0605010

Drive Coupling (Main Pump)…S0609000

Hydraulics

Hydraulic System Troubleshooting, Testing and Adjustment …S0702110

Accumulator…S0703000

Center Joint (Swivel)…S0704070

Cylinders…S0705000

Swing Motor…S0707250

Travel Motor…S0707350

MAin Pump (With Regulator, Steering Pump and Brake Pump) …S0708430

Brake Supply Valve …S0709220

Counterbalance Valve …S0709300

Main Control Valve (Toshiba dx28-60) …S0709440

Remote Control Valve (Work Lever / Joystick) …S0709450

Steering Valve …S0709710

Hydraulic Schematic (Solar 200W-V) …S0792100

Electrical System

Electrical System …S0802120

Electrical Schematic (Solar 200W-V)…S0892100

Attachments

Boom and Arm…S0902080

Bucket…S0904000

2023-7139E – Deawoo Solar S200W-V Shop Manual (Serial Number 0001 and Up)…2

Safety…8

Wheel Excavator Safety S0102020…10

To the Operator of a Daewoo Excavator…12

Learn the Signal Words Used with the Safety Alert Symbol…13

General Safety Essentials…14

Accessory Applications…14

Lifting Capacity Rating Configuration…14

Location of Safety Labels…14

Summary of Safety Precautions for Lifting in Digging Mode…15

Unauthorized Modifications…15

Work-site Precautions…16

Attachment Precautions…16

Avoid High-voltage Cables…16

Before Starting to Dig, Contact Authorities…16

Be Aware of Height Obstacles…16

Use Care on Loose Support…17

Use Solid Support Blocking…17

Overhangs Are Dangerous…17

Sloping Terrain Requires Caution…17

Stay Alert for People Moving through the Work Area…18

Be Aware of and Conform to Local Regulations…18

Operation…18

Operate While Seated at the Operator’s Station ONLY…18

Before Starting the Engine…19

Never Use Ether Starting Aids…19

Mounting and Dismounting…19

Observe General Safety Rules…20

Engine Ventilation…20

Asbestos Dust Hazard Prevention…20

Take Time to Provide Good Visibility…20

Fuel, Oil and Hydraulic Fluid Fire Hazards…21

Boost Starting or Charging Engine Batteries…21

Travel Controls May Produce Reversed Operations…22

Keep "Pinch Point" Areas Clear – Use Caution in Reverse & Swing…22

Travel Precautions…22

Operate Carefully on Snow and Ice and in Very Cold Temperatures…22

Parking the Machine…23

Shutdown Control Functions…23

Equipment…23

Rough Operation May Require Use of Certified Safety Equipment…23

Install Additional Safety Equipment If Conditions Require…24

Movement Alarms…24

Seat Belts Should Be Used at All Times…24

Window Glass Breaking Tool…25

Keep a Fire Extinguisher at Hand…25

Maintain Standard Safety Equipment in Good Condition…25

Safety-critical Parts Must Be Replaced Periodically…25

Hydraulic Cylinder Seals Require Periodic Replacement…26

High Pressure Hydraulic Lines Can Store a Great Deal of Energy…26

The Operator’s Cab and Turntable Deck Should Be Kept Clean…26

Wear Eye Protection and Safety Clothing…26

Breathing Masks, Ear Protection May Be Required…26

Battery Electrolyte and Explosive Gases Can Be Lethal…27

Disconnect Batteries for Electrical Service Before Electrical Welding…27

Use Low Heat Portable Lighting…27

Maintenance…27

Use Warning Tag Control Lockout Procedures During Service…27

Do not Run the Engine If Repairs or Work Is Being Performed Alone…28

Always Use Adequate Equipment Supports and Blocking…28

Do not Work on Hot Engines or Hot Cooling or Hydraulic Systems…28

Cool-down Is Required Prior to Radiator or Reservoir Checks…28

Pressurized Hydraulic Oil Fluid Leaks Can Be Dangerous…29

Obtain immediate medical attention if pressurized oil pierces the skin…29

Use Correct Replacement Fasteners Tightened to Proper Torque…29

Dispose of All Petroleum-based Oils and Fluids Properly…29

Shipping and Transportation…30

Obey State and Local Over-the-Road Regulations…30

Specifications…32

Specifications for Solar 200W-V S0202040…34

General Description…36

Component Location…37

General Dimensions…39

Dimensions…39

Working Range…41

Hydraulic Cylinders…43

Engine Specifications…44

Engine Performance Curves (Per KS-R1004 Standard)…46

Approximate Weight of Workload Materials…47

General Specifications…50

Hydraulic System Component Specifications…51

System Component Specifications…52

Drive System…52

Swing Mechanism…52

Brake System…53

Steering System…54

Chocking System…54

Performance Tests and Standards…55

Standards…55

Tests…56

Test Conditions…56

Travel Speed Tests…57

Swing Speed Test…58

Swing Speed Test…58

Swing Force Test…58

Cylinder Performance Tests…59

Boom Cylinders Test…59

Arm Cylinder Test…59

Hydraulic Cylinder Natural Drop Test…59

General Maintenance…60

General Maintenance Procedures S0302000…62

Welding Precautions and Guidelines…64

Hydraulic System – General Precautions…65

Maintenance Service and Repair Procedure…66

General Precautions…66

Hydraulic System Cleanliness And Oil Leaks…67

Maintenance Precautions for Hydraulic System Service…67

Oil Leakage Precautions…67

Cleaning and Inspection…68

General Guidelines…68

Bearing inspection…69

Standard Torques S0309000…76

Torque Values for Standard Metric Fasteners…78

Torque Values for Standard U.S. Fasteners…79

Type 8 Phosphate Coated Hardware…81

Torque Values for Hose Clamps…82

Torque Values for Split Flanges…83

Torque Wrench Extension Tools…84

Torque Multiplication…84

Other Uses for Torque Wrench Extension Tools…85

Tightening Torque Specifications (Metric)…85

Upper Structure…88

Cab S0402020…90

Removal…92

Installation…94

Window and Gasket Replacement…97

Falling Object Protective Structures (F.O.P.S.)…98

Counterweight S0403000…100

General…102

Removal…104

Installation…105

Fuel Tank S0405070…108

General Description…110

Parts List…111

Specifications…112

Removal…113

Installation…116

Start-up Procedures…117

Swing Bearing S0407010…118

Swing Bearing Maintenance…120

Operating Recommendation…120

Measuring Swing Bearing Axial Play…120

Measuring Bearing Lateral Play…120

Swing Bearing Basic Operation…121

Rebuilding Swing Bearing…121

Swing Reduction Gearbox S0408040…124

General Description…126

Theory of Operation…126

Parts List…127

Specifications…128

Special Tools and Materials…129

Special Tools…129

Troubleshooting, Testing and Adjustment…130

Removal…131

Disassembly…132

Cleaning and Inspection (Wear Limits and Tolerances)…137

Reassembly…138

Installation…147

Lower Structure and Chassis…148

Ram Lock Valve Operation S0503000…150

Theory of Operation…152

Engine and Drive Train…154

Front Axle S0602100…156

Special Tools…158

Hub Nut Tool…158

Disassembly…159

Planetary End…159

Differential Gear…166

Cleaning and Inspection (Wear Limits and Tolerances)…171

Reassembly…172

Differential Gear…172

Planetary End…183

Start-up Procedures…198

Axle Lubrication…198

Transmission, Final Drive and Rear Axle S0602110…200

Transmission Operation…203

Special Tools…204

Hub Nut Tool…204

Transmission Disassembly…205

Detaching Drive (Input) Housing…205

Disassembly of Input Shaft and Brake Assembly…206

Disassembly of Clutch…208

Disassembly of Planetary Carrier…213

Disassembly of Shift Lever and Helical Gear…214

Disassembly of Shift Lock (Version A)…219

Disassembly of Shift Lock (Version B)…221

Final Drive Disassembly…223

Rear Axle Disassembly…227

Differential Gear Disassembly…234

Cleaning and Inspection (Wear Limits and Tolerances)…239

Differential Gear Reassembly…240

Rear Axle Reassembly…252

Final Drive Reassembly…267

Transmission Reassembly…272

Reassembly of Helical Gear…272

Reassembly of Shift Lever…274

Reassembly of Planetary Carrier…275

Adjusting Shift Lever…277

Preassembling and Installing Clutch…278

Checking Clutch…285

Reassembly of Brake and Input Shaft Assembly…286

Installing Drive (Input) Housing…290

Assembly of Shift Lock (Version A)…293

Assembly of Shift Lock (Version B)…297

Installing Oil Pump…299

Installing Screw Plugs and Oil Lines…302

Start-up Procedures…303

Axle Lubrication…303

Lubrication…303

Air-Conditioner S0605010…304

General Description…306

Refrigerant Circulation…307

Control Panel…309

Control Specifications…310

Temperature Level Control and Display…311

Air Discharge According to Path Selection…312

Air-conditioning System Circuit Diagram…315

Troubleshooting…317

Refrigerant System Repairs…320

Refrigerant Safe Handling Procedures…320

Repair and Replacement Procedure…321

Refrigerant Recovery…323

Vacuuming Refrigerant System…323

Leakage Check…324

Refrigerant Charging…325

Inspecting System For Leakage…327

Drive Coupling (Main Pump) S0609000…328

Drive Coupling…330

Special Tools…331

Kawasaki Pump Tool…331

Uchida Pump Tool…333

Drive Coupling Installation…334

Installation Procedure…338

Hydraulics…340

Hydraulic System Troubleshooting, Testing and Adjustment S0702110…342

Hydraulic System – General Notes…345

Operation of Working Components…346

Boom Operating Circuit…346

Boom Up Circuit…346

Boom Down Circuit…346

Arm Operating Circuit…347

Arm Crowd Circuit…347

Arm Dump Circuit…347

Bucket Operating Circuit…348

Bucket Crowd Circuit…348

Bucket Dump Circuit…348

Swing Operating Circuit…349

Right Swing Operating Circuit…349

Left Swing Operating Circuit…349

Swing Relief Valve and Make-up Valve…349

Procedural Troubleshooting Baseline Recommendations…350

Initial Checks and Tests to Establish Operating Condition of the Excavator…350

Pilot Pressure…351

Adjustment and Testing…351

Power Mode Valve…352

Current Signal and Hydraulic Pressure Adjustments…352

Boom/Swing Priority Valve…353

Control Valve Pressure and Current Adjustments…353

Pressure Up Valve…355

Checks and Adjustments…355

Pump Input Power Control…356

Pump Regulator Adjustment…356

Flow Meter and Flow Meter Kit Installation and Testing…358

Swing System Troubleshooting…359

Precautions/Initial Checks…359

Swing Relief Valve Checking and Adjustment…360

Troubleshooting – Swing Gearbox…361

Troubleshooting – Hydraulic Problems…362

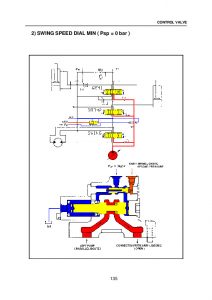

Troubleshooting – Control Valve…364

Troubleshooting – Joystick Control Valve…365

Accumulator S0703000…366

General Description…368

Specifications…369

Accumulator Charging…370

Charging the Accumulator with Nitrogen…370

Center Joint (Swivel) S0704070…372

General Description…374

Parts List…375

Troubleshooting, Testing and Adjustment…377

Inspection…377

Testing…377

Disassembly…378

Reassembly…379

Cylinders S0705000…380

General Description…382

Theory of Operation…382

Parts List…383

Special Tools and Materials…385

Piston Nut…385

Piston Jig…387

Disassembly…390

Reassembly…396

Swing Motor S0707250…400

General Description…402

Theory of Operation…402

Swing Motor Anti-cavitation Make-up Valve…403

Relief Valve…404

Swing Brake Operation…404

Parts List…407

Specifications…409

Special Tools…410

Disassembly…411

Cleaning and Inspection (Wear Limits and Tolerances)…418

Reassembly…420

Travel Motor S0707350…428

General Description…430

Theory of Operation…430

Parts List…431

Specifications…431

Travel Motor General Disassembly and Reassembly Instructions…432

Recommended Tools…432

Precautions for Disassembly and Assembly…432

Disassembly of Travel Motor…433

Appearance of Motor…433

Removal of counterbalance Valve…433

Removal of Outer Piping…434

Removal of Stroke Limiter…435

Removal of Oil Seal…436

Removal of Control Unit…436

Removal of Control Valve…438

Disassemble Control Valve…440

Disassemble Stroke Limiter…441

Reassemble Stroke Limiter…442

Reassemble Control Valve…442

Installation of Control Valve…443

Reassembly of Travel Motor…446

Assembly of Control Unit…446

Installation of Oil Seal…448

Installation of Stroke Limiter…449

Installation of Outer Piping…449

Installation of Counterbalance Valve…450

MAin Pump (With Regulator, Steering Pump and Brake Pump) S0708430…452

General Description…455

Gear (Pilot) Pump…457

Relief Valve…457

Pump Regulator Description…458

Horsepower Control…458

Power Shift Control…458

Negative Oil Discharge (Pump Bypass) Control…458

Pump Regulator Operation…459

Pump Output Decrease…461

Pump Discharge Decrease…461

Pump Discharge Increase…461

Horsepower Control…461

Overload Protection…462

Regulator Adjustment…462

Pump Input Power Control Adjustment…463

Parts List…465

Specifications…470

Hydraulic Pump Performance Characteristics…471

Troubleshooting, Testing and Adjustment…473

Main Pump…473

Disassembly…474

General Disassembly…474

Main Pump Disassembly…475

Pump Regulator Disassembly…477

Cleaning and Inspection (Wear Limits and Tolerances)…481

Reassembly…483

Pump Regulator Reassembly…483

Main Pump Reassembly…487

Brake Supply Valve S0709220…490

Parts List…493

Specifications…494

Counterbalance Valve S0709300…496

General Description…498

While Operating to Run Forward…498

While Operating to Stop…498

While Operating to Back…498

Adjustment of Relief Valve…499

Troubleshooting…500

Counterbalance Valve…501

Recommended Tools…501

Disassembly…501

Order of Disassembly and Torque Values…502

Reassembly…503

Main Control Valve (Toshiba dx28-60) S0709440…508

Control Valve Operation…512

Arm Priority Circuit…513

Bucket (Junction) Circuit…515

Main Relief Valve…517

Overload Relief Valve…518

Arm Load Holding Valve…520

Boom Load Holding Valve…523

Arm Regeneration…525

Boom Regeneration…527

Foot Relief Valve…528

Parts List…529

Specifications…538

Control Valve Drawing and Hydraulic Circuit…539

Disassembly and Reassembly…544

General Disassembly…544

General Reassembly…544

Plunger Replacement…545

Main Plunger Element – Disassembly and Assembly…546

Tool…546

Main Relief Valve…549

Overload Relief Valve…552

Arm Load Holding Valve…554

Boom Load Holding Valve…557

Arm Regeneration Valve…559

Bucket Unity Check…560

Foot Relief Valve…561

Center Bypass Valve (CB Valve)…562

Boom Parallel Switch Valve…563

Boom Unity Check Valve…565

Check Valve – Locations…566

Check Valve…567

Remote Control Valve (Work Lever / Joystick) S0709450…570

General Description…572

Theory of Operation…572

Parts List…573

Specifications…574

Hydraulic Specifications…575

Special Tools…576

Disassembly…577

Reassembly…582

Steering Valve S0709710…588

General Description…590

Theory of Operation…591

Parts List…593

Specifications…594

Disassembly and Reassembly…595

Tools Needed…595

Valve Disassembly…596

Valve Reassembly…602

Hydraulic Schematic (Solar 200W-V) S0792100…614

General Description…616

Solar 200W-V…617

General Notes…619

Electrical System…620

Electrical System S0802120…622

Troubleshooting – Electrical System…625

Wiring Harness Illustrations…626

Overview…626

Electric Supply System…627

Engine Starting Circuit…629

Operation During Start Process…629

Operation After Start Process…631

Engine Preheating System…633

Engine Stop System…634

Charging System…638

Monitoring System…639

Instrument Panel and Steering Console…640

iNstrument Panel and Steering Console Function Check…641

Monitoring System Schematic…643

Operation…645

Instruments…645

Mode Select Switch…646

Pilot Lamp…647

Initial Operation…648

Electronic Hydraulic Control System (EPOS – V)…649

Power Mode Control…651

Operation…653

Throttle Position Sensor…657

Power Mode Control – Circuit Diagram…658

Work Mode Control…659

Operation…660

Work Mode Control – Circuit Diagram…661

Engine Control System…662

Engine Control Motor…663

Engine Speed Control Dial…664

Engine Control Circuit Diagram…665

Automatic Deceleration Control (Auto Idle Control)…666

Engine Overheat Protection System…667

Power Boost Mode…668

Operation…668

Power Boost Control – Circuit Diagram…669

Cruise Control…671

Function…671

Cruse Control Circuit…673

Adjusting Method of Engine Control Unit…674

Adjusting Method of Engine Control System…674

Adjusting Method of Engine RPM…676

Adjustment of TPS (Throttle Position Sensor) (Refer to Figure 46 thru Figure 48)…682

Self-diagnostic Function…685

EPOS-V Controller…685

Engine Throttle Controller…689

Electrical Schematic (Solar 200W-V) S0892100…690

General Description…692

Solar 200W-V…693

Attachments…696

Boom and Arm S0902080…698

Front Attachment Pin Specifications…700

Front Attachment – Removal and Installation…701

Arm Removal Procedure…701

Boom Removal Procedure…703

Installation…704

Arm Installation Procedure…704

Boom Installation Procedure…704

Start-up Procedures…705

Bucket S0904000…706

Bucket Tooth Inspection and Replacement…708

Bucket O-ring Replacement…709

Bucket Shimming Procedures…711

New Bucket Installation…711

Shimming Procedures for Installed Bucket…711

Bucket Attachment, Removal and Reversal…712

Detaching the Bucket…712

Attaching The bucket…712

Reversing the Bucket…713

ELECTRIC SYSTEM OF SOLAR-V…714

SHOP MAN.-TRAVEL MOTOR-MAIN PUMP…816

TENSOLRV0002 Solar V Model…878

TENSOLRV0004 Solar V Model…1162

Daewoo Solar S200W-V Excavators Repair Service Manual