Complete service repair manual for Hyster H40-60XL (B177 / C177) Forklifts Trucks, with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster H40XL-H60XL (B177 / C177) workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

897414 – Hyster H40-60XL (B177 / C177) Service Manual.pdf

Total Pages: 868 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section |

Part No.

|

SRM Number | Rev Date |

| FRAME |

910165

|

0100 SRM 0137

|

01/97

|

| GM ENGINE |

899766

|

0600 SRM 0003

|

08/03

|

| MAZDA M4-121G ENGINE |

899767

|

0600 SRM 0066

|

04/96

|

| ISUZU C240 (2.4L) ENGINE |

899768

|

0600 SRM 0070

|

04/93

|

| COOLING SYSTEM |

897934

|

0700 SRM 0626

|

11/01

|

| ROCHESTER CARBURETOR (GM ENG) |

910057

|

0900 SRM 0011

|

02/97

|

| LPG FUEL SYSTEM |

899772

|

0900 SRM 0015

|

09/93

|

| GASOLINE CARBURETOR (MAZDA) |

910168

|

0900 SRM 0129

|

09/93

|

| SINGLE-SPEED PS TRANS – DESCR / OPER (T41,T42,T43) |

899323

|

1300 SRM 0255

|

01/97

|

| SINGLE-SPEED PS TRANS – REPAIR (T41,T42,T43) |

899324

|

1300 SRM 0256

|

04/94

|

| DRIVE AXLE |

910171

|

1400 SRM 0085

|

02/97

|

| STEERING AXLE |

899775

|

1600 SRM 0010

|

01/96

|

| STEERING CONTROL UNIT |

910458

|

1600 SRM 0257

|

07/00

|

| STEERING SYSTEM |

897407

|

1600 SRM 0459

|

05/94

|

| BRAKE SYSTEM |

897405

|

1800 SRM 0458

|

02/94

|

| HYDRAULIC SYSTEM and GEAR PUMP |

899780

|

1900 SRM 0130

|

03/97

|

| HYDRAULIC PUMP DRIVE ASSEMBLY |

897121

|

1900 SRM 0339

|

10/03

|

| MAIN CONTROL VALVE |

899782

|

2000 SRM 0077

|

07/00

|

| TILT CYLINDERS |

910102

|

2100 SRM 0103

|

10/03

|

| ALTERNATOR |

899784

|

09/02

|

|

| STARTER |

910107

|

2200 SRM 0106

|

02/01

|

| ELECTRICAL SYSTEM (MAZDA) |

899791

|

2200 SRM 0132

|

02/97

|

| ELECTRICAL SYSTEM (ISUZU) |

899792

|

2200 SRM 0134

|

06/93

|

| INSTRUMENT PANEL INDICATORS and SENDERS |

910110

|

2200 SRM 0143

|

12/03

|

| MSTS – GM LPG (EARLY CONTROL MODULES) |

897412

|

2200 SRM 0463

|

04/93

|

| MSTS – GM LPG (LATER CONTROL MODULES) |

1473385

|

2200 SRM 0765

|

11/01

|

| LIFT CYLINDERS |

910119

|

4000 SRM 0135

|

10/03

|

| VISTA MASTS – DESCRIPTION |

899237

|

4000 SRM 0222

|

12/92

|

| VISTA MASTS – REPAIR |

910435

|

4000 SRM 0223

|

01/97

|

| CAPACITIES and SPECIFICATIONS |

899803

|

8000 SRM 0048

|

05/97

|

| INCH (SAE) and METRIC FASTENERS |

910442

|

8000 SRM 0231

|

03/03

|

| PERIODIC MAINTENANCE |

910757

|

8000 SRM 0259

|

04/97

|

| DIAGRAMS |

897410

|

8000 SRM 0461

|

03/97

|

| PART NO. 897414 | |||

| Rev. 12/03 | |||

Microprocessor Spark Timing System (MSTS)…3

Safety Precautions Maintenance and Repair…4

General…7

Description…8

What MSTS Does…8

How MSTS Begins Operation…8

Operation…9

Distributor…9

Ignition Coil…9

Ignition Module…9

When Engine Is Being Started…10

When Engine Is Running…11

Manifold Absolute Pressure (MAP) Sensor…12

Engine Coolant Temperature (ECT) Sensor…12

MSTS Module Corrections…13

Troubleshooting…14

General…14

Tools and Test Equipment…16

MSTS…17

Troubleshooting Procedure…17

Where to Start…17

Visual/Physical Inspection…17

Knowledge/Tools Required…17

Damage from Static Discharge (Static Electricity)…17

Troubleshooting Information…18

Malfunction Indicator Lamp (MIL)…18

Connecting CodeMate Tester…18

Reading Diagnostic Trouble Codes (DTC)…19

Clearing Diagnostic Trouble Codes (DTC's)…20

On-Board Diagnostic (OBD) System Check…20

Test Description…20

No Malfunction Indicator Lamp…22

Circuit Description…22

Test Description…22

No DTC-12, Malfunction Indicator Lamp ON…24

Circuit Description…24

Test Description…24

Starter Rotates Engine, Engine Does Not Run…25

Test Description…25

DTC-14 Engine Coolant Temperature (ECT) (Low Temperature Indicat…29

Circuit Description…29

Test Description…29

DTC-15 Engine Coolant Temperature Sensor (ECT) (High Temperature…31

Circuit Description…31

Test Description…31

DTC-34 Manifold Absolute Pressure (MAP) Sensor…33

Circuit Description…33

Test Description…33

DTC-41 Electronic Spark Timing (EST) Open Circuit…36

Circuit Description…36

Test Description…36

DTC-42 Electronic Spark Timing (EST) Grounded Circuit…38

Circuit Description…38

Test Description…38

DTC-51 MSTS Failure…40

Circuit Description…40

Distributor Repair…40

Remove…40

Disassemble…41

Inspect…41

Assemble…41

Install…42

Ignition Timing…42

Ignition Module Repair…43

Test For Fault…43

Replace…44

Sensing Coil Repair…44

Test For Fault…44

Replace…44

Ignition Coil Repair…45

Test For Fault…45

Remove…45

Install…45

MSTS Module Repair…46

Remove…46

Install…46

ECT Sensor Replacement…46

MAP Sensor Replacement…47

tables…3

Table 1. MSTS Module Connections…15

Table 2. Pressure Conversion Chart…16

Table 3. MSTS Diagnostic Codes…18

hyster-897121-10-03-srm0339…51

toc…51

Hydraulic Pump Drive Assembly…51

Safety Precautions Maintenance and Repair…52

General…55

Description…55

Hydraulic Pump Drive Assembly Repair…57

Remove and Disassemble…57

Clean…58

Inspect…58

Assemble and Install…58

Troubleshooting…59

Radiator Cap…184

Thermostat…184

Water Pump…185

Fan and Fan Shroud…185

Cooling System Checks…185

Radiator…185

Thermostat…185

Water Pump…186

Exhaust Leaks…186

Fan and Fan Shroud…186

Radiator Cleaning…186

Drain…186

Clean…186

Fill…187

Cylinder Head and Valve Mechanism Repair…293

Cylinder Head, Remove…293

Cylinder Head, Disassemble…293

Clean and Inspect…293

Valves and Valve Seats…296

Studs for Rocker Arms…296

Hydraulic Valve Lifters, Replace…297

Hydraulic Valve Lifters, Clean and Inspect…297

Cylinder Head, Assemble…297

Cylinder Head, Install…297

Valve Clearance, Adjust…298

Rocker Arm Cover, Install…299

Timing Gear Cover Repair…299

Remove…299

Install…300

Camshaft Repair…301

Remove…301

Inspect…301

Camshaft Bearing…302

Remove…302

Install…302

Distributor Repair…303

Remove…303

Install…303

Lubrication System Repair…304

Oil Sump…304

Remove…304

Install…304

Oil Pump…304

Remove…304

Disassemble and Repair…304

Assemble…305

Install…305

Piston and Connecting Rod Assemblies Repair…305

Connecting Rod Bearings, Replace…305

Piston and Connecting Rod Assemblies, Remove…306

Piston and Connecting Rod Assemblies, Disassemble…307

Piston, Clean and Inspect…307

Cylinder Bores, Inspect and Repair…307

Piston Rings, Inspect…308

Piston and Connecting Rod Assemblies, Assemble…308

Piston and Connecting Rod Assemblies, Install…310

Crankshaft Repair…310

Main Bearings, Replace…310

Oil Seal for Rear Main Bearing, Replace (GM 4-181 and 3.0L Only)…311

Oil Seal for Rear Main Bearing, Replace (Engines That Have Two-P…311

Remove…313

Inspect and Repair…313

Main Bearing and Journal Clearance, Check…314

Install…314

Flywheel and Flywheel Housing Repair…315

Remove…316

Ring Gear, Replace…317

Install…317

Cooling System Repair…317

Coolant Pump…317

Fan Drive…317

Viscous Fan Drive…317

Engine Specifications…319

Engine Data…319

Cylinder Head…320

Hydraulic Valve Lifter…320

Camshaft…321

Pistons…322

Cylinder Bore…322

Crankshaft…323

Connecting Rods…323

Cooling System…324

Lubrication System…324

Torque Specifications…324

Troubleshooting…325

Remove…591

Disassemble…591

Clean…591

Assemble…592

Tilt Cylinders With O-Ring or Single-Lip Seals…592

Tilt Cylinders for XM and XMS Models…593

Tilt Cylinders for H700-800A and Early Model H700-920B…594

Install…595

Tilt Cylinders Using Chevron Packing…596

Install…597

Tilt Cylinder Leak Check…599

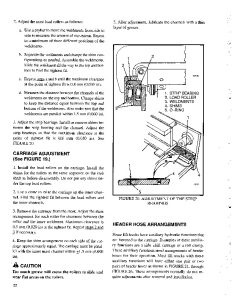

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment…600

Torque Specifications…601

Piston Rod Nut…601

Retainer…602

Troubleshooting…604

tables…587

Table 1. Movement Rates (Maximum) for Tilt Cylinders…600

hyster-910107-02-01-srm0106…607

toc…607

Starter…607

Safety Precautions Maintenance and Repair…608

General…611

Description and Operation…611

Starter Repair…613

Remove…613

Disassemble…613

Clean…614

Assemble…614

Install…615

General Checks and Adjustments…615

Troubleshooting…618

hyster-910110-12-03-srm0143…623

toc…623

Instrument Panel Indicators and Senders…623

Safety Precautions Maintenance and Repair…624

General…627

Description…628

Steering Column Gauges, Meters, and Indicators…628

LED Display Panel…628

Battery Discharge Indicators…628

Brush Wear Indicators…635

Motor Temperature Indicators…635

LX Series Display Panel…637

Hourmeter Functions…637

Battery Indicator Function…638

Status Code Function…639

ZX Series Display Panels…639

Display Panel…639

Basic Display Panels…639

Performance Display…642

Brush Wear Indicators…645

Adjustments – General…646

Replacement – General Information…646

Meter Replacement…647

Sender Replacement…648

Fuel Level Sender…648

Pressure and Temperature Sender…648

ITW Display Panel Replacement…649

Remove…649

Column Mount Display Panel (EV-100/200ZX Motor Controllers) Repl…650

Remove…650

Display Panel Assembly, Replace…650

Indicator LEDs…651

Battery Indicators…651

Digital Display (Performance Display Panel Only)…651

Status Code or Performance Level Switches and Indicator LEDs (Pe…651

Basic Display Panel, Replace Parts…651

Performance Display Panel, Replace Parts…653

Dash Mount Display Panel (EV100/200ZX Motor Controllers) Replace…654

Remove and Replace…654

Specifications…654

Meter Specifications…654

Sender Specifications…655

Troubleshooting…655

Meter…655

hyster-910119-10-03-srm0135…659

toc…659

Lift Cylinders…659

Safety Precautions Maintenance and Repair…660

Safety Procedures When Working Near Mast…663

General…667

Description…667

Lowering Control Valve…667

Cylinders (General)…670

Cylinders (H520-620B, H700-800A)…670

Retainer, Install…670

Cylinders (H360-460B)…672

Cylinders (Two-Speed)…674

Lift Cylinder Repair…676

Lift Cylinder Removal Without Removing Mast…676

Standard Masts With Main Lift Cylinder Fastened to Crossmember o…676

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to…676

Masts That Have Two Cylinders, Main Lift Cylinder and Free-Lift …676

Disassemble…678

Assemble…678

Lift Cylinder Installation in Mast…680

Standard Masts With Main Lift Cylinder Fastened to Crossmember o…680

Standard and Full Free-Lift Masts With Lift Cylinder Fastened to…680

Chevron-Style Packing…680

Chevron-Style Packing Installation on Piston…681

Chevron-Style Packing Installation in Packing Gland…683

Lift Cylinders for VISTA® Masts…684

Description…684

Lowering Control Valve…684

Remove…686

Disassemble…687

Assemble…688

Install…689

Main Lift Cylinders…689

Free-Lift Cylinder…689

Lift System Leak Check…690

Specifications…691

Troubleshooting…692

tables…659

Fastener Torque Tables…785

Conversion Table…787

tables…775

Table 1. Bolts and Screws…781

Table 2. Studs and Nuts…782

Table 3. Torque Nuts…783

Table 4. Torque Nuts With Nylon Insert…784

Table 5. Torque Values for Metric Fasteners*…785

Table 6. Torque Values for Inch Fasteners*…786

Table 7. Conversion Table for Metric and English units…787

Table 8. Cotter Pin Dimensional Data…788

Hyster H40-60XL (B177 / C177) Repair Service Manual