Complete service repair manual with Electrical Wiring Diagrams for John Deere FPT F32 (F5A) Diesel Engine (Tier 3_Stage III A platform), with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

John Deere FPT F32 (F5A) Diesel Engine workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

ctm408119 – FPT F32 (F5A) Diesel Engine (Tier 3_Stage III A platform) Component Technical Manual (EN).pdf

ctm408128 – Moteur diesel FPT F32 (F5A) (plate-forme Tier 3/phase III A) French.pdf

ctm408129 – FPT F32 (F5A) Dieselmotor (Tier 3/Stufe III A-Plattform) German.pdf

ctm408139 – Motore diesel FPT F32 (F5A) (Piattaforma Tier3/fase III A) Italian.pdf

ctm408153 – Silnik wysokoprężny FPT F32 (F5A) (platforma Tier 3/Stage III A) Polish.pdf

ctm408154 – Motor Diesel FPT F32 (F5A) (Plataforma Tier 3/Fase III A) Portuguese.pdf

PRODUCT DETAILS:

Total Pages: 381 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

TABLE OF CONTENTS

TABLE OF CONTENTS…………….1

Section 01: General Information…………….7

Group 000: Safety…………….7

Understand Signal Words…………….10

Avoid Heating Near Pressurized Fluid Lines…………….11

Avoid High-Pressure Fluids…………….12

Avoid Hot Exhaust…………….13

Construct Dealer-Made Tools Safely…………….14

Dispose of Waste Properly…………….15

Exhaust Filter Cleaning…………….16

Follow Safety Instructions…………….17

Handle Fluids Safely—Avoid Fires…………….18

Handling Batteries Safely…………….19

Illuminate Work Area Safely…………….21

Install All Guards…………….22

Live With Safety…………….23

Practice Safe Maintenance…………….24

Precautions for Welding…………….25

Prepare for Emergencies…………….27

Prevent Acid Burns…………….28

Prevent Battery Explosions…………….30

Prevent Machine Runaway…………….31

Protect Against High Pressure Spray…………….32

Protect Against Noise…………….33

Recognize Safety Information…………….34

Remove Paint Before Welding or Heating…………….35

Replace Safety Signs…………….36

Service Cooling System Safely…………….37

Service Machines Safely…………….38

Stay Clear of Rotating Drivelines…………….39

Support Machine Properly…………….40

Use Proper Lifting Equipment…………….41

Use Proper Tools…………….42

Wait Before Opening High-Pressure Fuel System…………….43

Wear Protective Clothing…………….44

Work in Clean Area…………….45

Work In Ventilated Area…………….46

Group 001: Engine Identification Information…………….8

Engine Serial Number Plate Information…………….49

Group 002: Fuels, Lubricants, and Coolants…………….8

Diesel Engine Oil — Tier 3, Stage III…………….53

Engine Oil and Filter Service Intervals…………….55

John Deere Break-In Plus™ Engine Oil…………….56

Transmission and Hydraulic Oil…………….57

Front-Wheel Drive Axle Oil…………….58

Multiluber Grease…………….60

Mixing of Lubricants…………….61

Lubricant Storage…………….62

Alternative and Synthetic Lubricants…………….63

Diesel Engine Coolant…………….64

Operating in Warm Temperature Climates…………….66

Testing Diesel Engine Coolant…………….67

Storing Fuel…………….68

Handling and Storing Diesel Fuel…………….70

Diesel Fuel…………….70

Minimizing the Effect of Cold Weather on Diesel Engines…………….72

Lubricity of Diesel Fuel…………….74

BioDiesel Fuel…………….75

Testing Diesel Fuel…………….77

Oilscan™ and CoolScan™…………….78

Section 02: Repair and Adjustments…………….79

Group 010: Engine Rebuild…………….79

Engine Disassembly…………….111

Engine Assembly…………….142

Final Checks…………….213

Group 020: Cylinder Head and Valves Repair and Adjustment…………….79

Rocker Arm Cover Blow-by Filter Disassembly/Assembly Procedure…………….227

Group 090: Electronic Fuel System Repair and Adjustment…………….79

Injection Pump Disassembly/Assembly Procedure…………….251

Group 100: Maintenance…………….79

Servicing Plan…………….263

Engine Oil Level Check…………….264

Check of Fuel System…………….266

Cooling System Check…………….267

Lubricating System Check…………….268

Check of Water Presence within Fuel Filter or Pre-Filter…………….269

Check of Belt’s Tear and Wear Status…………….270

Check and Setting of Rocker Arm Clearance…………….271

Engine Oil and Filter Replacement…………….273

Fuel Filter Replacement…………….275

Bleeding Procedure…………….276

Drive Belt Replacement…………….277

Section 03: Theory of Operation…………….279

Group 123: Cooling System…………….279

Engine Cooling System…………….283

Group 126: Lubrication System…………….279

Engine Oil Vapor Recirculation…………….287

Engine Lubrication System…………….288

Group 130: Electronic Fuel System…………….279

Fuel System Operation…………….302

Fuel Filter Operation…………….312

Group 135: Air Intake and Exhaust System…………….279

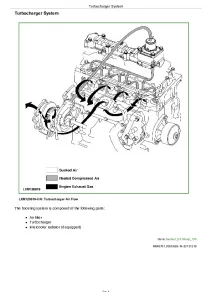

Turbocharger System…………….314

EGR Exhaust Gas Recycle System…………….315

Section 04: Diagnostics…………….317

Group 150: Observable Diagnostics and Tests…………….317

Troubleshooting Procedure…………….319

Engine Does Not Start…………….317

Engine Stops…………….317

Engine Overheating…………….317

Engine Power And Irregular Functioning…………….317

Engine Is Running Noisy…………….317

Engine Smokes Abnormally…………….317

Section 05: Tools and Other Materials…………….330

Group 170: Special Tools…………….330

99322205…………….332

JDG99340025…………….333

JDG99346259…………….334

JDG99346262…………….335

99360076…………….336

99360183…………….337

99360268…………….338

JDG99360288…………….339

JDG99360292…………….340

JDG99360339…………….341

JDG99360362…………….342

99360500…………….343

99360605…………….344

JDG99360612…………….345

JDG99361043…………….346

99370006…………….347

JDG99370415…………….348

JDG99395100…………….349

JDG99395216…………….350

99395603…………….351

Section 06: Specifications…………….352

Group 190: Repair and Diagnostic Specifications…………….352

Metric Bolt and Screw Torque Values…………….355

Unified Inch Bolt and Screw Torque Values…………….357

Torque Specifications…………….360

Main Engine Specifications…………….366

Cylinder Head Technical Specifications…………….369

Cylinder Block, Pistons, and Connecting Rods Technical Specifications…………….371

Crankshaft, Main Bearings, and Flywheel Technical Specifications…………….373

Electrical Specifications…………….375

John Deere FPT F32 (F5A) Diesel Engine Repair Service Manual (CTM408119)