Complete Component Technical Manual with Electrical Wiring Diagrams for John Deere PowerTech 9.0 L OEM Diesel Engines Base Engine Repair – (Worldwide Edition), with all the technical information to maintain, diagnose, repair, and rebuild like professional mechanics.

John Deere PowerTech 9.0 L OEM Diesel Engines Base Engine Repair – (Worldwide Edition) workshop service repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

ctm400 – PowerTechTM 9.0 L OEM Diesel Engines Base Engine Repair – (Worldwide Edition) Component Technical Manual.pdf

ctm401 – Motores diesel OEM PowerTech de 9.0 l Reparación del motor básico – (Edición mundial) Technical Manual.pdf

ctm402 – Moteurs diesel OEM PowerTech 9,0 l Remise en état des moteurs standard -: (Édition mondiale) Technical Manual.pdf

ctm403 – PowerTech 9,0-l-OEM-Dieselmotoren Reparatur des Grundmotors -: (Weltweite Ausgabe) Technical Manual.pdf

ctm404 – Motori diesel OEM PowerTech da 9,0 l Riparazione motore base -: (Edizione universale) Technical Manual.pdf

ctm407 – Дизельные двигатели OEM PowerTech объемом 9,0 л Ремонт основного двигателя -: (Исполнение для всех стран) Technical Manual.pdf

ctm408 – Motores Diesel OEM PowerTech 9,0 L Reparo do Motor Base -: (Edição Mundial) Technical Manual.pdf

ctm410 – PowerTech 9.0 升 OEM 柴油发动机 基本发动机 -: (世界通用机型) 维修技术手册.pdf

CTM400 (29AUG11) – PowerTech 9.0 L OEM Diesel Engines Base Engine Component Technical Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,012 pages

File Format: PDF/EPUB/MOBI/AZW (PC/Mac/Android/Kindle/iPhone/iPad; bookmarked, ToC, Searchable, Printable)

Language: English

ctm400 – PowerTech™ 9.0 L OEM Diesel Engines Base Engine Repair -: (Worldwide Edition)

Component Technical Manual

Table of Contents

Foreword

About this Manual

Identification Views – 6090 Tier 3 / Stage IIIA Emissions Certified Engines

Section 01: General

Group 000: Safety

Recognize Safety Information

Understand Signal Words

Follow Safety Instructions

Replace Safety Signs

California Proposition 65 Warning

Illuminate Work Area Safely

Work in Clean Area

Use Proper Tools

Live With Safety

Prevent Machine Runaway

Handle Fuel Safely—Avoid Fires

Prepare for Emergencies

Handle Starting Fluid Safely

In Case of Fire

Handle Fluids Safely—Avoid Fires

Avoid Static Electricity Risk When Refueling

Service Machines Safely

Wear Protective Clothing

Protect Against Noise

Handling Batteries Safely

Prevent Acid Burns

Stay Clear of Rotating Drivelines

Install All Guards

Practice Safe Maintenance

Remove Paint Before Welding or Heating

Avoid Heating Near Pressurized Fluid Lines

Avoid High-Pressure Fluids

Do Not Open High-Pressure Fuel System

Protect Against High Pressure Spray

Prevent Battery Explosions

Avoid Hot Exhaust

Work In Ventilated Area

Service Cooling System Safely

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Group 001: Engine Identification

Engine Model Designation

Engine Serial Number Plate Information

OEM Engine Option Code Label

Group 002: Fuels, Lubricants and Coolant

Diesel Fuel

Supplemental Diesel Fuel Additives

Lubricity of Diesel Fuel

Handling and Storing Diesel Fuel

BioDiesel Fuel

Testing Diesel Fuel

Fuel Filters

Minimizing the Effect of Cold Weather on Diesel Engines

Diesel Engine Break-In Oil — Non-Emissions Certified and Certified Tier 1, Tier 2, Tier 3, Stage I, Stage II, and Stage III

Engine Oil and Filter Service Intervals

Diesel Engine Oil — Tier 3 and Stage III

Mixing of Lubricants

Alternative and Synthetic Lubricants

Lubricant Storage

Oil Filters

Grease

Diesel Engine Coolant (engine with wet sleeve cylinder liners)

Water Quality for Mixing with Coolant Concentrate

Operating in Warm Temperature Climates

Testing Coolant Freeze Point

Disposing of Coolant

Section 02: Repair and Adjustments

Group 010: Engine Rebuild

Engine Overhaul Guidelines

Engine Repair Stand

Safety Precautions

Install Adapters on Engine Repair Stand

Install Engine Lift Straps

Engine Lifting Procedure

Clean Engine

Disconnect Turbocharger Oil Inlet Line

Mount Engine on Repair Stand

Engine Disassembly Sequence for Overhaul

Sealant Application Guidelines

Engine Assembly Sequence After Overhaul

Engine Break-In Guidelines

Perform Engine Break-In

Check Crankcase Ventilation System

Check Air Intake System

Check Exhaust System

Check and Service Cooling System

Check Electrical System

General Tune-Up Recommendations

Group 021: Cylinder Head and Valves Repair and Adjustment

Valve — Clearance Adjustment

Valve — Lift Check

Cylinder Head — Removal

Cylinder Head—Preparation and Measurement

Diagnosing Head Gasket Joint Failures

Head Gasket Diagnostic Charts

Head Gasket Inspection and Repair Sequence

Rocker Arm Assembly — Inspection

Rocker Arm Shaft Assembly — Removal and Tear Down

Valve — Recess Measurement

Preliminary Cylinder Head and Valve Checks

Valve — Assembly Removal

Valve Springs — Inspection

Valve Retainer, Valve Bridges, and Valve Retainer Locks — Inspection

Valve — Cleaning and Inspection

Valve — Measurement

Valve — Grinding

Cylinder Head — Cleaning and Inspection

Cylinder Head — Flatness Check

Cylinder Head — Thickness Measurement

Fuel Injector Sleeves — Remove

Fuel Injector Sleeves — Install

Valve Guide — Cleaning

Valve Guide — Measurement

Valve Guides — Removal

Valve Guides — Installation

Valve Seat — Cleaning and Inspection

Valve Seat — Recess Measurement

Valve Seat — Grinding

Valve Seat Inserts — Removal

Valve Seat Inserts — Installation

Cylinder Head Nozzle Bore — Cleaning and Inspection

Push Rod — Cleaning and Inspection

Cylinder Block Top Deck — Cleaning and Inspection

Valve Assembly — Reassemble

Cylinder Head — Installation

Cylinder Head Cap Screw Torque Procedure

Rocker Arm Shaft Assembly — Assemble

Rocker Arm Assembly — Installation

Rocker Arm Cover Vent hose — Inspection

Final Assembly — Fuel Pump Side of Engine

Final Assembly — Exhaust Manifold Side of Engine

Perform Engine Break— In

Group 030: Cylinder Block, Liners, Pistons, and Rods Repair and Adjustment

Preliminary Liner, Piston, and Rod Checks

Remove Pistons and Connecting Rod Assemblies

Cylinder Liner — Standout Measurement

Remove Cylinder Liners

Deglaze Cylinder Liners

Cylinder Liner — Cleaning

Piston and Connection Rod Assembly — Tear Down

Piston Ring — Removal

Clean Pistons

Visually Inspect Pistons

Inspect Piston Pin and Bore

Visually Inspect Cylinder Liners

Cylinder Liner Manufacturing Date Code Explanation

Piston to Liner — Clearance Check

Inspect Rod and Cap

Piston Pin and Bushing — Inspection

Piston Pin Bushing and Pin Bore — Removal

Measure Liner Flange

Inspect and Measure Connecting Rod Bearings

Piston Pin Bushing — Installation

Complete Disassembly of Cylinder Block (If Required)

Piston Cooling Orifices — Removal

Clean Cylinder Block

Measure Cylinder Block

Cylinder Block — Inspect and Reclaim

Piston Cooling Orifices — Installation

Install Packing on Cylinder Liner and O-Rings in Block

Install Cylinder Liner in Block

Piston Ring — Installation

Install Piston and Connecting Rod

Connecting Rod Cap Screw — Torque Procedure

Check Engine Rotation for Excessive Tightness

Complete Final Assembly

Group 040: Crankshaft, Main Bearings and Flywheel Repair and Adjustment

Crankshaft and Main Bearing Failure Analysis

Inspect Vibration Damper

Check Crankshaft End Play

Remove Crankshaft Vibration Damper (Straight Nose Crankshaft)

Remove Crankshaft Vibration Damper and Hub (Tapered Nose Crankshaft)

Crankshaft Dual Damper — Removal

Remove Crankshaft Front Oil Seal and Wear Sleeve (Straight Nose Crankshaft)

Remove Crankshaft Front Unitized Oil Seal (Tapered Nose Crankshaft)

Remove Timing Gear Cover—Engine Removed

Inspect and Measure Flywheel

Check Flywheel Housing Face Runout

Check Flywheel Face Flatness

Check Pilot Bearing Bore Concentricity

Remove Flywheel

Remove Flywheel (Tapered Nose Crankshaft)

Crankshaft Unitized Rear Oil Seal — Removal (Straight Nose Crankshaft)

Remove SAE 1 Flywheel Housing

Remove SAE 2 and 3 Flywheel Housing

Replace Flywheel Ring Gear

Remove Rear Oil Seal Housing—Engine Removed

Remove Main Bearing Caps

Check Main Bearing Oil Clearance

Remove Connecting Rod Caps and Remove Crankshaft

Crankshaft — Inspection

Measure Assembled I.D. of Bearings and O.D. of Crankshaft Journals

Main Bearing Cap Line Bore Specifications

Thrust Bearing New Part Specifications

Replace (Crankshaft) Oil Pump Drive Gear

Replace Crankshaft Gear

Inspect Thrust Bearings

Install Main Bearings and Crankshaft

Check Crankshaft Rear Oil Seal Housing Runout

Install Crankshaft Front Unitized Oil Seal (Straight Nose Crankshaft)

Install Crankshaft Front Unitized Oil Seal (Tapered Nose Crankshaft)

Install Vibration Damper (Straight Nose Crankshaft)

Install Vibration Damper and Hub (Tapered Nose Crankshaft)

Crankshaft Dual Damper — Installation (Tapered Nose Crankshaft)

Install Crankshaft Rear Oil Seal Housing

Crankshaft Rear Oil Seal Assembly Handling Precautions

Install Crankshaft Rear Unitized Oil Seal (Straight Nose Crankshaft)

Install Crankshaft Rear Unitized Oil Seal (Tapered Nose Crankshaft)

Install SAE 2 and 3 Flywheel Housing

Install Flywheel

Install Flywheel (Tapered Nose Crankshaft)

Install SAE 1 Flywheel Housing

Complete Final Assembly

Group 050: Camshaft and Timing Gear Train Repair and Adjustment

Check Camshaft End Play and Measure Gear Backlash

Remove Vibration Damper and Timing Gear Cover

Remove, Inspect, and Install Crankshaft Gear-Driven Auxiliary Drive — If Equipped

Remove Camshaft

Remove Camshaft Gears

Measure Thrust Washer Thickness

Inspect and Measure Camshaft Followers

Visually Inspect Camshaft

Measure Camshaft Journal O.D. and Bushing I.D.

Measure Camshaft Lobe Lift

Camshaft Gears — Installation

Service Camshaft Bushings Using JDG602 Adapter Set

Service Camshaft Bushings Using JDG606 Adapter Set

Camshaft Roller Followers — Install

Install Camshaft

Install Thrust Washer and Timing Gear Cover

Complete Final Assembly

Group 060: Lubrication System Repair and Adjustment

Diagnosing Lubrication System Malfunctions

Dipstick Tube and Dipstick — Installation

Dipstick Tube and Dipstick — Removal

Top-Load Oil Filter Assembly

Top Load Oil Filter – Theory of Operation

Install Oil Filter Assembly

Changing Top-Load Oil Filter

Oil Pressure Regulating Valve — Removal

Oil Pressure Regulating Valve — Installation

Engine Oil Cooler Assembly

Remove, Inspect, and Install Engine Oil Cooler

Remove Engine from Tractors for Access to Engine Oil Pump

Remove Oil Pan

Check Crankshaft Gear-to-Oil Pump Drive Gear Backlash

Remove Engine Oil Pump

Inspect and Clean Oil Pump

Check Drive Shaft End Play

Check Drive Shaft Side Movement

Check Pumping Gear Backlash

Inspect Oil Pump Drive Gear

Install Engine Oil Pump

Install Oil Bypass & Oil Pump Tubes & Oil Pump Adapter

Remove, Inspect, and Install Oil Pump Pickup Tube

Install Engine Oil Pan

Tighten Cap Screws on Front Frame/Oil Sump – Tractors

Group 070: Cooling System Repair and Adjustment

Inspect Fan Hub & Replace Bearings in Heavy-Duty, Adjustable Fan Drive Assembly

Replace Bearings in Coolant Manifold-Mounted, Fixed Fan Drive Assembly

Fan Drive Assembly

Checking Belt Tensioner Spring Tension and Belt Wear

Inspect and Install Fan Assembly

Visually Inspect Coolant Pump

Remove Coolant Pump Assembly

Install Coolant Pump Assembly

Replace Bypass Tube & O-Rings in Thermostat Housing

Remove and Test Thermostats

Remove Thermostat Housing

Install Thermostats

Install Thermostat Housing

Remove and Install Coolant Temperature Sensor

Servicing of Engine Coolant Heater

Remove Heat Exchanger or Top Tank (Marine)

Install Heat Exchanger or Top Tank (Marine)

Bleed Air from Coolant System

Complete Final Assembly

Group 080: Air Intake and Exhaust System Repair and Adjustment

Extending Turbocharger Life

Remove Turbocharger

Remove Turbocharger Oil Drain Line

Remove Turbocharger Oil Supply Line

Turbocharger — Failure Analysis

Turbocharger Inspection

Perform Radial Bearing Clearance Test

Repair Turbocharger

Prelube Turbocharger

Install Turbocharger

Turbocharger Break-In

Recommendations for Turbocharger Use

Install Turbocharger Oil Supply Line Brackets

Install Turbocharger Oil Supply Line

Install Turbocharger Oil Drain Line

Install Heat Shield & Turbocharger Oil Supply Line Bracket

Remove and Install Turbocharger Actuator

Install Actuator Coolant Line Fittings

Install Turbocharger Actuator Coolant Return Line

Install Turbocharger Actuator Coolant Supply Line

Install Actuator Coolant Supply Line – Tractors

Remove and Install Actuator Linkage

Remove and Install Turbocharger Actuator Linkage – Ball Type

Remove Exhaust Gas Recirculator (EGR) Assembly

Remove & Install EGR Valve

Remove and Install EGR Coolant Manifold

Remove and Install EGR Cooler Supply Line

Remove and Install EGR Cooler Return Line

Remove, Inspect, and Install Exhaust Manifold

Remove, Inspect, and Install Intake Manifold

Install EGR

Remove and Install Air Inlet/Heater

Group 081: PowerTech E Air Intake and Exhaust System Repair and Adjustment

Turbocharger — Extending Life

Turbocharger — Remove Oil Drain Line

Turbocharger — Install Oil Drain Line

Turbocharger — Remove

Turbocharger — Install

Exhaust Manifold — Remove

Exhaust Manifold — Install

Air Intake Assembly — Removal

Air Intake Assembly — Install

Group 082: Marine Engines Air Intake and Exhaust System Repair

Intake Manifold (Marine) – Removal

Intake Manifold (Marine) – Installation

Charge Air Cooler (Marine) — Removal

Charge Air Cooler (Marine) — Installation

Exhaust Manifold (Marine) — Removal

Exhaust Manifold (Marine) — Installation

Turbocharger (Marine) — Removal

Turbocharger (Marine) — Installation

Group 100: OEM Starting and Charging Systems Repair and Adjustment

Remove and Install Alternator (OEM Engines)

Remove and Install Starter Motor (OEM Engines)

Section 03: Theory of Operation

Group 120: Base Engine Operation

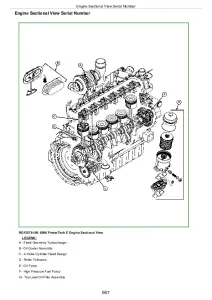

Engine Sectional View Serial Number

General Engine Operation

Lubrication System Operation

Cooling System Operation

Exhaust Gas Recirculator (EGR) and Variable Geometry Turbocharger (VGT)

Head Gasket Joint Construction and Operation

Air Intake and Exhaust System Operation

Turbocharger Operation

How the Turbocharger is Lubricated

Group 121: PowerTech E Base Engine Operation

Engine Sectional View Serial Number

General Engine Operation

Lubrication System Operation

Cooling System Operation

Air Intake and Exhaust System Operation

Turbocharger Operation

How the Turbocharger is Lubricated

Head Gasket Joint Construction and Operation

Section 04: Diagnostics

Group 150: Observable Diagnostics and Tests

About This Group of the Manual

9.0L – L1 -Excessive Oil Consumption

Engine Oil Consumption

9.0L – L2 – Engine Oil Pressure Low

9.0L – L2 – Engine Oil Pressure Low

9.0L – L3 – Engine Oil Pressure High

9.0L – L4 – Soot or Sludge in the Oil

9.0 L – C1 – Engine Coolant Temperature Above Normal

9.0L – C2 – Engine Coolant Temperature Below Normal

9.0L – C3 – Coolant In Oil or Oil In Coolant

9.0L – C4 – Coolant Leaking from Weep Hole

Test Engine Compression Pressure with Mechanical Gauge

Check Engine Cranking Speed

Check Engine Oil Pressure

Check for Excessive Engine Crankcase Pressure (Blow-By) (Base Pressure)

Excessive Fuel Filter Replacement

Check for Turbocharger Oil Seal Leak

Inspect Thermostat and Test Opening Temperature

Cooling System Pressure Test

EGR Cooler Test

Engine Coolant Leakage Diagnostic Procedure (After Engine Rebuild)

Intake Manifold Leakage Diagnostic

Charge Air System Diagnostic

Charge Air Cooler Test

Check for Head Gasket Failures

Measure Intake Manifold Pressure (Turbo Boost)

Check for Intake and Exhaust Restrictions

Check for Exhaust Air Leaks

Excessive Engine Vibration

Section 05: Tools and Other Materials

Group 170: Special Tools

205466

75240

D01062AA

D01168AA

D01207AA

D01209AA

D01299AA

D01251AA

D01300AA

D05012ST-A

D05104ST

D05223ST

D17006BR

D17015BR

D17024BR

D17030BR

D17525CI

D17526CI

D17527CI

DFRG3

DFRG9

DFRG11

JDE6

JDE93

JDE98A

JDE138

JDE41296

JDG22

JDG23

JDG337

JDG405

JDG451

JDG476(85)

JDG477(85)

JDG478

JDG602

JDG606

JDG681A

JDG721

JDG782A

JDG820

JDG839

JDG1020

JDG1069

JDG1145

JDG1571

JDG1649A

JDG1948

JDG1953

JDG1954

JDG1962

JDG1963

JDG2046

JDG2047A

JDG2047AP1

JDG10040

JDG10057

JDG10059A

JDG10194

JDG10254

JDG10539A

JDG10544

JDG10545

JDG10549

JDG10631

JDG10854

JDG10942

JDG10993

JDG10994

JDG10996

JDG10997

JDG10998

JDG10999

JDG11004A

JDG11055

JDG11056

JDG11083

JDG11253

JDG11263

JDG11334

JDG11864

JDH7

JT01674A

JT05536

JT05697A

Group 180: Lubricants, Sealants, and Other Materials

Group 021 — Cylinder Head and Valves – Other Materials

Group 030 — Cylinder Block, Liners, Pistons, and Rods Other Materials

Group 040 — Crankshaft, Main Bearings and Flywheel Other Materials

Group 050 — Camshaft and Timing Gear Train Other Materials

Group 060 — Lubrication System Other Materials

Group 070 — Cooling System Other Materials

Group 080 — Air Intake and Exhaust System Other Materials

Section 06: Specifications

Group 200: Repair and General OEM Specifications

General OEM Engine Specifications

Unified Inch Bolt and Screw Torque Values

Metric Bolt and Screw Torque Values

Group 020 — Cylinder Head and Valves Repair Specifications

Group 030 — Cylinder Block, Liners, Pistons and Rods Repair Specifications

Group 040 — Crankshaft, Main Bearings and Flywheel Repair Specifications

Group 050 — Camshaft and Timing Gear Train Repair Specifications

Group 060 — Lubrication System Repair Specifications

Group 070 — Cooling System Repair Specifications

Group 080 — Air Intake and Exhaust System Repair Specifications — PowerTech PSX

Group 081 — Air Intake and Exhaust System Repair Specifications — PowerTech PVX

OEM Starting and Charging Systems

Group 210: Diagnostic Specifications

Base Engine Diagnostic Specifications (Includes Dynamometer Specifications (OEM) and Turbocharger Boost Specifications)

Dynamometer Test Specifications

Intake Manifold Pressure (Turbocharger Boost) Specifications

Effects of Altitude and Temperature on Engine Performance

John Deere PowerTech 9.0 L OEM Diesel Engines Base Engine Repair Component Technical Manual (CTM400)