Complete technical manual for John Deere PowerTech 4.5L & 6.8L Diesel Engines, with all the workshop serivce information to maintain, diagnose, and repair like professional mechanics.

CTM104 (07NOV12) (ENGLISH) – John Deere PowerTech 4.5L & 6.8L Diesel Engines – John Deere Base Engine Component Technical Manual.pdf

CTM104 (19JUN00) – John Deere PowerTech 4.5L & 6.8L Diesel Engines – John Deere Base Engine Component Technical Manual.pdf

ctm105 – Moteurs diesel 4,5 et 6,8 l (Moteur standard) – (Édition internationale) Component Technical Manual.pdf

ctm106 – 4,5-l- und 6,8-l-Dieselmotoren (Grundmotor) – (Weltweite Ausgabe) Component Technical Manual.pdf

ctm107 – Motores diésel de 4.5 l y 6.8 l (Motor básico) – (Edición mundial) Component Technical Manual.pdf

ctm116 – Motori diesel da 4,5 l e 6,8 l (Motore base) – (Edizione universale) Component Technical Manual.pdf

ctm117 – 4,5 EN 6,8 L DIESELMOTOREN (STANDAARDMOTOR) – (WERELDWIJDE UITGAVE) Component Technical Manual.pdf

ctm165 – VZNĚTOVÉ MOTORY 4.5 l A 6.8 l (ZÁKLADNÍ MOTOR) (CELOSVĚTOVÉ VYDÁNÍ) Technický manuál komponentů.pdf

ctm180 – 4.5 升和 6.8 升柴油发动机 (基本发动机) – (世界通用机型) Component Technical Manual.pdf

ctm205 – Дизельные двигатели объемом 4,5 л и 6,8 л (основной двигатель) – (Исполнение для всех стран) Component Technical Manual.pdf

ctm206 – Motores Diesel 4,5 L e 6,8 L (Motor Básico) – (Edição Mundial) Component Technical Manual.pdf

ctm426 – 4,5 L OG 6,8 L DIESELMOTORER (BASISMOTOR) (GLOBAL UDGAVE) Komponent teknisk manual (Danish).pdf

ctm427 – 4,5 L:N JA 6,8 L:N DIESELMOOTTORIT (PERUSMOOTTORI) (MAAILMANLAAJUINEN PAINOS) Komponentin tekninen käsikirja (FIN).pdf

ctm428 – 4,5 L- OG 6,8 L DIESELMOTORER (GRUNNMOTOR) (GLOBAL VERSJON) Komponent teknisk håndbok (NOR).pdf

ctm429 – 4,5 L ÉS 6,8 L DÍZEL MOTOROK (ALAP MOTOR) (EGÉSZ VILÁGON ÉRVÉNYES KIADÁS) Alkatrész műszaki kézikönyv (HU).pdf

ctm430 – SILNIKI WYSOKOPRĘŻNE 4,5 L I 6,8 L (SILNIK PODSTAWOWY) (EDYCJA OGÓLNOŚWIATOWA) Podręcznik techniczny komponentów (Polish).pdf

ctm463 – ΚΙΝΗΤΗΡΕΣ ΝΤΙΖΕΛ 4,5 L ΚΑΙ 6,8 L (ΒΑΣΙΚΟΣ ΚΙΝΗΤΗΡΑΣ) (ΔΙΕΘΝΗΣ ΕΚΔΟΣΗ) Τεχνικό εγχειρίδιο εξαρτημάτων (Greek).pdf

ctm464 – 4,5 L i 6,8 L DIZELSKI MOTORI (OSNOVNI MOTOR) (SVJETSKO IZDANJE) Tehnički priručnik za komponente (Croatian).pdf

ctm465 – 4,5 L IR 6,8 L DYZELINIAI VARIKLIAI (BAZINIS VARIKLIS) (TARPTAUTINIS LEIDINYS) Komponento techninis vadovas (Lithuanian).pdf

ctm471 – DIZELSKI MOTORJI 4,5 L IN 6,8 L (OSNOVNI MOTOR) (IZVEDBA ZA VSE CELINE IN DRŽAVE) Technická príručka komponentov (Slovenian).pdf

ctm472 – NAFTOVÉ MOTORY S OBJEMOM 4,5 L A 6,8L(ZÁKLADNÝ MOTOR) (CELOSVETOVÉ VYDANIE) Bileşen Teknik Kılavuzu (Slovak).pdf

ctm473 – 4,5 l VE 6,8 l DİZEL MOTORLAR (ANA MOTOR) (DÜNYA ÇAPINDAKİ SÜRÜM) Bileşen Teknik Kılavuzu (Turkish).pdf

ctm474 – DIZEL MOTORI OD 4,5 L I 6,8 L (OSNOVNI MOTOR) (SVETSKO IZDANJE) Komponenta Tehnički priručnik (Bosnian).pdf

ctm731 – MOTOARE DIESEL DE 4,5 L ŞI 6,8 L (MOTORUL DE BAZĂ) (EDIŢIE MONDIALĂ) Manual tehnic pentru componente (RO).pdf

CTM104 (07NOV12) (ENGLISH) – John Deere PowerTech 4.5L & 6.8L Diesel Engines – John Deere Base Engine Component Technical Manual.pdf

CTM104 (19JUN00) – John Deere PowerTech 4.5L & 6.8L Diesel Engines – John Deere Base Engine Component Technical Manual.pdf

CTM104 – John Deere PowerTech 4.5L & 6.8L Diesel Engines – John Deere Base Engine Component Technical Manual.pdf

CTM528 (Hebrew) – ג’ון דיר PowerTech 4.5L ו-6.8L מנועי דיזל אלקטרוניים 11 מפלסים רכיבים מדריך טכני.pdf

CTM704 (Arabic) – John Deere PowerTech 4.5L & 6.8L محركات الديزل الإلكترونية ذات 11 مستوى من الدليل الفني للمكونات.pdf

CTM705 (Korean) – John Deere PowerTech 4.5L 및 6.8L 디젤 엔진 전자 11 레벨 구성 요소 기술 매뉴얼.pdf

PRODUCT DETAILS:

Total Pages: 1,760 pages

File Format: PDF (bookmarked, ToC, Searchable, Printable, high quality) & EPUB/MOBI/AZW for Kindle etc.

Language: English etc…

MAIN SECTIONS

Introduction….2

Forward….2

John Deere Dealers….3

POWERTECH 4.5 L Engine….5

POWERTECH 6.8 L Engine….6

Contents….7

General Information….9

Safety….11

Handle Fluids SafelyAvoid Fires….11

Handle Starting Fluid Safely….11

Service Cooling System Safely….12

Prevent Battery Explosions….12

Prepare for Emergencies….13

Handling Batteries Safely….14

Avoid High-Pressure Fluids….15

Wear Protective Clothing….15

Service Machines Safely….16

Work In Ventilated Area….16

Work in Clean Area….17

Remove Paint Before Welding or Heating….17

Avoid Heating Near Pressurized Fluid Lines….18

Illuminate Work Area Safely….18

Use Proper Lifting Equipment….19

Construct Dealer-Made Tools Safely….19

Practice Safe Maintenance….20

Use Proper Tools….20

Dispose of Waste Properly….21

Live With Safety….21

Engine Identification….23

Engine Model Designation….23

Engine Serial Number Plate Information ….24

OEM Engine Option Code Label….25

Engine Application Charts….26

Fuels, Lubricants and Coolants….33

Diesel Fuel ….33

Lubricity of Diesel Fuel….33

Engine Break-In Oil ….34

Diesel Engine Oil ….35

Extended Diesel Engine Oil Service Intervals….35

Alternative and Synthetic Lubricants ….36

Mixing of Lubricants….36

OILSCAN, OILSCAN Plus and COOLSCAN ….37

Grease….38

Diesel Engine Coolant Recommendations….39

Engine Coolant Specifications….40

Testing Diesel Engine Coolant ….43

Replenishing Supplemental Coolant Additives (SCAs) Between Coolant Changes….44

Operating in Warm Temperature Climates….45

Flush and Service Cooling System….46

Disposing of Coolant….47

Repair and Adjustments….49

Engine Rebuild….53

Engine Overhaul Guidelines….53

Engine Repair Stand….53

Engine Stand Safety Precautions ….54

Install Adapters on Engine Repair Stand….55

Engine Lifting Procedure….56

Clean Engine….57

Disconnect Turbocharger Oil Inlet Line….58

Mount Engine on Repair Stand….59

Engine Mounted on Repair Stand….60

Engine Disassembly Sequence….61

Sealant Application Guidelines….63

Engine Assembly Sequence….65

Engine Break-In Guidelines ….67

Perform Engine Break-In ….68

Cylinder Head and Valves….71

Check and Adjust Valve Clearance….71

Measure Valve Lift….74

Remove Cylinder Head….76

Disassemble and Inspect Rocker Arm Shaft Assembly….83

Assemble Rocker Arm Assembly….84

Inspect, Measure, and Install Fuel Supply Pump Push RodIf Applicable….84

Inspect, Measure, and Assemble Camshaft Followers….86

Measure Valve Recess in Cylinder Head….88

Preliminary Cylinder Head and Valve Checks ….89

Remove Valve Assembly….90

Inspect and Measure Valve Springs….90

Inspect Valve Rotators….91

Clean Valves….91

Inspect and Measure Valves….92

Grind Valves….93

Head Gasket Inspection and Repair Sequence….94

Inspect and Clean Cylinder Head….95

Check Cylinder Head Flatness….96

Measure Cylinder Head Thickness….97

Clean Injection Nozzle Bores….98

Clean Valve Guides….98

Measure Valve Guides….99

Knurl Valve Guides….100

Clean and Inspect Valve Seats….100

Grind Valve Seats….101

Remove Valve Seat Inserts….103

Measure Valve Seat Bore in Cylinder Head….106

Install Valve Seat Inserts….107

Install Valves….107

Clean and Inspect Cylinder Head Cap Screws….108

Inspect and Clean Exhaust Manifold….108

Clean and Inspect Top Deck of Cylinder Block….109

Measure Cylinder Liner Standout (Height above Block)….110

Install Cylinder Head….110

Torque-Turn Method for Proper Torque….113

Install Rocker Arm Assembly….114

Inspect and Clean Ventilator Outlet Hose….114

Install Rocker Arm Cover….115

Complete Final Assembly….116

Cylinder Block, Liners, Pistons and Rods….121

Connecting RodsGeneral Information….121

Remove Pistons and Connecting Rods ….122

Remove Cylinder Liners….125

Complete Disassembly of Cylinder Block (If Required)….127

Preliminary Liner, Piston and Rod Checks ….128

Disassemble Piston and Rod Assembly ….129

Clean Pistons….130

Visually Inspect Pistons….131

Clean Cylinder Liners….132

Visually Inspect Cylinder Liners….133

Check Piston Ring Groove Wear ….135

Measure Piston Pin Bore….136

Measure Piston Skirt….136

Measure Piston Height….136

Determine Piston-to-Liner Clearance ….137

Deglaze Cylinder Liners….139

Replace Piston and Liner Sets….139

Inspect and Measure Connecting Rod Bearings (Rods Removed from Engine)….140

Inspect and Measure Connecting Rod Bearings (Rod and Crankshaft in Engine)….141

Inspect Rod and Cap….142

Inspect Piston Pins and Bushings….144

Remove Piston Pin Bushing….145

Clean and Inspect Connecting Rod Pin Bore….147

Install Piston Pin Bushing in Connecting Rod….148

Measure Rod Center-to-Center Bores….149

Inspect and Clean Cylinder Block….150

Clean Cylinder Liner O-Ring Bore….152

Measure Cylinder Block Main Bearing Bore….153

Measure Camshaft Follower Machined Bore in Block….153

Measure Camshaft Bushing Bores in Block….154

Measure Balancer Shaft Bushing ID in Block4-Cylinder Engines….155

Measure Cylinder Liners and Block Bores ….156

Measure Liner Flange Counterbore Depth in Block….156

Measure Liner Flange Thickness….157

Measure Cylinder Block Top Deck Flatness….157

Remove, Inspect, and Install Piston Cooling Orifices….158

Measure Fuel Supply Pump Push Rod Bore and Push Rod OD….159

Measure Cylinder Liner Standout (Height above Block)….160

Install Packing on Cylinder Liner and O-Rings in Block….161

Install Cylinder Liner in Block….163

Assemble Piston and Connecting Rod ….165

Install Piston Rings….166

Install Piston and Connecting Rod Assembly ….167

Torque-Turn Connecting Rod Cap Screws….171

Check Engine Rotation for Excessive Tightness….172

Measure Piston Protrusion….173

Complete Final Assembly….174

Crankshaft, Main Bearings and Flywheel….175

Crankshaft and Main Bearing Failure Analysis ….175

Inspect Vibration Damper….176

Remove Pulley or Vibration Damper and Pulley ….177

Install Pulley or Vibration Damper and Pulley ….178

Replace Front Crankshaft Oil Seal and Wear Sleeve ….179

Check Crankshaft End Play….186

Inspect Flywheel….186

Check Flywheel Face Flatness….187

Check Pilot Bearing Bore Concentricity ….187

Remove Flywheel….188

Replace Flywheel Ring Gear….189

Replace Pilot Bearing in FlywheelIf Equipped….190

Install Flywheel….191

Crankshaft Rear Oil Seal and Wear Sleeve Handling Precautions….192

Remove Crankshaft Rear Oil Seal and Wear Sleeve ….192

Clean and Inspect Crankshaft Flange….197

Install Crankshaft Rear Oil Seal and Wear Sleeve….197

Remove Flywheel Housing….200

Remove and Install Crankshaft Timing Wheel (Engines with VP44 Fuel Injection Pump) ….201

Remove Crankshaft Main Bearings ….202

Check Main Bearing Oil Clearance ….203

Remove and Install Crankshaft Gear (Crankshaft Installed in Engine)….204

Remove Crankshaft….206

Inspect Crankshaft….207

Measure Crankshaft Journals and Main Bearing ID ….208

Measure Main Thrust Journal Width and Thrust Bearing Width….209

Crankshaft Grinding Guidelines….210

Crankshaft Grinding Specifications….211

Measure Assembled ID of Main Bearing Caps ….212

Remove, Inspect, and Install Piston Cooling Orifices….213

Install Main and Thrust Bearing Inserts in Block….214

Install Crankshaft….216

Install Flywheel Housing….219

Complete Final Assembly….221

Camshaft, Balancer Shafts and Timing Gear Train….223

Measure Valve Lift….223

Remove Timing Gear Cover….225

Remove and Install Camshaft Bushing with Front Plate Installed….228

Remove and Install Camshaft Gear-Driven Auxiliary Drive….232

Measure Camshaft End Play….233

Measure Balancer Shaft End Play (4-Cylinder Engines)….233

Measure Idler Gear End Play….234

Measure Timing Gear Backlash….234

Remove Camshaft….235

Visually Inspect Camshaft….237

Measure Camshaft Thrust Plate Clearance and Thickness….238

Inspect and Measure Camshaft Bushing ID and Journal OD….239

Measure Camshaft Lobe Height….240

Remove and Install Camshaft Gear….240

Inspect Camshaft Followers….241

Inspect, Measure, and Install Fuel Supply Pump Push Rod….242

Remove Balancer ShaftsIf Equipped (4-Cylinder Engines)….243

Inspect and Measure Balancer Shaft Bushings and Journals….244

Remove and Install Balancer Shaft Bushings (4-Cylinder Engines)….245

Inspect Balancer Shaft Gears and Thrust Plates….246

Remove and Install Balancer Shaft Gears….246

Remove Cylinder Block Front Plate….247

Measure Idler Gear Bushing and Shaft….250

Remove Idler Gear Bushings….251

Install Idler Gear Bushings….252

Remove Lower and Upper Idler Shafts….253

Clean and Inspect Front Plate….253

Transfer Fuel Injection Pump Timing Mark onto Replacement Front Plate ….254

Install Idler Shaft Spring Pins (If Equipped)….255

Install Upper Idler Shaft in Front Plate….255

Install Lower Idler Shaft in Front Plate….256

Install Cylinder Block Front Plate….256

Install and Time Balancer Shafts (4-Cylinder Engines)….258

Install Camshaft….262

Clean and Inspect Timing Gear Cover….265

Install Timing Gear Cover….266

Install Crankshaft Front Wear Sleeve and Oil Seal ….268

Remove and Install Magnetic Pick-Up Sensor ….270

Replace Mechanical Tachometer Adapter….271

Complete Final Assembly….272

Lubrication System….273

General Lubrication System Information….273

Remove, Inspect, and Install Oil Filter Base….273

Remove, Inspect, and Install Oil Cooler….277

Remove, Inspect, and Install Oil Bypass Valve….281

Remove and Install Oil Pressure Regulating Valve and Seat….281

Remove and Install Oil Fill Tube….284

Remove and Install Dipstick Tube with Oil Pan Installed….285

Remove and Install Dipstick Tube with Fitting….286

Remove, Inspect and Install Oil Pump Pick-Up Tube Assembly….287

Engine Oil Pump Assembly….287

Remove Engine Oil Pump….288

Inspect and Measure Clearances….289

Complete Oil Pump Disassembly….291

Assemble Engine Oil Pump….292

Install Engine Oil Pump….293

Install Oil Pan….295

Cooling System….297

Remove Water Manifold/Thermostat Cover and Thermostat ….297

Install Water Manifold/Thermostat Cover and Thermostat ….298

Remove and Install Water Manifold/Thermostat Cover and Thermostat (6010 Series Tractors with Single Thermostat) ….300

Remove and Install Water Manifold and Thermostats (Dual Thermostats) ….303

Test Thermostat(s)….304

Remove Water Pump….305

Water Pump Assembly….306

Disassemble Water Pump….307

Inspect, Clean, and Measure Water Pump Parts….308

Assemble Water Pump….309

Install Water Pump….310

Cooling System Deaeration….311

Remove and Install Automatic (Spring) Belt Tensioner….312

Checking Belt Tensioner Spring Tension and Belt Wear….312

Manual Belt Tensioner Adjustment ….314

Inspect and Install Fan Assembly….315

Remove and Inspect Fan Drive Assembly….316

Replace Bearings in Adjustable Fan Drive Assembly….317

Install Fan Drive Assembly….320

Remove and Install Fan Drive Assembly (2254 Combine)….323

Remove and Install Coolant HeaterIf Equipped….324

Remove and Install Cold Start Advance Switch (If Equipped)….325

Air Intake and Exhaust System….327

Extending Turbocharger Life….327

Remove Turbocharger….329

Turbocharger Failure Analysis….330

Turbocharger Seven-Step Inspection….332

Perform Radial Bearing Clearance Test….339

Perform Axial Bearing End Play Test….340

Adjust Turbocharger Wastegate Actuator (If Equipped)….341

Repair Turbocharger….341

Prelube Turbocharger….342

Install Turbocharger….343

Turbocharger Break-In….344

Recommendations for Turbocharger Use….345

Remove, Inspect, and Install Exhaust Manifold….346

Remove and Install Air-to-Air Aftercooler….346

Remove and Install Air Intake Pipe….347

Remove and Install Air Heater….348

Remove and Install Starting AidIf Equipped….349

Fuel System….351

Fuel System….351

Starting and Charging Systems….353

Remove and Install Starter….353

Remove and Install Alternator….354

Theory of Operation….357

Base Engine Operation….359

Base Engine Theory of Operation….359

General Engine Operation….360

General Engine OperationContinued….361

Lubrication System Operation ….362

Cooling System Operation ….364

Head Gasket Joint Construction and Operation….366

Air Intake and Exhaust System Operation….368

Air Cleaner Operation….369

Turbocharger Operation….370

How the Turbocharger Is Lubricated….370

Diagnostics….371

Observable Diagnostics and Tests….373

About This Section of the Manual….373

Diagnosing Lubrication System Malfunctions ….373

L1 – Excessive Oil Consumption….373

Check Oil in Coolant….374

Check for Excessive Crankcase Pressure (Blow-By)….374

Turbocharger Oil Seal Leak Check….375

Pistons, Rings, Cylinder Liners Check….375

L2 – Engine Oil Pressure Low ….376

L3 – Engine Oil Pressure High ….378

Diagnosing Cooling System Malfunctions….379

C1 – Engine Coolant Temperature Above Normal ….379

C2 – Engine Coolant Temperature Below Normal ….380

C3 – Coolant in Oil or Oil in Coolant ….380

Test Engine Compression Pressure….381

Test Engine Cranking Speed….384

Dynamometer Test….385

Engine Oil Consumption….386

Check Engine Oil Pressure ….387

Check for Excessive Engine Crankcase Pressure (Blow-By) ….389

Check for Turbocharger Oil Seal Leak….390

Inspect Thermostat and Test Opening Temperature….391

Pressure Test Cooling System and Radiator Cap ….392

Check for Head Gasket Failures ….394

Check and Service Cooling System….397

Check Air Intake System….399

Measure Intake Manifold Pressure (Turbocharger Boost) ….400

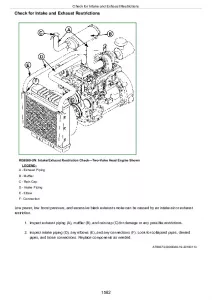

Check for Intake and Exhaust Restrictions ….402

Test for Intake Air Leaks….403

Check for Exhaust Air Leaks (Turbocharged Engines)….404

Test Turbocharger Wastegate….404

Test Air Filter Restriction Indicator Switch….405

Tools and Other Materials….407

Repair Tools and Other Materials….409

Cylinder Head and Valves Essential Tools….409

Cylinder Head and Valves Service Equipment and Tools….414

Cylinder Head and Valves Other Materials….416

Cylinder Block, Liners, Pistons and Rods Essential Tools….417

Cylinder Block, Liners, Pistons and Rods Service Equipment and Tools….422

Cylinder Block, Liners, Pistons and Rods Other Materials….423

Crankshaft, Main Bearings and Flywheel Essential Tools….424

Crankshaft, Main Bearings and Flywheel Service Equipment and Tools….429

Crankshaft, Main Bearings and Flywheel Other Materials….430

Camshaft, Balancer Shafts and Timing Gear Train Essential Tools….431

Camshaft, Balancer Shafts and Timing Gear Train Service Equipment and Tools….435

Camshaft, Balancer Shafts and Timing Gear Train Other Materials….436

Lubrication System Essential Tools….437

Lubrication System Service Equipment and Tools….440

Lubrication System Other Materials….441

Cooling System Essential Tools….442

Cooling System Service Equipment and Tools….443

Cooling System Other Materials….444

Air Intake and Exhaust System Other Materials….445

Starting and Charging System Essential Tools….446

Diagnostic Service Tools….447

Diagnostic Essential Tools….447

Diagnostic Service Equipment and Tools….449

Dealer Fabricated Service Tools….451

How to Make Tools ….451

DFRG3Cylinder Liner Holding Fixture….451

DFRG5Injection Pump Front Plate Timing Mark Transfer Tool….452

Engine Oil Dipstick Tube Driver (60106910 Series Tractor Engines)….453

Specifications….455

Repair and General OEM Specifications….457

Unified Inch Bolt and Cap Screw Torque Values ….457

Metric Bolt and Cap Screw Torque Values ….458

General OEM Engine Specifications….459

Engine Rebuild Specifications….459

Cylinder Head and Valves Specifications….460

Cylinder Block, Liners, Pistons and Rods Specifications….464

Crankshaft, Main Bearings and Flywheel Specifications….470

Camshaft, Balancer Shafts and Timing Gear Train Specifications….472

Lubrication System Specifications….477

Cooling System Specifications….480

Air Intake and Exhaust System Specifications….483

Starting and Charging Systems Specifications ….484

Diagnostic Specifications….485

Dynamometer Test Specifications….485

Intake Manifold Pressure (Turbocharger Boost) Specifications ….493

Effects of Altitude and Temperature on Engine Performance ….503

Engine Diagnostic Specifications….504

ctm104 – 4.5L AND 6.8L DIESEL ENGINES (BASE ENGINE) -: (WORLDWIDE EDITION)

Component Technical Manual

Table of Contents

Foreword

Identification Views

Related Manuals

Training Information

Definition of Terms

Trademarks

Section 01: General Information

Group 000: Safety

Understand Signal Words

Recognize Safety Information

Replace Safety Signs

Follow Safety Instructions

Park Machine Safely

Support Machine Properly

Use Proper Lifting Equipment

Prevent Machine Runaway

Construct Dealer-Made Tools Safely

Illuminate Work Area Safely

Work in Clean Area

Use Proper Tools

Install All Guards

Service Machines Safely

Practice Safe Maintenance

Handle Fuel Safely—Avoid Fires

Prepare for Emergencies

Handle Starting Fluid Safely

In Case of Fire

Handle Fluids Safely—Avoid Fires

Avoid Static Electricity Risk When Refueling

Protect Against Noise

Protect Against High Pressure Spray

Stay Clear of Rotating Drivelines

Avoid High-Pressure Fluids

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Wear Protective Clothing

Handling Batteries Safely

Prevent Acid Burns

Wait Before Opening High-Pressure Fuel System

Prevent Battery Explosions

Avoid Hot Exhaust

Work In Ventilated Area

Service Cooling System Safely

Service Cooling System Safely

Precautions for Welding

Live With Safety

Group 001: Engine Identification

Engine Serial Number Plate Information

OEM Engine Option Code Label

Information Relative to Emissions Regulations

Emissions Control System Certification Label

Group 002: Fuels, Lubricants, and Coolant

Storing Fuel

Diesel Fuel

Lubricity of Diesel Fuel

Handling and Storing Diesel Fuel

Supplemental Diesel Fuel Additives

BioDiesel Fuel

Testing Diesel Fuel

Minimizing the Effect of Cold Weather on Diesel Engines

Diesel Engine Coolant (engine with wet sleeve cylinder liners)

Diesel Engine Coolant (engine without wet sleeve cylinder liners)

Operating in Warm Temperature Climates

Water Quality for Mixing with Coolant Concentrate

Testing Coolant Freeze Point

Engine Oil and Filter Service Intervals — Tier 3 and Stage IIIA — OEM Applications

Diesel Engine Oil — Tier 3 and Stage III

Diesel Engine Break-In Oil — Non-Emissions Certified and Certified Tier 1, Tier 2, Tier 3, Stage I, Stage II, and Stage III

Oil Filters

Fuel Filters

Alternative and Synthetic Lubricants

Lubricant Storage

Mixing of Lubricants

Section 02A: Repair and Adjustments (4 Cylinder Engine)

Group 010: Engine Rebuild (4045)

Check Air Intake System (4045)

Check and Service Cooling System (4045)

Check Crankcase Vent System (4045)

Check Electrical System (4045)

Check Exhaust System (4045)

Clean Engine (4045)

Engine Break-In Guidelines (4045)

Engine Overhaul Guidelines (4045)

General Tune-Up Recommendations (4045)

Engine Repair Stand (4045)

Install JT07268 Engine Mounting Adapter to D05223ST Repair Stand (4045)

Install JDG11853 Engine Mounting Adapter to D05223ST Repair Stand (4045)

Lift Straps — Installation (4045)

Lift Straps — Removal (4045)

Lifting Procedure (4045)

Mount Engine to Repair Stand Using JT07268 (4045)

Mount Engine to Repair Stand Using JDG11853 (4045)

Safety Precautions (4045)

Sealant Application Guidelines (4045)

Group 020: Cylinder Head and Valve Repair and Adjustment (4045) (Two-Valve Head Engines)

Cylinder Block Top Deck — Cleaning and Inspection (4045) (Two-Valve Head)

Cylinder Head — Cleaning and Inspection (4045) (Two-Valve Head)

Cylinder Head — Flatness Check (4045) (Two-Valve Head)

Cylinder Head — Installation (4045) (Two-Valve Head)

Cylinder Head — Removal (4045) (Two-Valve Head)

Cylinder Head — Thickness Measurement (4045) (Two-Valve Head)

Cylinder Head Gasket — Inspection (4045) (Two-Valve Head)

Fuel Injector Heat Shield — Installation (4045) (Two-Valve Head)

Fuel Injector Heat Shield — Removal (4045) (Two-Valve Head)

Fuel Injector Sleeves — Installation (4045) (Two-Valve Head)

Fuel Injector Sleeves — Removal (4045) (Two-Valve Head)

Fuel Supply Pump Push Rod — Installation (4045) (Two-Valve Head)

Fuel Supply Pump Push Rod — Measurement (4045) (Two-Valve Head)

Fuel Supply Pump Push Rod — Removal (4045) (Two-Valve Head)

Push Rod — Cleaning and Inspection (4045) (Two-Valve Head)

Push Rod — Installation (4045) (Two-Valve Head)

Push Rod — Removal (4045) (Two-Valve Head)

Rocker Arm Cover Baffle — Installation (4045) (Two-Valve Head)

Rocker Arm Cover Baffle — Removal (4045) (Two-Valve Head)

Rocker Arm Cover — Installation (4045) (Two-Valve Head)

Rocker Arm Cover — Removal (4045) (Two-Valve Head)

Rocker Arm Shaft Assembly — Tear Down (4045) (Two-Valve Head)

Rocker Arm Shaft Assembly — Inspection (4045) (Two-Valve Head)

Rocker Arm Shaft Assembly — Assemble (4045) (Two-Valve Head)

Rocker Arm Shaft Assembly — Installation (4045) (Two-Valve Head)

Rocker Arm Shaft Assembly — Removal (4045) (Two-Valve Head)

Valve — Cleaning and Visual Inspection (4045) (Two-Valve Head)

Valve — Clearance Adjustment (4045) (Two-Valve Head)

Valve — Grinding (4045) (Two-Valve Head)

Valve — Measurement (4045) (Two-Valve Head)

Valve — Recess Measurement (4045) (Two-Valve Head)

Valve Assembly — Installation (4045) (Two-Valve Head)

Valve Assembly — Removal (4045) (Two-Valve Head)

Valve Guide — Cleaning (4045) (Two-Valve Head)

Valve Guide — Measurement (4045) (Two-Valve Head)

Valve Guide — Knurling (4045) (Two-Valve Head)

Valve Keeper, Rocker Arm Insert, and Valve Rotator — Inspection (4045) (Two-Valve Head)

Valve Seat — Cleaning and Inspection (4045) (Two-Valve Head)

Valve Seat — Grinding and Measurement (4045) (Two-Valve Head)

Valve Seat Inserts — Installation (4045) (Two-Valve Head)

Valve Seat Inserts — Removal (4045) (Two-Valve Head)

Valve Spring — Inspection and Measurement (4045) (Two-Valve Head)

Group 021: Cylinder Head and Valve Repair and Adjustment (4045) (Four-Valve Head Engines)

Cylinder Block Top Deck — Cleaning and Inspection (4045) (Four-Valve Head)

Cylinder Head — Cleaning and Inspection (4045) (Four-Valve Head)

Cylinder Head — Flatness Check (4045) (Four-Valve Head)

Cylinder Head — Installation (4045) (Four-Valve Head)

Cylinder Head — Removal (4045) (Four-Valve Head)

Cylinder Head — Thickness Measurement (4045) (Four-Valve Head)

Cylinder Head Gasket — Inspection (4045) (Four-Valve Head)

Fuel Leak-Off Line Heat Shield — Installation (4045) (Four-Valve Head)

Fuel Leak-Off Line Heat Shield — Removal (4045) (Four-Valve Head)

Fuel Injector Sleeves — Installation (4045) (Four-Valve Head)

Fuel Injector Sleeves — Removal (4045) (Four-Valve Head)

Fuel Supply Pump Push Rod — Installation (4045) (Four-Valve Head)

Fuel Supply Pump Push Rod — Measurement (4045) (Four-Valve Head)

Fuel Supply Pump Push Rod — Removal (4045) (Four-Valve Head)

Push Rod — Cleaning and Inspection (4045) (Four-Valve Head)

Push Rod — Installation (4045) (Four-Valve Head)

Push Rod — Removal (4045) (Four-Valve Head)

Glow Plug — Installation (4045) (Four-Valve Head)

Glow Plug — Removal (4045) (Four-Valve Head)

Glow Plug Bore — Cleaning and Inspection (4045) (Four-Valve Head)

Rocker Arm Cover Baffle — Installation (4045) (Four-Valve Head)

Rocker Arm Cover Baffle — Removal (4045) (Four-Valve Head)

Rocker Arm Cover — Installation (4045) (Four-Valve Head)

Rocker Arm Cover — Removal (4045) (Four-Valve Head)

Rocker Arm Shaft Assembly — Tear Down (4045) (Four-Valve Head)

Rocker Arm Shaft Assembly — Inspection (4045) (Four-Valve Head)

Rocker Arm Shaft Assembly — Assemble (4045) (Four-Valve Head)

Rocker Arm Shaft Assembly — Installation (4045) (Four-Valve Head)

Rocker Arm Shaft Assembly — Removal (4045) (Four-Valve Head)

Rocker Arm Shaft Carrier Assembly — Installation (External Fuel Leak-Off System) (4045) (Four-Valve Head)

Rocker Arm Shaft Carrier Assembly — Installation (Internal Fuel Leak-Off System) (4045) (Four-Valve Head)

Rocker Arm Shaft Carrier Assembly — Removal (4045) (Four-Valve Head)

Rocker Arm Shaft Carrier — Inspection (4045) (Four-Valve Head)

Valve — Cleaning and Visual Inspection (4045) (Four-Valve Head)

Valve — Clearance Adjustment (4045) (Four-Valve Head)

Valve — Grinding (4045) (Four-Valve Head)

Valve — Measurement (4045) (Four-Valve Head)

Valve — Recess Measurement (4045) (Four-Valve Head)

Valve Assembly — Installation (4045) (Four-Valve Head)

Valve Assembly — Removal (4045) (Four-Valve Head)

Valve Guide — Cleaning (4045) (Four-Valve Head)

Valve Guide — Measurement (4045) (Four-Valve Head)

Valve Guide — Knurling (4045) (Four-Valve Head)

Valve Keeper, Valve Bridges, and Valve Rotator — Inspection (4045) (Four-Valve Head)

Valve Seat — Cleaning and Inspection (4045) (Four-Valve Head)

Valve Seat — Grinding and Measurement (4045) (Four-Valve Head)

Valve Seat Inserts — Installation (4045) (Four-Valve Head)

Valve Seat Inserts — Removal (4045) (Four-Valve Head)

Valve Spring — Inspection and Measurement (4045) (Four-Valve Head)

Group 030: Cylinder Block, Liners, Pistons, and Rods Repair and Adjustment (4045)

Connecting Rod — Center-to-Center Bore Measurement (4045)

Connecting Rod — General Information (4045)

Connecting Rod and Cap — Inspection (4045)

Connecting Rod Bearing — Inspection and Measurement (4045)

Connecting Rod Bearing — Inspection and Measurement (Rod and Crankshaft in Engine) (4045)

Connecting Rod Cap Screw — Torque Procedure (4045)

Connecting Rod Pin Bore — Cleaning and Inspection (4045)

Connecting Rod Piston Pin Bushing — Installation (4045)

Connecting Rod Piston Pin Bushing — Removal (4045)

Cylinder Block — Inspection and Plug Installation (4045)

Cylinder Block Components — Measurement (4045)

Cylinder Block O-Ring — Installation (4045)

Cylinder Liner — Cleaning (4045)

Cylinder Liner — Installation (4045)

Cylinder Liner — Removal (4045)

Cylinder Liner — Standout Measurement (4045)

Cylinder Liner — Visual Inspection (4045)

Cylinder Liner Flange — Measurement (4045)

Cylinder Liner O-Ring Bore — Cleaning (4045)

Cylinder Liner Packing — Installation (4045)

Piston — Cleaning (4045)

Piston — Visual Inspection (4045)

Piston and Connecting Rod Assembly — Assemble (4045)

Piston and Connecting Rod Assembly — Installation (4045)

Piston and Connecting Rod Assembly — Removal (4045)

Piston and Connecting Rod Assembly — Tear Down (4045)

Piston — Height Measurement (4045)

Piston — Protrusion Measurement (4045)

Piston Pin Bore — Measurement (4045)

Piston Pin — Inspection (4045)

Piston Rings — Installation (4045)

Piston Skirt — Measurement (4045)

Piston Spray Jet — Cleaning and Inspection (4045)

Piston Spray Jet — Installation (4045)

Piston Spray Jet — Removal (4045)

Piston to Cylinder Liner — Clearance Check (4045)

Group 040: Crankshaft, Main Bearings, and Flywheel Repair and Adjustment (4045)

Crankshaft — End Play Check (4045)

Crankshaft — Grinding Specifications (4045)

Crankshaft — Inspection (4045)

Crankshaft — Installation (4045)

Crankshaft — Removal (4045)

Crankshaft Gear — Installation (4045)

Crankshaft Gear — Removal (4045)

Crankshaft Grinding — Guidelines (4045)

Crankshaft Journal and Main Bearing — Measurement (4045)

Crankshaft Main Bearing Cap — Removal (4045)

Crankshaft Main Bearing Cap — Line Bore Specification (4045)

Crankshaft Main Bearing Cap — Oil Clearance Check (4045)

Crankshaft Pulley — Removal (4045)

Crankshaft Pulley — Installation (4045)

Crankshaft Pulley — Removal (Add-On Pulley Capable) (4045)

Crankshaft Pulley — Installation (Add-On Pulley Capable) (4045)

Crankshaft Rear Oil Seal — Installation (4045)

Crankshaft Rear Oil Seal — Removal (4045)

Crankshaft Front Oil Seal — Installation (4045)

Crankshaft Front Oil Seal — Removal (4045)

Crankshaft Thrust Bearing — Inspection (4045)

Crankshaft Timing Wheel — Installation (4045)

Crankshaft Timing Wheel — Removal (4045)

Flywheel — Inspection (4045)

Flywheel — Installation (4045)

Flywheel — Removal (4045)

Flywheel Face — Flatness Check (4045)

Flywheel Housing — Installation (4045)

Flywheel Housing — Removal (4045)

Flywheel Pilot Bearing Bore — Concentricity Check (4045)

Flywheel Ring Gear — Installation (4045)

Flywheel Ring Gear — Removal (4045)

Flywheel Sleeve — Installation (4045)

Flywheel Sleeve — Removal (4045)

Group 050: Camshaft, Balancing Shaft and Timing Gear Train Repair and Adjustment (4045)

Balancer Shaft — Installation (4045)

Balancer Shaft — Measure End Play (4045)

Balancer Shaft — Removal (4045)

Balancer Shaft — Visual Inspection and Measurement (4045)

Balancer Shaft and Lower Idler Gear — Timing (4045)

Balancer Shaft Bushing — Installation (4045)

Balancer Shaft Bushing — Removal (4045)

Balancer Shaft Gear — Check and Replace Components (4045)

Balancer Shaft Thrust Plate — Measure Clearance and Thickness (4045)

Balancer Shaft Weight — Installation (4045)

Balancer Shaft Weight — Removal (4045)

Camshaft — Installation (4045)

Camshaft — Measure End Play (4045)

Camshaft — Removal (4045)

Camshaft — Visual Inspection (4045)

Camshaft and Upper Idler Gear — Timing (4045)

Camshaft Bushing — Installation (4045)

Camshaft Bushing Journal #1 — Measurement (4045)

Camshaft Bushing — Removal (4045)

Camshaft Follower — Inspection and Measurement (4045)

Camshaft Follower — Installation (4045)

Camshaft Follower — Removal (4045)

Camshaft Gear — Inspection (4045)

Camshaft Gear-Driven Auxiliary Drive — Installation (4045)

Camshaft Gear-Driven Auxiliary Drive — Removal (4045)

Camshaft Journal — Measurement (4045)

Camshaft Lobe — Lift Measurement (4045)

Camshaft Thrust Plate — Measure Clearance and Thickness (4045)

Camshaft and Fuel Injection Pump — Timing (4045)

Front Plate — Installation (4045)

Front Plate — Removal (4045)

Idler Gears — Measure End Play (4045)

Idler Gear Bushing — Removal (4045)

Idler Gear Bushing — Installation (4045)

Idler Shaft Spring Pin — Installation (4045)

Lower Idler Gear — Check and Replace Components (4045)

Lower Idler Gear — Installation (4045)

Lower Idler Gear — Removal (4045)

Lower Idler Shaft — Installation (4045)

Lower Idler Shaft — Removal (4045)

Timing Gear Cover — Installation (4045)

Timing Gear Cover — Removal (4045)

Timing Gears — Check Backlash (4045)

Upper Idler Gear — Check and Replace Components (4045)

Upper Idler Gear — Installation (4045)

Upper Idler Gear — Removal (4045)

Group 060: Lubrication System Repair and Adjustment (4045)

Open Crankcase Ventilation System — Installation (4045)

Open Crankcase Ventilation System — Removal (4045)

Closed Crankcase Ventilation System — Inspection (4045)

Closed Crankcase Ventilation System — Installation (4045)

Closed Crankcase Ventilation System — Removal (4045)

Dipstick Tube and Dipstick — Installation (4045)

Dipstick Tube and Dipstick — Removal (4045)

Oil Cooler Assembly — Installation (4045)

Oil Cooler Assembly — Removal and Inspection (4045)

Oil Cooler Coolant Adapter — Removal (4045)

Oil Cooler Coolant Adapter — Installation (4045)

Oil Fill Adapter — Installation (4045)

Oil Fill Adapter — Removal (4045)

Oil Fill Adapter Cover Plate — Installation (4045)

Oil Fill Adapter Cover Plate — Removal (4045)

Oil Filter Bypass Valve — Installation (4045)

Oil Filter Bypass Valve — Removal (4045)

Oil Filter Header — Installation (4045)

Oil Filter Header — Removal (4045)

Oil Pan — Installation (4045)

Oil Pan — Removal (4045)

Oil Pump and Tube — Installation (4045)

Oil Pump and Tube — Removal (4045)

Oil Pick-Up Tube — Installation (4045)

Oil Pick-Up Tube — Removal (4045)

Oil Pressure Regulating Valve — Installation (Old Version) (4045)

Oil Pressure Regulating Valve — Removal (Old Version) (4045)

Oil Pressure Regulating Valve — Installation (New Version) (4045)

Oil Pressure Regulating Valve — Removal (New Version) (4045)

Open Crankcase Ventilation System — Inspection (4045)

Group 070: Cooling System Repair and Adjustment (4045)

Belt — Wear Check (4045)

Belt Tensioner — Adjustment (4045)

Belt Tensioner — Installation (4045)

Belt Tensioner — Removal (4045)

Belt Tensioner — Spring Tension Check (4045)

Cold Start Advance Switch — Servicing (4045)

Coolant Heater — Servicing (4045)

Coolant Pump Assembly — Assemble (4045)

Coolant Pump Assembly — Disassembly (4045)

Coolant Pump Assembly — Installation (4045)

Coolant Pump Assembly — Removal (4045)

Coolant Pump Inlet Adapter — Installation (4045)

Coolant Pump Inlet Adapter — Removal (4045)

Coolant Pump Pulley — Installation (4045)

Coolant Pump Pulley — Removal (4045)

Coolant Pump — Visual Inspection (4045)

Cooling System — Air Bleeding (4045)

Fan Drive Assembly — Installation (4045)

Fan Drive Assembly — Removal and Inspection (4045)

Fan Drive Idler Pulley — Installation (4045)

Fan Drive Idler Pulley — Removal (4045)

Fan Drive Pulley — Installation (4045)

Fan Drive Pulley — Removal (4045)

Fan (Fixed Speed Fan) — Inspection and Installation (4045)

Fan (Fixed Speed Fan) — Removal (4045)

Thermostat and Cover — Installation (4045)

Thermostat and Cover — Removal (4045)

Group 080: Air Intake and Exhaust System Repair and Adjustment (4045)

Air Heater — Servicing (4045)

Air Inlet and Mixing Sleeve — Installation (4045)

Air Inlet and Mixing Sleeve — Removal (4045)

EGR Cooler Assembly — Installation (4045)

EGR Cooler Assembly — Removal (4045)

EGR Cooler Coolant Inlet Tube — Installation (4045)

EGR Cooler Coolant Inlet Tube — Removal (4045)

EGR Cooler Gas Outlet Tube — Installation (4045)

EGR Cooler Gas Outlet Tube — Removal (4045)

Exhaust Manifold — Installation (4045)

Exhaust Manifold — Removal (4045)

Extending Turbocharger Life (4045)

Intake Manifold — Installation (4045)

Intake Manifold — Removal (4045)

Turbocharger — Break-In (4045)

Turbocharger — Recommendations for Use (4045)

Turbocharger — Inspection (4045)

Turbocharger — Failure Analysis (4045)

Turbocharger — Installation (4045)

Turbocharger — Removal (4045)

Turbocharger Oil Drain Line — Installation (4045)

Turbocharger Oil Drain Line — Removal (4045)

Turbocharger Oil Supply Line — Installation (4045)

Turbocharger Oil Supply Line — Removal (4045)

VGT Actuator Coolant Return Line — Installation (4045)

VGT Actuator Coolant Return Line — Removal (4045)

VGT Actuator Coolant Supply Line — Installation (4045)

VGT Actuator Coolant Supply Line — Removal (4045)

Group 090: Electronic Fuel System Repair and Adjustment (4045)

Fuel System (4045)

Group 100: OEM Starting and Charging Systems Repair and Adjustment (4045)

Alternator — Installation (4045)

Alternator — Removal (4045)

Starter Motor — Installation (4045)

Starter Motor — Removal (4045)

Section 02B: Repair and Adjustments (6 Cylinder Engine)

Group 010: Engine Rebuild (6068)

Check Air Intake System (6068)

Check and Service Cooling System (6068)

Check Crankcase Vent System (6068)

Check Electrical System (6068)

Check Exhaust System (6068)

Clean Engine (6068)

Engine Break-In Guidelines (6068)

Engine Overhaul Guidelines (6068)

General Tune-Up Recommendations (6068)

Engine Repair Stand (6068)

Install JT07268 Engine Mounting Adapter to D05223ST Repair Stand (6068)

Install JDG11853 Engine Mounting Adapter to D05223ST Repair Stand (6068)

Lift Straps — Installation (6068)

Lift Straps — Removal (6068)

Lifting Procedure (6068)

Mount Engine to Repair Stand Using JT07268 (6068)

Mount Engine to Repair Stand Using JDG11853 (6068)

Safety Precautions (6068)

Sealant Application Guidelines (6068)

Group 020: Cylinder Head and Valve Repair and Adjustment (6068) (Two-Valve Head Engines)

Cylinder Block Top Deck — Cleaning and Inspection (6068) (Two-Valve Head)

Cylinder Head — Cleaning and Inspection (6068) (Two-Valve Head)

Cylinder Head — Flatness Check (6068) (Two-Valve Head)

Cylinder Head — Installation (6068) (Two-Valve Head)

Cylinder Head — Removal (6068) (Two-Valve Head)

Cylinder Head — Thickness Measurement (6068) (Two-Valve Head)

Cylinder Head Gasket — Inspection (6068) (Two-Valve Head)

Fuel Injector Heat Shield — Installation (6068) (Two-Valve Head)

Fuel Injector Heat Shield — Removal (6068) (Two-Valve Head)

Fuel Injector Sleeves — Installation (6068) (Two-Valve Head)

Fuel Injector Sleeves — Removal (6068) (Two-Valve Head)

Fuel Supply Pump Push Rod — Installation (6068) (Two-Valve Head)

Fuel Supply Pump Push Rod — Measurement (6068) (Two-Valve Head)

Fuel Supply Pump Push Rod — Removal (6068) (Two-Valve Head)

Push Rod — Cleaning and Inspection (6068) (Two-Valve Head)

Push Rod — Installation (6068) (Two-Valve Head)

Push Rod — Removal (6068) (Two-Valve Head)

Rocker Arm Cover Baffle — Installation (6068) (Two-Valve Head)

Rocker Arm Cover Baffle — Removal (6068) (Two-Valve Head)

Rocker Arm Cover — Installation (6068) (Two-Valve Head)

Rocker Arm Cover — Removal (6068) (Two-Valve Head)

Rocker Arm Shaft Assembly — Tear Down (6068) (Two-Valve Head)

Rocker Arm Shaft Assembly — Inspection (6068) (Two-Valve Head)

Rocker Arm Shaft Assembly — Assemble (6068) (Two-Valve Head)

Rocker Arm Shaft Assembly — Installation (6068) (Two-Valve Head)

Rocker Arm Shaft Assembly — Removal (6068) (Two-Valve Head)

Valve — Cleaning and Visual Inspection (6068) (Two-Valve Head)

Valve — Clearance Adjustment (6068) (Two-Valve Head)

Valve — Grinding (6068) (Two-Valve Head)

Valve — Measurement (6068) (Two-Valve Head)

Valve — Recess Measurement (6068) (Two-Valve Head)

Valve Assembly — Installation (6068) (Two-Valve Head)

Valve Assembly — Removal (6068) (Two-Valve Head)

Valve Guide — Cleaning (6068) (Two-Valve Head)

Valve Guide — Measurement (6068) (Two-Valve Head)

Valve Guide — Knurling (6068) (Two-Valve Head)

Valve Keeper, Rocker Arm Insert, and Valve Rotator — Inspection (6068) (Two-Valve Head)

Valve Seat — Cleaning and Inspection (6068) (Two-Valve Head)

Valve Seat — Grinding and Measurement (6068) (Two-Valve Head)

Valve Seat Inserts — Installation (6068) (Two-Valve Head)

Valve Seat Inserts — Removal (6068) (Two-Valve Head)

Valve Spring — Inspection and Measurement (6068) (Two-Valve Head)

Group 021: Cylinder Head and Valve Repair and Adjustment (6068) (Four-Valve Head Engines)

Cylinder Block Top Deck — Cleaning and Inspection (6068) (Four-Valve Head)

Cylinder Head — Cleaning and Inspection (6068) (Four-Valve Head)

Cylinder Head — Flatness Check (6068) (Four-Valve Head)

Cylinder Head — Installation (6068) (Four-Valve Head)

Cylinder Head — Removal (6068) (Four-Valve Head)

Cylinder Head — Thickness Measurement (6068) (Four-Valve Head)

Cylinder Head Gasket — Inspection (6068) (Four-Valve Head)

Fuel Leak-Off Line Heat Shield — Installation (6068) (Four-Valve Head)

Fuel Leak-Off Line Heat Shield — Removal (6068) (Four-Valve Head)

Fuel Injector Sleeves — Installation (6068) (Four-Valve Head)

Fuel Injector Sleeves — Removal (6068) (Four-Valve Head)

Fuel Supply Pump Push Rod — Installation (6068) (Four-Valve Head)

Fuel Supply Pump Push Rod — Measurement (6068) (Four-Valve Head)

Fuel Supply Pump Push Rod — Removal (6068) (Four-Valve Head)

Push Rod — Cleaning and Inspection (6068) (Four-Valve Head)

Push Rod — Installation (6068) (Four-Valve Head)

Push Rod — Removal (6068) (Four-Valve Head)

Glow Plug — Installation (6068) (Four-Valve Head)

Glow Plug — Removal (6068) (Four-Valve Head)

Glow Plug Bore — Cleaning and Inspection (6068) (Four-Valve Head)

Rocker Arm Cover Baffle — Installation (6068) (Four-Valve Head)

Rocker Arm Cover Baffle — Removal (6068) (Four-Valve Head)

Rocker Arm Cover — Installation (6068) (Four-Valve Head)

Rocker Arm Cover — Removal (6068) (Four-Valve Head)

Rocker Arm Shaft and Components — Tear Down (6068) (Four-Valve Head)

Rocker Arm Shaft Assembly — Inspection (6068) (Four-Valve Head)

Rocker Arm Shaft Assembly — Assemble (6068) (Four-Valve Head)

Rocker Arm Shaft Assembly — Installation (6068) (Four-Valve Head)

Rocker Arm Shaft Assembly — Removal (6068) (Four-Valve Head)

Rocker Arm Shaft Carrier — Installation (External Fuel Leak-Off System) (6068) (Four-Valve Head)

Rocker Arm Shaft Carrier Assembly — Installation (Internal Fuel Leak-Off System) (6068) (Four-Valve Head)

Rocker Arm Shaft Carrier — Removal (6068) (Four-Valve Head)

Rocker Arm Shaft Carrier — Inspection (6068) (Four-Valve Head)

Valve — Cleaning and Visual Inspection (6068) (Four-Valve Head)

Valve — Clearance Adjustment (6068) (Four-Valve Head)

Valve — Grinding (6068) (Four-Valve Head)

Valve — Measurement (6068) (Four-Valve Head)

Valve — Recess Measurement (6068) (Four-Valve Head)

Valve Assembly — Installation (6068) (Four-Valve Head)

Valve Assembly — Removal (6068) (Four-Valve Head)

Valve Guide — Cleaning (6068) (Four-Valve Head)

Valve Guide — Measurement (6068) (Four-Valve Head)

Valve Guide — Knurling (6068) (Four-Valve Head)

Valve Keeper, Valve Bridges, and Valve Rotator — Inspection (6068) (Four-Valve Head)

Valve Seat — Cleaning and Inspection (6068) (Four-Valve Head)

Valve Seat — Grinding and Measurement (6068) (Four-Valve Head)

Valve Seat Inserts — Installation (6068) (Four-Valve Head)

Valve Seat Inserts — Removal (6068) (Four-Valve Head)

Valve Spring — Inspection and Measurement (6068) (Four-Valve Head)

Group 030: Cylinder Block, Liners, Pistons, and Rods Repair and Adjustment (6068)

Connecting Rod — Center-to-Center Bore Measurement (6068)

Connecting Rod — General Information (6068)

Connecting Rod and Cap — Inspection (6068)

Connecting Rod Bearing — Inspection and Measurement (6068)

Connecting Rod Bearing — Inspection and Measurement (Rod and Crankshaft in Engine) (6068)

Connecting Rod Cap Screw — Torque Procedure (6068)

Connecting Rod Pin Bore — Cleaning and Inspection (6068)

Connecting Rod Piston Pin Bushing — Installation (6068)

Connecting Rod Piston Pin Bushing — Removal (6068)

Cylinder Block — Inspection and Plug Installation (6068)

Cylinder Block Components — Measurement (6068)

Cylinder Block O-Ring — Installation (6068)

Cylinder Liner — Cleaning (6068)

Cylinder Liner — Installation (6068)

Cylinder Liner — Removal (6068)

Cylinder Liner — Standout Measurement (6068)

Cylinder Liner — Visual Inspection (6068)

Cylinder Liner Flange — Measurement (6068)

Cylinder Liner O-Ring Bore — Cleaning (6068)

Cylinder Liner Packing — Installation (6068)

Piston — Cleaning (6068)

Piston — Visual Inspection (6068)

Piston and Connecting Rod Assembly — Assemble (6068)

Piston and Connecting Rod Assembly — Installation (6068)

Piston and Connecting Rod Assembly — Removal (6068)

Piston and Connecting Rod Assembly — Tear Down (6068)

Piston — Height Measurement (6068)

Piston — Protrusion Measurement (6068)

Piston Pin Bore — Measurement (6068)

Piston Pin — Inspection (6068)

Piston Rings — Installation (6068)

Piston Skirt — Measurement (6068)

Piston Spray Jet — Cleaning and Inspection (6068)

Piston Spray Jet — Installation (6068)

Piston Spray Jet — Removal (6068)

Piston to Cylinder Liner — Clearance Check (6068)

Group 040: Crankshaft, Main Bearings, and Flywheel Repair and Adjustment (6068)

Crankshaft — End Play Check (6068)

Crankshaft — Grinding Specifications (6068)

Crankshaft — Installation (6068)

Crankshaft — Inspection (6068)

Crankshaft — Removal (6068)

Crankshaft Gear — Installation (6068)

Crankshaft Gear — Removal (6068)

Crankshaft Grinding — Guidelines (6068)

Crankshaft Journal and Main Bearing — Measurement (6068)

Crankshaft Main Bearing Cap — Removal (6068)

Crankshaft Main Bearing Cap — Line Bore Specification (6068)

Crankshaft Main Bearing — Oil Clearance Check (6068)

Crankshaft Vibration Damper — Installation (6068)

Crankshaft Vibration Damper — Removal (6068)

Crankshaft Vibration Damper — Inspection (6068)

Crankshaft Vibration Damper Add-On Pulley — Installation (6068)

Crankshaft Vibration Damper Add-On Pulley — Removal (6068)

Crankshaft Rear Oil Seal — Installation (6068)

Crankshaft Rear Oil Seal — Removal (6068)

Crankshaft Front Oil Seal — Installation (6068)

Crankshaft Front Oil Seal — Removal (6068)

Crankshaft Thrust Bearing — Inspection (6068)

Crankshaft Timing Wheel — Installation (6068)

Crankshaft Timing Wheel — Removal (6068)

Flywheel — Installation (6068)

Flywheel — Inspection (6068)

Flywheel — Removal (6068)

Flywheel Face — Flatness Check (6068)

Flywheel Housing — Installation (6068)

Flywheel Housing — Removal (6068)

Flywheel Pilot Bearing Bore — Concentricity Check (6068)

Flywheel Ring Gear — Installation (6068)

Flywheel Ring Gear — Removal (6068)

Flywheel Sleeve — Installation (6068)

Flywheel Sleeve — Removal (6068)

Group 050: Camshaft and Timing Gear Train Repair and Adjustment (6068)

Camshaft — Installation (6068)

Camshaft — Measure End Play (6068)

Camshaft — Removal (6068)

Camshaft — Visual Inspection (6068)

Camshaft and Upper Idler Gear — Timing (6068)

Camshaft Bushing — Installation (6068)

Camshaft Bushing Journal #1 — Measurement (6068)

Camshaft Bushing — Removal (6068)

Camshaft Follower — Inspection and Measurement (6068)

Camshaft Follower — Installation (6068)

Camshaft Follower — Removal (6068)

Camshaft Gear — Inspection (6068)

Camshaft Gear-Driven Auxiliary Drive — Removal (6068)

Camshaft Gear-Driven Auxiliary Drive — Installation (6068)

Camshaft Journal — Measurement (6068)

Camshaft Lobe — Lift Measurement (6068)

Camshaft Thrust Plate — Measure Clearance and Thickness (6068)

Camshaft and Fuel Pump — Timing (6068)

Front Plate — Installation (6068)

Front Plate — Removal (6068)

Idler Gears — Measure End Play (6068)

Idler Gear Bushing — Removal (6068)

Idler Gear Bushing — Installation (6068)

Idler Shaft Spring Pin — Installation (6068)

Lower Idler Gear — Check and Replace Components (6068)

Lower Idler Gear — Installation (6068)

Lower Idler Gear — Removal (6068)

Timing Gear Cover — Installation (6068)

Timing Gear Cover — Removal (6068)

Timing Gears — Check Backlash (6068)

Upper Idler Gear — Check and Replace Components (6068)

Upper Idler Gear — Removal (6068)

Upper Idler Gear — Installation (6068)

Group 060: Lubrication System Repair and Adjustment (6068)

Open Crankcase Ventilation System — Installation (6068)

Open Crankcase Ventilation System — Removal (6068)

Crankcase Vent Hose — Installation (6068)

Crankcase Vent Hose — Removal (6068)

Dipstick Tube and Dipstick — Installation (6068)

Dipstick Tube and Dipstick — Removal (6068)

Oil Cooler Assembly — Installation (6068)

Oil Cooler Assembly — Removal and Inspection (6068)

Oil Fill Adapter — Removal (6068)

Oil Fill Adapter — Installation (6068)

Oil Filter Bypass Valve — Installation (6068)

Oil Filter Bypass Valve — Removal (6068)

Oil Filter Header — Installation (6068)

Oil Filter Header — Removal (6068)

Oil Pan — Installation (6068)

Oil Pan — Removal (6068)

Oil Pump and Tube — Installation (6068)

Oil Pump and Tube — Removal (6068)

Oil Pick-up Tube — Installation (6068)

Oil Pick-Up Tube — Removal (6068)

Oil Pressure Regulating Valve — Installation (Old Version) (6068)

Oil Pressure Regulating Valve — Removal (Old Version) (6068)

Oil Pressure Regulating Valve — Installation (New Version) (6068)

Oil Pressure Regulating Valve — Removal (New Version) (6068)

Open Crankcase Ventilation Hose — Inspection (6068)

Group 070: Cooling System Repair and Adjustment (6068)

Belt — Wear Check (6068)

Belt Tensioner — Adjustment (6068)

Belt Tensioner — Installation (6068)

Belt Tensioner — Removal (6068)

Belt Tensioner — Spring Tension Check (6068)

Cold Start Advance Switch — Servicing (6068)

Coolant Heater — Servicing (6068)

Coolant Pump Assembly — Assemble (6068)

Coolant Pump Assembly — Disassemble (6068)

Coolant Pump Assembly — Installation (6068)

Coolant Pump Assembly — Removal (6068)

Coolant Pump Inlet Adapter — Installation (6068)

Coolant Pump Inlet Adapter — Removal (6068)

Coolant Pump Pulley — Installation (6068)

Coolant Pump Pulley — Removal (6068)

Coolant Pump — Visual Inspection (6068)

Cooling System — Air Bleeding (6068)

Fan Drive Assembly — Installation (6068)

Fan Drive Assembly — Removal and Inspection (6068)

Fan Drive Pulley — Installation (6068)

Fan Drive Pulley — Removal (6068)

Fan (Fixed Speed Fan) — Inspection and Installation (6068)

Fan (Fixed Speed Fan) — Removal (6068)

Thermostat and Cover — Installation (6068)

Thermostat and Cover — Removal (6068)

Group 080: Air Intake and Exhaust System Repair and Adjustment (6068)

Air Heater — Servicing (6068)

Air Inlet and Mixing Sleeve — Installation (6068)

Air Inlet and Mixing Sleeve — Removal (6068)

EGR Cooler Assembly — Installation (6068)

EGR Cooler Assembly — Removal (6068)

EGR Cooler Coolant Inlet Tube — Installation (6068)

EGR Cooler Coolant Inlet Tube — Removal (6068)

EGR Cooler Gas Outlet Tube — Installation (6068)

EGR Cooler Gas Outlet Tube — Removal (6068)

Exhaust Manifold — Installation (6068)

Exhaust Manifold — Removal (6068)

Extending Turbocharger Life (6068)

Intake Manifold — Installation (6068)

Intake Manifold — Removal (6068)

Turbocharger — Break-In (6068)

Turbocharger — Recommendations for Use (6068)

Turbocharger — Inspection (6068)

Turbocharger — Failure Analysis (6068)

Turbocharger — Installation (6068)

Turbocharger — Removal (6068)

Turbocharger Oil Drain Line — Installation (6068)

Turbocharger Oil Drain Line — Removal (6068)

Turbocharger Oil Supply Line — Installation (6068)

Turbocharger Oil Supply Line — Removal (6068)

VGT Actuator Coolant Return Line — Installation (6068)

VGT Actuator Coolant Return Line — Removal (6068)

VGT Actuator Coolant Supply Line — Installation (6068)

VGT Actuator Coolant Supply Line — Removal (6068)

Group 090: Electronic Fuel System Repair and Adjustment (6068)

Fuel System (6068)

Group 100: OEM Starting and Charging Systems Repair and Adjustment (6068)

Alternator — Installation (6068)

Alternator — Removal (6068)

Starter Motor — Installation (6068)

Starter Motor — Removal (6068)

Section 03: Base Engine Theory of Operation

Group 120: Base Engine Operation

General Engine Operation

Head Gasket Joint Construction and Operation

Group 123: Cooling System

Cooling System Operation

Group 126: Lubrication System

Lubrication System Operation

Group 130: Electronic Fuel System

Electronic Fuel System Operation

Group 135: Air Intake and Exhaust System

Air Intake and Exhaust System Operation

Section 04: Diagnostics

Group 150: Observable Diagnostics and Tests

About This Section of the Manual

4.5L/6.8L — L1 — Excessive Oil Consumption

4.5L/6.8L — L2 — Engine Oil Pressure Low

4.5L/6.8L — L3 — Engine Oil Pressure High

4.5L/6.8L — L4 — Soot or Sludge in Oil

4.5L/6.8L — C1 — Engine Coolant Temperature Above Normal

4.5L/6.8L — C2 — Engine Coolant Temperature Below Normal

4.5L/6.8L — C3 — Coolant in Oil or Oil in Coolant

4.5L/6.8L — C4 — Coolant Leaking from Weep Hole

Test Engine Compression Pressure

Test Engine Cranking Speed

Engine Oil Consumption

Check Engine Oil Pressure

Check for Excessive Engine Crankcase Pressure (Blow-By) (Base Pressure)

Check for Turbocharger Oil Seal Leak

Inspect Thermostat and Test Opening Temperature

Cooling System Pressure Test

Pressure Test EGR Cooler for Air Leaks

Check for Head Gasket Failures

Check and Service Cooling System

Check Air Intake System

Measure Intake Manifold Pressure (Turbocharger Boost for Tier 3/Stage IIIA Engines)

Measure Intake Manifold Pressure (Turbocharger Boost/Power Check)

Check for Intake and Exhaust Restrictions

Test for Intake Air Leaks

Check for Exhaust Air Leaks (Turbocharged Engines)

Turbocharger Wastegate Check

Excessive Engine Vibration

Section 05: Tools and Other Materials

Group 170: Special Tools

75240

D01045AA

D01061AA

D01062AA

D01168AA

D01200AA

D01218AA

D01300AA

D05012ST-A

D05022ST

D05104ST

D05223ST

D05226ST

D15001NU

D17015BR

D17024BR

D17525CI

D17526CI

D17527CI

DFRG9

DFRG11

DFRG14

DFRG15

DFYZ49

FKM10002

JD244

JD248A

JD249

JD252

JD254A

JD286

JDE81-4

JDE83

JDE85

JDE88

JDE138

JDE41296

JDG22

JDG23

JDG451

JDG536

JDG537

JDG576

JDG675

JDG676

JDG678

JDG680

JDG698A

JDG738-2

JDG739B

JDG739-1

JDG739-3

JDG739-4

JDG739-5B

JDG739-7

JDG739-8

JDG782A

JDG791A

JDG820

JDG839

JDG886

JDG953

JDG953-1

JDG953-2

JDG954B

JDG954-1B

JDG954-2

JDG954-3

JDG954-4

JDG954-5

JDG954-6

JDG954-7

JDG954-8

JDG956

JDG963

JDG965

JDG966

JDG992-1

JDG992-2

JDG1069

JDG1145

JDG1146

JDG1341

JDG1517

JDG1517-1

JDG1517-2

JDG1520

JDG1559

JDG1571

JDG1649A

JDG1651

JDG1653

JDG1653-1

JDG1653-2

JDG1923A

JDG2047A

JDG2047AP1

JDG2074A

JDG10539A

JDG10576

JDG10631

JDG10824

JDG11064

JDG11065A

JDG11205

JDG11413

JDG11853

JDG11864

JT01674A

JT05470

JT05697A

JT07268

JT07336

JT30040B

JT30041A

JT30042

KCD10001

KJD10123

KJD10140

KJD10213

KJD10233

Group 180: Lubricants, Sealants, and Other Materials

Other Materials

Section 06: Specifications

Group 200: Repair and General OEM Specifications

Unified Inch Bolt and Screw Torque Values

Metric Bolt and Screw Torque Values

Cylinder Head and Valves Specifications (Two-Valve Head)

Cylinder Head and Valves Specifications (Four-Valve Head)

Cylinder Block, Liners, Pistons, and Rods Specifications

Crankshaft, Main Bearings, and Flywheel Specifications

Camshaft, Balancer Shafts, and Timing Gear Train Specifications

Lubrication System Specifications

Cooling System Specifications

Air Intake and Exhaust System Specifications

Starting and Charging System Specifications

John Deere PowerTech 4.5L & 6.8L Diesel Engines Base Engine Component Technical Manual (CTM104)