Component Technical Manual with Electrical Wiring Diagrams for John Deere PowerTech E 4.5L & 6.8L Diesel Engines, with all the shop information to maintain, diagnostic, repair, refurbish/rebuild like professional mechanics.

Component Technical Manual for John Deere PowerTech E 4.5L & 6.8L Diesel Engines workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

ctm503 – Dizelski motor 4045-6068 – ECU Nivel 16 – (Edición mundial) Tehnični priročnik za komponente.pdf

ctm504 – Moteur diesel 4045-6068 — Contrôleur ECU de niveau 16 – (Édition globale) Manuel technique des composants.pdf

ctm505 – Dieselmotor 4045-6068 – ECU (Stufe 16) – (Weltweite Ausgabe) Technisches Komponentenhandbuch.pdf

ctm506 – Motore diesel 4045–6068 – Livello ECU 16 – Manuale tecnico dei componenti (edizione universale).pdf

ctm507 – Motor Diesel 4045–6068 — ECU Nível 16 – (Edição Mundial) Manual técnico de Componentes.pdf

ctm511 – Дизельные двигатели 4045, 6068 — Блок управления двигателем (ECU), уровень 16 — (Глобальная версия) Техническое руководство по компонентам.pdf

ctm513 – 4045-6068 柴油发动机 — 16 级 ECU – (世界通用机型 ) 维修手册.pdf

ctm517 – Silnik Diesla 4045–6068 – Poziom ECU 16 – (Wydanie ogólnoświatowe) Podręcznik techniczny komponentów.pdf

ctm608 – 4045-6068 Dizel Motor — Seviye 16 ECU (Dünya Çapında Sürüm) Bileşen Teknik Kılavuzu.pdf

CTM502 (09NOV12) (ENGLISH) – John Deere PowerTech E 4.5L & 6.8L Diesel Engines (Level 16 Electronic Fuel System with Denso HPCR) Component Technical Manual.pdf

CTM502 – John Deere Level 16 Electronic Fuel System with Denso HPCR Component Technical Manual.pdf

PRODUCT DETAILS:

Total Pages: 1,501 pages

File Format: PDF (Internal Links, Bookmarked, Table of Contents, Searchable, Printable, high quality)

Language: English

ctm502 – 4045-6068 Diesel Engine — Level 16 ECU -: (Worldwide Edition) Component Technical Manual – Table of Contents

Foreword

Trademarks

Section 01: General

Group 000: Safety

Avoid Heating Near Pressurized Fluid Lines

Avoid High-Pressure Fluids

Avoid Hot Exhaust

Avoid Static Electricity Risk When Refueling

Construct Dealer-Made Tools Safely

Decommissioning — Proper Recycling and Disposal of Fluids and Components

Follow Safety Instructions

Handle Agricultural Chemicals Safely

Handle Fluids Safely—Avoid Fires

Handling Batteries Safely

Illuminate Work Area Safely

Install All Guards

Live With Safety

Park Machine Safely

Practice Safe Maintenance

Precautions for Welding

Prepare for Emergencies

Prevent Acid Burns

Prevent Battery Explosions

Prevent Machine Runaway

Protect Against High Pressure Spray

Protect Against Noise

Recognize Safety Information

Remove Paint Before Welding or Heating

Replace Safety Signs

Service Cooling System Safely

Service Machines Safely

Stay Clear of Rotating Drivelines

Support Machine Properly

Understand Signal Words

Use Proper Lifting Equipment

Use Proper Tools

Use Steps and Handholds Correctly

Wait Before Opening High-Pressure Fuel System

Wear Protective Clothing

Work in Clean Area

Work In Ventilated Area

Group 001: Engine Identification

Engine Serial Number Plate Information

OEM Engine Option Code Label

Information Relative to Emissions Regulations

Emissions Control System Certification Label

Group 002: Fuels, Lubricants, and Coolant

Diesel Fuel

Diesel Fuel Additive Products

BioDiesel Fuel

Minimizing the Effect of Cold Weather on Diesel Engines

Handling and Storing Diesel Fuel

Lubricity of Diesel Fuel

Testing Diesel Fuel

Engine Oil and Filter Service Intervals

Diesel Engine Oil — Tier 3 and Stage III

Diesel Engine Break-In Oil — Non-Emissions Certified and Certified Tier 1, Tier 2, Tier 3, Stage I, Stage II, and Stage III

Oil Filters

Grease

Alternative and Synthetic Lubricants

Lubricant Storage

Mixing of Lubricants

Diesel Engine Coolant (engine with wet sleeve cylinder liners)

Supplemental Coolant Additives

Operating in Warm Temperature Climates

Additional Information About Diesel Engine Coolants and John Deere LIQUID COOLANT CONDITIONER

Diesel Engine Coolant

Testing Diesel Engine Coolant

Drain Intervals for Diesel Engine Coolant

Section 02: Repair and Adjustments

Group 090: Electronic Fuel System Repair and Adjustments

Fuel System – General Information

Relieve Fuel System Pressure

Fuel System Components

Replace Fuel Filter Element (Primary or Final)

Remove and Install Fuel Filter Base (Primary and Final)

Remove Fuel Transfer Pump

Install Fuel Transfer Pump

Remove and Install High-Pressure Fuel Pump

Remove and Install Suction Control Valve

Remove and Install High-Pressure Common Rail

Remove and Install Flow Dampers

Remove and Install Pressure Limiter

Remove and Install Fuel Injection Wire Harness Assembly

Injector Identification Tag Information

Remove Electronic Injector (EI)

Clean Electronic Injector (EI) Bore

Clean Electronic Injector (EI) Orifice

Clean Electronic Injector (EI) Body

Inspect Electronic Injector (EI) Body

Install Electronic Injector (EI)

Remove and Install Fuel Leak-Off Line

Clean Electronic injectors (In Engine)

Group 110: Electronic Engine Control Repair and Adjustment

Engine Control Unit (ECU) Maintenance

Welding

High Pressure Washing

Remove and Install Engine Control Unit (ECU) on Engine (Optional Equipment)

Remove and Install Adaptation Parts for Engine Control Unit (ECU) Mounted on Engine (Optional Equipment)

Remove and Install Engine Coolant Temperature (ECT) Sensor

Remove and Install Fuel Temperature Sensor

Remove and Install Manifold Air Temperature (MAT) Sensor

Remove and Install Oil Pressure Sensor

Remove and Install Fuel Rail Pressure Sensor

Remove and Install Fuel Transfer Pump Pressure Sensor

Remove and Install Crankshaft Position Sensor

Remove and Install Pump Position Sensor

Remove and Install Water-In-Fuel (WIF) Sensor

Install Wiring Harness for Engine Mount ECU

Install Wiring Harness for Remote ECU

Connectors

Connector Repair

Installation of Repair Wire Assembly (RWA)

Repair WEATHERPACK Connector

Repair Cinch FlexBox Connector

Repair Metri-Pack Connectors (Push Type)

Repair DT Series DEUTSCH Connectors

Repair HD Series DEUTSCH Connectors

Section 03: Theory Of Operation

Group 130: Electronic Fuel System Operation

About This Group

Fuel System Operation

Prefilter Operation

Mechanical Fuel Transfer Pump Operation

Electric Fuel Transfer Pump Operation

Final Fuel Filter Operation

Type 1 High Pressure Fuel Pump Operation

High Pressure Common Rail (HPCR) Operation

Electronic Injector (EI) Operation

Group 135: Air and Exhaust Operation

Air Intake and Exhaust System Operation

Air Cleaner Operation

Turbocharger Operation

How the Turbocharger Is Lubricated

Group 140: Electronic Control System Operation

About This Group

Electronic Control System Terminology

Electronic Control Unit (ECU) System Operation

Component Location Diagram 1

Component Location Diagram 2

Component Location Diagram 3

Component Location Diagram 4

Component Location Diagram 5

Component Location Diagram 6

Component Location Diagram 7

Component Location Diagram 8

Component Location Diagram 9

Component Location Diagram 10

Component Location Diagram 11

Component Location Diagram 12

Component Location Diagram 13

Component Location Diagram 14

Component Location Diagram 15

Component Location Diagram 16

Engine Control Unit (ECU)

Controller Area Network (CAN)

Pilot Injection Operation

Monitoring Engine Parameters

Measuring Temperature

Engine Control Unit (ECU) Temperature Sensor

Engine Coolant Temperature (ECT) Sensor

Fuel Temperature Sensor

Intake Manifold Air Temperature (MAT)

Turbo Turbine Inlet Temperature

Measuring Pressure

Barometric Air Pressure (BAP) Sensor

Fuel Rail Pressure Sensor

Fuel Transfer Pump Pressure Sensor

Manifold Air Pressure (MAP) Sensor

Oil Pressure Sensor

Dual Fuel Rail Pressure Sensor (Redundant ECU Applications)

Measuring Speed

Crank Position Sensor

Pump Position Sensor

Throttle Descriptions

CAN Throttle

Pulse-Width-Modulated (PWM) Throttle

Analog Throttle

Digital Multi-State Throttle

Dual-State Throttle

Tri-State Throttle

Ramp Throttle

Throttle Adjustments

Throttle Offsets

Self-Calibration

Combination Throttle

Marine Throttle

Engine Derate and Shutdown Protection

Electronic Injector (EI) Wiring Harness Connector

Intake Air Heater Operation

Torque Curve Selection

Governor Droop Mode Selection

Suction Control Valve

Water in Fuel (WIF) Sensor

Cruise Control Operation

Power Supply #1

Power Supply #2

Power Supply #3

Section 04: Diagnostics

Group 150: Observable Diagnostics and Tests

About This Group

E1 – Engine Cranks/Won’t Start

E2 – Engine Misfires/Runs Irregularly

E3 – Engine Does Not Develop Full Power

E4 – Engine Emits Excessive White Exhaust

E5 – Engine Emits Excessive Black or Gray Exhaust

E6 – Engine Will Not Crank

E7 – Engine Idles Poorly

E8 – Abnormal Engine Noise

E9 – Primary Analog Throttle Does Not Respond

E10 – Secondary Analog Throttle Does Not Respond

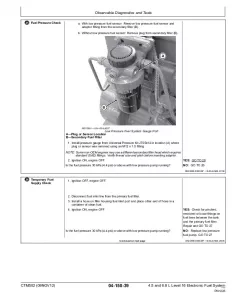

F1 – Low-Pressure Fuel Supply System Test

F2 – High-Pressure Fuel Supply System Test

F3 – Excessive Fuel Consumption

F4 – Fuel in Oil

F5 – Excessive Fuel Filter Replacement

D1 – ECU Does Not Communicate with Service ADVISOR

D2 – ECU Does Not Communicate with Diagnostic Gauge or Gauge Displays CAN Bus Error

D5 – ECU Does Not Program With Service ADVISOR

A1 – Intake Air Heater Check

Bleed the Fuel System

Charge Air Cooler Test

Charge Air System

Check and Adjust High-Pressure Fuel Pump Static Timing

Check Engine Oil Pressure

Check for Restricted Fuel Leak-off Line

Check Fuel Supply Quality

Cylinder Leak-Down Test

Cooling System Test

EGR Cooler Test

Engine Coolant Temperature Below Normal

Excessive Engine Crankcase Pressure (Blow-By) Test

Test for Air in Fuel

Thermostat — Testing

Group 160: Trouble Code Diagnostics and Tests

About This Group

Change Fan Speed Table

Communication Error Test Instructions

Connecting to Service ADVISOR

Control Unit Information and Overview Test

Cylinder Cutout Test Instructions

Cylinder Electronic Compression Test Instructions

Cylinder Misfire Test Instructions

Diagnostic Gauge Active DTC Viewing Instructions

Diagnostic Gauge Data Parameters Viewing Instructions

Diagnostic Gauge Stored DTC Clearing Instructions

Diagnostic Gauge Stored DTC Viewing Instructions

Diagnostic Test Box — Using

Diagnostic Trouble Code Designations

Diagnostic Trouble Code List

Digital Multimeter — Using

Electrical Circuit Concepts

Electrical Noise — Possible Causes

Electronic Injector — Calibration Information

Engine Hours — Updating Instructions

Failure Mode Indicator Designations

Fuel Rail Cap and Plug Kit

Harness Diagnostic Mode Test

Interactive Tests and Calibration Results — Printing, Exporting, or Saving Instruction

Intermittent DTC Diagnostics

Internal Data Monitor — Instructions

Keep Electronic Control Unit Connectors Clean

Load Profile Information Test — Instructions

Engine Control Unit (ECU) — Level Identification

Engine Control Unit (ECU) — Donating this Engine’s ECU to be Used Elsewhere

Engine Control Unit (ECU) — Replacing Current ECU with Another ECU

Engine Control Unit (ECU) — Replacing Current ECU with Another ECU — Cannot Communicate with Current ECU

Engine Control Unit (ECU) — Reprogramming Current ECU

Engine Control Unit (ECU) — Reprogramming Instructions

Problem Not Found Procedure

Service Advisor Data Parameter Description

Short to Voltage Procedure

Snapshot Instructions

Software and Hardware Verification

Terminal Test

Trim Options Information

Verification Procedure

Wiggle Test

000028.03 – Digital Throttle Signal Out of Range High

000028.04 – Digital Throttle Signal Out of Range Low

000028.14 – Digital Throttle Inhibited

000029.03 – Secondary Analog Throttle Signal Out of Range High

000029.04 – Secondary Analog Throttle Signal Out of Range Low

000029.14 – Secondary Analog Throttle Inhibited

000084.31 – ECU Calculated Vehicle Speed and CAN Vehicle Speed Mismatch

000091.03 – Primary Analog Throttle Signal Out of Range High

000091.04 – Primary Analog Throttle Signal Out of Range Low

000091.09 – Primary Analog Throttle Signal Erratic

000091.14 – Primary Analog Throttle Inhibited

000094.03 – Low-Pressure Fuel Signal Out of Range High

000094.04 – Low-Pressure Fuel Signal Out of Range Low

000094.17 – Low Pressure Fuel Signal Slightly Low

000094.18 – Low-Pressure Fuel Signal Moderately Low

000097.03 – Water-In-Fuel Signal Out of Range High

000097.04 – Water-In-Fuel Signal Out of Range Low

000097.16 – Water-In-Fuel Detected

000100.01 – Engine Oil Pressure Signal Extremely Low

000100.04 – Engine Oil Pressure Signal Out of Range Low

000100.18 – Engine Oil Pressure Signal Moderately Low

000100.31 – Engine Oil Pressure Detected with Engine Stopped

000105.00 – Manifold Air Temperature Signal Extremely High

000105.03 – Manifold Air Temperature Signal Out of Range High

000105.04 – Manifold Air Temperature Signal Out of Range Low

000105.15 – Manifold Air Temperature Signal Slightly High

000105.16 – Manifold Air Temperature Signal Moderately High

000107.00 – Air Filter Restriction Switch Activated

000107.31 – Air Filter Restriction Switch Activated

000108.02 – Barometric Air Pressure Signal Invalid

000110.00 – Coolant Temperature Signal Extremely High

000110.03 – Coolant Temperature Signal Out of Range High

000110.04 – Coolant Temperature Signal Out of Range Low

000110.15 – Coolant Temperature Signal Slightly High

000110.16 – Coolant Temperature Signal Moderately High

000110.17 – Engine Coolant Temperature Signal Slightly Low

000111.01 – Coolant Level Extremely Low

000157.03 – Fuel Rail Pressure Signal Out of Range High

000157.04 – Fuel Rail Pressure Signal Out of Range Low

000157.10 – Fuel Rail Pressure Loss Detected

000157.17 – Fuel Rail Pressure Not Developed

000158.17 – ECU Power Down Error

000160.02 – Vehicle Speed Signal Invalid

000171.03 – Ambient Air Temperature Out of Range High

000171.04 – Ambient Air Temperature Out of Range Low

000174.00 – Fuel Temperature Signal Extremely High

000174.03 – Fuel Temperature Signal Out of Range High

000174.04 – Fuel Temperature Signal Out of Range Low

000174.16 – Fuel Temperature Signal Moderately High

000189.00 – Engine Speed Derate Condition Exists

000190.00 – Engine Speed Extremely High

000190.16 – Engine Speed Moderately High

000237.02 – VIN Security Data Invalid

000237.13 – VIN Option Code Security Data Conflict

000237.31 – VIN Security Data Missing

000569.03 – Rear Axle Differential Lock Signal Out of Range High

000569.04 – Rear Axle Differential Lock Signal Out of Range Low

000611.03 – Injector Shorted to Voltage Source

000611.04 – Injector Shorted to Ground

000627.01 – All Injector Circuits Have High Resistance

000627.18 – Injector Power Supply Voltage Out of Range Low

000629.12 – ECU EEPROM Error

000629.13 – ECU Boot Block Error

000636.02 – Camshaft Position Signal Invalid

000636.05 – Camshaft Position Circuit Has High Resistance

000636.06 – Camshaft Position Circuit Has Low Resistance

000636.08 – Camshaft Position Signal Missing

000636.10 – Camshaft Position Signal Rate of Change Abnormal

000637.02 – Crankshaft Position Signal Invalid

000637.05 – Crankshaft Position Circuit Has High Resistance

000637.06 – Crankshaft Position Circuit Has Low Resistance

000637.07 – Crankshaft and Camshaft Position Signals Out of Sync

000637.08 – Crankshaft Position Signal Missing

000637.10 – Crankshaft Position Signal Rate of Change Abnormal

000640.31 – External Derate Commanded

000647.05 – Engine Fan Drive Circuit Has High Resistance

000647.31 – Engine Fan Drive Manual Purge Switch Active Too Long

000651.02 – Injector #1 Part Number Invalid

000651.05 – Injector #1 Circuit Has High Resistance

000651.06 – Injector #1 Circuit Has Low Resistance

000651.13 – Injector #1 Calibration Fault

000652.02 – Injector #2 Part Number Invalid

000652.05 – Injector #2 Circuit Has High Resistance

000652.06 – Injector #2 Circuit Has Low Resistance

000652.13 – Injector #2 Calibration Fault

000653.02 – Injector #3 Part Number Invalid

000653.05 – Injector #3 Circuit Has High Resistance

000653.06 – Injector #3 Circuit Has Low Resistance

000653.13 – Injector #3 Calibration Fault

000654.02 – Injector #4 Part Number Invalid

000654.05 – Injector #4 Circuit Has High Resistance

000654.06 – Injector #4 Circuit Has Low Resistance

000654.13 – Injector #4 Calibration Fault

000655.02 – Injector #5 Part Number Invalid

000655.05 – Injector #5 Circuit Has High Resistance

000655.06 – Injector #5 Circuit Has Low Resistance

000655.13 – Injector #5 Calibration Fault

000656.02 – Injector #6 Part # Data Invalid

000656.05 – Injector #6 Circuit Has High Resistance

000656.06 – Injector #6 Circuit Has Low Resistance

000656.13 – Injector #6 Calibration Fault

000676.03 – Cold Start Aid Signal Received When Not Expected

000676.05 – Cold Start Aid Circuit Has High Resistance

000898.09 – Engine Speed CAN Message Invalid

000970.31 – External Shutdown Switch Activated

000970.31 – External Shutdown Switch Activated

000971.31 – External Derate Switch Activated

001069.31 – Tire Size Invalid

001075.05 – Low Pressure Fuel Pump Circuit Has High Resistance

001075.06 – Low Pressure Fuel Pump Circuit Has Low Resistance

001109.31 – Approaching Engine Protection Shutdown

001110.31 – Engine Protection Shutdown Active

001136.00 – ECU Temperature Signal Extremely High

001136.02 – ECU Temperature Signal Invalid

001136.16 – ECU Temperature Signal Moderately High

001321.05 – Starter Solenoid Lockout Relay Drive Circuit Has High Resistance

001321.06 – Starter Solenoid Lockout Relay Drive Circuit Has Low Resistance

001321.30 – Starter Solenoid Lockout Relay Drive Circuit Fault

001347.03 – Suction Control Valve Signal Out of Range High

001347.05 – Suction Control Valve Circuit Has High Resistance

001347.07 – Fuel Rail Pressure Actual to Desired Mismatch

001349.02 – Fuel Rail Pressure Signals Mismatch

001349.03 – Redundant Fuel Rail Pressure Signal Out of Range High

001349.04 – Redundant Fuel Rail Pressure Signal Out of Range Low

001569.31 – Engine in Power Derate Condition

001638.09 – Hydraulic Oil Temperature Erratic

001639.01 – Fan Speed Signal Extremely Low

001639.16 – Fan Speed Signal Moderately High

002000.13 – Incorrect ECU for Application

002003.09 – No CAN Message Received From Source Address 3

002004.09 – No CAN Message Received From Source Address 4

002023.09 – No CAN Message From Source Address 23

002033.09 – No CAN Message Received From Source Address 33

002033.14 – Incorrect CAN Message Received From Source Address 33

002033.19 – Synchronizing Problem with Source Address 33

002057.09 – No CAN Message Received From Source Address 57

002071.09 – No CAN Message From Source Address 71

003509.03 – Sensor Supply #1 Voltage Out of Range High

003509.04 – Sensor Supply #1 Voltage Out of Range Low

003510.03 – Sensor Supply #2 Voltage Out of Range High

003510.04 – Sensor Supply #2 Voltage Out of Range Low

003511.03 – Sensor Supply #3 Voltage Out of Range High

003511.04 – Sensor Supply #3 Voltage Out of Range Low

523792.04 – EPGDS LTC Pump Signal Out of Range Low

524099.11 – EPGDS LTC Pump Blockage

524037.02 – MFWD Switch Circuit Fault

524223.03 – Rear Axle Differential Lock Circuit Fault

524225.31 – Engine Start Protection Bypass Detected

524235.03 – MFWD Solenoid Signal Out of Range High

524235.04 – MFWD Solenoid Signal Out of Range Low

Section 05: Tools and Other Materials

Group 170: Special Tools

75240

D05104ST

D17030BR

DFRG11

J-35616-20

JDE83

JDG145

JDG359

JDG360

JDG361

JDG362

JDG363

JDG364

JDG776

JDG777

JDG782A

JDG783

JDG785

JDG820

JDG839

JDG865

JDG1560

JDG1571

JDG1652A

JDG1725

JDG1727

JDG1744

JDG1869

JDG10234

JDG10244

JDG10273

JDG10273P1

JDG10407

JDG10408

JDG10415

JDG10416

JDG10446

JDG10447

JDG10452

JDG10453

JDG10456

JDG10457

JDG10460

JDG10461

JDG10466

JDG10467

JDG10539A

JDG10576

JDG10760

JDG10854

JDG11072

JDG11100A

JDG11233

JDG11263

JDG11264

JDG11269

JDG11409

JT03513C

JT05412

JT05470

JT05536

JT07253

JT07306

Group 180: Lubricants, Sealants, and Other Materials

Other Materials (Consumables)

Section 06: Specifications

Group 200: Repair Specifications

Unified Inch Bolt and Cap Screw Torque Values

Metric Bolt and Cap Screw Torque Values

Electronic Fuel System Repair and Adjustment Specifications

Electronic Engine Control Repair and Adjustment Specifications

Group 210: Diagnostic Specifications

Fuel System Diagnostic Specifications

Application Specifications

OEM Engines – Derate Specifications

OEM Engines – Air Heater Specifications

4.5L 12V ECU Wiring Diagram 1

4.5L 12V ECU Wiring Diagram 2

4.5L 12V ECU Wiring Diagram 3

4.5L 12V ECU Wiring Diagram 4

4.5L 12V ECU Wiring Diagram 5

4.5L 12V ECU Wiring Diagram 6

4.5L 12V ECU Wiring Diagram 7

4.5L 24V ECU Wiring Diagram 1

4.5L 24V ECU Wiring Diagram 2

4.5L 24V ECU Wiring Diagram 3

4.5L 24V ECU Wiring Diagram 4

4.5L 24V ECU Wiring Diagram 5

4.5L 24V ECU Wiring Diagram 6

4.5L 24V ECU Wiring Diagram 7

6.8L 12V ECU Wiring Diagram 1

6.8L 12V ECU Wiring Diagram 2

6.8L 12V ECU Wiring Diagram 3

6.8L 12V ECU Wiring Diagram 4

6.8L 12V ECU Wiring Diagram 5

6.8L 12V ECU Wiring Diagram 6

6.8L 12V ECU Wiring Diagram 7

6.8L 24V ECU Wiring Diagram 1

6.8L 24V ECU Wiring Diagram 2

6.8L 24V ECU Wiring Diagram 3

6.8L 24V ECU Wiring Diagram 4

6.8L 24V ECU Wiring Diagram 5

6.8L 24V ECU Wiring Diagram 6

6.8L 24V ECU Wiring Diagram 7

OEM Instrument Panel / Engine Start Components Electrical Wiring Diagram

OEM Instrument Panel / Engine Start Components Electrical Wiring Diagram – Continued

4.5L Wire Splice Location Diagrams

6.8L Wire Splice Location Diagrams

Oil Temperature Switch Option

Redundant ECU Option 4.5L Wiring Diagrams

Redundant ECU Option 6.8L Wiring Diagrams

Redundant ECU Option Wire Splice Location Diagrams