Complete service repair manual for Hyster Lift Trucks H70-120XM (K005), with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

Hyster Service Manual H70XM-H120XM (K005) workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

1467766 – Hyster Service Manual H70-120XM (K005) .pdf

Total Pages: 1,080 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

| Section | Part No. | SRM Number | Rev Date |

| FRAME | 1467898 | 0100 SRM 0726 | 11/03 |

| OPERATOR’S CAB | 1471864 | 0100 SRM 0778 | 02/04 |

| GM V-6 4.3L ENGINE | 897800 | 0600 SRM 0590 | 11/03 |

| PERKINS 1004.42 DIESEL ENGINE (AR) | 1455747 | 0600 SRM 0705 | 09/03 |

| COOLING SYSTEM | 1466271 | 0700 SRM 0740 | 02/04 |

| LPG FUEL SYSTEM | 1466265 | 0900 SRM 0745 | 09/03 |

| DUAL FUEL SYSTEM | 1467755 | 0900 SRM 0768 | 05/01 |

| 2-SPD POWERSHIFT TRANSMISSION – DESCR / OPER | 1466259 | 1300 SRM 0727 | 09/03 |

| 2-SPD POWERSHIFT TRANSMISSION – REPAIR | 1466253 | 1300 SRM 0728 | 09/03 |

| SINGLE-SPD POWERSHIFT TRANS – DESCR / OPER | 1467756 | 1300 SRM 0751 | 09/03 |

| SINGLE-SPD POWERSHIFT TRANSMISSION – REPAIR | 1467757 | 1300 SRM 0752 | 09/03 |

| DRIVE AXLE | 1466247 | 1400 SRM 0731 | 09/03 |

| STEERING CONTROL UNIT | 1466241 | 1600 SRM 0732 | 10/03 |

| STEERING AXLE | 1466235 | 1600 SRM 0733 | 09/03 |

| BRAKE SYSTEM | 1466229 | 1800 SRM 0734 | 09/03 |

| HYDRAULIC SYSTEM | 1466217 | 1900 SRM 0743 | 10/03 |

| HYDRAULIC GEAR PUMP | 1466223 | 1900 SRM 0753 | 09/03 |

| MAIN CONTROL VALVE | 1466211 | 2000 SRM 0754 | 12/03 |

| TILT CYLINDERS | 1466205 | 2100 SRM 0735 | 09/03 |

| ALTERNATOR | 899784 | 2200 SRM 0002 | 10/03 |

| HIGH ENERGY IGNITION SYSTEM | 899788 | 2200 SRM 0107 | 03/02 |

| CARBURETED ENGINE MANAGEMENT SYSTEM | 1466175 | 2200 SRM 0744 | 09/03 |

| STARTER | 1466193 | 2200 SRM 0755 | 10/03 |

| INSTRUMENT PANEL INDICATORS and SENDERS | 1468474 | 2200 SRM 0756 | 11/03 |

| MICROPROCESSOR SPARK TIMING SYSTEM (MSTS) | 1473385 | 2200 SRM 0765 | 11/01 |

| ELECTRONIC ENGINE CONTROL-DESCR/OPER (GM 4.3L) | 1467758 | 2200 SRM 0766 | 08/02 |

| ELECTRONIC ENGINE CONTROL-REPAIR (GM 4.3L) | 1467759 | 2200 SRM 0767 | 08/02 |

| MAST | 1466163 | 4000 SRM 0736 | 10/03 |

| LIFT CYLINDER | 1466169 | 4000 SRM 0741 | 10/03 |

| INCH (SAE) and METRIC FASTENERS | 910442 | 8000 SRM 0231 | 03/03 |

| PERIODIC MAINTENANCE | 1467763 | 8000 SRM 0737 | 12/03 |

| CAPACITIES and SPECIFICATIONS | 1467764 | 8000 SRM 0738 | 09/03 |

| DIAGRAMS | 1467765 | 8000 SRM 0757 | 12/03 |

| PART NO. 1467766 | |||

| Rev. 02/04 | |||

Perkins Diesel Engines….3

Safety Precautions Maintenance and Repair….4

General….11

General Safety Rules….11

Description….12

Engine Serial Number Codes….15

Engine Data….15

Engine Removal and Installation….17

Lift Engine….17

Cylinder Head Assembly Repair….17

Valve Cover….17

Remove….17

Install….18

Rocker Arm Assembly….18

Remove….18

Install….18

Disassemble….18

Inspect….18

Assemble….19

Valve Clearance Adjustments….19

Four-Cylinder Engines….20

Six-Cylinder Engines….20

Valve Springs….20

Cylinder Head Assembly….22

Remove….22

Install….24

Valves and Valve Springs….28

Remove….28

Inspect….28

Install….29

Valve Guides….29

Inspect….29

Remove….30

Install….30

Cylinder Head and Valve Seats….30

Inspect….30

Repair….30

New Valve Seats, Install….30

Piston and Connecting Rod Assemblies Repair….32

Rod Bearings….32

Remove….33

Install….33

Piston and Connecting Rod Assembly….34

Service Note….34

Remove….34

Install….35

Piston Rings….36

Remove….36

Inspect….36

Install….36

Piston and Connecting Rod….37

Disassemble….37

Inspect….38

How to Select Correct Replacements….38

Install….39

Piston Cooling Jets….39

Remove….39

Install….40

Crankshaft Assembly Repair….40

General….40

Crankshaft Pulley….41

Engine AR, Remove….41

Engines YG and YH, Remove….41

Inspect….42

Engine AR, Install….42

Engines YG and YH, Install….42

Rear Oil Seal….43

Replace….43

Main Bearings….44

Remove….44

Inspect….45

Install….45

Thrust Washers….45

Crankshaft Axial Movement, Check….45

Remove….46

Install….46

Crankshaft….47

Remove….47

Inspect….47

Install….47

Flywheel….49

Remove….49

Ring Gear, Replace….49

Install….49

Flywheel Housing….50

Remove….50

Install….50

Timing Case and Timing Gears Repair….51

General….51

Timing Case Cover….51

Remove….51

Install….52

Front Oil Seal….52

Remove….52

Install….52

Crankshaft Pulley Wear Sleeve….53

Install….53

Idler Gear and Hub….53

Remove….53

Install….54

Air Compressor Drive, Bendix….55

Disassemble….55

Assemble….56

Fuel Injection Pump Gear….56

Remove….57

Install….57

Camshaft Gear….58

Remove….58

Install….58

Crankshaft Gear….59

Remove….59

Install….59

Timing Case….59

Remove….59

Install….60

Camshaft and Tappets….61

Remove….61

Install….61

Cylinder Block Assembly Repair….62

Description….62

Cylinder Block….62

Disassemble….62

Inspect….63

Assemble….63

Cylinder Bore (Four-Cylinder Engines)….64

Cylinder Liner (Six-Cylinder Engines)….64

Inspect….64

Cylinder Liner Condition, Check….64

Remove….65

Service Liner, Install….66

Partially Finished Liner, Install….67

Engine Timing….68

Description….68

How to Set Number One Piston to TDC on Compression Stroke….69

How to Set Number One Piston to TDC on Compression Stroke (Alter….70

Valve Timing, Check….70

Fuel Injection Pump Timing, Check….71

Turbocharger – Engine YH Repair….72

General….72

Remove….72

Install….72

Impeller and Compressor Housing, Clean….73

Lubrication System Repair….74

General….74

Oil Filter, Replace….74

Filter Head….75

Remove and Install….75

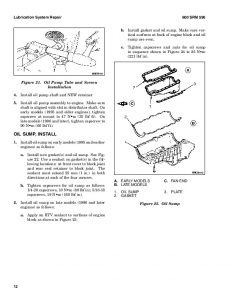

Oil Sump….75

Remove….75

Install….76

Oil Pump….76

Remove….76

Inspect….76

Install….77

Relief Valve….77

Remove….77

Disassemble….78

Inspect….78

Assemble….78

Install….78

Idler Gear Shaft, Replace….79

Remove….79

Remove (Alternative)….79

Install….80

Install (Alternative)….80

Install (Alternative for Four-Cylinder Engines Only)….81

Fuel System Repair….81

Description….81

Fuel Injection Pump….82

Remove….82

Install….83

Check and Adjust….84

Fuel System, Remove Air….84

Fuel Filter, Replace….85

Canister Type….86

Quick Release Canister Type….86

Fuel Injectors….87

Remove….87

Inspect….88

Install….88

Fuel Pump….89

Remove….89

Disassemble….89

Assemble….89

Install….90

Test….90

Cooling System Repair….91

General….91

Thermostat….91

Remove….91

Install….91

Test….92

Coolant Pump….92

Remove….92

Disassemble….92

Assemble….94

Install….96

Fan and Fan Drive….97

Remove….97

Install….97

Oil Cooler (Six-Cylinder Engines)….98

Remove….98

Disassemble and Assemble….98

Install….98

Oil Cooler By-Pass Valve….98

Electrical Equipment Repair….99

Drive Belts….99

Alternator….100

Remove….100

Install….100

Starter Motor….100

Remove….100

Install….100

Cold Start Aid….100

Air Compressor – Engines YG and YH….100

General….100

Repair….101

Remove….101

Install….101

Rotary Exhauster Replacement….102

Remove….102

Clean….102

Install….102

Engine Specifications….103

Cylinder Head Assembly….103

Piston and Connecting Rods….106

Crankshaft Assembly….109

Crankshaft Overhaul….110

Timing Case and Drive Assembly….112

Engine Block Assembly….113

Turbocharger….116

Lubrication System….116

Fuel System….118

Cooling System….120

Flywheel and Housing….120

Electrical Equipment….121

Torque Specifications….122

Cylinder Head Assembly….122

Piston and Connecting Rod Assemblies….122

Crankshaft Assembly….122

Timing Case and Drive Assembly….122

Turbocharger….122

Lubrication System….122

Fuel System….122

Cooling System….123

Flywheel….123

Auxiliary Equipment….123

Special Torque Specifications….124

Flywheel and Housing….124

Turbocharger….124

Electrical Equipment….124

Auxiliary Equipment….124

Special Tools….125

Troubleshooting….129

tables….3

Table 1. Cylinder Head….103

Table 2. Valve Guides….103

Table 3. Inlet Valves….104

Table 4. Exhaust Valves….105

Table 5. Valve Springs….106

Table 6. Tappets….106

Table 7. Rocker Arm Shaft….106

Table 8. Rocker Arms and Bushings….106

Table 9. Pistons (Engine AR)….106

Table 10. Pistons (Engines YG and YH)….107

Table 11. Piston Rings (Engine AR)….107

Table 12. Piston Rings (Engines YG and YH)….108

Table 13. Piston Pins….108

Table 14. Connecting Rods….108

Table 15. Small End Bushings….108

Table 16. Connecting Rod Bearings (Engines AR and YG)….109

Table 17. Connecting Rod Bearings (Engine YH)….109

Table 18. Piston Cooling Jets….109

Table 19. Crankshaft….109

Table 20. Main Bearings….110

Table 21. Crankshaft Thrust Washers….110

Table 22. Crankshaft Heat Treatment….110

Table 23. Crankshaft Overhaul Specifications….111

Table 24. Maximum Variation (Run-out)….112

Table 25. Camshaft….112

Table 26. Camshaft Thrust Washer….112

Table 27. Camshaft Gear….113

Table 28. Gear for Fuel Injection Pump….113

Table 29. Crankshaft Gear….113

Table 30. Idler Gear and Hub….113

Table 31. Cylinder Block (Engine AR)….114

Table 32. Cylinder Bore Specifications….114

Table 33. Cylinder Block (Engines YG and YH)….115

Table 34. Cylinder Liners (Engines YG and YH)….115

Table 35. Cylinder Liner Specifications (Partially Finished)….116

Table 36. Oil Pump (Engine AR)….116

Table 37. Oil Pump (Engines YG and YH)….117

Table 38. Idler Gear for Oil Pump….117

Table 39. Relief Valve….117

Table 40. Oil Filter….117

Table 41. Lucas Fuel Injection Pump….118

Table 42. Fuel Pump (Engine AR)….118

Table 43. Fuel Pump (Engines YG and YH)….118

Table 44. Fuel Filter….118

Table 45. Fuel Injector Codes….119

Table 46. Coolant Pump….120

Table 47. Thermostat….120

Table 48. Fan Drive Housing….120

Table 49. Limits for Flywheel Run Out and Alignment (Total Indic….120

Table 50. Alternator….121

Table 51. Starter Motor….121

Table 52. Cold Start Aid….121

Table 53. List of Possible Causes….130

hyster-1466163-10-03-srm0736….135

toc….135

Masts….135

Safety Precautions Maintenance and Repair….136

General….139

Description and Operation….139

Carriages….139

Two-Stage Mast With Limited Free-Lift….139

Two-Stage Mast With Full Free-Lift….140

Three-Stage Mast With Full Free-Lift….141

Safety Procedures When Working Near Mast….143

Fork Replacement….145

Remove….146

Install….146

Carriage Repair….147

Remove….147

Sideshift Carriage Repair….148

Remove….148

Disassemble….148

Assemble….148

Install….149

Two-Stage Mast With Limited Free-Lift Repair….150

Remove – H3.50-5.50XM (H70-120XM) Model Lift Trucks….150

Remove – S3.50-5.50XM (S70-120XM) and E3.50-5.50XL 3 (E70-120XL ….150

Disassemble….150

Clean and Inspect….154

Assemble….155

Install – H3.50-5.50XM (H70-120XM) Lift Truck Models….156

Install – S3.50-5.50XM (S70-120XM) and E3.50-5.50XL 3 (E70-120XL….158

Two-Stage Mast With Full Free-Lift Repair….160

Remove….160

Disassemble….160

Clean and Inspect….162

Assemble….162

Install….162

Three-Stage Mast With Full Free-Lift Repair….164

Remove….164

Disassemble….164

Clean and Inspect….167

Assemble….167

Install….169

Mast Operation Check….173

Lift and Tilt System Leak Check….173

Lift System….173

Tilt System….174

Tilt Cylinder Stroke and Backward Tilt Angle Adjustment….175

Lift Chain Adjustments….176

Mast Adjustments….179

Carriage Adjustment….181

Troubleshooting….181

tables….135

Table 1. Tilt Cylinder Leak Check Specifications, S3.50-5.50XM (….175

Table 2. Hook type Carriage Chain Adjustment….177

Table 3. Pin-Type Carriage Chain Adjustment….177

hyster-1466169-10-03-srm0741….187

toc….187

Lift Cylinders….187

Safety Precautions Maintenance and Repair….188

Safety Procedures When Working Near Mast….191

General….193

Description….193

Lowering Control Valve (Velocity Fuse)….193

Lift Cylinder Repair….196

Remove….196

Disassemble….197

Assemble….197

Install….198

Lift System Leak Check….198

Troubleshooting….199

Carbureted Engine Management System (CEMS)….203

Safety Precautions Maintenance and Repair….204

Description….207

Ignition Control System….208

Setting Timing Reference….208

Idle Speed Control System….208

Curb Idle Setting Procedure….209

Governor Control System….209

Closed-Loop Fuel System….210

Closed-Loop Fuel Control….210

Entering Closed-Loop Control….210

Normal Closed-Loop Operation….210

Closed-Loop Diagnostics….210

O.E. Tune Valve Action at Engine Shutdown….210

Diagnostic System….211

Closed-Loop Diagnostic Troubleshooting….212

Diagnostic Troubleshooting….212

tables….203

Table 1. Diagnostic Codes….211

Table 2. Diagnostic Troubleshooting….212

Starter….221

Safety Precautions Maintenance and Repair….222

General….225

Description….225

Yoke Assembly….226

Armature Assembly….226

Clutch Assembly….226

Magnetic Switch Assembly….226

Operation….226

Starter Repair….227

Remove….227

Disassemble….228

Clean….232

Assemble….232

Install….235

General Checks and Adjustments….236

Armature Tests….237

Armature Short Circuit Test….237

Armature Winding Ground Test….237

Commutator Run-Out Test….237

Yoke Test….238

Brush and Brush Holder Check….238

Brush Holder Insulation Test….238

Clutch Test….238

Magnetic Switch Test….239

Pull-In Test….239

Hold-In Test….239

Return Test….239

Performance Tests….240

No-Load Test….240

Troubleshooting….240

Tilt Cylinders….245

Safety Precautions Maintenance and Repair….246

General….249

Description….249

Tilt Cylinder Repair….249

Remove….249

Disassemble….250

Clean….251

Inspect….251

Assemble….251

Install….251

Tilt Cylinder Leak Check….252

Tilt Cylinder Stroke and Mast Tilt Angle Adjustment….252

Troubleshooting….252

Main Control Valve….257

Safety Precautions Maintenance and Repair….258

General….261

Description….261

Operation….261

Lift Section….261

Tilt and Auxiliary Sections….265

Reattaching the Clevis End of the Tilt Spool….266

Relief Valve….266

Main Control Valve Repair….266

Remove and Disassemble….266

Clean and Inspect….268

Assemble….270

Install….270

Pressure Relief Valve Check and Adjustment….271

Main Relief Valve (Lift)….271

Steering Relief Valve….271

Secondary Relief Valve (Tilt and Auxiliary)….274

Specifications….275

Troubleshooting….275

Hydraulic System….281

Safety Precautions Maintenance and Repair….282

General….285

Description….285

Operation….287

Hydraulic Pump H3.50-5.50XM (H70-120XM)….287

Hydraulic Pump S3.50-5.50XM (S70-120XM)….287

Main Control Valve….288

Steering Control Unit….288

Specifications….289

Hydraulic System Capacity….289

Hydraulic Tank Capacity….289

Relief Pressures @ 2200 rpm, 50 to 80 C ( 120 to 180 F)….289

Hydraulic Pump Flow to Valve….289

Steering Priority Flow….289

Troubleshooting….290

Lift, Lower and Tilt Circuit….290

Steering Circuit….291

hyster-1466223-09-03-srm0753….295

toc….295

Hydraulic Gear Pump….295

Safety Precautions Maintenance and Repair….296

General….299

Description….299

Operation….299

Hydraulic Gear Pump Repair….300

Remove….300

Disassemble….300

Clean….300

Inspect….302

Assemble….302

Install….303

Pump Output Check….304

Method No. 1….304

Method No. 2….305

Hydraulic System Air Check….306

Troubleshooting….306

Brake System….311

Safety Precautions Maintenance and Repair….312

General….315

Description and Operation….315

Brake Booster and Master Cylinder….315

Service Brake Assembly….315

Parking Brake….316

Brake Shoe Assemblies Repair….316

Remove and Disassemble….316

Clean….317

Inspect….319

Assemble and Install….319

Brake Booster and Master Cylinder Repair….321

Remove….321

Disassemble….321

Clean and Inspect….321

Assemble….321

Install….321

Parking Brake Repair….324

Remove and Disassemble….324

Assemble and Install….324

Brake System Air Removal….324

Brake Pedal Adjustment….324

Parking Brake Adjustment….325

Parking Brake Not Applied Switch Test….325

Parking Brake Switch Test (MONOTROL® Pedal Only)….326

Brake Shoes Adjustment….326

Troubleshooting….327

Steering Axle….333

Safety Precautions Maintenance and Repair….334

General….337

Description….337

Steering Axle Assembly Repair….338

Remove….338

Install….338

Wheels and Hub Repair….339

Remove and Disassemble….339

Clean….339

Inspect….339

Assemble and Install….339

Spindles and Bearings Repair….340

Remove….340

Clean….340

Inspect….340

Assemble and Install….340

Tie Rods Repair….341

Remove….341

Clean….341

Inspect….341

Install….341

Steering Cylinder Repair….341

Remove and Disassemble….341

Clean and Inspect….342

Assemble and Install….342

Troubleshooting….343

hyster-1466241-10-03-srm0732….347

toc….347

Steering Control Unit….347

Safety Precautions Maintenance and Repair….348

General….351

Description….351

Operation….351

Steering Wheel and Column Assembly Repair….353

Remove and Disassemble….353

Assemble and Install….353

Steering Control Unit….356

Disassemble….356

Clean….358

Assemble….359

System Air Removal….362

Troubleshooting….362

hyster-1466247-09-03-srm0731….367

toc….367

Drive Axle….367

Safety Precautions Maintenance and Repair….368

General….371

Description….371

Drive Axle Repair….371

Remove and Disassemble….371

Clean and Inspect….373

Assemble and Install….373

Troubleshooting….375

Two-Speed Powershift Transmission….379

Safety Precautions Maintenance and Repair….380

General….383

Transmission Repair….383

Remove….383

Install….383

Clutch Packs Repair….386

Remove and Disassemble….386

Clutch Assemblies, Disassemble….387

Inspect….389

Assemble and Install….389

Clutch Assemblies, Assemble and Install….389

Differential Repair….395

Remove and Disassemble….395

Inspect….396

Original Parts, Assemble and Install….396

New Parts, Assemble and Install….396

Adjustments With Original Shim Pack….397

Adjustments Without Original Shim Pack….398

Differential and Ring Gear Assembly, Assemble….400

Control Valve Repair….404

Remove and Disassemble….404

Inspect….407

Assemble and Install….407

MONOTROL® Pedal Repair….408

Remove and Disassemble….408

Assemble and Install….408

Direction Control Lever….411

Remove and Disassemble….411

Assemble and Install….411

Stall Test….412

Inching/Brake Pedal Adjustment….412

MONOTROL® Pedal Neutral Start Switch Adjustment….414

MONOTROL® Pedal Neutral Start Switch Test….415

Test 1….415

Test 2….415

Electronic Control Unit Check….416

Oil Pressure Check….417

Transmission Pump Relief Valve, Test Port 1, Check….417

Reverse Clutch Pressure, Test Port 2, Check….418

Forward Clutch Pressure, Test Ports 3 and 4, Check….418

Torque Converter Regulator, Test Port 5, Check….418

Lubrication Circuit Oil Pressure, Test Port 6, Check….418

Modulator Pressure, Test Port 7, Check….418

Troubleshooting….419

Troubleshooting – Pressure Tests….422

tables….379

Table 1. Pinion Variation Numbers Examples….397

Table 2. Stall Speeds (New Engines)….412

Table 3. Electronic Control Unit Connector….416

Table 4. Transmission Pressure Port Check….417

hyster-1466259-09-03-srm0727….427

toc….427

Two-Speed Powershift Transmission….427

Safety Precautions Maintenance and Repair….428

General….431

Mechanical Description….431

Torque Converter….432

Transmission Pump….432

Shaft Assemblies….432

Input Shaft….432

Forward Clutch Shafts….432

Clutch Assemblies….432

Output Gear and Pinion….433

Electronic Control Unit….433

Hydraulic Operation….434

Torque Converter….434

Seal Rings….435

Control Valve….435

Clutch Pressure Regulator….435

Inching Spool Assembly….435

Direction Spool….437

Modulator Circuit….437

Torque Converter Regulator….437

MONOTROL® Pedal….438

MONOTROL Pedal Start Circuit….438

Direction Control Lever….439

Oil Flow Diagrams….439

Neutral….439

Modulator Operation….441

Forward-Low….444

Forward-Low-Inching….444

Reverse….448

hyster-1466265-09-03-srm0745….455

toc….455

LPG Fuel System….455

Safety Precautions Maintenance and Repair….456

General….459

Description and Operation….459

Fuel Tank….459

Fuel Filter and Fuel Valve Unit….459

LPG Convertor Vaporizer (IMPCO)….459

LPG Controller (Dana EPIC/Teleflex-GFI)….463

Filter Section….463

Lock-Off Section….463

Converter Section – Primary Regulation (Stage 1)….463

Converter Section – Secondary Regulation (Stage 2)….463

Carburetor….464

Governor….467

Two-Way Valves, Open-Loop System….467

Closed-Loop Fuel Control….467

O.E. Tune Valve, Closed-Loop Fuel System….468

Oxygen Sensor, Closed-Loop Fuel System….468

LPG Tank Repair….468

Remove….468

Install….468

Hydrostatic Relief Valve Repair….469

Remove and Install….469

Filter Unit Repair….470

Fuel Filter Element, Replace….470

Diaphragm and Fuel Valve, Replace….470

Hoses Replacement….470

LPG Convertor Vaporizer (IMPCO) Repair….472

Remove….472

Disassemble….472

Clean….472

Inspect….472

Assemble….474

Install….478

LPG Controller (Dana EPIC/Teleflex-GFI) Repairs….478

Remove….478

Disassemble….478

Converter Section….478

Filter Section….480

Lock-Off Section….480

Clean….482

Inspect….482

LPG Controller Assembly….482

Filter Section….482

Lock-Off Section….482

Converter Section….482

Carburetor Repair….484

Remove….484

Disassemble….484

Clean….484

Assemble….485

Install….485

Governor Assembly Repair….486

Governor Motor Repair….488

Remove….488

Install….488

Filter Unit Check….488

Vaporizer Check….489

Pressure Reducer Valve….489

Vapor Valve….489

Carburetor Adjustment….489

Idle Mixture….489

Idle Speed….489

Throttle Linkage Adjustment….489

LPG Controller Adjustments (Dana EPIC/Teleflex-GFI)….490

Filter and Lock-Off Sections Leak Check….490

Lock-Off Section Functional Check….491

Controller Pressure Test….491

Adjustment of Secondary Lever….492

Final Adjustment Check….492

Troubleshooting….493

hyster-1466271-02-04-srm0740….503

toc….503

Cooling System….503

Safety Precautions Maintenance and Repair….504

General….507

Description….507

Radiator….507

Radiator Cap….507

Thermostat….507

Water Pump….508

Fan and Fan Shroud….508

Drive Shaft….508

Cooling System Checks….508

Exhaust Leaks into Cooling System….508

Radiator Repair….508

Checks….508

Clean….508

Cooling System….510

Drain….510

Fill….510

Water Pump Repair….510

Checks….510

Thermostat Repair….511

Checks….511

Fan Assembly Repair….511

Remove….511

Inspect….511

Install….511

Fan Belt Repair….514

Remove….514

Install….514

Drive Shaft Repair….514

Remove….514

Install….514

Troubleshooting….514

hyster-1467755-05-01-srm0768….519

toc….519

Dual Fuel System….519

Safety Precautions Maintenance and Repair….520

General….523

Description….524

Operation….524

LPG Solenoid Valve Repair….524

Fuel Selector Switch Repair….524

Adjustments….525

Troubleshooting….525

hyster-1467756-09-03-srm0751….529

toc….529

Single-Speed Powershift Transmission….529

Safety Precautions Maintenance and Repair….530

General….533

Mechanical Description….533

Torque Converter….533

Transmission Pump….534

Shaft Assemblies….534

Input Shaft….534

Forward Clutch Shaft….534

Clutch Assemblies….534

Output Gear and Pinion….534

Hydraulic Operation….535

Torque Converter….535

Seal Rings….536

Control Valve….537

Clutch Pressure Regulator….538

Inching Spool Assembly….538

Direction Spool….538

Modulator Circuit….538

Torque Converter Regulator….538

MONOTROL® Pedal….539

MONOTROL Pedal Start Circuit….539

Creep Speed Switch (Optional)….539

Direction Control Lever….540

Oil Flow Diagrams….540

Neutral….540

Modulator Operation….543

Forward….543

Forward-Inching….547

Reverse….547

hyster-1467757-09-03-srm0752….555

toc….555

Single-Speed Powershift Transmission….555

Safety Precautions Maintenance and Repair….556

General….559

Transmission Repair….559

Remove….559

Install….559

Clutch Assemblies Repair….562

Remove and Disassemble….562

Clutch Assemblies, Disassemble….563

Inspect….564

Assemble and Install….565

Clutch Assemblies, Assemble and Install….565

Differential Repair….570

Remove and Disassemble….570

Inspect….570

Original Parts, Assemble and Install….571

New Parts, Assemble and Install….572

Adjustments With Original Shim Pack….572

Adjustments Without Original Shim Pack….573

Assemble Differential and Ring Gear Assembly….574

Control Valve Repair….580

Remove and Disassemble….580

Inspect….581

Assemble and Install….582

MONOTROL® Pedal Repair….582

Remove and Disassemble….582

Assemble and Install….582

Direction Control Lever Repair….586

Remove and Disassemble….586

Assemble and Install….586

Stall Test….586

Inching/Brake Pedal Adjustment….587

Neutral Start Switch Adjustment, MONOTROL® Pedal….589

Neutral Start Switch Test, MONOTROL® Pedal….590

Oil Pressures Check….591

Check Relief Valve for Transmission Pump, TEST PORT 1….591

Check Reverse Clutch Pressure, TEST PORT 2….592

Check Forward Clutch Pressure, TEST PORT 3….592

Check Torque Converter Regulator, TEST PORT 4….592

Check Lubrication Circuit Oil Pressure, TEST PORT 5….592

Check Modulator Pressure, TEST PORT 6….592

Troubleshooting….593

Troubleshooting – Pressure Tests….596

tables….555

Table 1. Pinion Variation Numbers Examples….573

Table 2. Stall Speeds….587

Table 3. Check Ports for Transmission Pressure….591

hyster-1467758-08-02-srm0766….601

toc….601

Electronic Engine Control….601

Safety Precautions Maintenance and Repair….602

General….605

Description and Operation….605

General….605

ECM (Electronic Control Module)….605

Diagnostic Connector….605

How ECM Begins Operation….607

Electronic Engine Control….607

What ECM Does….607

Pulse Generator, EST Distributor….609

EST Module….609

When Engine is Being Started….610

When Engine is Running….611

Electronic Control Module (ECM) With EST Distributor, Correction….611

Fuel Control….612

Injection Throttle Body….613

Fuel Injectors….613

Fuel Pressure Regulator….613

Governor Throttle Body Assembly….614

Throttle Position Sensor (TPS)….615

Idle Air Control….615

Vacuum Ports….616

Fuel Pump….616

ECM Sensors and Controllers….617

Manifold Absolute Pressure (MAP)….617

Coolant Temperature Sensor (CTS)….617

hyster-1467759-08-02-srm0767….621

toc….621

Electronic Engine Control….621

Safety Precautions Maintenance and Repair….622

General….627

Engine Data….627

Light Bulb Check….627

System Check….628

Troubleshooting With Fault Monitor System in ECM….630

How to Clear a Code….632

Fault In the ECM….632

Fuel Control….632

Idle Air Control (IAC)….632

Fuel Pump Circuit….632

Coolant Temperature Sensor (CTS)….633

Manifold Absolute Pressure Sensor (MAP)….633

Throttle Position Sensor (TPS)….633

Throttle Position Sensor Output Check….633

Electronic Spark Timing (EST)….633

Distributor Reference Signal….634

A-1 – No Service Engine Soon Light….634

Circuit Description….634

Test Description….635

Other Troubleshooting Checks:….635

A-2 – No Diagnostic Data or Code 12….637

Circuit Description….637

Test Description….637

A-3 – Starter Cranks Engine, But Does Not Run….639

Circuit Description….639

Test Description….639

Other Troubleshooting Checks:….639

A-4 – Fuel Injector Circuit….641

Circuit Description….641

Test Description….641

A-5 – Fuel Pump Relay Circuit….643

Circuit Description….643

Test Description….643

A-6 – Fuel System Pressure Test….645

Circuit Description….645

Test Description….646

A-7 – MAP Output Check….648

Circuit Description….648

Test Description….648

A-8 – Ignition System Troubleshooting….650

Circuit Description….650

Test Description….650

A-9 – Idle Air Control (IAC) System….654

Circuit Description….654

IAC Valve Reset Procedures….654

Test Description….654

Fault Code 14 – Coolant Temperature Sensor Circuit (Indicates Lo….656

Circuit Description….656

Test Description….657

Fault Code 15 – Coolant Temperature Sensor Circuit (Indicates Hi….659

Circuit Description….659

Test Description….659

Fault Code 21 – Throttle Position Sensor Circuit (Signal Voltage….662

Circuit Description….662

Test Description….662

Fault Code 22 – Throttle Position Sensor Circuit (Signal Voltage….664

Circuit Description….664

Test Description….664

Fault Code 31 – Engine Governor Circuit….666

Circuit Description….666

Test Description….666

Other Troubleshooting Checks….667

Fault Code 33 – MAP Sensor Circuit, Signal Voltage High (Low Vac….669

Circuit Description….669

Test Description….669

Other Troubleshooting Checks….669

Fault Code 34 – MAP Sensor Circuit, Signal Voltage Low (High Vac….671

Circuit Description….671

Test Description….671

Other Troubleshooting Checks….671

Fault Code 41 – Electronic Spark Timing (EST), Open Circuit….673

Circuit Description….673

Test Description….673

Fault Code 42 – EST, Grounded IC Circuit, Open or Grounded Bypas….675

Circuit Description….675

Test Description….675

Other Troubleshooting Checks….676

Fault Code 51 – ECM Failure….678

Coolant Temperature Sensor (CTS) Replacement….698

Manifold Absolute Pressure (MAP) Sensor Replacement….698

Oil Pressure Sender Replacement….698

Low Coolant Sender Replacement….699

Wire Harness….699

Connectors and Terminals….700

Electronic Control Module (ECM)….702

Special Tools….707

tables….621

Table 1. ECM Diagnostic Codes….631

Table 2. ECM Connector J1 Identification….705

Table 3. ECM Connector J2 Identification….706

hyster-1467763-12-03-srm0737….713

toc….713

Periodic Maintenance….713

Safety Precautions Maintenance and Repair….714

General….719

Serial Number Data….719

How to Move Disabled Lift Truck….719

How to Tow Lift Truck….719

How to Put Lift Truck on Blocks….720

How to Raise Drive Tires….720

How to Raise Steering Tires….720

Maintenance Schedule….721

Maintenance Procedures Every 8 Hours or Daily….733

How to Make Checks With Engine Stopped….733

Engine Oil….733

Hydraulic System Oil….733

Cooling System….734

Heavy Duty Precleaner….735

Fuel System….735

Battery….736

Tires and Wheels….736

Forks….737

Adjust….738

Hook Fork, Remove….738

Hook Fork, Install….738

Forks, Mast, and Lift Chains, Inspect….738

Operator Restraint System….739

Safety Labels….740

How to Make Checks With Engine Running….740

Gauges, Lights, Horn, and Fuses….741

Engine Oil Pressure….741

Cooling System….742

Powershift Transmission Oil Level Check….743

Hydrostatic Transmission Oil Level Check….744

Control Levers and Pedals….744

Lift System Operation….744

Inching/Brake Pedal….745

Service Brakes….745

Parking Brake….745

Steering System….745

Maintenance Procedures Every 250 Hours or 6 Weeks….746

Engine Oil and Filter, GM V-6 EPA Compliant Engine (Americas Onl….746

Air Filter, GM V-6 EPA Compliant Engine….746

Maintenance Procedures Every 500 Hours or 2 Months….747

Lift Chains Lubrication….747

Air Filter….747

Hydraulic Pump Drive Shaft….747

Engine Oil and Filter, Diesel and GM V-6 (European Only)….748

Drive Belts….748

Fan Drive Belts….748

Perkins Diesel Engine….748

Alternator Drive Belt….748

GM 4.3L Engine….749

Serpentine Drive Belt….749

Hydraulic Tank Breather, Clean and Check….750

Hydrostatic Transmission Filter….750

Filter Cartridge, Replace….750

Filter Head, Replace….750

Brake Fluid….751

Lift Chains Wear Check….751

Forks, Wear and Damage Check….752

Mast, Lubrication….752

Control Levers and Pedals, Lubrication….753

Steering Axle, Lubrication….753

Fuel System, Checks and Adjustments….753

LPG Carburetor….753

Fuel Injection (Perkins Engine)….753

GM V-6 Engine….753

Cooling System, Clean Debris from Radiator Core….753

Maintenance Procedures Every 1000 Hours or 6 Months….754

PCV Valve, GM V-6….754

Crankcase Breather, GM-V6….754

Spark Plug Replacement….754

Remove….754

Install….754

Valve Clearance, Check and Adjust….754

Water Separator, Diesel Engine….755

Fuel Filter, Replace (Diesel Engine)….755

Fuel System Air Removal, Perkins (1004.42 Diesel Engine)….755

Differential and Drive Axle….757

Cooling System, GM V-6 EPA Compliant Engine….757

LPG Fuel Filter GM V-6 EPA Compliant Engine, Replace….757

Inspect Engine Electrical System, Connectors, and FCVS Connectio….758

Maintenance Procedures Every 2000 Hours or Yearly….758

Differential Thrust Screw….758

Hydraulic System….759

Hydraulic Oil and Filter, Replace….759

Powershift Transmission Oil and Filter, Replace….760

Hydrostatic Transmission Oil and Filter, Replace….760

Cooling System….761

Wheel Bearings….761

Steering Wheels, Lubrication….761

Drive Wheels, Lubrication….761

PCV Valve, GM V-6….761

Service Brakes….761

LPG Filter, Replace (Pre-2004)….762

Gasoline Fuel Filter, Replace….762

Operator Restraint System….762

Oxygen Sensor (Pre 2004)….762

Oxygen Sensor GM V-6 EPA Compliant Engine….762

Air Filter Element, GM V-6 EPA Compliant Engine….763

Inspect Low Pressure Regulator (LPR) for Oil Buildup and Leaks….763

Check Throttle Shaft for Sticking….764

Inspect Exhaust Manifold and Piping for Leaks….764

Test LPG/GAS Regulator Pressure….764

Safety Procedures When Working Near Mast….764

Lift Chain Adjustments….766

Fuel Injectors Repair….768

Lift and Tilt System Leak Check….768

Lift Cylinders, Leak Check….768

Tilt Cylinders, Leak Check….769

Welding Repairs….769

Overhead Guard Changes….770

Wheel and Tire Replacement….771

Remove Wheels From Lift Truck….771

Remove Wheel From Tire….771

Remove Tire From Two-Piece Wheel….772

Remove Tire From Three- and Four-Piece Wheel….774

Install Wheel in Tire….775

Install Tire on Three- or Four-Piece Wheel….776

Install Tire in Two-Piece Wheel….777

Add Air to Tires….778

Wheels, Install….778

Dual Drive Wheels Installation….778

Solid Rubber Tire Repair….779

Wheel, Tire Remove….779

Wheel, Tire Install….781

SIT Tire, Change for H3.50-5.50XM (European Trucks Only)….782

Remove SIT Solid Tire From Wheel….783

Install SIT Solid Tire on Wheel….784

Adhesives and Sealants….785

Hydraulic Oil, Lubricant, and Coolant Specifications….786

tables….713

Table 1. Maintenance Schedule….722

Table 2. Hook-Type Carriage Chain Adjustment….767

Table 3. Pin-Type Carriage Chain Adjustment….767

hyster-1467764-09-03-srm0738….789

toc….789

Capacities and Specifications….789

Safety Precautions Maintenance and Repair….790

Lift Truck Weights….793

Electrical System….793

Stall Speeds….793

Capacities….794

Tire Pressure….795

Engine Specifications….795

Transmission Oil Pressures….796

Hydraulic System….797

Mast Speeds….798

Torque Specifications….799

Brake System….799

Differential….799

Drive Axle….799

Engine, GM V-6 4.3 liter….799

Engine, Perkins 1004-42….800

Frame….800

Lift Cylinders….800

Main Control Valve….801

Masts….801

Powershift Transmission….801

Steering System….801

Tilt Cylinders….801

Hydrostatic Components….801

tables….789

Table 1. Single-Speed….796

Table 2. Two-Speed….796

Table 3. Hydrostatic Transmission….797

hyster-1467765-12-03-srm0757….805

toc….805

Diagrams….805

Safety Precautions Maintenance and Repair….806

hyster-1467898-11-03-srm0726….843

toc….843

Frame….843

Safety Precautions Maintenance and Repair….844

General….847

Description….847

Counterweight Repair….847

Remove….847

Install….848

Hood Repair….848

Remove….848

Install….848

Overhead Guard Repair….850

Remove….850

Inspect….850

Install….850

Operator Restraint System Repair….850

Radiator Repair….851

Remove….851

Install….851

Exhaust System Repair….853

Muffler….853

Remove….853

Install….853

LPG/Gas Engine Exhaust Pipe – Lift Trucks Without Low Emissions….856

Remove….856

Install….856

EPA Compliant LPG/Gas Engine Exhaust System….857

Remove….857

Install….857

Diesel Engine Exhaust Pipe….857

Remove….857

Install….860

Engine Repair….860

Remove….860

Install….862

Fuel and Hydraulic Tanks Repair….864

Inspect….864

Small Leaks, Repair….864

Large Leaks, Repair….864

Clean….864

Steam Method….865

Chemical Solution Method….865

Other Preparation Methods for Repair….865

Safety Labels….866

tables….843

Table 1. Weight of Counterweights….847

hyster-1468474-11-03-srm0756….871

toc….871

Instrument Panel Indicators and Senders….871

Safety Precautions Maintenance and Repair….872

General….875

Description….875

Instruments and Senders….875

Password Function….882

Supervisor Password Function….882

Entering Operator Passwords….882

Deleting Operator Passwords….883

Retrieve the Most Recent Operator Password Used to Enable the Tr….883

Display All Operator Passwords Programmed Into the System….883

Enable and Disable Operator Passwords Function….883

Allow Supervisor Password to Enable the Truck to Start….883

Operator Passwords Function….883

Component Replacement – General Information….884

Sender Replacement….884

Fuel Level Sender….884

Pressure and Temperature Sender….885

Display Panel Replacement….886

Specifications….888

Troubleshooting….889

tables….871

Table 1. Instrument Panel Description….876

Table 2. Sender Description….881

Table 3. Meter and Sender Specifications….888

hyster-1471864-02-04-srm0778….893

toc….893

Operators Cab….893

Safety Precautions Maintenance and Repair….894

General….897

Cab Repair….898

Remove….898

Install….899

Switch Panel….899

Window Wipers Replacement….900

Front Wiper Assembly….900

Rear Wiper Assembly….900

Door Handle Assembly….903

Fuse Panel….904

Heater Assembly….904

Remove….904

Install….904

Window Replacement….906

Options….908

Rear Strobe Lights….908

Heavy-Duty Air Cleaner….908

Label Replacement….909

Electrical Schematics….909

tables….893

Table 1. Material Specifications for Cab Windows….906

hyster-1473385-11-01-srm0765….915

hyster-897800-11-03-srm0590….963

toc….963

GM Engines….963

Safety Precautions Maintenance and Repair….964

General….967

Description….967

Engine Removal and Installation….968

Cylinder Head Repair….968

Remove and Disassemble….968

Clean and Inspect….968

Valve Guides and Seats, Repairs….969

Valves, Repair….969

Valve Seats, Repair….970

Valve Springs….971

Rocker Arm Studs (Early Models)….971

Rocker Arm Studs (Late Models)….972

Assemble and Install….972

Cylinder Block Cleaning and Inspection….976

Piston Bore Preparation….976

Engine Mounts Installation….976

Lubrication System Repair….977

Oil Pump, Remove and Disassemble….977

Clean and Inspect….977

Oil Pump, Assemble and Install….977

Oil Sump, Install….978

Timing Cover, Timing Sprockets, Camshaft, and Valve Lifters….979

Timing Cover….979

Remove….979

Install….981

Timing Sprockets….981

Remove….981

Install….981

Camshaft….982

Remove….982

Inspect….982

Install….982

Balance Shaft….983

Remove….983

Install….984

Hydraulic Valve Lifters….984

Remove….984

Disassemble….985

Clean and Inspect….985

Assemble….985

Install….986

Crankshaft Repair….987

Remove….987

Inspect and Repair….987

How to Check Clearance Between Main Bearings and Their Journals….988

Install….989

Piston and Connecting Rod Assemblies Repair….990

Connecting Rod Bearings, Replace….990

Piston and Connecting Rod Assemblies, Remove….991

Disassemble….991

Piston, Clean and Inspect….992

Cylinder Bores, Inspect and Repair….992

Piston Rings….993

Assemble….994

Piston and Connecting Rod Assemblies, Install….994

Flywheel and Flywheel Housing Repair….995

Flywheel, Repair….995

Flywheel, Install….995

H3.50-5.00XL (H70-110XL), S3.50-5.50XL (S70-120XL), S6.00-7.00XL….995

H6.00-7.00XL (H135-155XL)….995

Flywheel Housing H3.50-5.00XL (H70-110XL), H3.50-5.50XM (H70-120….995

Engine Adapter H6.00-7.00XL (H135-155XL)….995

Coolant Pump Repair….996

Thermostat Replacement….996

Fan Mount Repair (Early Models)….996

Fan Mount Assembly Repair (Late Models)….996

Drive Belt Installation….998

Valve Clearance Adjustment (Early Models)….999

Valve Clearance Adjustment (New Models)….1000

Compression Check….1000

Engine Specifications….1000

Engine Data….1000

Cylinder Head….1001

Hydraulic Valve Lifter….1001

Camshaft….1001

Pistons….1001

Crankshaft….1002

Connecting Rods….1003

Balance Shaft….1003

Cooling System….1003

Lubrication System….1003

Torque Specifications….1004

Troubleshooting….1005

tables….963

Table 1. Piston Rings Arrangement on Piston….994

hyster-899784-10-03-srm0002….1011

toc….1011

Alternator with Regulator….1011

Safety Precautions Maintenance and Repair….1012

General….1015

Description….1015

Alternator Repair….1017

Alternator Type A….1017

Remove and Disassemble….1017

Clean….1018

Assemble….1019

Install….1019

Alternator Type B….1022

Remove and Disassemble….1022

Clean….1022

Assemble….1023

Install….1024

General Check and Adjustment….1025

Low Output Check (Type A or Type B)….1025

High Output Check (Type A or Type B)….1027

Brushes Circuit Check….1028

Delco Alternators….1028

Motorola Alternators….1029

Diodes Check….1030

Diode Bridge Check….1030

Delco and Leece-Neville Alternators….1030

Motorola Alternators….1030

Rotor Field Winding Check….1031

Stator Windings Check….1032

Voltage Regulator Check….1032

Troubleshooting….1032

hyster-899788-03-02-srm0107….1037

toc….1037

High Energy Ignition (HEI) System….1037

Safety Precautions Maintenance and Repair….1038

Description….1041

Distributor Repair….1043

Remove….1043

Disassemble….1043

Assemble….1048

Install, If Crankshaft WAS NOT Rotated when Distributor was Remo….1049

Install, If Crankshaft WAS Rotated when Distributor was Removed….1049

Ignition Coil Replacement….1050

Some Four- and Six-Cylinder Models….1050

Remove….1050

Install….1051

V8, Some Four- and Six-Cylinder Models….1051

Remove….1051

Install….1052

Electronic Module Replacement….1053

Remove….1053

Install….1053

Sensing Coil Replacement….1054

Remove….1054

Install….1054

Spark Plugs Replacement….1054

Remove….1054

Install….1055

Visual Check….1055

High Voltage Wires Check….1055

Ignition Coil Check….1056

Coil in Distributor Cap Design….1056

Separate Coil Design….1056

Sensing Coil, Check….1057

Electronic Module Check….1057

Ignition Timing Adjustment….1057

GM V8-366 (6-liter) Ignition System Check….1059

GM V6-LPG (4.3 liter) GM V6-LPG (4.3 liter) Ignition Timing and ….1059

Specifications….1059

Troubleshooting….1060

hyster-910442-03-03-srm0231….1065

toc….1065

Metric and Inch (SAE) Fasteners….1065

Safety Precautions Maintenance and Repair….1066

General….1069

Threaded Fasteners….1069

Nomenclature, Threads….1069

Strength Identification….1070

Cotter (Split) Pins….1070

Fastener Torque Tables….1075

Conversion Table….1077

tables….1065

Table 1. Bolts and Screws….1071

Table 2. Studs and Nuts….1072

Table 3. Torque Nuts….1073

Table 4. Torque Nuts With Nylon Insert….1074

Table 5. Torque Values for Metric Fasteners*….1075

Table 6. Torque Values for Inch Fasteners*….1076

Table 7. Conversion Table for Metric and English units….1077

Table 8. Cotter Pin Dimensional Data….1078

Hyster H70-120XM (K005) Repair Service Manual