Complete service repair manual for Hyster H25-35XM, H40XMS (D001) Forklifts Trucks, with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster H25XM, H35XM, H40XMS (D001) workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

897595 – Hyster H25-35XM, H40XMS (D001) Service Manual.pdf

Total Pages: 685 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section |

Part No.

|

SRM Number | Rev Date |

| FRAME |

897559

|

0100 SRM 0545

|

02/01

|

| MAZDA M4-2.0G ENGINE |

897477

|

0600 SRM 0496

|

02/01

|

| MAZDA M4-2.5D ENGINE |

897551

|

0600 SRM 0538

|

02/01

|

| COOLING SYSTEM |

897934

|

0700 SRM 0626

|

11/01

|

| LPG FUEL SYSTEM (EXCEPT AISAN SYSTEM) |

897508

|

0900 SRM 0523

|

01/96

|

| GASOLINE FUEL SYSTEM |

897591

|

0900 SRM 0547

|

02/01

|

| LPG FUEL SYSTEM (AISAN SYSTEM) |

1488917

|

0900 SRM 0925

|

08/02

|

| SINGLE-SPEED PS TRANS – DESCR/OPER/REPAIR |

897557

|

1300 SRM 0543

|

12/03

|

| DRIVE AXLE |

897556

|

1400 SRM 0542

|

12/03

|

| STEERING CONTROL UNIT (ROSS HGF) |

910458

|

1600 SRM 0257

|

07/00

|

| STEERING AXLE |

897545

|

1600 SRM 0532

|

02/01

|

| STEERING HOUSING |

897649

|

1600 SRM 0565

|

11/94

|

| BRAKE SYSTEM |

897554

|

1800 SRM 0540

|

02/01

|

| HYDRAULIC SYSTEM and GEAR PUMP |

897553

|

1900 SRM 0539

|

02/01

|

| MAIN CONTROL VALVE |

897555

|

2000 SRM 0541

|

02/01

|

| TILT CYLINDERS |

910102

|

2100 SRM 0103

|

10/03

|

| INSTRUMENT CLUSTER |

897495

|

2200 SRM 0514

|

01/04

|

| ELECTRICAL SYSTEM (MAZDA M4-2.0G) |

897509

|

2200 SRM 0524

|

02/01

|

| ELECTRICAL SYSTEM (MAZDA M4-2.5D) |

897594

|

2200 SRM 0550

|

02/01

|

| MAST – DESCRIPTION |

897506

|

4000 SRM 0521

|

11/03

|

| MAST – REPAIR |

897507

|

4000 SRM 0522

|

11/03

|

| INCH (SAE) and METRIC FASTENERS |

910442

|

8000 SRM 0231

|

03/03

|

| PERIODIC MAINTENANCE |

1459331

|

8000 SRM 0531

|

06/00

|

| DIAGRAMS |

897558

|

8000 SRM 0544

|

01/03

|

| CAPACITIES and SPECIFICATIONS |

897590

|

8000 SRM 0546

|

02/01

|

| PART NO. 897595 | |||

| Rev. 01/04 | |||

…

LPG Fuel System…50

Safety Precautions Maintenance and Repair…51

General…54

Description and Operation…54

Fuel Tank…55

Regulator…55

Start Mode…57

Idle Mode…57

Run Mode…57

Resonator…57

Carburetor…58

Start Mode…58

Idle Mode…58

Run Mode…58

Governor…59

Hoses Replacement…60

LPG Tank Repair…60

Remove…60

Install…61

Relief Valve Repair…61

Remove and Install…61

Carburetor Repair…61

Remove…61

Disassemble…61

Clean…62

Assemble…63

Install…63

Governor Repair…63

Remove…63

Inspect…63

Install…63

Regulator Repair…64

Remove…64

Disassemble…64

Clean…64

Inspect…64

Assemble…66

Install…67

Regulator Adjustment…67

Regulator Height Adjustment…67

Regulator Assembly Air Tightness Test…68

Carburetor Adjustment…69

Idle Speed and Fuel Mixture…69

Idle Control Adjustment…69

Governor Adjustment…70

Checks…70

Adjustments…70

Throttle Linkage Adjustment S/H2.00-3.20XM (S/H40-65XM)…71

MONOTROL® Pedal Check…72

Throttle Linkage Adjustment S/H1.50-2.00XMS (S/H25-40XMS)…73

Troubleshooting…74

tables…50

Table 1. Power Adjusting Screw…63

Table 2. Air Adjusting Screw…63

Table 3. Idle Mixture Adjusting Screw…66

Table 4. Idle Mixture Adjusting Screw…69

hyster-897477-02-01-srm0496…82

toc…82

Mazda Engine…82

Safety Precautions Maintenance and Repair…83

General…86

Description…86

Engine Removal and Installation…86

Cylinder Head, Camshaft, and Valve Mechanism Repair…87

Remove…87

Clean…88

Inspect and Repair…89

Cylinder Head…89

Rocker Shaft Assembly…89

Camshaft…89

Valve Guides…90

Valve Seats…91

Valves…91

Valve Springs…92

Install…92

Crankshaft and Main Bearings Repair…95

Remove…95

Inspect and Repair…95

Crankshaft…95

Main Bearings…95

Install…96

Pistons and Connecting Rods Repair…97

Remove and Disassemble…97

Clean…97

Inspect and Repair…97

Pistons…97

Piston Rings…97

Connecting Rods and Bearings…98

Assemble and Install…98

Cylinder Block Repair…100

Oil Pump Repair…100

Remove…100

Disassemble…101

Clean…101

Inspect…102

Assemble…102

Install…103

Cooling System Repair…103

Thermostat…103

Replace…103

Fan Assembly…103

Remove and Disassemble…103

Assemble and Install…104

Water Pump…104

Remove and Disassemble…104

Assemble and Install…105

Distributor Repair…106

Remove…106

Install…106

Flywheel and Ring Gear Repair S/H2.00-3.20XM (S/H40-65XM)…107

Remove…107

Ring Gear, Replace…107

Install…107

Flywheel Repair H1.50-175XM, H2.00XMS (S/H25-35XM, S/H40XMS)…108

Remove…108

Install…108

Valve Adjustment…109

Compression Pressure Check…110

Engine Timing Adjustment…110

Throttle Linkage Adjustment…111

Gasoline Engines…111

LPG Engines (IMPCO)…111

LPG Engines (AISAN)…111

Engine Specifications…111

Engine Data…111

Thermostat…111

Cylinder Head…111

Valve Mechanism…112

Camshaft…112

Crankshaft…112

Connecting Rods…113

Cylinder Block…113

Pistons…113

Oil Pump…113

Torque Specifications…114

Troubleshooting…115

hyster-897495-01-04-srm0514…120

toc…120

Instrument Cluster…120

Safety Precautions Maintenance and Repair…121

General…124

Description…124

Display Panels on Steering Column, Internal Combustion…124

Display Panels on Steering Column, Electric Lift Trucks…129

Standard Display Panel…129

Enhanced Display Panel…130

Curtis 1215 Display Panel…134

Description and Features…134

Operation…134

Cluster-Type Display Panel (Internal Combustion) Replacement…135

Remove and Disassemble…135

Assemble and Install…138

Cluster Display Panel (Electric Lift Truck) Replacement…140

Display Panel Assembly, Replace…140

LED Indicators…140

Battery Indicators…141

Digital Display (Enhanced Display Panel Only)…141

Status Code or Performance Level Switches and LED indicators (En…141

Standard Display Panel Parts, Replace…141

Enhanced Display Panel Parts, Replace…142

Curtis 1215 Display Panel Replacement…142

Remove…142

Install…142

tables…120

Table 1. Instrument Cluster, Internal Combustion…124

hyster-897506-11-03-srm0521…146

toc…146

Mast…146

Safety Precautions Maintenance and Repair…147

General…150

Description and Operation…150

Carriages…150

Mast Mounts…152

Two-Stage Mast, Limited Free-Lift (LFL)…153

Description and Operation…153

Two-Stage Mast, Full Free-Lift (FFL)…155

Description and Operation…155

Three-Stage Mast, Full Free-Lift (FFL)…157

Description and Operation…157

Cylinder Cushion During Lifting Sequence…160

Cylinder Cushion During Lowering Sequence…161

Mast…164

Safety Precautions Maintenance and Repair…165

General…168

Safety Procedures When Working Near Mast…168

Forks Repair…170

Remove…170

Install…170

Carriages Repair…171

Standard Carriage, Remove…171

Hang-On Sideshift Carriage, Remove…172

Standard Carriage and Hang-On Sideshift Carriage, Repair…173

Standard Carriage, Install…173

Hang-On Sideshift Carriage, Install…174

Integral Sideshift Carriage…174

Remove…174

Clean and Inspect…176

Repair…176

Install…177

Mast Repair…177

Remove…177

Two-Stage LFL and Two-Stage FFL Masts, Disassemble…179

Three-Stage FFL Mast…186

Disassemble…186

Mast and Chains, Clean and Inspect…190

Two-Stage LFL and Two-Stage FFL Mast, Assemble…191

Three-Stage FFL Mast, Assemble…192

Install…193

Lift Cylinders Repair…194

Main Lift Cylinders, Remove…194

Free-Lift Cylinder, Remove…195

Lift Cylinders, Disassemble…195

Lift Cylinders, Assemble…198

Main Lift Cylinders, Install…199

Free-Lift Cylinder, Install…199

Header Hose Arrangements…200

Two-Stage LFL Mast, New Hose Install…200

Two-Stage LFL Mast, Adjust Hoses After Installation…205

Two-Stage FFL Mast, New Hose Install…206

Two-Stage FFL Mast, Adjust Hoses After Installation…212

Three-Stage FFL Mast, New Hose Install…212

Three-Stage FFL Mast, Adjust Hoses After Installation…223

Header Hose Arrangement…224

Two-Stage LFL Mast, New Hose Install…224

Two-Stage LFL Mast, Adjust Hoses After Installation…228

Two-Stage FFL Mast, New Hose Install…228

Two-Stage FFL Mast, Adjust Hoses After Installation…233

Three-Stage FFL Mast, New Hose Install…235

Three-Stage FFL Mast, Adjust Hoses After Install…243

Lift and Tilt System Leak Check…244

Lift Cylinders Leak Check…244

Tilt Cylinders Leak Check…244

Tilt Cylinders Adjustment…245

Lift Chains Adjustment…246

Mast Adjustment…248

Carriage Adjustment…250

Troubleshooting…250

tables…164

Table 1. Hook-Type Carriage Chain Adjustment…247

Table 2. Pin-Type Carriage Chain Adjustment…247

Electrical System…282

Safety Precautions Maintenance and Repair…283

General…286

Description…286

Starting System…286

Ignition System…286

Charging System…287

Starter Repair…288

Remove and Disassemble…288

Assemble and Install…288

Coil Replacement…290

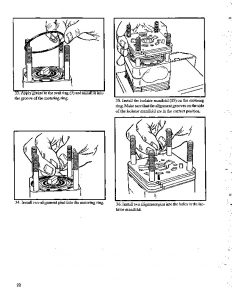

Distributor Repair H1.50-1.75XM, H2.00XMS (S/H25-35XM, S/H40XMS)…291

Remove and Disassemble…291

Assemble and Install…291

Distributor Repair S/H2.00-3.20XM (S/H40-65XM)…293

Remove and Disassemble…293

Assemble and Install…295

Alternator Repair…295

Remove and Disassemble…295

Assemble and Install…297

General Checks and Adjustments…297

Starter Checks…297

Operation, Check…297

Brush Holder, Check…298

Armature, Check…298

Field Windings, Check…298

Clutch and Bearing, Check…299

Ignition System Check and Adjustment…299

Engine Timing, Adjust…299

Spark Plugs, Check…300

Charging Circuit Checks…300

Low Output, Check…300

High Output, Check…301

Diodes, Check…301

Rotor Field Winding, Check…302

Stator Windings, Check…302

Brushes and Bearings, Check…303

Voltage Regulator, Check…303

Troubleshooting…303

hyster-897545-02-01-srm0532…308

toc…308

Steering Axle…308

Safety Precautions Maintenance and Repair…309

General…312

Description…312

Steering Axle Assembly Repair…313

Remove…313

Install…313

Wheels and Hubs Repair…313

Pneumatic Tires, Remove and Disassemble…313

Cushion Tires, Remove and Disassemble…315

Pneumatic Tires, Assemble and Install…315

Cushion Tires, Assemble and Install…315

Spindles, Bearings, and Tie Rods Repair…316

Pneumatic Tires, Remove…316

Cushion Tires, Remove…316

Pneumatic Tires, Install…316

Cushion Tires, Install…317

Steering Cylinder Repair…317

Remove and Disassemble…317

Clean and Inspect…317

Assemble and Install…317

Torque Specifications…318

Troubleshooting…319

hyster-897551-02-01-srm0538…322

toc…322

Mazda Engine…322

Safety Precautions Maintenance and Repair…323

General…326

Description…326

Engine Removal and Installation…327

Cylinder Head and Valve Mechanism Repair…327

Remove…327

Clean…328

Inspect and Repair…328

Cylinder Head…328

Rocker Shaft Assembly…328

Valve Guides…329

Valve Seats…329

Valves…329

Valve Springs…330

Push Rods…331

Cylinder Head…331

Assemble…331

Install…331

Timing Gears Repair…333

Remove…333

Clean and Inspect…333

Install…333

Crankshaft and Main Bearings Repair…335

Remove…335

Inspect and Repair…335

Crankshaft…335

Main Bearings…336

Install…336

Pistons and Connecting Rods Repair…336

Remove and Disassemble…336

Clean…337

Inspect and Repair…337

Pistons…337

Piston Rings…337

Connecting Rods and Bearings…337

Assemble and Install…338

Cylinder Block and Liners Repair…339

Inspect and Repair…339

Lubrication System Repair…341

Oil Pump…341

Remove…341

Disassemble…341

Clean…341

Inspect…341

Assemble…343

Install…343

Oil Filter Mount…343

Remove…343

Install…343

Cooling System Repair…344

Thermostat…344

Remove and Install…344

Water Pump…344

Remove…344

Disassemble…344

Inspect…345

Assemble…345

Install…346

Fuel System Description and Operation…346

Fuel Injection Pump Repair…348

Remove…348

Install…349

Fuel Filter Repair…349

New Filter, Install…349

Water Sensor, Check…349

Fuel System Air Removal…350

Fuel Injectors Repair…351

Remove and Disassemble…351

Assemble…351

Inspect and Adjust…351

Install…352

Flywheel Repair…353

Remove…353

Install…353

Valves Adjustment…354

Compression Pressure Check…354

Throttle Linkage Adjustment…355

Fuel Injection Pump Timing Check…355

Engine Specifications…356

Engine Model M4-2.5D…356

Torque Specifications…357

Troubleshooting…358

tables…322

Table 1. Crankshaft Journal Diameters…335

hyster-897553-02-01-srm0539…366

toc…366

Hydraulic System and Gear Pump Assembly…366

Safety Precautions Maintenance and Repair…367

General…370

Description and Operation…370

Hydraulic System…370

Gear Pump Assembly…372

Pump Drive Shaft…374

Steering Flow Divider…375

Relief Valve (Steering)…375

Relief Valve (Main Hydraulic)…376

Gear Pump Assembly Repair…377

Remove and Disassemble…377

Assemble and Install…377

Pump Drive Shaft Repair…377

Disassemble…377

Assemble and Install…378

Steering Relief Pressure Check and Adjust…378

Gear Pump Flow Check…378

Troubleshooting…379

Brake System…384

Safety Precautions Maintenance and Repair…385

General…388

Description and Operation…388

Service Brake…388

Parking Brake…389

Service Brakes Repair…389

Remove and Disassemble…389

Clean…392

Inspect…392

Assemble and Install…393

Adjust…395

Parking Brake Repair…396

Remove and Disassemble…396

Assemble and Install…397

Adjust…397

Master Cylinder Repair…397

Remove…397

Disassemble…397

Clean and Inspect…397

Assemble…399

Install…399

Service Brakes Adjustment…399

Brake System Air Removal…400

Parking Brake Not Applied Switch Test…400

Parking Brake Switch Test (MONOTROL® Pedal Only)…400

Inching/Brake Pedal Adjustment…401

Torque Specifications…401

Troubleshooting…403

Main Control Valve…408

Safety Precautions Maintenance and Repair…409

General…412

Description…412

Operation…413

Lift Section…414

Tilt Section…414

Tilt Backward…414

Tilt Forward…414

Steering Flow Divider…417

Relief Valve (Steering)…417

Relief Valve (Main Hydraulic)…417

Main Control Valve Repair…418

Remove…418

Disassemble…418

Clean and Inspect…418

Assemble…418

Install…418

Pressure Relief Valve Check and Adjustment…425

Steering Relief Valve…425

Main Hydraulic Relief Valve…425

Troubleshooting…426

Drive Axle…430

Safety Precautions Maintenance and Repair…431

General…434

Description…435

Drive Axle Repair…435

Remove and Disassemble…435

Clean and Inspect…436

Assemble and Install…436

Torque Specifications…438

Troubleshooting…438

Single-Speed Powershift Transmission…442

Safety Precautions Maintenance and Repair…443

General…446

Torque Converter Description and Operation…447

Description…447

Operation…447

Clutch Assemblies Description and Operation…449

Description…449

Operation…450

Hydraulic System Operation…451

Control Valve Operation…453

Regulator for Clutch Pressure…453

Inching Spool Assembly…453

Direction Spool…453

Modulator Circuit…453

Regulator for the Torque Converter…453

MONOTROL® Pedal Operation…454

Direction Control Lever Operation…454

Differential Operation…454

Torque Converter and Transmission Pump Repair…454

Remove and Disassemble…454

Inspect…455

Assemble and Install…455

Clutch Assemblies Repair…456

Remove and Disassemble…456

Inspect…459

Assemble and Install…459

Differential Repair…460

Remove and Disassemble…460

Inspect…460

Assemble and Install…460

New Ring and Pinion Assembly, Install…461

Pinion Assembly, Install…464

Differential and Ring Gear Assembly, Assemble…465

Control Valve Repair…466

Remove…466

Disassemble, Earlier Models…466

Disassemble, Later Models…467

Inspect…467

Assemble, Earlier Models…467

Assemble, Later Models…468

Install…468

MONOTROL® Pedal Repair…469

Remove and Disassemble…469

Assemble and Install…469

Direction Control Lever Repair…472

Remove and Disassemble…472

Assemble and Install…472

Torque Converter Stall Test…473

Transmission Pressure Tests…474

Transmission Pump Pressure Check, Test Port No. 1…475

Torque Converter Inlet Pressure Check, Test Port No. 2…475

Clutch Pressure Check, Test Port No. 3…475

Inching/Brake Pedal Adjustment…475

Troubleshooting…475

tables…442

Table 1. Pinion Assembly Shims Adjustment…462

Table 2. Ring and Pinion Tooth Contact Adjustment…463

Table 3. Stall Speeds…474

Table 4. Pressure Test Ports…474

hyster-897558-01-03-srm0544…484

toc…484

Diagrams…484

Safety Precautions Maintenance and Repair…485

hyster-897559-02-01-srm0545…514

toc…514

Frame…514

Safety Precautions Maintenance and Repair…515

General…518

Description…518

Operator Module Repair…518

Remove…518

Install…519

Hood and Side Covers Repair…520

Remove…520

Install…520

Overhead Guard Repair…522

Remove and Install…522

Counterweight Repair…523

Remove…523

Install…524

Exhaust System Repair…525

Muffler, Replace…525

Radiator and Cooling System Repair…529

Remove…529

Install…529

Operator Restraint System Repair…530

Engine Repair…531

Remove (Engine Only)…531

Remove (Engine and Transmission)…531

Install (Engine Only)…531

Install (Engine and Transmission)…532

Fuel and Hydraulic Tanks Repair…533

Clean…533

Steam Method of Cleaning…533

Chemical Solution Method of Cleaning…533

Inspect…533

Repair…533

Small Leaks…533

Large Leaks…534

Safety Labels…534

tables…514

Table 1. Weight of Counterweights…523

hyster-897590-02-01-srm0546…540

toc…540

Capacities and Specifications…540

Safety Precautions Maintenance and Repair…541

Engine Specifications…544

Electrical System…544

Hydraulic System…545

Lift Truck Weights…545

Torque Converter Stall Speeds…545

Tire Pressure…546

Capacities…546

Mast Speeds…547

Mazda M4-1.5G Engine Mast Speeds…547

Mazda M4-2.0G Engine Mast Speeds…547

Mazda M4-2.5D Engine Mast Speeds…548

Transmission Oil Pressures…548

Torque Specifications…549

Brake System…549

Drive Axle…549

Engine – Mazda M4-1.5G…549

Engine – Mazda M4-2.0G…549

Engine – Mazda M4-2.5D…550

Frame…551

Mast…551

Steering System…551

Transmission and Differential…551

hyster-897591-02-01-srm0547…554

toc…554

Gasoline Fuel System…554

Safety Precautions Maintenance and Repair…555

Description…558

Governor…558

Carburetor Repair…559

Remove…559

Disassemble…561

Clean…563

Inspect…563

Assemble…564

Install…567

Carburetor Checks and Adjustments…567

Idle Speed and Mixture, Adjust…567

Throttle Linkage, Adjust…567

Governor Checks and Adjustments…569

Troubleshooting…570

hyster-897594-02-01-srm0550…576

toc…576

Electrical System…576

Safety Precautions Maintenance and Repair…577

General…580

Description…580

Starting Circuit…580

Charging System…581

Starter Repair…582

Remove and Disassemble…582

Assemble and Install…582

Alternator Repair…584

Remove and Disassemble…584

Assemble and Install…585

General Checks and Adjustments…586

Starter Checks…586

Operation Check…586

Solenoid Coil Checks…587

Brush Holder Check…587

Armature Check…587

Field Windings Check…587

Clutch and Bearing Check…587

Cold Start Aid Checks…588

Glow Plugs…588

Fuse…588

Relay and Controller…588

Charging Circuit Checks…589

Low-Output Check…589

High-Output Check…590

Diodes Check…590

Rotor Field Winding Check…591

Stator Windings Check…592

Brushes and Bearings…592

Voltage Regulator Check…592

Troubleshooting…593

hyster-897649-11-94-srm0565…598

…598

…599

…600

…601

…602

…603

…604

…605

hyster-897934-11-01-srm0626…606

toc…606

Cooling System…606

Safety Precautions Maintenance and Repair…607

General…610

Description…611

Radiator…611

Radiator Cap…611

Thermostat…611

Water Pump…612

Fan and Fan Shroud…612

Cooling System Checks…612

Radiator…612

Thermostat…612

Water Pump…613

Exhaust Leaks…613

Fan and Fan Shroud…613

Radiator Cleaning…613

Drain…613

Clean…613

Fill…614

Troubleshooting…615

hyster-910102-10-03-srm0103…618

toc…618

Tilt Cylinders…618

Safety Precautions Maintenance and Repair…619

General…622

Description…622

Tilt Cylinder Repair…622

Remove…622

Disassemble…622

Clean…622

Assemble…623

Tilt Cylinders With O-Ring or Single-Lip Seals…623

Tilt Cylinders for XM and XMS Models…624

Tilt Cylinders for H700-800A and Early Model H700-920B…625

Install…626

Tilt Cylinders Using Chevron Packing…627

Install…628

Tilt Cylinder Leak Check…630

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…631

Torque Specifications…632

Piston Rod Nut…632

Retainer…633

Troubleshooting…635

tables…618

Table 1. Movement Rates (Maximum) for Tilt Cylinders…631

hyster-910442-03-03-srm0231…638

toc…638

Metric and Inch (SAE) Fasteners…638

Safety Precautions Maintenance and Repair…639

General…642

Threaded Fasteners…642

Nomenclature, Threads…642

Strength Identification…643

Cotter (Split) Pins…643

Fastener Torque Tables…648

Conversion Table…650

tables…638

Table 1. Bolts and Screws…644

Table 2. Studs and Nuts…645

Table 3. Torque Nuts…646

Table 4. Torque Nuts With Nylon Insert…647

Table 5. Torque Values for Metric Fasteners*…648

Table 6. Torque Values for Inch Fasteners*…649

Table 7. Conversion Table for Metric and English units…650

Table 8. Cotter Pin Dimensional Data…651

hyster-910458-07-00-srm0257…654

Hyster H25-35XM, H40XMS (D001) Repair Service Manual