Complete service repair manual with Electrical Wiring Diagrams for Hyster Lift Trucks H25-35XM, H40XMS (E001), with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster Service Manual H25XM, H35XM, H40XMS (E001) workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

1492514 – Hyster Service Manual H25-35XM, H40XMS (E001) .pdf

Total Pages: 686 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section |

Part No.

|

SRM Number | Rev Date |

| FRAME |

897559

|

0100 SRM 0545

|

02/01

|

| MAZDA M4-2.0G ENGINE |

897477

|

0600 SRM 0496

|

02/01

|

| MAZDA M4-2.5D ENGINE |

897551

|

0600 SRM 0538

|

02/01

|

| COOLING SYSTEM |

897934

|

0700 SRM 0626

|

11/01

|

| GASOLINE FUEL SYSTEM |

897591

|

0900 SRM 0547

|

02/01

|

| LPG FUEL SYSTEM (AISAN OPEN LOOP SYSTEM) |

1488917

|

0900 SRM 0925

|

08/02

|

| LPG FUEL SYSTEM (AISAN CLOSED LOOP SYSTEM) |

1495954

|

0900 SRM 0948

|

02/04

|

| SINGLE-SPEED PS TRANS – DESCR / OPER / REPAIR |

897557

|

1300 SRM 0543

|

12/03

|

| DRIVE AXLE |

897556

|

1400 SRM 0542

|

12/03

|

| STEERING AXLE |

897545

|

1600 SRM 0532

|

02/01

|

| STEERING CONTROL UNIT |

1459370

|

1600 SRM 0720

|

11/03

|

| BRAKE SYSTEM |

897554

|

1800 SRM 0540

|

02/01

|

| HYDRAULIC SYSTEM and GEAR PUMP |

897553

|

1900 SRM 0539

|

02/01

|

| MAIN CONTROL VALVE |

897555

|

2000 SRM 0541

|

02/01

|

| TILT CYLINDERS |

910102

|

2100 SRM 0103

|

10/03

|

| INSTRUMENT CLUSTER |

897495

|

2200 SRM 0514

|

01/04

|

| ELECTRICAL SYSTEM (MAZDA M4-2.0G) |

897509

|

2200 SRM 0524

|

02/01

|

| ELECTRICAL SYSTEM (MAZDA M4-2.5D) |

897594

|

2200 SRM 0550

|

02/01

|

| MAST – DESCRIPTION |

897506

|

4000 SRM 0521

|

11/03

|

| MAST – REPAIR |

897507

|

4000 SRM 0522

|

11/03

|

| INCH (SAE) and METRIC FASTENERS |

910442

|

8000 SRM 0231

|

03/03

|

| DIAGRAMS |

897558

|

8000 SRM 0544

|

01/03

|

| CAPACITIES and SPECIFICATIONS |

897590

|

8000 SRM 0546

|

02/01

|

| PERIODIC MAINTENANCE |

1498509

|

8000 SRM 0959

|

12/03

|

| PART NO. 1492514 | |||

| Rev. 02/04 | |||

Steering Housing and Control Unit…2

Safety Precautions Maintenance and Repair…3

General…6

Description…6

Operation…7

Steering Wheel and Column Assembly Repair…8

Assembly Components, Remove…8

Steering Control Unit, Disassemble…10

Steering Control Unit, Clean…10

Steering Control Unit, Assemble…12

Assembly Components, Install…15

System Air Removal…17

Troubleshooting…17

LPG Fuel System…22

Safety Precautions Maintenance and Repair…23

General…26

Description and Operation…26

Fuel Tank…27

Regulator…27

Start Mode…29

Idle Mode…29

Run Mode…29

Resonator…29

Carburetor…30

Start Mode…30

Idle Mode…30

Run Mode…30

Governor…31

Hoses Replacement…32

LPG Tank Repair…32

Remove…32

Install…33

Relief Valve Repair…33

Remove and Install…33

Carburetor Repair…33

Remove…33

Disassemble…33

Clean…34

Assemble…35

Install…35

Governor Repair…35

Remove…35

Inspect…35

Install…35

Regulator Repair…36

Remove…36

Disassemble…36

Clean…36

Inspect…36

Assemble…38

Install…39

Regulator Adjustment…39

Regulator Height Adjustment…39

Regulator Assembly Air Tightness Test…40

Carburetor Adjustment…41

Idle Speed and Fuel Mixture…41

Idle Control Adjustment…41

Governor Adjustment…42

Checks…42

Adjustments…42

Throttle Linkage Adjustment S/H2.00-3.20XM (S/H40-65XM)…43

MONOTROL® Pedal Check…44

Throttle Linkage Adjustment S/H1.50-2.00XMS (S/H25-40XMS)…45

Troubleshooting…46

tables…22

Table 1. Power Adjusting Screw…35

Table 2. Air Adjusting Screw…35

Table 3. Idle Mixture Adjusting Screw…38

Table 4. Idle Mixture Adjusting Screw…41

hyster-1495954-02-04-srm0948…54

toc…54

LPG Fuel System…54

Safety Precautions Maintenance and Repair…55

General…58

Description and Operation…59

Fuel Tank…59

Oxygen Sensor…60

Regulator…60

Start Mode…63

Idle Mode…63

Run Mode…63

Resonator…63

Carburetor…64

Start Mode…64

Idle Mode…65

Run Mode…65

Governor…65

Hoses Replacement…66

LPG Tank Repair…66

Remove…66

Install…67

Relief Valve Repair…67

Remove and Install…67

Carburetor Repair…67

Remove…67

Disassemble…67

Clean…68

Assemble…68

Install…69

Fuel Injector Repair…69

Remove…69

Clean and Inspect…69

Install…69

Governor Repair…70

Remove…70

Inspect…70

Install…70

Regulator Repair…70

Remove…70

Install…70

Oxygen Sensor Repair…71

Remove and Install…71

Vacuum Switches Repair…71

Remove and Install…71

Inspect…71

Resistor Repair…71

Remove and Install…71

Inspect…71

Carburetor and New Regulator Adjustment…71

Idle Speed and Fuel Mixture…71

Idle Control Adjustment…72

Governor Checks and Adjustments…73

Checks…73

Adjustments…73

Throttle Linkage Adjustment…74

MONOTROL Pedal Check…75

Check Engine Light…75

Inspect Warning Lamp…75

Check Feedback Operation…75

Check VAC1 and VAC2 Signals…75

Check Resistor…75

Check Fuel Injector…76

Check Oxygen Sensor…76

Check Vacuum Switch 1…76

Check Vacuum Switch 2…76

After Completing Checks…76

Troubleshooting…77

tables…54

Table 1. Adjusting Screw…69

hyster-1498509-12-03-srm0959…86

toc…86

Periodic Maintenance…86

Safety Precautions Maintenance and Repair…87

General…92

Serial Number…92

How to Move Disabled Lift Truck…92

How to Tow Lift Truck…92

How to Put Lift Truck on Blocks…93

How to Raise Drive Tires…93

How to Raise Steering Tires…93

Maintenance Schedule…94

Maintenance Procedures Every 8 Hours or Daily…103

How to Make Checks With Engine Stopped…103

Tires and Wheels…103

Forks…104

Adjust…104

Remove…105

Install…106

Inspection of Forks, Mast, and Lift Chains…106

Safety Labels…107

Operator Restraint System…107

Steering Column Latch…107

Fuel, Oil, or Coolant Leaks Check…108

Drive Belts…108

Engine Oil Level…109

Brake Fluid…109

Hydraulic Oil Level…110

Transmission Oil…110

Gasoline and LPG Fuel Filters…110

Diesel Fuel Filter…110

How to Drain Water From Fuel Filter…110

Battery Electrolyte…111

How to Make Checks With Engine Running…111

Gauges, Indicator Lights, Horn, Fuses, and Relays…111

Control Levers and Pedals…111

Steering System…111

Service Brakes…112

Parking Brake…113

Cooling System…113

Lift System Operation…114

Maintenance Procedures Every 250 Hours or 6 Weeks…114

Engine Oil and Filter…114

Changing Engine Oil and Filter…114

Air Filter…114

Transmission Oil Level…115

Battery…115

Wheel Nuts…116

Engine Speed…116

LPG Engine…116

Gasoline Engine…116

Diesel Engine…116

Lift Chains…116

Lubrication…116

Wear Check…116

Mast…117

Spark Plugs, Mazda M4-2.0G Engine…118

Differential…118

Drive Belts…118

Mazda M4-2.0G Gasoline and LPG Engines…118

Mazda M4-2.5D Diesel Engine…119

Inching/Brake Pedal…119

Forks…119

Maintenance Procedures Every 500 Hours or 3 Months…119

PCV Valve…119

Diesel Fuel System…120

Replace Diesel Fuel Filter…120

Remove Air From Fuel System…120

Drain Tar From LPG Regulator…120

Steering Axle…121

Maintenance Procedures Every 1000 Hours or 6 Months…121

Pedals, Levers, Cables, and Other Linkages…121

Air Filter…121

LPG Fuel Filter…121

IMPCO Fuel Filter…121

Regulator Pressure/Diaphragm and O-Ring Checks…121

Spark Plugs…121

Ignition System, Mazda M4-2.0G Engines…122

Injection Pump Timing, Mazda M4-2.5D Diesel Engine…122

Valve Clearance Adjustment…123

Integral Sideshift Carriage, Check Bearings…123

Hydraulic Pump Drive Shaft…124

Maintenance Procedures Every 2000 Hours or Yearly…124

Throttle Cable…124

Differential…124

Main Solenoid Valve (LPG Engine)…124

Hydraulic System…125

Replace Hydraulic Oil and Filter…125

Clean Hydraulic Tank Breather…125

Timing Belt, Mazda…125

Cooling System…125

Transmission…126

Replace Transmission Oil and Filter…126

Fuel Injectors…126

LPG Engine (Closed-Loop)…126

Integral Sideshift Carriage, Replace Bearings…126

Gasoline Fuel Filter…126

LPG Fuel Filter…127

Aisan Fuel Filter…127

Hood Latch Check…127

Latch, Adjust…127

Safety Procedures When Working Near Mast…128

Lift and Tilt System Leak Check…130

Lift Cylinders, Leak Check…130

Tilt Cylinders, Leak Check…130

Tilt Cylinder Adjustment…130

Lift Chain Adjustments…131

Service Brake Check…133

Diesel Engine Fuel Injector Check…134

Welding Repairs…134

Overhead Guard Changes…135

Wheel and Tire Replacement…135

General…135

How to Change Solid Rubber Tire (S Series) …135

Remove and Install Tire on Wheel…135

Pneumatic Tire, Repair…136

Remove Wheels From Lift Truck…136

Remove Tire From Wheel…136

Remove Tire From Two-Piece Wheel…137

Remove Tire From Three- and Four-Piece Wheels…138

Install Wheel in Tire…139

Install Two-Piece Wheel in Tire…140

Install Three- or Four-Piece Wheel in Tire…141

Add Air to Pneumatic Tires…142

Wheels, Install…142

Solid Rubber Tires on Pneumatic Wheels, Change…142

Remove Tire From Wheel…143

Install Tire on Wheel…144

Operating Procedures for New or Rebuilt Engine…146

tables…86

Table 1. Maintenance Schedule…94

Table 2. Hook-Type Carriage Chain Adjustment…132

Table 3. Pin-Type Carriage Chain Adjustment…132

hyster-897477-02-01-srm0496…150

toc…150

Mazda Engine…150

Safety Precautions Maintenance and Repair…151

General…154

Description…154

Engine Removal and Installation…154

Cylinder Head, Camshaft, and Valve Mechanism Repair…155

Remove…155

Clean…156

Inspect and Repair…157

Cylinder Head…157

Rocker Shaft Assembly…157

Camshaft…157

Valve Guides…158

Valve Seats…159

Valves…159

Valve Springs…160

Install…160

Crankshaft and Main Bearings Repair…163

Remove…163

Inspect and Repair…163

Crankshaft…163

Main Bearings…163

Install…164

Pistons and Connecting Rods Repair…165

Remove and Disassemble…165

Clean…165

Inspect and Repair…165

Pistons…165

Piston Rings…165

Connecting Rods and Bearings…166

Assemble and Install…166

Cylinder Block Repair…168

Oil Pump Repair…168

Remove…168

Disassemble…169

Clean…169

Inspect…170

Assemble…170

Install…171

Cooling System Repair…171

Thermostat…171

Replace…171

Fan Assembly…171

Remove and Disassemble…171

Assemble and Install…172

Water Pump…172

Remove and Disassemble…172

Assemble and Install…173

Distributor Repair…174

Remove…174

Install…174

Flywheel and Ring Gear Repair S/H2.00-3.20XM (S/H40-65XM)…175

Remove…175

Ring Gear, Replace…175

Install…175

Flywheel Repair H1.50-175XM, H2.00XMS (S/H25-35XM, S/H40XMS)…176

Remove…176

Install…176

Valve Adjustment…177

Compression Pressure Check…178

Engine Timing Adjustment…178

Throttle Linkage Adjustment…179

Gasoline Engines…179

LPG Engines (IMPCO)…179

LPG Engines (AISAN)…179

Engine Specifications…179

Engine Data…179

Thermostat…179

Cylinder Head…179

Valve Mechanism…180

Camshaft…180

Crankshaft…180

Connecting Rods…181

Cylinder Block…181

Pistons…181

Oil Pump…181

Torque Specifications…182

Troubleshooting…183

hyster-897495-01-04-srm0514…188

toc…188

Instrument Cluster…188

Safety Precautions Maintenance and Repair…189

General…192

Description…192

Display Panels on Steering Column, Internal Combustion…192

Display Panels on Steering Column, Electric Lift Trucks…197

Standard Display Panel…197

Enhanced Display Panel…198

Curtis 1215 Display Panel…202

Description and Features…202

Operation…202

Cluster-Type Display Panel (Internal Combustion) Replacement…203

Remove and Disassemble…203

Assemble and Install…206

Cluster Display Panel (Electric Lift Truck) Replacement…208

Display Panel Assembly, Replace…208

LED Indicators…208

Battery Indicators…209

Digital Display (Enhanced Display Panel Only)…209

Status Code or Performance Level Switches and LED indicators (En…209

Standard Display Panel Parts, Replace…209

Enhanced Display Panel Parts, Replace…210

Curtis 1215 Display Panel Replacement…210

Remove…210

Install…210

tables…188

Table 1. Instrument Cluster, Internal Combustion…192

hyster-897506-11-03-srm0521…214

toc…214

Mast…214

Safety Precautions Maintenance and Repair…215

General…218

Description and Operation…218

Carriages…218

Mast Mounts…220

Two-Stage Mast, Limited Free-Lift (LFL)…221

Description and Operation…221

Two-Stage Mast, Full Free-Lift (FFL)…223

Description and Operation…223

Three-Stage Mast, Full Free-Lift (FFL)…225

Description and Operation…225

Cylinder Cushion During Lifting Sequence…228

Cylinder Cushion During Lowering Sequence…229

hyster-897507-11-03-srm0522…232

toc…232

Mast…232

Safety Precautions Maintenance and Repair…233

General…236

Safety Procedures When Working Near Mast…236

Forks Repair…238

Remove…238

Install…238

Carriages Repair…239

Standard Carriage, Remove…239

Hang-On Sideshift Carriage, Remove…240

Standard Carriage and Hang-On Sideshift Carriage, Repair…241

Standard Carriage, Install…241

Hang-On Sideshift Carriage, Install…242

Integral Sideshift Carriage…242

Remove…242

Clean and Inspect…244

Repair…244

Install…245

Mast Repair…245

Remove…245

Two-Stage LFL and Two-Stage FFL Masts, Disassemble…247

Three-Stage FFL Mast…254

Disassemble…254

Mast and Chains, Clean and Inspect…258

Two-Stage LFL and Two-Stage FFL Mast, Assemble…259

Three-Stage FFL Mast, Assemble…260

Install…261

Lift Cylinders Repair…262

Main Lift Cylinders, Remove…262

Free-Lift Cylinder, Remove…263

Lift Cylinders, Disassemble…263

Lift Cylinders, Assemble…266

Main Lift Cylinders, Install…267

Free-Lift Cylinder, Install…267

Header Hose Arrangements…268

Two-Stage LFL Mast, New Hose Install…268

Two-Stage LFL Mast, Adjust Hoses After Installation…273

Two-Stage FFL Mast, New Hose Install…274

Two-Stage FFL Mast, Adjust Hoses After Installation…280

Three-Stage FFL Mast, New Hose Install…280

Three-Stage FFL Mast, Adjust Hoses After Installation…291

Header Hose Arrangement…292

Two-Stage LFL Mast, New Hose Install…292

Two-Stage LFL Mast, Adjust Hoses After Installation…296

Two-Stage FFL Mast, New Hose Install…296

Two-Stage FFL Mast, Adjust Hoses After Installation…301

Three-Stage FFL Mast, New Hose Install…303

Three-Stage FFL Mast, Adjust Hoses After Install…311

Lift and Tilt System Leak Check…312

Lift Cylinders Leak Check…312

Tilt Cylinders Leak Check…312

Tilt Cylinders Adjustment…313

Lift Chains Adjustment…314

Mast Adjustment…316

Carriage Adjustment…318

Troubleshooting…318

tables…232

Table 1. Hook-Type Carriage Chain Adjustment…315

Table 2. Pin-Type Carriage Chain Adjustment…315

hyster-897509-02-01-srm0524…322

toc…322

Electrical System…322

Safety Precautions Maintenance and Repair…323

General…326

Description…326

Starting System…326

Ignition System…326

Charging System…327

Starter Repair…328

Remove and Disassemble…328

Assemble and Install…328

Coil Replacement…330

Distributor Repair H1.50-1.75XM, H2.00XMS (S/H25-35XM, S/H40XMS)…331

Remove and Disassemble…331

Assemble and Install…331

Distributor Repair S/H2.00-3.20XM (S/H40-65XM)…333

Remove and Disassemble…333

Assemble and Install…335

Alternator Repair…335

Remove and Disassemble…335

Assemble and Install…337

General Checks and Adjustments…337

Starter Checks…337

Operation, Check…337

Brush Holder, Check…338

Armature, Check…338

Field Windings, Check…338

Clutch and Bearing, Check…339

Ignition System Check and Adjustment…339

Engine Timing, Adjust…339

Spark Plugs, Check…340

Charging Circuit Checks…340

Low Output, Check…340

High Output, Check…341

Diodes, Check…341

Rotor Field Winding, Check…342

Stator Windings, Check…342

Brushes and Bearings, Check…343

Voltage Regulator, Check…343

Troubleshooting…343

hyster-897545-02-01-srm0532…348

toc…348

Steering Axle…348

Safety Precautions Maintenance and Repair…349

General…352

Description…352

Steering Axle Assembly Repair…353

Remove…353

Install…353

Wheels and Hubs Repair…353

Pneumatic Tires, Remove and Disassemble…353

Cushion Tires, Remove and Disassemble…355

Pneumatic Tires, Assemble and Install…355

Cushion Tires, Assemble and Install…355

Spindles, Bearings, and Tie Rods Repair…356

Pneumatic Tires, Remove…356

Cushion Tires, Remove…356

Pneumatic Tires, Install…356

Cushion Tires, Install…357

Steering Cylinder Repair…357

Remove and Disassemble…357

Clean and Inspect…357

Assemble and Install…357

Torque Specifications…358

Troubleshooting…359

hyster-897551-02-01-srm0538…362

toc…362

Mazda Engine…362

Safety Precautions Maintenance and Repair…363

General…366

Description…366

Engine Removal and Installation…367

Cylinder Head and Valve Mechanism Repair…367

Remove…367

Clean…368

Inspect and Repair…368

Cylinder Head…368

Rocker Shaft Assembly…368

Valve Guides…369

Valve Seats…369

Valves…369

Valve Springs…370

Push Rods…371

Cylinder Head…371

Assemble…371

Install…371

Timing Gears Repair…373

Remove…373

Clean and Inspect…373

Install…373

Crankshaft and Main Bearings Repair…375

Remove…375

Inspect and Repair…375

Crankshaft…375

Main Bearings…376

Install…376

Pistons and Connecting Rods Repair…376

Remove and Disassemble…376

Clean…377

Inspect and Repair…377

Pistons…377

Piston Rings…377

Connecting Rods and Bearings…377

Assemble and Install…378

Cylinder Block and Liners Repair…379

Inspect and Repair…379

Lubrication System Repair…381

Oil Pump…381

Remove…381

Disassemble…381

Clean…381

Inspect…381

Assemble…383

Install…383

Oil Filter Mount…383

Remove…383

Install…383

Cooling System Repair…384

Thermostat…384

Remove and Install…384

Water Pump…384

Remove…384

Disassemble…384

Inspect…385

Assemble…385

Install…386

Fuel System Description and Operation…386

Fuel Injection Pump Repair…388

Remove…388

Install…389

Fuel Filter Repair…389

New Filter, Install…389

Water Sensor, Check…389

Fuel System Air Removal…390

Fuel Injectors Repair…391

Remove and Disassemble…391

Assemble…391

Inspect and Adjust…391

Install…392

Flywheel Repair…393

Remove…393

Install…393

Valves Adjustment…394

Compression Pressure Check…394

Throttle Linkage Adjustment…395

Fuel Injection Pump Timing Check…395

Engine Specifications…396

Engine Model M4-2.5D…396

Torque Specifications…397

Troubleshooting…398

tables…362

Table 1. Crankshaft Journal Diameters…375

hyster-897553-02-01-srm0539…406

toc…406

Hydraulic System and Gear Pump Assembly…406

Safety Precautions Maintenance and Repair…407

General…410

Description and Operation…410

Hydraulic System…410

Gear Pump Assembly…412

Pump Drive Shaft…414

Steering Flow Divider…415

Relief Valve (Steering)…415

Relief Valve (Main Hydraulic)…416

Gear Pump Assembly Repair…417

Remove and Disassemble…417

Assemble and Install…417

Pump Drive Shaft Repair…417

Disassemble…417

Assemble and Install…418

Steering Relief Pressure Check and Adjust…418

Gear Pump Flow Check…418

Troubleshooting…419

hyster-897554-02-01-srm0540…424

toc…424

Brake System…424

Safety Precautions Maintenance and Repair…425

General…428

Description and Operation…428

Service Brake…428

Parking Brake…429

Service Brakes Repair…429

Remove and Disassemble…429

Clean…432

Inspect…432

Assemble and Install…433

Adjust…435

Parking Brake Repair…436

Remove and Disassemble…436

Assemble and Install…437

Adjust…437

Master Cylinder Repair…437

Remove…437

Disassemble…437

Clean and Inspect…437

Assemble…439

Install…439

Service Brakes Adjustment…439

Brake System Air Removal…440

Parking Brake Not Applied Switch Test…440

Parking Brake Switch Test (MONOTROL® Pedal Only)…440

Inching/Brake Pedal Adjustment…441

Torque Specifications…441

Troubleshooting…443

hyster-897555-02-01-srm0541…448

toc…448

Main Control Valve…448

Safety Precautions Maintenance and Repair…449

General…452

Description…452

Operation…453

Lift Section…454

Tilt Section…454

Tilt Backward…454

Tilt Forward…454

Steering Flow Divider…457

Relief Valve (Steering)…457

Relief Valve (Main Hydraulic)…457

Main Control Valve Repair…458

Remove…458

Disassemble…458

Clean and Inspect…458

Assemble…458

Install…458

Pressure Relief Valve Check and Adjustment…465

Steering Relief Valve…465

Main Hydraulic Relief Valve…465

Troubleshooting…466

hyster-897556-12-03-srm0542…470

toc…470

Drive Axle…470

Safety Precautions Maintenance and Repair…471

General…474

Description…475

Drive Axle Repair…475

Remove and Disassemble…475

Clean and Inspect…476

Assemble and Install…476

Torque Specifications…478

Troubleshooting…478

hyster-897557-12-03-srm0543…482

toc…482

Single-Speed Powershift Transmission…482

Safety Precautions Maintenance and Repair…483

General…486

Torque Converter Description and Operation…487

Description…487

Operation…487

Clutch Assemblies Description and Operation…489

Description…489

Operation…490

Hydraulic System Operation…491

Control Valve Operation…493

Regulator for Clutch Pressure…493

Inching Spool Assembly…493

Direction Spool…493

Modulator Circuit…493

Regulator for the Torque Converter…493

MONOTROL® Pedal Operation…494

Direction Control Lever Operation…494

Differential Operation…494

Torque Converter and Transmission Pump Repair…494

Remove and Disassemble…494

Inspect…495

Assemble and Install…495

Clutch Assemblies Repair…496

Remove and Disassemble…496

Inspect…499

Assemble and Install…499

Differential Repair…500

Remove and Disassemble…500

Inspect…500

Assemble and Install…500

New Ring and Pinion Assembly, Install…501

Pinion Assembly, Install…504

Differential and Ring Gear Assembly, Assemble…505

Control Valve Repair…506

Remove…506

Disassemble, Earlier Models…506

Disassemble, Later Models…507

Inspect…507

Assemble, Earlier Models…507

Assemble, Later Models…508

Install…508

MONOTROL® Pedal Repair…509

Remove and Disassemble…509

Assemble and Install…509

Direction Control Lever Repair…512

Remove and Disassemble…512

Assemble and Install…512

Torque Converter Stall Test…513

Transmission Pressure Tests…514

Transmission Pump Pressure Check, Test Port No. 1…515

Torque Converter Inlet Pressure Check, Test Port No. 2…515

Clutch Pressure Check, Test Port No. 3…515

Inching/Brake Pedal Adjustment…515

Troubleshooting…515

tables…482

Table 1. Pinion Assembly Shims Adjustment…502

Table 2. Ring and Pinion Tooth Contact Adjustment…503

Table 3. Stall Speeds…514

Table 4. Pressure Test Ports…514

hyster-897558-01-03-srm0544…524

toc…524

Diagrams…524

Safety Precautions Maintenance and Repair…525

hyster-897559-02-01-srm0545…554

toc…554

Frame…554

Safety Precautions Maintenance and Repair…555

General…558

Description…558

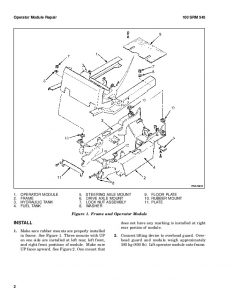

Operator Module Repair…558

Remove…558

Install…559

Hood and Side Covers Repair…560

Remove…560

Install…560

Overhead Guard Repair…562

Remove and Install…562

Counterweight Repair…563

Remove…563

Install…564

Exhaust System Repair…565

Muffler, Replace…565

Radiator and Cooling System Repair…569

Remove…569

Install…569

Operator Restraint System Repair…570

Engine Repair…571

Remove (Engine Only)…571

Remove (Engine and Transmission)…571

Install (Engine Only)…571

Install (Engine and Transmission)…572

Fuel and Hydraulic Tanks Repair…573

Clean…573

Steam Method of Cleaning…573

Chemical Solution Method of Cleaning…573

Inspect…573

Repair…573

Small Leaks…573

Large Leaks…574

Safety Labels…574

tables…554

Table 1. Weight of Counterweights…563

hyster-897590-02-01-srm0546…580

toc…580

Capacities and Specifications…580

Safety Precautions Maintenance and Repair…581

Engine Specifications…584

Electrical System…584

Hydraulic System…585

Lift Truck Weights…585

Torque Converter Stall Speeds…585

Tire Pressure…586

Capacities…586

Mast Speeds…587

Mazda M4-1.5G Engine Mast Speeds…587

Mazda M4-2.0G Engine Mast Speeds…587

Mazda M4-2.5D Engine Mast Speeds…588

Transmission Oil Pressures…588

Torque Specifications…589

Brake System…589

Drive Axle…589

Engine – Mazda M4-1.5G…589

Engine – Mazda M4-2.0G…589

Engine – Mazda M4-2.5D…590

Frame…591

Mast…591

Steering System…591

Transmission and Differential…591

hyster-897591-02-01-srm0547…594

toc…594

Gasoline Fuel System…594

Safety Precautions Maintenance and Repair…595

Description…598

Governor…598

Carburetor Repair…599

Remove…599

Disassemble…601

Clean…603

Inspect…603

Assemble…604

Install…607

Carburetor Checks and Adjustments…607

Idle Speed and Mixture, Adjust…607

Throttle Linkage, Adjust…607

Governor Checks and Adjustments…609

Troubleshooting…610

hyster-897594-02-01-srm0550…616

toc…616

Electrical System…616

Safety Precautions Maintenance and Repair…617

General…620

Description…620

Starting Circuit…620

Charging System…621

Starter Repair…622

Remove and Disassemble…622

Assemble and Install…622

Alternator Repair…624

Remove and Disassemble…624

Assemble and Install…625

General Checks and Adjustments…626

Starter Checks…626

Operation Check…626

Solenoid Coil Checks…627

Brush Holder Check…627

Armature Check…627

Field Windings Check…627

Clutch and Bearing Check…627

Cold Start Aid Checks…628

Glow Plugs…628

Fuse…628

Relay and Controller…628

Charging Circuit Checks…629

Low-Output Check…629

High-Output Check…630

Diodes Check…630

Rotor Field Winding Check…631

Stator Windings Check…632

Brushes and Bearings…632

Voltage Regulator Check…632

Troubleshooting…633

hyster-897934-11-01-srm0626…638

toc…638

Cooling System…638

Safety Precautions Maintenance and Repair…639

General…642

Description…643

Radiator…643

Radiator Cap…643

Thermostat…643

Water Pump…644

Fan and Fan Shroud…644

Cooling System Checks…644

Radiator…644

Thermostat…644

Water Pump…645

Exhaust Leaks…645

Fan and Fan Shroud…645

Radiator Cleaning…645

Drain…645

Clean…645

Fill…646

Troubleshooting…647

hyster-910102-10-03-srm0103…650

toc…650

Tilt Cylinders…650

Safety Precautions Maintenance and Repair…651

General…654

Description…654

Tilt Cylinder Repair…654

Remove…654

Disassemble…654

Clean…654

Assemble…655

Tilt Cylinders With O-Ring or Single-Lip Seals…655

Tilt Cylinders for XM and XMS Models…656

Tilt Cylinders for H700-800A and Early Model H700-920B…657

Install…658

Tilt Cylinders Using Chevron Packing…659

Install…660

Tilt Cylinder Leak Check…662

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…663

Torque Specifications…664

Piston Rod Nut…664

Retainer…665

Troubleshooting…667

tables…650

Table 1. Movement Rates (Maximum) for Tilt Cylinders…663

hyster-910442-03-03-srm0231…670

toc…670

Metric and Inch (SAE) Fasteners…670

Safety Precautions Maintenance and Repair…671

General…674

Threaded Fasteners…674

Nomenclature, Threads…674

Strength Identification…675

Cotter (Split) Pins…675

Fastener Torque Tables…680

Conversion Table…682

tables…670

Table 1. Bolts and Screws…676

Table 2. Studs and Nuts…677

Table 3. Torque Nuts…678

Table 4. Torque Nuts With Nylon Insert…679

Table 5. Torque Values for Metric Fasteners*…680

Table 6. Torque Values for Inch Fasteners*…681

Table 7. Conversion Table for Metric and English units…682

Table 8. Cotter Pin Dimensional Data…683

Hyster H25-35XM, H40XMS (E001) Repair Service Manual