Complete service repair manual for Komatsu 450FXL Crawler Feller Bunchers/Harvesters, with all the shop information to maintain, diagnose, repair, and rebuild like professional mechanics.

Komatsu 450FXL Crawler Feller Bunchers/Harvesters workshop service & repair manual includes:

* Numbered table of contents easy to use so that you can find the information you need fast.

* Detailed sub-steps expand on repair procedure information

* Numbered instructions guide you through every repair procedure step by step.

* Troubleshooting and electrical service procedures are combined with detailed wiring diagrams for ease of use.

* Notes, cautions and warnings throughout each chapter pinpoint critical information.

* Bold figure number help you quickly match illustrations with instructions.

* Detailed illustrations, drawings and photos guide you through every procedure.

* Enlarged inset helps you identify and examine parts in detail.

CEBM023102 – Komatsu 450FXL Crawler Feller Bunchers_Harvesters Shop Manual (SN 450FXL-1 A10001 & up – Engine QSC 8.3).pdf

PRODUCT DETAILS:

Total Pages: 410 pages

File Format: PDF

Language: English

TABLE OF CONTENTS

01 GENERAL . . . . 01-1

30 TESTING AND ADJUSTING . . . . 30-1

40 TROUBLESHOOTING . . . . 40-1

50 DISASSEMBLY AND ASSEMBLY. . . . 50-1

60 AIR CONDITIONER . . . . 60-1

90 DIAGRAMS AND SCHEMATICS. . . . 90-1

CEBM023102 450FXL-1….1

CONTENTS….7

00 – FOREWORD….8

Safety Notice….8

Important Safety Notice….8

General Precautions….8

Preparations For Work….8

Precautions During Work….8

GENERAL….11

HOW TO READ THE SHOP MANUAL….12

Volumes….12

Distribution And Updating….12

Filing Method….12

Revised Edition Mark….12

Revisions….12

Symbols….12

HOISTING INSTRUCTIONS….13

Hoisting….13

Wire Ropes….13

HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS….14

Points To Remember When Handling Electric Equipment….14

Points To Remember When Handling Hydraulic Equipment….20

PUSH PULL COUPLER….22

Type 1….22

Disconnection….22

Connection….22

Type 2….23

Disconnection….23

Connection….23

Type 3….24

Disconnection….24

Connection….24

EXPLANATION OF MAINTENANCE STANDARD TERMS….25

STANDARD TIGHTENING TORQUE….27

Bolts And Nuts….27

GENERAL INSTRUCTIONS….28

Introduction….28

Cleaning….28

Replacement….28

Hoses and Tubes….28

Inspection….28

Installation….28

Hydraulic Pumps….29

Replacement….29

Pressure Testing….29

Leveling Cylinders and Debris Deflector Skirting….29

Hydraulic Fitting Torque Values….31

JIC 37 Flare Torque Values….31

37 Flare, Tube To Fitting Assembly….32

SAE Straight Thread O-Ring Fitting (Adjustable) To Port Assembly….33

Seal-Lok Straight and Adjustable Fitting (Steel)….34

Flare and Flareless Port Ends….34

SAE Straight Thread O-Ring Fitting (Non-Adjustable)….35

Fitting To Port Assembly….35

Port Assembly For SAE Straight Thread Plugs….36

4-Bolt Split Flange Assembly, Fitting To Port SAE….37

Code 61 (3000 psi) and Code 62 (6000 psi)….37

Pipe Thread Port Assembly, Fitting To Port….38

Standard Bolt Torque Chart (Inches)….39

CONVERSION TABLES….40

Method Of Using The Conversion Table….40

COATING MATERIALS….46

01 – GENERAL….49

SPECIFICATIONS….51

Dimensions….51

BOOM AND ARM SWEEP DIAGRAMS….52

SPECIFICATIONS….56

Engine….57

Fuel Quality Requirements….58

Engine Oil Performance Information….58

Hydraulic and Engine Oil Selection, Lubricating Oils, and Grease….59

New Engine “Break-in” Oils….59

Coolant Quality Requirements….59

Coolant and Water for Dilution….59

Hydraulic Oil Information….60

Hydraulic Oil Type….60

Hydraulic Oil Viscosity….60

Hydraulic Oil Viscosity Selection….61

ISO Code Rating….61

General Hydraulic Oil Specification….62

Minimum Technical Hydraulic Oil Requirements….62

Track Final Drive Oil Information….62

Hydraulic System….63

General:….63

Pump Drive:….63

Implement Pump:….63

Track Drive Pump (2):….63

Track Drive Charge Pump:….63

Return Oil Filtration:….63

Hydraulic Tank:….63

Implement Control Valve:….63

Typical Hydraulic Valve Set-up….64

VOAC K220 Valve, Typical….65

VOAC L90LS Valve, Typical….67

Lubricant and Fill Capacities….69

30 – TESTING AND ADJUSTING….71

30 TESTING AND ADJUSTING….71

FIRE SUPPRESSION SYSTEM (OPTIONAL)….73

Ansul™ Fire Suppression Controls (Optional)….73

Ansul Fire Suppression Daily Inspections….73

Ansul Fire Suppression Monthly Inspections….74

Maintenance….74

HYDRAULIC PRESSURE SETTINGS….75

Hydraulic Pressure Gauges….75

Implement Pump Pressure Settings….75

Implement Pump Stand-By Pressure….75

Implement Pump POR (Pressure Over-Ride) Pressure….77

Auxiliary Implement Pump Pressure Settings….78

Common Pressure Port Stand-by Pressure Adjustment….78

Common Pressure Port POR (Pressure Over-Ride) Pressure Adjustment….79

Separate Pressure Port Stand-by Pressure Adjustment….80

Separate Pressure Port POR Pressure Adjustment….81

Track Drive Circuit Pressure Settings….82

Hydrostatic Charge Pressure Relief Adjustment….82

Hydrostatic Main Relief Adjustment Procedure….82

Drive Pump Null….85

CONTROL VALVE CIRCUIT PRESSURE ADJUSTMENTS….87

Differential Pressure Adjustment….87

Load Sense Max Pressure Adjustment….88

Feed Reducer Pressure Adjustments….90

Adjustment Procedure….90

Main Control Valve Port Reliefs….91

40 – TROUBLESHOOTING….93

RELAY & FUSE LOCATIONS….95

Relay Location and Identification….95

Mini Fuse Bank A Location and Identification….96

Mini Fuse Bank A Location….97

Mini Fuse Bank B Location and Identification….98

Mini Fuse Bank B Location….99

Maxi Fuse Bank C Location and Identification….100

Maxi Fuse Bank D Location and Identification….100

GENERAL INFORMATION….101

Points to Remember….101

Sequence of Events….103

Handling Electric Equipment and Hydraulic Components….104

Connectors for Tier 3 Engines….112

Checks Before Troubleshooting….116

GENERAL HYDRAULIC PROBLEMS….117

MACHINE OVERHEAT PROBLEMS….127

IMPLEMENT FUNCTION PROBLEMS….132

TRACK DRIVE PROBLEMS….136

ENGINE PROBLEMS….146

ELECTRICAL PROBLEMS….149

AIR CONDITIONER / HEATER PROBLEMS….156

DISC SAW CIRCUIT PROBLEMS….163

50 – DISASSEMBLY AND ASSEMBLY….169

HOW TO READ THIS MANUAL….173

Removal And Installation Of Assemblies….173

Special Tools….173

Removal….173

Installation….173

Disassembly And Assembly Of Assemblies….174

Special Tools….174

Disassembly….174

Assembly….175

SPECIAL TOOLS LIST….176

CONNECTOR REPAIR PROCEDURES….177

Stripping Insulation….177

Wire Inspection….177

Contact Terminal Removal (HD30 Type)….178

Crimping Contact Terminal (HD30 Type)….179

Insertion Of Contact Terminal (HD30 Type)….180

Contact Terminal Removal (DT Type)….181

Crimping Contact Terminal (DT Type)….182

Insertion Of Contact Terminal (DT Type)….183

PRECAUTIONS DURING OPERATION….184

Precautions when Performing Removal Work….184

Precautions when Performing Installation Work….185

Precautions when Completing The Operations….186

Other Precautions….186

ARM….187

Stick ARM….187

Removal….187

Installation….188

Main Boom….190

Removal….190

Installation….191

Tool Tilt Cylinder….193

Removal….193

Installation….194

Stick Cylinder….195

Removal….195

Installation….195

Main Boom Cylinder….196

Removal….196

Installation….197

HYDRAULIC SYSTEM….199

Hydraulic Oil Tank….199

Draining….199

Removal and Disassembly….200

Cleaning….203

Assembly….204

Installation….205

Filling the Hydraulic Tank….207

Auxiliary Oil Cooler….208

Removal (Hydraulic Driven Fan)….208

Hydraulic Tank Vacuum Pump….209

Removal….209

Installation….209

Machine Start-Up After Hydraulic Component Replacement….210

Hydraulic System Start-Up for Machines Without A Vacuum Pump….210

Hydraulic System Start-Up for Machines With A Vacuum Pump….211

Rotary Manifold….212

Removal….212

Inspection….214

Installation….214

Swing Motor….216

Removal….216

Installation….217

Swing Motor Anti-Cavitation Valve….219

Removal….219

Installation….219

Swing Motor Gearbox Brake….220

Disassembly….220

Assembly….220

Swing Motor/Gearbox Assembly….221

Removal….221

Installation….221

SWING BEARING….222

Removal….222

Installation….224

Fill and Check Swing Pinion Grease Level….226

LEVELING COMPONENTS….227

Leveling Cylinder Removal….227

Leveling Cylinder Installation….228

Turntable Casting….230

Removal….230

Installation….233

Intermediate Leveler….236

Removal….236

Installation….238

Auxiliary Pump….241

45 cc Auxiliary Pump Removal….241

45 cc Auxiliary Pump Installation….242

71 cc Auxiliary Pump Removal….243

71 cc Auxiliary Pump Installation….244

Implement Pump….246

Removal….246

Installation….248

Auxiliary Oil Cooler Fan Pump….251

Removal….251

Installation….252

Charge Pump….254

Removal….254

Charge Pump Installation….255

Right Side Drive Pump….256

Removal….256

Installation….258

Left Side Drive Pump….262

Removal….262

Installation….264

FINAL DRIVE ASSEMBLY….268

Removal….268

Disassembly….270

Disassembly of Number 1 Carrier….276

Assembly of Number 1 Carrier….276

Disassembly of Number 2 Carrier….276

Assembly of Number 2 Carrier….277

Assembly….277

Installation….287

MAIN CONTROL VALVE….289

Removal….289

Installation….290

FILL PUMP….292

Removal….292

Installation….292

CHARGE MANIFOLD HEATER….293

Removal….293

Installation….294

CHARGE FILTER MANIFOLD….296

Removal….296

Installation….297

PILOT PRESSURE MANIFOLD….298

Removal and Installation….298

RETURN OIL MANIFOLD (LOGIC BLOCK)….299

SAW STOP VALVE….300

Removal and Installation….300

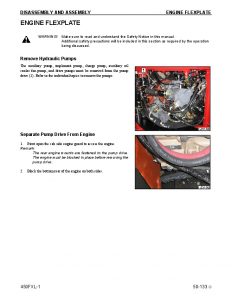

ENGINE FLEXPLATE….301

Remove Hydraulic Pumps….301

Separate Pump Drive From Engine….301

Flexplate Removal….303

Flexplate Installation….303

Pump Drive Installation….304

Install Hydraulic Pumps….305

ENGINE….306

Removal….306

Installation Preparation….319

Installation….326

TRACK SYSTEM….339

Track Tension….339

Checking Track Tension….339

Increasing Track Tension….339

Decreasing Track Tension….339

Track Shoe Removal and Installation….340

Track Removal and Installation….340

Idler Wheel, Recoil Spring and Track Adjuster Assembly….345

Idler Wheel and Recoil Spring Removal….345

Idler Wheel and Recoil Spring Installation….346

Idler Wheel….346

Disassembly….346

Assembly….347

Recoil Spring….350

Disassembly….350

Assembly….351

Track Roller….352

Removal….352

Disassembly….353

Assembly….354

Installation….356

Final Drive Sprocket….357

Removal….357

Installation….357

Track Slider….358

Removal….358

Installation….358

Upper Track Roller….359

Removal….359

Installation….359

Track Frame….359

Removal….359

Installation….360

CAB….362

Removal….362

Installation….368

60 – AIR CONDITIONER….373

AIR CONDITIONER/HEATER….373

CHARGING AIR CONDITIONING SYSTEM….373

Technician Training and Certification….373

Air Conditioner/Heater Access….374

90 – DIAGRAMS AND SCHEMATICS….375

TRACK DRIVE CIRCUIT: 83381 REV. A….377

COMBINATION BAR SAW AND DISC SAW: 83382-B….378

DISC SAW: 83383-B….379

DUAL FLOW PROCESSOR #2: 83385-B….380

COMBINED FLOW PROCESSOR #3: 83386-B….381

COMBINED FLOW PROCESSOR #4: 83387-B….382

INTERMITTENT DISC SAW: 83388-B….383

BAR SAW: 83389-B….384

DUAL FLOW PROCESSOR #5: 85801-A….385

ELECTRICAL MAXI HEAD COMPUTER: 00860148; 1/2….386

ELECTRICAL MAXI HEAD COMPUTER: 00860148; 2/2….387

ELECTRICAL: 00860154 ; 1/2….388

ELECTRICAL: 00860154; 2/2….389

HYDRAULIC: 00860150….390

IQAN 1/6….391

IQAN 2/6….392

IQAN 3/6….393

IQAN 4/6….394

IQAN 5/6….395

IQAN 6/6….396

1/18 MAIN ELECTRICAL CTR, FUSE LEGEND: 28606-E 1/2….397

1/18 MAIN ELECTRICAL CTR, FUSE LEGEND: 28606-E 2/2….398

1/18 DASH PANEL: 28411-A….399

5/18 UPPER CAB HARNESS: 28413-A….400

6/18 RADIO ADAPTER: 28414-B….401

7/18 REAR UPPER LIGHT HARNESS: 28415-A….402

8/18 LOWER CAB SUB HARNESS (SHIFT COIL) : 28416-A….403

11/18 LOWER CAB HARNESS: 28417-A….404

12/18 FOPS LIGHT HARNESS: 28418-A….405

15/18 ENGINE HARNESS: 28703-B….406

16/18 VISOR LIGHT HARNESS: 28422-B….407

18/18 MAXI INTERFACE HARNESS: 83093-A….408

VAC/VENT SUB HARNESS: 27309….409

ROLLY II INSTALLATION KIT, FUSE RELAY: 28701 REV A….410

CUMMINS QSC ENGINE SCHEMATIC: 83093-A….411

Komatsu 450FXL Crawler Feller Bunchers/Harvesters Repair Service Manual