Complete service repair manual for Hyster H360-650C TO S/N1550 (C008) & H370-700C S/N1550-UP (C008), with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster H360C-H650C (C008) & H370C-H700C workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

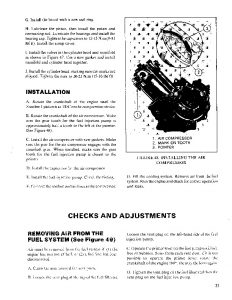

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

599974 – Hyster H360-650C TO S/N1550 (C008) & H370-700C S/N1550-UP (C008) Service Repair Manual.pdf

Total Pages: 804 pages

File Format: PDF

Language: English

Three-Speed Powershift Transmission…3

Safety Precautions Maintenance and Repair…4

General…7

Mechanical Description…8

General…8

Torque Converter…8

Description…8

Operation…8

Clutch Assemblies…8

Description…8

Operation…8

Forward Shaft…10

Reverse Shaft…11

First Speed Shaft…11

Output Shaft…11

Hydraulic Operation…13

Sump, Filter, and Pump…13

Shift Control Valve…13

Solenoid Valves…13

Inching Spool…13

Direction Spools…13

Range Spools…16

Modulator Valve and Manifold Block…16

Operation…16

Transmission Control System H17.00-32.00C (H370-700C)…19

Transmission Control System H20.00-32.00F (H440-700F) (without a…19

Transmission Control System H20.00-32.00F (with auto shift APC 1…25

Gear Selector…25

Automatic Powershift Control…26

Bypass Box and Bypass Plug…27

Hydraulic Circuits…27

Cooling and Lubrication…27

Operation of Transmission, Neutral…27

Operation of Transmission, Forward – First…27

Operation of Transmission, Reverse – First…27

Operation of Transmission, Forward – Second…30

Operation of Transmission, Forward – Third – Inching…31

Cooling System…163

Safety Precautions Maintenance and Repair…164

General…167

Description…168

Radiator…168

Radiator Cap…168

Thermostat…168

Water Pump…169

Fan and Fan Shroud…169

Cooling System Checks…169

Radiator…169

Thermostat…169

Water Pump…170

Exhaust Leaks…170

Fan and Fan Shroud…170

Radiator Cleaning…170

Drain…170

Clean…170

Fill…171

Troubleshooting…172

General…201

Description…201

Alternator Repair…203

Alternator Type A…203

Remove and Disassemble…203

Clean…204

Assemble…205

Install…205

Alternator Type B…208

Remove and Disassemble…208

Clean…208

Assemble…209

Install…210

General Check and Adjustment…211

Low Output Check (Type A or Type B)…211

High Output Check (Type A or Type B)…213

Brushes Circuit Check…214

Delco Alternators…214

Motorola Alternators…215

Diodes Check…216

Diode Bridge Check…216

Delco and Leece-Neville Alternators…216

Motorola Alternators…216

Rotor Field Winding Check…217

Stator Windings Check…218

Voltage Regulator Check…218

Troubleshooting…218

Planetary Gear Axle…287

Safety Precautions Maintenance and Repair…288

General…291

Description…291

Operation…292

Planetary Gear Axle Repair…293

Remove…293

Disassemble…293

Planetary Axle, Disassemble…296

Assemble and Install…300

Planetary Axle, Assemble…301

Torque Specifications…306

Troubleshooting…309

tables…287

Table 1. Axle-to-Frame Fasteners…300

Table 2. Standard Torque Values for Axle Fasteners…306

Table 3. Drive Wheel Nut Torque…306

Remove…333

Differential Carrier From Axle Housing, Remove…333

Differential and Ring Gear From Differential Carrier, Remove…337

Drive Pinion and Pinion Carrier From Differential Carrier, Remov…339

Disassemble…340

Differential and Ring Gear Assembly, Disassemble…340

Drive Pinion and Pinion Carrier, Disassemble…342

Clean and Inspect…344

Assemble…345

Pinion, Bearings, and Pinion Carrier, Assemble…345

Pinion Bearings, Adjust Preload…346

Press Method…346

Yoke or Flange Method…346

Triple-Lip Seal, Install…347

Pinion Carrier Shim Set, Adjust Thickness (Depth of Pinion)…348

Differential and Ring Gear, Assemble…350

Differential Gears Rotating Torque, Check…353

Differential and Ring Gear Assembly, Install…354

Differential Bearings, Preload Adjust…355

Ring Gear, Runout Check…356

Ring Gear Backlash, Adjust…356

Gear Set, Tooth Contact Pattern Check…358

Thrust Screw, Install and Adjust…360

Install…361

Differential Assembly Into Axle Housing, Install…361

Specifications…363

Troubleshooting…367

tables…329

Table 1. Ring Gear Backlash Adjustment Specifications…357

Table 2. Ring and Pinion Tooth Contact Adjustment…359

Table 3. General Specifications…363

Table 4. Rivet Installation Pressure…363

Table 5. Pinion Adjustment…363

Table 6. Pinion Preload Pressure…364

Table 7. Torque Specifications…365

Table 8. Torque Specifications for Metric Hardware…366

Table 9. Torque Specifications for Metric (Fine) Hardware…366

hyster-910091-10-03-srm0097…371

toc…371

Hydraulic Gear Pumps…371

Safety Precautions Maintenance and Repair…372

Description…375

Operation…376

Flow Control Valve…376

Relief Valve…377

Hydraulic Gear Pump Repair…377

Remove…377

Disassemble…378

Clean…378

Inspect…379

Assemble…382

Install…384

Pump Output Check…384

Method No. 1…384

Method No. 2…385

Hydraulic System Air Check…386

Troubleshooting…387

Tilt Cylinders for H700-800A and Early Model H700-920B…410

Install…411

Tilt Cylinders Using Chevron Packing…412

Install…413

Tilt Cylinder Leak Check…415

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…416

Torque Specifications…417

Piston Rod Nut…417

Retainer…418

Troubleshooting…420

tables…403

Table 1. Movement Rates (Maximum) for Tilt Cylinders…416

Instrument Panel Indicators and Senders…439

Safety Precautions Maintenance and Repair…440

General…443

Description…444

Steering Column Gauges, Meters, and Indicators…444

LED Display Panel…444

Battery Discharge Indicators…444

Brush Wear Indicators…451

Motor Temperature Indicators…451

LX Series Display Panel…453

Hourmeter Functions…453

Battery Indicator Function…454

Status Code Function…455

ZX Series Display Panels…455

Display Panel…455

Basic Display Panels…455

Performance Display…458

Brush Wear Indicators…461

Adjustments – General…462

Replacement – General Information…462

Meter Replacement…463

Sender Replacement…464

Fuel Level Sender…464

Pressure and Temperature Sender…464

ITW Display Panel Replacement…465

Remove…465

Column Mount Display Panel (EV-100/200ZX Motor Controllers) Repl…466

Remove…466

Display Panel Assembly, Replace…466

Indicator LEDs…467

Battery Indicators…467

Digital Display (Performance Display Panel Only)…467

Status Code or Performance Level Switches and Indicator LEDs (Pe…467

Basic Display Panel, Replace Parts…467

Performance Display Panel, Replace Parts…469

Dash Mount Display Panel (EV100/200ZX Motor Controllers) Replace…470

Remove and Replace…470

Specifications…470

Meter Specifications…470

Sender Specifications…471

Troubleshooting…471

Table 2. Studs and Nuts…510

Table 3. Torque Nuts…511

Table 4. Torque Nuts With Nylon Insert…512

Table 5. Torque Values for Metric Fasteners*…513

Table 6. Torque Values for Inch Fasteners*…514

Table 7. Conversion Table for Metric and English units…515

Table 8. Cotter Pin Dimensional Data…516

| Section |

Part No.

|

SRM Number | Rev Date |

| FRAME |

910467

|

0100 SRM 0267

|

02/97

|

| PERKINS DIESEL ENGINES TV8.540, TV8.640 |

910760

|

0600 SRM 0269

|

08/87

|

| COOLING SYSTEM |

897934

|

0700 SRM 0626

|

11/01

|

| THREE-SPEED PS TRANS-DESCR /OPER (HYSTER) |

910188

|

1300 SRM 0017

|

06/84

|

| THREE-SPEED PS TRANS-REPAIR (HYSTER) |

910015

|

1300 SRM 0171

|

06/84

|

| THREE-SPEED PS TRANS-REPAIR (HYSTER) |

897240

|

1300 SRM 0375

|

11/01

|

| THREE-SPEED PS TRANS-REPAIR (CLARK) |

897241

|

1300 SRM 0376

|

09/97

|

| DIFFERENTIAL |

910072

|

1400 SRM 0046

|

11/03

|

| PLANETARY GEAR AXLE |

910030

|

1400 SRM 0047

|

11/03

|

| STEERING CONTROL UNIT |

899776

|

1600 SRM 0058

|

07/80

|

| STEERING AXLE |

910031

|

1600 SRM 0071

|

07/97

|

| BRAKE SYSTEM (TO S/N 1550) |

910755

|

1800 SRM 0273

|

02/97

|

| BRAKE SYSTEM (S/N 1550-UP) |

897359

|

1800 SRM 0425

|

06/89

|

| HYDRAULIC GEAR PUMPS |

910091

|

1900 SRM 0097

|

10/03

|

| HYDRAULIC SYSTEM |

910462

|

1900 SRM 0253

|

01/97

|

| REMOTE CONTROL VALVE |

910450

|

2000 SRM 0249

|

01/97

|

| MAIN CONTROL VALVE |

910451

|

2000 SRM 0250

|

01/97

|

| ATACHMENT CONTROL VALVE |

910452

|

2000 SRM 0251

|

01/97

|

| FLOW CONTROL VALVE |

910463

|

2000 SRM 0252

|

01/97

|

| TILT CONTROL VALVE |

910101

|

2100 SRM 0102

|

07/94

|

| TILT CYLINDERS |

910102

|

2100 SRM 0103

|

10/03

|

| ALTERNATOR |

899784

|

2200 SRM 0002

|

10/03

|

| STARTER |

910107

|

2200 SRM 0106

|

02/01

|

| INSTRUMENT PANEL INDICATORS and SENDERS |

910110

|

2200 SRM 0143

|

12/03

|

| UPRIGHT |

910468

|

4000 SRM 0268

|

02/97

|

| EXTENDABLE CONTAINER ATTACHMENT |

910457

|

5000 SRM 0265

|

11/97

|

| FIXED CONTAINER ATTACHMENT |

910466

|

5000 SRM 0266

|

11/97

|

| INCH (SAE) and METRIC FASTENERS |

910442

|

8000 SRM 0231

|

03/03

|

| PERIODIC MAINTENANCE (TO S/N 1550) |

910752

|

8000 SRM 0271

|

05/84

|

| DIAGRAMS |

910751

|

8000 SRM 0276

|

01/97

|

| CAPACITIES and SPECIFICATIONS (TO S/N 1550) |

910758

|

8000 SRM 0277

|

07/87

|

| PERIODIC MAINTENANCE (S/N 1550-UP) |

897381

|

8000 SRM 0440

|

08/89

|

| CAPACITIES and SPECIFICATIONS (S/N 1550-UP) |

897387

|

8000 SRM 0446

|

07/89

|

| PART NO. 599974 | |||

| Rev. 12/03 | |||